Predicting Field Efficiency of Round-Baling Operations in High-Yielding Biomass Crops

Abstract

1. Introduction

2. Materials and Methods

- Cm = material capacity sometimes referred to as throughput, Mg/h

- v = field speed, km/h

- W = implement working width, m

- Ef = field efficiency, decimal

- Y = unit yield of the field, Mg/ha

- K1 = 10 km-m/ha.

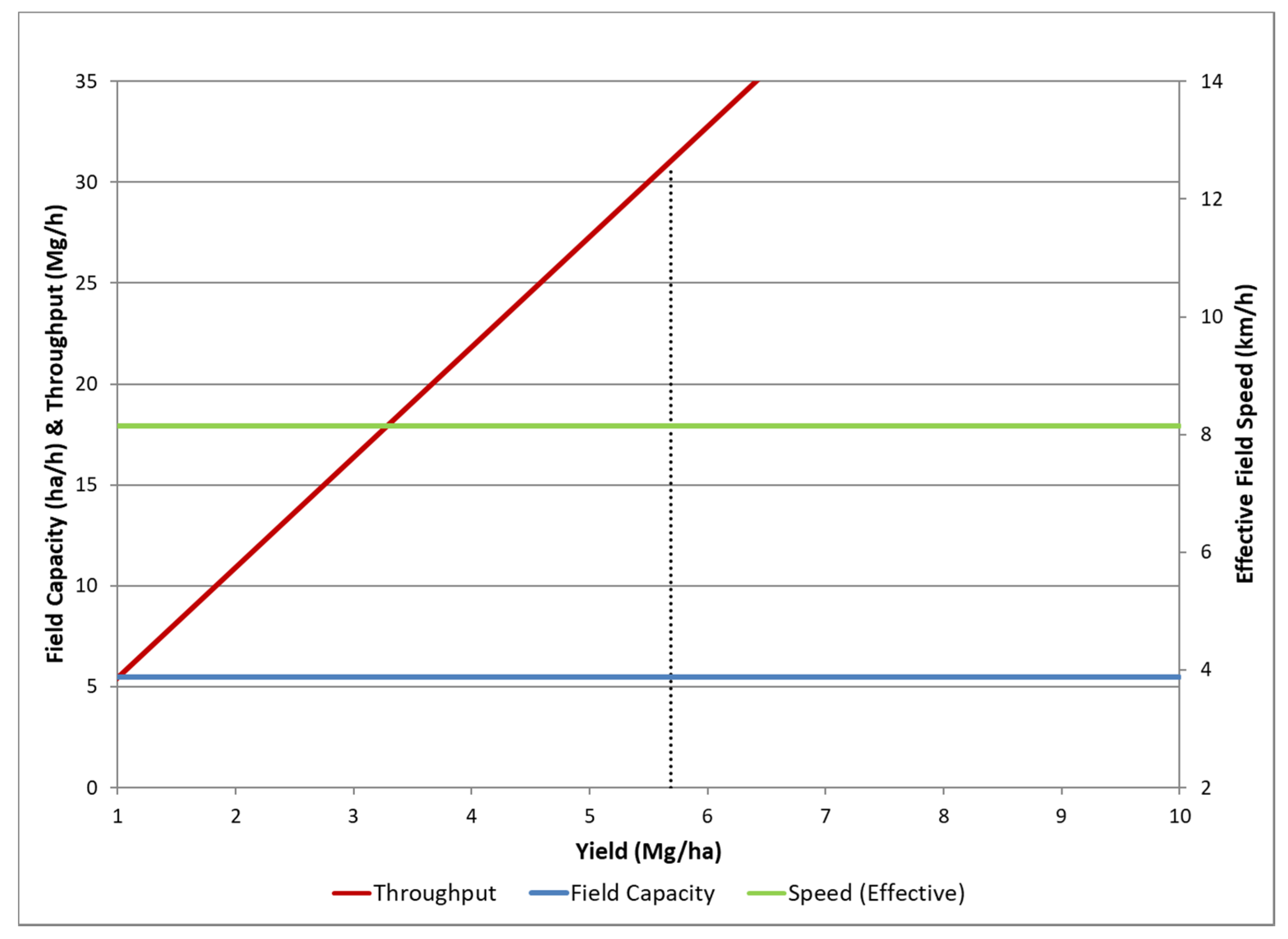

