Review of Recent Developments in the Formulation of Graphene-Based Coatings for the Corrosion Protection of Metals and Alloys

Abstract

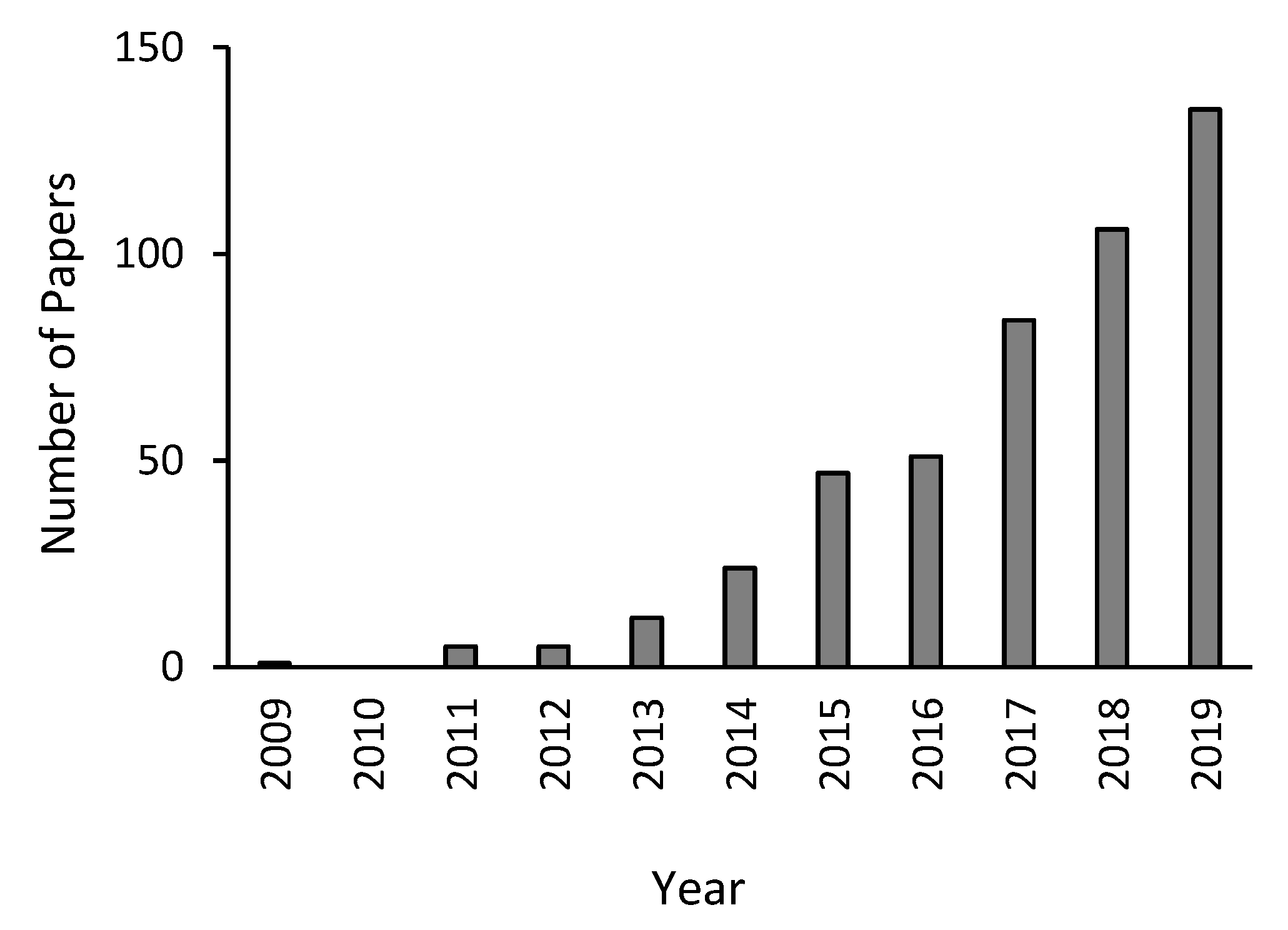

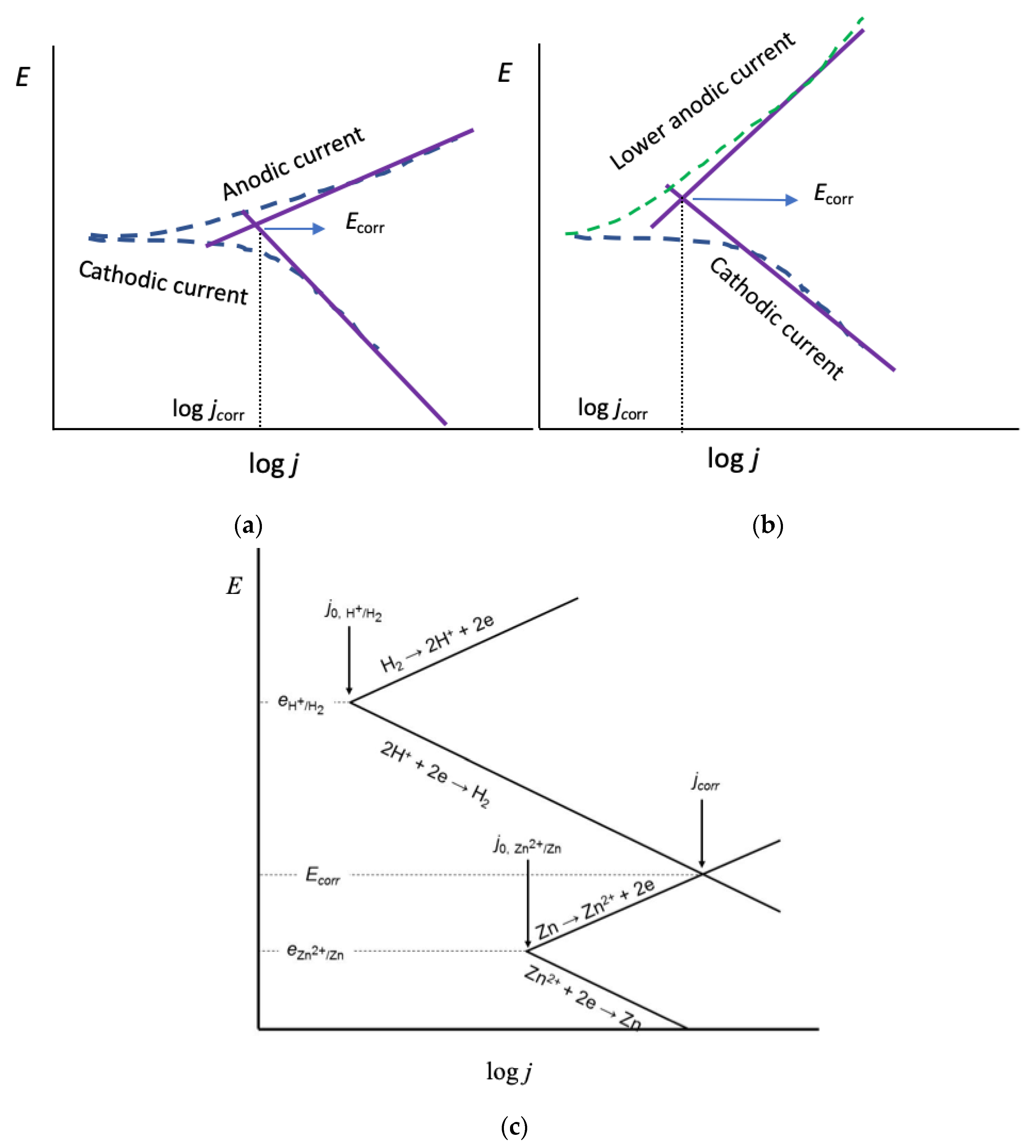

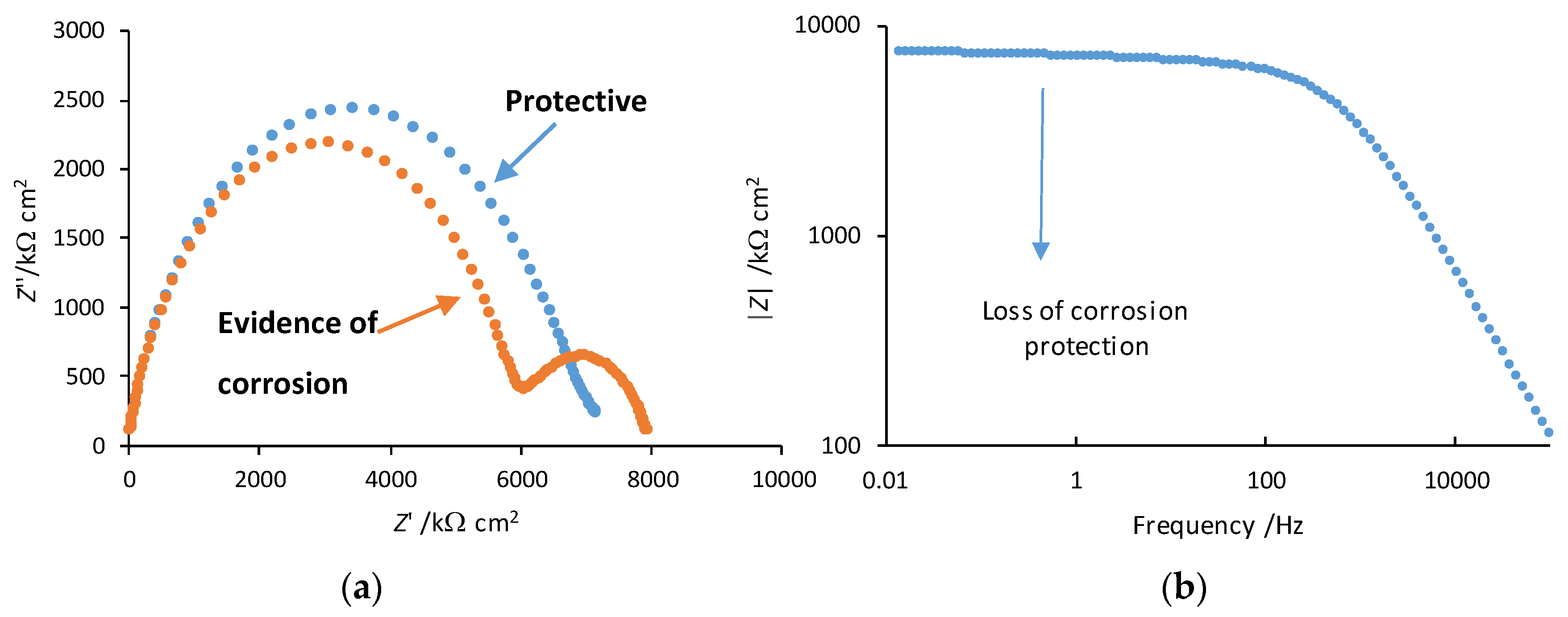

1. Introduction

2. Graphene-Based Metallic-Like Coatings

3. Graphene as a Nanofiller in Non-Conducting Anti-Corrosion Coatings

3.1. Functionalized GO

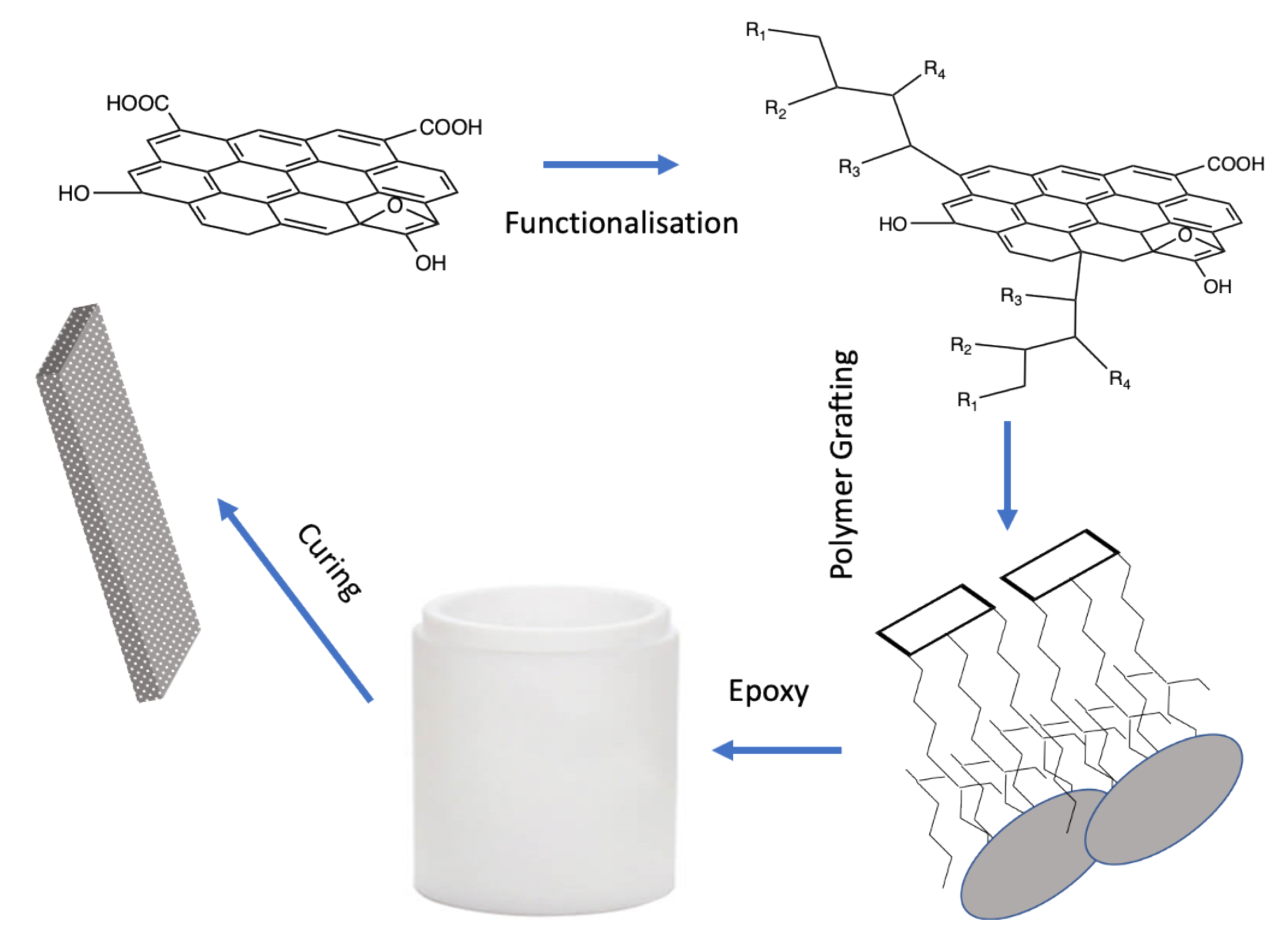

3.2. Polymer Grafted GO

4. Graphene Combined with Conducting Polymers

5. Graphene Multilayers Combined with Polymers

6. Graphene Modified Zinc Rich Coatings

7. Graphene Combined with Sol-Gels as Protective Coatings

8. Graphene and Layered Double Hydroxides or MOFs

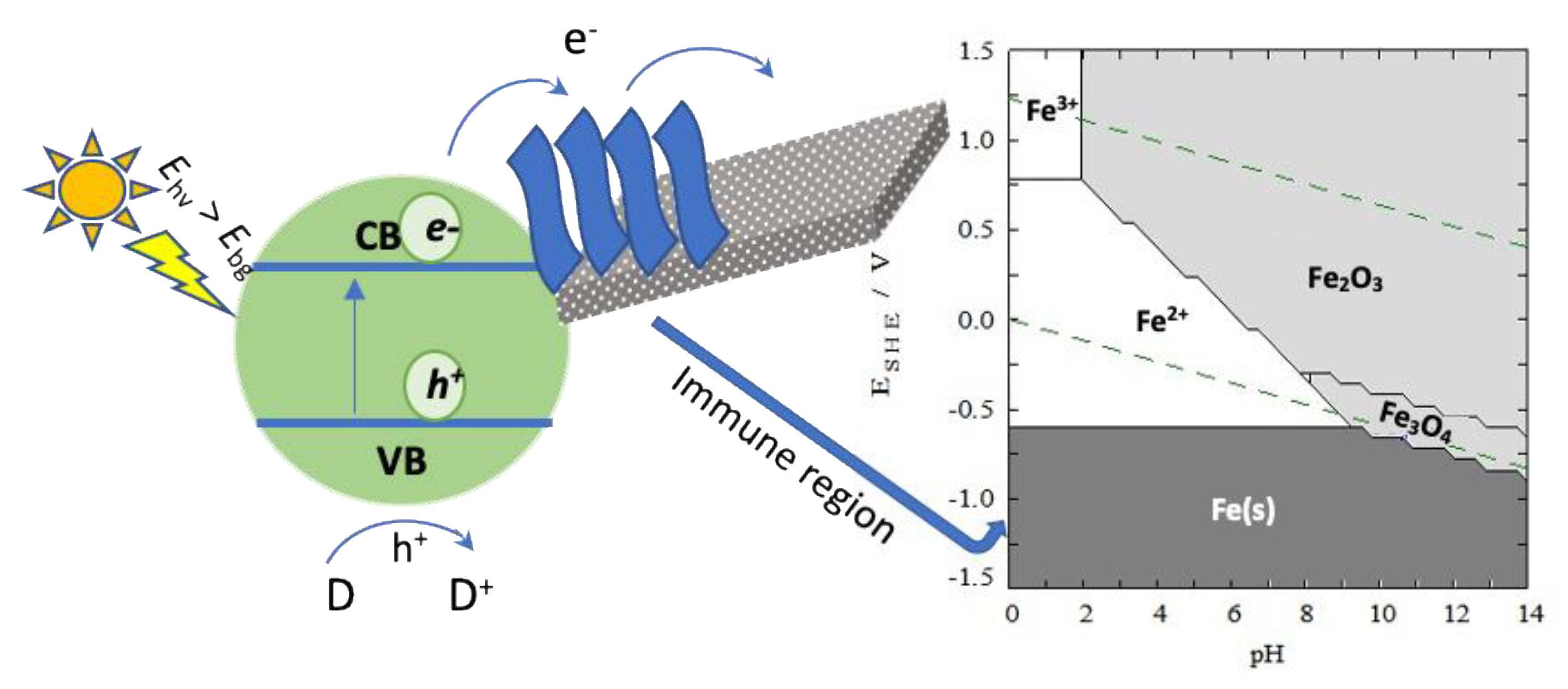

9. Nanoparticle Decorated and Metal Oxide Modified Graphene

10. Hexagonal Boron Nitride and Graphitic Carbon Nitride

11. Conclusions and Future Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Usman, B.J.; Scenini, F.; Curioni, M. Corrosion Testing of Anodized Aerospace Alloys: Comparison between Immersion and Salt Spray Testing using Electrochemical Impedance Spectroscopy. J. Electrochem. Soc. 2020, 167, 041505. [Google Scholar] [CrossRef]

- Rathish, R.J.; Prabha, S.S.; Dorothy, R.; Jancyrani, S.; Rajendran, S.; Singh, G.; Kumaran, S.S. Corrosion issues in electronic equipments—An overview. Int. J. Corros. Scale Inhib. 2019, 8, 799–815. [Google Scholar] [CrossRef]

- Li, J.; Luo, X.; Ma, G.; Wang, J.; Pan, J.; Ruan, Q. The effect of cold rolled reduction ratios on grain boundary character and mechanical properties of the SUS301L austenitic stainless steel. Mater. Res. Express 2019, 6, 126587. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Z.M.; Song, G.-L. Batch transportation of oil and water for reducing pipeline corrosion. J. Pet. Sci. Eng. 2020, 195, 107583. [Google Scholar] [CrossRef]

- Saito, N.; Tsuchiya, Y.; Akai, Y.; Omura, H.; Takada, T.; Hara, N. Corrosion performance of metals for supercritical water, oxidation-utilized organic waste-processing reactors. Corrosion 2006, 62, 383–394. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Panjagari, N.R. Review on metal packaging: Materials, forms, food applications, safety and recyclability. J. Food Sci. Technol. 2020, 57, 2377–2392. [Google Scholar] [CrossRef]

- Sumant, A.V.; Krauss, A.R.; Gruen, D.M.; Auciello, O.; Erdemir, A.; Williams, M.; Artiles, A.F.; Adams, W. Ultrananocrystalline diamond film as a wear-resistant and protective coating for mechanical seal applications. Tribol. Trans. 2005, 48, 24–31. [Google Scholar] [CrossRef]

- Tan, L.; Ren, X.; Sridharan, K.; Allen, T.R. Corrosion behavior of Ni-base alloys for advanced high temperature water-cooled nuclear plants. Corros. Sci. 2008, 50, 3056–3062. [Google Scholar] [CrossRef]

- Qu, D.R.; Zheng, Y.G.; Jing, H.M.; Yao, Z.M.; Ke, W. High temperature naphthenic acid corrosion and sulphidic corrosion of Q235 and 5Cr1/2Mo steels in synthetic refining media. Corros. Sci. 2006, 48, 1960–1985. [Google Scholar] [CrossRef]

- Becker, M. Chromate-free chemical conversion coatings for aluminum alloys. Corros. Rev. 2019, 37, 321–342. [Google Scholar] [CrossRef]

- Szklarska-Smialowska, Z. Pitting corrosion of aluminum. Corros. Sci. 1999, 41, 1743–1767. [Google Scholar] [CrossRef]

- Walsh, F.C.; Wang, S.; Zhou, N. The electrodeposition of composite coatings: Diversity, applications and challenges. Curr. Opin. Electrochem. 2020, 20, 8–19. [Google Scholar] [CrossRef]

- Carragher, U.; Branagan, D.; Breslin, C.B. The influence of carbon nanotubes on the protective properties of polypyrrole formed at copper. Materials 2019, 12, 2587. [Google Scholar] [CrossRef] [PubMed]

- Mao, S.; Li, W.; Zeng, X.; Yi, A.; Liao, Z.; Zhu, W. Multiple transitional metal oxides conversion coating on AA6063 toward corrosion protection and electrical conductivity. Surf. Coat. Technol. 2020, 397, 125819. [Google Scholar] [CrossRef]

