Harvester Evaluation Using Real-Time Kinematic GNSS and Hiring Service Model

Abstract

1. Introduction

2. Methodology

2.1. Experimental Locations

2.2. Selected Harvesting Machines

2.3. In-Field Activities and Performance Indicators

2.4. Data Collection during Mechanical Harvesting

2.5. Data Analyses

- (i)

- Positioning

- (ii)

- Mapping

- (iii)

- Identification of operations

2.6. Cost Determination

2.6.1. Fixed Cost

- (i)

- Depreciation cost: Depreciation is the reduction in the value of a machine as a result of use (wear and tear) and obsolescence (availability of newer and better models). In the calculation of a fixed cost, sinking-fund depreciation is assumed and was calculated by the following equation [30]:where D = depreciation, USD year−1; P = purchase price, USD; S = salvage value (10% of P), USD; L = effective working life of machine, years; n = age of the machine in years at the beginning of the year, years; and I = annual bank interest rate, decimal.

- (ii)

- Interest on investment: The interest on investment for a combine harvester is included in the fixed cost estimation. The following equation was used for the calculation of interest on investment [30]:where P = purchase price, USD; S = resale value, USD; and i = annual interest rate.

- (iii)

- Taxes, Shelter, and Insurance (STI): The shelter, tax, and insurance were considered in calculating the fixed cost of the harvesting machine. The following equation was used for the calculation of STI [30]:where P = purchase price of the harvester, USD.STI = 2.5% of P

