1. Introduction

Infrastructure projects are large, intricate, and typically cost millions. These projects can affect millions of people, possess a long-life cycle, involve complicated management, and have considerable uncertainty. Building Information Modeling (BIM) is an emerging and effective technology and process that has rapidly changed how buildings are conceived, designed, constructed, and operated [

1]. The rapid development of BIM provides novel opportunities to ameliorate the efficiency and effectiveness of the construction procedure and improve the employment of emerging technologies throughout the project life cycle, not only in buildings but also in infrastructure [

2]. BIM is defined as “the systematic process of managing and disseminating the overall information generated during the development and operation of the project’s design” [

3,

4], fundamentally describes the exchange, interpretation, and use of metadata around computer-aided design (CAD) models, and supports the multiple roles of various stakeholders in the construction and operation process [

5]. Integrating BIM into each project’s early design phase provides an intriguing opportunity for project management [

6,

7]. Compared with a set of CAD drawings, BIM is a “richer repository”; that is, some multi-disciplinary methods can build construct information and the characteristics of buildings’ BIM models digitally and graphically. By sharing and exporting the data required by the project team, BIM enables the usage of information in the architectural model, reducing the need to recreate the model and accelerating the design whilst allowing for some more repetition [

8]. In broad terms, BIM increases design and construction quality, lowers project labor and costs, and is a quicker and more effective method to manage construction [

9].

Because of overpopulation and the increasing complexity of construction projects, the project manager should balance the project’s time, cost, quality, and risk at the early stages of the project. Evidence suggests that most project activities can be consummated earlier than scheduled in construction projects by reducing their time or allocating additional resources and equipment, thus increasing project costs exponentially. In addition, shortening the operating time can reduce project quality and increase risk because uncertainty decreases with increasing time. Therefore, optimization problems are prominent topics in scientific and practical engineering research. Based on the number of optimized goal functions, optimization problems can be divided into single-objective and multi-objective.

Regarding multi-objective optimization (MOP) problems, two or more objective functions must be computed simultaneously. In addition, these objective functions are always inconsistent [

10]. Time–Cost–Quality–Risk Trade-off Problems (TCQRTP) are one of the significant challenges in project management. In this situation, there are some practical solutions. Various optimization techniques have been proposed for TCQRT problems. The Critical Path Method (CPM) can be used as a basic quantitative technique for project management with no time limit and resource constraints. Assuming an ideal completion time, the CPM sets the minimum time required to complete the project. However, it has been abolished due to limitations such as its arithmetic complexity, especially in large construction projects [

11]. Mathematical programming methods transform TCQRTP into mathematical models and use linear programming [

12]. As a method for achieving the best results, linear programming (LP) was proposed by Volkerson and Perra, assuming a continuous time–cost relationship represented by linear relationships. However, it can only be used considering a linear relationship between time and cost for any activity on the network. As the number of activities increases, the network becomes too intricate; the LP method requires much computational effort [

13,

14].

Furthermore, heuristic methods are based on general rules and lack mathematical precision. They provide but do not guarantee optimality. Most innovative methods only consider linear time–cost–quality–risk relationships in a project’s activities [

12], thus indicating its inefficiency in TCQRTP. However, over the last few years, researchers have most frequently used meta-heuristic optimization algorithms to solve TCQRTP. Meta-heuristic optimization algorithms are designed by imitating insects, animals, and birds [

15]. In general, nature-inspired meta-heuristic algorithms fall into four main groups: (i) evolution-based algorithms, (ii) swarm-based algorithms, physics-based algorithms, and (iii) human behavior-based algorithms.

Chassiakos, Samaras, and Theodorakopoulos [

14] presented a time–cost tradeoff model based on the CPM method that can be used for any discrete cost–time relationship for project activities. Feng, Liu, and Burns [

12] developed a new algorithm using the GA and Pareto methods for time–cost tradeoff (TCT) problems. In another paper, the authors presented the time–cost tradeoff model under uncertainty using genetic algorithms (GA) with simulation techniques [

16]. El-kholy [

17] presented a TCT model that considers budget variability and time uncertainty based on a linear programming model. Aziz et al. [

18] proposed a new approach called the Smart Critical Path Method System (SCPMS), which combines CPM and GA. The authors aimed to optimize resources to simultaneously reduce project time and cost with maximum quality. Ballesteros-Pérez et al. [

