Recycling-Oriented Characterization of Space Waste Through Clean Hyperspectral Imaging Technology in a Circular Economy Context

Abstract

1. Introduction

2. Materials and Methods

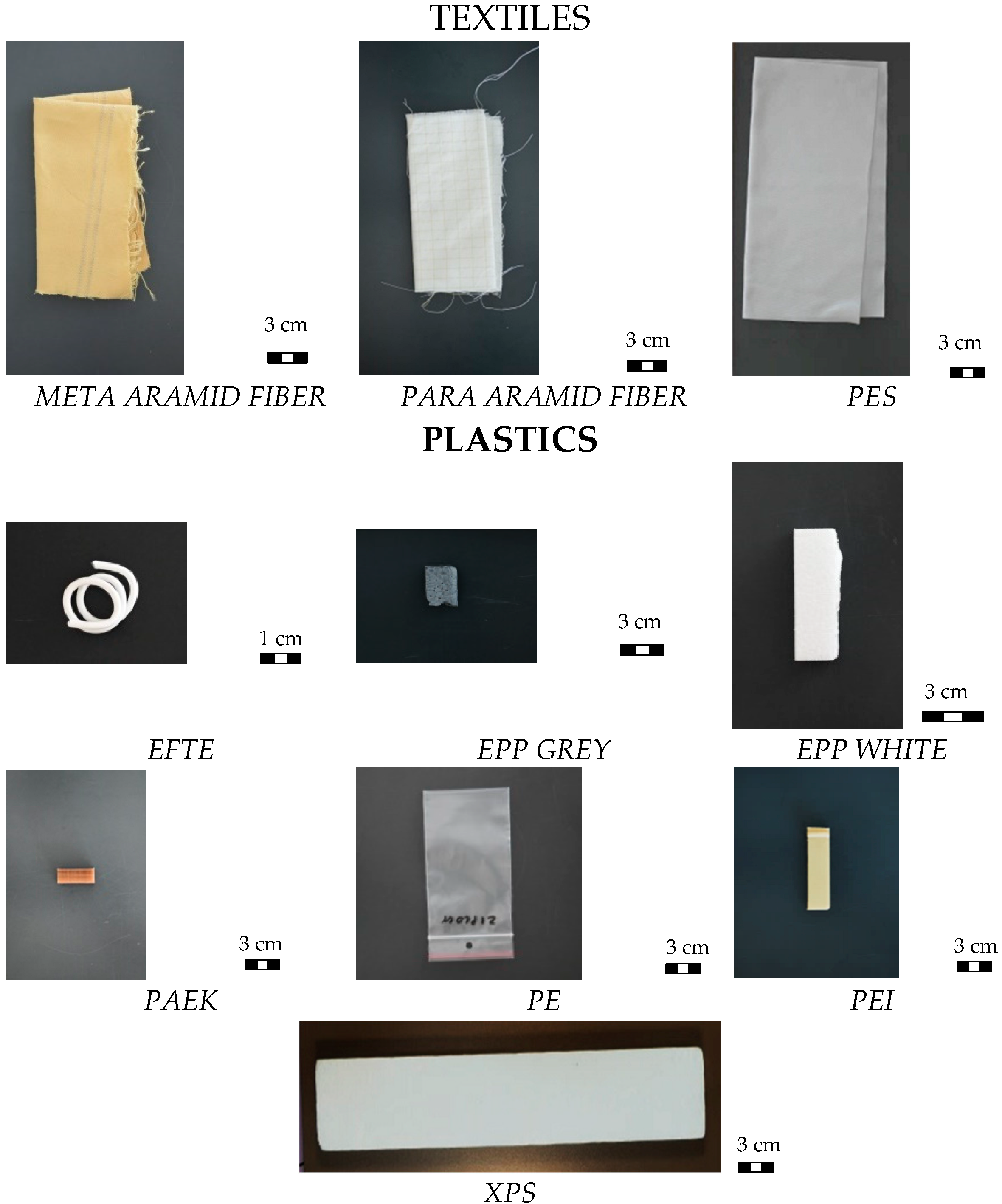

2.1. Samples and Experimental Set-Up

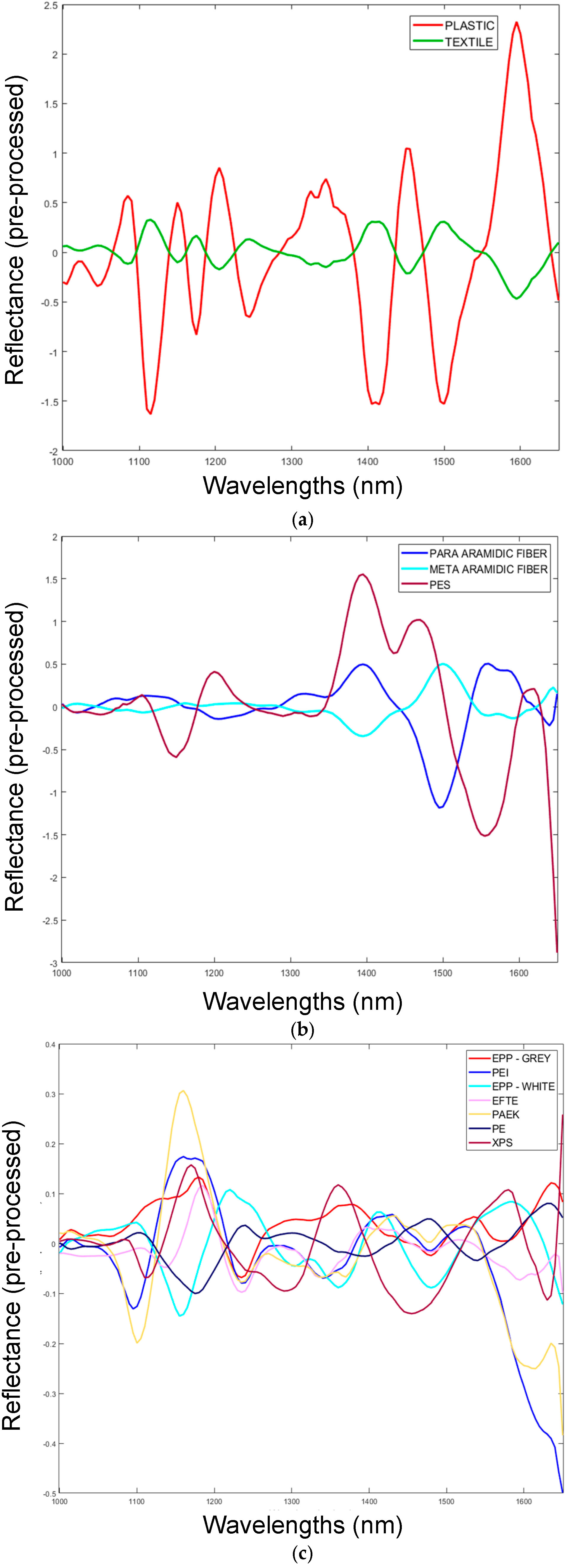

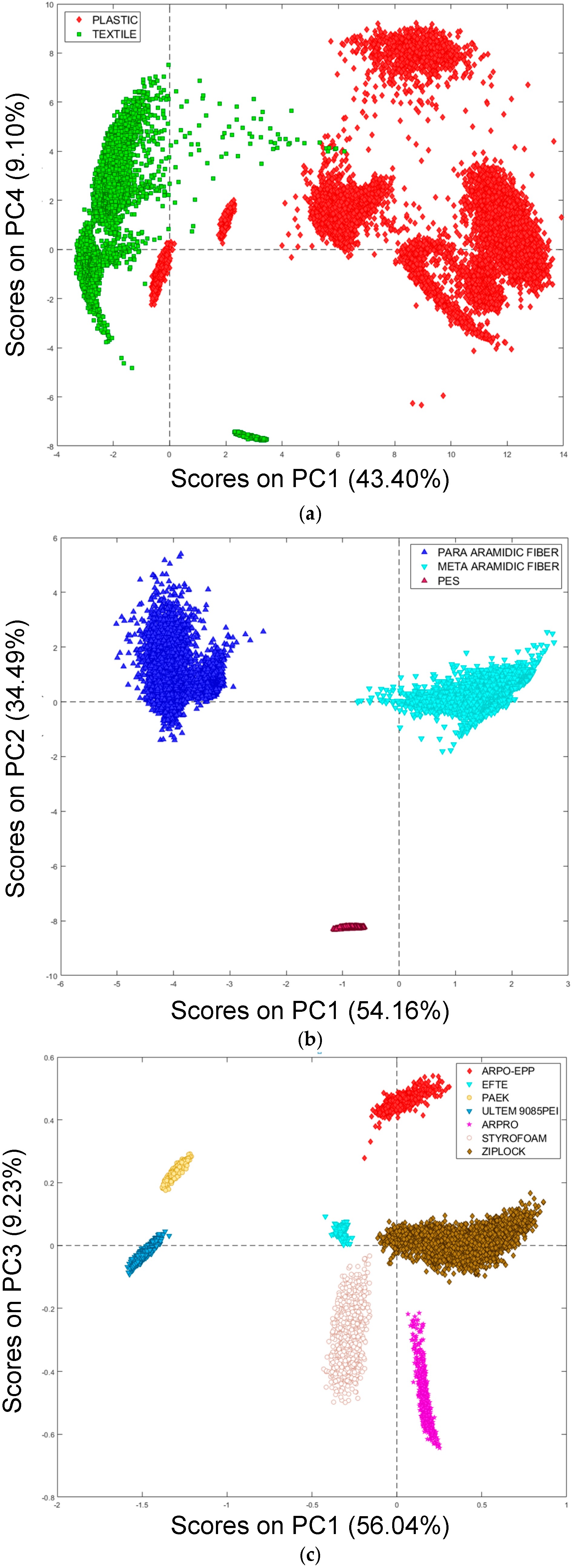

- Set-up No. 1—all the samples were used to perform the analysis to recognize “plastic particles” from “textile particles”;

- Set-up No. 2—a classification model was built to recognize textile categories (i.e., meta-aramid fiber, para-aramid fiber, knitted textured polyester—PES) in the classified textile particles in set-up No. 1;

- Set-up No. 3—a classification model was built to recognize polymer type (i.e., ethylenetetrafluoroethylene—EFTE; expanded polypropylene—EPP; polyaryletherketone—PAEK; polyethylene—PE; polyetherimide—PEI; extruded polystyrene—XPS) in the classified plastic particles in set-up No. 1.