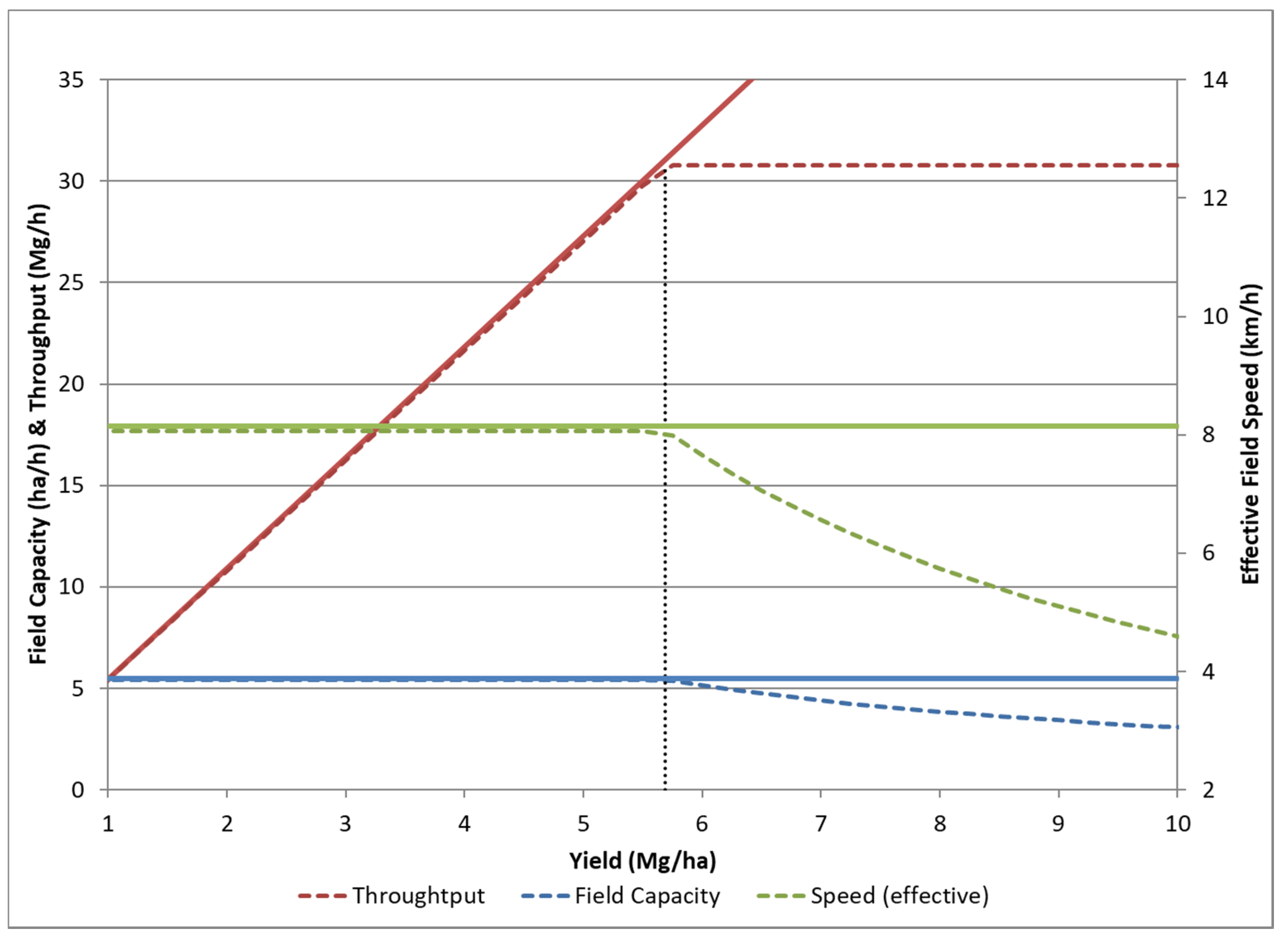

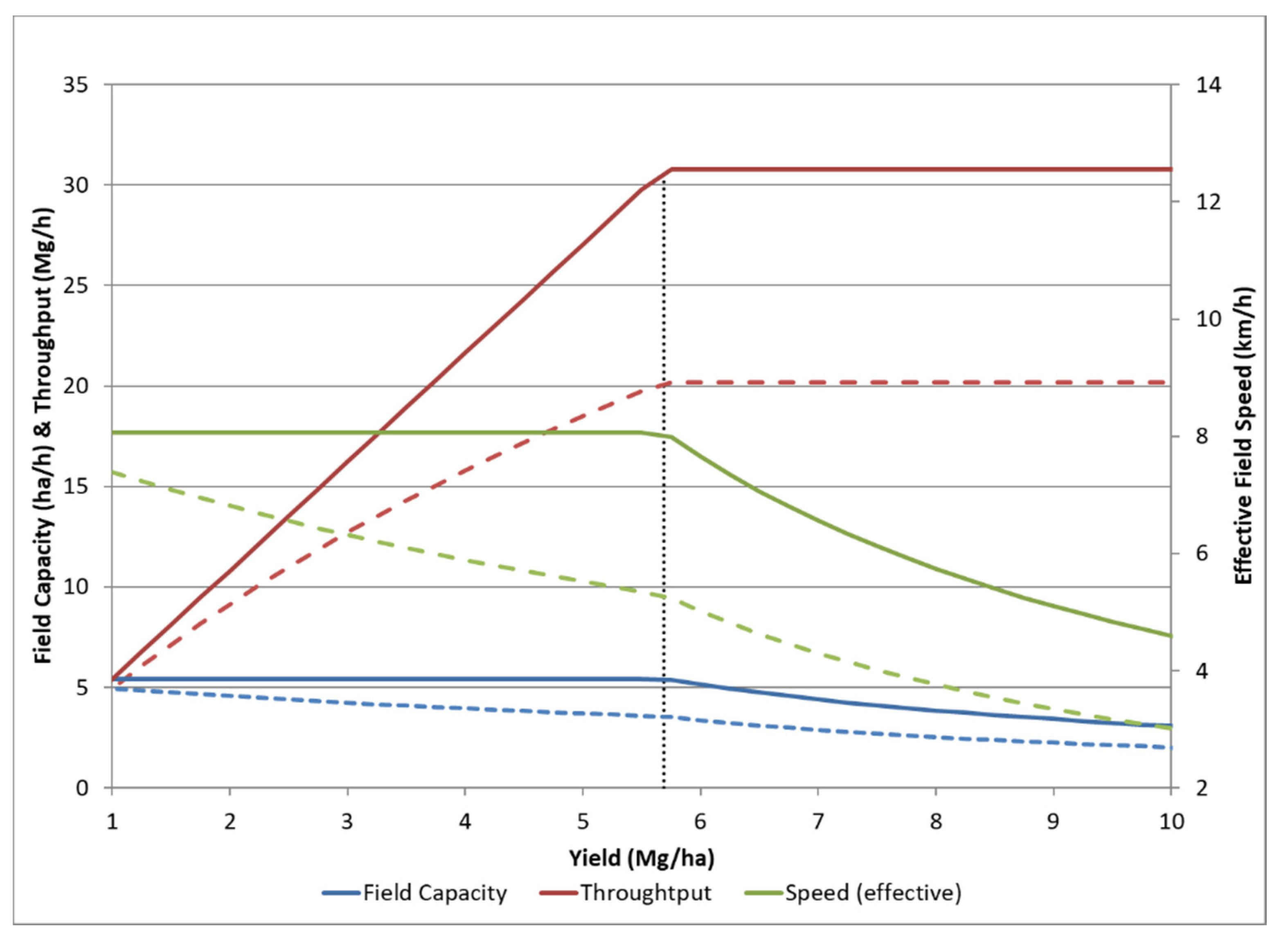

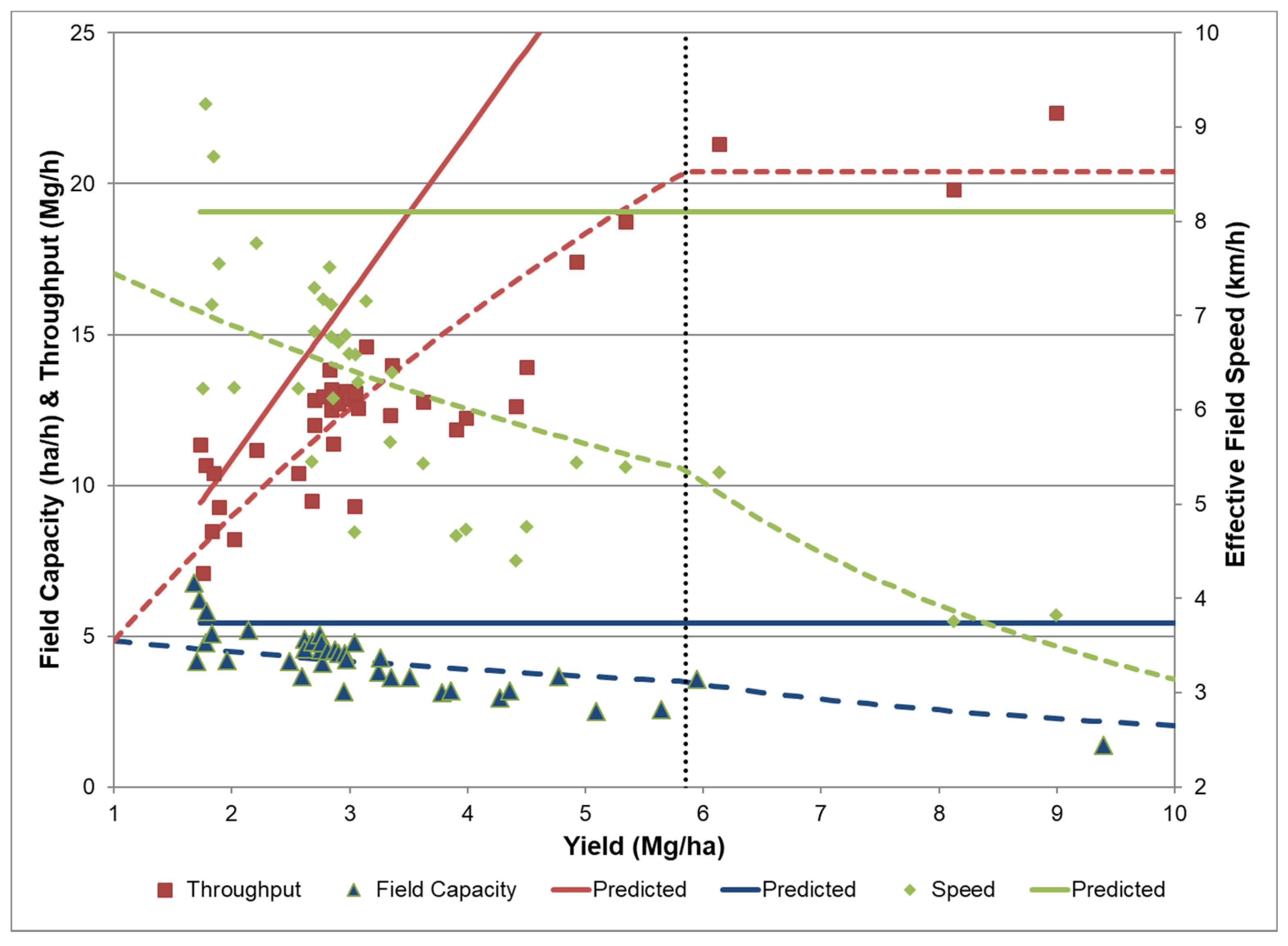

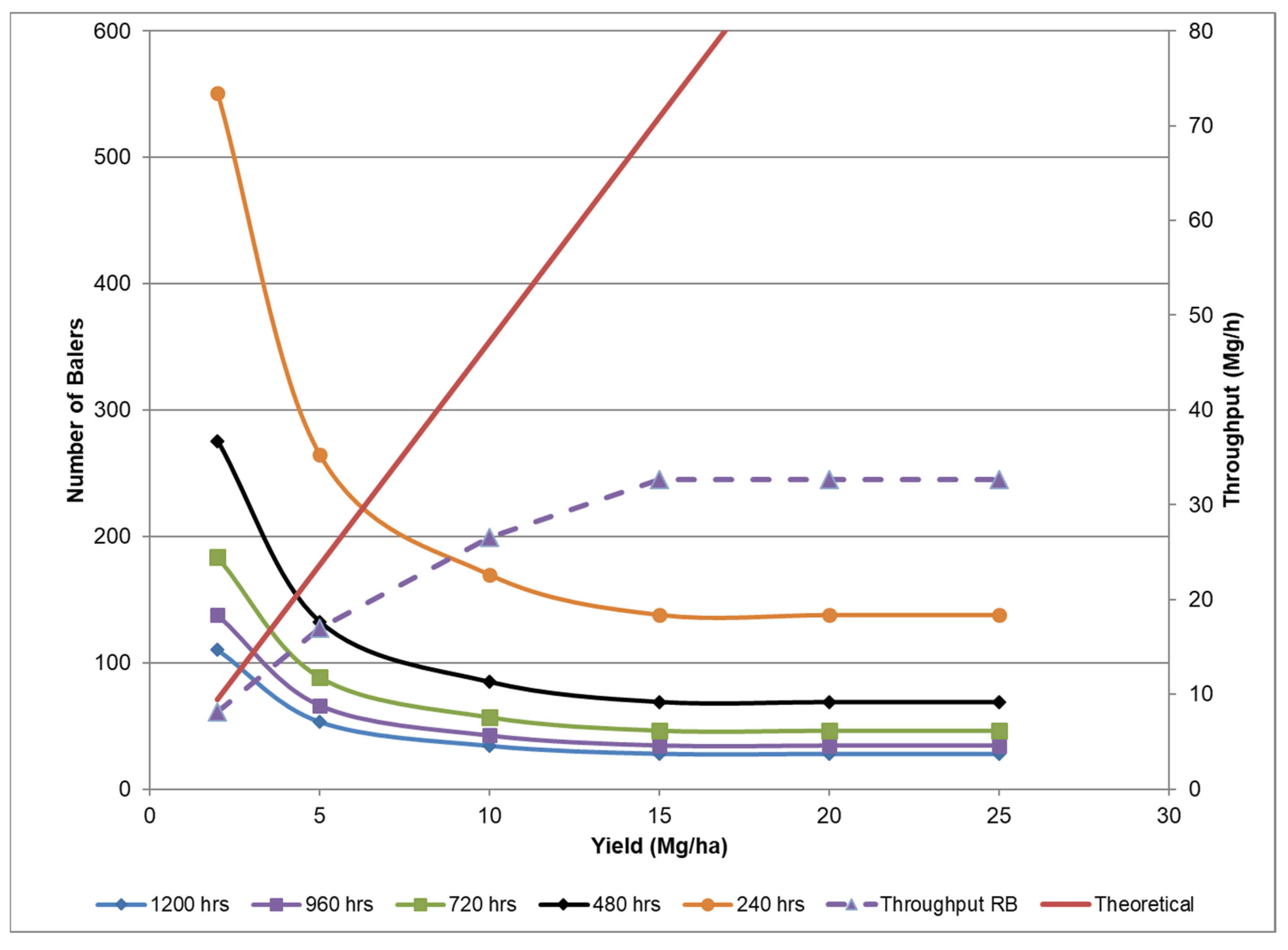

Impact of Higher Yield on Round Balers

- Bm/Cm = the time to form a bale, h

- tw = time to wrap/eject a bale, s

- K2 = 3600 s/h.