19] proposed a non-linear model for TCT problems with three main variables: crashed durations, crashed costs, and the number of resources. The authors concluded that the proposed models allow both discrete and continuous configurations and definite and random ones. Chen and Tsai [

20] analyzed time–cost tradeoff problems with fuzzy parameters, a practical method for complex project networks. Since the fuzzy environment in TCT problems includes only membership functions, with uncertainty about projects and their duration, Abdel-Basset et al. [

21] used the neutrosophic theory to solve TCT problems. Albayrak [

22] proposed a new hybrid algorithm (NHA) developed by combining particle swarm optimization (PSO) and a genetic algorithm to solve TCT problems. However, with the development of countries worldwide, various projects, in addition to time and cost, added other parameters, such as quality, safety, risk, etc., to their contracts. These novels and emerging contracts put more pressure on decision-makers in the construction industry to find optimal/near-optimal models while maximizing quality and minimizing construction costs and time [

23].

Regarding the time–cost–quality tradeoff, Babu and Suresh [

7] suggested that the quality element should be included in the TCT problems. A linear programming model was created by the authors in order to address time–cost–quality tradeoff (TCQT) problems; Khang and Myint [

24] employed the model at a cement factory in Bangkok, Thailand in order to validate the suggested model. El-Rayes and Kandil [

23] developed a three-dimensional time–cost–quality tradeoff analysis rather than conventional two-dimensional analysis. The authors used this model to minimize a highway construction project’s time and cost while maximizing its quality. Tareghian and Taheri [

25] solved a TCQT problem using an electromagnetic scattering search that can be performed on large projects. In addition, Kannimuthu et al. [

26] designed a framework for TCQT problems in a multi-state resource-constrained project planning environment solved by the Relaxed-Restricted Pareto Filtering (RR-PARETO3) algorithm. Tran et al. [

27] developed the opposition multiple objective symbiotic organisms search (OMOSOS) approach, an appropriate method to solve time, cost, quality, and work continuity tradeoff problems. Using an opposition-based multiple objective differential evolution algorithms, which employs an opposition-based learning strategy for early population onset and generational leap, Luong et al. [

28] solved the TCQT problem. On the other hand, there have not been many studies on tradeoff concerns, including time, cost, and quality. To put it another way, researchers have hardly ever considered the risk component in TCQT issues. Mohammadipour and Sadjadi [

29] considered risk in the cost–quality tradeoff. The authors used appropriate linear programming to reduce not just the total extra cost of the project but also the overall risk of the project as well as the overall decline in the quality of the project as a whole. Safaei [

30] developed a multi-objective mathematical programming model for the sake of the time–cost–quality–risk tradeoff solved by the Multipurpose Genetic Algorithm (NSGAII). Some other applications of metaheuristic algorithms can be found in [

31,

32,

33,

34,

35].

However, several papers on integrating BIM and optimization for different purposes in the architect, engineering, and construction (AEC) industry have been published recently. Although various meta-heuristic algorithms can solve optimization problems, genetic algorithms (GAs) have been the most commonly used in previous studies, indicating their appropriate and efficient performance in optimization problems in civil engineering [

36,

37,

38,

39,

40]. In dam construction projects, there are a wide variety of resources, each of which has its own time and cost, affecting the project’s risk and quality. Hence, the project managers should balance them to achieve the minimum time, cost, and risk and maximum quality. In this study, for the time–cost–quality–risk tradeoff, five meta-heuristic optimization algorithms were used, including Genetic Algorithm (GA), Annealing Simulation (SA), Black Widow Optimization Algorithm (BWO), Battle Royale Optimization Algorithm (BRO), and Black Hole Mechanical Optimization Algorithm (BHMO). The primary purpose of selecting the mentioned algorithms was to compare the performance of traditional and novel meta-heuristic optimization algorithms in a civil construction project. However, being parameter-free and having a fast convergence behavior and the lowest possible objective function evaluation could be deemed the privileges of the meta-heuristic algorithm. For this purpose, the Ghocham storage dam was selected as a case study. Five different modes were implemented for this problem; in four cases, each component of the survival pyramid was optimized separately, and finally, all four cases were traded off simultaneously. Research has rarely focused on the time–cost–quality–risk tradeoff of construction projects based on the BIM process. Hence, the key novelty of this research work is the employment of novel and classic metaheuristic algorithms to resource tradeoffs in dam construction projects based on the Building Information Modeling (BIM) approach. In contrast, previous papers have assessed the capabilities of metaheuristic algorithms in resource tradeoff problems in residential buildings. The core purposes of this research were:

Evaluating the role of the Building Information Modeling (BIM) process in reducing the execution time and cost of infrastructure projects;

Providing a model for optimizing the components of the survival pyramid (time, cost, quality, and risk) of a dam construction project;

Comparing the performance of novel and traditional meta-heuristic optimization algorithms with each other.