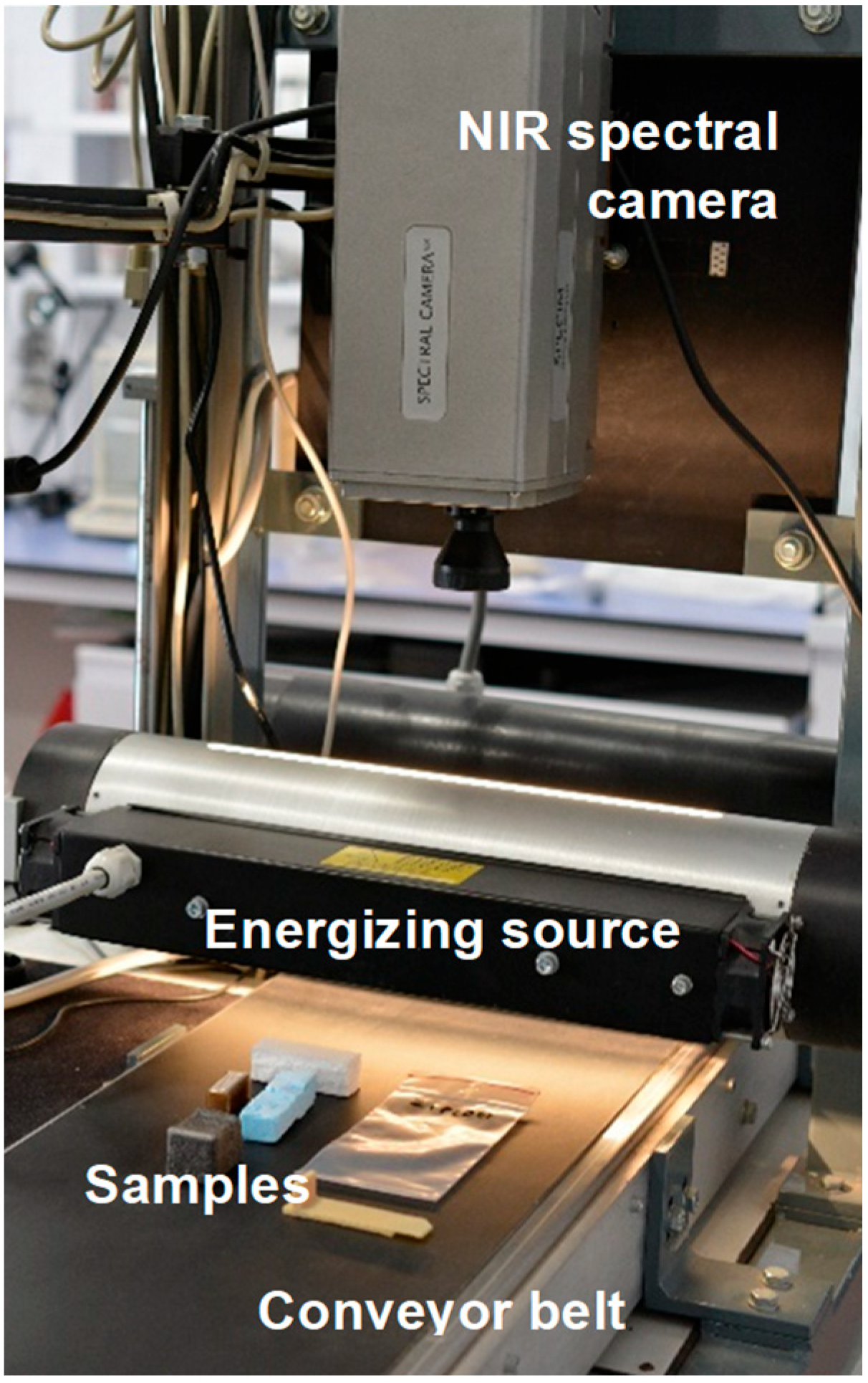

2.2. Hyperspectral Imaging System

3. Data Analysis

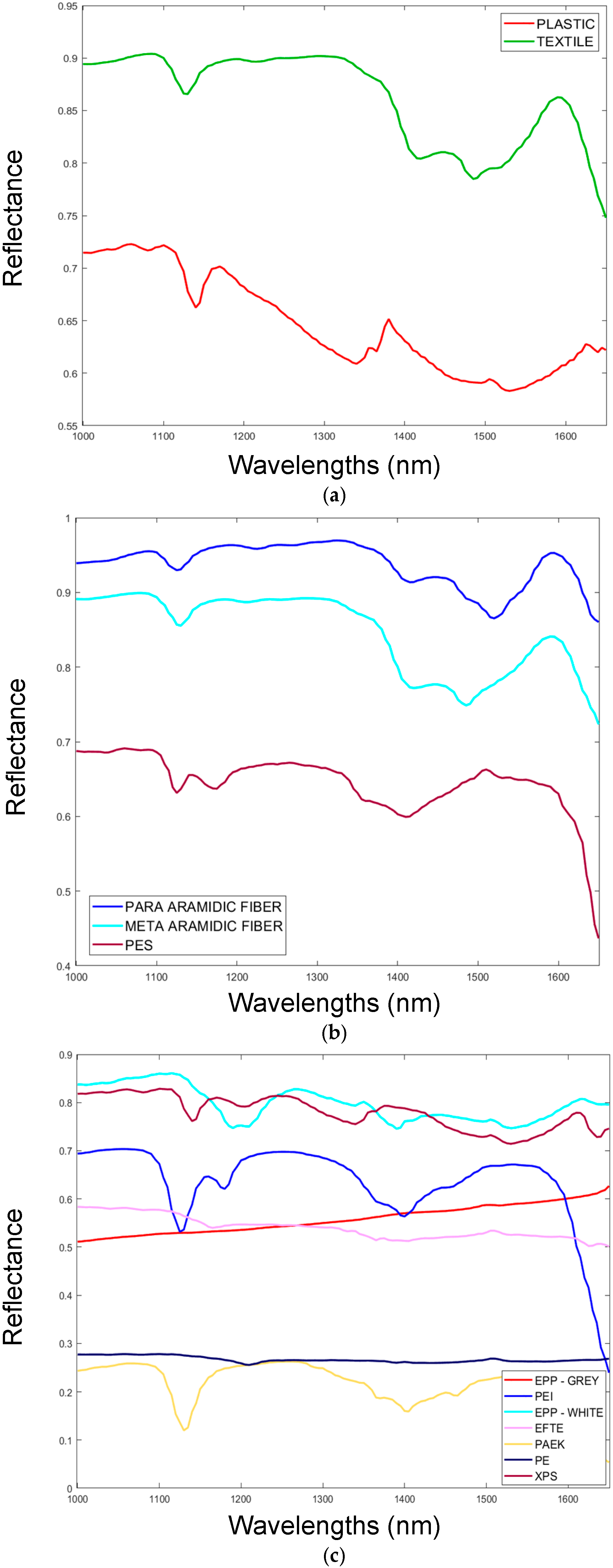

3.1. Spectrum Pre-Processing and Principal Component Analysis (PCA)

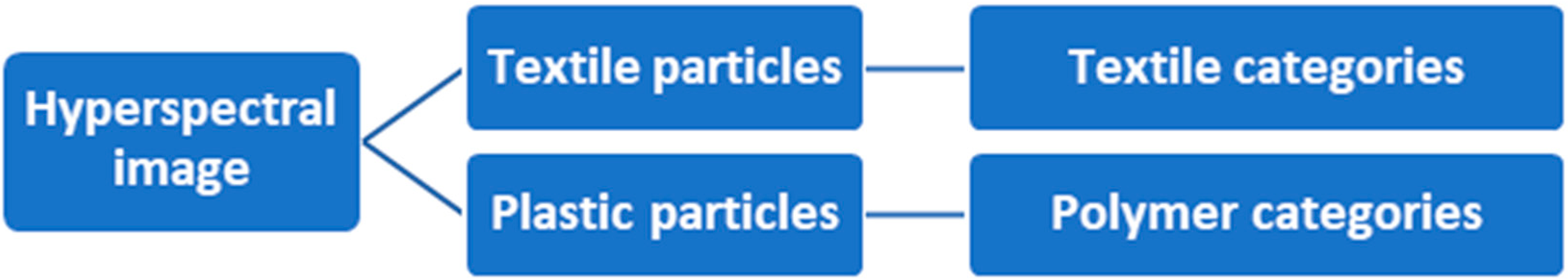

3.2. PLS-DA-Based Cascade Detection

4. Results

- Set-up No. 1: textile and polymer recognition;

- Set-up No. 2: textile recognition;

- Set-up No. 3: polymer recognition.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kirchherr, J.; Yang, N.-H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the circular economy (revisited): An analysis of 221 definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Ferrante, M.; Vitti, M.; Facchini, F.; Sassanelli, C. Mapping the relations between the circular economy rebound effects dimensions: A systematic literature review. J. Clean. Prod. 2024, 456, 142399. [Google Scholar] [CrossRef]

- Chioatto, E.; Sospiro, P. Transition from waste management to circular economy: The European Union roadmap. Environ. Dev. Sustain. 2023, 25, 249–276. [Google Scholar] [CrossRef]

