The Development of a New Bioabsorbable Plastically Deformed Mg-Based Composite with Hydroxyapatite Nanopowder Addition: Towards Improved Degradation and Biological Assessment

Abstract

1. Introduction

2. Materials Preparation

3. Methodology

3.1. Powder Characterization

3.2. Microstructure Characterization

3.3. Corrosion Studies

3.4. Early Biological Assessment

4. Results

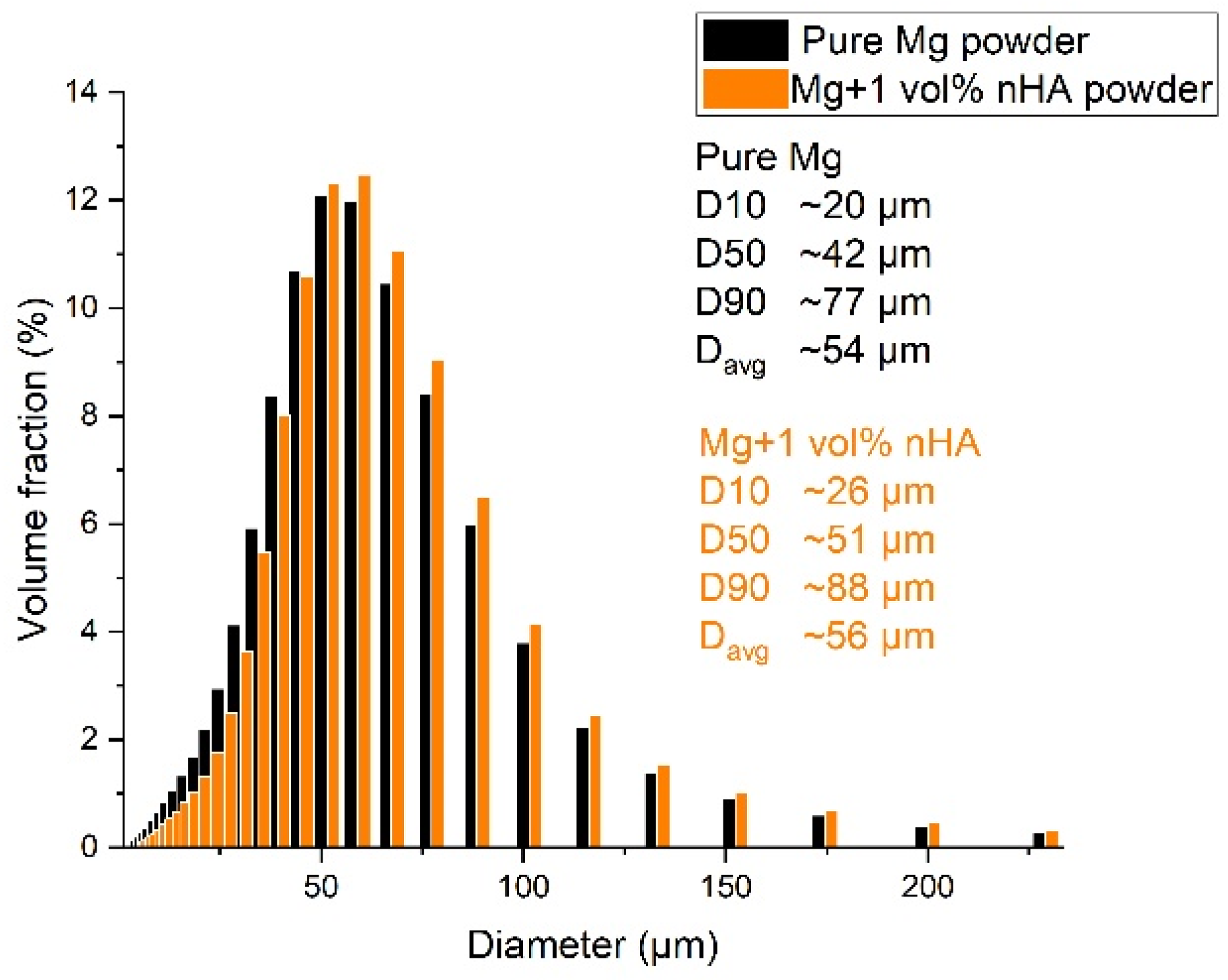

