Turbulent Kinetic Energy Distribution of Nutrient Solution Flow in NFT Hydroponic Systems Using Computational Fluid Dynamics

Abstract

1. Introduction

2. Materials and Methods

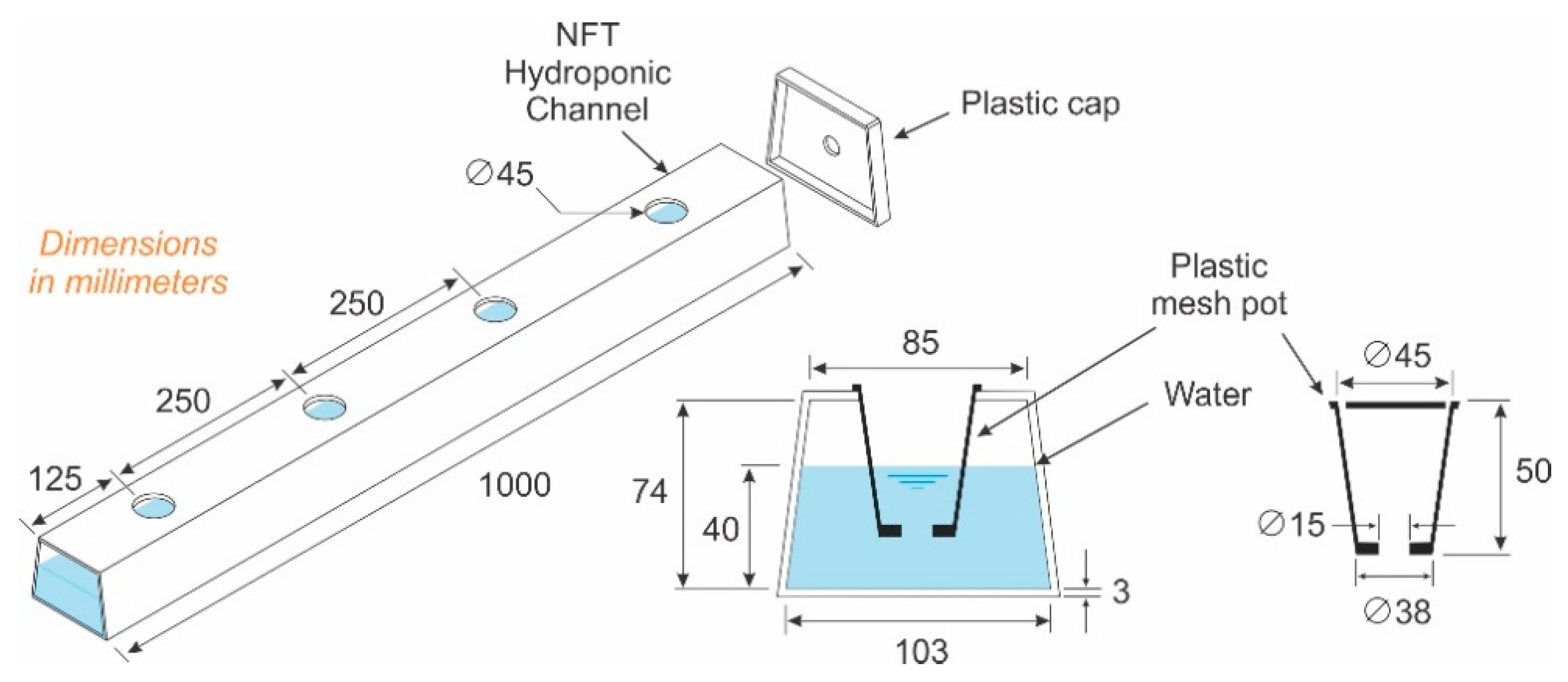

2.1. Modeling the Virtual NFT Hydroponic System

2.2. Governing Equations

2.3. Reynolds Number

2.4. Boundary Conditions

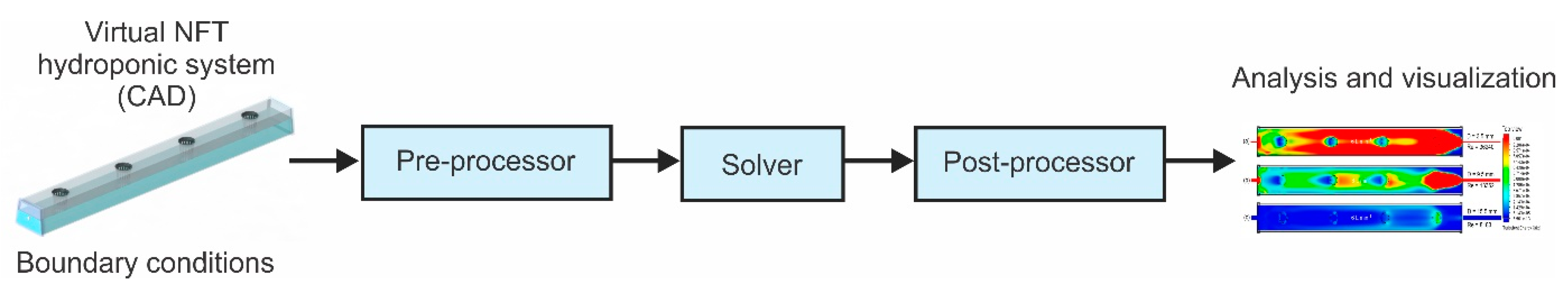

2.5. CFD Simulations

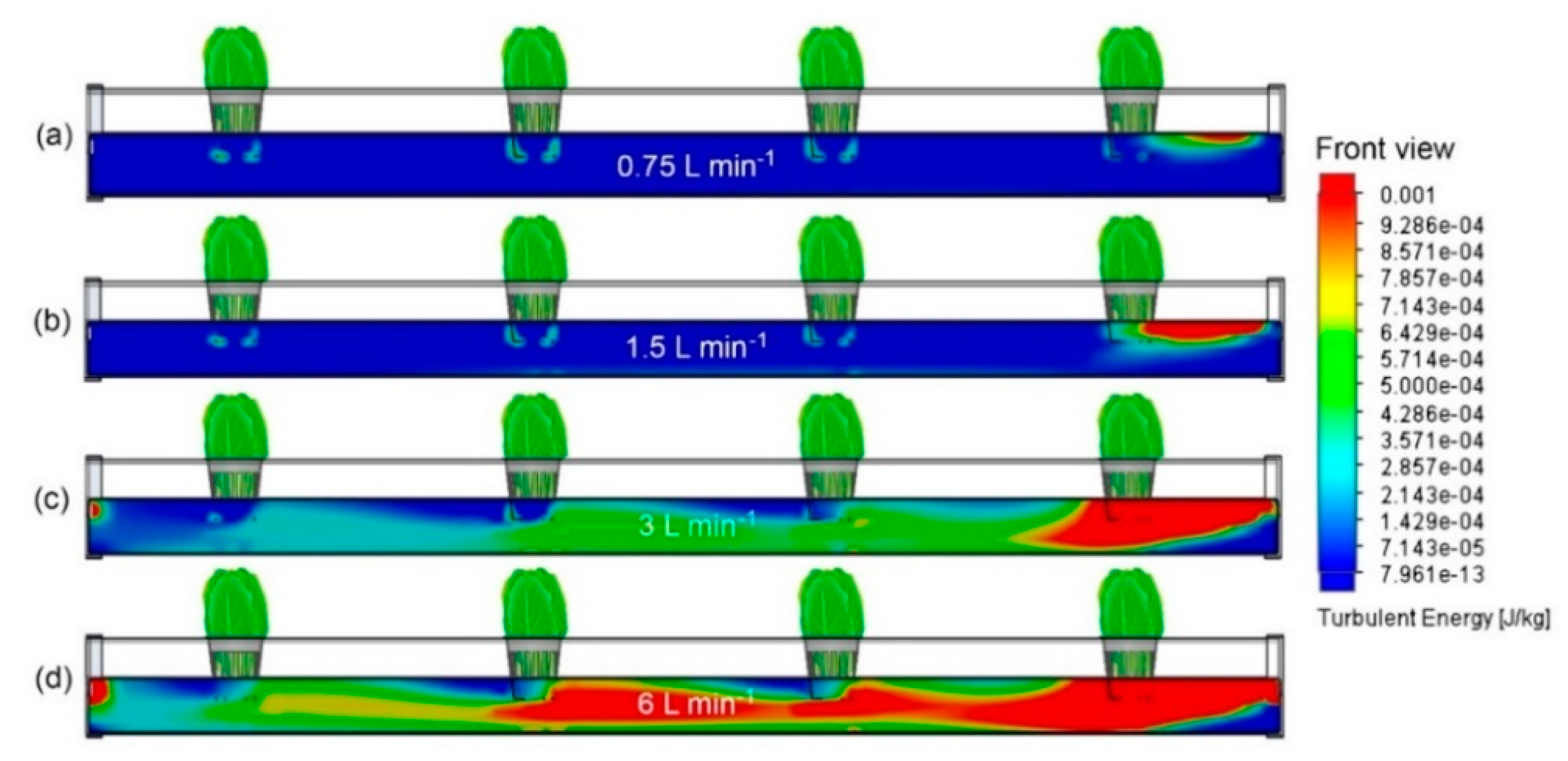

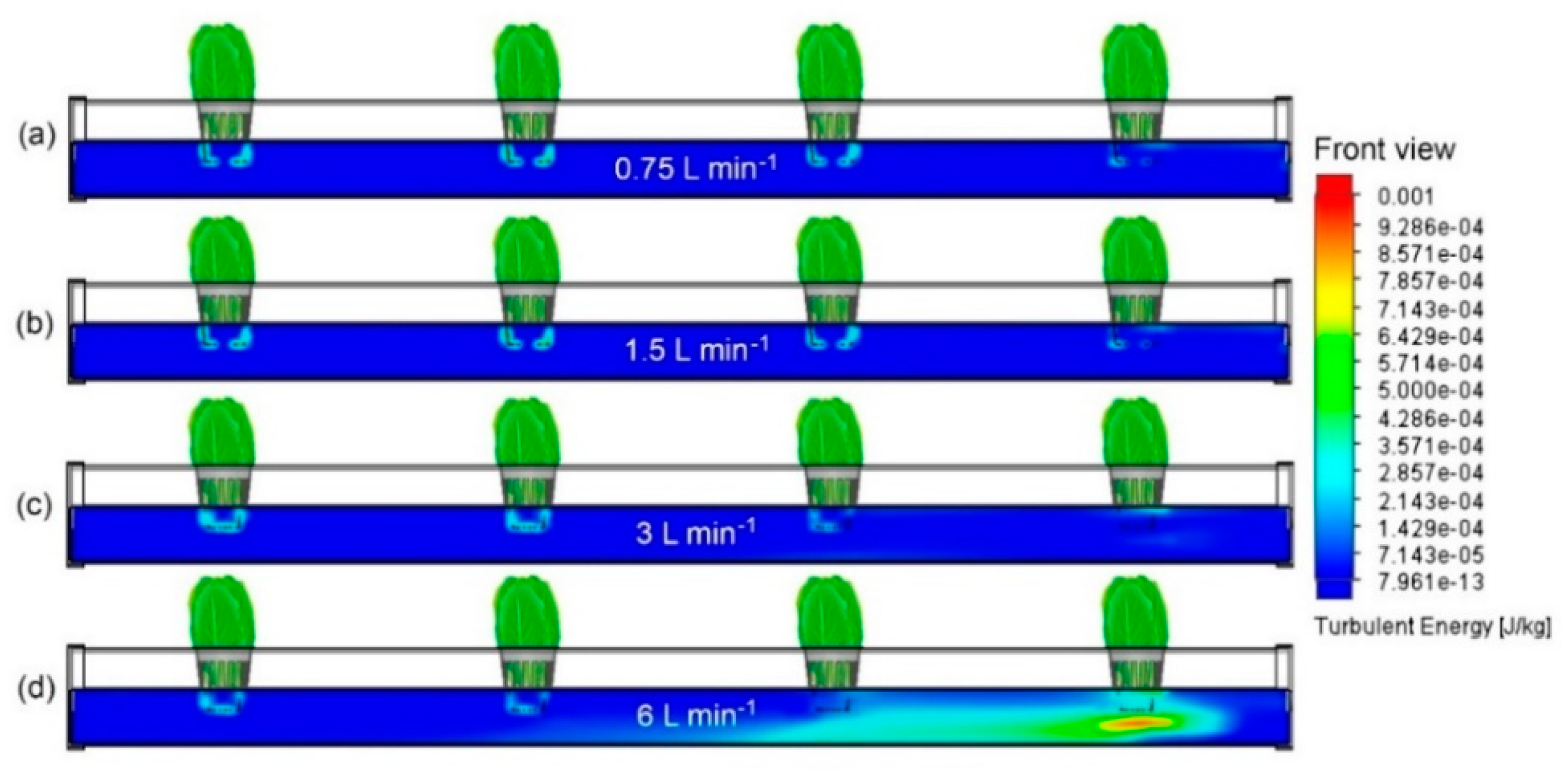