- Hondroyiannis, G.; Sardianou, E.; Nikou, V.; Evangelinos, K.; Nikolaou, I. Circular economy and macroeconomic performance: Evidence across 28 European countries. Ecol. Econ. 2024, 215, 108002. [Google Scholar] [CrossRef]

- Chen, C.-C.; Pao, H.-T. Circular economy and ecological footprint: A disaggregated analysis for the EU. Ecol. Indic. 2024, 160, 111809. [Google Scholar] [CrossRef]

- Claudio-Quiroga, G.; Poza, C. Measuring the circular economy in Europe: Big differences among countries, great opportunities to converge. Sustain. Dev. 2024, 32, 4707–4725. [Google Scholar] [CrossRef]

- D’Adamo, I.; Daraio, C.; Di Leo, S.; Gastaldi, M.; Rossi, E.N. Driving EU sustainability: Promoting the circular economy through municipal waste efficiency. Sustain. Prod. Consum. 2024, 50, 462–474. [Google Scholar] [CrossRef]

- Sondh, S.; Upadhyay, D.S.; Patel, S.; Patel, R.N. Strategic approach towards sustainability by promoting circular economy-based municipal solid waste management system-A review. Sustain. Chem. Pharm. 2024, 37, 101337. [Google Scholar] [CrossRef]

