Modelling Factors Influencing IoT Adoption: With a Focus on Agricultural Logistics Operations

Abstract

:1. Introduction

Gap in Knowledge

| Authors | Relation to Agricultural Logistics Operations | Hypothetical Results/Findings |

|---|---|---|

| Leng et al. [20] | Impact of IoT on distribution in agricultural supply chains | Improved distribution efficiency, reduced spoilage, faster delivery times |

| Zhang et al. [22] | Impact of IoT on distribution in agricultural supply chains | Increased accuracy in product distribution and minimized losses |

| Srinivasan et al. [23] | Frameworks for enhancing inventory transparency | Real-time inventory visibility, optimization, and reduced carrying costs |

| Duan [24] | IoT’s influence on risk management and information flow | Improved risk assessment and mitigation, smoother information flow |

| Mo [25] | IoT’s influence on risk management and information flow | Enhanced risk management and information sharing in agricultural operations |

| Yan et al. [26] | IoT’s influence on risk management and information flow | Improved risk mitigation and efficient information exchange |

| Alifah et al. [27] | Three-layer architecture for IoT in rice supply chain | Enhanced efficiency and traceability in the rice supply chain |

| Yadav, Luthra, & Garg [28] | Role of IoT enablers in agricultural operations | Successful integration of IoT technologies into agricultural logistics |

| Aamer, Al-Awlaqi, Affia, Arumsari, & Mandahawi [29]) | Analysis of challenges and barriers to IoT adoption | Identification of common obstacles in IoT implementation |

| Lin, Lee, & Lin [30] | Analysis of challenges and barriers to IoT adoption | Identification of challenges faced during IoT implementation |

| Mattos and Novais Filho [31] | Formulation of business models for IoT adoption | Proposed business models for IoT implementation in agriculture |

| Del Sarto et al. [32] | Formulation of business models for IoT adoption | Economic feasibility and potential returns on investment in IoT adoption |