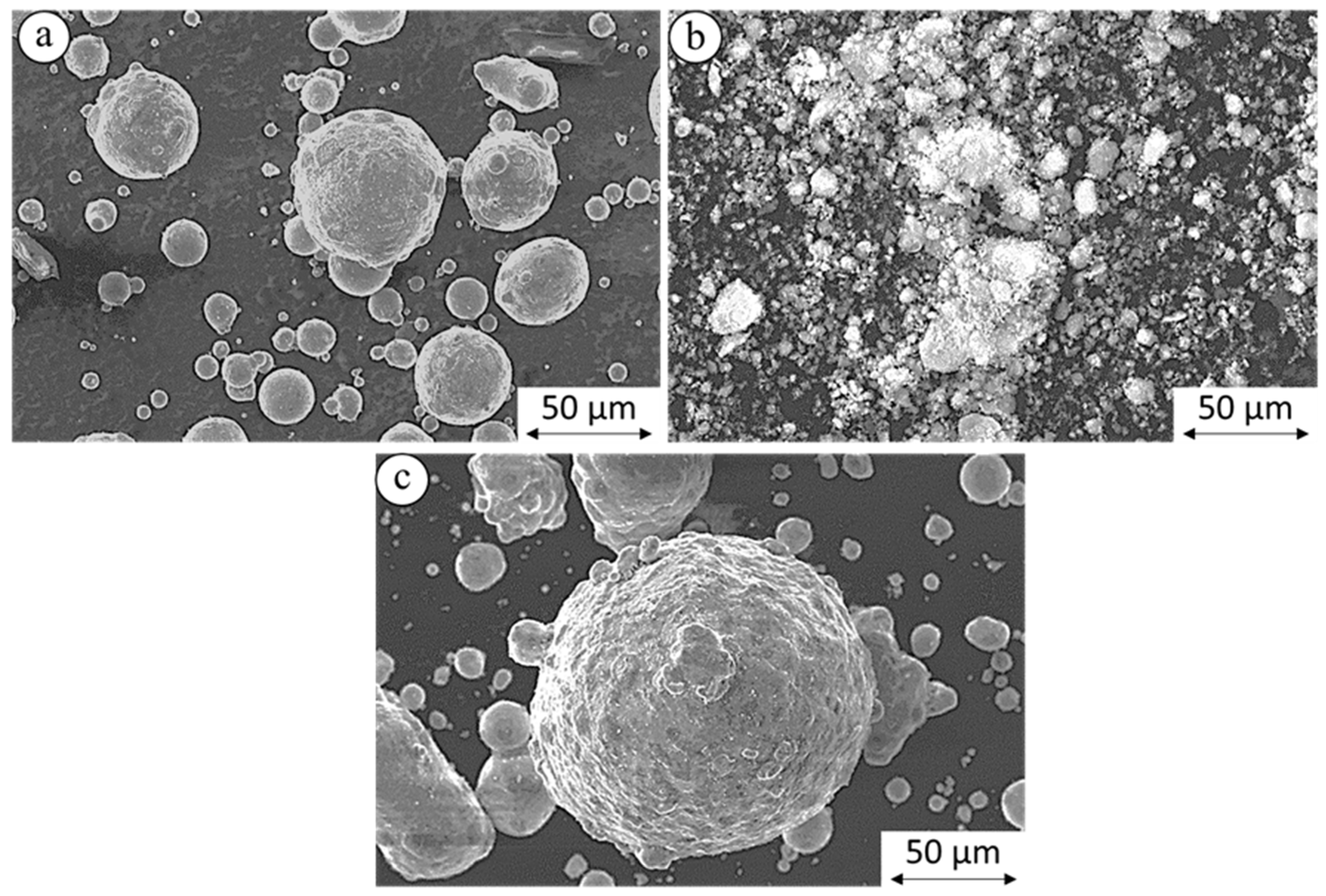

4.1. Powder Characterization

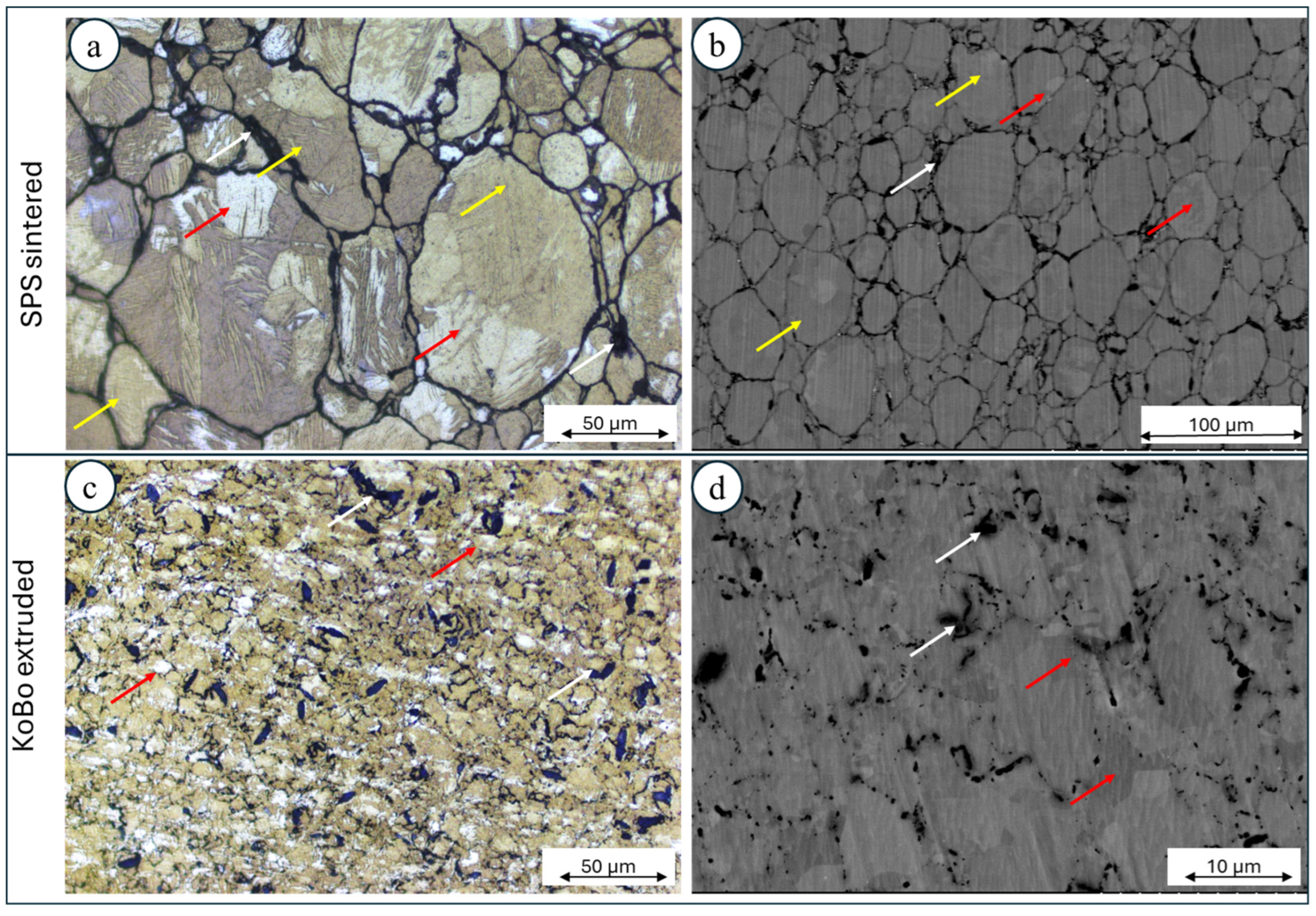

4.2. Microstructure Characterization of the Composites

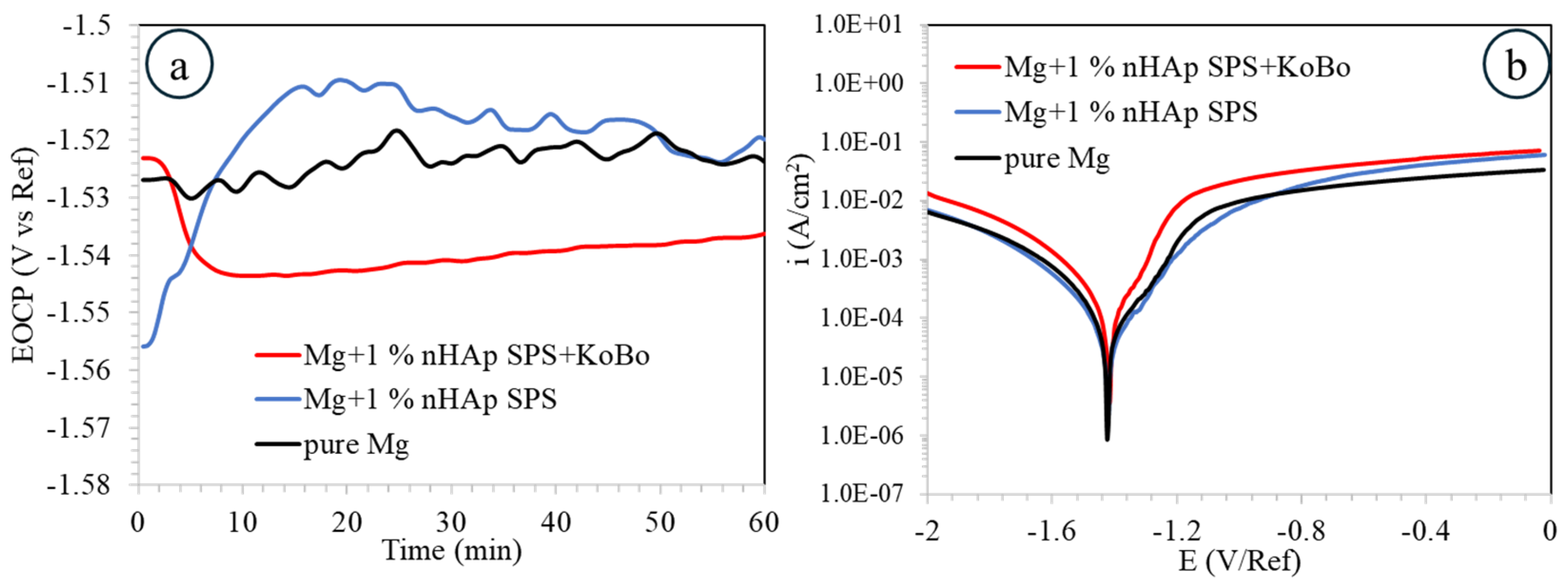

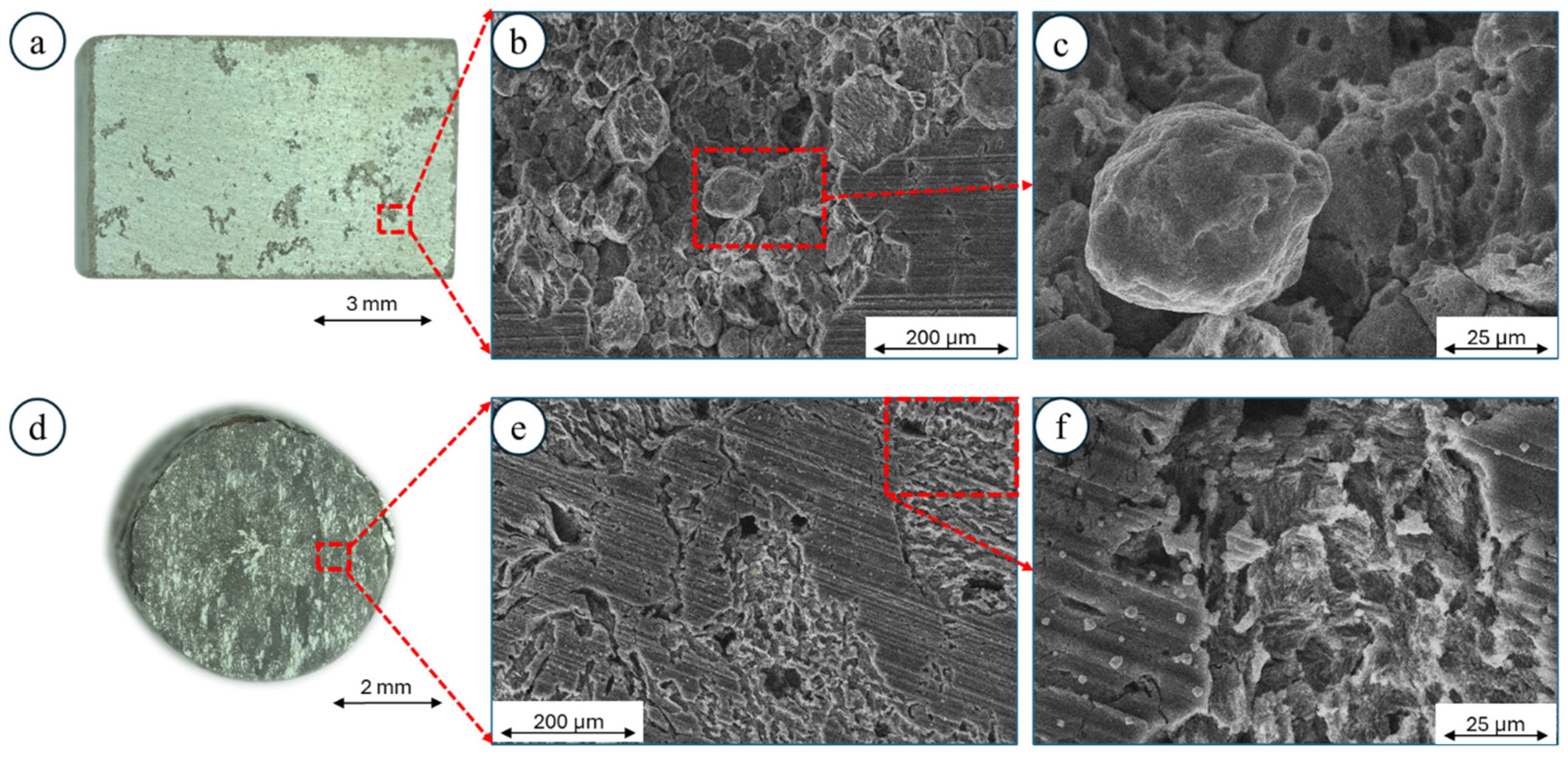

4.3. Corrosion Performance

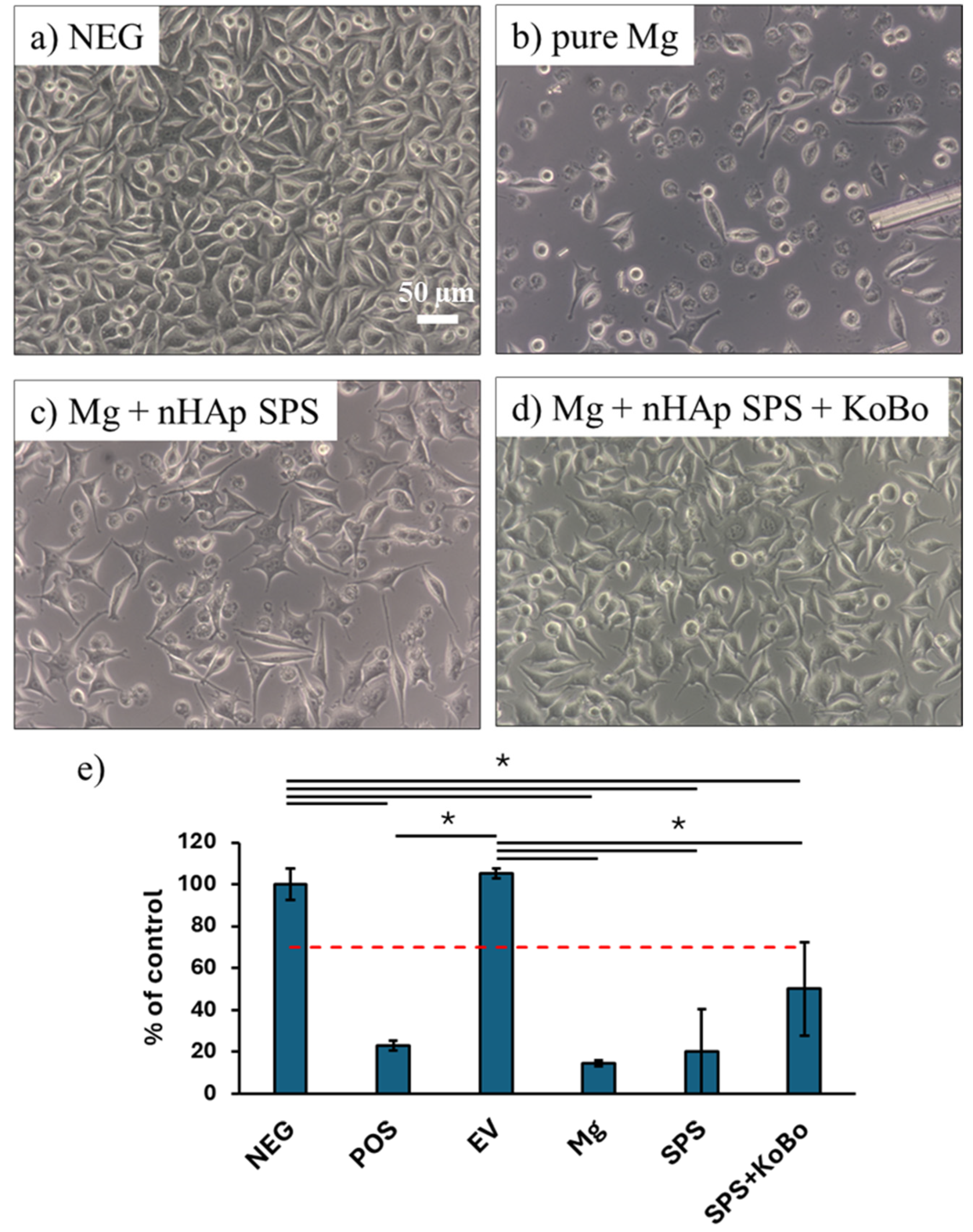

4.4. Cytotoxic Effect of Corrosion Products

5. Discussion

6. Conclusions

- It is possible to plastically deform Mg + 1 vol. % nHAp at a high extrusion ratio (R = 8:1) via extrusion without preheating of the initial billet. During deformation, a significant reduction in grain size occurs, alongside refinement of the ceramic filler. This leads to a more uniform distribution of nHAp in the Mg matrix.

- The addition of nHAp improves cell viability. Simultaneously, its higher refinement after KoBo deformation and its bimodally distributed grain sizes accelerate the degradation of the plastically deformed samples.

- Since an implant working in the human body should possess essential strength to support fractures and stabilize the area of a given fracture, the subsequent plastic deformation of Mg+1 vol.% HAp may have a detrimental effect on its application. Independently, microstructural changes leading to an improvement in cell viability may cause poor cell adhesion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Esmaily, M.; Svensson, J.E.; Fajardo, S.; Birbilis, N.; Frankel, G.S.; Virtanen, S.; Arrabal, R.; Thomas, S.; Johansson, L.G. Fundamentals and advances in magnesium alloy corrosion. Prog. Mater. Sci. 2017, 89, 92–193. [Google Scholar] [CrossRef]