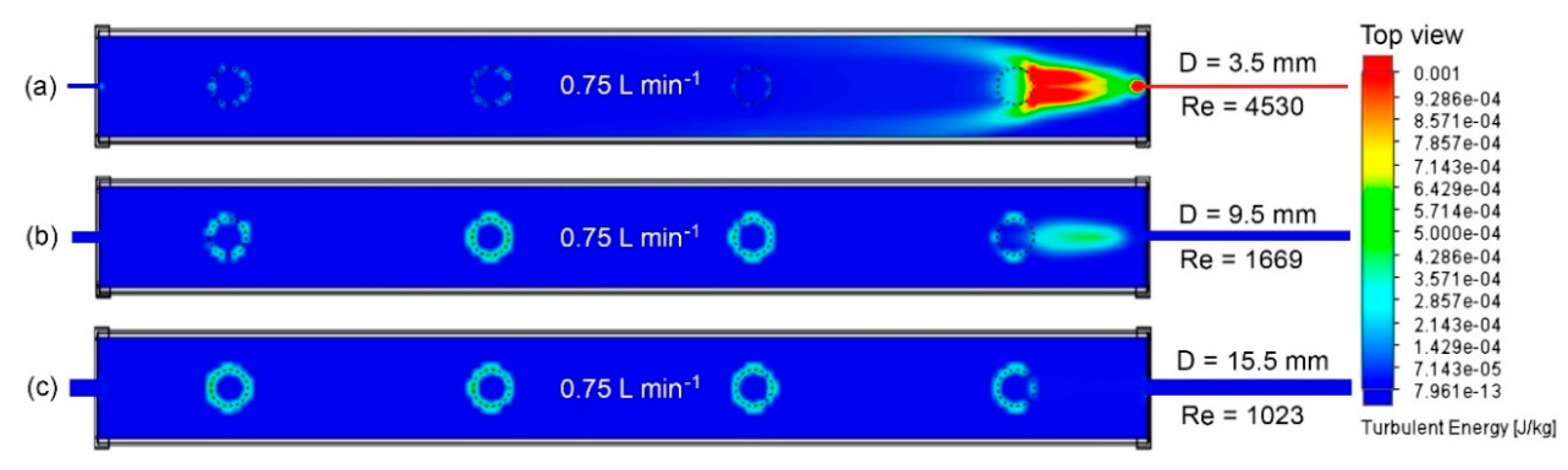

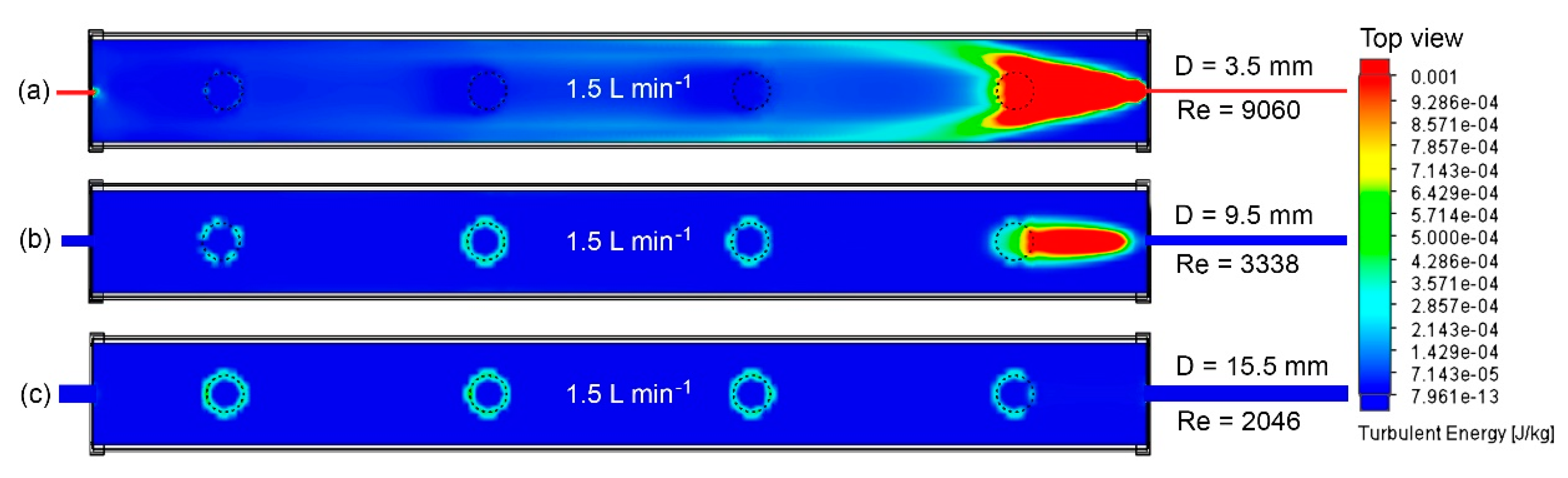

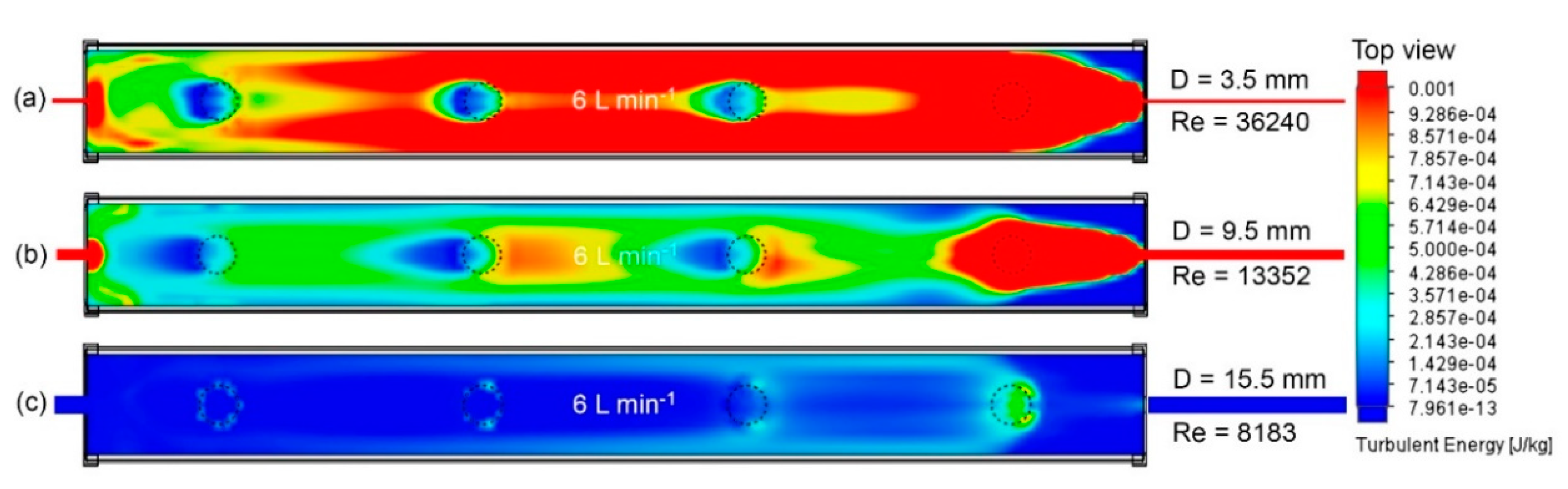

3. Simulation Results

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Guzmán, C.H.; Carrera, J.L.; Durán, H.A.; Berumen, J.; Ortiz, A.A.; Guirette, O.A.; Arroyo, A.; Brizuela, J.A.; Gómez, F.; Blanco, A.; et al. Implementation of Virtual Sensors for Monitoring Temperature in Greenhouses Using CFD and Control. Sensors 2019, 19, 60. