Influence of Surface Treatment of Wood-Based Acoustic Panels on Their Fire Performance

Abstract

1. Introduction

2. Materials and Methods

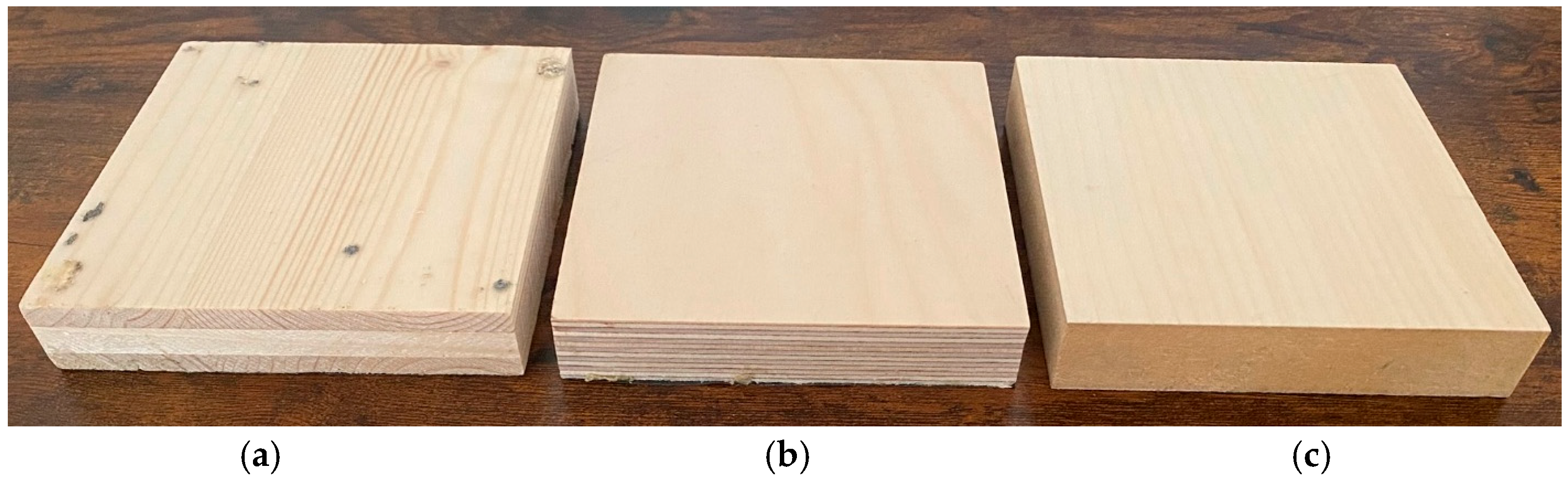

2.1. Material

- A three-layer B/C spruce solid wood panel with a thickness of 19.4 mm;

- A 13-layer birch plywood with a thickness of 18.1 mm;

- An MDF board with a thickness of 19.2 mm, which was veneered on the face surface with ash veneer.