- Jaiswal, S.; Dubey, A.; Lahiri, D. In Vitro Biodegradation and Biocompatibility of Mg–HA-Based Composites for Orthopaedic Applications: A Review. J. Indian Inst. Sci. 2019, 99, 303–327. [Google Scholar] [CrossRef]

- Lane, J.M.; Mait, J.E.; Unnanuntana, A.; Hirsch, B.P.; Shaffer, A.D.; Shonuga, O.A. Materials in Fracture Fixation. In Comprehensive Biomaterials; Ducheyne, P., Ed.; Elsevier: Oxford, UK, 2011; pp. 219–235. ISBN 978-0-08-055294-1. [Google Scholar] [CrossRef]

- Xing, F.; Li, S.; Yin, D.; Xie, J.; Rommens, P.M.; Xiang, Z.; Liu, M.; Ritz, U. Recent progress in Mg-based alloys as a novel bioabsorbable biomaterials for orthopedic applications. J. Magnes. Alloys 2022, 10, 1428–1456. [Google Scholar] [CrossRef]

- Alghamdi, H.S.; Junker, R.; Bronkhorst, E.M.; Jansen, J.A. Bone regeneration related to calcium phosphate-coated implants in osteoporotic animal models: A meta-analysis. Tissue Eng. Part B Rev. 2012, 18, 383–395. [Google Scholar] [CrossRef]

- Suh, J.S.; Suh, B.C.; Bae, J.H.; Kim, Y.M. Machine learning-based design of biodegradable Mg alloys for load-bearing implants. Mater. Des. 2023, 225, 111442. [Google Scholar] [CrossRef]

- Haghshenas, M. Mechanical characteristics of biodegradable magnesium matrix composites: A review. J. Magnes. Alloys 2017, 5, 189–201. [Google Scholar] [CrossRef]

- Radha, R.; Sreekanth, D. Insight of magnesium alloys and composites for orthopedic implant applications—A review. J. Magnes. Alloys 2017, 5, 286–312. [Google Scholar] [CrossRef]

- Khalil, K.A. A new-developed nanostructured Mg/HAp nanocomposite by high frequency induction heat sintering process. Int. J. Electrochem. Sci. 2012, 7, 10698–10710. [Google Scholar] [CrossRef]

- Arora, G.S.; Saxena, K.K.; Mohammed, K.A.; Prakash, C.; Dixit, S. Manufacturing Techniques for Mg-Based Metal Matrix Composite with Different Reinforcements. Crystals 2022, 12, 945. [Google Scholar] [CrossRef]

- Ghasali, E.; Bordbar-Khiabani, A.; Alizadeh, M.; Mozafari, M.; Niazmand, M.; Kazemzadeh, H.; Ebadzadeh, T. Corrosion behavior and in-vitro bioactivity of porous Mg/Al2O3 and Mg/Si3N4 metal matrix composites fabricated using microwave sintering process. Mater. Chem. Phys. 2019, 225, 331–339. [Google Scholar] [CrossRef]

- Tun, K.S.; Gupta, M. Improving mechanical properties of magnesium using nano-yttria reinforcement and microwave assisted powder metallurgy method. Compos. Sci. Technol. 2007, 67, 2657–2664. [Google Scholar] [CrossRef]

- Shahin, M.; Munir, K.; Wen, C.; Li, Y. Magnesium matrix nanocomposites for orthopedic applications: A review from mechanical, corrosion, and biological perspectives. Acta Biomater. 2019, 96, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Rahim, S.A.; Mohan, K.S.S.; Rabeeh, V.P.M.; Joseph, M.A.; Mubarak Ali, M.; Hanas, T. Hot rolled Mg-Ca/nHA composite for biodegradable implant material—A novel approach. Mater. Today Commun. 2023, 35, 106235. [Google Scholar] [CrossRef]

- Ali, F.; Kalva, S.N.; Koç, M. Additive Manufacturing of Polymer/Mg-Based Composites for Porous Tissue Scaffolds. Polymers 2022, 14, 5460. [Google Scholar] [CrossRef] [PubMed]

- Sunil, B.R.; Dumpala, R. Magnesium-Based Composites for Degradable Implant Applications. In Encyclopedia of Materials: Composites; Brabazon, D., Ed.; Elsevier: Oxford, UK, 2021; pp. 770–780. ISBN 978-0-12-819731-8. [Google Scholar] [CrossRef]

- Cui, Z.; Zhang, Y.; Cheng, Y.; Gong, D.; Wang, W. Microstructure, mechanical, corrosion properties and cytotoxicity of beta-calcium polyphosphate reinforced ZK61 magnesium alloy composite by spark plasma sintering. Mater. Sci. Eng. C 2019, 99, 1035–1047. [Google Scholar] [CrossRef]

- Li, Q.; Tian, B. Compression behavior of magnesium/carbon nanotube composites. J. Mater. Res. 2013, 28, 1877–1884. [Google Scholar] [CrossRef]