2.6.2. Variable Cost

2.6.3. Operating Cost

2.7. Sinking Fund Annual Payment (SFP) or Payment for Replacement

2.8. Rent-Out Charge

2.9. Economic Analysis for Custom-Hire Service Business

2.9.1. Net Present Value (NPV)

2.9.2. Benefit–Cost Ratio (BCR)

2.9.3. Internal Rate of Return (IRR)

2.9.4. Payback Period (PP)

2.10. Break-Even Use

3. Results and Discussion

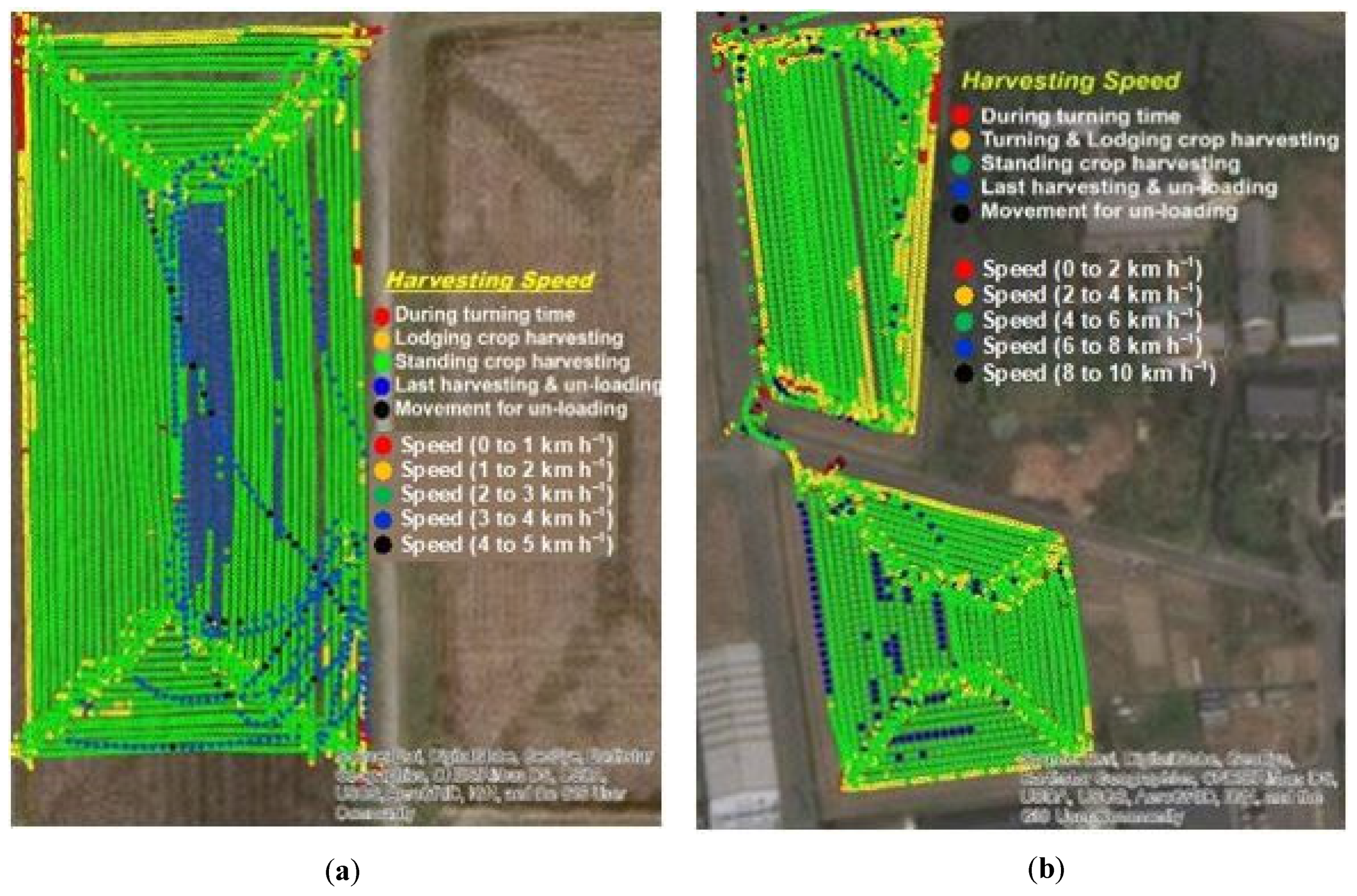

3.1. Harvesting Track and Harvested Area of the Combine Harvester

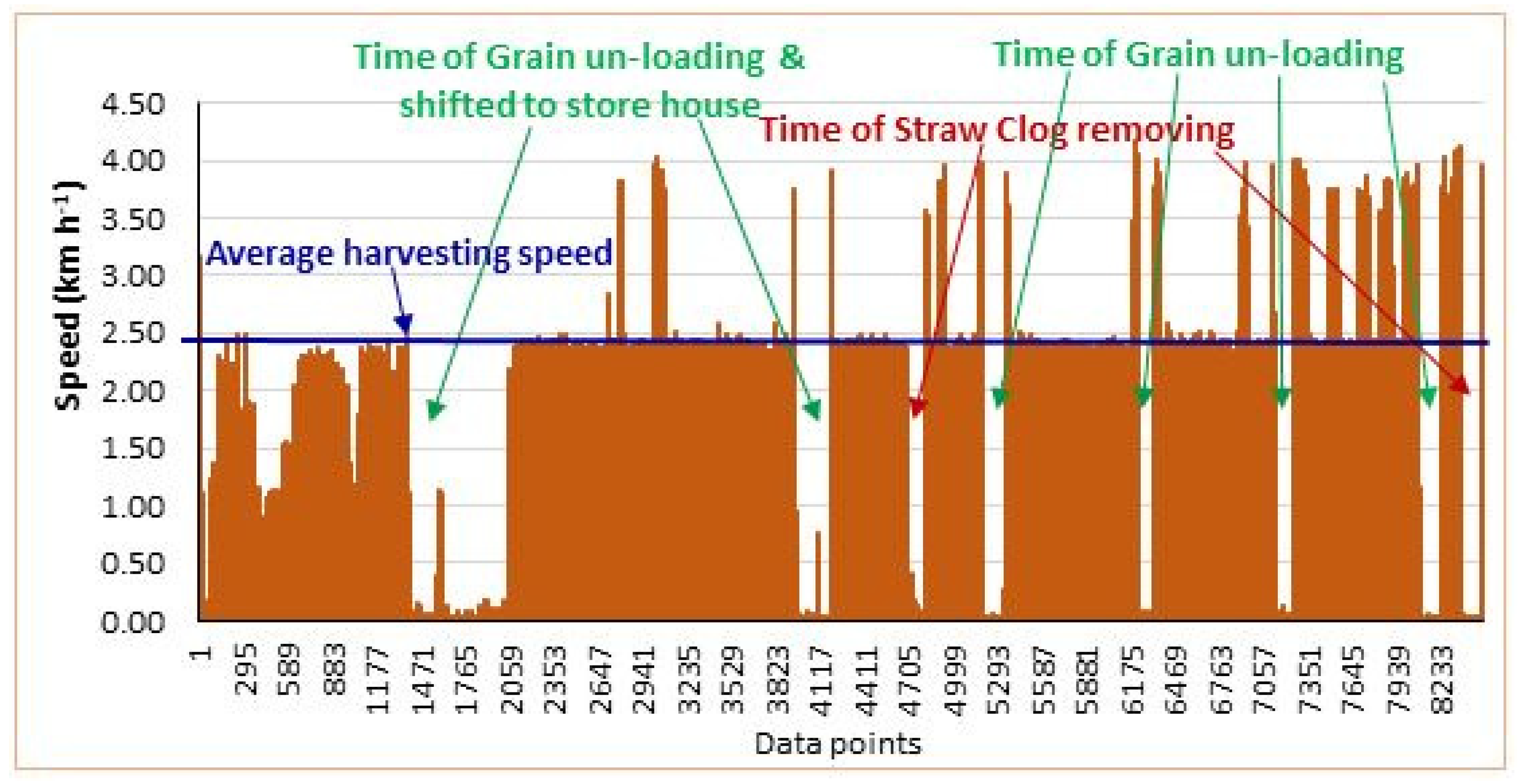

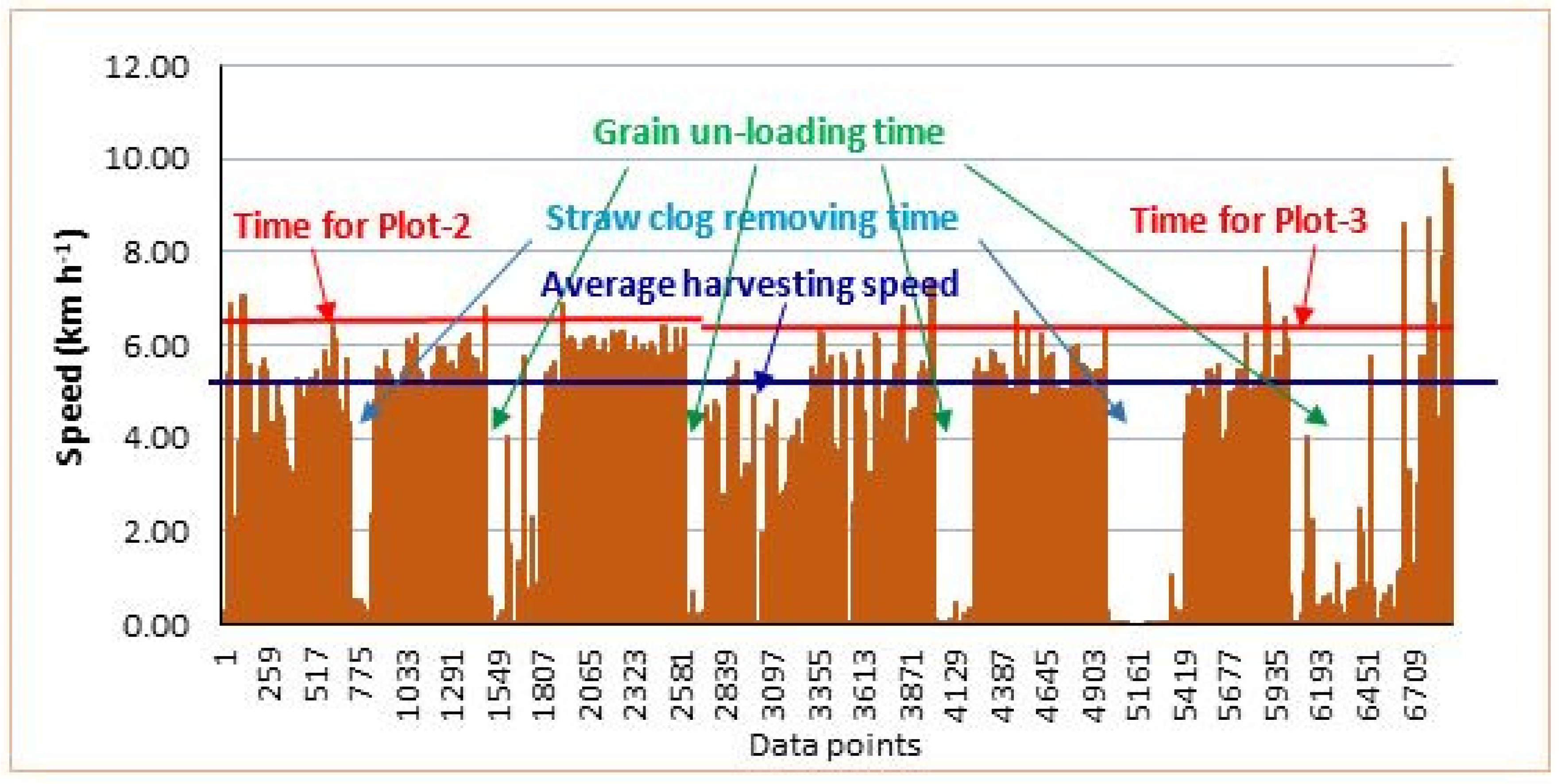

3.2. Speed Variation during Harvesting and Turning Loss Measurement

3.3. Estimating Average Harvesting Speed and Idle Time of Harvesting

3.4. Technical Performances of Harvester

3.5. Economic Performances

3.5.1. Operating Cost of a Combine Harvesters

3.5.2. Comparison of Financial Features of Harvesters for Custom-Hire Business

PV, IRR, BCR, and PP of Harvesters

Sinking Fund Annual Payment (SFP) of Combine Harvesters

Rent-Out Charge of Harvester Operation for Custom-Hire Service Business

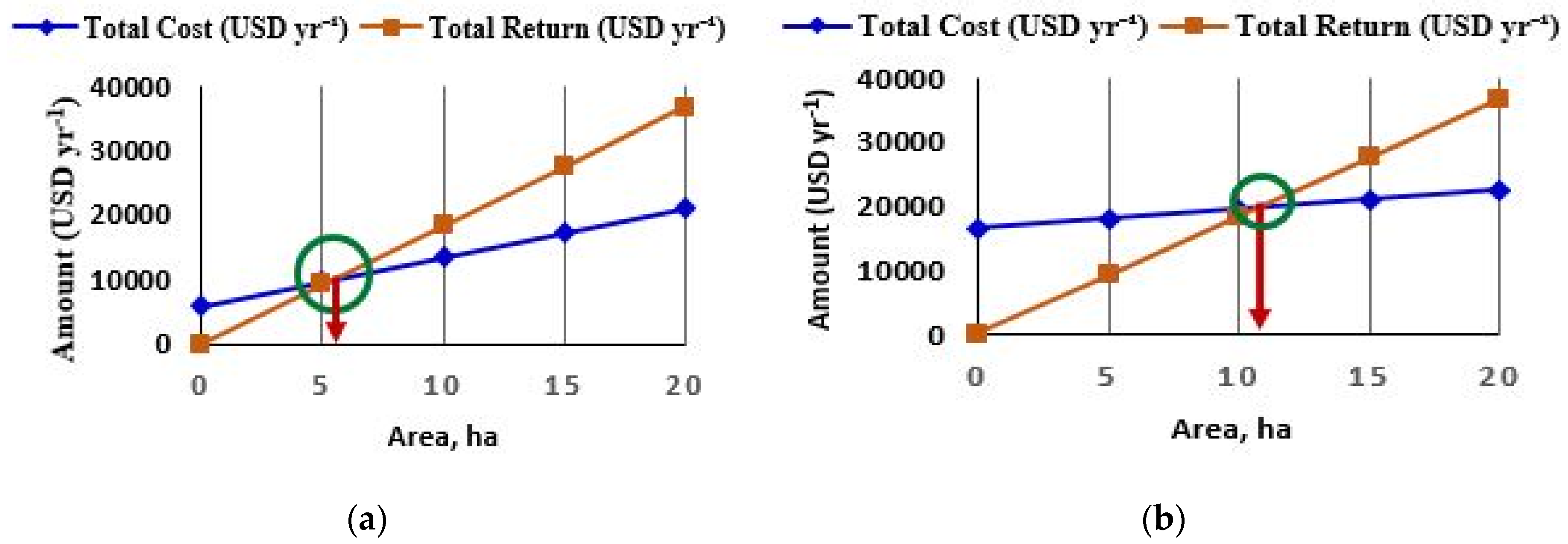

Break-Even Use of Medium and Large Combine Harvesters

3.5.3. Project Worth Analysis

3.5.4. BCR, IRR, PP, and BEU of Combine Harvesters for Project Worth Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, G. Estimation of a Mechanisation Index and Its Impact on Production and Economic Factors—A Case Study in India. Biosyst. Eng. 2006, 93, 99–106. [Google Scholar] [CrossRef]