2. Agricultural Supply Chain and Logistics Background

3. Internet of Things

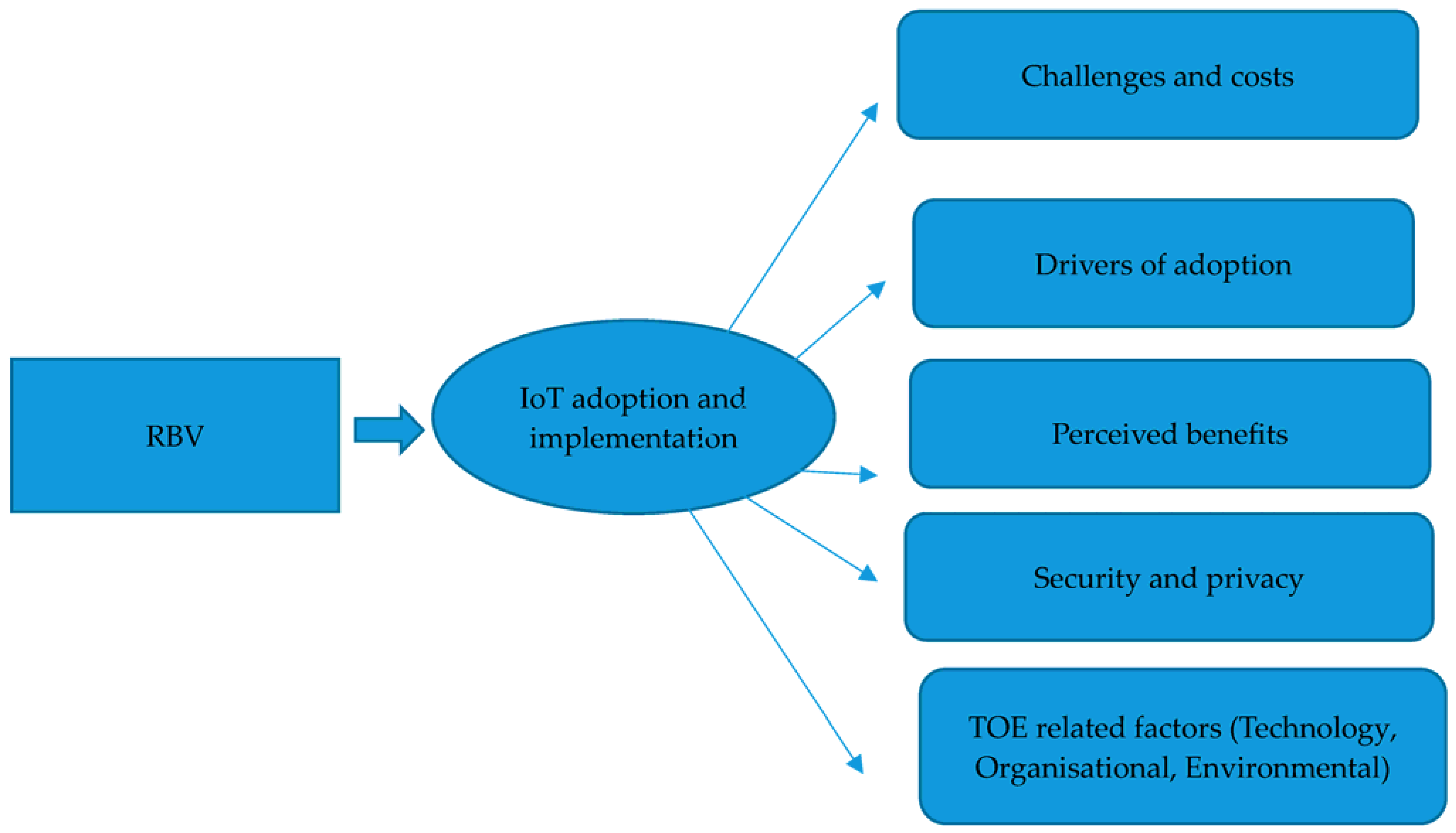

4. Current State of Knowledge on IoT Adoption and Implementation

5. Materials and Methods

5.1. Resource Based View Theory

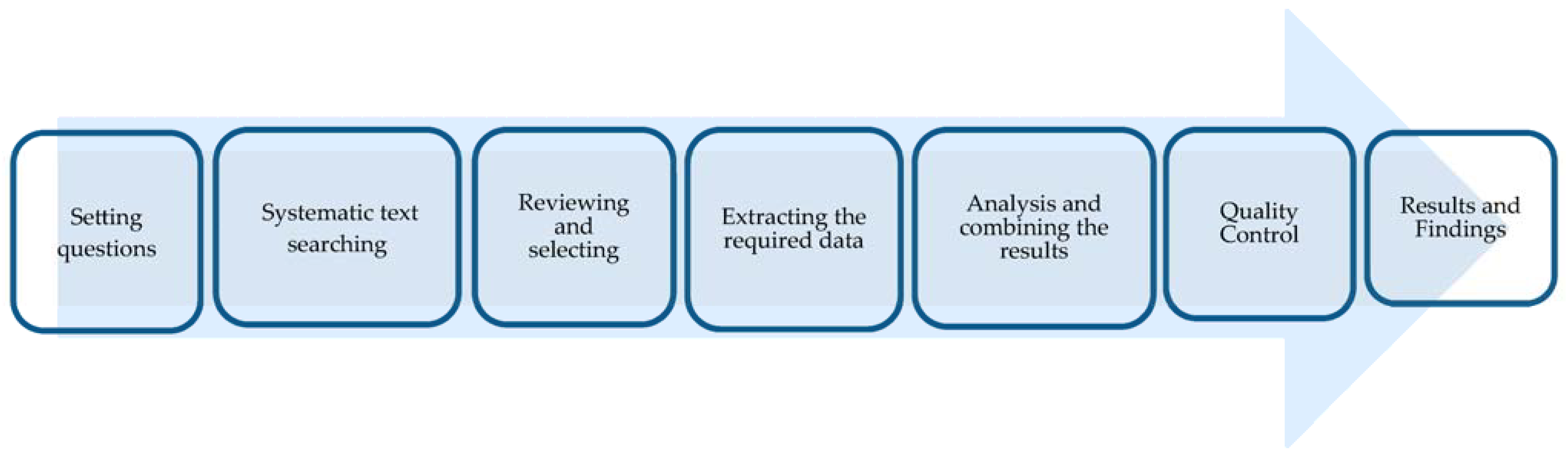

5.2. Research Methodology

5.2.1. Setting Questions

5.2.2. Systematic Text Searching

5.2.3. Reviewing and Selecting the Appropriate Texts

5.2.4. Extracting and Synthesising Data

5.2.5. Quality Control

- The component use is essential.

- The component is useful, but it is not necessary to use it.

- It is not necessary to use the component.