- El Abedin, S.Z.; Welz-Biermann, U.; Endres, F. A study on the electrodeposition of tantalum on NiTi alloy in an ionic liquid and corrosion behaviour of the coated alloy. Electrochem. Commun. 2005, 7, 941–946. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, S.; Chi, C.; Hao, J.; Zhao, J.; Xu, Y.; Li, Y. Electrodeposition of a continuous, dendrite-free aluminum film from an ionic liquid and its electrochemical properties. J. Mater. Sci. Mater. Electron. 2020, 31, 9937–9945. [Google Scholar] [CrossRef]

- Guo, S.; Dong, S. Graphene nanosheet: Synthesis, molecular engineering, thin film, hybrids and energy and analytical applications. Chem. Soc. Rev. 2011, 40, 2644–2672. [Google Scholar] [CrossRef]

- Lee, C.W.; Suh, J.M.; Jang, H.W. Chemical Sensors Based on Two-Dimensional (2D) Materials for Selective Detection of Ions and Molecules in Liquid. Front. Chem. 2019, 7, 708. [Google Scholar] [CrossRef]

- Nag, A.; Mitra, A.; Mukhopadhyay, S.C. Graphene and its sensor-based applications: A review. Sens. Actuators A Phys. 2018, 270, 177–194. [Google Scholar] [CrossRef]

- Chang, Y.-M.; Lin, H.-W.; Li, L.-J.; Chen, H.-Y. Two-dimensional materials as anodes for sodium-ion batteries. Mater. Today Adv. 2020, 6, 100054. [Google Scholar] [CrossRef]

- Divyapriya, G.; Nidheesh, P.V. Importance of Graphene in the Electro-Fenton Process. ACS Omega 2020, 5, 4725–4732. [Google Scholar] [CrossRef] [PubMed]

- Yu, T.; Breslin, C.B. Graphene-modified composites and electrodes and their potential applications in the electro-fenton process. Materials 2020, 13, 2254. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Lai, W.-Y.; Zhang, Y.-Z.; Huang, W. Printable Transparent Conductive Films for Flexible Electronics. Adv. Mater. 2018, 30, 1704738. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Que, W.; Yang, C.; Tian, Y.; Yang, Y.; Yin, X. Nitrogen-doped graphene/multiphase nickel sulfides obtained by Ni-C3N3S3 (metallopolymer) assisted synthesis for high-performance hybrid supercapacitors. Electrochim. Acta 2019, 301, 332–341. [Google Scholar] [CrossRef]

- Geng, P.; Zheng, S.; Tang, H.; Zhu, R.; Zhang, L.; Cao, S.; Xue, H.; Pang, H. Transition metal sulfides based on graphene for electrochemical energy storage. Adv. Energy Mater. 2018, 8, 1703259. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef]

- Hummers, W.S.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Eda, G.; Chhowalla, M. Chemically derived graphene oxide: Towards large-area thin-film electronics and optoelectronics. Adv. Mater. 2010, 22, 2392–2415. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, H.; Shen, G.; Cheng, P.; Zhang, J.; Guo, S. Reduction of graphene oxide vial-ascorbic acid. Chem. Commun. 2010, 46, 1112–1114. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, X.; Zhang, J.; Boey, F.; Zhang, H. Direct electrochemical reduction of single-layer graphene oxide and subsequent functionalization with glucose oxidase. J. Phys. Chem. C 2009, 113, 14071–14075. [Google Scholar] [CrossRef]

- Guo, H.-L.; Wang, X.-F.; Qian, Q.-Y.; Wang, F.-B.; Xia, X.-H. A green approach to the synthesis of graphene nanosheets. ACS Nano 2009, 3, 2653–2659. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Wang, J.; Engelhard, M.; Wang, C.; Lin, Y. Facile and controllable electrochemical reduction of graphene oxide and its applications. J. Mater. Chem. 2010, 20, 743–748. [Google Scholar] [CrossRef]

- Nine, M.J.; Cole, M.A.; Tran, D.N.H.; Losic, D. Graphene: A multipurpose material for protective coatings. J. Mater. Chem. A. 2015, 3, 12580–12602. [Google Scholar] [CrossRef]

- Ding, R.; Li, W.; Wang, X.; Gui, T.; Li, B.; Han, P.; Tian, H.; Liu, A.; Wang, X.; Liu, X.; et al. A brief review of corrosion protective films and coatings based on graphene and graphene oxide. J. Alloys Compd. 2018, 764, 1039–1055. [Google Scholar] [CrossRef]

- Othman, N.H.; Ismail, M.C.; Mustapha, M.; Sallih, N.; Kee, K.E.; Jaal, R.A. Graphene-based polymer nanocomposites as barrier coatings for corrosion protection. Prog. Org. Coat. 2019, 135, 82–99. [Google Scholar] [CrossRef]

- Ding, R.; Chen, S.; Lv, J.; Zhang, W.; Zhao, X.-D.; Liu, J.; Wang, X.; Gui, T.-J.; Li, B.-J.; Tang, Y.-Z.; et al. Study on graphene modified organic anti-corrosion coatings: A comprehensive review. J. Alloys Compd. 2019, 806, 611–635. [Google Scholar] [CrossRef]