2.2. Methods

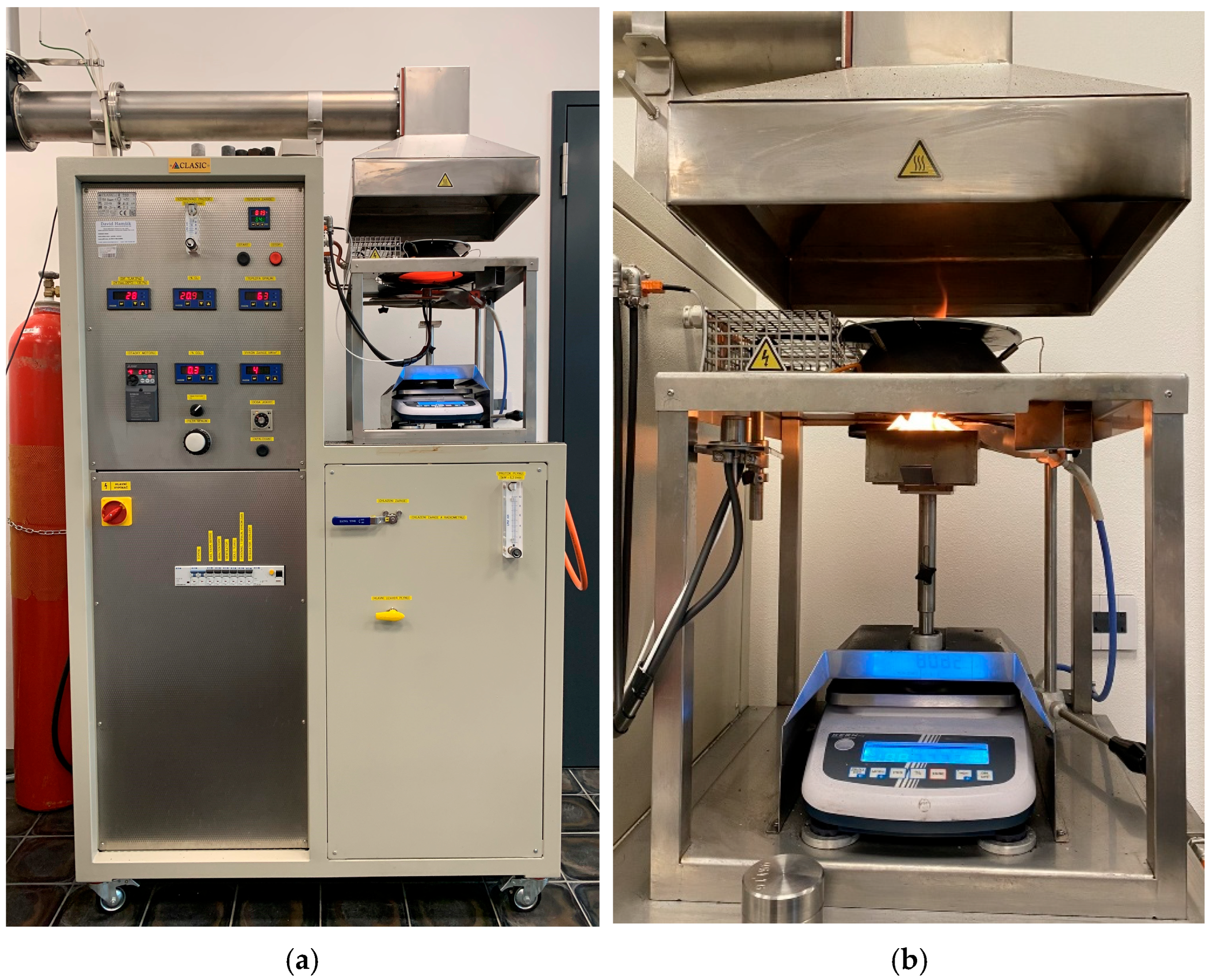

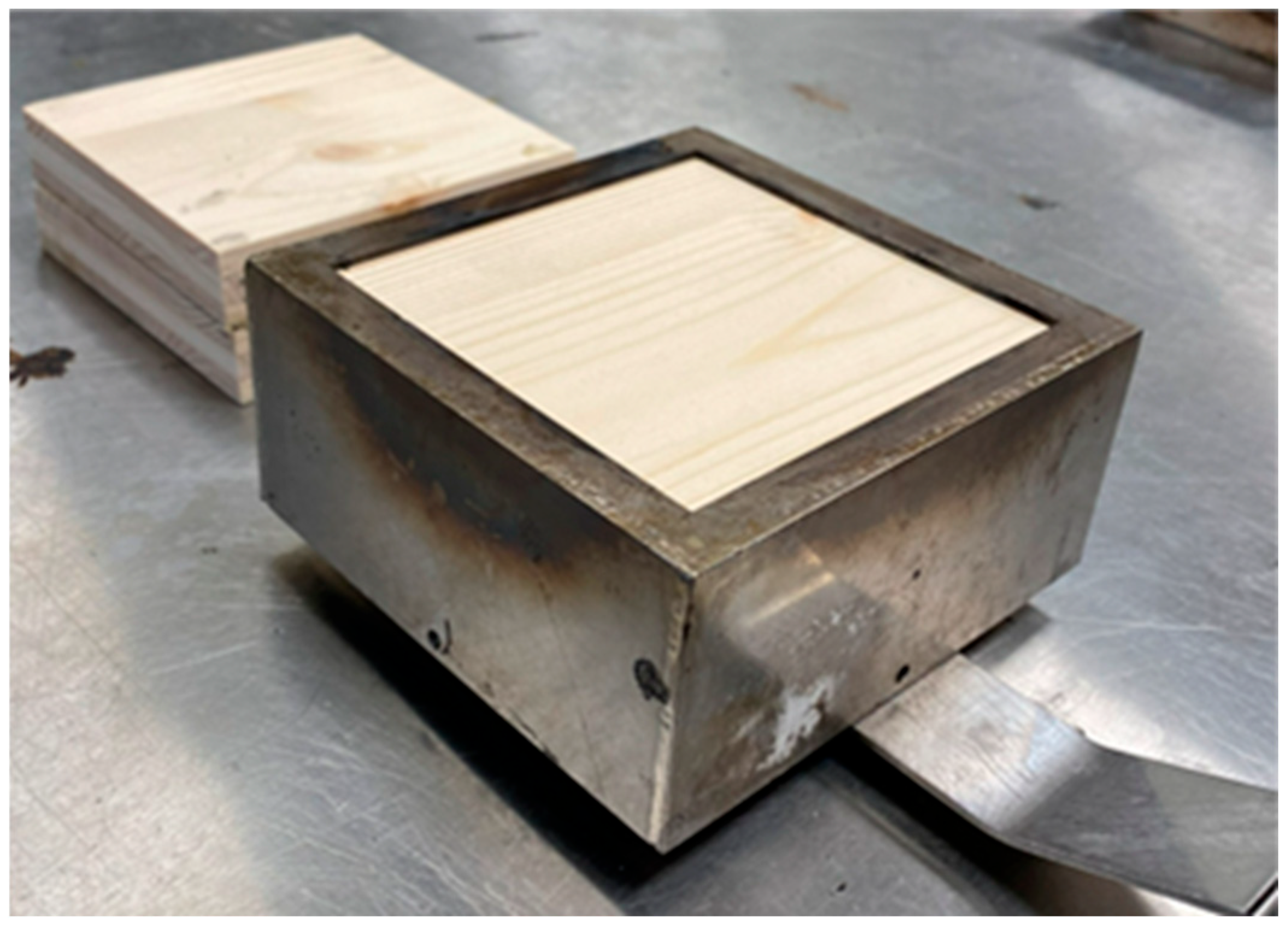

2.2.1. Cone Calorimeter Method

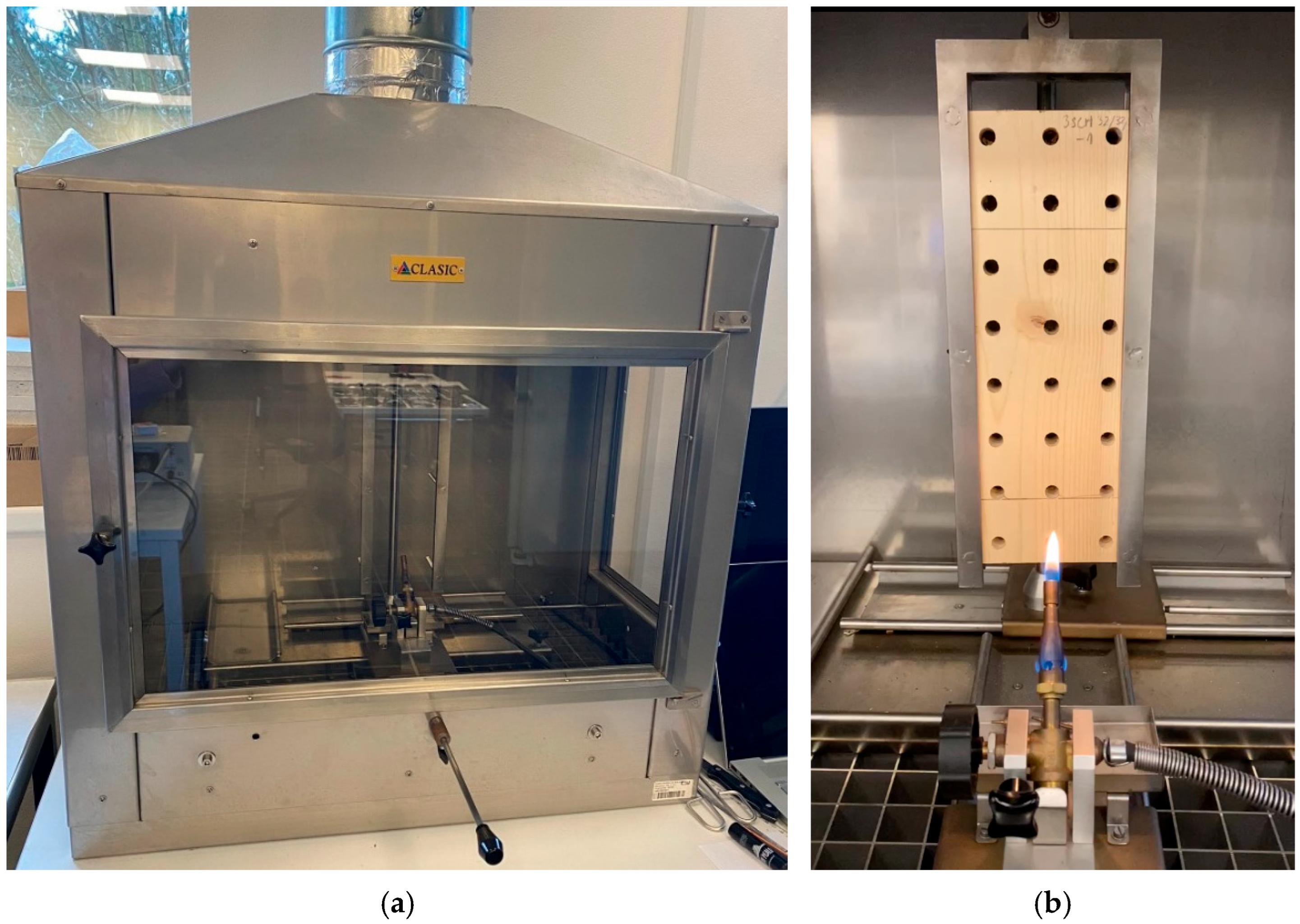

2.2.2. Single-Flame Source Test

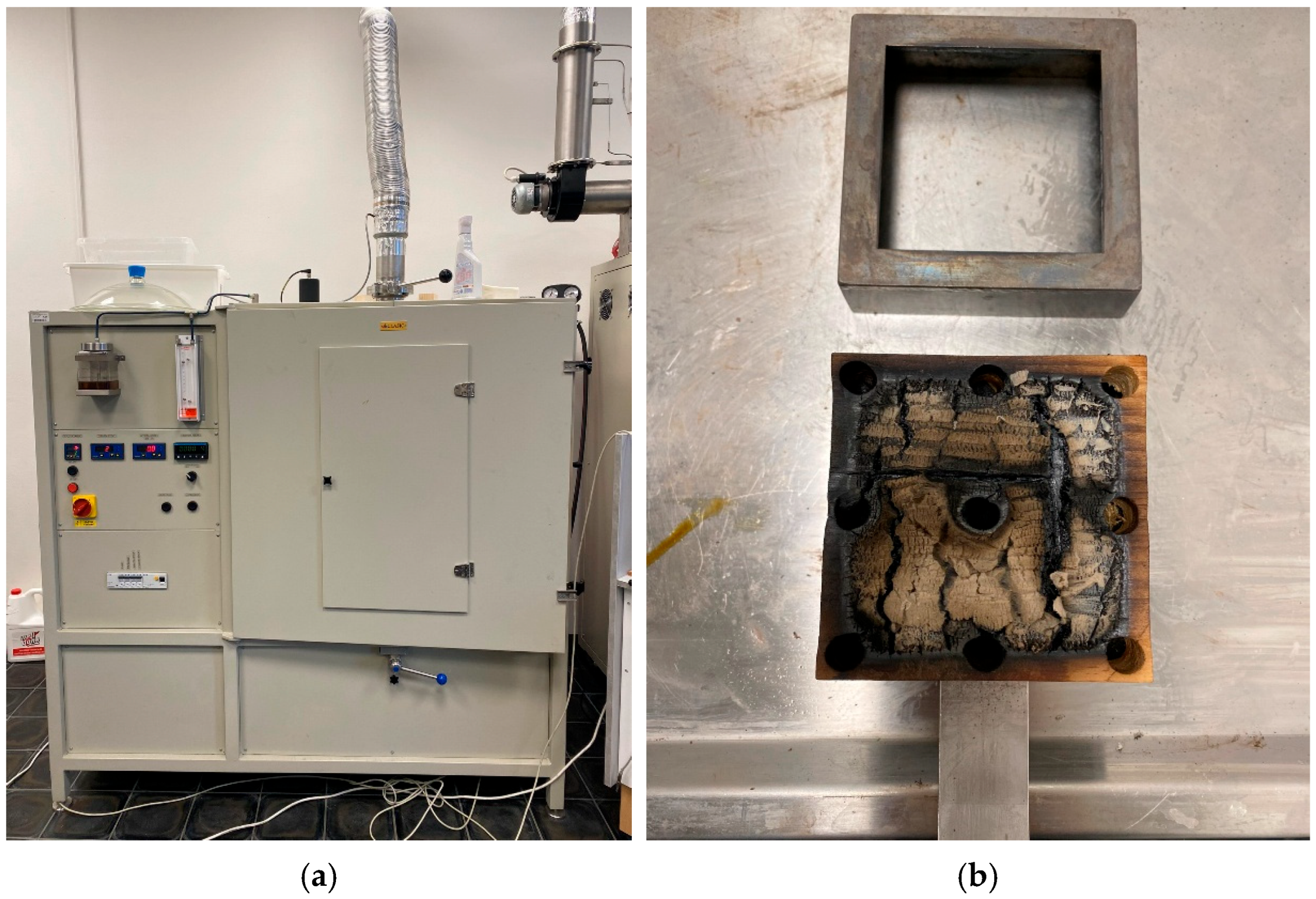

2.2.3. Smoke Generation—Determination of Optical Density

2.2.4. Statistical Evaluation

3. Results and Discussion

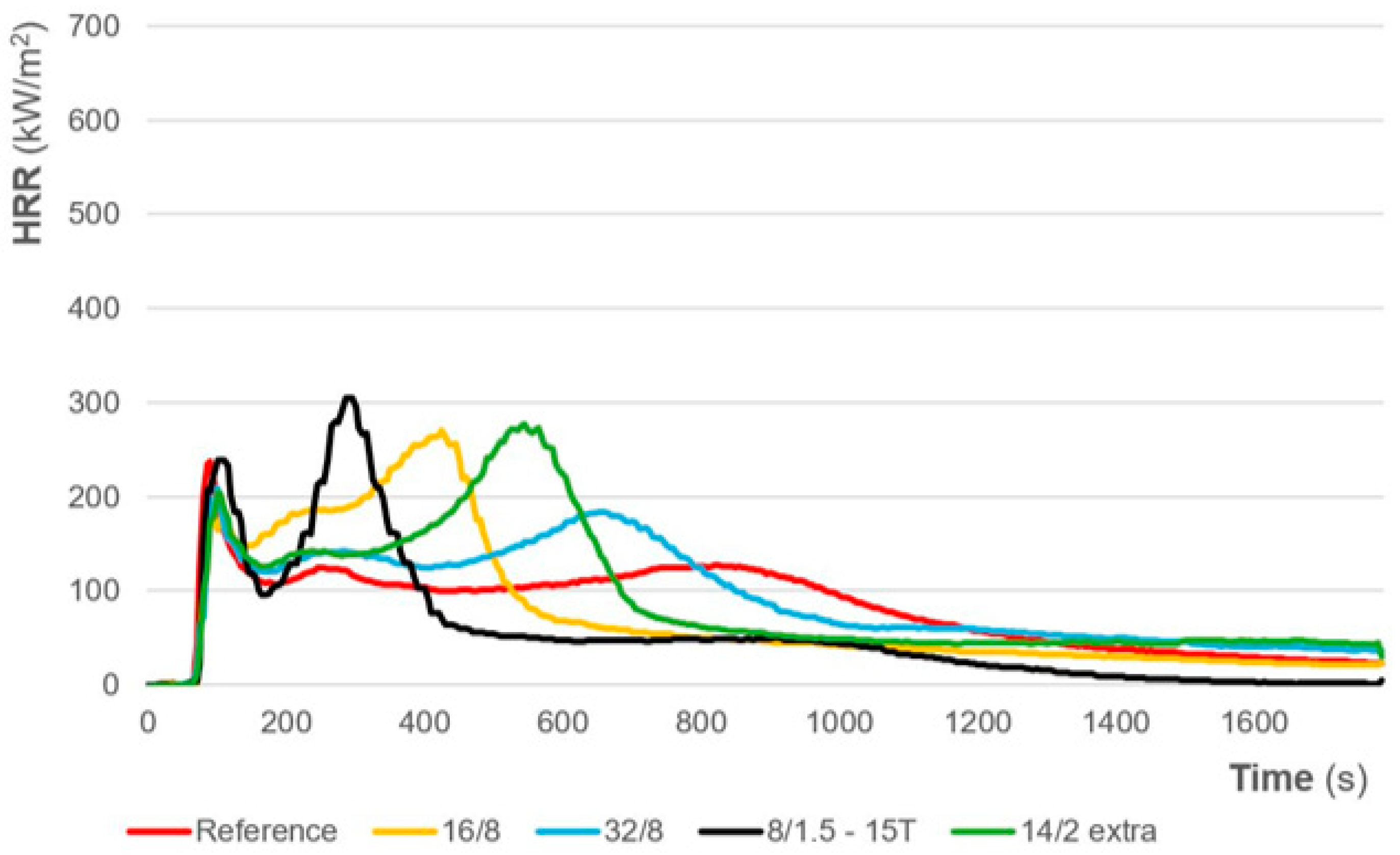

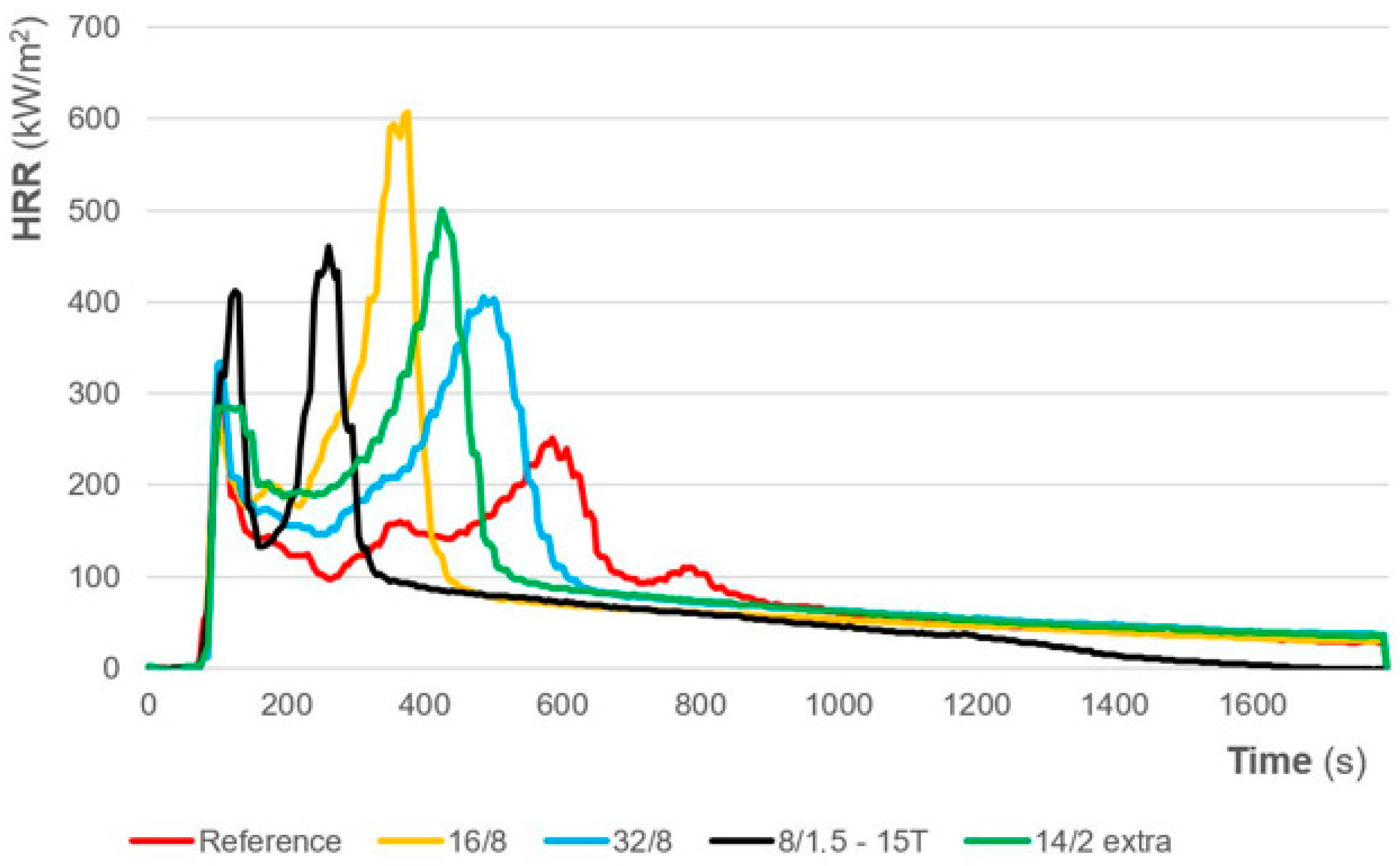