6. Results and Findings

6.1. IoT Macro Category

6.1.1. IoT Deployment Requirements

6.1.2. IoT Adoption

6.1.3. IoT Complementary Technologies

6.1.4. IoT Adoption and Implementation Challenges

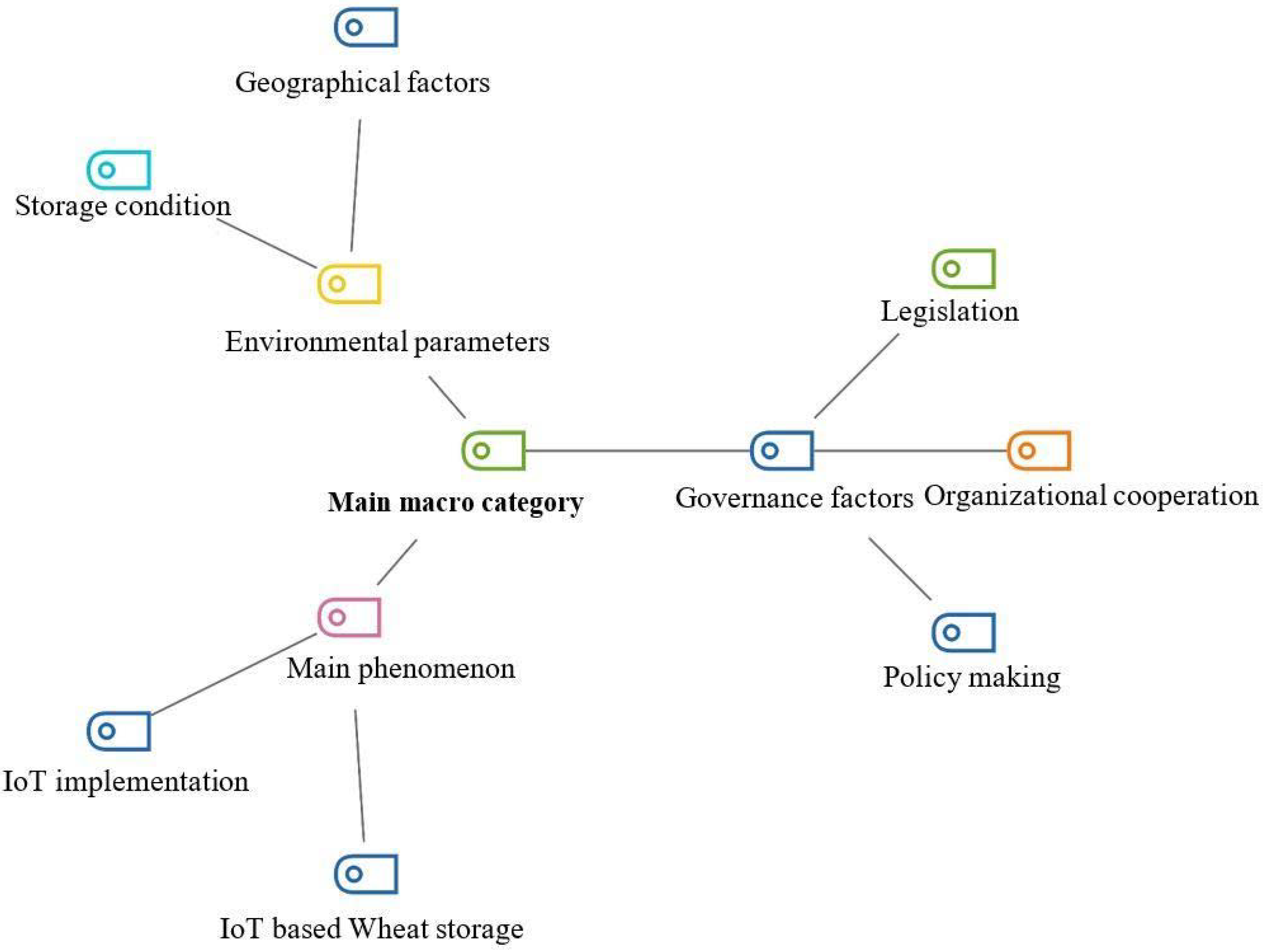

6.2. The Main Macro Category (IoT-Based Logistics Management)

6.2.1. The Main Phenomenon/IoT-Base Agricultural Logistics

6.2.2. Governance Factors

6.2.3. Environmental Parameters

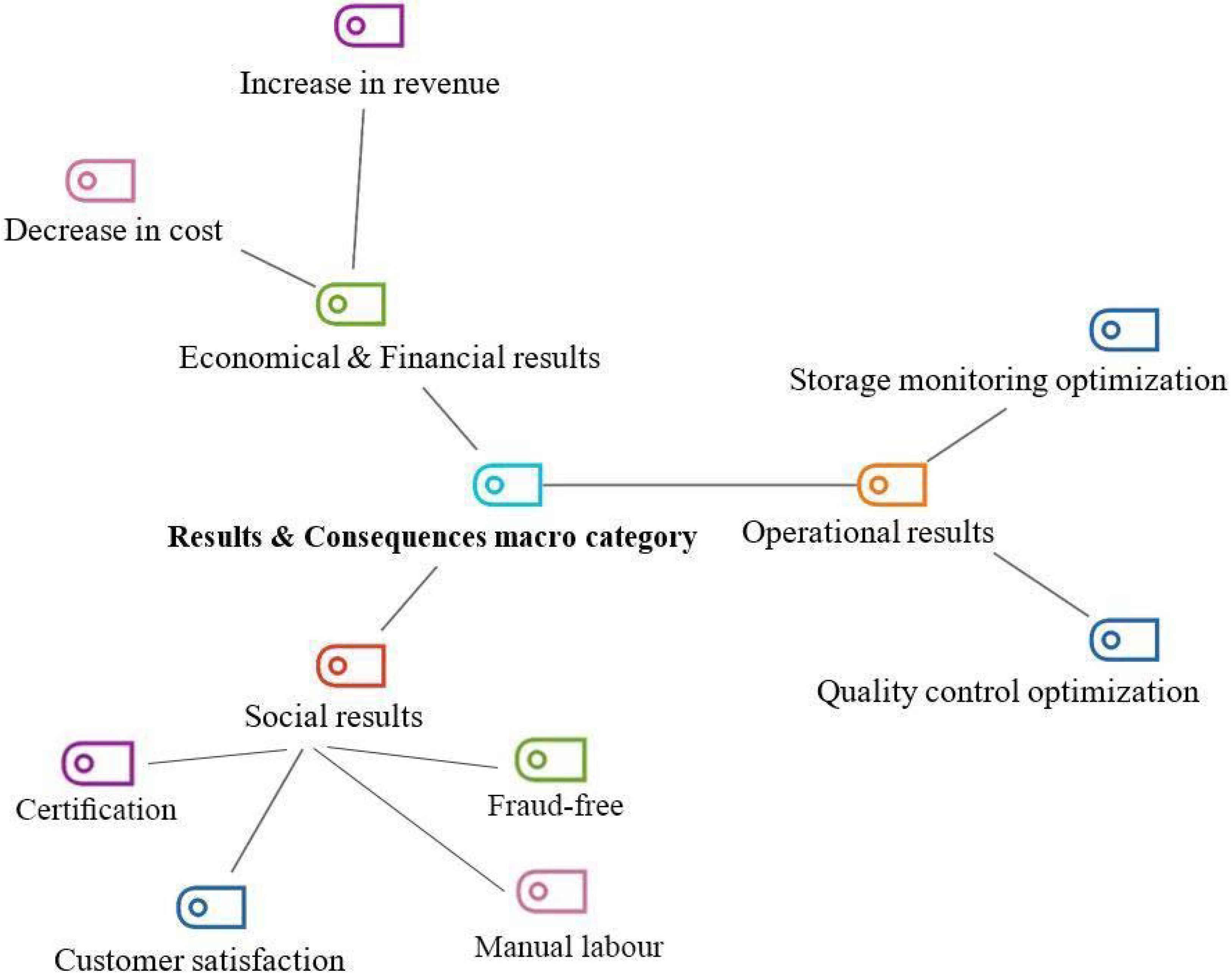

6.3. Results/IoT implementation Implications and Benefits

6.3.1. Financial and Economic Benefits

6.3.2. Operational Benefits

6.3.3. Social Results and Consequences

7. Meta Synthesis and Framework Development

8. Conclusions, Discussion and Future Research Direction

9. Managerial Implications

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, S.; Zhan, Y.; Ouyang, J.; Ding, Y.; Tan, K.H.; Fu, L. Power, supply chain integration and quality performance of agricultural products: Evidence from contract farming in China. Prod. Plan. Control 2020, 32, 1119–1135. [Google Scholar] [CrossRef]

- Latino, M.E.; Menegoli, M.; Lazoi, M.; Corallo, A. Voluntary traceability in food supply chain: A framework leading its implementation in Agriculture 4.0. Technol. Forecast. Soc. Chang. 2022, 178, 121564. [Google Scholar] [CrossRef]

- Zkik, K.; Belhadi, A.; Rehman Khan, S.A.; Kamble, S.S.; Oudani, M.; Touriki, F.E. Exploration of barriers and enablers of blockchain adoption for sustainable performance: Implications for e-enabled agriculture supply chains. Int. J. Logist. Res. Implement. 2022, 26, 1498–1535. [Google Scholar] [CrossRef]

- Giunipero, L.C.; Eltantawy, R.A. Securing the upstream supply chain: A risk management approach. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 698–713. [Google Scholar] [CrossRef]

- Chaudhary, S.; Suri, P.K. Agri-tech: Experiential learning from the Agri-tech growth leaders. Technol. Anal. Strateg. Manag. 2022, 1–14. [Google Scholar] [CrossRef]

- Kayikci, Y.; Subramanian, N.; Dora, M.; Bhatia, M.S. Food supply chain in the era of Industry 4.0: Blockchain technology implementation opportunities and impediments from the perspective of people, process, performance, and technology. Prod. Plan. Control 2020, 33, 301–321. [Google Scholar] [CrossRef]

- Zekhnini, K.; Cherrafi, A.; Bouhaddou, I.; Benabdellah, A.C.; Raut, R. A holonic architecture for the supply chain performance in industry 4.0 context. Int. J. Logist. Res. Implement. 2021, 1–28. [Google Scholar] [CrossRef]

- Durugbo, C.M.; Al-Balushi, Z. Supply chain management in times of crisis: A systematic review. Manag. Rev. Q. 2022, 73, 1179–1235. [Google Scholar] [CrossRef]

- Zielske, M.; Held, T. Agile methods used by traditional logistics companies and logistics start-ups A systematic literature review. J. Syst. Softw. 2022, 190, 111328. [Google Scholar] [CrossRef]

- Veile, J.W.; Schmidt, M.C.; Müller, J.M.; Voigt, K.I. The transformation of supply chain collaboration and design through Industry 4.0. Int. J. Logist. Res. Implement. 2022, 1–29. [Google Scholar] [CrossRef]

- Kittipanya-Ngam, P.; Tan, K.H. A framework for food supply chain digitalization: Lessons from Thailand. Prod. Plan. Control 2020, 31, 158–172. [Google Scholar] [CrossRef]

- Núñez-Merino, M.; Maqueira-Marín, J.M.; Moyano-Fuentes, J.; Castaño-Moraga, C.A. Industry 4.0 and supply chain. A Systematic Science Mapping analysis. Technol. Forecast. Soc. Chang. 2022, 181, 121788. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The internet of things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Boehmer, J.H.; Shukla, M.; Kapletia, D.; Tiwari, M.K. The impact of the Internet of Things (IoT) on servitization: An exploration of changing supply relationships. Prod. Plan. Control 2020, 31, 203–219. [Google Scholar] [CrossRef]

- Coronado Mondragon, A.E.; Coronado Mondragon, C.E.; Coronado, E.S. Managing the food supply chain in the age of digitalisation: A conceptual approach in the fisheries process. Prod. Plan. Control 2020, 32, 242–255. [Google Scholar] [CrossRef]

- Kim, D.; Sundaram, D.; Park, Y. The adoption of the Internet of Things in the supply chain: The key determinants and their relationships. Sustainability 2019, 11, 2066. [Google Scholar]

- Liu, L.; Zhang, C. Internet of things technology and its application in agricultural supply chain management. J. Clean. Prod. 2021, 296, 126567. [Google Scholar]

- Weng, S.; Peng, L.; Wang, Y. A comprehensive review on internet of things applications in agriculture: Principles, technologies, and challenges. J. Clean. Prod. 2021, 305, 127550. [Google Scholar]

- Aithal, R.K.; Choudhary, V.; Maurya, H.; Pradhan, D.; Sarkar, D.N. Factors influencing technology adoption amongst small retailers: Insights from thematic analysis. Int. J. Retail. Distrib. Manag. 2023, 51, 81–102. [Google Scholar] [CrossRef]