- Cui, G.; Bi, Z.; Zhang, R.; Liu, J.; Yu, X.; Li, Z. A comprehensive review on graphene-based anti-corrosive coatings. Chem. Eng. J. 2019, 373, 104–121. [Google Scholar] [CrossRef]

- Hussain, A.K.; Al Naib, U.M.B. Recent developments in graphene based metal matrix composite coatings for corrosion protection application: A review. J. Met. Mater. Miner. 2019, 29, 1–9. [Google Scholar] [CrossRef]

- Akhtar, S.; Laoui, T.; Ibrahim, A.; Kumar, A.M.; Ahmed, J.; Toor, I.-U.-H. Few-layers graphene film and copper surface morphology for improved corrosion protection of copper. J. Mater. Eng. Perform. 2019, 28, 5541–5550. [Google Scholar] [CrossRef]

- Yang, S.; Zhuo, K.; Sun, D.; Wang, X.; Wang, J. Preparation of graphene by exfoliating graphite in aqueous fulvic acid solution and its application in corrosion protection of aluminum. J. Colloid Interface Sci. 2019, 543, 263–272. [Google Scholar] [CrossRef]

- Mayavan, S.; Siva, T.; Sathiyanarayanan, S. Graphene ink as a corrosion inhibiting blanket for iron in an aggressive chloride environment. RSC Adv. 2013, 3, 24868–24871. [Google Scholar] [CrossRef]

- Singhbabu, Y.N.; Sivakumar, B.; Singh, J.K.; Bapari, H.; Pramanick, A.K.; Sahu, R.K. Efficient anti-corrosive coating of cold-rolled steel in a seawater environment using an oil-based graphene oxide ink. Nanoscale 2015, 7, 8035–8047. [Google Scholar] [CrossRef]

- Qiang, R.; Hou, K.; Wang, J.; Yang, S. Smooth and dense graphene quantum dots-based lubricating coatings prepared by electrophoretic deposition. Appl. Surf. Sci. 2020, 509, 145338. [Google Scholar] [CrossRef]

- Chavez-Valdez, A.; Shaffer, M.S.P.; Boccaccini, A.R. Applications of graphene electrophoretic deposition. A review. J. Phys. Chem. B. 2013, 117, 1502–1515. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.P.; Nayak, S.; Nanda, K.K.; Jena, B.K.; Bhattacharjee, S.; Besra, L. The production of a corrosion resistant graphene reinforced composite coating on copper by electrophoretic deposition. Carbon 2013, 61, 47–56. [Google Scholar] [CrossRef]

- Ma, Y.; Han, J.; Wang, M.; Chen, X.; Jia, S. Electrophoretic deposition of graphene-based materials: A review of materials and their applications. J. Mater. 2018, 4, 108–120. [Google Scholar] [CrossRef]

- Quezada-Rentería, J.A.; Cházaro-Ruiz, L.F.; Rangel-Mendez, J.R. Synthesis of reduced graphene oxide (rGO) films onto carbon steel by cathodic electrophoretic deposition: Anticorrosive coating. Carbon 2017, 122, 266–275. [Google Scholar] [CrossRef]

- Hwang, M.-J.; Kim, M.-G.; Kim, S.; Kim, Y.C.; Seo, H.W.; Cho, J.K.; Park, I.-K.; Suhr, J.; Moon, H.; Koo, J.C.; et al. Cathodic electrophoretic deposition (EPD) of phenylenediamine-modified graphene oxide (GO) for anti-corrosion protection of metal surfaces. Carbon 2019, 142, 68–77. [Google Scholar] [CrossRef]

- Kamil, M.P.; Kim, M.J.; Ko, Y.G. Direct electro-co-deposition of Ni-reduced graphene oxide composite coating for anti-corrosion application. Mater. Lett. 2020, 273, 127911. [Google Scholar] [CrossRef]

- Boukhvalov, D.W.; Bazylewski, P.F.; Kukharenko, A.I.; Zhidkov, I.S.; Ponosov, Y.S.; Kurmaev, E.Z.; Cholakh, S.O.; Lee, Y.H.; Chang, G.S. Atomic and electronic structure of a copper/graphene interface as prepared and 1.5 years after. Appl. Surf. Sci. 2017, 426, 1167–1172. [Google Scholar] [CrossRef]

- Xu, X.; Yi, D.; Wang, Z.; Yu, J.; Zhang, Z.; Qiao, R.; Sun, Z.; Hu, Z.; Gao, P.; Peng, H.; et al. Greatly enhanced anticorrosion of Cu by commensurate graphene coating. Adv. Mater. 2018, 30, 1702944. [Google Scholar] [CrossRef] [PubMed]

- Scardamaglia, M.; Struzzi, C.; Zakharov, A.; Reckinger, N.; Zeller, P.; Amati, M.; Gregoratti, L. Highlighting the dynamics of graphene protection toward the oxidation of copper under operando conditions. ACS Appl. Mater. Interfaces 2019, 11, 29448–29457. [Google Scholar] [CrossRef]

- Álvarez-Fraga, L.; Rubio-Zuazo, J.; Jiménez-Villacorta, F.; Climent-Pascual, E.; Ramírez-Jiménez, R.; Prieto, C.; de Andrés, A. Oxidation mechanisms of copper under graphene: The role of oxygen encapsulation. Chem. Mater. 2017, 29, 3257–3264. [Google Scholar] [CrossRef]

- Schriver, M.; Regan, W.; Gannett, W.J.; Zaniewski, A.M.; Crommie, M.F.; Zettl, A. Graphene as a long-term metal oxidation barrier: Worse than nothing. ACS Nano 2013, 7, 5763–5768. [Google Scholar] [CrossRef] [PubMed]

- Bellucci, F. Galvanic corrosion between nonmetallic composites and metals. I. Effect of metal and of temperature. Corrosion 1991, 47, 808–819. [Google Scholar] [CrossRef]

- Naghdi, S.; Jaleh, B.; Ehsani, A. Electrophoretic deposition of graphene oxide on aluminum: Characterization, low thermal annealing, surface and anticorrosive properties. Bull. Chem. Soc. Jpn. 2015, 88, 722–728. [Google Scholar] [CrossRef]

- Jang, H.; Kim, J.-H.; Kang, H.; Bae, D.; Chang, H.; Choi, H. Reduced graphene oxide as a protection layer for Al. Appl. Surf. Sci. 2017, 407, 1–7. [Google Scholar] [CrossRef]

- Hares, E.; El-Shazly, A.H.; El-Kady, M.F.; Hammad, A.S. Electrophoretic deposition of graphene oxide nanosheets on copper pipe for corrosion protection. Arab. J. Sci. Eng. 2019, 44, 5559–5569. [Google Scholar] [CrossRef]

- Ho, C.-Y.; Huang, S.-M.; Lee, S.-T.; Chang, Y.-J. Evaluation of synthesized graphene oxide as corrosion protection film coating on steel substrate by electrophoretic deposition. Appl. Surf. Sci. 2019, 477, 226–231. [Google Scholar] [CrossRef]

- Ryu, S.; Kwon, Y.J.; Kim, Y.; Lee, J.U. Corrosion protection coating of three-dimensional metal structure by electrophoretic deposition of graphene oxide. Mater. Chem. Phys. 2020, 250, 123039. [Google Scholar] [CrossRef]

- Jena, G.; Vanithakumari, S.C.; Polaki, S.R.; George, R.P.; Philip, J.; Amarendra, G. Electrophoretically deposited graphene oxide–polymer bilayer coating on Cu-Ni alloy with enhanced corrosion resistance in simulated chloride environment. J. Coat. Technol. Res. 2019, 16, 1317–1335. [Google Scholar] [CrossRef]

- Jena, G.; Anandkumar, B.; Vanithakumari, S.C.; George, R.P.; Philip, J.; Amarendra, G. Graphene oxide-chitosan-silver composite coating on Cu-Ni alloy with enhanced anticorrosive and antibacterial properties suitable for marine applications. Prog. Org. Coat. 2020, 139, 105444. [Google Scholar] [CrossRef]

- Srimaneepong, V.; Rokaya, D.; Thunyakitpisal, P.; Qin, J.; Saengkiettiyut, K. Corrosion resistance of graphene oxide/silver coatings on Ni–Ti alloy and expression of IL-6 and IL-8 in human oral fibroblasts. Sci. Rep. 2020, 10, 3247. [Google Scholar] [CrossRef]

- Asgar, H.; Deen, K.M.; Rahman, Z.U.; Shah, U.H.; Raza, M.A.; Haider, W. Functionalized graphene oxide coating on Ti6Al4V alloy for improved biocompatibility and corrosion resistance. Mater. Sci. Eng. C 2019, 94, 920–928. [Google Scholar] [CrossRef]

- Senthilvasan, P.A.; Rangarajan, M. Corrosion protection of mild steel by graphene-based films. Mater. Res. Express 2018, 5, 085020. [Google Scholar] [CrossRef]

- Xu, H.; Zang, J.; Yuan, Y.; Tian, P.; Wang, Y. In situ preparation of graphene coating bonded to stainless steel substrate via Cr–C bonding for excellent anticorrosion and wear resistant. Appl. Surf. Sci. 2019, 492, 199–208. [Google Scholar] [CrossRef]

- Pinto, D.; Bernardo, L.; Amaro, A.; Lopes, S. Mechanical properties of epoxy nanocomposites using titanium dioxide as reinforcement—A review. Constr. Build. Mater. 2015, 95, 506–524. [Google Scholar] [CrossRef]

- Oliveira, J.D.; Rocha, R.C.; Galdino, A.G.D.S. Effect of Al2O3 particles on the adhesion, wear, and corrosion performance of epoxy coatings for protection of umbilical cables accessories for subsea oil and gas production systems. J. Mater. Res. Technol. 2019, 8, 1729–1736. [Google Scholar] [CrossRef]

- Ruhi, G.; Bhandari, H.; Dhawan, S.K. Designing of corrosion resistant epoxy coatings embedded with polypyrrole/SiO2 composite. Prog. Org. Coat. 2014, 77, 1484–1498. [Google Scholar] [CrossRef]

- Behzadnasab, M.; Mirabedini, S.M.; Esfandeh, M. Corrosion protection of steel by epoxy nanocomposite coatings containing various combinations of clay and nanoparticulate zirconia. Corros. Sci. 2013, 75, 134–141. [Google Scholar] [CrossRef]

- Wan, C.; Chen, B. Reinforcement and interphase of polymer/graphene oxide nanocomposites. J. Mater. Chem. 2012, 22, 3637–3646. [Google Scholar] [CrossRef]

- Li, Z.; Li, J.; Cui, J.; Qiu, H.; Yang, G.; Zheng, S.; Yang, J. Dispersion and parallel assembly of sulfonated graphene in waterborne epoxy anticorrosion coatings. J. Mater. Chem. A 2019, 7, 17937–17946. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, C.; Liu, W.; Liang, L.; Wang, S.; Zhang, F.; Shi, H.; Yang, M. A novel approach to fabricate polyacrylate modified graphene oxide for improving the corrosion resistance of epoxy coatings. Colloids Surf. A Physicochem. Eng. Asp. 2020, 593, 124627. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Haeri, Z.; Ramezanzadeh, M. A facile route of making silica nanoparticles-covered graphene oxide nanohybrids (SiO2-GO); fabrication of SiO2-GO/epoxy composite coating with superior barrier and corrosion protection performance. Chem. Eng. J. 2016, 303, 511–528. [Google Scholar] [CrossRef]

- Yu, Z.; Di, H.; Ma, Y.; Lv, L.; Pan, Y.; Zhang, C.; He, Y. Fabrication of graphene oxide-alumina hybrids to reinforce the anti-corrosion performance of composite epoxy coatings. Appl. Surf. Sci. 2015, 351, 986–996. [Google Scholar] [CrossRef]

- Ji, W.F.; Chen, K.Y.; Ke, C.J.; Liao, Y.J.; Liu, W.J.; Tsai, M.H.; Yeh, J.M. Comparative corrosion protection studies of electroactive/non-electroactive epoxy thermoset composites containing conductive rGO/non-conductive GO platelets. Express Polym. Lett. 2019, 13, 604–617. [Google Scholar] [CrossRef]

- Dutta, D.; Ganda, A.N.F.; Chih, J.-K.; Huang, C.-C.; Tseng, C.-J.; Su, C.-Y. Revisiting graphene-polymer nanocomposite for enhancing anticorrosion performance: A new insight into interface chemistry and diffusion model. Nanoscale 2018, 10, 12612–12624. [Google Scholar] [CrossRef]

- Um, J.G.; Jun, Y.-S.; Elkamel, A.; Yu, A. Engineering investigation for the size effect of graphene oxide derived from graphene nanoplatelets in polyurethane composites. Can. J. Chem. Eng. 2020, 98, 1084–1096. [Google Scholar] [CrossRef]

- Jiang, F.; Zhao, W.; Wu, Y.; Dong, J.; Zhou, K.; Lu, G.; Pu, J. Anti-corrosion behaviors of epoxy composite coatings enhanced via graphene oxide with different aspect ratios. Prog. Org. Coat. 2019, 127, 70–79. [Google Scholar] [CrossRef]

- Adeel, M.; Bilal, M.; Rasheed, T.; Sharma, A.; Iqbal, H.M.N. Graphene and graphene oxide: Functionalization and nano-bio-catalytic system for enzyme immobilization and biotechnological perspective. Int. J. Biol. Macromol. 2018, 120, 1430–1440. [Google Scholar] [CrossRef]