- Noby, M.M.; Hasan, M.K.; Ali, M.R.; Saha, C.K.; Alam, M.M.; Hossain, M.M. Performance evaluation of modified BAU self-propelled reaper for paddy. J. Bangladesh Agric. Univ. 2018, 16, 171–177. [Google Scholar] [CrossRef]

- Samson, B.; Duff, B. The Pattern and Magnitude of Field Grain Losses in Paddy Production; IRRI Saturday Seminar Paper; International Rice Research Institute: Los Banos, Philippines, 1973; p. 30. [Google Scholar]

- Hasan, M.K.; Ali, M.R.; Saha, C.K.; Alam, M.M.; Hossain, M.M. Assessment of Paddy Harvesting Practices in Southern Delta Region of Bangladesh. Progress. Agric. 2019, 30, 57–64. [Google Scholar] [CrossRef]

- Jones, M.; Alam, M.M.; Rahman, M.H.; Ali, M.R.; Hasan, M.K.; Pathan, M.S.I.A. Gender Technology Assessment of Harvesting Technologies in Bangladesh. Agrilinks, the Online Hub, Is a Part of the U.S. Government’s Feed the Future. 2019. Available online: https://www.agrilinks.org/sites/default/files/resources/bangladesh_harvester_tech_profile_2019_08_final.pdf (accessed on 20 April 2021).

- Hossain, M.A.; Hoque, M.A.; Wohab, M.A.; Miah, M.A.M.; Hassan, M.S. Technical and Economic Performance of Combined Harvester in Farmers’ Field. Bangladesh J. Agric. Res. 2015, 40, 291–304. [Google Scholar] [CrossRef]