- Chen, Y.H.; Gao, X.Y.; Nie, K.B.; Li, Y.N.; Deng, K.K. Different effects of SiC dimensions on the microstructure and mechanical properties of magnesium matrix composites. Mater. Sci. Eng. A 2022, 847, 143273. [Google Scholar] [CrossRef]

- Sambasivam, S.; Shirbhate, S.; Abed, A.S.; Patil, P.P.; Khan, I.; Singh, R.; Kansal, L.; Awasthi, A. Significance of reinforcement in Mg-based MMCs for various applications: A review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Kavasi, R.M.; Coelho, C.C.; Platania, V.; Quadros, P.A.; Chatzinikolaidou, M. In vitro biocompatibility assessment of nano-hydroxyapatite. Nanomaterials 2021, 11, 1152. [Google Scholar] [CrossRef]

- Sadat-Shojai, M.; Khorasani, M.; Dinpanah-Khoshdargi, E.; Jamshidi, A. Synthesis methods for nanosized hydroxyapatite with diverse structures. Acta Biomater. 2013, 9, 7591–7621. [Google Scholar] [CrossRef]

- Lim, P.N.; Lam, R.N.; Zheng, Y.F.; Thian, E.S. Magnesium-calcium/hydroxyapatite (Mg-Ca/HA) composites with enhanced bone differentiation properties for orthopedic applications. Mater. Lett. 2016, 172, 193–197. [Google Scholar] [CrossRef]

- Xu, L.; Pan, F.; Yu, G.; Yang, L.; Zhang, E.; Yang, K. In vitro and in vivo evaluation of the surface bioactivity of a calcium phosphate coated magnesium alloy. Biomaterials 2009, 30, 1512–1523. [Google Scholar] [CrossRef] [PubMed]

- Jayasathyakawin, S.; Ravichandran, M.; Ismail, S.O.; Srinivasan, D. Effects of hydroxyapatite addition on the microstructure and mechanical properties of sintered magnesium matrix composites. Mater. Today Commun. 2023, 35, 105582. [Google Scholar] [CrossRef]

- Sun, J.; Chen, M.; Cao, G.; Bi, Y.; Liu, D.B.; Wei, J. The effect of nano-hydroxyapatite on the microstructure and properties of Mg–3Zn–0.5Zr alloy. J. Compos. Mater. 2014, 48, 825–834. [Google Scholar] [CrossRef]

- Khodaei, M.; Nejatidanesh, F.; Shirani, M.J.; Iyengar, S.; Sina, H.; Savabi, O. Magnesium/Nano-hydroxyapatite Composite for Bone Reconstruction: The Effect of Processing Method. J. Bionic Eng. 2020, 17, 92–99. [Google Scholar] [CrossRef]

- Moradi, E.; Ebrahimian-Hosseinabadi, M.; Khodaei, M.; Toghyani, S. Magnesium/nano-hydroxyapatite porous biodegradable composite for biomedical applications. Mater. Res. Express 2019, 6, 75408. [Google Scholar] [CrossRef]

- Bochniak, W.; Ostachowski, P.; Korbel, A.; Łagoda, M. Potential of the KOBO extrusion process for nonferrous metals in the form of solids and chips. Int. J. Adv. Manuf. Technol. 2023, 127, 733–750. [Google Scholar] [CrossRef]

- Dobkowska, A.; Kruszewski, M.J.; Ciftci, J.; Morończyk, B.; Zgłobicka, I.; Zybała, R.; Żrodowski, Ł. Microstructure and Corrosion of Mg-Based Composites Produced from Custom-Made Powders of AZ31 and Ti6Al4V via Pulse Plasma Sintering. Materials 2024, 17, 1602. [Google Scholar] [CrossRef]

- Dobkowska, A.; Adamczyk-cie, B.; Aydee, M.; Garcia, G. Effect of High Deformation without Preheating on Microstructure and Corrosion of Pure Mg. Metals 2024, 14, 949. [Google Scholar] [CrossRef]

- Dobkowska, A.; Żrodowski, Ł.; Chlewicka, M.; Koralnik, M.; Adamczyk-Cieślak, B.; Ciftci, J.; Morończyk, B.; Kruszewski, M.; Jaroszewicz, J.; Kuc, D.; et al. A comparison of the microstructure-dependent corrosion of dual-structured Mg-Li alloys fabricated by powder consolidation methods: Laser powder bed fusion vs pulse plasma sintering. J. Magnes. Alloys 2022, 10, 3553–3564. [Google Scholar] [CrossRef]

- ASTM B90/B90M-12; Standard Specification for Magnesium-Alloy Sheet and Plate. ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- Pałgan, D.; Dobkowska, A.; Zielińska, A.; Drozdenko, D.; Máthis, K.; Święszkowski, W. The Role of LPSO Structures in Corrosion Resistance of Mg-Y-Zn Alloys. Crystals 2022, 12, 1723. [Google Scholar] [CrossRef]