- Leng, Y.; Huang, H.; Chen, Y.; Yang, X. An IoT-based identification model for agricultural products throughout the supply chain. J. Ambient Intell. Humaniz. Comput. 2019, 10, 3137–3149. [Google Scholar]

- Li, Z. A study of agricultural products distribution using the internet of things. Int. J. Simul. Syst. Sci. Technol. 2016, 17, 13.11–13.15. [Google Scholar]

- Zhang, Y.; Zhao, L.; Qian, C. Modeling of an IoT-enabled supply chain for perishable food with two-echelon supply hubs. Ind. Manag. Data Syst. 2017, 117, 1890–1905. [Google Scholar] [CrossRef]

- Srinivasan, R.; Srivastava, S.K.; Kim, H.W. A framework for transparent inventory management using the internet of things. Int. J. Prod. Res. 2017, 55, 7016–7035. [Google Scholar]

- Duan, Y.E. Research on Integrated Information Platform of Agricultural Supply Chain Management Based on Internet of Things. J. Softw. 2011, 6, 944–950. [Google Scholar] [CrossRef]

- Mo, L.-G. Study on supply-chain of modern agricultural products based on IOT in order to guarantee the quality and safety. Adv. J. Food Sci. Technol. 2014, 6, 520–526. [Google Scholar]

- Yan, B.; Wang, X.; Shi, P. Risk assessment and control of agricultural supply chains under Internet of Things. Agrekon 2017, 56, 1–12. [Google Scholar] [CrossRef]

- Alifah, M.; Susanto, A.; Utomo, A. Architecture for implementing internet of things (IoT) in strategic rice product supply chain logistics. Int. J. Supply Chain. Manag. 2018, 7, 105–116. [Google Scholar]

- Yadav, S.; Luthra, S.; Garg, D. Internet of things (IoT) based coordination system in Agri-food supply chain: Development of an efficient framework using DEMATEL-ISM. Oper. Manag. Res. 2020, 15, 1–27. [Google Scholar] [CrossRef]

- Aamer, A.M.; Al-Awlaqi, M.A.; Affia, I.; Arumsari, S.; Mandahawi, N. The internet of things in the food supply chain: Adoption challenges. Benchmarking Int. J. 2021, 28, 2521–2541. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.; Lin, K. Research on effect factors evaluation of internet of things (IOT) adoption in Chinese agricultural supply chain. In Proceedings of the 2016 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bali, Indonesia, 4–7 December 2016. [Google Scholar]

- Mattos, C.A.; Novais Filho, M.J. Mechanisms to develop a business model through the Internet of things: A multiple case study in manufacturing companies. Technol. Anal. Strateg. Manag. 2023, 1–17. [Google Scholar] [CrossRef]

- Del Sarto, N.; Cesaroni, F.; Di Minin, A.; Piccaluga, A. One size does not fit all. Business models heterogeneity among Internet of Things architecture layers. Technol. Anal. Strateg. Manag. 2022, 34, 787–802. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef]

- Sharma, R.; Shishodia, A.; Kamble, S.; Gunasekaran, A.; Belhadi, A. Agriculture supply chain risks and COVID-19: Mitigation strategies and implications for the practitioners. Int. J. Logist. Res. Implement. 2020, 1–27. [Google Scholar] [CrossRef]

- Despoudi, S.; Papaioannou, G.; Dani, S. Producers responding to environmental turbulence in the Greek agricultural supply chain: Does buyer type matter? Prod. Plan. Control 2020, 32, 1223–1236. [Google Scholar] [CrossRef]

- Agyemang, M.; Kusi-Sarpong, S.; Agyemang, J.; Jia, F.; Adzanyo, M. Determining and evaluating socially sustainable supply chain criteria in agri-process of developing countries: Insights from West Africa cashew industry. Prod. Plan. Control 2020, 33, 1115–1133. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Subramanian, N.; Tiwari, M.K.; Yan, B.; Yan, C.; Ke, C.; Tan, X. Information sharing in supply chain of agricultural products based on the Internet of Things. Ind. Manag. Data Syst. 2016, 116, 1397–1416. [Google Scholar] [CrossRef]

- Svensson, G. A conceptual framework for the analysis of vulnerability in supply chains. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 731–750. [Google Scholar] [CrossRef]

- Moazzam, M.; Akhtar, P.; Garnevska, E.; Marr, N.E. Measuring agri-food supply chain performance and risk through a new analytical framework: A case study of New Zealand dairy. Prod. Plan. Control 2018, 29, 1258–1274. [Google Scholar] [CrossRef]

- Jeong, B.; Jung, H.S.; Park, N.K. A computerized causal forecasting system using genetic algorithms in supply chain management. J. Syst. Softw. 2002, 60, 223–237. [Google Scholar] [CrossRef]

- Gunders, D. Wasted: How America is losing up to 40 percent of its food from farm to fork to landfill. Nat. Resour. Def. Counc. 2012, 26, 1–26. [Google Scholar]

- Smith, J. Challenges in Agricultural Supply Chains. Agric. Supply Chain J. 2018, 10, 45–62. [Google Scholar]

- Brown, A. Sustainability in Agricultural Supply Chains. Sustain. Res. Rev. 2019, 7, 221–239. [Google Scholar]

- Johnson, M. Resilience of Agricultural Supply Chains. Resil. Risk Manag. J. 2020, 15, 87–105. [Google Scholar]

- Gupta, R. Technological Innovations in Agricultural Supply Chains. Technol. Agric. 2021, 25, 301–318. [Google Scholar]

- Elnadi, M.; Abdallah, Y.O. Industry 4.0: Critical investigations and synthesis of key findings. Manag. Rev. Q. 2023, 1–34. [Google Scholar] [CrossRef]

- Soni, G.; Kumar, S.; Mahto, R.V.; Mangla, S.K.; Mittal, M.L.; Lim, W.M. A decision-making framework for Industry 4.0 technology implementation: The case of FinTech and sustainable supply chain finance for SMEs. Technol. Forecast. Soc. Chang. 2022, 180, 121686. [Google Scholar] [CrossRef]

- Dixit, V.; Verma, P. Identification, assessment, and quantification of new risks for Logistics 4.0. Int. J. Logist. Res. Implement. 2022, 1–25. [Google Scholar] [CrossRef]

- Karttunen, E.; Pynnönen, M.; Treves, L.; Hallikas, J. Capabilities for the internet of things enabled product-service systemg business models. Technol. Anal. Strateg. Manag. 2021, 1–17. [Google Scholar]

- Teixeira, S.; Agrizzi, B.A.; Pereira Filho, J.G.; Rossetto, S.; Pereira, I.S.A.; Costa, P.D.; Branco, A.F.; Martinelli, R.R. LAURA architecture: Towards a simpler way of building situation-aware and business-aware IoT implementation. J. Syst. Softw. 2020, 161, 110494. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How smart, connected products are transforming competition. Harv. Bus. Rev. 2014, 92, 64–88. [Google Scholar]

- Mastrocinque, E.; Ramírez, F.J.; Honrubia-Escribano, A.; Pham, D.T. Industry 4.0 enabling sustainable supply chain development in the renewable energy process: A multi-criteria intelligent approach. Technol. Forecast. Soc. Chang. 2022, 182, 121813. [Google Scholar] [CrossRef]

