1. Introduction

Wild blueberries (

Vaccinium angustifolium) are a perennial, small fruit crop which are typically managed on a biennial cycle in order to maximize yields and apply pesticides which otherwise would damage the crop [

1,

2,

3,

4,

5,

6,

7]. This two-year cycle sees vigorous vegetative growth in the first year followed by flower and fruit production in the second year. Following harvest of the crop, fields are pruned and the cycle repeats itself. Wild blueberries are native to northeastern North America and represent one of Nova Scotia’s most important agricultural products, with an export value of

$76.3 million in 2017 [

8]. That said, with rising labor costs, low fruit prices, and per hectare expenses nearing

$4000 for normal operation, there is a significant demand within the industry to find ways of cutting costs [

9,

10].

Mechanical wild blueberry harvesters were first developed in 1956 by modifying an existing cranberry picker for the wild blueberry crop. This original harvester utilized six raking combs rotating opposite the direction of travel and was prone to high fruit losses and soil digging [

11]. In subsequent years, the design was improved upon to include many of the features common to the modern design. These include the advent of the hollow picking reel, variable speed picking heads, picking head rotation concurrent with the direction of travel, and hydraulic control of the picking head height [

12,

13,

14]. Currently, there is only one large scale producer of wild blueberry harvesters, that being Doug Bragg Enterprises (DBE) in Collingwood, Nova Scotia. The DBE harvester is a side mounted tractor implement which, harvests, removes debris and stores wild blueberries in either large bins (1.22 × 1.22 × 0.3 m) or small boxes (0.4 × 0.51 × 0.15 m) depending on the configuration of the handling system. DBE has been the driving force behind many of the efficiency improvements done to the harvester including, the implementation of the hydraulic control system for precise harvester head height control. A single hydraulic actuator with a 203.2 mm stroke moves the picking point up or down a total of 101.6 mm. Maintaining the picking point at the correct level is essential to maximizing harvester picking efficiency and doing so requires near constant manipulation by the operator [

15]. For a single or double headed machine this is possible, but as the company intends to add more heads to their machines in future, the need to design a control system for these larger machines is critical. Additionally, the company aims to transition towards an automated head for their harvesters.

Automated crop harvesting has seen some success in greenhouses, row crops, and tree crops [

16,

17,

18,

19,

20,

21,

22,

23,

24], however the unique environment of wild blueberry fields create a number of further challenges. The first challenge is the drastic variations in slope within wild blueberry fields. Zaman et al. [

25] found that across four fields the slope varied from 0.8 to 31.0 degrees. This drastic variation in slope, both within fields and between fields, requires a large degree of adaptability for an autonomous harvester. Secondly, the location of the fruit on the blueberry plant also varies significantly. Farooque et al. [

15] found that fruit zones across four fields varied from 74.0 mm to 346.0 mm off the ground. Coupling these two factors together demonstrates the required variability in harvester head height position during harvest. In order to automate this process, the first step is to develop a system which precisely and accurately provides feedback for head height positioning. Additionally, as the industry aims to move toward multi-headed machines, this factor must be incorporated into the design of the new control system. Finally, the developed control system should provide quality of life improvements for harvester operators, operating multiple heads, until the point where full automation can be achieved.

Similar control and feedback systems have been employed previously in agricultural machinery. Examples include feedback and control of chopping parameters on combine harvesters [

26], semi-automated combine harvesters [

27], real time soil property feedback in tillage operations [

28], soil moisture sensing and actuation of irrigation valves [

29], product flow monitoring on sprayers [

30], pressure and flow dynamics on sprayers [

31], automation of crop residue spreaders on combine harvesters [

32] and motion analysis for control of variable rate spreaders [

33]. While there are hundreds of other examples, what each of these systems have in common is that they use and provide feedback from a sensor and allow either the manual or automatic operation of an actuator. Currently, wild blueberry harvesters provide very little in the way of feedback beyond picker reel speed. This project aims to improve upon that by adding precise picker head height while meeting a number of other industry demands.