- Niyogi, S.; Bekyarova, E.; Itkis, M.E.; McWilliams, J.L.; Hamon, M.A.; Haddon, R.C. Solution properties of graphite and graphene. J. Am. Chem. Soc. 2006, 128, 7720–7721. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Li, D.; Sun, Y.; Wang, Z.; Hou, C.; Chen, L.; Cao, Y.; Liu, Y. Mechanical and anticorrosive properties of graphene/epoxy resin composites coating prepared by in-situ method. Int. J. Mol. Sci. 2015, 16, 2239–2251. [Google Scholar] [CrossRef] [PubMed]

- Sari, M.G.; Ramezanzadeh, B. Epoxy composite coating corrosion protection properties reinforcement through the addition of hydroxyl-terminated hyperbranched polyamide non-covalently assembled graphene oxide platforms. Constr. Build. Mater. 2020, 234, 117421. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Pu, J.; Wang, Y.; Zhao, H.; Wang, L. Poly(o-phenylenediamine) modified graphene toward the reinforcement in corrosion protection of epoxy coatings. Corros. Sci. 2019, 159, 108131. [Google Scholar] [CrossRef]

- Calovi, M.; Dirè, S.; Ceccato, R.; Deflorian, F.; Rossi, S. Corrosion protection properties of functionalised graphene–acrylate coatings produced via cataphoretic deposition. Prog. Org. Coat. 2019, 136, 105261. [Google Scholar] [CrossRef]

- Zhang, C.; Dai, X.; Wang, Y.; Sun, G.; Li, P.; Qu, L.; Sui, Y.; Dou, Y. Preparation and corrosion resistance of ETEO modified graphene oxide/epoxy resin coating. Coatings 2019, 9, 46. [Google Scholar] [CrossRef]

- Chilkoor, G.; Sarder, R.; Islam, J.; ArunKumar, K.E.; Ratnayake, I.; Star, S.; Jasthi, B.K.; Sereda, G.; Koratkar, N.; Meyyappan, M.; et al. Maleic anhydride-functionalized graphene nanofillers render epoxy coatings highly resistant to corrosion and microbial attack. Carbon 2020, 159, 586–597. [Google Scholar] [CrossRef]

- Tian, Y.; Xie, Y.; Dai, F.; Huang, H.; Zhong, L.; Zhang, X. Ammonium-grafted graphene oxide for enhanced corrosion resistance of waterborne epoxy coatings. Surf. Coat. Technol. 2020, 383, 125227. [Google Scholar] [CrossRef]

- Feng, C.; Zhu, L.; Cao, Y.; Di, Y.; Yu, Z.; Gao, G. Performance of coating based on β-CD-g-GO/epoxy composites for the corrosion protection of steel. Int. J. Electrochem. Sci. 2019, 14, 1855–1868. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, H.; Zhu, R.; Chen, R.; Sheng, X.; Xie, D.; Mei, Y. Green modification of graphene oxide with phytic acid and its application in anticorrosive water-borne epoxy coatings. Prog. Org. Coat. 2020, 143, 105601. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Niroumandrad, S.; Ahmadi, A.; Mahdavian, M.; Mohamadzadeh Moghadam, M.H. Enhancement of barrier and corrosion protection performance of an epoxy coating through wet transfer of amino functionalized graphene oxide. Corros. Sci. 2016, 103, 283–304. [Google Scholar] [CrossRef]

- Wang, S.; Hu, Z.; Shi, J.; Chen, G.; Zhang, Q.; Weng, Z.; Wu, K.; Lu, M. Green synthesis of graphene with the assistance of modified lignin and its application in anticorrosive waterborne epoxy coatings. Appl. Surf. Sci. 2019, 484, 759–770. [Google Scholar] [CrossRef]

- Rajitha, K.; Mohana, K.N.S.; Mohanan, A.; Madhusudhana, A.M. Evaluation of anti-corrosion performance of modified gelatin-graphene oxide nanocomposite dispersed in epoxy coating on mild steel in saline media. Colloids Surf. A Physicochem. Eng. Asp. 2020, 587, 124341. [Google Scholar] [CrossRef]

- Rajitha, K.; Mohana, K.N.S. Synthesis of graphene oxide-based nanofillers and their influence on the anticorrosion performance of epoxy coating in saline medium. Diam. Relat. Mater. 2020, 108, 107974. [Google Scholar] [CrossRef]

- Parhizkar, N.; Shahrabi, T.; Ramezanzadeh, B. A new approach for enhancement of the corrosion protection properties and interfacial adhesion bonds between the epoxy coating and steel substrate through surface treatment by covalently modified amino functionalized graphene oxide film. Corros. Sci. 2017, 123, 55–75. [Google Scholar] [CrossRef]

- Pourhashem, S.; Rashidi, A.; Vaezi, M.R.; Bagherzadeh, M.R. Excellent corrosion protection performance of epoxy composite coatings filled with amino-silane functionalized graphene oxide. Surf. Coat. Technol. 2017, 317, 1–9. [Google Scholar] [CrossRef]

- Liu, C.; Du, P.; Zhao, H.; Wang, L. Synthesis of l-Histidine-Attached Graphene Nanomaterials and Their Application for Steel Protection. ACS Appl. Nano Mater. 2018, 1, 1385–1395. [Google Scholar] [CrossRef]

- Javidparvar, A.A.; Naderi, R.; Ramezanzadeh, B. L-cysteine reduced/functionalized graphene oxide application as a smart/control release nanocarrier of sustainable cerium ions for epoxy coating anti-corrosion properties improvement. J. Hazard. Mater. 2020, 389, 122135. [Google Scholar] [CrossRef]

- Palaniappan, N.; Cole, I.S.; Kuznetsov, A.E.; Balasubramanian, K.; Justin Thomas, K.R. Experimental and computational studies of a graphene oxide barrier layer covalently functionalized with amino acids on Mg AZ13 alloy in salt medium. RSC Adv. 2019, 9, 32441–32447. [Google Scholar] [CrossRef]

- Ramezanzadeh, M.; Ramezanzadeh, B.; Sari, M.G.; Saeb, M.R. Corrosion resistance of epoxy coating on mild steel through polyamidoamine dendrimer-covalently functionalized graphene oxide nanosheets. J. Ind. Eng. Chem. 2020, 82, 290–302. [Google Scholar] [CrossRef]

- Chen, Y.; Ren, B.; Gao, S.; Cao, R. The sandwich-like structures of polydopamine and 8-hydroxyquinoline coated graphene oxide for excellent corrosion resistance of epoxy coatings. J. Colloid Interface Sci. 2020, 565, 436–448. [Google Scholar] [CrossRef]

- Xiao, Y.-K.; Ji, W.-F.; Chang, K.-S.; Hsu, K.-T.; Yeh, J.-M.; Liu, W.-R. Sandwich-structured rGO/PVDF/PU multilayer coatings for anti-corrosion application. RSC Adv. 2017, 7, 33829–33836. [Google Scholar] [CrossRef]

- Bai, T.; Lv, L.; Du, W.; Fang, W.; Wang, Y. Improving the tribological and anticorrosion performance of waterborne polyurethane coating by the synergistic effect between modified graphene oxide and polytetrafluoroethylene. Nanomaterials 2020, 10, 137. [Google Scholar] [CrossRef] [PubMed]

- Um, J.G.; Habibpour, S.; Jun, Y.-S.; Elkamel, A.; Yu, A. Development of π–π interaction-induced functionalized graphene oxide on mechanical and anticorrosive properties of reinforced polyurethane composites. Ind. Eng. Chem. Res. 2020, 59, 3617–3628. [Google Scholar] [CrossRef]

- Wen, J.-G.; Geng, W.; Geng, H.-Z.; Zhao, H.; Jing, L.-C.; Yuan, X.-T.; Tian, Y.; Wang, T.; Ning, Y.-J.; Wu, L. Improvement of corrosion resistance of waterborne polyurethane coatings by covalent and noncovalent grafted graphene oxide nanosheets. ACS Omega 2019, 4, 20265–20274. [Google Scholar] [CrossRef] [PubMed]

- Zhu, K.; Li, X.; Li, J.; Fei, G.; Wang, J. Synthesis and anticorrosive properties of waterborne isocyanate functionalized graphene/polyurethane nanocomposite emulsion. J. Funct. Mater. 2016, 47, 06016–06021. [Google Scholar] [CrossRef]

- Mo, M.; Zhao, W.; Chen, Z.; Yu, Q.; Zeng, Z.; Wu, X.; Xue, Q. Excellent tribological and anti-corrosion performance of polyurethane composite coatings reinforced with functionalized graphene and graphene oxide nanosheets. RSC Adv. 2015, 5, 56486–56497. [Google Scholar] [CrossRef]

- Wang, H.; He, Y.; Fei, G.; Wang, C.; Shen, Y.; Zhu, K.; Sun, L.; Rang, N.; Guo, D.; Wallace, G.G. Functionalizing graphene with titanate coupling agents as reinforcement for one-component waterborne poly(urethane-acrylate) anticorrosion coatings. Chem. Eng. J. 2019, 359, 331–343. [Google Scholar] [CrossRef]

- Zhao, Z.; Guo, L.; Feng, L.; Lu, H.; Xu, Y.; Wang, J.; Xiang, B.; Zou, X. Polydopamine functionalized graphene oxide nanocomposites reinforced the corrosion protection and adhesion properties of waterborne polyurethane coatings. Eur. Polym. J. 2019, 120, 109249. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, W.; Liang, L.; Wang, S.; Shi, H.; Xie, Y.; Yang, M.; Pi, K. The effect of functional graphene oxide nanoparticles on corrosion resistance of waterborne polyurethane. Colloids Surf. A Physicochem. Eng. Asp. 2020, 591, 124565. [Google Scholar] [CrossRef]

- Rajitha, K.; Mohana, K.N. Application of modified graphene oxide—Polycaprolactone nanocomposite coating for corrosion control of mild steel in saline medium. Mater. Chem. Phys. 2020, 241, 122050. [Google Scholar] [CrossRef]

- Liu, Q.; Ma, R.; Du, A.; Zhang, X.; Yang, H.; Fan, Y.; Zhao, X.; Cao, X. Investigation of the anticorrosion properties of graphene oxide doped thin organic anticorrosion films for hot-dip galvanized steel. Appl. Surf. Sci. 2019, 480, 646–654. [Google Scholar] [CrossRef]

- Rajitha, K.; Mohana, K.N.S.; Nayak, S.R.; Hegde, M.B.; Madhusudhana, A.M. An efficient and eco-friendly anti-corrosive system based on beeswax-graphene oxide nanocomposites on mild steel in saline medium. Surf. Interfaces 2020, 18, 100393. [Google Scholar] [CrossRef]

- Wang, S.; Sun, H.; Ang, H.M.; Tadé, M.O. Adsorptive remediation of environmental pollutants using novel graphene-based nanomaterials. Chem. Eng. J. 2013, 226, 336–347. [Google Scholar] [CrossRef]

- Javidparvar, A.A.; Naderi, R.; Ramezanzadeh, B. Manipulating graphene oxide nanocontainer with benzimidazole and cerium ions: Application in epoxy-based nanocomposite for active corrosion protection. Corros. Sci. 2020, 165, 108379. [Google Scholar] [CrossRef]

- Yu, Z.; Lv, L.; Ma, Y.; Di, H.; He, Y. Covalent modification of graphene oxide by metronidazole for reinforced anti-corrosion properties of epoxy coatings. RSC Adv. 2016, 6, 18217–18226. [Google Scholar] [CrossRef]

- Daradmare, S.; Pradhan, M.; Raja, V.S.; Parida, S. 8-Hydroxyquinoline encapsulated graphene oxide stabilized polystyrene containers based anticorrosion coatings. In Proceedings of the European Corrosion Congress EUROCORR 2017, 20th Internacional Corrosion Congress and the Process Safety Congress 2017, Prague, Czech Republic, 3–7 September 2017. [Google Scholar]

- Chen, C.; He, Y.; Xiao, G.; Zhong, F.; Li, H.; Wu, Y.; Chen, J. Synergistic effect of graphene oxide@phosphate-intercalated hydrotalcite for improved anti-corrosion and self-healable protection of waterborne epoxy coating in salt environments. J. Mater. Chem. C 2019, 7, 2318–2326. [Google Scholar] [CrossRef]

- Kasaeian, M.; Ghasemi, E.; Ramezanzadeh, B.; Mahdavian, M.; Bahlakeh, G. Construction of a highly effective self-repair corrosion-resistant epoxy composite through impregnation of 1H-Benzimidazole corrosion inhibitor modified graphene oxide nanosheets (GO-BIM). Corros. Sci. 2018, 145, 119–134. [Google Scholar] [CrossRef]

- Cao, K.; Yu, Z.; Yin, D.; Chen, L.; Jiang, Y.; Zhu, L. Fabrication of BTA-MOF-TEOS-GO nanocomposite to endow coating systems with active inhibition and durable anticorrosion performances. Prog. Org. Coat. 2020, 143, 105629. [Google Scholar] [CrossRef]

- Qian, B.; Ren, J.; Song, Z.; Zhou, Y. One pot graphene-based nanocontainers as effective anticorrosion agents in epoxy-based coatings. J. Mater. Sci. 2018, 53, 14204–14216. [Google Scholar] [CrossRef]

- Zhong, F.; He, Y.; Wang, P.; Chen, C.; Xie, P.; Li, H.; Chen, J. One-step hydrothermal synthesis of reduced graphene oxide/aspartic acid intercalated layered double hydroxide for enhancing barrier and self-healing properties of epoxy coating. React. Funct. Polym. 2019, 145, 104380. [Google Scholar] [CrossRef]