- De Vass, T.; Shee, H.; Miah, S.J. Iot in supply chain management: A narrative on retail process sustainability. Int. J. Logist. Res. Implement. 2021, 24, 605–624. [Google Scholar] [CrossRef]

- Ding, Y.; Jin, M.; Li, S.; Feng, D. Smart logistics based on the internet of things technology: An overview. Int. J. Logist. Res. Implement. 2021, 24, 323–345. [Google Scholar] [CrossRef]

- Chatziantoniou, D.; Pramatari, K.; Sotiropoulos, Y. Supporting real-time supply chain decisions based on RFID data streams. J. Syst. Softw. 2011, 84, 700–710. [Google Scholar] [CrossRef]

- Qader, G.; Junaid, M.; Abbas, Q.; Mubarik, M.S. Industry 4.0 enables supply chain resilience and supply chain performance. Technol. Forecast. Soc. Chang. 2022, 185, 122026. [Google Scholar] [CrossRef]

- Singh, S.; Singh, S.K.; Yadav, A.K. Internet of Things (IoT) in agriculture: A review. Comput. Electron. Agric. 2020, 175, 104571. [Google Scholar]

- Xu, T.; Sun, L. The application of Internet of Things (IoT) in agriculture: A systematic literature review. J. Clean. Prod. 2019, 228, 1035–1049. [Google Scholar] [CrossRef]

- Zanetti, M.C.; Furlan, L.T.; Silva, R.V. Internet of Things (IoT) in agriculture: A systematic literature review. Comput. Electron. Agric. 2019, 165, 104943. [Google Scholar] [CrossRef]

- Li, M.; Liu, L.; Liu, Q.; Zhang, J. The application of blockchain in agricultural supply chain management. J. Agric. Inform. 2021, 33, 39–48. [Google Scholar]

- Miah, M.R.U.; Khan, A.; Mahmud, M.; Hossain, M.A. IoT-enabled precision agriculture for sustainable food production: A review. J. Clean. Prod. 2021, 282, 124239. [Google Scholar]

- Miao, L.; Zhang, X.; Wang, X.; Tao, X. IoT-based smart farming: A review of the literature. IEEE Access 2020, 8, 123793–123808. [Google Scholar]

- Islam, M.S.; Hasan, M.M.; Al Mamun, M.A.; Ahamed, S.I. IoT-enabled traceability in food supply chain management: A review. IEEE Access 2019, 7, 45445–45459. [Google Scholar]

- Zhang, Z.; Chen, H.; Xu, X.; Zhao, Y. An IoT-based supply network modeling for agricultural products. J. Intell. Manuf. 2017, 28, 857–872. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Implementation, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Chen, Y. The IOT and Smart Logistics Model as the Center of Agricultural Products IOT Port. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 945, pp. 3237–3240. [Google Scholar]

- Kodan, R.; Parmar, P.; Pathania, S. Internet of Things for Food Process: Status Quo and Projected Potential. Food Rev. Int. 2019, 36, 584–600. [Google Scholar] [CrossRef]

- Barney, J.B. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X. Resource-based view of cloud computing adoption in Chinese SMEs. J. Organ. End User Comput. 2016, 28, 17–30. [Google Scholar]

- Li, X.; Wang, X. The effects of resource-based and institutional factors on technology adoption: Evidence from China. J. Technol. Manag. China 2014, 9, 144–160. [Google Scholar]

- Chen, H.; Chen, T. Resource-based view and technology adoption: An empirical investigation. J. Bus. Res. 2018, 89, 138–147. [Google Scholar] [CrossRef]

- Paterson, B.L.; Thorne, S.E.; Canam, C.; Jillings, C. Meta-Study of Qualitative Health Research: A Practical Guide to Meta-Analysis and Meta-Synthesis; Sage: Newcastle upon Tyne, UK, 2001; Volume 3. [Google Scholar]

- Bench, S.; Day, T. The user experience of critical care discharge: A meta-synthesis of qualitative research. Int. J. Nurs. Stud. 2010, 47, 487–499. [Google Scholar] [CrossRef] [PubMed]

- Zimmer, L. Qualitative meta-synthesis: A question of dialoguing with texts. J. Adv. Nurs. 2006, 53, 311–318. [Google Scholar] [CrossRef] [PubMed]

- Sandelowski, M.; Barroso, J. Handbook for Synthesizing Qualitative Research; Springer Publishing Company: New York, NY, USA, 2007. [Google Scholar]

- Hauge, Ø.; Ayala, C.; Conradi, R. Adoption of open source software in software-intensive organizations–A systematic literature review. Inf. Softw. Technol. 2010, 52, 1133–1154. [Google Scholar] [CrossRef]

- Nouri, A.; Mehrmohammadi, M. Defining the Boundaries for Neuroeducation as a Field of Study. Educ. Res. J. 2012, 27, 1–25. [Google Scholar]

- Strauss, A.; Corbin, J. Basics of Qualitative Research Techniques; Sage Publications: Thousand Oaks, CA, USA, 1998. [Google Scholar]

- Creswell, J. Planning, conducting, and evaluating quantitative and qualitative research. In Educational Research; Pearson: London, UK, 2005. [Google Scholar]

- Kvalseth, T.O. Note on Cohen’s kappa. Psychol. Rep. 1989, 65, 223–226. [Google Scholar] [CrossRef]

- Landis, J.R.; Koch, G.G. The measurement of observer agreement for categorical data. Biometrics 1977, 33, 159–174. [Google Scholar] [CrossRef] [PubMed]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students; Pearson Education: London, UK, 2009. [Google Scholar]

- Lawshe, C.H. A quantitative approach to content validity 1. Pers. Psychol. 1975, 28, 563–575. [Google Scholar] [CrossRef]

- Bazi, H.R.; Moeini, A.; Hasanzadeh, A. Proposing Hybrid Architecture to Implement Cloud Computing in Higher Education Institutions Using a Meta-synthesis Appro. J. Inf. Technol. Manag. 2017, 9, 701–728. [Google Scholar]

- Chadwick, B.A.; Bahr, H.; Albrecht, S. Social Science Research Methods; Prentice-Hall: Englewood Cliffs, NJ, USA, 1984. [Google Scholar]

- Cui, Y.; Liu, W.; Rani, P.; Alrasheedi, M. Internet of Things (IoT) adoption barriers for the circular economy using Pythagorean fuzzy SWARA-CoCoSo decision-making approach in the manufacturing process. Technol. Forecast. Soc. Chang. 2021, 171, 120951. [Google Scholar] [CrossRef]

- Giordano, G.; Palomba, F.; Ferrucci, F. On the use of artificial intelligence to deal with privacy in IoT systems: A systematic literature review. J. Syst. Softw. 2022, 193, 111475. [Google Scholar] [CrossRef]

- Sicari, S.; Rizzardi, A.; Grieco, L.; Coen-Porisini, A. Security, privacy and trust in Internet of Things: The road ahead. Comput. Netw. 2015, 76, 146–164. [Google Scholar] [CrossRef]

- Zhao, Y.L. Research on data security technology in internet of things. Appl. Mech. Mater. 2013, 433, 1752–1755. [Google Scholar] [CrossRef]