The industry’s outline for this project was to develop a control system which could precisely and accurately control multiple harvester heads within a tolerance of 20 mm of one another. This 20 mm discrepancy was used as a successful minimum standard in all tests. Current controller designs do not allow for the operation of multiple heads on a single control box. Furthermore, DBE was looking for a number of quality-of-life improvements including the tandem operation, baseline and set-to-one functions as well as numeric positional feedback for the operator. Each of these ameliorations were included in the design of the novel control box with detail on their success available throughout the document.

2. Materials and Methods

2.1. Development of Novel Control System

The basis for the novel control system was an Arduino mega controller (A000067, Arduino, Turin, Italy) operated in a closed loop, drawing feedback from a linear potentiometer as shown in

Figure 1. The Arduino’s control algorithm produced a counting integer (set value) that was scaled to match the feedback from the potentiometer. This set value was controlled by a three-position momentary rocker switch which scaled values up or down within the range of the actuator (minimum of 0 mm, maximum of 203.2 mm). In this way, if the feedback from the potentiometer did not match the set value, the actuator would be told to move up or down to compensate for the difference. When the value was deemed to be the same, no signal is sent and the actuator does not move. To account for any analog noise which might be interpreted as a difference by the system, a programed tolerance variable was incorporated and fine-tuned to match the constraints of the harvester. In all, the system was designed to operate up to five harvester heads at a time by incorporating a rocker switch for each head.

The original design for the control system utilized two single-pole double-throw mechanical relays (SLA-05VDC-SL-C, Ningbo Songle Relay Co., LTD, Yuyao, China) to control the actuator. The normally closed connection was used to maintain the actuator in in static state while the two normally open connections were used to operate the actuator, one for each direction of travel. This first prototype of the control system had some complications however, as it was prone to signal interference which caused the relays to switch unpredictably. Furthermore, the nature of mechanical relays is that they wear out with heavy use and due to the high number of inputs required in this system, they do not make the best choice. As a replacement, two H-bridge motor drivers (RB-Pol-381, Pololu, Las Vegas, NV, USA) were used in their place. These H-bridges utilize solid state MOSFET transistors, which are faster and more reliant than mechanical relays. By replacing the mechanical relays with H-bridges the experienced signal interference was eliminated. The full wiring of the control box can be observed in

Figure 2.