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Tang, B.; Gu, M. Growth Responses and Root Characteristics of Lettuce Grown in Aeroponics, Hydroponics, and Substrate Culture. Horticulturae 2018, 4, 35. [Google Scholar] [CrossRef]

- Mauceri, C.; Nicoletto, C.; Junge, R.; Schmautz, Z.; Sambo, P.; Borin, M. Hydroponic systems and water management in aquaponics: A review. Ital. J. Agron. 2017, 13, 1–11. [Google Scholar] [CrossRef]

- Junior, C.H.; Rezende, R.; de Freitas, P.S.; Gonçalves, A.C.; Frizzone, J.A. Influência da condutividade elétrica, concentração iônica e vazão de soluções nutritivas na produção de alface hidropônica. Ciência E Agrotecnologia 2008, 32, 1142–1147. [Google Scholar] [CrossRef]

- Genuncio, G.D.; Gomes, M.; Ferrari, A.C.; Majerowicz, N.; Zonta, E. Hydroponic lettuce production in different concentrations and flow rates of nutrient solution. Hortic. Bras. 2012, 30, 526–530. [Google Scholar] [CrossRef]

- Al-Tawaha, A.R.; Al-Karaki, G.; Al-Tawaha, A.R.; Sirajuddin, S.N.; Makhadmeh, I.; Megat-Wahab, P.E.; Youssef, R.A.; Sultan, W.A.; Massadeh, A. Effect of water flow rate on quantity and quality of lettuce (Lactuca sativa L.) in nutrient fi lm technique (NFT) under hydroponics conditions. Bulg. J. Agric. Sci. 2018, 5, 793–800. [Google Scholar]

- Carrera-Escobedo, J.L.; Ortiz-Rivera, A.; Guzmán-Valdivia, C.H.; García-Ruiz, M.A.; Désiga-Orenday, O. Computational fluid dynamics analysis for improving temperature distribution in a chili dryer. Therm. Sci. 2018, 22, 2615–2623. [Google Scholar] [CrossRef]

- Langtry, R.; Menter, F. Transition modeling for general CFD applications in aeronautics. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; p. 522. [Google Scholar]

- Mehl, M.; Chen, J.-Y.; Pitz, W.J.; Sarathy, S.M.; Westbrook, C.K. An approach for formulating surrogates for gasoline with application toward a reduced surrogate mechanism for CFD engine modeling. Energy Fuels. 2011, 25, 5215–5223. [Google Scholar] [CrossRef]