3. Results and Discussion

Based on

Table 3, the total project time based on the contractor’s offers, BIM, and actual was 790, 906, and 1489 days, respectively. Additionally, the total costs of the project based on offers, BIM, and actual were USD 35,825,939.56, USD 44,670,213.59, and USD 48,244,124.9 according to the project contracts in 2010, respectively. BIM could significantly reduce the time and cost of the Ghocham dam since BIM can detect clashes and provide beneficial communication and cooperation among stakeholders and the project team. Since balancing time, cost, quality, and risk of the project within the project’s scope has become an important criterion for evaluating a project’s success, seeking a time–cost–quality–risk tradeoff is becoming the main concern of stakeholders and project teams.

In this research, the lowest time (T

min) and maximum time (T

max) were equal to 521.4379 and 546.7391 days, respectively; the lowest cost (C

min) and the highest cost (C

max) were equivalent to 35,524,075.6 and 36,266,567.6

$, respectively. The lowest quality (Q

min) and the highest quality (Q

max) were equivalent to 73 and 77.967035, respectively, and the lowest risk (R

min) and the highest risk (R

max) were equal to 0.293685 and 0.31941, respectively. The number of optimization variables in each scenario was 17, which corresponded to the 17 rows of the sample of the status of Ghocham dam.

Table 3 presents the optimization results for the first scenario (time) using different algorithms. So, the GA had the 1st rank among other meta-heuristic algorithms; subsequently, BHMO achieved the 2nd rank. So, the GA algorithm achieved good results, which means that the genetic algorithm balances between exploration and exploitation processes. On the other hand, SA algorithms gave the largest value for the time of the Ghocham dam, indicating their weak capability in providing the optimum and least times in dam construction projects. Hence, project managers should employ the GA for time optimization purposes in their construction projects.