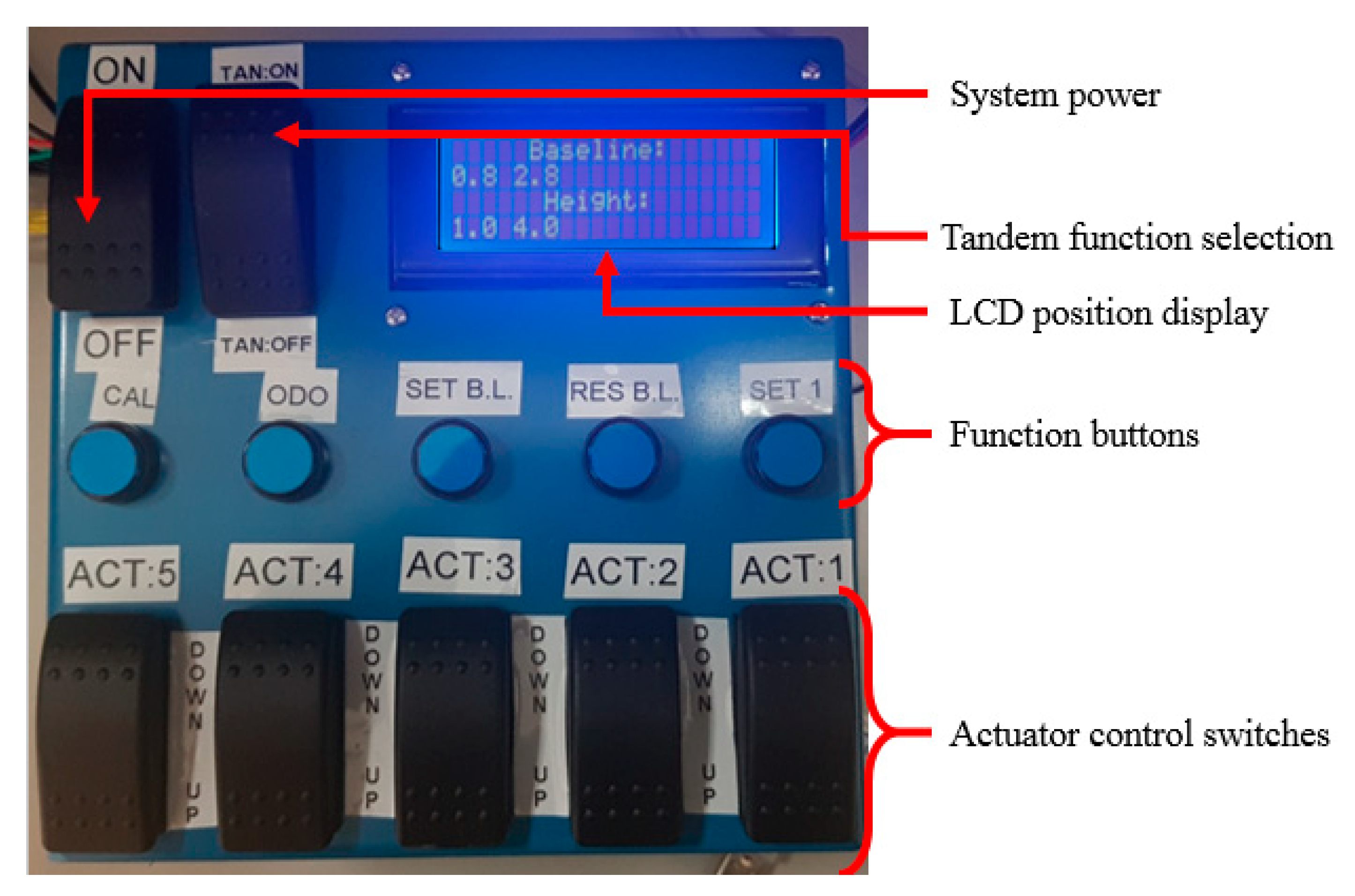

In addition to the basic functionality of the control system, three further functions were added to the control box. The first was the tandem function which, locks multiple harvester heads together at a set distance and allows them all to be moved at the same time using a single switch while maintaining the set distance. The second was the baseline function which, allows the user to define a pre-set position and through the press of a single button, returns a single or all heads to the baseline position. The final function was the set-to-one function which allows the user to move a single or all heads to the same position as the first head through the press of a single button. The control system also provided individual or tandem control for up to five harvester heads. Finally, the system included a ‘calibrate’ function which extended the actuator to its maximum and then its minimum and set the displayed minimum and maximum at these extension values. All of the positioning feedback was relayed to the operator via a 20 × 4 I2C-LCD (QK51, Quimat, Shenzhen, China). The developed control box can be observed in

Figure 3.

2.2. Design Considerations

Two separate designs were considered for how best to receive positional feedback from the linear actuator. The first was to utilize an electric linear actuator [