- Roman, R.; Alcaraz, C.; Lopez, J.; Sklavos, N. Key management systems for sensor networks in the context of the Internet of Things. Comput. Electr. Eng. 2019, 37, 147–159. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Wang, J.Z.G. Research on adopting implementation in agricultural products supply Chain based on internet of things. Bio-Technol. Indian J. 2014, 10, 11. [Google Scholar]

- Flechsig, C.; Anslinger, F.; Lasch, R. Robotic Process Automation in purchasing and supply management: A multiple case study on potentials, barriers, and implementation. J. Purch. Supply Manag. 2021, 28, 100718. [Google Scholar] [CrossRef]

- Laubengaier, D.A.; Cagliano, R.; Canterino, F. It Takes Two to Tango: Analyzing the Relationship between Technological and Administrative Process Innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2022, 180, 121675. [Google Scholar] [CrossRef]

- Ghadimi, P.; Donnelly, O.; Sar, K.; Wang, C.; Azadnia, A.H. The successful implementation of industry 4.0 in manufacturing: An analysis and prioritization of risks in Irish industry. Technol. Forecast. Soc. Chang. 2022, 175, 121394. [Google Scholar] [CrossRef]

- Stentoft, J.; Adsbøll Wickstrøm, K.; Philipsen, K.; Haug, A. Drivers and barriers for Industry 4.0 readiness and practice: Empirical evidence from small and medium-sized manufacturers. Prod. Plan. Control 2020, 32, 811–828. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.R. New trends in cold chain monitoring implementation-A review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Wang, L.; Da Xu, L.; Bi, Z.; Xu, Y. Data cleaning for RFID and WSN integration. IEEE Trans. Ind. Inform. 2014, 10, 408–418. [Google Scholar] [CrossRef]

- Astill, J.; Dara, R.A.; Campbell, M.; Farber, J.M.; Fraser, E.D.; Sharif, S.; Yada, R.Y. Transparency in food supply chains: A review of enabling technology solutions. Trends Food Sci. Technol. 2019, 91, 240–247. [Google Scholar] [CrossRef]

- Tzounis, A.; Katsoulas, N.; Bartzanas, T.; Kittas, C. Internet of Things in agriculture, recent advances and future challenges. Biosyst. Eng. 2017, 164, 31–48. [Google Scholar] [CrossRef]

- Rahman, M.; Kamal, M.M.; Aydin, E.; Haque, A.U. Impact of Industry 4.0 drivers on the performance of the service process: Comparative study of cargo logistic firms in developed and developing regions. Prod. Plan. Control 2020, 33, 228–243. [Google Scholar] [CrossRef]

- Thibaud, M.; Chi, H.; Zhou, W.; Piramuthu, S. Internet of Things (IoT) in high-risk Environment, Health and Safety (EHS) industries: A comprehensive review. Decis. Support Syst. 2018, 108, 79–95. [Google Scholar] [CrossRef]

- Kirchhof, J.C.; Rumpe, B.; Schmalzing, D.; Wortmann, A. Montithings: Model-driven development and deployment of reliable iot implementation. J. Syst. Softw. 2022, 183, 111087. [Google Scholar] [CrossRef]

- Nadkarni, S.; Prügl, R. Digital transformation: A review, synthesis and opportunities for future research. Manag. Rev. Q. 2021, 71, 233–341. [Google Scholar] [CrossRef]

- Ozdemir, S.; Xiao, Y. Secure data aggregation in wireless sensor networks: A comprehensive overview. Comput. Netw. 2009, 53, 2022–2037. [Google Scholar] [CrossRef]

- Zhong-Cheng, L. Design and Implementation of the Internet of Things in Intelligent Warehouse Management. Comput. Syst. Implement. 2011, 210, 11–15. [Google Scholar]

- Khader, B.F.; Yigezu, Y.A.; Duwayri, M.A.; Niane, A.A.; Shideed, K. Where in the value chain are we losing the most food? The case of agricultural in Jordan. Food Secur. 2019, 11, 1009–1027. [Google Scholar]

- Verdouw, C.; Robbemond, R.; Verwaart, T.; Wolfert, J.; Beulens, A. A reference architecture for IoT-based logistic information systems in agri-food supply chains. Enterp. Inf. Syst. 2015, 12, 755–779. [Google Scholar] [CrossRef]

- Xu, L.D.; EL Xu Li, L. Industry 4.0: State of the Art and Future Trend. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Kumar, N.M.; Mallick, P.K. The Internet of Things: Insights into the building blocks, component interactions, and architecture layers. In Proceedings of the Procedia Computer Science, International Conference on Computational Intelligence and Data Science (ICCIDS 2018), Gurugram, India, 7–8 April 2018. [Google Scholar]

- Manda, J.; Khonje, M.G.; Alene, A.D.; Tufa, A.H.; Abdoulaye, T.; Mutenje, M.; Setimela, P.; Manyong, V. Does cooperative membership increase and accelerate agricultural technology adoption? Empirical evidence from Zambia. Technol. Forecast. Soc. Chang. 2020, 158, 120160. [Google Scholar] [CrossRef]

- Bandyopadhyay, D.; Sen, J. Internet of things: Adoption and challenges in technology and standardization. Wirel. Pers. Commun. 2011, 58, 49–69. [Google Scholar] [CrossRef]

- Verdouw, C.; Sundmaeker, H.; Tekinerdogan, B.; Conzon, D.; Montanaro, T. Architecture framework of IoT-based food and farm systems: A multiple case study. Comput. Electron. Agric. 2019, 165, 104939. [Google Scholar] [CrossRef]

- Sinha, A.; Shrivastava, G.; Kumar, P. Architecting user-centric internet of things for smart agriculture. Sustain. Comput. Inform. Syst. 2019, 23, 88–102. [Google Scholar] [CrossRef]

- Carter, C.R. Purchasing social responsibility and firm performance: The key mediating roles of organizational learning and supplier performance. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 177–194. [Google Scholar] [CrossRef]

- Kaur, H. Modelling internet of things driven sustainable food security system. Benchmarking Int. J. 2019, 28, 1740–1760. [Google Scholar] [CrossRef]

- Tseng, H.T.; Aghaali, N.; Hajli, N. Customer agility and big data analytics in new product context. Technol. Forecast. Soc. Chang. 2022, 180, 121690. [Google Scholar] [CrossRef]

- Lo, F.Y.; Campos, N. Blending Internet-of-Things (IoT) solutions into relationship marketing strategies. Technol. Forecast. Soc. Chang. 2018, 137, 10–18. [Google Scholar] [CrossRef]

- Lezoche, M.; Hernandez, J.E.; Díaz, M.D.M.E.A.; Panetto, H.; Kacprzyk, J. Agri-food 4.0: A survey of the supply chains and technologies for the future agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Botta, A.; De Donato, W.; Persico, V.; Pescapé, A. Integration of cloud computing and internet of things: A survey. Future Gener. Comput. Syst. 2016, 56, 684–700. [Google Scholar] [CrossRef]

- Jacobs, N.; Edwards, P.; Cottrill, C.D.; Salt, K. Governance and Accountability in Internet of Things (IoT) Networks. In The Oxford Handbook of Digital Technology and Society; Oxford University Press: Oxford, UK, 2020. [Google Scholar]