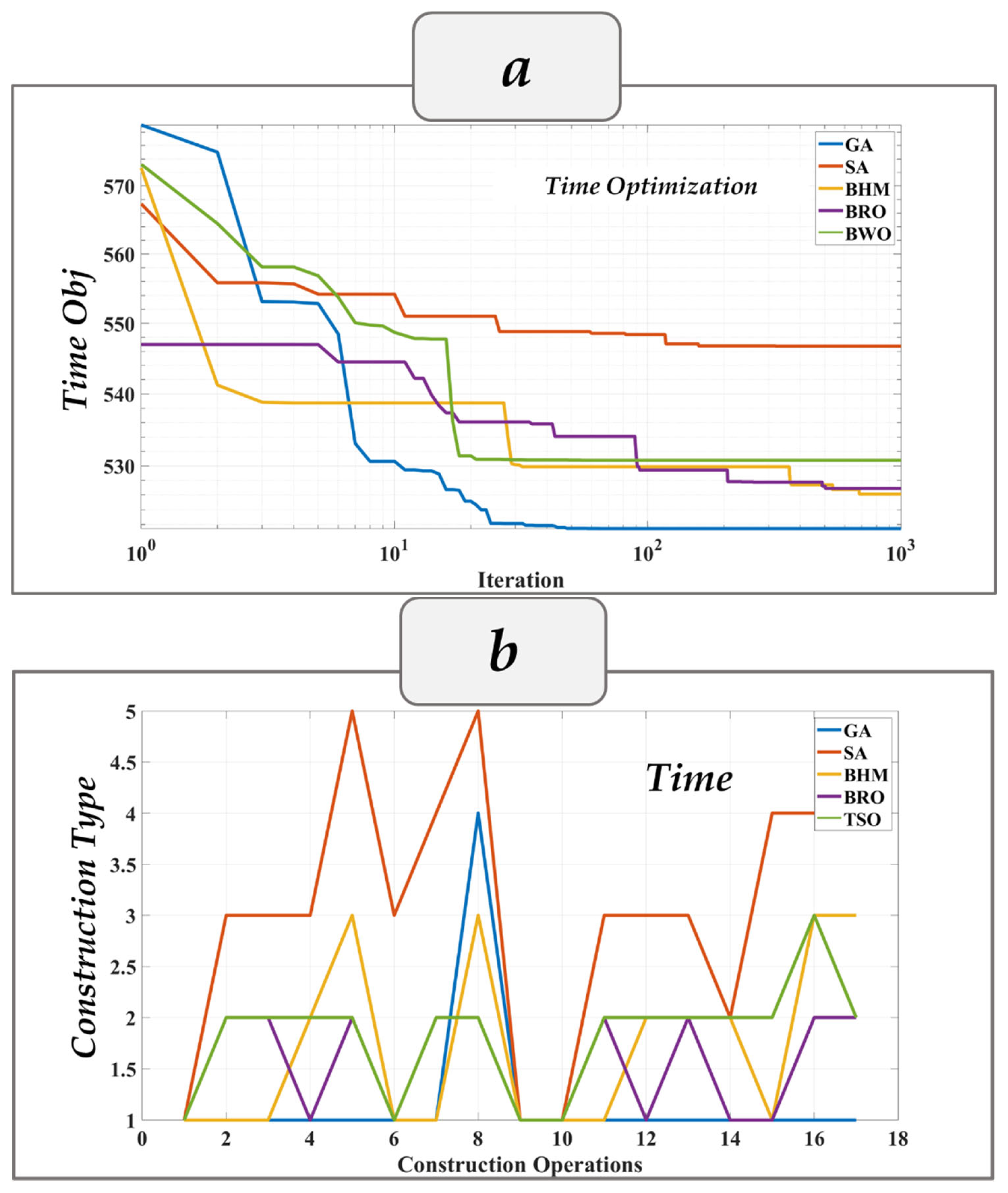

Figure 4a shows the convergence curves for the first scenario (time) using different algorithms. It can be observed that the GA algorithm converged quickly to the optimal value of 521.43 days in the first iterations, while the convergence speed of other algorithms was slower. Therefore, in comparison to the results produced using other methods, the convergence curves validated the GA’s quick convergence tendency. The GA method starts with the initialization of search agents, evaluates them using the cost function, and then updates the search agents in accordance with the function evaluation, which is how the computational complexity of the GA is expressed using big-oh notation. Moreover, the highest error percentage was related to the SA algorithm, with 4.62%, and the lowest was connected to the BHMO algorithm, which had an error of 0.89%. Hence, the GA and BHMO algorithms should be deemed appropriate in the time optimization of the Ghocham dam project. However,

Figure 4b indicates the optimization variables’ status or the genotype space during the optimization process for this scenario. As shown through the mentioned figure, the selected algorithms of the stated scenario tended to mode number 1, representing the contractor’s offers. Furthermore, some algorithms selected mode 3 or BIM as the optimum value in some activities.

In contrast, the proportion of other executive modes, including the number 4 and the number 5, included lower values. It is important to note that in some cases, algorithms also leaned towards modes 2 and 3, requiring more attention to the interpolation process. It is apparent from the data that the contractors proposed an ideal close to the optimum time at the project’s initial phase regarding the algorithm’s results. Still, they did not consider risks and uncertainties. The emergence of reworks in the project and lack of cooperation and communication among contractors and owners could cause time overrun, considered a project failure. However, in dam construction projects, utilizing BIM processes from the whole life cycle could decrease the total executing time of the project, of which there was an exponential decrease of 583 days from 1489 to 906 days in the Ghocham dam.

The statistical results of the optimum time for different optimization algorithms based on 30 independent runs are presented in

Table 4. The value of N

fe (number of function evaluation) was assumed to be a constant value for all algorithms to compare and analyze the algorithms. Overall, it is notable that the GA optimization algorithm gave better results than other algorithms in the time optimization of the Ghocham dam. It can be observed that the computational time (CT) of the BWO optimization algorithms took significantly longer than other optimization algorithms, registered at nearly 14 s. In contrast, the second-lowest CT in any optimization algorithm was seen in the BHMO algorithm, accounting for approximately 1.71 s. Turning to the Standard Deviation (Std.), the lowest value of Std. was seen for the GA algorithms, which was nearly zero, while the SA algorithm gave the highest weight of Std., which means the data were more spread out. The large difference between the “best” and the “worst” values can influence the Std values. The greatest Std number indicates that the algorithm was unable to provide an analytical result that was consistent since the Std value measures how near the results from the 30 distinct trials are to its average value (mean value). This occurred because the algorithms were always trapped in the local results, especially for high-dimensional problems [

61]. Regarding the worst cost obtained from algorithms, the SA optimization algorithms calculated the highest worst value, indicating the SA algorithm’s uncertainty in a single run.