- Asaldoust, S.; Ramezanzadeh, B. Synthesis and characterization of a high-quality nanocontainer based on benzimidazole-zinc phosphate (ZP-BIM) tailored graphene oxides; a facile approach to fabricating a smart self-healing anti-corrosion system. J. Colloid Interface Sci. 2020, 564, 230–244. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Zhao, X.; Xiong, L.; Xue, B.; Kong, X.; Liu, J.; Li, S. Improvement of corrosion protection of coating system via inhibitor response order. Coatings 2018, 8, 365. [Google Scholar] [CrossRef]

- Dehghani, A.; Bahlakeh, G.; Ramezanzadeh, B. Synthesis of a non-hazardous/smart anti-corrosion nano-carrier based on beta-cyclodextrin-zinc acetylacetonate inclusion complex decorated graphene oxide (β-CD-ZnA-MGO). J. Hazard. Mater. 2020, 398, 122962. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.D.; Nguyen, A.S.; Tran, B.A.; Vu, K.O.; Tran, D.L.; Phan, T.T.; Scharnagl, N.; Zheludkevich, M.L.; To, T.X.H. Molybdate intercalated hydrotalcite/graphene oxide composite as corrosion inhibitor for carbon steel. Surf. Coat. Technol. 2020, 399, 126165. [Google Scholar] [CrossRef]

- Mo, Z.-H.; Luo, Z.; Huang, Q.; Deng, J.-P.; Wu, Y.-X. Superhydrophobic hybrid membranes by grafting arc-like macromolecular bridges on graphene sheets: Synthesis, characterization and properties. Appl. Surf. Sci. 2018, 440, 359–368. [Google Scholar] [CrossRef]

- Li, Y.; Alain-Rizzo, V.; Galmiche, L.; Audebert, P.; Miomandre, F.; Louarn, G.; Bozlar, M.; Pope, M.A.; Dabbs, D.M.; Aksay, I.A. Functionalization of Graphene Oxide by Tetrazine Derivatives: A versatile approach toward covalent bridges between graphene sheets. Chem. Mater. 2015, 27, 4298–4310. [Google Scholar] [CrossRef]

- Gonalves, G.; Marques, P.A.A.P.; Barros-Timmons, A.; Bdkin, I.; Singh, M.K.; Emami, N.; Grácio, J. Graphene oxide modified with PMMA via ATRP as a reinforcement filler. J. Mater. Chem. 2010, 20, 9927–9934. [Google Scholar] [CrossRef]

- Qi, K.; Sun, Y.; Duan, H.; Guo, X. A corrosion-protective coating based on a solution-processable polymer-grafted graphene oxide nanocomposite. Corros. Sci. 2015, 98, 500–506. [Google Scholar] [CrossRef]

- Jiang, F.; Zhao, W.; Wu, Y.; Wu, Y.; Liu, G.; Dong, J.; Zhou, K. A polyethyleneimine-grafted graphene oxide hybrid nanomaterial: Synthesis and anti-corrosion applications. Appl. Surf. Sci. 2019, 479, 963–973. [Google Scholar] [CrossRef]

- Huang, H.; Tian, Y.; Xie, Y.; Mo, R.; Hu, J.; Li, M.; Sheng, X.; Jiang, X.; Zhang, X. Modification of graphene oxide with acrylate phosphorus monomer via thiol-Michael addition click reaction to enhance the anti-corrosive performance of waterborne epoxy coatings. Prog. Org. Coat. 2020, 146, 105724. [Google Scholar] [CrossRef]

- Jin, T.; Xie, Z.; Fullston, D.; Huang, C.; Zeng, R.; Bai, R. Corrosion resistance of copolymerization of acrylamide and acrylic acid grafted graphene oxide composite coating on magnesium alloy. Prog. Org. Coat. 2019, 136, 105222. [Google Scholar] [CrossRef]

- Harley, C.C.; Annibaldi, V.; Yu, T.; Breslin, C.B. The selective electrochemical sensing of dopamine at a polypyrrole film doped with an anionic β−cyclodextrin. J. Electroanal. Chem. 2019, 855, 113614. [Google Scholar] [CrossRef]

- Carragher, U.; Breslin, C.B. Polypyrrole doped with dodecylbenzene sulfonate as a protective coating for copper. Electrochim. Acta 2018, 291, 362–372. [Google Scholar] [CrossRef]

- Annibaldi, V.; Rooney, A.D.; Breslin, C.B. Corrosion protection of copper using polypyrrole electrosynthesised from a salicylate solution. Corros. Sci. 2012, 59, 179–185. [Google Scholar] [CrossRef]

- Samanta, P.N.; Das, K.K. Deciphering the impact of surface defects and functionalization on the binding strength and electronic properties of graphene-polypyrrole nanocomposites: A first-principles approach. J. Phys. Chem. C 2019, 123, 5447–5459. [Google Scholar] [CrossRef]

- Qiu, S.; Li, W.; Zheng, W.; Zhao, H.; Wang, L. Synergistic effect of polypyrrole-intercalated graphene for enhanced corrosion protection of aqueous coating in 3.5% NaCl solution. ACS Appl. Mater. Interfaces 2017, 9, 34294–34304. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, E.; Liu, X.; Song, W.; Li, Y.; Wang, X.; Liu, C. Epoxy coating with in-situ synthesis of polypyrrole functionalized graphene oxide for enhanced anticorrosive performance. Prog. Org. Coat. 2020, 140, 105488. [Google Scholar] [CrossRef]

- Jiang, L.; Syed, J.A.; Lu, H.; Meng, X. In-situ electrodeposition of conductive polypyrrole-graphene oxide composite coating for corrosion protection of 304SS bipolar plates. J. Alloys Compd. 2019, 770, 35–47. [Google Scholar] [CrossRef]

- Li, M.; Ji, X.; Cui, L.; Liu, J. In situ preparation of graphene/polypyrrole nanocomposite via electrochemical co-deposition methodology for anti-corrosion application. J. Mater. Sci. 2017, 52, 12251–12265. [Google Scholar] [CrossRef]

- Merisalu, M.; Kahro, T.; Kozlova, J.; Niilisk, A.; Nikolajev, A.; Marandi, M.; Floren, A.; Alles, H.; Sammelselg, V. Graphene-polypyrrole thin hybrid corrosion resistant coatings for copper. Synth. Met. 2015, 200, 16–23. [Google Scholar] [CrossRef]

- Jiang, L.; Syed, J.A.; Zhang, G.; Ma, Y.; Ma, J.; Lu, H.; Meng, X. Enhanced anticorrosion performance of PPY-graphene oxide/PPY-camphorsulfonic acid composite coating for 304SS bipolar plates in proton exchange membrane fuel cell. J. Ind. Eng. Chem. 2019, 80, 497–507. [Google Scholar] [CrossRef]

- Jiang, S.; Liu, Z.; Jiang, D.; Cheng, H.; Han, J.; Han, S. Graphene as a nanotemplating auxiliary on the polypyrrole pigment for anticorrosion coatings. High. Perform. Polym. 2016, 28, 747–757. [Google Scholar] [CrossRef]

- Bethencourt, M.; Botana, F.J.; Marcos, M.; Osuna, R.M.; Sánchez-Amaya, J.M. Inhibitor properties of “green” pigments for paints. Prog. Org. Coat. 2003, 46, 280–287. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, E.; Liu, X.; Song, W.; Zhao, M.; Zi, L.; Wang, X.; Liu, C. Synergistic effect of polypyrrole functionalized graphene oxide and zinc phosphate for enhanced anticorrosion performance of epoxy coatings. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105752. [Google Scholar] [CrossRef]

- Wang, H.; Hao, Q.; Yang, X.; Lu, L.; Wang, X. A nanostructured graphene/polyaniline hybrid material for supercapacitors. Nanoscale 2010, 2, 2164–2170. [Google Scholar] [CrossRef]

- Yuan, T.H.; Zhang, Z.H.; Li, J.; Zhang, D.Q.; Gao, L.X.; Li, W.G.; Fan, Z.F. Corrosion protection of aluminum alloy by epoxy coatings containing polyaniline modified graphene additives. Mater. Corros. 2019, 70, 1298–1305. [Google Scholar] [CrossRef]

- Harfouche, N.; Gospodinova, N.; Nessark, B.; Perrin, F.X. Electrodeposition of composite films of reduced graphene oxide/polyaniline in neutral aqueous solution on inert and oxidizable metal. J. Electroanal. Chem. 2017, 786, 135–144. [Google Scholar] [CrossRef]

- Jin, T.; Zhang, Q.; Yin, H.; Cole, I.S.; Zhao, P.; Wang, Y.; Liu, X. Corrosion resistance of itaconic acid doped polyaniline/nanographene oxide composite coating. Nanotechnology 2020, 31, 285704. [Google Scholar] [CrossRef]

- Hayatgheib, Y.; Ramezanzadeh, B.; Kardar, P.; Mahdavian, M. A comparative study on fabrication of a highly effective corrosion protective system based on graphene oxide-polyaniline nanofibers/epoxy composite. Corros. Sci. 2018, 133, 358–373. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Don, T.-M.; Wong, C.-J.; Meng, F.-C.; Lin, Y.-J.; Lee, S.-Y.; Lee, C.-F.; Chiu, W.-Y. Improvement of mechanical properties and anticorrosion performance of epoxy coatings by the introduction of polyaniline/graphene composite. Surf. Coat. Technol. 2019, 374, 1128–1138. [Google Scholar] [CrossRef]

- Mooss, V.A.; Bhopale, A.A.; Deshpande, P.P.; Athawale, A.A. Graphene oxide-modified polyaniline pigment for epoxy based anti-corrosion coatings. Chem. Pap. 2017, 71, 1515–1528. [Google Scholar] [CrossRef]

- Andreoli, E.; Annibaldi, V.; Rooney, D.A.; Breslin, C.B. Electrochemical fabrication of copper-based hybrid microstructures and mechanism of formation of related hierarchical structures on polypyrrole films. J. Phys. Chem. C 2011, 115, 20076–20083. [Google Scholar] [CrossRef]

- Fazli-Shokouhi, S.; Nasirpouri, F.; Khatamian, M. Polyaniline-modified graphene oxide nanocomposites in epoxy coatings for enhancing the anticorrosion and antifouling properties. J. Coat. Technol. Res. 2019, 16, 983–997. [Google Scholar] [CrossRef]

- Lei, Y.; Qiu, Z.; Liu, J.; Li, D.; Tan, N.; Liu, T.; Zhang, Y.; Chang, X.; Gu, Y.; Yin, Y. Effect of conducting polyaniline/graphene nanosheet content on the corrosion behavior of zinc-rich epoxy primers in 3.5% NaCl solution. Polymers 2019, 11, 850. [Google Scholar] [CrossRef]

- Hao, Y.; Zhao, Y.; Li, B.; Song, L.; Guo, Z. Self-healing effect of graphene@PANI loaded with benzotriazole for carbon steel. Corros. Sci. 2020, 163, 108246. [Google Scholar] [CrossRef]

- Zhong, F.; He, Y.; Wang, P.; Chen, C.; Yu, H.; Li, H.; Chen, J. Graphene/V2O5@polyaniline ternary composites enable waterborne epoxy coating with robust corrosion resistance. React. Funct. Polym. 2020, 151, 104567. [Google Scholar] [CrossRef]

- Liu, J.; Lei, Y.; Qiu, Z.; Li, D.; Liu, T.; Zhang, F.; Sun, S.; Chang, X.; Fan, R.; Yin, Y. Insight into the impact of conducting polyaniline/graphene nanosheets on corrosion mechanism of zinc-rich epoxy primers on low alloy DH32 steel in artificial sea water. J. Electrochem. Soc. 2018, 165, C878–C889. [Google Scholar] [CrossRef]

- Shen, L.; Li, Y.; Zhao, W.; Miao, L.; Xie, W.; Lu, H.; Wang, K. Corrosion protection of graphene-modified zinc-rich epoxy coatings in dilute NaCl Solution. ACS Appl. Nano Mater. 2019, 2, 180–190. [Google Scholar] [CrossRef]

- Yang, N.; Yang, T.; Wang, W.; Chen, H.; Li, W. Polydopamine modified polyaniline-graphene oxide composite for enhancement of corrosion resistance. J. Hazard. Mater. 2019, 377, 142–151. [Google Scholar] [CrossRef]

- Ye, Y.; Zhang, D.; Liu, T.; Liu, Z.; Pu, J.; Liu, W.; Zhao, H.; Li, X.; Wang, L. Superior corrosion resistance and self-healable epoxy coating pigmented with silanzied trianiline-intercalated graphene. Carbon 2019, 142, 164–176. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, S.; Zhao, Z.; Zhou, Y.; Li, W. Preparation and corrosion protection of VB2 modified trimer aniline-reduced graphene oxide(VTA-rGO) coatings. Prog. Org. Coat. 2019, 132, 95–99. [Google Scholar] [CrossRef]

- Ye, Y.; Yang, D.; Zhang, D.; Chen, H.; Zhao, H.; Li, X.; Wang, L. POSS-tetraaniline modified graphene for active corrosion protection of epoxy-based organic coating. Chem. Eng. J. 2020, 383, 123160. [Google Scholar] [CrossRef]

- Gu, L.; Liu, S.; Zhao, H.; Yu, H. Facile Preparation of water-dispersible graphene sheets Stabilized by Carboxylated Oligoanilines and Their Anticorrosion Coatings. ACS Appl. Mater. Interfaces 2015, 7, 17641–17648. [Google Scholar] [CrossRef]

- Rohwerder, M.; Michalik, A. Conducting polymers for corrosion protection: What makes the difference between failure and success? Electrochim. Acta 2007, 53, 1300–1313. [Google Scholar] [CrossRef]

- Ryan, E.M.; Breslin, C.B. Formation of polypyrrole with dexamethasone as a dopant: Its cation and anion exchange properties. J. Electroanal. Chem. 2018, 824, 188–194. [Google Scholar] [CrossRef]