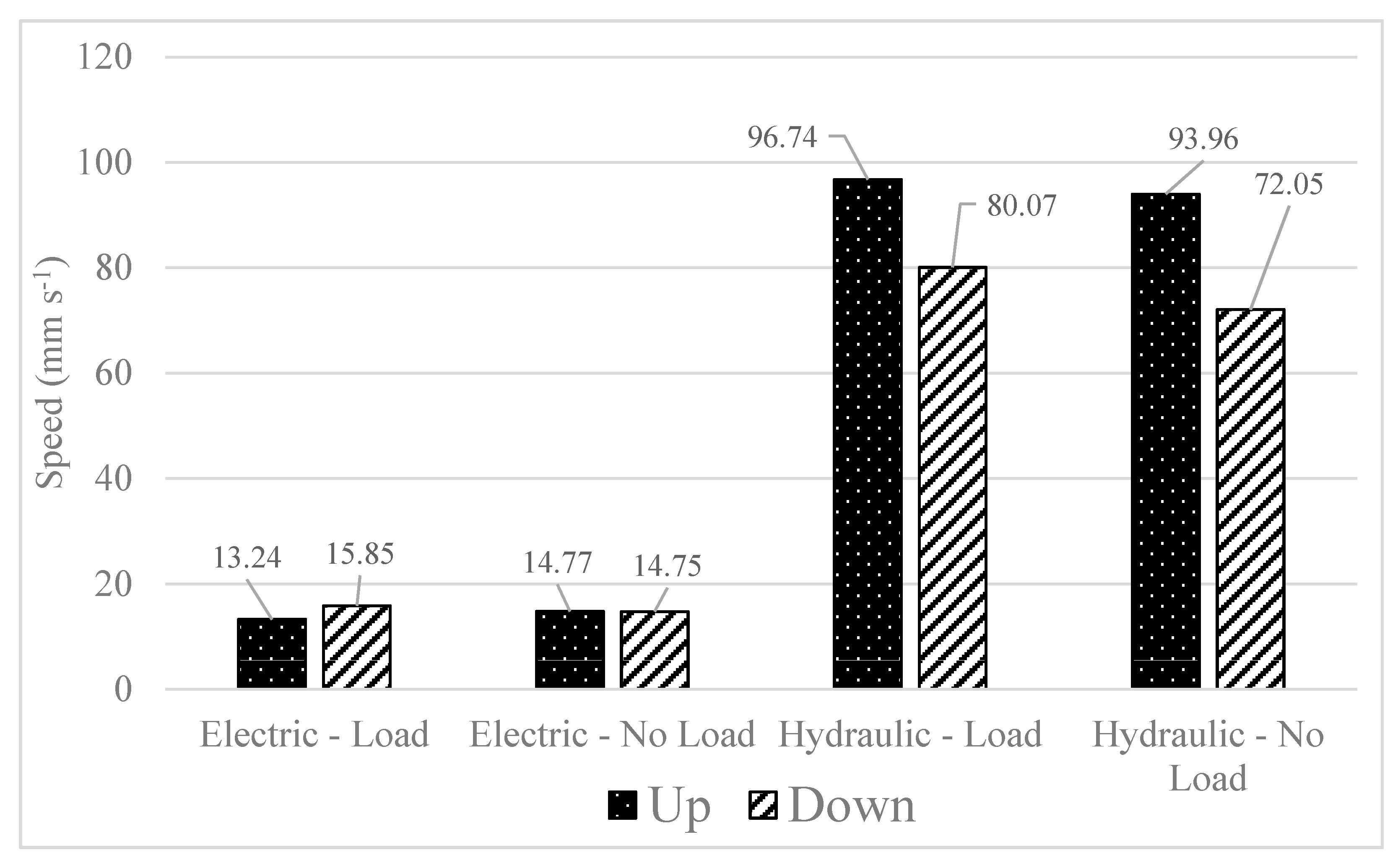

34] with a built in potentiometer. The second option was to use the existing hydraulic actuator but incorporate an external linear potentiometer to provide positional feedback. While both designs accomplished the task of providing precise and accurate positional feedback, ultimately, the hydraulic actuator and external linear potentiometer were chosen due to their quicker actuation speeds, ease of installation, lower power requirements, and overall lower cost.