- Zgłobicka, I.B.; Dobkowska, A.; Zielińska, A.; Borucinska, E.; Kruszewski, M.J.; Zybała, R.; Płociński, T.; Idaszek, J.; Jaroszewicz, J.; Paradowski, K.; et al. In-depth analysis of the influence of bio-silica filler (Didymosphenia geminata frustules) on the properties of Mg matrix composites. J. Magnes. Alloys 2023, 11, 2853–2871. [Google Scholar] [CrossRef]

- Dobkowska, A.; Koralnik, M.; Adamczyk-Cieślak, B.; Kuc, D.; Chromiński, W.; Kubasek, J.; Mizera, J. The Effect of Extrusion Ratio on the Corrosion Resistance of Ultrafine-Grained Mg-4Li-3Al-Zn Alloy Deformed Using Extrusion with a Forward-Backward Oscillating Die. J. Mater. Eng. Perform. 2022, 31, 8932–8939. [Google Scholar] [CrossRef]

- Nakahata, I.; Tsutsumi, Y.; Kobayashi, E. Mechanical Properties and Corrosion Resistance of Magnesium—Hydroxyapatite Composites Fabricated. Metals 2020, 10, 1314. [Google Scholar] [CrossRef]

- Khalil, K.A.; Almajid, A.A. Effect of high-frequency induction heat sintering conditions on the microstructure and mechanical properties of nanostructured magnesium/hydroxyapatite nanocomposites. Mater. Des. 2012, 36, 58–68. [Google Scholar] [CrossRef]

- Razavi, M.; Huang, Y. Effect of hydroxyapatite (HA) nanoparticles shape on biodegradation of Mg/HA nanocomposites processed by high shear solidification/equal channel angular extrusion route. Mater. Lett. 2020, 267, 127541. [Google Scholar] [CrossRef]

- Dobkowska, A.; Adamczyk–Cieślak, B.; Kuc, D.; Hadasik, E.; Płociński, T.; Ura-Bińczyk, E.; Mizera, J. Influence of bimodal grain size distribution on the corrosion resistance of Mg–4Li–3Al–1Zn (LAZ431). J. Mater. Res. Technol. 2021, 13, 346–358. [Google Scholar] [CrossRef]

| Sample | Ecorr (V/Ref) | icorr (µA/cm2) | Corrosion Rate (mpy) |

|---|---|---|---|

| Pure Mg | −1.42 | 97 ± 3 | 203 |

| Mg + 1 vol.% nHAp SPS | −1.42 | 58 ± 4 | 122 |

| Mg + 1 vol.% nHAp SPS + KoBo | −1.42 | 113 ± 4 | 236 |

| Sample | Corrosion Rate (mpy) |

|---|---|

| Pure Mg | 324 ± 67 |

| Mg + 1 vol% nHAp SPS | 95 ± 23 |

| Mg + 1 vol% nHAp SPS + KoBo | 2132 ± 203 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, Z.; Idaszek, J.; Kaszyca, K.; Zybała, R.; Tkocz, M.; Kuc, D.; Mizera, J.; Dobkowska, A. The Development of a New Bioabsorbable Plastically Deformed Mg-Based Composite with Hydroxyapatite Nanopowder Addition: Towards Improved Degradation and Biological Assessment. Corros. Mater. Degrad. 2025, 6, 12. https://doi.org/10.3390/cmd6010012

Hassan Z, Idaszek J, Kaszyca K, Zybała R, Tkocz M, Kuc D, Mizera J, Dobkowska A. The Development of a New Bioabsorbable Plastically Deformed Mg-Based Composite with Hydroxyapatite Nanopowder Addition: Towards Improved Degradation and Biological Assessment. Corrosion and Materials Degradation. 2025; 6(1):12. https://doi.org/10.3390/cmd6010012

Chicago/Turabian StyleHassan, Zohaib, Joanna Idaszek, Kamil Kaszyca, Rafał Zybała, Marek Tkocz, Dariusz Kuc, Jarosław Mizera, and Anna Dobkowska. 2025. "The Development of a New Bioabsorbable Plastically Deformed Mg-Based Composite with Hydroxyapatite Nanopowder Addition: Towards Improved Degradation and Biological Assessment" Corrosion and Materials Degradation 6, no. 1: 12. https://doi.org/10.3390/cmd6010012

APA StyleHassan, Z., Idaszek, J., Kaszyca, K., Zybała, R., Tkocz, M., Kuc, D., Mizera, J., & Dobkowska, A. (2025). The Development of a New Bioabsorbable Plastically Deformed Mg-Based Composite with Hydroxyapatite Nanopowder Addition: Towards Improved Degradation and Biological Assessment. Corrosion and Materials Degradation, 6(1), 12. https://doi.org/10.3390/cmd6010012