- Deshpande, P.P.; Jadhav, N.G.; Gelling, V.J.; Sazou, D. Conducting polymers for corrosion protection: A review. J. Coat. Technol. Res. 2014, 11, 473–494. [Google Scholar] [CrossRef]

- Batrakov, K.; Kuzhir, P.; Maksimenko, S.; Paddubskaya, A.; Voronovich, S.; Lambin, P.; Kaplas, T.; Svirko, Y. Flexible transparent graphene/polymer multilayers for efficient electromagnetic field absorption. Sci. Rep. 2014, 4, 7191. [Google Scholar] [CrossRef]

- Fan, F.; Zhou, C.; Wang, X.; Szpunar, J. Layer-by-layer assembly of a self-healing anticorrosion coating on magnesium alloys. ACS Appl. Mater. Interface 2015, 7, 27271–27278. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, W.; Wei, L.; Pu, L.; Liu, J.; Liu, H.; Li, Y.; Fan, J.; Ding, T.; Guo, Z. Alternating multilayer structural epoxy composite coating for corrosion protection of steel. Macromol. Mater. Eng. 2019, 304, 1900374. [Google Scholar] [CrossRef]

- Yu, F.; Camilli, L.; Wang, T.; Makenzie, M.A.; Curioni, M.; Akid, R.; Bøggild, P. Complete long-term corrosion protection with chemical vapor deposited graphene. Carbon 2018, 132, 78–84. [Google Scholar] [CrossRef]

- Gao, F.; Hu, Y.; Gong, Z.; Liu, T.; Gong, T.; Liu, S.; Zhang, C.; Quan, L.; Kaveendran, B.; Pan, C. Fabrication of chitosan/heparinized graphene oxide multilayer coating to improve corrosion resistance and biocompatibility of magnesium alloys. Mater. Sci. Eng. C 2019, 104, 109947. [Google Scholar] [CrossRef] [PubMed]

- Hayatdavoudi, H.; Rahsepar, M. A mechanistic study of the enhanced cathodic protection performance of graphene-reinforced zinc rich nanocomposite coating for corrosion protection of carbon steel substrate. J. Alloys Compd. 2017, 727, 1148–1156. [Google Scholar] [CrossRef]

- Kalendová, A.; Veselý, D.; Kohl, M.; Stejskal, J. Anticorrosion efficiency of zinc-filled epoxy coatings containing conducting polymers and pigments. Prog. Org. Coat. 2015, 78, 1–20. [Google Scholar] [CrossRef]

- Teng, S.; Gao, Y.; Cao, F.; Kong, D.; Zheng, X.; Ma, X.; Zhi, L. Zinc-reduced graphene oxide for enhanced corrosion protection of zinc-rich epoxy coatings. Prog. Org. Coat. 2018, 123, 185–189. [Google Scholar] [CrossRef]

- Liu, J.; Liu, T.; Guo, Z.; Guo, N.; Lei, Y.; Chang, X.; Yin, Y. Promoting barrier performance and cathodic protection of zinc-rich epoxy primer via single-layer graphene. Polymers 2018, 10, 591. [Google Scholar] [CrossRef]

- Cao, X.; Huang, F.; Huang, C.; Liu, J.; Cheng, Y.F. Preparation of graphene nanoplate added zinc-rich epoxy coatings for enhanced sacrificial anode-based corrosion protection. Corros. Sci. 2019, 159, 108120. [Google Scholar] [CrossRef]

- Ding, R.; Wang, X.; Jiang, J.; Gui, T.; Li, W. Study on evolution of coating state and role of graphene in graphene-modified low-zinc waterborne epoxy anticorrosion coating by electrochemical impedance spectroscopy. J. Mater. Eng. Perform. 2017, 26, 3319–3335. [Google Scholar] [CrossRef]

- Huang, S.; Kong, G.; Yang, B.; Zhang, S.; Che, C. Effects of graphene on the corrosion evolution of zinc particles in waterborne epoxy zinc-containing coatings. Prog. Org. Coat. 2020, 140, 105531. [Google Scholar] [CrossRef]

- Ge, T.; Zhao, W.; Wu, X.; Wu, Y.; Shen, L.; Ci, X.; He, Y. Design alternate epoxy-reduced graphene oxide/epoxy-zinc multilayer coatings for achieving long-term corrosion resistance for Cu. Mater. Des. 2020, 186, 108299. [Google Scholar] [CrossRef]

- Taheri, N.N.; Ramezanzadeh, B.; Mahdavian, M. Application of layer-by-layer assembled graphene oxide nanosheets/polyaniline/zinc cations for construction of an effective epoxy coating anti-corrosion system. J. Alloys Compd. 2019, 800, 532–549. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, C.; Han, D.; Ma, S.; Guo, W.; Cai, H.; Wang, X. Effect of graphene on corrosion resistance of waterborne inorganic zinc-rich coatings. J. Alloys Compd. 2019, 774, 255–264. [Google Scholar] [CrossRef]

- Ding, R.; Chen, S.; Zhou, N.; Zheng, Y.; Li, B.-J.; Gui, T.-J.; Wang, X.; Li, W.-H.; Yu, H.-B.; Tian, H.-W. The diffusion-dynamical and electrochemical effect mechanism of oriented magnetic graphene on zinc-rich coatings and the electrodynamics and quantum mechanics mechanism of electron conduction in graphene zinc-rich coatings. J. Alloys Compd. 2019, 784, 756–768. [Google Scholar] [CrossRef]

- Wang, X.; Lv, J.; Ding, R.; Gui, T.-J.; Sun, M.-L. Application of EIS and transmission line model to study the effect of arrangement of graphene on electromagnetic shielding and cathodic protection performance of zinc-rich waterborne epoxy coatings. Int. J. Electrochem. Sci. 2020, 15, 4089–4101. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, P.; Wang, G.; Wang, A.; Chen, X.; Wei, S.; Xie, J. Effect of graphene oxide concentration in electrolyte on corrosion behavior of electrodeposited Zn-electrochemical reduction graphene composite coatings. Coatings 2019, 9, 758. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, L.; Liu, C.; Mai, Y.; Zhang, Y.; Jie, X. Deposition of Zn-G/Al composite coating with excellent cathodic protection on low-carbon steel by low-pressure cold spraying. J. Alloy. Compd. 2020, 821, 153483. [Google Scholar] [CrossRef]

- Li, R.; Liang, J.; Hou, Y.; Chu, Q. Enhanced corrosion performance of Zn coating by incorporating graphene oxide electrodeposited from deep eutectic solvent. RSC Adv. 2015, 5, 60698–60707. [Google Scholar] [CrossRef]

- Moshgi Asl, S.; Afshar, A.; Yaghoubinezhad, Y. An Electrochemical synthesis of reduced graphene oxide/zinc nanocomposite coating through pulse-potential electrodeposition technique and the consequent corrosion resistance. Int. J. Corros. 2018, 2018, 3028693. [Google Scholar] [CrossRef]

- Karimi Azar, M.M.; Shooshtari Gugtapeh, H.; Rezaei, M. Evaluation of corrosion protection performance of electroplated zinc and zinc-graphene oxide nanocomposite coatings in air saturated 3.5 wt. % NaCl solution. Colloids Surf. A Physicochem. Eng. Asp. 2020, 601, 125051. [Google Scholar] [CrossRef]

- Rekha, M.Y.; Srivastava, C. Microstructure and corrosion properties of zinc-graphene oxide composite coatings. Corros. Sci. 2019, 152, 234–248. [Google Scholar] [CrossRef]

- Rekha, M.Y.; Kamboj, A.; Srivastava, C. Electrochemical behaviour of SnZn-graphene oxide composite coatings. Thin Solid Film. 2017, 636, 593–601. [Google Scholar] [CrossRef]

- Rekha, M.Y.; Srivastava, C. Microstructural evolution and corrosion behavior of ZnNi-graphene oxide composite coatings. Metall. Mater. Trans. A. 2019, 50, 5896–5913. [Google Scholar] [CrossRef]

- Wang, D.; Bierwagen, G.P. Sol-gel coatings on metals for corrosion protection. Prog. Org. Coat. 2009, 64, 327–338. [Google Scholar] [CrossRef]

- Ciriminna, R.; Fidalgo, A.; Pandarus, V.; Béland, F.; Ilharco, L.M.; Pagliaro, M. The sol-gel route to advanced silica-based materials and recent applications. Chem. Rev. 2013, 113, 6592–6620. [Google Scholar] [CrossRef]

- Zheng, S.; Li, J. Inorganic-organic sol gel hybrid coatings for corrosion protection of metals. J. Sol. Gel Sci. Technol. 2010, 54, 174–187. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Ahmadi, A.; Mahdavian, M. Enhancement of the corrosion protection performance and cathodic delamination resistance of epoxy coating through treatment of steel substrate by a novel nanometric sol-gel based silane composite film filled with functionalized graphene oxide nanosheets. Corros. Sci. 2016, 109, 182–205. [Google Scholar] [CrossRef]

- Xue, B.; Yu, M.; Liu, J.; Liu, J.; Li, S.; Xiong, L. Corrosion protection of AA2024-T3 by sol-gel film modified with graphene oxide. J. Alloys Compd. 2017, 725, 84–95. [Google Scholar] [CrossRef]

- Afsharimani, N.; Durán, A.; Galusek, D.; Castro, Y. Hybrid sol–gel silica coatings containing graphene nanosheets for improving the corrosion protection of AA2024-T3. Nanomaterials 2020, 10, 1050. [Google Scholar] [CrossRef]

- Li, T.; Li, L.; Qi, J.; Chen, F. Corrosion protection of Ti6Al4V by a composite coating with a plasma electrolytic oxidation layer and sol-gel layer filled with graphene oxide. Prog. Org. Coat. 2020, 144, 105632. [Google Scholar] [CrossRef]

- Yu, M.; Dong, H.; Shi, H.; Xiong, L.; He, C.; Liu, J.; Li, S. Effects of graphene oxide-filled sol-gel sealing on the corrosion resistance and paint adhesion of anodized aluminum. Appl. Surf. Sci. 2019, 479, 105–113. [Google Scholar] [CrossRef]

- Parhizkar, N.; Ramezanzadeh, B.; Shahrabi, T. Enhancement of the corrosion protection properties of a hybrid sol-gel based silane film through impregnation of functionalized graphene oxide nanosheets. J. Electrochem. Soc. 2017, 164, C1044–C1058. [Google Scholar] [CrossRef]

- Tian, S.; Liu, Z.; Shen, L.; Pu, J.; Liu, W.; Sun, X.; Li, Z. Performance evaluation of mercapto functional hybrid silica sol-gel coating and its synergistic effect with f-GNs for corrosion protection of copper surface. RSC Adv. 2018, 8, 7438–7449. [Google Scholar] [CrossRef]

- Parhizkar, N.; Ramezanzadeh, B.; Shahrabi, T. Corrosion protection and adhesion properties of the epoxy coating applied on the steel substrate pre-treated by a sol-gel based silane coating filled with amino and isocyanate silane functionalized graphene oxide nanosheets. Appl. Surf. Sci. 2018, 439, 45–59. [Google Scholar] [CrossRef]

- Xiong, L.; Liu, J.; Li, Y.; Li, S.; Yu, M. Enhancing corrosion protection properties of sol-gel coating by pH-responsive amino-silane functionalized graphene oxide-mesoporous silica nanosheets. Prog. Org. Coat. 2019, 135, 228–239. [Google Scholar] [CrossRef]

- Xue, B.; Yu, M.; Liu, J.; Li, S.; Xiong, L.; Kong, X. Synthesis of inhibitor nanocontainers with two-dimensional structure and their anticorrosion action in sol-gel coating on AA2024-T3 aluminum alloy. J. Electrochem. Soc. 2017, 164, C641–C652. [Google Scholar] [CrossRef]

- Maeztu, J.D.; Rivero, P.J.; Berlanga, C.; Bastidas, D.M.; Palacio, J.F.; Rodriguez, R. Effect of graphene oxide and fluorinated polymeric chains incorporated in a multilayered sol-gel nanocoating for the design of corrosion resistant and hydrophobic surfaces. Appl. Surf. Sci. 2017, 419, 138–149. [Google Scholar] [CrossRef]

- Fernández-Hernán, J.P.; López, A.J.; Torres, B.; Rams, J. Silicon oxide multilayer coatings doped with carbon nanotubes and graphene nanoplatelets for corrosion protection of AZ31B magnesium alloy. Prog. Org. Coat. 2020, 148, 105836. [Google Scholar] [CrossRef]

- Chen, M.; Huang, Z.; Liang, S.; Pei, F.; Lin, Z.; Dang, Z.; Wu, P. Immobilized Co2+ and Cu2+ induced structural change of layered double hydroxide for efficient heterogeneous degradation of antibiotic. J. Hazard. Mater. 2020, 403, 123554. [Google Scholar] [CrossRef]

- Gong, M.; Li, Y.; Wang, H.; Liang, Y.; Wu, J.Z.; Zhou, J.; Wang, J.; Regier, T.; Wei, F.; Dai, H. An advanced Ni-Fe layered double hydroxide electrocatalyst for water oxidation. J. Am. Chem. Soc. 2013, 135, 8452–8455. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, J.; Li, Z.; Yang, W.; Wang, B.; Hou, M.; He, Y.; Liu, Q.; Mann, T.; Yang, P.; et al. Graphene nanosheet/Ni2+/Al3+ layered double-hydroxide composite as a novel electrode for a supercapacitor. Chem. Mater. 2011, 23, 3509–3516. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, L.; Chen, H.; Xu, S.; Evans, D.G.; Duan, X. Corrosion resistance of superhydrophobic layered double hydroxide films on aluminum. Angew. Chem. Int. Ed. 2008, 47, 2466–2469. [Google Scholar] [CrossRef]