- Crookston, K. A top 10 list of developments and issues impacting crop management and ecology during the past 50years. Crop Sci. 2006, 46, 2253–2262. [Google Scholar] [CrossRef]

- Zarco-Tejada, P.J.; Neil, H.; Philippe, L. Precision Agriculture: An Opportunity for EU Farmers—Potential Support with CAP 2014–2020; European Union: Brussels, Belgium, 2014; Available online: www.europarl.europa.eu›2014›IPOL-AGRI_NT(2014)529049_EN (accessed on 12 April 2021).

- Mulla, D.J. Twenty five years of remote sensing in precision agriculture: Key advances and remaining knowledge gaps. Biosyst. Eng. 2013, 114, 358–371. [Google Scholar] [CrossRef]

- Shibusawa, S. Precision Farming and Terra-mechanics. In Proceedings of the Fifth ISTVS Asia-Pacific Regional Conference, Seoul, Korea, 20–22 October 1998. [Google Scholar]

- Chen, J.; Yang, G.J.; Xu, K.; Cai, Y.Y. On Research on Combine Harvester Positioning algorithm and Aided-navigation System. In Proceedings of the International Conference on Advances in Mechanical Engineering and Industrial Informatics, Zhengzhou, China, 11–12 April 2015; pp. 848–853. [Google Scholar]

- Zhang, Z.; Cao, R.; Peng, C.; Liu, R.; Sun, Y.; Zhang, M.; Li, H. Cut-Edge Detection Method for Rice Harvesting Based on Machine Vision. Agronomy 2020, 10, 590. [Google Scholar] [CrossRef]