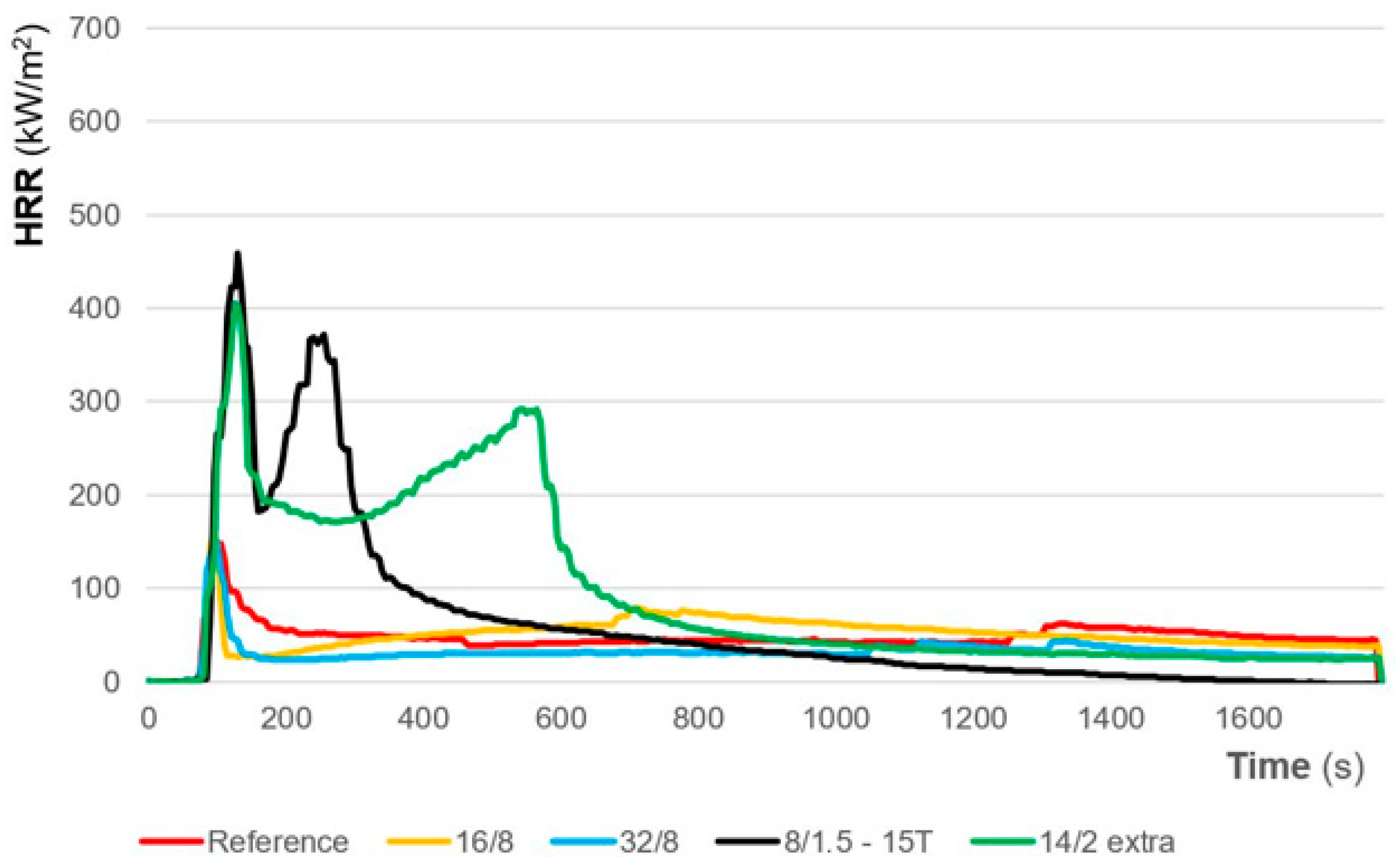

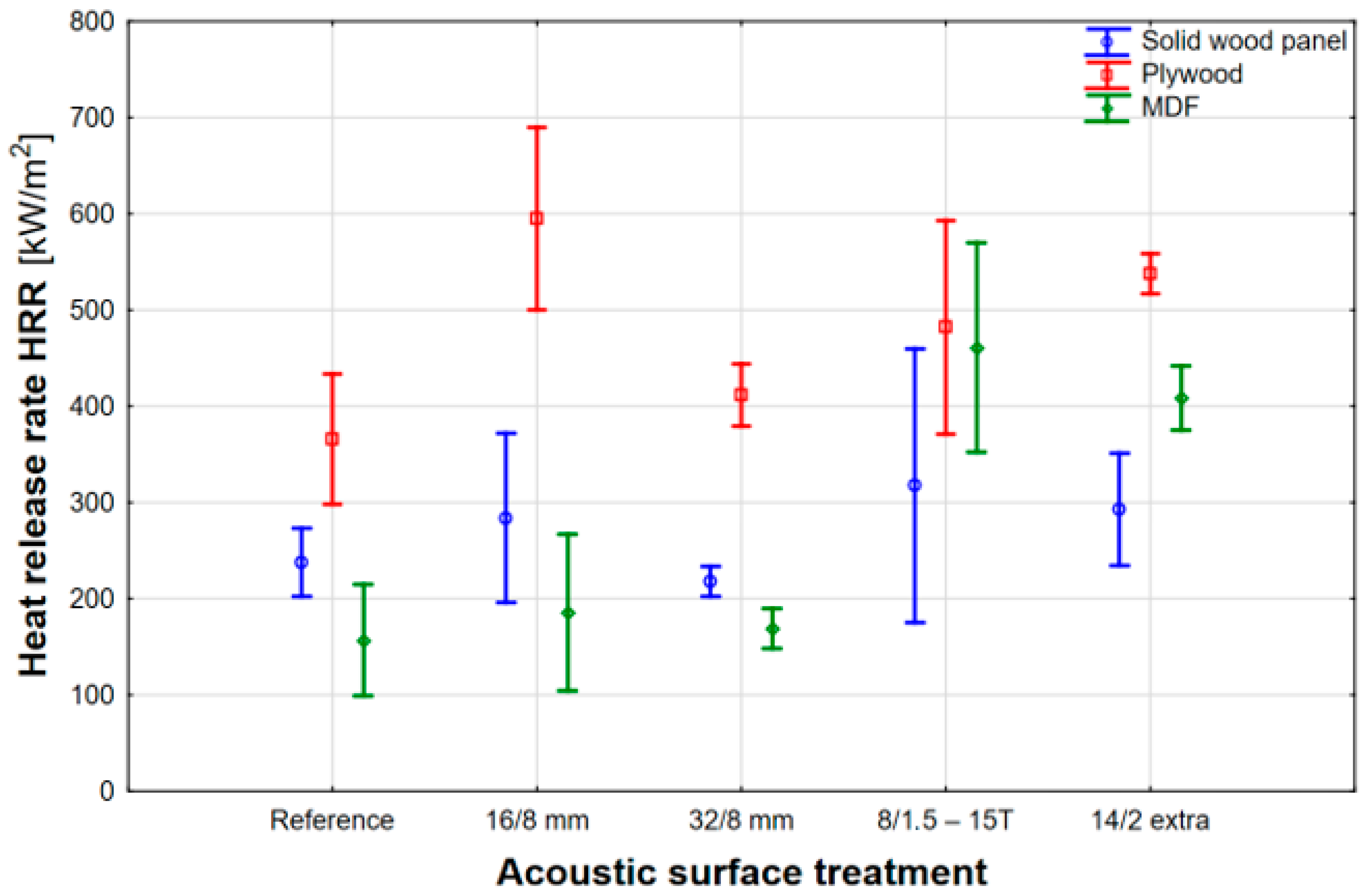

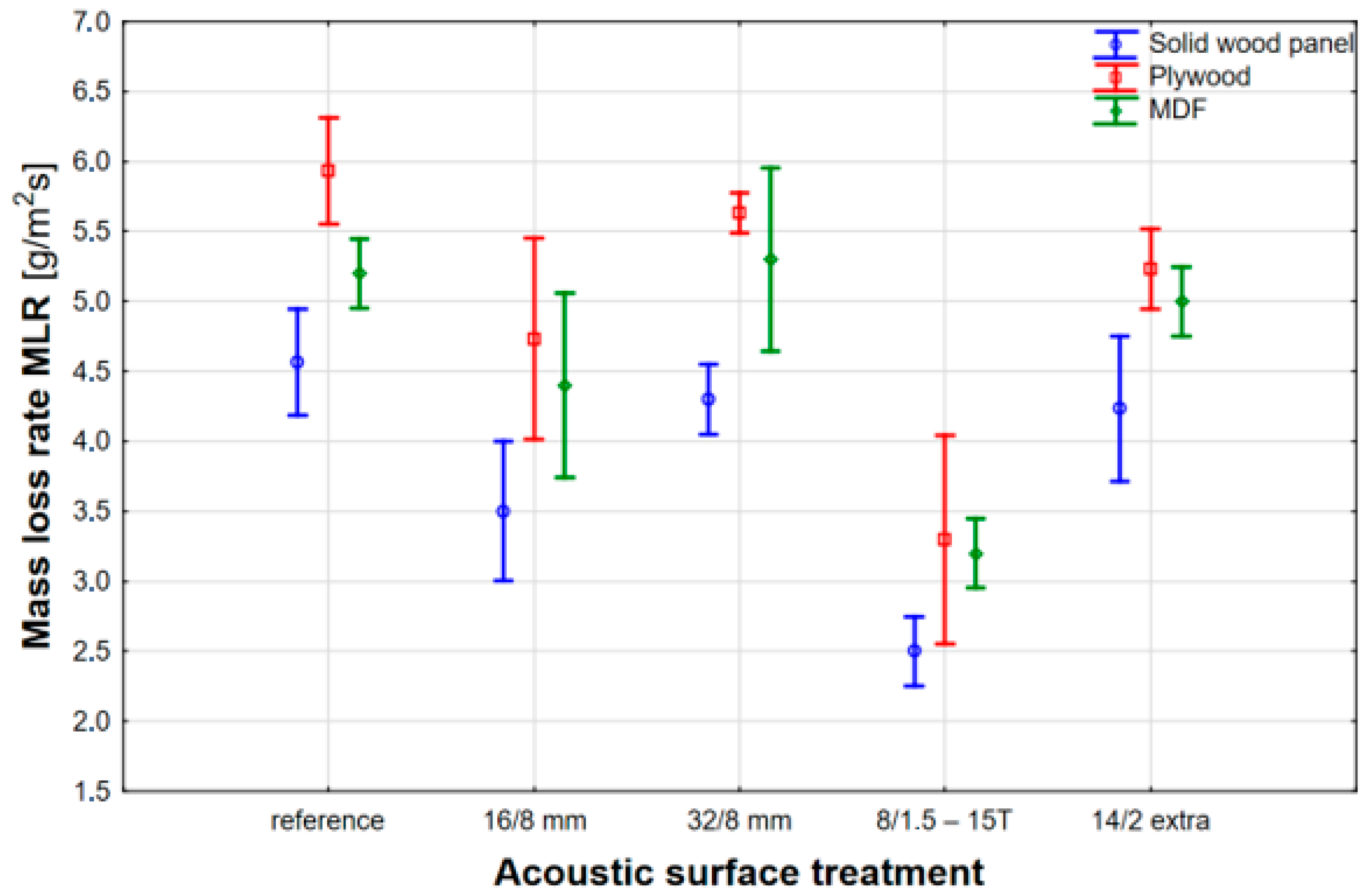

3.1. Cone Calorimeter

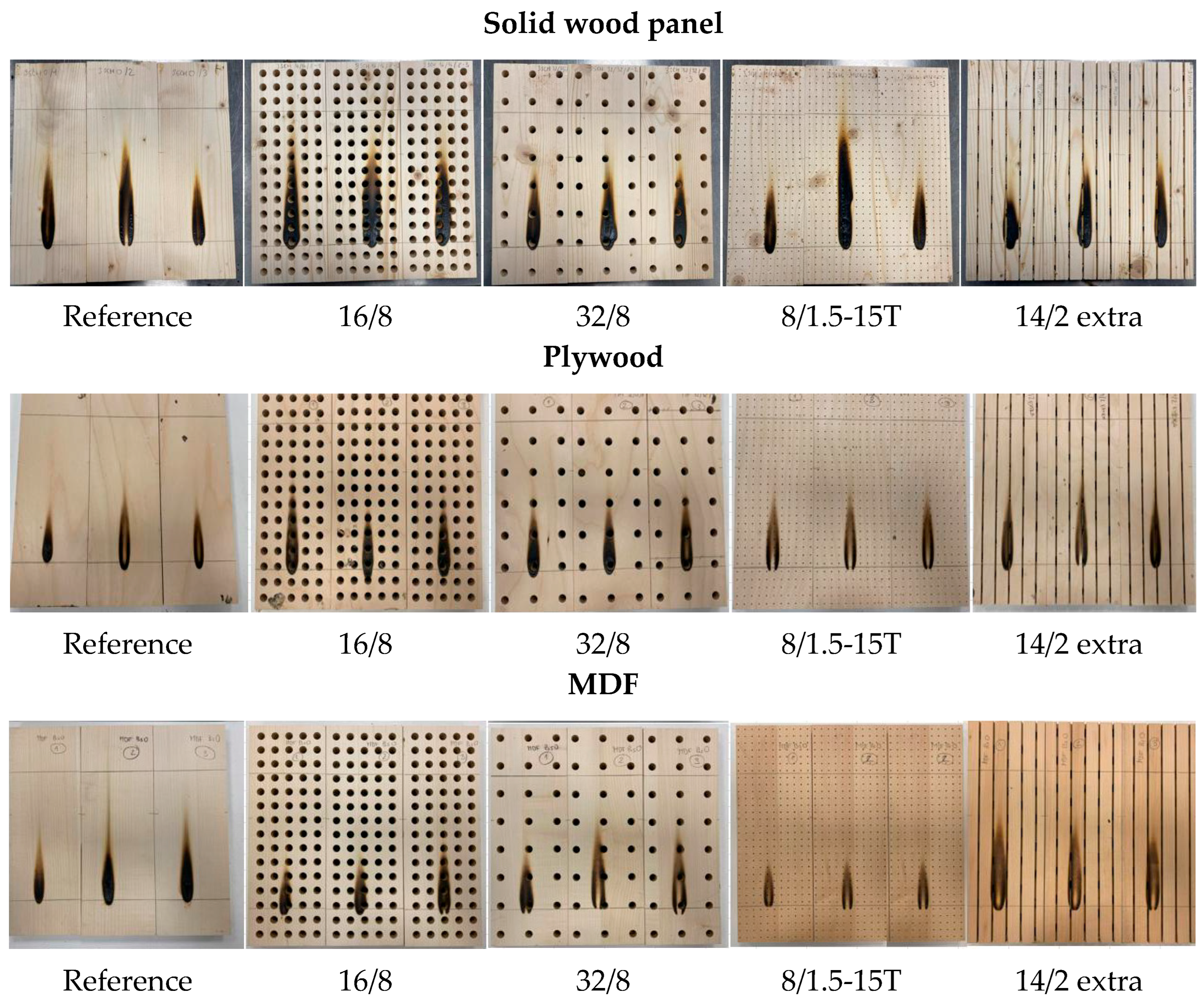

3.2. Single-Flame Source

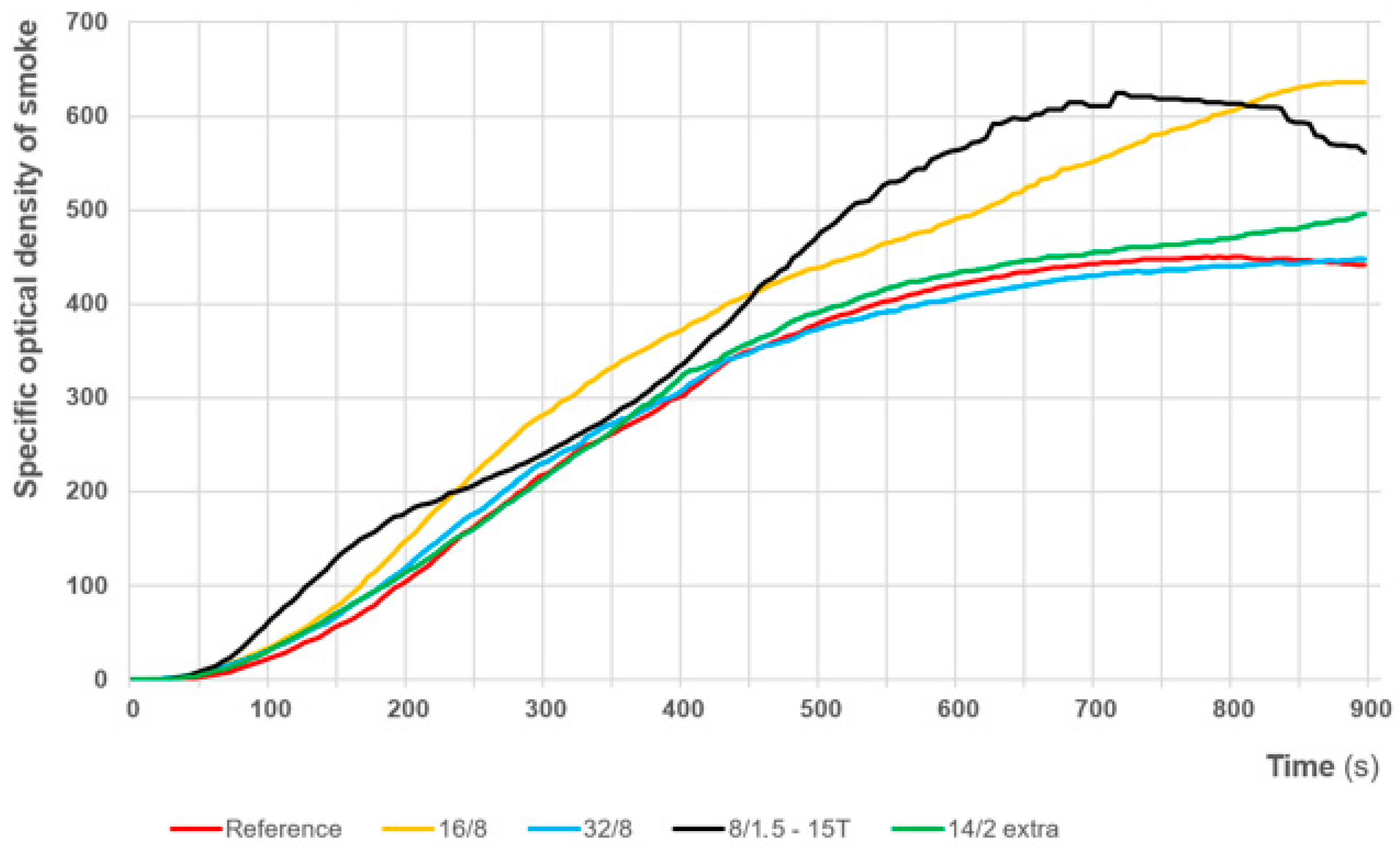

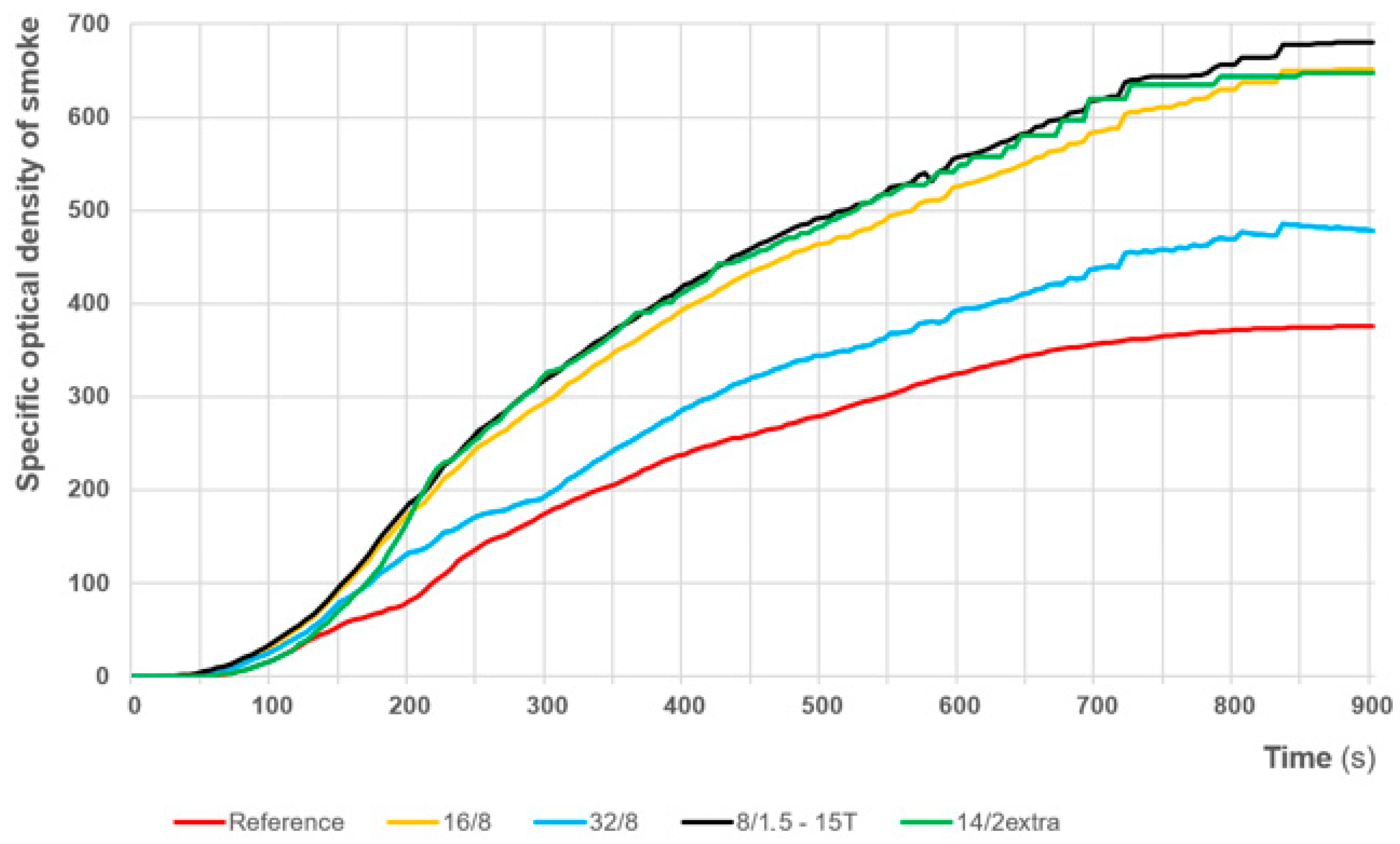

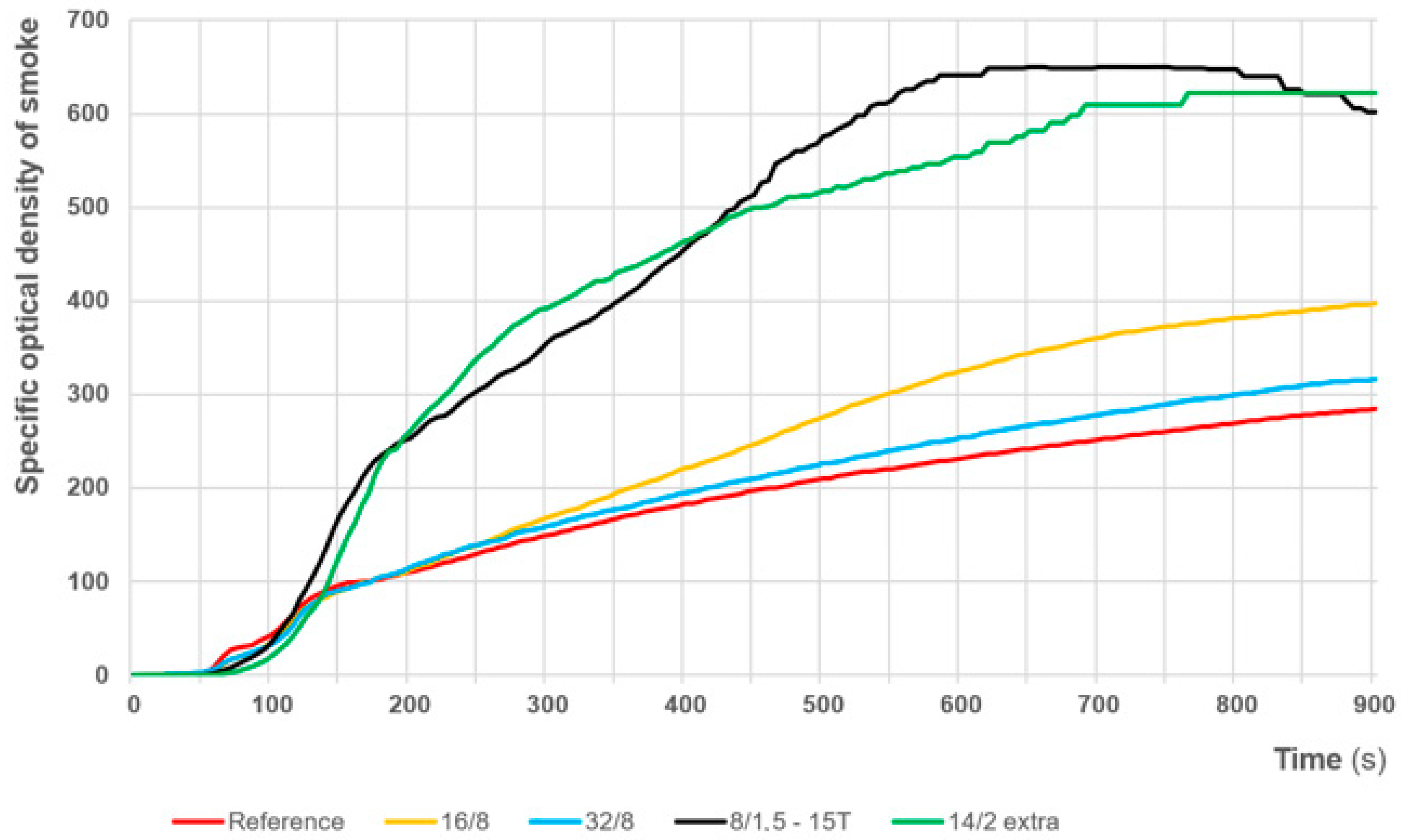

3.3. Smoke