- Guo, X.; Xu, S.; Zhao, L.; Lu, W.; Zhang, F.; Evans, D.G.; Duan, X. One-step hydrothermal crystallization of a layered double hydroxide/alumina bilayer film on aluminum and its corrosion resistance properties. Langmuir 2009, 25, 9894–9897. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Liu, Z.-G.; Zeng, R.-C.; Li, S.-Q.; Cui, H.-Z.; Song, L.; Han, E.-H. Corrosion resistance of Mg-Al-LDH coating on magnesium alloy AZ31. Surf. Coat. Technol. 2014, 258, 1152–1158. [Google Scholar] [CrossRef]

- Zheludkevich, M.L.; Poznyak, S.K.; Rodrigues, L.M.; Raps, D.; Hack, T.; Dick, L.F.; Nunes, T.; Ferreira, M.G.S. Active protection coatings with layered double hydroxide nanocontainers of corrosion inhibitor. Corros. Sci. 2010, 52, 602–611. [Google Scholar] [CrossRef]

- Tedim, J.; Poznyak, S.K.; Kuznetsova, A.; Raps, D.; Hack, T.; Zheludkevich, M.L.; Ferreira, M.G.S. Enhancement of active corrosion protection via combination of inhibitor-loaded nanocontainers. ACS Appl. Mater. Interfaces 2010, 2, 1528–1535. [Google Scholar] [CrossRef]

- Du, P.; Wang, J.; Liu, G.; Zhao, H.; Wang, L. Facile synthesis of intelligent nanocomposites as encapsulation for materials protection. Mater. Chem. Front. 2019, 3, 321–330. [Google Scholar] [CrossRef]

- Tedim, J.; Kuznetsova, A.; Salak, A.N.; Montemor, F.; Snihirova, D.; Pilz, M.; Zheludkevich, M.L.; Ferreira, M.G.S. Zn-Al layered double hydroxides as chloride nanotraps in active protective coatings. Corros. Sci. 2012, 55, 1–4. [Google Scholar] [CrossRef]

- Yan, L.; Zhou, M.; Pang, X.; Gao, K. One-step in situ synthesis of reduced graphene oxide/Zn-Al layered double hydroxide film for enhanced corrosion protection of magnesium alloys. Langmuir 2019, 35, 6312–6320. [Google Scholar] [CrossRef]

- Luo, X.; Yuan, S.; Pan, X.; Zhang, C.; Du, S.; Liu, Y. Synthesis and enhanced corrosion protection performance of reduced graphene oxide nanosheet/ZnAl layered double hydroxide composite films by hydrothermal continuous flow method. ACS Appl. Mater. Interfaces 2017, 9, 18263–18275. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, P.; Wang, J.; Li, Y.; Chen, F.; Wei, K.; Zuo, Y. LDHs/graphene film on aluminum alloys for active protection. Appl. Surf. Sci. 2018, 433, 927–933. [Google Scholar] [CrossRef]

- Yu, D.; Wen, S.; Yang, J.; Wang, J.; Chen, Y.; Luo, J.; Wu, Y. RGO modified ZnAl-LDH as epoxy nanostructure filler: A novel synthetic approach to anticorrosive waterborne coating. Surf. Coat. Technol. 2017, 326, 207–215. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, F.; Chen, Y.-Q.; Hu, J.-M. Coatings embedded with GO/MOFs nanocontainers having both active and passive protecting properties. Corros. Sci. 2020, 168, 108563. [Google Scholar] [CrossRef]

- Ramezanzadeh, M.; Ramezanzadeh, B.; Mahdavian, M.; Bahlakeh, G. Development of metal-organic framework (MOF) decorated graphene oxide nanoplatforms for anti-corrosion epoxy coatings. Carbon 2020, 161, 231–251. [Google Scholar] [CrossRef]

- Goncalves, G.; Marques, P.A.A.P.; Granadeiro, C.M.; Nogueira, H.I.S.; Singh, M.K.; Grácio, J. Surface modification of graphene nanosheets with gold nanoparticles: The role of oxygen moieties at graphene surface on gold nucleation and growth. Chem. Mater. 2009, 21, 4796–4802. [Google Scholar] [CrossRef]

- Jin, J.; Zhang, L.; Shi, M.; Zhang, Y.; Wang, Q. Ti-GO-Ag nanocomposite: The effect of content level on the antimicrobial activity and cytotoxicity. Int. J. Nanomed. 2017, 12, 4209–4224. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.-S.; Liu, X.-C.; Wang, G.-C.; Liang, R.-P.; Qiu, J.-D. Preparation of nitrogen-doped graphene supporting Pt nanoparticles as a catalyst for oxygen reduction and methanol oxidation. J. Electroanal. Chem. 2014, 728, 41–50. [Google Scholar] [CrossRef]

- Long, M.; Qin, Y.; Chen, C.; Guo, X.; Tan, B.; Cai, W. Origin of visible light photoactivity of reduced graphene oxide/TiO2 by in situ hydrothermal growth of undergrown TiO2 with graphene oxide. J. Phys. Chem. C 2013, 117, 16734–16741. [Google Scholar] [CrossRef]

- Zhong, L.; Yun, K. Graphene oxide-modified ZnO particles: Synthesis, characterization, and antibacterial properties. Int. J. Nanomed. 2015, 10, 79–92. [Google Scholar] [CrossRef]

- Boruah, P.K.; Sharma, B.; Karbhal, I.; Shelke, M.V.; Das, M.R. Ammonia-modified graphene sheets decorated with magnetic Fe3O4 nanoparticles for the photocatalytic and photo-Fenton degradation of phenolic compounds under sunlight irradiation. J. Hazard. Mater. 2017, 325, 90–100. [Google Scholar] [CrossRef]

- Du, Y.J.; Damron, M.; Tang, G.; Zheng, H.; Chu, C.-J.; Osborne, J.H. Inorganic/organic hybrid coatings for aircraft aluminum alloy substrates. Prog. Org. Coat. 2001, 41, 226–232. [Google Scholar] [CrossRef]

- Ma, Y.; Di, H.; Yu, Z.; Liang, L.; Lv, L.; Pan, Y.; Zhang, Y.; Yin, D. Fabrication of silica-decorated graphene oxide nanohybrids and the properties of composite epoxy coatings research. Appl. Surf. Sci. 2016, 360, 936–945. [Google Scholar] [CrossRef]

- Song, B.; Shi, Y.; Liu, Q. An inorganic route to decorate graphene oxide with nanosilica and investigate its effect on anti-corrosion property of waterborne epoxy. Polym. Adv. Technol. 2020, 31, 309–318. [Google Scholar] [CrossRef]

- Wang, T.; Ge, H.; Zhang, K. A novel core-shell silica@graphene straticulate structured antistatic anticorrosion composite coating. J. Alloys Compd. 2018, 745, 705–715. [Google Scholar] [CrossRef]

- Bouibed, A.; Doufnoune, R. Synthesis and characterization of hybrid materials based on graphene oxide and silica nanoparticles and their effect on the corrosion protection properties of epoxy resin coatings. J. Adhes. Sci. Technol. 2019, 33, 834–860. [Google Scholar] [CrossRef]

- Zhang, X.; Wen, J.; Hu, B.; Yuan, J.; Wang, J.; Zhu, L.; Pan, M. Dispersity control and anti-corrosive performance of graphene oxide modified by functionalized nanosilica in waterborne polyurethane. Nanotechnology 2020, 31, 205708. [Google Scholar] [CrossRef]

- Shuai, C.; Wang, B.; Bin, S.; Peng, S.; Gao, C. Interfacial strengthening by reduced graphene oxide coated with MgO in biodegradable Mg composites. Mater. Des. 2020, 191, 108612. [Google Scholar] [CrossRef]

- Palaniappan, N.; Cole, I.S.; Caballero-Briones, F.; Balasubaramanian, K.; Lal, C. Praseodymium-decorated graphene oxide as a corrosion inhibitor in acidic media for the magnesium AZ31 alloy. RSC Adv. 2018, 8, 34275–34286. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Ismail, A.F.; Aziz, M.; Akbari, M.; Hadisi, Z.; Khoshnava, S.M.; Pagan, E.; Chen, X. Co-incorporation of graphene oxide/silver nanoparticle into poly-L-lactic acid fibrous: A route toward the development of cytocompatible and antibacterial coating layer on magnesium implants. Mater. Sci. Eng. C 2020, 111, 110812. [Google Scholar] [CrossRef]

- Liu, Z.; Tian, S.; Li, Q.; Wang, J.; Pu, J.; Wang, G.; Zhao, W.; Feng, F.; Qin, J.; Ren, L. Integrated Dual-Functional ORMOSIL Coatings with AgNPs@rGO Nanocomposite for Corrosion Resistance and Antifouling Applications. ACS Sustain. Chem. Eng. 2020, 8, 6786–6797. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Q.; Yu, M.; Li, S.; Zhao, K.; Xue, B.; Zu, H. Silane modification of titanium dioxide-decorated graphene oxide nanocomposite for enhancing anticorrosion performance of epoxy coatings on AA-2024. J. Alloys Compd. 2018, 744, 728–739. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Gunashri, R.; Sathish, P. Corrosion protection behaviour of r-GO/TiO2 hybrid composite coating on magnesium substrate in 3.5 wt.% NaCl. Prog. Org. Coat. 2018, 125, 358–364. [Google Scholar] [CrossRef]

- Nazeer, A.A.; Al-Hetlani, E.; Amin, M.O.; Quiñones-Ruiz, T.; Lednev, I.K. A poly(butyl methacrylate)/graphene oxide/TiO2 nanocomposite coating with superior corrosion protection for AZ31 alloy in chloride solution. Chem. Eng. J. 2019, 361, 485–498. [Google Scholar] [CrossRef]

- Razavizadeh, O.; Ghorbani, M. Surface modification of carbon steel by ZnO-graphene nano-hybrid thin film. Surf. Coat. Technol. 2019, 363, 1–11. [Google Scholar] [CrossRef]

- Othman, N.H.; Yahya, W.Z.N.; Che Ismail, M.; Mustapha, M.; Koi, Z.K. Highly dispersed graphene oxide–zinc oxide nanohybrids in epoxy coating with improved water barrier properties and corrosion resistance. J. Coat. Technol. Res. 2020, 17, 101–114. [Google Scholar] [CrossRef]

- Tang, H.; Liu, Y.; Bian, D.; Guo, Y.; Zhao, Y. Fabrication of ZnO–GO hybrid for enhancement of chemically bonded phosphate ceramic coatings corrosion protection performance on AISI304L stainless steel. Int. J. Appl. Ceram. Technol. 2020. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.; Yang, J.; Zhang, J.; Ding, H. Large CeO2 nanoflakes modified by graphene as barriers in waterborne acrylic coatings and the improved anticorrosion performance. Prog. Org. Coat. 2020, 143, 105607. [Google Scholar] [CrossRef]

- Arora, S.; Srivastava, C. Microstructure and corrosion properties of NiCo-graphene oxide composite coatings. Thin Solid Film. 2019, 677, 45–54. [Google Scholar] [CrossRef]

- Yang, M.; Liu, B.; Xia, J.; Liu, Y.; Shi, Z.; Lv, X. Study on the properties of a novel electrostatic conductive and anti-corrosive composite coating improved by graphene nanosheets. Prog. Org. Coat. 2019, 136, 105244. [Google Scholar] [CrossRef]

- Amrollahi, S.; Ramezanzadeh, B.; Yari, H.; Ramezanzadeh, M.; Mahdavian, M. In-situ growth of ceria nanoparticles on graphene oxide nanoplatelets to be used as a multifunctional (UV shield/radical scavenger/anticorrosive) hybrid compound for exterior coatings. Prog. Org. Coat. 2019, 136, 105241. [Google Scholar] [CrossRef]

- Park, H.; Kim, K.Y.; Choi, W. Photoelectrochemical approach for metal corrosion prevention using a semiconductor photoanode. J. Phys. Chem. B 2002, 106, 4775–4781. [Google Scholar] [CrossRef]

- Lu, X.; Liu, L.; Xie, X.; Cui, Y.; Oguzie, E.E.; Wang, F. Synergetic effect of graphene and Co(OH)2 as cocatalysts of TiO2 nanotubes for enhanced photogenerated cathodic protection. J. Mater. Sci. Technol. 2020, 37, 55–63. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Wei, Q.; Liu, X.; Qian, Z.; Hou, B. Enhanced photocathodic protection performance of Ag/graphene/TiO2 composite for 304SS under visible light. Nanotechnology 2017, 28, 225701. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Du, T.; Ru, Q.; Zuo, S.; Cai, Y.; Yao, C. Preparation of graphene/WO3/TiO2 composite and its photocathodic protection performance for 304 stainless steel. Mater. Res. Bull. 2018, 102, 399–405. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, L.; Cao, G.; Song, Z.; Zhao, M. Fabrication of reduced graphene oxide wrapped TiO2/SnO2 photoanode and its anticorrosion property. Optik 2020, 202, 163573. [Google Scholar] [CrossRef]

- Lv, R.; Robinson, J.A.; Schaak, R.E.; Sun, D.; Sun, Y.; Mallouk, T.E.; Terrones, M. Transition metal dichalcogenides and beyond: Synthesis, properties, and applications of single- and few-layer nanosheets. Acc. Chem. Res. 2015, 48, 56–64. [Google Scholar] [CrossRef]

- Wang, Y.; Mayorga-Martinez, C.C.; Chia, X.; Sofer, Z.; Pumera, M. Nonconductive layered hexagonal boron nitride exfoliation by bipolar electrochemistry. Nanoscale 2018, 10, 7298–7303. [Google Scholar] [CrossRef]