- Ball, D.; Upcroft, B.; Wyeth, G.; Corke, P.; English, A.; Ross, P.; Patten, T.; Fitch, R.; Sukkarieh, S.; Bate, A. Vision-based Obstacle Detection and Navigation for an Agricultural Robot. J. Field Robot 2016, 33, 1107–1130. [Google Scholar] [CrossRef]

- Adamchuk, V.I.; Grisso, R.D.; Kocher, M. Machinery performance assessment based on records of geographic position. In Proceedings of the 2004 ASAE/CSAE Annual International Meeting, Ottawa, ON, Canada, 1–4 August 2004; p. 11. [Google Scholar] [CrossRef]

- Amponsah, S.K.; Addo, A.; Dzisi, K.A.; Moreira, J.; Ndindeng, S.A. Performance Evaluation and Field Characterization of The Sifang Mini Rice Combine Harvester. Appl. Eng. Agric. Am. Soc. Agric. Biol. Eng. 2017, 33, 479–489. [Google Scholar] [CrossRef]

- Taylor, R.K.; Schrock, M.D.; Staggenborg, S.A. Extracting machinery management information from GPS data. In Proceedings of the ASAE Annual International Meeting, Chicago, IL, USA, 28–31 July 2002; Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.490.2662&rep=rep1&type=pdf (accessed on 15 April 2021).

- Pandey, M.M.; Devnani, R.S. Analytical determination of an optimum mechanical harvesting pattern for high field efficiency and low-cost of operation. J. Agric. Eng. Res. 1987, 36, 261–274. [Google Scholar] [CrossRef]

- Niehaus, C.R. Evaluation of Corn Harvesting Operations with the Use of Geo-Referenced Data. Master’s Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 2014. [Google Scholar]

- Mehta, C.R.; Pajnoo, R.K. Role of Japan in Promotion of Agricultural Mechanization in India. Agric. Mech. Asia Afr. Lat. Am. 2013, 44, 15–17. [Google Scholar]

- Hegazy, R.; Schmidley, A.; Bautista, E.; Sumunistrado, D.; Gummert, M.; Elepano, A. Mechanization in Rice Farming—Lessons Learned from Other Countries; Asia Rice Foundation, Los Banos, Philippines, 2013. Available online: https://www.researchgate.net/publication/258951878_Mechanization_in_rice_farming_lessons_learned_from_other_countries (accessed on 28 March 2021).

- Hasan, M.D.; Tanaka, T.S.T.; Alam, M.M.; Ali, M.R.; Saha, C.K. Impact of Modern Rice Harvesting Practices over Traditional Ones. Rev. Agric. Sci. 2020, in press. [Google Scholar] [CrossRef]

- Justice, S.; Biggs, S. Rural and agricultural mechanization in Bangladesh and Nepal: Status, processes and outcomes. In Mechanization for Rural Development: A Review of Patterns and Progress from around the World; Kienzle, J., Ashburner, J.E., Sims, B.G., Eds.; Food and Agriculture Organization of the United Nations (UNFAO): Rome, Italy, 2013; pp. 67–98. [Google Scholar]

- IDE (International Development Enterprises). Commercialization of Selected Agriculture Machineries in Bangladesh; International Development Enterprises (IDE): Dhaka, Bangladesh, 2012; Available online: http://repository.cimmyt.org/xmlui/bitstream/handle/10883/3394/98527.pdf (accessed on 14 May 2015).

- Shidu, R.S.; Kamal, V. Improving Economic Viability of Farming: A Study of Cooperative Agro Machinery Service Centres in Punjab. Agric. Econ. Res. Rev. 2012, 25, 427–434. [Google Scholar]

- Hossain, M.I.; Siddiqui, M.N.A.; Panaullah, G.M.; Duxbury, J.M.; Lauren, J.G. Raised beds: A resource conserving technology for improved crop production in Bangladesh. In A Booklet under Cornell University-Food of Ithaca, NY, USA for Progress Programme in Bangladesh; Bangladesh Agricultural Research Institute (BARI): Gazipur, Bangladesh, 2014. [Google Scholar]

- d-maps. Available online: https://d-maps.com (accessed on 28 May 2021).

- Hofmann-Wellenhof, B.; Lichtenegger, H.; Collins, J. Global Positioning System: Theory and Practice, 5th ed.; Springer: New York, NY, USA, 2001. Available online: https://trove.nla.gov.au/version/41748624 (accessed on 20 March 2021).

- Takasu, T.; Yasuda, A. Development of the low-cost RTK-GPS receiver with an open source program package RTKLIB. In Proceedings of the International Symposium on GPS/GNSS 2009, Jeju, Korea, 4–6 November 2009; Available online: http://gpspp.sakura.ne.jp/paper2005/isgps_2009_rtklib_revA.pdf (accessed on 10 April 2021).

- Barnard, C.S.; Nix, J.S. Farm Planning and Control, 2nd ed.; Cambridge University Press: Cambridge, UK, 1979. Available online: https://trove.nla.gov.au/version/45672432 (accessed on 25 March 2021).