Table 5 illustrates the optimization results for the second scenario (cost) using different algorithms. The current table presents the percentage of changes or rate of the error to the best answer reported by the best algorithms, which were GA and BWO algorithms in this scenario. The BWO algorithm provides a proper balance between the exploration and exploitation stages, one of the most critical features of meta-heuristic algorithms. The mentioned algorithm could obtain outstanding results compared to other experimental algorithms, especially compared to BRO. However, regarding the results, the SA optimization algorithm was ineffective in optimizing the Ghocham dam’s cost, providing the highest cost in the Ghocham dam. Consequently, project managers ought to utilize the GA for cost optimization purposes in their construction projects.

Figure 5a shows the convergence curves for the second scenario (cost) using different algorithms. It can be observed that the GA and BWO algorithms converged quickly to the optimal value of 35,524,075.6 and 35,670,839.86

$, respectively, in the first iterations, while the convergence speed of other algorithms was slower. Moreover, the highest error percentage of 2.09%, was related to the SA algorithm, and the lowest error of 0.41% was related to the BWO algorithm.

Figure 5b elucidates the genotype space during the optimization process for this scenario. As can be seen, the selected algorithms of this scenario, in most cases, tended to mode number 1, which represents the contractor’s offers, while the proportion of other executive modes, including mode number 3 (BIM) and mode number 5, were lower values.

In some cases, the algorithms also leaned to modes 2 and 4, which required more attention to the interpolation process. Like the first scenario, the contractors had a nearly optimum quantity surveying and estimating at the initial stage of the project; however, increasing clashes and reworks, lack of effective cost and budget management, and squandering materials could trigger a cost overrunning. BIM significantly reduced the project’s cost from USD 48,244,124.9 to USD 44,670,213.59, a 7.40% reduction in cost.

Table 6 shows the statistical results of the optimum cost of the Ghocham dam for different optimization algorithms based on 30 independent runs. Overall, GA and BWO algorithms gave the best objective function value for the second scenario. Like the first scenario, the BRO optimization algorithm took a longer computational time than the other algorithms, followed by the BWO optimization algorithm with nearly 14.05 s. In comparison, the better and lower value of CT in any optimization algorithms was seen in the BHMO algorithm, registered at nearly 1.81 s. Regarding the worst value obtained from algorithms, the SA optimization algorithms calculated the highest worst value, which means the SA algorithm is not an appropriate algorithm for a single run of cost optimization. However, the lowest value of the Std of the BRO optimization algorithm indicates how close the results obtained from the 30 different trials to its mean value, while the GA optimization algorithm could not provide a consistent result in the analysis.

Table 7 shows the optimization results for the third scenario (quality) using different algorithms. This table presents the percentage of changes or errors to the best answer reported by the best algorithms. However, only the GA algorithm provided high quality rather than other meta-heuristic algorithms, registered at a mere 97.89, followed by the BWO optimization algorithm. In stark contrast, the BHMO gave the least and improper quality value in this project, elucidating its weak performance in providing the highest quality in dam construction projects.

Figure 6a shows the convergence curves for the third scenario (quality) using different algorithms. It can be observed that the GA algorithm converged quickly to the optimal value of approximately 97.89 in the first iterations, while the convergence speed of other algorithms was slower. Moreover, the highest error, with 25.03%, was related to the BHMO algorithm, and the lowest error, with 23.53%, was related to the BWO algorithm. However, the values of quality obtained by the SA and BHMO algorithms were nearly close.

Figure 6b demonstrates the genotype space during the third scenario’s optimization process.

In most cases, the selected algorithms of this scenario tended to mode number 3, which BIM obtained, while the proportion of other executive modes, including modes number 1 and number 5, were lower values. It is important to emphasize that the algorithms also tended to modes 2 and 4, requiring more attention to the interpolation process. It can be understood that utilizing BIM in dam construction management can provide an optimum quality value for organizations.