Generation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alao, P.F.; Dembovski, K.H.; Rohumaa, A.; Ruponen, J.; Kers, J. The Effect of Birch (Betula pendula Roth) Face Veneer Thickness on the Reaction to Fire Properties of Fire-Retardant Treated Plywood. Constr. Build. Mater. 2024, 426, 136242. [Google Scholar] [CrossRef]

- Kartal, S.N.; Green, F. Decay and Termite Resistance of Medium Density Fiberboard (MDF) Made from Different Wood Species. Int. Biodeterior. Biodegrad. 2003, 51, 29–35. [Google Scholar] [CrossRef]

- Li, K.; Pau, D.; Wang, J.; Ji, J. Modelling Pyrolysis of Charring Materials: Determining Flame Heat Flux Using Bench-Scale Experiments of Medium Density Fibreboard (MDF). Chem. Eng. Sci. 2015, 123, 39–48. [Google Scholar] [CrossRef]

- Krzysik, A.M.; Muehl, J.H.; Youngquist, J.A.; Franca, F.S. Medium Density Fiberboard Made from Eucalyptus saligna. For. Prod. J. 2001, 51, 47–50. [Google Scholar]

- Ab Latib, H.; Choon Liat, L.; Ratnasingam, J.; Law, E.L.; Abdul Azim, A.A.; Mariapan, M.; Natkuncaran, J. Suitability of Paulownia Wood from Malaysia for Furniture Application. BioResources 2020, 15, 4727–4737. [Google Scholar] [CrossRef]

- Barbu, M.C.; Radauer, H.; Petutschnigg, A.; Tudor, E.M.; Kathriner, M. Lightweight Solid Wood Panels Made of Paulownia Plantation Wood. Appl. Sci. 2023, 13, 11234. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Singh, J.; Singh, S.; Singh, G. Emerging Progressive Developments in the Fibrous Composites for Acoustic Applications. J. Manuf. Process. 2023, 102, 443–477. [Google Scholar] [CrossRef]

- Lashgari, M.; Taban, E.; SheikhMozafari, M.J.; Soltani, P.; Attenborough, K.; Khavanin, A. Wood Chip Sound Absorbers: Measurements and Models. Appl. Acoust. 2024, 220, 109963. [Google Scholar] [CrossRef]