- Yi, M.; Shen, Z.; Zhao, X.; Liang, S.; Liu, L. Boron nitride nanosheets as oxygen-atom corrosion protective coatings. Appl. Phys. Lett. 2014, 104, 143101. [Google Scholar] [CrossRef]

- Galbiati, M.; Stoot, A.C.; Mackenzie, D.M.A.; Bøggild, P.; Camilli, L. Real-time oxide evolution of copper protected by graphene and boron nitride barriers. Sci. Rep. 2017, 7, 39770. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Zhang, G.; Liu, S.; Zhao, H.; Wang, L.; Xue, Q. Corrosion performance of hexagonal boron nitride doped waterborne epoxy coating. J. Chin. Soc. Corros. Prot. 2016, 36, 566–572. [Google Scholar] [CrossRef]

- Zhao, H.; Ding, J.; Yu, H. The efficient exfoliation and dispersion of hBN nanoplatelets: Advanced application to waterborne anticorrosion coatings. New J. Chem. 2018, 42, 14433–14443. [Google Scholar] [CrossRef]

- Li, L.H.; Xing, T.; Chen, Y.; Jones, R. Boron nitride nanosheets for metal protection. Adv. Mater. Interfaces 2014, 1, 1300132. [Google Scholar] [CrossRef]

- Han, R.; Khan, M.H.; Angeloski, A.; Casillas, G.; Yoon, C.W.; Sun, X.; Huang, Z. Hexagonal boron nitride Nanosheets Grown via Chemical Vapor Deposition for Silver Protection. ACS Appl. Nano Mater. 2019, 2, 2830–2835. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, Z.; Ma, L.; Yang, Q.; Tang, Z.; Song, X.; Zeng, H.; Zhi, C. Boron ink assisted in situ boron nitride coatings for anti-oxidation and anti-corrosion applications. Nanotechnology 2019, 30, 335704. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Chen, J.; Liu, S.; Zhang, G.; Zhao, H.; Wang, L.; Xue, Q. Anticorrosive performance of waterborne epoxy coatings containing water-dispersible hexagonal boron nitride (h-BN) nanosheets. Appl. Surf. Sci. 2017, 397, 77–86. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Qin, S.; Xue, Q.; Zhao, H.; Wang, L. Processable poly(2-butylaniline)/hexagonal boron nitride nanohybrids for synergetic anticorrosive reinforcement of epoxy coating. Corros. Sci. 2018, 131, 187–198. [Google Scholar] [CrossRef]

- Shi, H.; Liu, W.; Liu, C.; Yang, M.; Xie, Y.; Wang, S.; Zhang, F.; Liang, L.; Pi, K. Polyethylenimine-assisted exfoliation of h-BN in aqueous media for anticorrosive reinforcement of waterborne epoxy coating. Prog. Org. Coat. 2020, 142, 105591. [Google Scholar] [CrossRef]

- Zhang, C.; He, Y.; Zhan, Y.; Zhang, L.; Shi, H.; Xu, Z. Poly(dopamine) assisted epoxy functionalization of hexagonal boron nitride for enhancement of epoxy resin anticorrosion performance. Polym. Adv. Technol. 2017, 28, 214–221. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Qin, S.; Xue, Q.; Zhao, H.; Wang, L. Non-covalent functionalized hexagonal boron nitride nanoplatelets to improve corrosion and wear resistance of epoxy coatings. RSC Adv. 2017, 7, 44043–44053. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, W.; Liu, G.; Wu, Y.; Wang, D. Anti-corrosion mechanism of 2D nanosheet materials in waterborne epoxy coatings. Surf. Topogr. Metrol. Prop. 2018, 6, 034019. [Google Scholar] [CrossRef]

- Zhang, C.; He, Y.; Li, F.; Di, H.; Zhang, L.; Zhan, Y. h-BN decorated with Fe3O4 nanoparticles through mussel-inspired chemistry of dopamine for reinforcing anticorrosion performance of epoxy coatings. J. Alloys Compd. 2016, 685, 743–751. [Google Scholar] [CrossRef]

- Wan, P.; Zhao, N.; Qi, F.; Zhang, B.; Xiong, H.; Yuan, H.; Liao, B.; Ouyang, X. Synthesis of PDA-BN@f-Al2O3 hybrid for nanocomposite epoxy coating with superior corrosion protective properties. Prog. Org. Coat. 2020, 146, 105713. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, J.; Zhao, W.; Wang, C.; Wu, B.; Lu, G. Investigating the anti-corrosion behaviors of the waterborne epoxy composite coatings with barrier and inhibition roles on mild steel. Prog. Org. Coat. 2019, 133, 8–18. [Google Scholar] [CrossRef]

- Husain, E.; Narayanan, T.N.; Taha-Tijerina, J.J.; Vinod, S.; Vajtai, R.; Ajayan, P.M. Marine corrosion protective coatings of hexagonal boron nitride thin films on stainless steel. ACS Appl. Mater. Interfaces 2013, 5, 4129–4135. [Google Scholar] [CrossRef]

- Sun, W.; Wang, L.; Wu, T.; Pan, Y.; Liu, G. Communication—Multi-layer boron nitride nanosheets as corrosion-protective coating fillers. J. Electrochem. Soc. 2016, 163, C16–C18. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Antonietti, M. Polymeric graphitic carbon nitride as a heterogeneous organocatalyst: From photochemistry to multipurpose catalysis to sustainable chemistry. Angew. Chem. 2012, 51, 68–89. [Google Scholar] [CrossRef]

- Yang, G.; Chen, T.; Feng, B.; Weng, J.; Duan, K.; Wang, J.; Lu, X. Improved corrosion resistance and biocompatibility of biodegradable magnesium alloy by coating graphite carbon nitride (g-C3N4). J. Alloys Compd. 2019, 770, 823–830. [Google Scholar] [CrossRef]

- Kumar, A.M.; Khan, A.; Khan, M.Y.; Suleiman, R.K.; Jose, J.; Dafalla, H. Hierarchical graphitic carbon nitride-ZnO nanocomposite: Viable reinforcement for the improved corrosion resistant behavior of organic coatings. Mater. Chem. Phys. 2020, 251, 122987. [Google Scholar] [CrossRef]

- Karimi, M.A.; Haji Aghaei, V.; Nezhadali, A.; Ajami, N. Investigation of copper corrosion in sodium chloride solution by using a new coating of polystyrene/g-C3N4. J. Mater. Sci. Mater. Electron. 2019, 30, 6300–6310. [Google Scholar] [CrossRef]

- Zuo, S.; Chen, Y.; Liu, W.; Yao, C.; Li, Y.; Ma, J.; Kong, Y.; Mao, H.; Li, Z.; Fu, Y. Polyaniline/g-C3N4 composites as novel media for anticorrosion coatings. J. Coat. Technol. Res. 2017, 14, 1307–1314. [Google Scholar] [CrossRef]

- Malav, J.K.; Rathod, R.; Umare, S.; Vidyasagar, D. Structural, thermal and anticorrosion properties of electroactive polyimide/gC3N4 composites. Mater. Res. Express. 2018, 5, 095309. [Google Scholar] [CrossRef]

- Kumar, A.M.; Khan, M.Y.; Suleiman, R.K.; Khan, A.; Dafalla, H. Promising graphitic carbon nitride/MoOx nanocomposites: For surface protective performance of AA2024 alloys in marine environment. Surf. Coat. Technol. 2019, 374, 579–590. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, L.; Liu, Y.; Chen, H.; Lei, J.; Zhang, J. Visible-light-driven photocatalytic H2O2 production on g-C3N4 loaded with CoP as a noble metal free cocatalyst. Eur. J. Inorg. Chem. 2017, 2017, 4797–4802. [Google Scholar] [CrossRef]

- Haider, Z.; Cho, H.-I.; Moon, G.-H.; Kim, H.-I. Minireview: Selective production of hydrogen peroxide as a clean oxidant over structurally tailored carbon nitride photocatalysts. Catal. Today 2019, 335, 55–64. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, G.; Li, W.; Wu, D. Graphitic carbon nitride homojunction films for photocathodic protection of 316 stainless steel and Q235 carbon steel. J. Electroanal. Chem. 2020, 857, 113703. [Google Scholar] [CrossRef]

| System | Deposition Conditions | Ecorr/mV | jcorr/μA cm−2 | Ref |

|---|---|---|---|---|

| Cu GO/Cu | EPD 20.0 V/60 s | −211 −195 | 25.0 12.7 | [58] |

| Steel GO/steel | EPD 4.0 V | – | 1.47 0.095 | [59] |

| Fe GO/Fe (GO flakes, 20 ± 5 μm) | EPD 2.3 V/60 min | −0.57 −0.42 | 3.01 2.01 | [60] |

| Carbon Steel Ni rGO/Ni coated carbon steel | EPD 100 mA cm−2 | −444 −412 −343 | 77.7 63.2 4.23 | [49] |

| CuNi GO/CuNi GO/acrylic polymer-CuNi | – | −37 90 220 | 1.66 2.92 0.003 | [61] |

| CuNi GO/chitosan-Ag Cu-Ni | EPD 10 V/60 s | −36 30 | 8.56 1.10 | [62] |

| NiTi GO/NiTi GO/Ag-NiTi | EPD 10 V/10 min | −170 31 8 | 0.158 0.017 0.002 | [63] |

| Ti6Al4V GO/Ti6Al4V | EPD 50 V/5 min | −395 −205 | 0.143 0.032 | [64] |

| Mild steel (MS) rGO-MS rGO/TiO2-MS | Slurry deposition | −692 −420 −386 | 650 0.0051 0.0028 | [65] |

| SS GO/SS | Ball milling | −407 −284 | 5.5 0.3 | [66] |

| Cu (annealed) G/Cu (annealed in 20% H2) | CVD | −388 −239 | 90.1 0.15 | [39] |

| GO/Al G/FA-Al | Spin coating | −426 −548 | 9.54 0.84 | [40] |

| CS CS/GO | GO ink | −714 −474 | 9 0.00065 | [42] |

| Substrate | System | Coating/μm | Rc/kΩ cm2 | Cc/μF | Ref |

|---|---|---|---|---|---|

| Q 235 steel | Lignin/OH/GO | 50 ± 5 | 28 | – | [92] |

| Mild steel | Gelatin/GO | 35.7 ± 0.5 | 6.0 | 2.8 × 10−4 | [93] |

| Carbon steel | Sulfonated/GO | 15 | 389 | 1.4 × 10−3 | [72] |

| Mild steel | Aminothiazole/GO | 23.5 ± 0.5 | 101 | 0.26 | [94] |

| Mild steel | Amino-naphthyl thiazole/GO | 23.5 ± 0.5 | 6.5 × 104 | 0.15 | [94] |

| Q 235 steel | Phytic acid/GO | – | – | – | [90] |

| Mild steel | Amino/GO | – | 7.3 × 106 | 8.0 × 10−4 | [91] |

| Steel | Aminopropyltriethoxysilane/GO | 50 ± 5 | 4.8 | 53 | [95] |

| Mild steel | Amino-silane modified/GO | 150 ± 10 | 1 × 104 | – | [96] |

| Steel | L-histidine/GO | 30 ± 3 | 1 × 108 (0.01 Hz) | – | [97] |

| Steel | L-cysteine/GO | 60 ± 5 | 28 | 47.9 | [98] |

| Mg AZ31 | Leucine/GO | – | 38 Ω | 2.7 | [99] |

| Steel | Polyamidoamine dendrimer/GO | 60 ± 5 | 270 | 2.34 | [100] |

| Mg alloy | Polydopamine and hydroxyquinoline/GO | – | 14.3 | 2.4 × 10−4 | [101] |

| System | Time/Days | Filler/wt% | Rc/kΩ cm2 | Ref |

|---|---|---|---|---|

| GO/epoxy | 1 20 40 | 0.1 | 1.80 × 107 5.50 × 106 1.60 × 105 | [73] [73] [73] |

| Polyacrylate/GO/epoxy | 1 20 40 | 1.45 × 107 5.05 × 107 1.50 × 107 | [73] [73] [73] | |

| Acrylamide/acrylic functionalised GO composites/Mg | – | – | 53 | [133] |

| Polymethylmethacrylate (PMMA) brushes on GO | 1 h 5 h 10 h 100 h | – | 3.75 × 104 3.45 × 104 0.99 × 103 1.4 × 102 | [130] [130] [130] [130] |

| PAM100/GO/epoxy | 1 20 40 | 0.5 | 6.62 × 103 6.12 × 103 4.63 × 103 | [132] [132] [132] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Healy, B.; Yu, T.; da Silva Alves, D.; Breslin, C.B. Review of Recent Developments in the Formulation of Graphene-Based Coatings for the Corrosion Protection of Metals and Alloys. Corros. Mater. Degrad. 2020, 1, 296-327. https://doi.org/10.3390/cmd1030015

Healy B, Yu T, da Silva Alves D, Breslin CB. Review of Recent Developments in the Formulation of Graphene-Based Coatings for the Corrosion Protection of Metals and Alloys. Corrosion and Materials Degradation. 2020; 1(3):296-327. https://doi.org/10.3390/cmd1030015

Chicago/Turabian StyleHealy, Bronach, Tian Yu, Daniele da Silva Alves, and Carmel B. Breslin. 2020. "Review of Recent Developments in the Formulation of Graphene-Based Coatings for the Corrosion Protection of Metals and Alloys" Corrosion and Materials Degradation 1, no. 3: 296-327. https://doi.org/10.3390/cmd1030015

APA StyleHealy, B., Yu, T., da Silva Alves, D., & Breslin, C. B. (2020). Review of Recent Developments in the Formulation of Graphene-Based Coatings for the Corrosion Protection of Metals and Alloys. Corrosion and Materials Degradation, 1(3), 296-327. https://doi.org/10.3390/cmd1030015