- Taheri, F.; D’Haese, M.; Fiems, D.; Azadi, H. The intentions of agricultural professionals towards diffusing wireless sensor networks: Implementation of technology acceptance model in Southwest Iran. Technol. Forecast. Soc. Chang. 2022, 185, 122075. [Google Scholar] [CrossRef]

- Almeida, V.A.; Doneda, D.; Monteiro, M. Governance challenges for the Internet of Things. IEEE Internet Comput. 2015, 19, 56–59. [Google Scholar] [CrossRef]

| Author (Year) | Study/Paper Title | Key Issues/Findings |

|---|---|---|

| Smith [42] | Challenges in Agricultural Supply Chains | Lack of transparency in supply chain operations, inefficient transportation and distribution, quality control issues leading to product losses. |

| Brown [43] | Sustainability in Agricultural Supply Chains | Environmental concerns (e.g., pesticide use), social issues (e.g., labor conditions), the need for sustainable sourcing and practices. |

| Johnson [44] | Resilience of Agricultural Supply Chains | Vulnerability to extreme weather events, dependence on a limited number of suppliers, lack of contingency plans for disruptions. |

| Gupta [45] | Technological Innovations in Agricultural Supply Chains | Potential benefits of IoT and blockchain technology, data-driven supply chain optimization, improved traceability and food safety. |

| Author Name & Year. | IoT Adoption Model/Framework | Impact |

|---|---|---|

| Miao et al. [62] | IoT-based Smart Agriculture System | Improved efficiency, reduced costs, better decision-making, and increased productivity |

| Li et al. [60] | Blockchain and IoT-based Traceability Framework | Improved supply chain transparency, reduced food fraud, and enhanced consumer trust |

| Sharma et al. [34] | IoT-based Smart Agriculture System | Improved crop yield, reduced wastage, and better resource utilization |

| Gupta et al. [45] | IoT-enabled Supply Chain Management System | Improved transparency, traceability, and quality control in the supply chain |

| Miah et al. [61] | IoT-based Crop Monitoring and Management System | Improved crop yield, reduced resource consumption, and increased efficiency |

| Leng et al. [20] | Identification of agricultural products using IoT | Improved traceability and transparency in the supply chain |

| Alifah et al. [27] | IoT-based logistics architecture | Improved efficiency and effectiveness of logistics processes in the supply chain |

| Srinivasan et al. [23] | IoT-based transparency framework | Improved inventory management and visibility in the supply chain |

| Yan et al. [26] | Mathematical model for risk management using IoT | Improved risk management and decision-making in the supply chain |

| Zhang et al. [22] | IoT-based supply network modelling | Improved understanding and analysis of supply network dynamics |

| Quality Assessment Score | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Papers | 0 | 0 | 2 | 2 | 5 | 5 | 4 | 6 | 11 | 26 | 61 |

| Election Criteria | Description | Results |

|---|---|---|

| Paper inclusion criteria | Subject: Articles whose main focus was on the IoT and the agricultural and food supply chain Language: Articles written in English Period: Articles published between 1 January 2005 and 10 November 2020 Type of research: Research articles published in high quality and high impact-factor journals Subject Area: Information systems, management, computer science, social sciences, agricultural and food science | |

| Keywords | Supply Chain or Logistics Management, Internet of Things or IoT, Agriculture and Food | |

| Search | Online databases were searched with the above keywords. | Clarivate Analytics & Scopus |

| Identified articles | 163 articles | |

| Synthesis | The results of database searches were considered to examine their relevance through title, abstract and keyword analysis. | |

| Unsuitable/irrelevant articles were omitted after first evaluation | 68 articles | |

| Duplicate articles indexed in both Scopus citation database and Web of Science database were removed. | 27 articles | |

| Articles omitted due to lack of focus on the Internet of Things. | 12 articles | |

| Articles omitted due to lack of focus on the agri-food supply chain. | 29 articles | |

| Snowball view | Articles added as a result of using the reversed snowball view | 25 articles |

| Articles that were removed due to non-compliance with the inclusion and exclusion criteria. | 14 articles | |

| Selected sample for analysis | 70 articles | |

| Content evaluation | Articles that received high quality rating | 61 articles |

| Final sample | 61 articles |

| Categories | Themes | Codes |

|---|---|---|

| Internet of things adoption | Organizational features | Organizational readiness |

| Organization size | ||

| Top management support | ||

| Organizational Culture | ||

| Trust | ||

| Skilled human resources availability | ||

| Environmental features | External pressures | |

| Governmental support | ||

| Uncertainty | ||

| Time-to-market | ||

| Financial factors | Reduced costs | |

| Value creation | ||

| Implementation cost (reverse effect) | ||

| High energy consumption (reverse effect) | ||

| Technology cost (reverse effect) | ||

| Long term return on investment (reverse effect) | ||

| Technological features | Perceived benefits | |

| Complexity | ||

| Adaptability | ||

| Technological infrastructure | ||

| Lack of standardization (reverse effect) | ||

| Safety and privacy | ||

| Establishment requirements | Technological requirements | IoT components |

| IoT architecture | ||

| Implementation requirements | Budget allocation | |

| Appropriate technical infrastructure | ||

| Stakeholder cooperation | ||

| Security requirements | Confidentiality | |

| Authentication | ||

| Access control | ||

| Cyber attacks | ||

| Data security | ||

| Challenges of IoT implementation | Economic and social | Long term return on investment |

| Cost of implementation | ||

| Environmental changes | ||

| Business model | ||

| Energy efficiency | ||

| Legislation | ||

| Staff training | ||

| Technological | Integration with existing ICT technology | |

| Non-functional data | ||

| High number of required sensors | ||

| Data reliability | ||

| Standardization | ||

| Security and privacy | Scalability of data | |

| Networking | ||

| Safety and security | ||

| Complementary IoT technologies | Cloud computing | Data management |

| Software as a service | ||

| Hardware as a service | ||

| Reduce the cost of data storage | ||

| Fog computing | Data processing close to devices | |

| Blockchain | Trust issues | |

| Improve transaction security | ||

| Reduce potential waste | ||

| Big Data | Prediction by big data analytics | |

| The main phenomenon | IoT-based agricultural storage | Storage conditions |

| Warehouse input-output management | ||

| Storage procedure | ||

| Need for quarantine | ||

| IoT implementation | Implementation layer | |

| Transport layer | ||

| Perception layer | ||

| Governance factors | Legislation | Setting legal rules |

| Food safety rules | ||

| Rules on security and operations standards | ||

| Policy making | Supportive policies | |

| Policymaking about new technologies | ||

| Organizational collaborations | Cooperation between public and private organizations | |

| Environmental parameters | Storage conditions | Temperature |

| Humidity | ||

| Microbiology | ||

| Warehouse pests | ||

| Geographical factors | Weather | |

| Consequences and results of IoT implementation | Reduce storage costs | Cost reduction due to improved storage conditions |

| Reduce management costs | ||

| Reducing labor costs | ||

| Reduce insurance costs | ||

| Reduce energy costs | ||

| Improved quality control | Freshness | |

| Taste | ||

| Texture | ||

| Color | ||

| Nutrients | ||

| Increased revenue | Higher quality | |

| Improved storage monitoring | Real-time monitoring | |

| Safety and quality | ||

| Transparency | ||

| Increase customer satisfaction | Quality and safety tracking |

| Significance Level | Estimate T | Estimated Standard Deviation | Value | Degree of Cohen’s Kappa Agreement |