- Hunt, D. Farm Power and Machinery Management, 10th ed.; Iowa State University Press: Iowa City, IA, USA, 2001. Available online: https://trove.nla.gov.au/work/10793375 (accessed on 25 February 2021).

- White, J.A.; Agee, M.H.; Case, K.E. Principles of Engineering Economic Analysis, 3rd ed.; London-New York-Melbourne; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1989. [Google Scholar] [CrossRef]

- Gittinger, J.P. Economic Analysis of Agricultural Projects; John Hopkins University Press: Baltimore, MD, USA, 1982. [Google Scholar]

- Sarma, A.K. Methods/Criteria of Project Evaluation or Measures of Project Worth of Investment; Agricultural Economics, Faculty of Agriculture, Assam Agricultural University: Jorhat, India, 2010. [Google Scholar]

- Jaim, W.M.H. Can Potential Capacity of Deep Tube Wells Be Utilized? HRDP, Winrock International: Dhaka, Bangladesh, 1993. [Google Scholar]

- George, J.A.; Shorey, O.M. Current Tillage Practices and Needs. In ASEAN, ACIAR, Proceedings Series; Australian Centre for International Agricultural Research: Canberra, Australia, 1978. [Google Scholar]

- Miah, M.T.H.; Hardaker, J.B. Benefit-cost analysis of deep and shallow tube well projects in Tangail District in Bangladesh. Bangladesh J. Agric. Econ. 1998, 4, 21–30. [Google Scholar]

- Hasan, M.K.; Ali, M.R.; Saha, C.K.; Alam, M.M.; Haque, M.E. Combine Harvester: Impact on paddy production in Bangladesh. J. Bangladesh Agric. Univ. 2019, 17, 583–591. [Google Scholar] [CrossRef]

- Veerangouda, M.; Sushilendra, K.; Prakash, V.; Anantachar, M. Performance evaluation of tractor operated combine harvester. Kamataka J. Agric. Sci. 2010, 23, 282–285. [Google Scholar]

- Alam, S.M.S.; Rashedujjaman, M.; Hossain, M.M.; Hossain, K.M.D. Comparative harvesting and threshing cost of paddy by combine harvester and self-propelled reaper and thresher. J. Environ. Sci. Nat. Resour. 2017, 10, 133–136. [Google Scholar] [CrossRef][Green Version]

- Hasan, M.K.; Ali, M.R.; Saha, C.K.; Alam, M.M.; Rahman, M.S. Provision of custom hiring service of mini-combine harvester for paddy harvesting: An experimental evidence from Bangladesh. Int. J. Agric. Innov. Technol. Glob. 2020, 1, 338–353. [Google Scholar] [CrossRef]

- Acharya, P.; Regmi, P.P.; Gauchan, D.; KC, D.B.; KC, G.B. Benefit Cost Analysis of Adoption of Small Farm Machineries for Rice Cultivation in Nepal. Int. J. Appl. Sci. Biotechnol. 2020, 8, 448–453. [Google Scholar] [CrossRef]

- Hasan, M.K.; Ali, M.R.; Saha, C.K.; Rahman, M.S.; Alam, M.M. Custom Hiring Service of Reaper for Harvesting Paddy. J. Bangladesh Agric. Univ. 2020, 18, 872–879. [Google Scholar] [CrossRef]

| Testing Item | Designed Value | |

|---|---|---|

| Model | ER329 | ER6120 |

| Overall dimension (L × W × H) (mm) | 3890 × 1870 × 2090 | 4850 × 2325 × 2660 |

| Weight (kg) | 1950 | 4160 |

| Header width (mm) | 1219 | 1981 |

| Forward speed (during harvesting) (m s−1) | 0–1.05 | 0–2.00 |

| Capacity (ha h−1) | 0.20–0.40 | 0.50–0.80 |

| Fuel consumption (L h−1) | 03–06 | 12–20 |

| Engine type | Diesel engine | Diesel engine |

| Engine power (kW) | 21.3 | 88.3 |

| Cutting row | 3 | 6 |

| Machine | Plot | Total Turns, No. | Average Turning Loss, s Turn−1 | Total Turning Loss, h | Active Harvesting Time, h | Harvesting Area, ha | Turning Loss with Active Harvesting Time, % | Turning Loss with Harvesting Area, h ha−1 |

|---|---|---|---|---|---|---|---|---|

| Medium combine (Model: ER329) | Plot 1 | 73 | 14.33 | 0.2906 | 1.8175 | 0.3029 | 15.99 | 0.96 |

| Large combine (Model: ER6120) | Plot 2 | 54 | 12.67 | 0.1901 | 0.5425 | 0.3150 | 35.03 | 0.60 |

| Machines | Idle Times | Total Idle Time, h | Total Operational Time, h | Effective Harvesting Timed, h | Idle Time Loss % | ||

|---|---|---|---|---|---|---|---|

| Nos. a | Item Names | Time, s | |||||

| Medium combine (Model: ER329) (Plot 1) | 1 | Grain unloading and shifting to storehouse | 673 | 0.55 | 2.37 | 1.82 | 23.14 |