Table 8 elucidates the statistical results of the optimum quality of the Ghocham dam for different optimization algorithms based on 30 independent runs. Overall, the GA optimization algorithm gave the best objective function value for the third scenario in the Ghocham dam. The worst value was given by the BHMO algorithm, indicating its insufficiency for a single run of quality optimization. Although the BWO optimization algorithm had a longer computational time than the other algorithms and lasted roughly 14.35 s, it provided the highest quality value compared to all optimization algorithms, not considering the GA. Furthermore, the lowest value of the Std of the BHMO algorithm indicates how close the results obtained from the 30 different trials were to their mean value. The GA optimization algorithm could not provide a consistent result in the analysis. Nonetheless, based on the results obtained, the BHMO algorithm demonstrated an unsatisfactory role in the quality optimization of the Ghocham dam.

Table 9 shows the optimization results for the fourth scenario (risk) utilizing different algorithms. In this table, the percentage of changes or the error to the best answer reported by the best algorithms, GA and BRO algorithms, was also presented. On the other hand, the highest risk value was obtained by the SA algorithm, which could be deemed as an unacceptable algorithm in giving the least risk in dam construction projects.

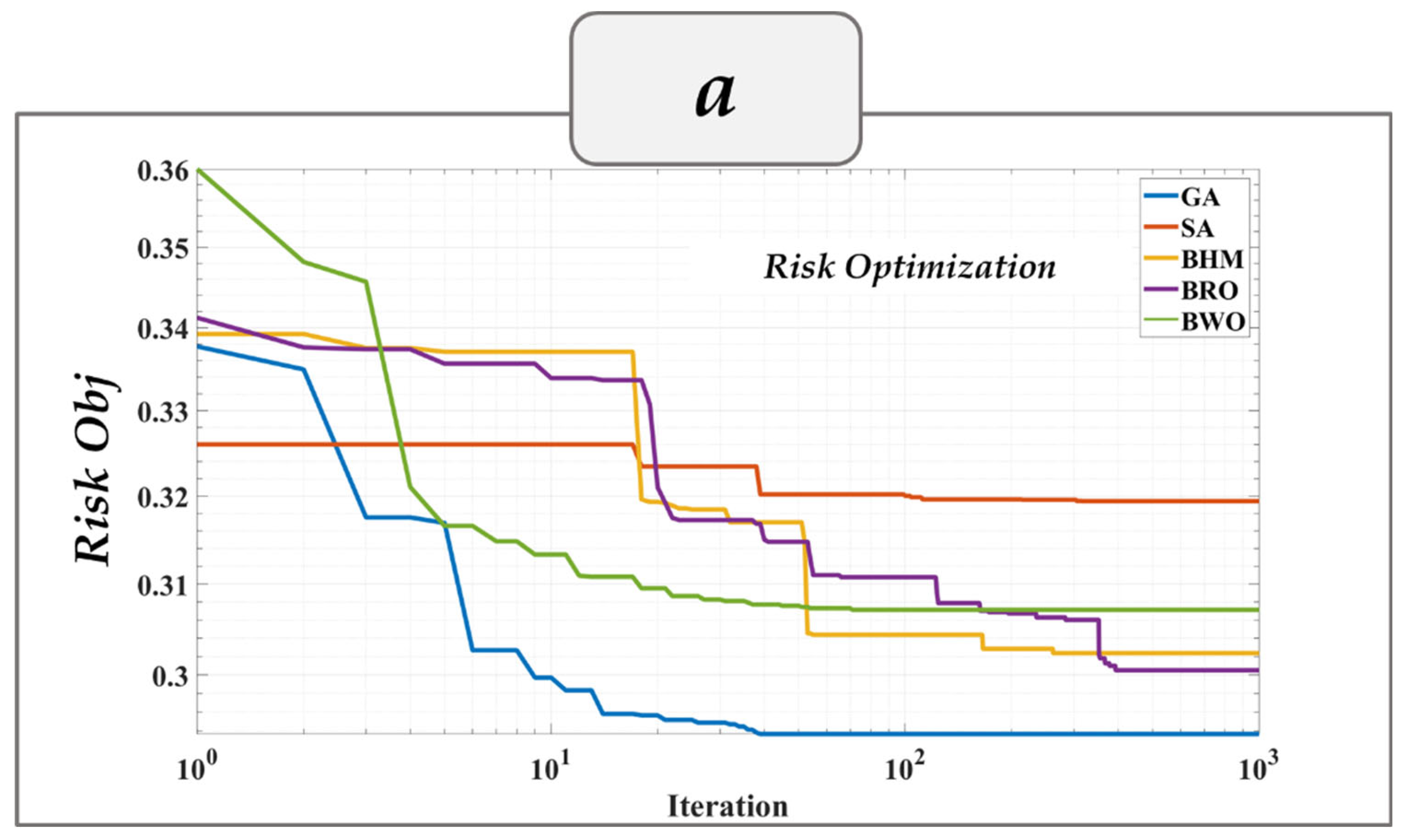

Figure 7a shows the convergence curves for the fourth scenario (risk) using different algorithms. It can be observed that the GA and BRO algorithms converged quickly to the optimal value of 0.293 and 0.300, respectively, in the first iterations. In contrast, the convergence speed of the other algorithms was slower. Moreover, the highest error, with an 8.75 percent error, was related to the SA algorithm, and the lowest error, with 2.33, was related to the BRO algorithm.