- Ma, W.; Liu, T.; Hao, J.L.; Wu, W.; Gu, X. Towards a circular economy for construction and demolition waste management in China: Critical success factors. Sustain. Chem. Pharm. 2023, 35, 101226. [Google Scholar] [CrossRef]

- Molla, A.H.; Shams, H.; Harun, Z.; Kasim, A.N.C.; Nallapaneni, M.K.; Rahman, M.N.A. Evaluation of end-of-life vehicle recycling system in India in responding to the sustainability paradigm: An explorative study. Sci. Rep. 2023, 13, 4169. [Google Scholar] [CrossRef]

- Voukkali, I.; Papamichael, I.; Loizia, P.; Economou, F.; Stylianou, M.; Naddeo, V.; Zorpas, A.A. Fashioning the Future: Green chemistry and engineering innovations in biofashion. Chem. Eng. J. 2024, 497, 155039. [Google Scholar] [CrossRef]

- Angelo, A.C.M.; Saraiva, A.B.; Clímaco, J.C.N.; Infante, C.E.; Valle, R. Life Cycle Assessment and Multi-criteria Decision Analysis: Selection of a strategy for domestic food waste management in Rio de Janeiro. J. Clean. Prod. 2017, 143, 744–756. [Google Scholar] [CrossRef]

- Mishra, K.; Siwal, S.S.; Thakur, V.K. E-waste recycling and utilization: A review of current technologies and future perspectives. Curr. Opin. Green Sustain. Chem. 2024, 47, 100900. [Google Scholar] [CrossRef]