|---|---|---|---|---|

| 4.29 | 0 | 0.12 | 0.68 | High |

| No. of Panelists | Min. Value | No. of Panelists | Min. Value |

|---|---|---|---|

| 5 | 0.99 | 13 | 0.54 |

| 6 | 0.99 | 14 | 0.51 |

| 7 | 0.99 | 15 | 0.49 |

| 8 | 0.75 | 20 | 0.42 |

| 9 | 0.78 | 25 | 0.37 |

| 10 | 0.62 | 30 | 0.33 |

| 11 | 0.59 | 35 | 0.31 |

| 12 | 0.56 | 40 | 0.29 |

| Categories | Themes | Factors | Average | CVR | CVI |

|---|---|---|---|---|---|

| IoT adoption | Organizational characteristics | Organizational readiness | 1.875 | 0.75 | 0.84 |

| Organizational Culture | 2 | 1 | |||

| Top Management support | 2 | 1 | |||

| Organization size | 1.75 | 0.5 | |||

| The trust | 1.75 | 0.5 | |||

| Skilled manpower availability | 2 | 1 | |||

| Environmental characteristics | External pressures | 2 | 1 | ||

| Government support | 2 | 1 | |||

| Unreliability | 1.875 | 0.75 | |||

| Time-to-market | 1.75 | 0.5 | |||

| Financial factors | Costs saving | 2 | 1 | ||

| Value creation | 2 | 1 | |||

| Implementation cost (Reverse effect) | 2 | 1 | |||

| High energy consumption (Reverse effect) | 1.75 | 0.5 | |||

| Technology cost (Reverse effect) | 1.875 | 0.75 | |||

| Long capital return (Reverse effect) | 1.875 | 0.875 | |||

| Technology features | Perceived benefits | 2 | 1 | ||

| Complexity | 1.875 | 0.75 | |||

| Adaptability | 2 | 1 | |||

| Technology infrastructure | 2 | 1 | |||

| Lack of standardization (Reverse) | 1.875 | 0.75 | |||

| Safety and privacy | 2 | 1 | |||

| IoT deployment requirements | Technological requirements | IoT components | 2 | 1 | 0.97 |

| IoT architecture | 2 | 1 | |||

| Implementation requirements | Budget allocation | 2 | 1 | ||

| Appropriate technical infrastructure | 2 | 1 | |||

| Stakeholder cooperation | 1.875 | 0.75 | |||

| Security requirements | Confidentiality | 2 | 1 | ||

| Authentication | 2 | 1 | |||

| Access control | 2 | 1 | |||

| Cyber attacks | 2 | 1 | |||

| Data security | 2 | 1 | |||

| IoT challenges | Economic and social | Long return on investment | 2 | 1 | 0.93 |

| Cost of use | 2 | 1 | |||

| Variable environment | 1.75 | 0.5 | |||

| Business model | 2 | 1 | |||

| Energy efficiency | 1.875 | 0.75 | |||

| Regulation | 2 | 1 | |||

| Staff training | 2 | 1 | |||

| Technological | Integration with existing ICT technology | 2 | 1 | ||

| Non-functional data | 2 | 1 | |||

| High number of required sensors | 2 | 1 | |||

| Data reliability | 2 | 1 | |||

| Standardization | 2 | 1 | |||

| Data scalability | 2 | 1 | |||

| Networking | 1.875 | 0.75 | |||

| Security and privacy | Safety and security | 2 | 1 | ||

| Complementary IoT technologies | Cloud computing | Data management | 2 | 1 | 0.94 |

| Software as a service | 2 | 1 | |||

| Hardware as a service | 2 | 1 | |||

| Reduce data storage costs | 2 | 1 | |||

| Fog computing | Data processing close to devices | 2 | 1 | ||

| Blockchain | Trust issues | 2 | 1 | ||

| Improve transaction security | 2 | 1 | |||

| Reduce potential waste | 1.75 | 0.5 | |||

| Big Data technology | Prediction by Big Data Analytics | 2 | 1 | ||

| The main phenomenon | IoT-based agricultural storage | Storage conditions | 2 | 1 | 0.93 |

| Warehouse input-output management | 2 | 1 | |||

| Storage procedure | 2 | 1 | |||

| Need for quarantine | 1.75 | 0.5 | |||

| IoT implementation | Implementation layer | 2 | 1 | ||

| Network layer | 2 | 1 | |||

| Perception layer | 2 | 1 | |||

| Governance factors | Legislation | Setting legal rules | 2 | 1 | 0.83 |

| Food safety rules | 1.75 | 0.5 | |||

| Rules on security and operations standards | 2 | 1 | |||

| Policy making | Supportive policies | 2 | 1 | ||

| Policy-making in the field of new technologies | 2 | 1 | |||

| Organizational collaborations | Cooperation between public and private organizations | 1.75 | 0.5 | ||

| Environmental parameters | Storage conditions | Temperature | 2 | 1 | 1 |

| Humidity | 2 | 1 | |||

| Microbiology | 2 | 1 | |||

| Warehouse pests | 2 | 1 | |||

| Geographical factors | Weather | 2 | 1 | ||

| IoT deployment effects | Decrease in cost | Cost reduction due to improved storage conditions | 2 | 1 | 0.94 |

| Decrease management costs | 2 | 1 | |||

| Decrease labor costs | 2 | 1 | |||

| Decrease insurance costs | 1.75 | 0.5 | |||

| Decrease energy costs | 1.75 | 0.5 | |||

| Increase revenue | Higher price | 2 | 1 | ||

| Quality control optimization | Freshness | 2 | 1 | ||

| Taste | 2 | 1 | |||

| Visual quality | 2 | 1 | |||

| Color | 2 | 1 | |||

| Storage monitoring optimization | Real-time monitoring | 2 | 1 | ||

| Safety and quality | 2 | 1 | |||

| Transparency | 2 | 1 | |||

| Customer satisfaction | Pursue quality and safety | 2 | 1 | ||

| Froud-free | Following the products across the entire supply chain | 2 | 1 | ||

| Manual labor | Decrease the required manual labor | 2 | 1 | ||

| Certification | Organic products | 2 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajabzadeh, M.; Fatorachian, H. Modelling Factors Influencing IoT Adoption: With a Focus on Agricultural Logistics Operations. Smart Cities 2023, 6, 3266-3296. https://doi.org/10.3390/smartcities6060145

Rajabzadeh M, Fatorachian H. Modelling Factors Influencing IoT Adoption: With a Focus on Agricultural Logistics Operations. Smart Cities. 2023; 6(6):3266-3296. https://doi.org/10.3390/smartcities6060145

Chicago/Turabian StyleRajabzadeh, Mohsen, and Hajar Fatorachian. 2023. "Modelling Factors Influencing IoT Adoption: With a Focus on Agricultural Logistics Operations" Smart Cities 6, no. 6: 3266-3296. https://doi.org/10.3390/smartcities6060145

APA StyleRajabzadeh, M., & Fatorachian, H. (2023). Modelling Factors Influencing IoT Adoption: With a Focus on Agricultural Logistics Operations. Smart Cities, 6(6), 3266-3296. https://doi.org/10.3390/smartcities6060145