Figure 7b shows the risk scenario’s genotype space during the optimization process. As can be seen, the selected algorithms of this scenario, in most cases, tended to mode number 5, which was obtained by the contractor’s offers, whereas the proportion of other executive modes, including mode number 1 and number 3 (obtained from BIM), which were lower values. It is worth noting that the algorithms also tended to modes 2 and 4, which require more attention to the interpolation process.

Table 10 demonstrates the statistical results of the optimum risk of the Ghocham dam for different optimization algorithms based on 30 independent runs. The GA optimization algorithm gave the best objective function value for the fourth Ghocham dam scenario. While the worst value was given by the SA optimization algorithms, signifying its poor reliability for a single trial run of risk optimization. Although the BWO optimization algorithm took a longer computational time than the other algorithms and lasted nearly 13.04 s, it provided the lowest risk value compared to the SA optimization algorithm. However, the CT for the GA algorithm was 1.81, greater than that of SA.

Furthermore, the BWO optimization algorithm obtained the lowest value of the Std, which shows how close the results obtained from the 30 different trials were to their mean value. In stark contrast, due to the higher value of Std rather than other algorithms, the SA optimization algorithm could not provide a consistent result in the analysis. Nonetheless, based on the results obtained, the GA and BRO optimization algorithms demonstrated an unsatisfactory role in the risk optimization of the Ghocham dam.

Table 11 shows the optimization results for the fifth scenario (total) using different algorithms. The percentage of changes or rate of the error to the best answer reported by the best algorithms, which in this scenario was the GA algorithm, are presented. Consequently, the GA algorithm can be considered an ideal algorithm for TCQRT problems in hydropower construction projects with a higher level of complexity.