- Moustakas, K.; Loizidou, M. Effective waste management with emphasis on circular economy. Environ. Sci. Pollut. Res. 2023, 30, 8540–8547. [Google Scholar] [CrossRef]

- Moustakas, K.; Loizidou, M. Waste management & circular economy. Sustain. Chem. Pharm. 2023, 32, 100969. [Google Scholar]

- Fernández-Miguel, A.; García-Muiña, F.E.; Settembre-Blundo, D.; Tarantino, S.C.; Riccardi, M.P. Exploring Systemic Sustainability in Manufacturing: Geoanthropology’s Strategic Lens Shaping Industry 6.0. Glob. J. Flex. Syst. Manag. 2024, 25, 579–600. [Google Scholar] [CrossRef]

- Wilson, A.R.; Vasile, M. The space sustainability paradox. J. Clean. Prod. 2023, 423, 138869. [Google Scholar] [CrossRef]

- Leonard, R.; Williams, I.D. Viability of a circular economy for space debris. Waste Manag. 2023, 155, 19–28. [Google Scholar] [CrossRef]

- Paladini, S.; Saha, K.; Pierron, X. Sustainable space for a sustainable Earth? Circular economy insights from the space sector. J. Environ. Manag. 2021, 289, 112511. [Google Scholar] [CrossRef]

- Wood, D.; Rathnasabapathy, M.; Stober, K.J.; Menon, P. Challenges and progress in applying space technology in support of the sustainable development goals. Acta Astronaut. 2024, 219, 678–692. [Google Scholar] [CrossRef]

- Hall, P.B. Recycling In-Space Plastic Waste for Deep-Space Additive Manufacturing: Capability Assessment and Technology Development, Part-II1. In Marshall Space Flight Center Faculty Fellowship Program; Marshall Space Flight Center: Huntsville, AL, USA, 2021; p. 94. [Google Scholar]

- Ailor, W. Protecting the LEO environment. J. Space Saf. Eng. 2022, 9, 449–454. [Google Scholar] [CrossRef]

- Makaya, A.; Pambaguian, L.; Ghidini, T.; Rohr, T.; Lafont, U.; Meurisse, A. Towards out of earth manufacturing: Overview of the ESA materials and processes activities on manufacturing in space. CEAS Space J. 2023, 15, 69–75. [Google Scholar] [CrossRef]

- Wilson, A.R.; Vasile, M.; Maddock, C.A.; Baker, K.J. Ecospheric life cycle impacts of annual global space activities. Sci. Total Environ. 2022, 834, 155305. [Google Scholar] [CrossRef] [PubMed]

- Allwood, J.M. Material efficiency—Squaring the circular economy: Recycling within a hierarchy of material management strategies. In Handbook of Recycling; Elsevier: Amsterdam, The Netherlands, 2024; pp. 45–78. [Google Scholar]

- Malik, M.; Sharma, S.; Uddin, M.; Chen, C.-L.; Wu, C.-M.; Soni, P.; Chaudhary, S. Waste classification for sustainable development using image recognition with deep learning neural network models. Sustainability 2022, 14, 7222. [Google Scholar] [CrossRef]

- Shi, C.; Tan, C.; Wang, T.; Wang, L. A waste classification method based on a multilayer hybrid convolution neural network. Appl. Sci. 2021, 11, 8572. [Google Scholar] [CrossRef]

- Shreya, M.; Katyal, J.; Ramesh, R. Technical solutions for waste classification and management: A mini-review. Waste Manag. Res. 2023, 41, 801. [Google Scholar]

- Ionescu, G.; Rada, E.C.; Ragazzi, M.; Mărculescu, C.; Badea, A.; Apóstol, T. Integrated municipal solid waste scenario model using advanced pretreatment and waste to energy processes. Energy Convers. Manag. 2013, 76, 1083–1092. [Google Scholar] [CrossRef]

- Linne, D.L.; Palaszewski, B.A.; Gokoglu, S.A.; Balasubramaniam, B.; Hegde, U.G.; Gallo, C. Waste management options for long-duration space missions: When to reject, reuse, or recycle. In Proceedings of the 7th Symposium on Space Resource Utilization, National Harbor, MD, USA, 13–17 January 2014; p. 0497. [Google Scholar]

- Zhou, C.; Xu, Z.; Wang, L.; Qiao, R.; Li, Y.; Chang, R.; Ai, W. The Production of Solid Wastes in CELSS and the Difficulties in Recycling by Composting: A Review. Space Sci. Technol. 2024, 4, 0154. [Google Scholar] [CrossRef]