2.3. Harvester Modifications

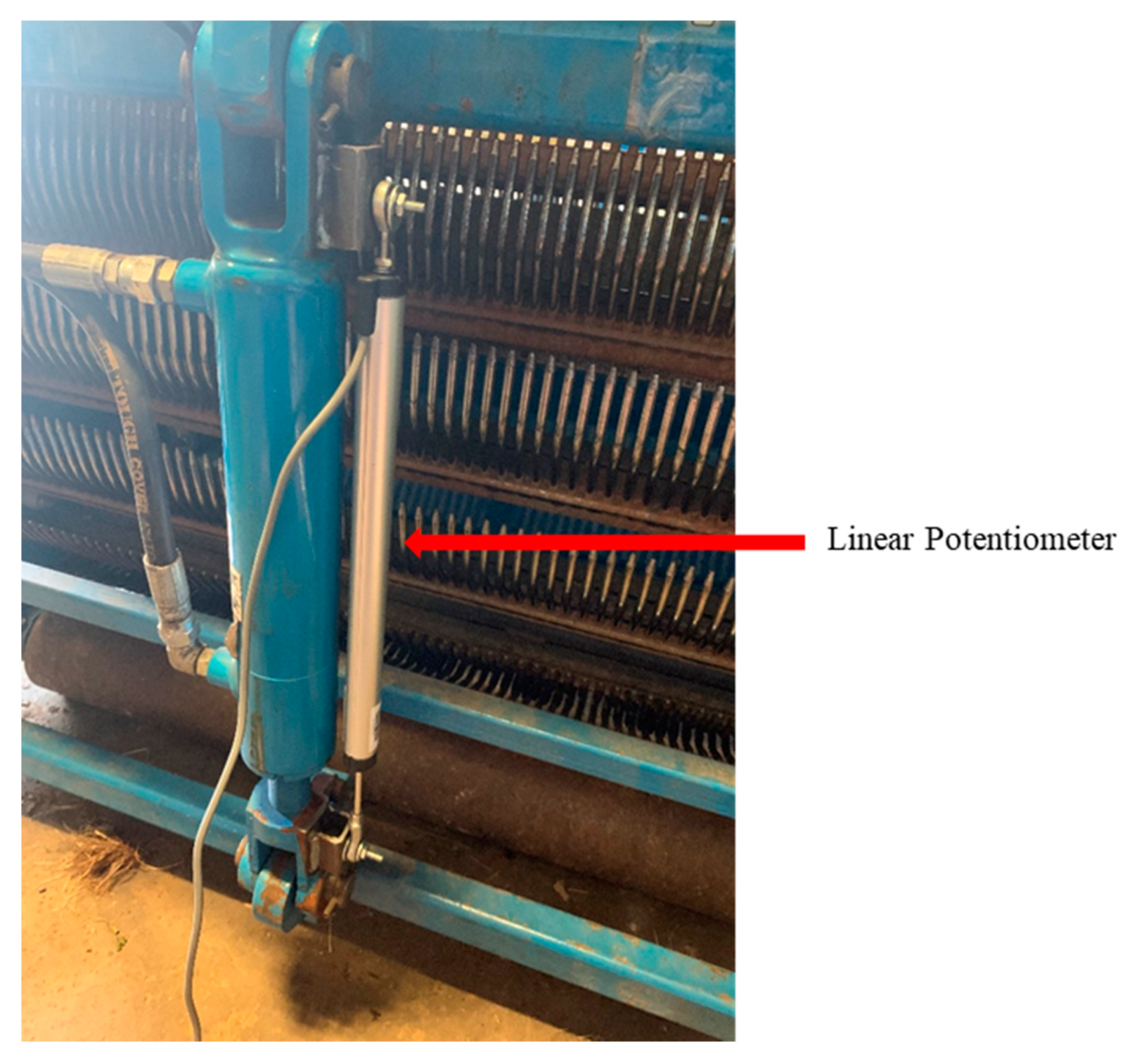

In order to accommodate the developed control system, the harvester required only a single modification. This modification was the addition of an electric linear potentiometer in line with the existing hydraulic actuator as can be seen in

Figure 4.

The current design of the harvester allows for the potentiometer to be welded to the same fastening points as the actuator, ensuring that as little error as possible was introduced into the system. While other points on the harvester head where the potentiometer would see less wear and tear were considered, ultimately it was determined that they would not provide feedback as precise as the selected location.