| 2 | Grain unloading | 271 | |||||

| 3 | Straw clog removing | 133 | |||||

| 4 | Grain unloading | 194 | |||||

| 5 | Grain unloading | 172 | |||||

| 6 | Grain unloading | 179 | |||||

| 7 | Grain unloading | 216 | |||||

| 8 | Straw clog removing | 136 | |||||

| Large combine (Model: ER6120) (Plot 1 + Plot 2) | 1 | Straw clog removing | 129 | 0.80 | 1.93 | 1.13 | 41.46 |

| 2 | Grain unloading | 381 | |||||

| 3 | Grain unloading | 301 | |||||

| 4 | Grain unloading | 496 | |||||

| 5 | Straw clog removing | 632 | |||||

| 6 | Waiting for pick-up and grain unloading | 940 | |||||

| Place and Use of Harvester Model | Plots | Forward Speed (km h−1) | Fuel Consumption (L h−1) | Fuel Consumption (L ha−1) | Effective Field Capacity (ha h−1) | Effective Field Capacity (Decimal h−1) |

|---|---|---|---|---|---|---|

| Gifu University farm in Gifu, Japan Model: ER329 | Plot 1 | 2.50 | 3.18 | 19.08 | 0.17 | 42 |

| Kaizu city farm in Gifu, Japan Model: ER6120 | Plot 2 | 5.84 | 12.18 | 20.98 | 0.58 | 143 |

| Plot 3 | 5.20 | 11.68 | 22.24 | 0.53 | 131 | |

| Average for Model: ER6120 | 5.52 | 11.93 | 21.61 | 0.55 | 137 | |

| Items | Unit * | Amount | |

|---|---|---|---|

| Medium Combine (Model: ER329) | Large Combine (Model: ER6120) | ||

| Purchase price of combine (P) | USD | 50,275 | 143,578 |

| Salvage value (S) (10% of P) | USD | 5028 | 14,358 |

| Working life (L) | years | 10 | 10 |

| Average working hours per year | hr year−1 | 240 | 240 |

| Field capacity of harvester | ha h−1 | 0.17 | 0.55 |

| Average working hectare per year | ha year−1 | 40.80 | 132.00 |

| Annual fixed cost | USD year−1 | 5822.51 | 16,628.15 |

| Fixed cost per hour | USD h−1 | 24.26 | 69.28 |

| A. Fixed cost per hectare | USD ha−1 | 142.71 | 125.97 |

| Fuel cost per hour | USD h−1 | 3.27 | 11.99 |

| Lubricant cost per hour | USD h−1 | 0.49 | 1.80 |

| Repair and maintenance cost (0.025% of P) | USD h−1 | 12.57 | 35.89 |

| Labor cost | USD h−1 | 11.01 | 11.01 |

| Operator cost | USD h−1 | 13.76 | 13.76 |

| Straw and paddy bag collection cost per hour | USD h−1 | 88.07 | 88.07 |

| Variable cost per hour | USD h−1 | 129.18 | 162.53 |

| Annual variable cost | USD year−1 | 31,002.53 | 39,007.74 |

| B. Variable cost per hectare | USD ha−1 | 759.87 | 295.51 |

| Operating cost of a harvester (A+B) | USD ha−1 | 903 | 421 |

| Items | Unit | Amount (Harvesting to Cleaning) | |

|---|---|---|---|

| Medium Combine Model: ER329 | Large Combine Model: ER6120 | ||

| Purchase price of combine (P) | USD | 50,275 | 143,578 |

| Working life (L) | years | 10 | 10 |

| Rent out charge (Including operating cost, profit, and SFP) | USD ha−1 | 1835 | 1835 |

| Operating cost | USD ha−1 | 903 | 421 |

| Profit | USD ha−1 | 823 | 1317 |

| Sinking fund payment (SFP) | USD ha−1 | 109 | 97 |

| Sinking fund payment (SFP) | USD year−1 | 4474 | 12,777 |

| Net present value (NPV) at 10% DF | USD | 219,225 | 1,104,962 |

| Benefit–cost ratio (BCR) | % | 1.91 | 3.88 |

| Internal rate of return (IRR) | - | 87% | 142% |

| Payback period (PP) | years | 1.15 | 0.71 |

| Break-even use | ha year−1 | 5.42 | 10.80 |

| Year | Fixed Cost (USD) | Variable Cost (USD year−1) | Gross Benefit (USD year−1) | Cash Flow (USD) | Present Value of Cash Flow (USD) | Present Value of Cost (USD) | Present Value of Benefit (USD) | Balance (USD) |