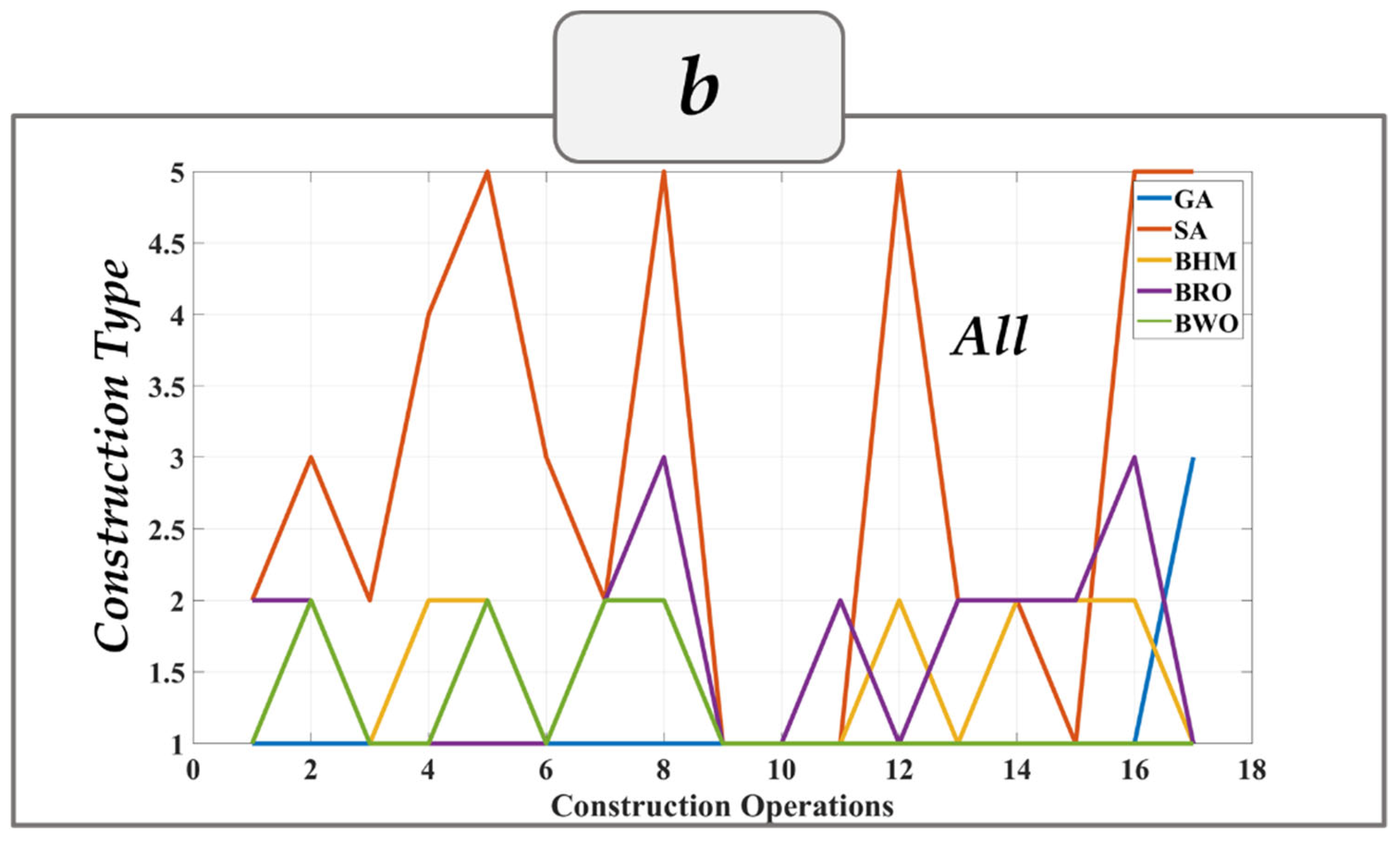

Figure 8a shows the convergence curves for the fifth scenario (total) using different algorithms. It can be observed that the GA and BWO algorithms converged quickly to the optimal value of 1.92 in the first iterations. On the other hand, the convergence speed of other algorithms was slower. Moreover, the highest error percentage was related to the SA algorithm, with an 83.14 percentage error, and the lowest error was connected to the BWO algorithm, which had an error of 31.77.

Figure 8b shows the status of the optimization variables or the genotype space during the optimization process for this scenario. As can be seen, the selected algorithms of this scenario, in most cases, tended to mode number 1, which represents the contractor’s offers, while the proportion of other executive modes, including mode number 3 (obtained from BIM) and mode number 5, which were lower values. In some cases, the algorithms also leaned to modes 2 and 4, which required more attention to the interpolation process.

Table 12 demonstrates the statistical results of the Time–Cost–Quality–Risk Trade-off of the Ghocham dam for different optimization algorithms based on 30 independent runs. Overall, the GA optimization algorithm gave the best value of the objective function for the fifth scenario in the Ghocham dam, which means the GA algorithm provided relevant results for the Time–Cost–Quality–Risk Trade-off of the Ghocham dam, while the worst value was given by the SA optimization algorithms, signifying its poor reliability for a single trial run of risk optimization. Like all previous scenarios, the BWO optimization algorithm took a longer computational time than the other algorithms; its CT lasted nearly 12.57 s. However, the CT for the GA algorithm was 1.88, greater than that of SA.

Furthermore, the BHMO algorithm obtained the lowest value of the Std, which shows how close the results obtained from the 30 different trials were to their mean value. On the other hand, because of the higher value of Std rather than other algorithms, the SA optimization algorithm could not provide a consistent result in the analysis. Nonetheless, based on the results obtained, only the GA optimization algorithm played a satisfactory role in the Time–Cost–Quality–Risk Trade-off in the Ghocham dam.