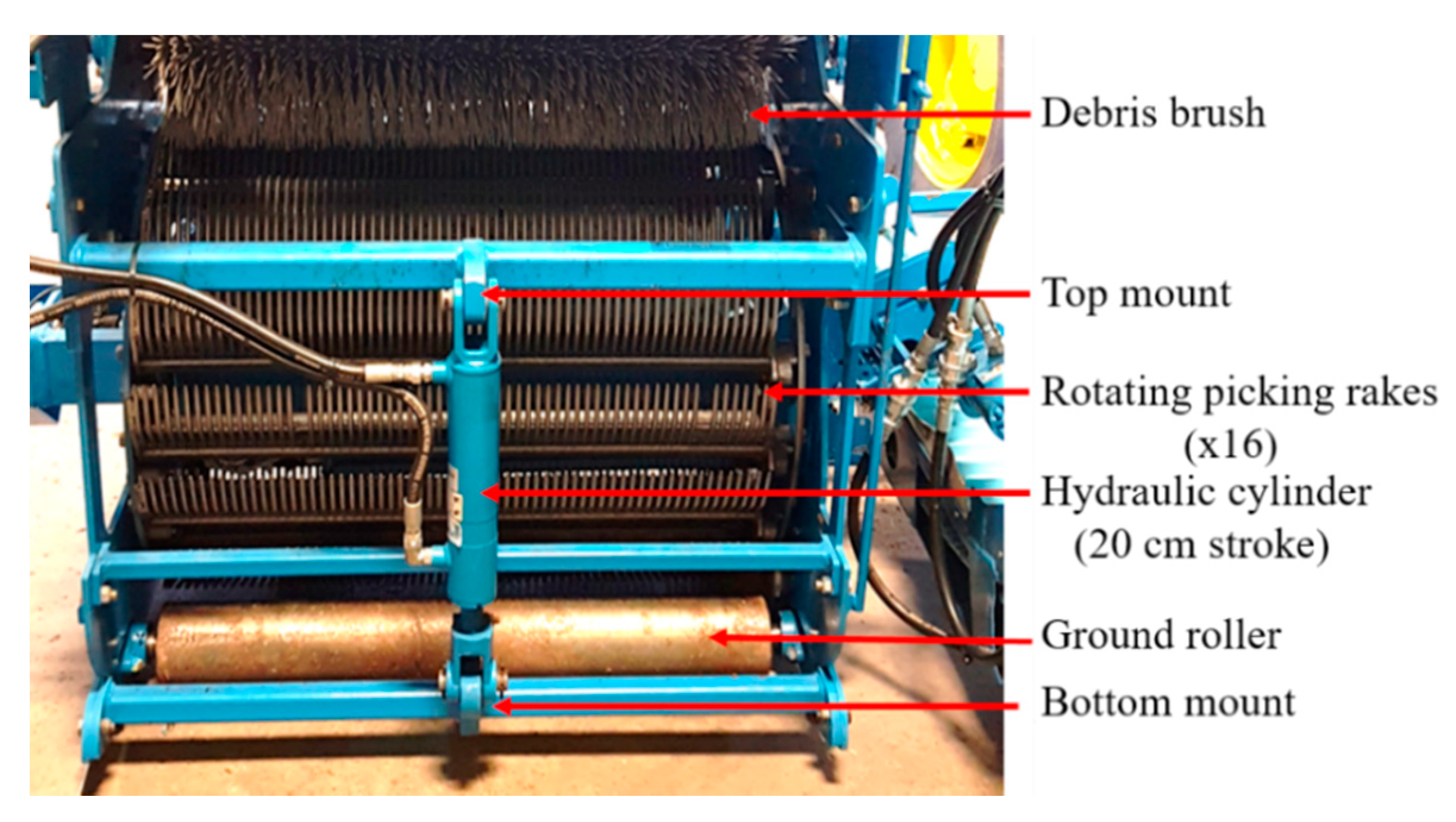

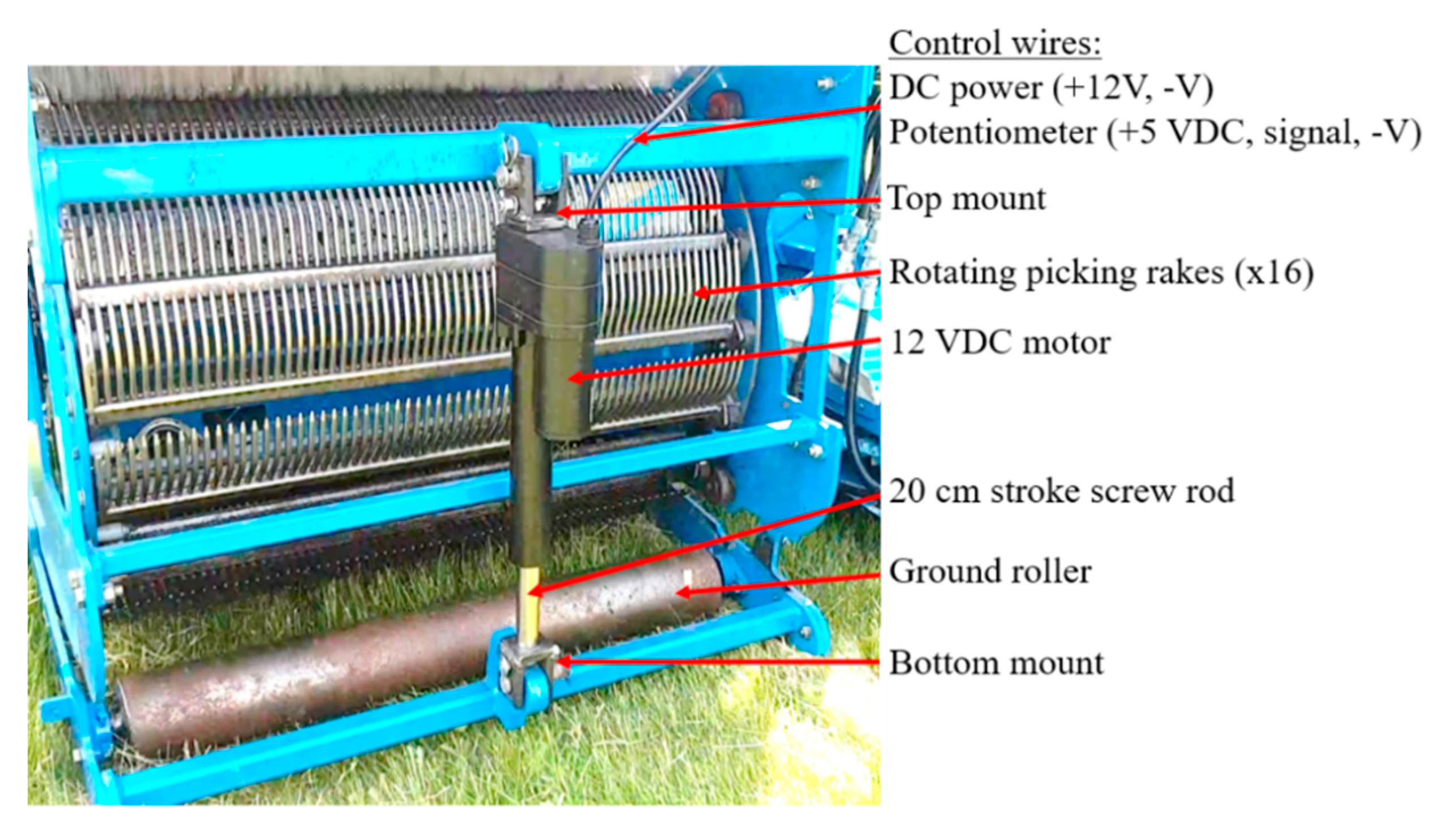

For comparisons between the electric and hydraulic actuators, the two actuators can easily be swapped in and out via two hitch pins denoted as the top and bottom mounts in

Figure 5 and

Figure 6.

2.4. Lab Evaluation of Electric and Hydraulic Actuators

In order to assess the viability of both the electric and hydraulic actuators, a laboratory scale test was used to determine their actuation speeds both under and without load. First, the actuation speed was determined for both actuators when they were disconnected from the harvester head (no load). Being that the full stroke of both actuators is 203.2 mm, the speed is simple to calculate by timing a full stroke. Timing was performed manually and speeds were taken as the average of 16 samples for both the upward and downward stroke directions. Manual timing can introduce some degree of error; however, the speed determination did not require a high degree of accuracy to make a definite conclusion due to the significant difference in operational speeds between the two actuators. The actuators were then attached to the harvester heads (under load) as seen in

Figure 5 and

Figure 6 and the same analysis was carried out to determine their actuation speeds under load and in both directions.

2.5. Field Evaluation Setup

For tests involving comparison between multiple actuators, a hydraulic linear actuator under the load of the harvester head was compared with an electric linear actuator under no load. This was done in order to assess the potential for a linear potentiometer to precisely and accurately provide positional feedback for a hydraulic actuator, similar to what is already incorporated with the electric actuator. The electric actuator was not placed under load as optimal system performance should see negligible differences regardless of load. All data collection was performed in triplicate and were blocked across two fields. The two fields used in this study were Dalhousie’s Wild Blueberry Research Centre’s Western field (45.441248, −63.451062) and the East Mines’ Northern field (45.427082, −63.481812) both in Debert, Nova Scotia. All data was analyzed using Fisher’s least significant difference (LSD) multiple means comparison.

2.6. Tandem Function Evaluation

The tandem function was evaluated by offsetting the actuators a given distance in a random order and then adjusting them to a second, predetermined, and randomly selected position. In each of the cases, one of the actuators was positioned at the minimum stroke distance of 0 mm and the other was offset. A summary of the initial offset positions can be observed in

Table 1.