- Bhutta, M.M.A.; Hayat, N.; Bashir, M.H.; Khan, A.R.; Ahmad, K.N.; Khan, S. CFD applications in various heat exchangers design: A review. Appl. Therm. Eng. 2012, 32, 1–12. [Google Scholar] [CrossRef]

- Rusly, E.; Aye, L.; Charters, W.; Ooi, A. CFD analysis of ejector in a combined ejector cooling system. Int. J. Refrig. 2005, 28, 1092–1101. [Google Scholar] [CrossRef]

- Hartwanger, D.; Horvat, A. 3D modelling of a wind turbine using CFD. In Proceedings of the NAFEMS Conference, Cheltenham, UK, 10–11 June 2008; pp. 1–14. [Google Scholar]

- Bougoul, S.; Boulard, T. Water dynamics in two rockwool slab growing substrates of contrasting densities. Sci. Hortic. 2006, 107, 399–404. [Google Scholar] [CrossRef]

- Niam, A.G.; Suhardiyanto, H.; Seminar, K.B.; Maddu, A. CFD Simulation of Cooling Pipes Distance in The Growing Medium for Hydroponic Substrate in Tropical Lowland. Int. J. Eng. Res. Dev. 2017, 15, 56–63. [Google Scholar]

- Blazek, J. Computational Fluid Dynamics: Principles and Applications, 3rd ed.; Butterworth-Heinemann: Waltham, MA, USA, 2015. [Google Scholar]

- Sun, P.N.; Colagrossi, A.; Marrone, S.; Antuono, M.; Zhang, A.M. Multi-resolution Delta-plus-SPH with tensile instability control: Towards high Reynolds number flows. Comput. Phys. Commun. 2018, 224, 63–80. [Google Scholar] [CrossRef]

- Hydro Environment. 2019. Available online: https://hydroenv.com.mx (accessed on 25 March 2019).

| Parameter | Value |

|---|---|

| Inlet temperature | 20.05 °C |

| Environment pressure | 101 kPa |

| Inlet volume flow rate | Variable |

| Number of cells in X, Y, Z | 16 |

| Number of cells in Y | 10 |

| Number of cells in Z | 72 |

| Total cells | 67,401 |

| Fluid cells | 67,401 |

| Fluid cells containing solids | 28,496 |

| Pipe Diameter (mm) | Volumetric Flow Rate (L min−1) | |||

|---|---|---|---|---|

| 0.75 | 1.5 | 3 | 6 | |

| 3.5 | 4530 | 9060 | 18120 | 36240 |

| 9.5 | 1669 | 3338 | 6676 | 13352 |

| 15.5 | 1023 | 2046 | 4092 | 8183 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzmán-Valdivia, C.H.; Talavera-Otero, J.; Désiga-Orenday, O. Turbulent Kinetic Energy Distribution of Nutrient Solution Flow in NFT Hydroponic Systems Using Computational Fluid Dynamics. AgriEngineering 2019, 1, 283-290. https://doi.org/10.3390/agriengineering1020021

Guzmán-Valdivia CH, Talavera-Otero J, Désiga-Orenday O. Turbulent Kinetic Energy Distribution of Nutrient Solution Flow in NFT Hydroponic Systems Using Computational Fluid Dynamics. AgriEngineering. 2019; 1(2):283-290. https://doi.org/10.3390/agriengineering1020021

Chicago/Turabian StyleGuzmán-Valdivia, Cesar H., Jorge Talavera-Otero, and Omar Désiga-Orenday. 2019. "Turbulent Kinetic Energy Distribution of Nutrient Solution Flow in NFT Hydroponic Systems Using Computational Fluid Dynamics" AgriEngineering 1, no. 2: 283-290. https://doi.org/10.3390/agriengineering1020021

APA StyleGuzmán-Valdivia, C. H., Talavera-Otero, J., & Désiga-Orenday, O. (2019). Turbulent Kinetic Energy Distribution of Nutrient Solution Flow in NFT Hydroponic Systems Using Computational Fluid Dynamics. AgriEngineering, 1(2), 283-290. https://doi.org/10.3390/agriengineering1020021