|---|---|---|---|---|---|---|---|---|

| 0 | 50,275 | 50,275 | −50275 | 50275 | 0 | −50275 | −50275 | |

| 1 | 0 | 31,003 | 74,862 | 43,860 | 28,184 | 68,057 | 39,873 | −6,415 |

| 2 | 0 | 31,003 | 74,862 | 43,860 | 25,622 | 61,870 | 36,248 | 37,444 |

| 3 | 0 | 31,003 | 74,862 | 43,860 | 23,293 | 56,245 | 32,953 | 81,304 |

| 4 | 0 | 31,003 | 74,862 | 43,860 | 21,175 | 51,132 | 29,957 | 125,164 |

| 5 | 0 | 31,003 | 74,862 | 43,860 | 19,250 | 46,484 | 27,234 | 169,024 |

| 6 | 0 | 31,003 | 74,862 | 43,860 | 17,500 | 42,258 | 24,758 | 212,884 |

| 7 | 0 | 31,003 | 74,862 | 43,860 | 15,909 | 38,416 | 22,507 | 256,744 |

| 8 | 0 | 31,003 | 74,862 | 43,860 | 14,463 | 34,924 | 20,461 | 300,604 |

| 9 | 0 | 31,003 | 74,862 | 43,860 | 13,148 | 31,749 | 18,601 | 344,463 |

| 10 | 0 | 31,003 | 74,862 | 43,860 | 11,953 | 28,863 | 16,910 | 388,323 |

| NPV = USD 219,225; BCR = 1.91; IRR= 87%; PP = 1.15 years | ||||||||

| Year | Fixed Cost (USD) | Variable Cost (USD year−1) | Gross Benefit (USD year−1) | Cash Flow (USD) | Present Value of Cash Flow (USD) | Present Value of Cost (USD) | Present Value of Benefit (USD) | Balance (USD) |

|---|---|---|---|---|---|---|---|---|

| 0 | 143,578 | 143,578 | −143,578 | 143,578 | 0 | −143,578 | −143,578 | |

| 1 | 0 | 39,008 | 242,202 | 203,194 | 35,462 | 220,183 | 184,722 | 59,616 |

| 2 | 0 | 39,008 | 242,202 | 203,194 | 32,238 | 200,167 | 167,929 | 262,810 |

| 3 | 0 | 39,008 | 242,202 | 203,194 | 29,307 | 181,970 | 152,663 | 466,004 |

| 4 | 0 | 39,008 | 242,202 | 203,194 | 26,643 | 165,427 | 138,784 | 669,198 |

| 5 | 0 | 39,008 | 242,202 | 203,194 | 24,221 | 150,388 | 126,168 | 872,392 |

| 6 | 0 | 39,008 | 242,202 | 203,194 | 22,019 | 136,717 | 114,698 | 1,075,587 |

| 7 | 0 | 39,008 | 242,202 | 203,194 | 20,017 | 124,288 | 104,271 | 1,278,781 |

| 8 | 0 | 39,008 | 242,202 | 203,194 | 18,197 | 112,989 | 94,792 | 1,481,975 |

| 9 | 0 | 39,008 | 242,202 | 203,194 | 16,543 | 102,717 | 86,174 | 1,685,169 |

| 10 | 0 | 39,008 | 242,202 | 203,194 | 15,039 | 93,379 | 78,340 | 1,888,363 |

| NPV = USD 1,104,962; BCR = 3.88; IRR= 142%; PP = 0.71 years | ||||||||

| Items | Value | Remarks |

|---|---|---|

| Benefit–cost ratio (BCR) | 1.91 | If greater than 1.0 (1.91 > 1.0), acceptable as profitable |

| Internal rate of return (IRR) | 87% | If greater than prevailing interest rate (87% > 9%), acceptable |

| Payback period (PP) | 1.15 years | If less than economic life (1.15 years < 10 years), acceptable |

| Break-even use (BEU) | 5.42 ha year−1 | If less than service area (5.42 ha year−1 < 40.80 ha year−1), acceptable |

| Items | Value | Remarks |

|---|---|---|

| Benefit–cost ratio (BCR) | 3.88 | If greater than 1.0 (3.88 > 1.0), acceptable as profitable |

| Internal rate of return (IRR) | 142% | If greater than prevailing interest rate (142% > 0.25%), acceptable |

| Payback period (PP) | 0.71 year | If less than economic life (0.71 year < 10 years), acceptable |

| Break-even point (BEU) | 10.80 ha year−1 | If less than service area (10.80 ha year−1 < 132.00 ha year−1), acceptable |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, M.K.; Tanaka, T.S.T.; Ali, M.R.; Saha, C.K.; Alam, M.M. Harvester Evaluation Using Real-Time Kinematic GNSS and Hiring Service Model. AgriEngineering 2021, 3, 363-382. https://doi.org/10.3390/agriengineering3020024

Hasan MK, Tanaka TST, Ali MR, Saha CK, Alam MM. Harvester Evaluation Using Real-Time Kinematic GNSS and Hiring Service Model. AgriEngineering. 2021; 3(2):363-382. https://doi.org/10.3390/agriengineering3020024

Chicago/Turabian StyleHasan, Md. Kamrul, Takashi S. T. Tanaka, Md. Rostom Ali, Chayan Kumer Saha, and Md. Monjurul Alam. 2021. "Harvester Evaluation Using Real-Time Kinematic GNSS and Hiring Service Model" AgriEngineering 3, no. 2: 363-382. https://doi.org/10.3390/agriengineering3020024

APA StyleHasan, M. K., Tanaka, T. S. T., Ali, M. R., Saha, C. K., & Alam, M. M. (2021). Harvester Evaluation Using Real-Time Kinematic GNSS and Hiring Service Model. AgriEngineering, 3(2), 363-382. https://doi.org/10.3390/agriengineering3020024