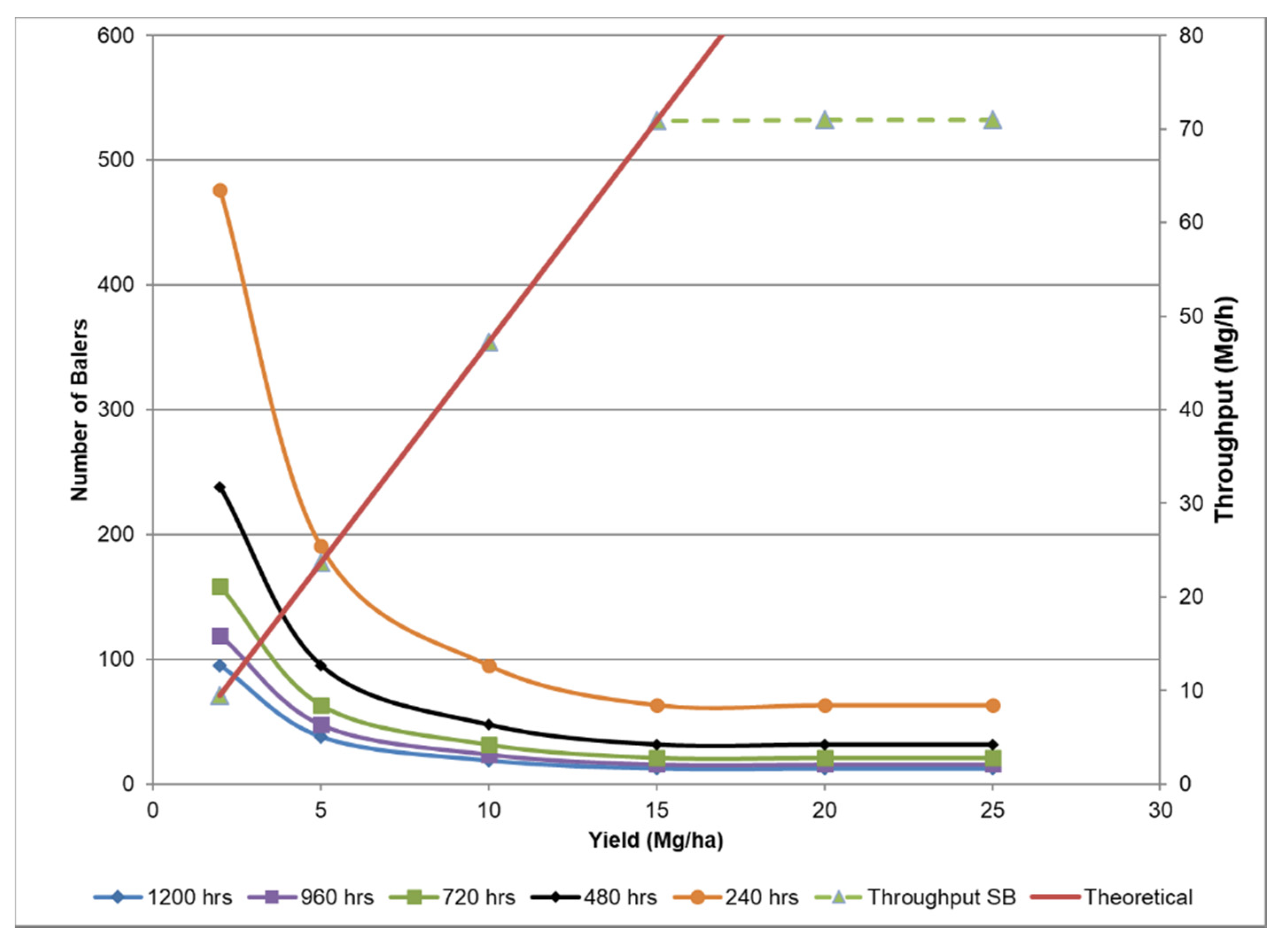

3. Results

3.1. Example Use of Relationships

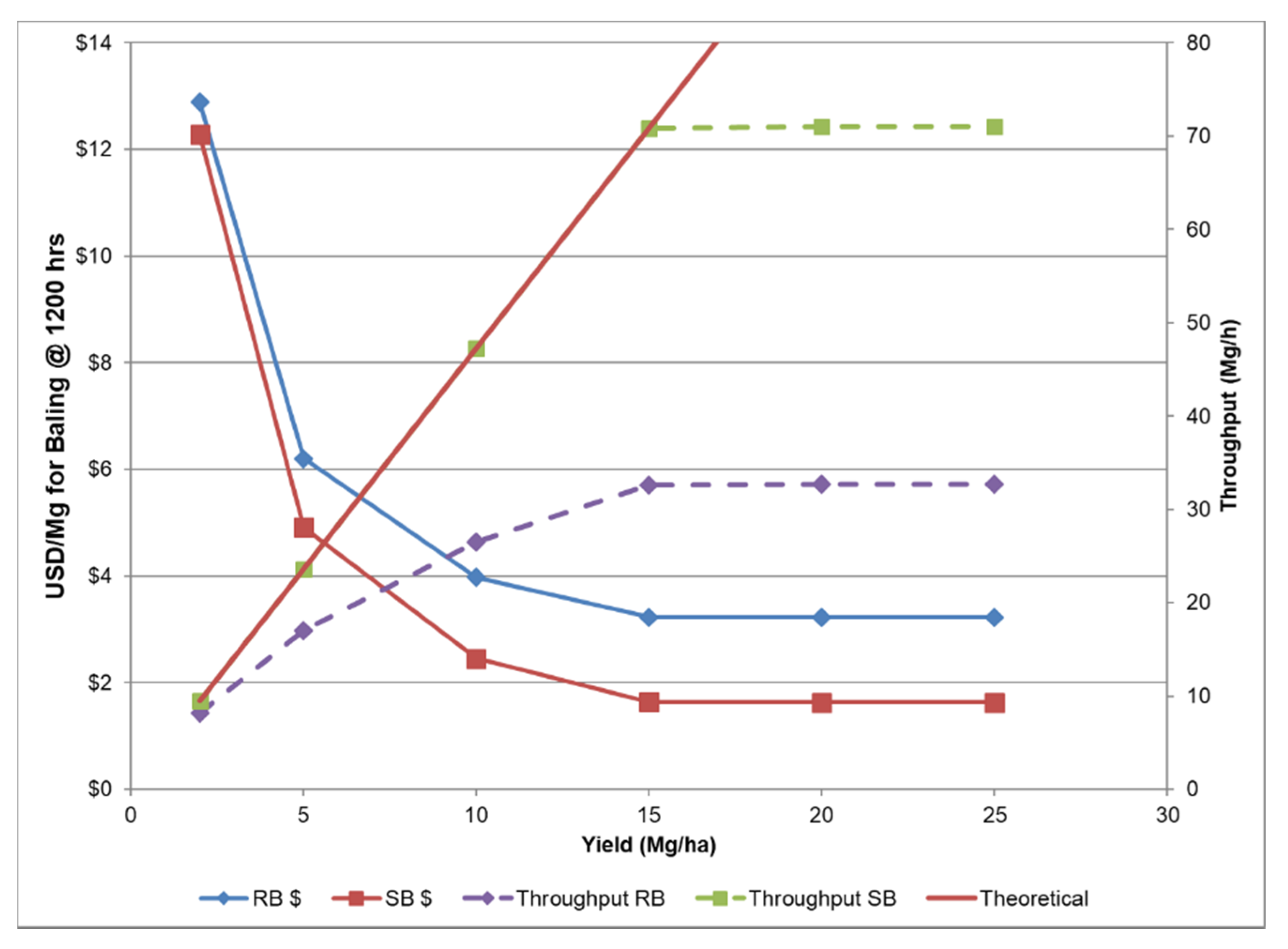

3.2. Impact on Cost Calculations

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- U.S. Department of Energy. U.S. Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry; Perlack, R.D., Stokes, B.J., Eds.; ORNL/TM-2011/224; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2011; 227p.

- Liu, J.; Grisso, R.D.; Cundiff, J.S. Harvest systems and analysis for herbaceous biomass, Chapter 6. In Biomass Now-Cultivation and Utilization; Book 2; Miodrag Darko Matovic, IntechOpen: London, UK, 2013; ISBN 980-953-51-1106-1. [Google Scholar] [CrossRef][Green Version]

- Grisso, R.D.; Moxley, G.; Webb, E.; Cundiff, J.S.; Sokhansanj, S. In-field performance of hay balers using DGPS. In Proceedings of the 2013 ASABE Annual International Meeting, Kansas City, MO, USA, 21–24 July 2013. ASABE Paper No. 131538975. [Google Scholar]

- Bransby, D.I.; Sladden, S.E.; Downing, M. Yield effects on bale density and time required for commercial harvesting and baling of switchgrass. In Proceedings of the BIOENERGY ’96—The Seventh National Bioenergy Conference: Partnerships to Develop and Apply Biomass Technologies, Nashville, TN, USA, 15–20 September 1996. [Google Scholar]

- Shinners, K.J.; Boettcher, G.C.; Muck, R.E.; Wiemer, P.J.; Casler, M.D. Harvest and storage of two perennial grasses as biomass feedstocks. Trans. ASABE 2010, 53, 359–370. [Google Scholar] [CrossRef]

- Womac, A.R.; Hart, W.E.; Bita, V.S.P.; Kraus, T. Biomass harvesting of high-yield low-moisture switchgrass: Equipment performance and moisture relations. Appl. Eng. Agric. 2012, 28, 775–786. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Turhollow, A.F.; Wilkerson, E.G. Development of the Integrated Biomass Supply Analysis and Logistics Model (IBSAL); Technical Memorandum ORNL/TM-2006/57; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2008. [Google Scholar]