Once the offset was locked in by the control system, the actuators were then moved to a second, predetermined position in a random order. The second positions were based off the reading from the linear potentiometer and were 0, 25.4, 50.8, 76.2, 101.6, 127.0, 152.4, 177.8, and 203.2 mm of extension. It should be noted that not all combinations were possible for each test due to the values of the initial offset. Additionally, following each adjustment the actuators were returned to their initial offset position in order to account for any compounding error which might occur. All movements were performed while the harvester was in motion and actively harvesting in order to account for the vibrations of the harvesting process. Once the actuators were moved to their second position, measurements of their second position were recorded manually, using a ruler and compared versus the initial offset to see how well the system maintained the offset. All tests were performed in triplicate.

A second similar test was performed where one of the actuators was set to the maximum extension (203.2 mm) and the other was retracted a predetermined distance. A summary of this initial condition can be observed in

Table 2.

This second evaluation of the tandem function was performed in order to observe any differences between upward and downward strokes of the actuators and how that might affect the tandem operation.

2.7. Baseline Function Evaluation

The baseline function was evaluated by setting the hydraulic actuator to one of three predetermined and randomly selected initial baseline positions as determined by the potentiometer’s output. These initial positions were 50.8, 101.6, and 15.24 mm of extension. Once the baselines were set, the hydraulic actuator was moved to one of nine predetermined and randomly selected points. These points were 0, 25.4, 50.8, 76.2, 101.6, 127.0, 152.4, 177.8, and 203.2 mm of extension. Once at the test point, the return to baseline function was engaged and a measurement was taken manually, using a ruler, to determine how precisely the actuator returned to its initial position. All movements of the actuator were performed while the harvester was moving and actively harvesting to account for any vibrations from the harvesting process. All tests were performed in triplicate.

2.8. Set-to-One Function Evaluation

The set-to-one function was evaluated by setting the electric actuator to one of three predetermined and randomly selected initial positions. These positions were 50.8, 101.6, and 152.4 mm of extension. The hydraulic actuator was then randomly positioned into one of nine predetermined and randomly selected points. These points were 0, 25.4, 50.8, 76.2, 101.6, 127.0, 152.4, 177.8, and 203.2 mm of extension. Once positioned, the set-to-one function was engaged and a ruler was used to take manual measurements of the hydraulic actuator’s extension to observe how well it matched the position of the electric actuator. All movements of the actuator were performed while the harvester was moving and actively harvesting to account for any vibrations from the harvesting process. All tests were performed in triplicate.

2.9. Real-Time Fruit Zone Mapping

The final function which was added to the control system was the logging of real time fruit zone information. This was done by recording the extension of the actuator every second and relating that to the height of the picker teeth from the ground. While similar work has been done before in isolation [

35], this system removes the requirement for additional hardware to the fastened to the harvester. Additionally, it does not measure the plant height; rather, it indirectly measures the fruit zone, which as mentioned, can fluctuate from 74.0 mm to 346.0 mm off the ground [

15]. This new method of fruit zone determination is reliant on the operator’s ability to maintain the picking teeth within the fruit zone. As it is not a direct measurement and only an estimation, it was not analyzed in this study. With that said, it could provide valuable feedback to growers who choose to utilize this functionality.

4. Conclusions

In all, the developed control system performed well, with a highest absolute discrepancy across all tests of 3.20 mm. As the industry was targeting a maximum absolute discrepancy of 20 mm across all functions, the results are more than satisfactory. Though some significant differences were apparent in the data, they remain comparatively small compared to the target and are likely the result of the large sample size and low variation. The next steps in full automation of the harvester will be to develop a ground, object, and fruit sensing system which can be interfaced with this control system. If that is achieved, the two systems can work concurrently to reposition the harvester head without the need for manual input. In addition, there is a need to assess the viability of using automated guidance systems for harvesting wild blueberries. There exists some concern that, due to the relatively small working width of the wild blueberry harvester and the fact that it is a side mounted implement, it may not be suitable for automated guidance without a significant reduction in precision and accuracy. In order to achieve full automation this area, further research will be required.