- Olawade, D.B.; Fapohunda, O.; Wada, O.Z.; Usman, S.O.; Ige, A.O.; Ajisafe, O.; Oladapo, B.I. Smart waste management: A paradigm shift enabled by artificial intelligence. Waste Manag. Bull. 2024, 2, 244–263. [Google Scholar] [CrossRef]

- Palmieri, R.; Gasbarrone, R.; Fiore, L. Hyperspectral Imaging for Sustainable Waste Recycling. Sustainability 2023, 15, 7752. [Google Scholar] [CrossRef]

- Bonifazi, G.; Gasbarrone, R.; Palmieri, R.; Serranti, S. End-of-Life Textile Recognition in a Circular Economy Perspective: A Methodological Approach Based on Near Infrared Spectroscopy. Sustainability 2022, 14, 10249. [Google Scholar] [CrossRef]

- Calvini, R.; Ulrici, A.; Amigo, J.M. Growing applications of hyperspectral and multispectral imaging. Data Handl. Sci. Technol. 2020, 32, 605–629. [Google Scholar]

- Caballero, D.; Bevilacqua, M.; Amigo, J.M. Application of hyperspectral imaging and chemometrics for classifying plastics with brominated flame retardants. J. Spectr. Imaging 2019, 8, a1. [Google Scholar] [CrossRef]

- Alagappan, S.; Kolobaric, A.; Hoffman, L.C.; Cozzolino, D. Current and Potential Applications of Vibrational Spectroscopy as a Tool in Black Soldier Fly Production and the Circular Economy. Appl. Sci. 2024, 14, 7318. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Meidiana, C.; Goh, H.H.; Zhang, D.; Othman, M.H.D.; Aziz, F.; Anouzla, A.; Sarangi, P.K.; Pasaribu, B.; Ali, I. Unlocking synergies between waste management and climate change mitigation to accelerate decarbonization through circular-economy digitalization in Indonesia. Sustain. Prod. Consum. 2024, 46, 522–542. [Google Scholar] [CrossRef]

- Menezes, J.; Hemachandra, N.; Isidro, K. Role of big data analytics and hyperspectral imaging in waste management for circular economy. Discov. Sustain. 2024, 5, 298. [Google Scholar] [CrossRef]

- de Lima Ribeiro, A.; Fuchs, M.C.; Lorenz, S.; Röder, C.; Heitmann, J.; Gloaguen, R. Multi-sensor characterization for an improved identification of polymers in WEEE recycling. Waste Manag. 2024, 178, 239–256. [Google Scholar] [CrossRef]

- Patel, D.; Bhise, S.; Kapdi, S.S.; Bhatt, T. Non-destructive hyperspectral imaging technology to assess the quality and safety of food: A review. Food Prod. Process. Nutr. 2024, 6, 69. [Google Scholar] [CrossRef]

- Wu, X.; Liang, X.; Wang, Y.; Wu, B.; Sun, J. Non-Destructive Techniques for the Analysis and Evaluation of Meat Quality and Safety: A Review. Foods 2022, 11, 3713. [Google Scholar] [CrossRef]

- Nikzadfar, M.; Rashvand, M.; Zhang, H.; Shenfield, A.; Genovese, F.; Altieri, G.; Matera, A.; Tornese, I.; Laveglia, S.; Paterna, G.; et al. Hyperspectral Imaging Aiding Artificial Intelligence: A Reliable Approach for Food Qualification and Safety. Appl. Sci. 2024, 14, 9821. [Google Scholar] [CrossRef]

- Feng, C.-H. Colour Analysis of Sausages Stuffed with Modified Casings Added with Citrus Peel Extracts Using Hyperspectral Imaging Combined with Multivariate Analysis. Sustainability 2024, 16, 8683. [Google Scholar] [CrossRef]

- Cabral, S.; Klimenka, M.; Bademosi, F.; Lau, D.; Pender, S.; Villaggi, L.; Stoddart, J.; Donnelly, J.; Storey, P.; Benjamin, D. A Contactless Multi-Modal Sensing Approach for Material Assessment and Recovery in Building Deconstruction. Sustainability 2025, 17, 585. [Google Scholar] [CrossRef]

- Geladi, P.; Grahn, H.; Burger, J. Multivariate images, hyperspectral imaging: Background and equipment. In Techniques and Applications of Hyperspectral Image Analysis; John Wiley & Sons: West Sussex, UK, 2007; pp. 1–15. [Google Scholar]