- Srivastava, A.K.; Goering, C.E.; Rohrbach, R.P.; Buckmaster, D.R. Machinery Selection and Management. Chapter 15. In Engineering Principles of Agricultural Machines, 2nd ed.; Copyright American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005; pp. 525–552. [Google Scholar]

- ASABE. ASABE Standards, D497.7, Agricultural Machinery Management Data; Copyright American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2011. [Google Scholar]

- ASABE. ASABE Standards, EP496.3, Agricultural Machinery Management; Copyright American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006. [Google Scholar]

- Grisso, R.D.; McCullough, D.; Cundiff, J.S.; Judd, J.D. Harvest schedule to fill storage for year-round delivery of grasses to biorefinery. Biomass Bioenergy 2013, 55, 331–338. [Google Scholar] [CrossRef]

- Martelli, R.; Bentini, M.; Monti, A. Harvest storage and handling of round and square bales of giant reed and switchgrass: An economic and technical evaluation. Biomass Bioenergy 2015, 83, 551–558. [Google Scholar] [CrossRef]

- Kemmerer, B.; Liu, J. Large square baling and bale handling efficiency e a case study. Agric. Sci. 2012, 3, 178–183. [Google Scholar] [CrossRef]

- Shastri, Y.N.; Hansen, A.C.; Rodriguez, L.F.; Ting, K.C. Impact of probability of working day on planning and operation of biomass feedstock production systems. Biofuels Bioprod. Bioref. 2011, 6, 281–291. [Google Scholar] [CrossRef]

- Thorsell, S.; Epplin, F.M.; Huhnke, R.L.; Taliaferro, C.M. Economics of a coordinated biorefinery feedstock harvest system: Lignocellulosic biomass harvest cost. Biomass Bioenergy 2004, 27, 327–337. [Google Scholar] [CrossRef]

- Cundiff, J.S.; Grisso, R.D.; McCullough, D. Comparison of bale operations for smaller production fields in the southeast. In Proceedings of the 2011 ASABE Annual International Meeting, Louisville, KY, USA, 7–10 August 2011. ASABE Paper No. 1110922. [Google Scholar]

| Cost Factors | Round | Large-Square |

|---|---|---|

| Purchase price (USD) | 45,000 | 112,000 |

| Design life (h) | 1500 | 3000 |

| Interest rate (%) | 8% | 8% |

| Tax rate: | 1.00% | 1.00% |

| Housing: | 0.75% | 0.75% |

| RF1 | 0.43 | 0.1 |

| RF2 | 1.8 | 1.8 |

| Labor cost (including benefits) (USD/h) | 15 | 15 |

| Salvage value | 10% | 10% |

| Round Baler | Large-Square Baler | |||||

|---|---|---|---|---|---|---|

| h | n | USD/h | USD Annual | n | USD/h | USD Annual |

| 1200 | 1.3 | 105.37 | 126,445 | 2.5 | 116.06 | 139,271 |

| 960 | 1.6 | 106.02 | 101,781 | 3.1 | 117.68 | 112,973 |

| 720 | 2.1 | 107.11 | 77,118 | 4.2 | 120.38 | 86,676 |

| 480 | 3.1 | 109.28 | 52,454 | 6.3 | 125.79 | 60,379 |

| 240 | 6.3 | 115.80 | 27,791 | 12.5 | 142.01 | 34,081 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grisso, R.“.; Cundiff, J.S.; Webb, E.G. Predicting Field Efficiency of Round-Baling Operations in High-Yielding Biomass Crops. AgriEngineering 2020, 2, 447-457. https://doi.org/10.3390/agriengineering2030030

Grisso R“, Cundiff JS, Webb EG. Predicting Field Efficiency of Round-Baling Operations in High-Yielding Biomass Crops. AgriEngineering. 2020; 2(3):447-457. https://doi.org/10.3390/agriengineering2030030

Chicago/Turabian StyleGrisso, Robert “Bobby”, John S. Cundiff, and Erin G. Webb. 2020. "Predicting Field Efficiency of Round-Baling Operations in High-Yielding Biomass Crops" AgriEngineering 2, no. 3: 447-457. https://doi.org/10.3390/agriengineering2030030

APA StyleGrisso, R. “., Cundiff, J. S., & Webb, E. G. (2020). Predicting Field Efficiency of Round-Baling Operations in High-Yielding Biomass Crops. AgriEngineering, 2(3), 447-457. https://doi.org/10.3390/agriengineering2030030