- Amigo, J.M.; Martí, I.; Gowen, A. Hyperspectral imaging and chemometrics: A perfect combination for the analysis of food structure, composition and quality. In Data Handling in Science and Technology; Elsevier: Amsterdam, The Netherlands, 2013; Volume 28, pp. 343–370. [Google Scholar]

- Hyvarinen, T.S.; Herrala, E.; Dall’Ava, A. Direct sight imaging spectrograph: A unique add-in component brings spectral imaging to industrial applications. In Proceedings of the Digital Solid State Cameras: Designs and Applications, San Jose, CA, USA, 28–29 January 1998; pp. 165–175. [Google Scholar]

- Bonifazi, G.; Gasbarrone, R.; Palmieri, R.; Serranti, S. A Characterization Approach for End-of-Life Textile Recovery Based on Short-Wave Infrared Spectroscopy. Waste Biomass Valorization 2024, 15, 1725–1738. [Google Scholar] [CrossRef]

- Aversano, N.; Bonifazi, G.; D’Adamo, I.; Palmieri, R.; Serranti, S.; Simone, A. Circular and sustainable space: Findings from hyperspectral imaging. J. Clean. Prod. 2024, 471, 143386. [Google Scholar] [CrossRef]

- Wise, B.M.; Gallagher, N.B.; Bro, R.; Shaver, J.M.; Windig, W.; Koch, R.S. Chemometrics Tutorial for PLS_toolbox and Solo; Eigenvector Research Inc.: Wenatchee, WA, USA, 2006. [Google Scholar]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Ballabio, D.; Consonni, V. Classification tools in chemistry. Part 1: Linear models. PLS-DA. Anal. Methods 2013, 5, 3790–3798. [Google Scholar] [CrossRef]

| Set-Up No 1 | |||||||

|---|---|---|---|---|---|---|---|

| PLASTIC | TEXTILE | ||||||

| Sensitivity (Cal) | 1.000 | 0.999 | |||||

| Specificity (Cal) | 0.999 | 1.000 | |||||

| Sensitivity (CV) | 1.000 | 0.999 | |||||

| Specificity (CV) | 0.999 | 1.000 | |||||

| Set-Up No 2: TEXTILES | |||||||

| Para-Aramid Fiber | Meta-Aramid Fiber | PEI | |||||

| Sensitivity (Cal) | 1.000 | 1.000 | 1.000 | ||||

| Specificity (Cal) | 1.000 | 1.000 | 1.000 | ||||

| Sensitivity (CV) | 1.000 | 1.000 | 1.000 | ||||

| Specificity (CV) | 1.000 | 1.000 | 1.000 | ||||

| Set-Up No 3: PLASTICS | |||||||

| EPP-GREY | PEI | EPP-WHITE | EFTE | PAEK | PE | XPS | |

| Sensitivity (Cal) | 0.999 | 1.000 | 0.991 | 1.000 | 1.000 | 1.000 | 1.000 |

| Specificity (Cal) | 1.000 | 1.000 | 0.995 | 1.000 | 0.999 | 0.999 | 1.000 |

| Sensitivity (CV) | 0.999 | 1.000 | 0.989 | 1.000 | 1.000 | 1.000 | 1.000 |

| Specificity (CV) | 1.000 | 1.000 | 0.995 | 1.000 | 0.999 | 0.999 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonifazi, G.; D’Adamo, I.; Palmieri, R.; Serranti, S. Recycling-Oriented Characterization of Space Waste Through Clean Hyperspectral Imaging Technology in a Circular Economy Context. Clean Technol. 2025, 7, 26. https://doi.org/10.3390/cleantechnol7010026

Bonifazi G, D’Adamo I, Palmieri R, Serranti S. Recycling-Oriented Characterization of Space Waste Through Clean Hyperspectral Imaging Technology in a Circular Economy Context. Clean Technologies. 2025; 7(1):26. https://doi.org/10.3390/cleantechnol7010026

Chicago/Turabian StyleBonifazi, Giuseppe, Idiano D’Adamo, Roberta Palmieri, and Silvia Serranti. 2025. "Recycling-Oriented Characterization of Space Waste Through Clean Hyperspectral Imaging Technology in a Circular Economy Context" Clean Technologies 7, no. 1: 26. https://doi.org/10.3390/cleantechnol7010026

APA StyleBonifazi, G., D’Adamo, I., Palmieri, R., & Serranti, S. (2025). Recycling-Oriented Characterization of Space Waste Through Clean Hyperspectral Imaging Technology in a Circular Economy Context. Clean Technologies, 7(1), 26. https://doi.org/10.3390/cleantechnol7010026