- Titze, M.; Misol, M.; Monner, H.P. Examination of the Vibroacoustic Behavior of a Grid-Stiffened Panel with Applied Passive Constrained Layer Damping. J. Sound Vib. 2019, 453, 174–187. [Google Scholar] [CrossRef]

- Cucharero, J.; Hänninen, T.; Lokki, T. Influence of Sound-Absorbing Material Placement on Room Acoustical Parameters. Acoustics 2019, 1, 644–660. [Google Scholar] [CrossRef]

- Kumar Saini, M.; Kumar Bagha, A.; Kumar, S. Experimental Study to Measure the Transmission Loss of Double Panel Natural Fibers. Mater. Today Proc. 2020, 26, 482–486. [Google Scholar] [CrossRef]

- Jang, J.-Y.; Park, C.-S.; Song, K. Lightweight Soundproofing Membrane Acoustic Metamaterial for Broadband Sound Insulation. Mech. Syst. Signal Process. 2022, 178, 109270. [Google Scholar] [CrossRef]

- Lee, B.-H.; Kim, H.-S.; Kim, S.; Kim, H.-J.; Lee, B.; Deng, Y.; Feng, Q.; Luo, J. Evaluating the Flammability of Wood-Based Panels and Gypsum Particleboard Using a Cone Calorimeter. Constr. Build. Mater. 2011, 25, 3044–3050. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.-H.; Kim, S. Estimating the Fire Behavior of Wood Flooring Using a Cone Calorimeter. J. Therm. Anal. Calorim. 2012, 110, 677–683. [Google Scholar] [CrossRef]

- Jiang, X.; Li, C.; Chi, Y.; Yan, J. TG-FTIR Study on Urea-Formaldehyde Resin Residue during Pyrolysis and Combustion. J. Hazard. Mater. 2010, 173, 205–210. [Google Scholar] [CrossRef]

- Fateh, T.; Rogaume, T.; Luche, J.; Richard, F.; Jabouille, F. Characterization of the Thermal Decomposition of Two Kinds of Plywood with a Cone Calorimeter–FTIR Apparatus. J. Anal. Appl. Pyrolysis 2014, 107, 87–100. [Google Scholar] [CrossRef]

- Xu, Q.; Chen, L.; Harries, K.A.; Zhang, F.; Liu, Q.; Feng, J. Combustion and Charring Properties of Five Common Constructional Wood Species from Cone Calorimeter Tests. Constr. Build. Mater. 2015, 96, 416–427. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Mathys, Z.; Gibson, A.G. Heat Release of Polymer Composites in Fire. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1040–1054. [Google Scholar] [CrossRef]

- White, R.H.; Dietenberger, M.A. Fire Safety of Wood Construction. In Wood Handbook: Wood as an Engineering Material: Chapter 18, Centennial ed.; General Technical Report FPL-GTR-190; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; Volume 190, pp. 18.1–18.22. [Google Scholar]

- Babrauskas, V. Heat Release Rates. In SFPE Handbook of Fire Protection Engineering; Hurley, M.J., Gottuk, D., Hall, J.R., Harada, K., Kuligowski, E., Puchovsky, M., Torero, J., Watts, J.M., Wieczorek, C., Eds.; Springer: New York, NY, USA, 2016; pp. 799–904. [Google Scholar]

- Bekhta, P.; Bryn, O.; Sedliačik, J.; Novák, I. Effect of Different Fire Retardants on Birch Plywood Properties. Acta Fac. Xylologiae Zvolen 2016, 58, 59−66. [Google Scholar] [CrossRef]

- Grexa, O.; Horváthová, E.; Bešinová, O.; Lehocký, P. Flame Retardant Treated Plywood. Polym. Degrad. Stab. 1999, 64, 529–533. [Google Scholar] [CrossRef]

- Platon, L.I. Energy and Environmental Efficiency of Contemporary Interior Design under Geoclimatic Changes. Art Des. 2024, 2, 54–64. [Google Scholar] [CrossRef]

- Wade, C.; Baker, G. Fire Hazard Assessment of Wall and Ceiling Fire Spread in Rooms. In Flammability Testing of Materials Used in Construction, Transport and Mining; Woodhead Publishing: Cambridge, UK, 2022; pp. 127–156. [Google Scholar]

- ČSN EN 13501-1; Fire Classification of Construction Products and Building Elements-Part 1: Classification Using Test Data from Reaction to Fire Tests. Czech Standardization Agency: Prague, Czech Republic, 2019.

- ISO 5660-1; Reaction-to-Fire Tests-Heat Release, Smoke Production and Mass Loss Rate-Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization: Geneva, Switzerland, 2015.

- ČSN EN ISO 5659-2; Plastics–Smoke Generation–Part 2: Determination of Optical Density by a Single-Chamber Test. Czech Standardization Agency: Prague, Czech Republic, 2017.

- Tsai, K.-C. Influence of Substrate on Fire Performance of Wall Lining Materials. Constr. Build. Mater. 2009, 23, 3258–3263. [Google Scholar] [CrossRef]

- Song, L.; Liu, F.; Yuan, R.; Tang, D.; Xiong, Y. Fire Safety and Flame-Retardant Property of Representative Wood-Based Composites. In Proceedings of the Fifth International Conference on Green Energy, Environment, and Sustainable Development (GEESD 2024), Mianyang, China, 28–30 June 2024; SPIE: Bellingham, WA, USA, 2024; Volume 13279, pp. 378–383. [Google Scholar]

- ISO 13061-1; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- ČSN EN ISO 11925-2; Reaction to Fire Tests–Ignitability of Products Subjected to Direct Impingement of Flame–Part 2: Single-Flame Source Test. Czech Standardization Agency: Prague, Czech Republic, 2020.

- Li, K.-Y.; Huang, X.; Fleischmann, C.; Rein, G.; Ji, J. Pyrolysis of Medium-Density Fiberboard: Optimized Search for Kinetics Scheme and Parameters via a Genetic Algorithm Driven by Kissinger’s Method. Energy Fuels 2014, 28, 6130–6139. [Google Scholar] [CrossRef]

- Lowden, L.A.; Hull, T.R. Flammability Behaviour of Wood and a Review of the Methods for Its Reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef]

- Lee, M.-K.; Park, S.-H. Effects of Thermal Thickness and Charring Properties of Solid Combustibles on Heat Release and CO Emission Characteristics. Int. J. Fire Sci. Eng. 2022, 36, 1–8. [Google Scholar] [CrossRef]

- Šejna, J.; Průšová, K.; Cábová, K.; Rušarová, S.; Wald, F. Cracks in the Charred Layer of Timber Panels: Fire Experiments and Probabilistic Solution. Case Stud. Therm. Eng. 2025, 74, 106788. [Google Scholar] [CrossRef]

- Anca-Couce, A.; Dieguez-Alonso, A.; Zobel, N.; Berger, A.; Kienzl, N.; Behrendt, F. Influence of Heterogeneous Secondary Reactions during Slow Pyrolysis on Char Oxidation Reactivity of Woody Biomass. Energy Fuels 2017, 31, 2335–2344. [Google Scholar] [CrossRef]

- Liu, B.; Fan, Q.; Wu, W.; Hu, Y. Structure and Reactivity of Rice Husk Chars under Different Bulk Densities. BioResources 2019, 14, 8289–8303. [Google Scholar] [CrossRef]

- Hostikka, S.; Matala, A. Pyrolysis Model for Predicting the Heat Release Rate of Birch Wood. Combust. Sci. Technol. 2017, 189, 1373–1393. [Google Scholar] [CrossRef]

- Gabriel, G.F. Volatile Chemical Component Differences between Fully and Partially Dried Merbau (Intsia sp.) Wood Using Gas Chromatography-Mass Spectrometry (GC-MS) in Malaysia. J. Sains Kesihat. Malays. (Malays. J. Health Sci.) 2019, 17, 85–97. [Google Scholar]

- Morrisset, D.; Hadden, R.M.; Bartlett, A.I.; Law, A.; Emberley, R. Time Dependent Contribution of Char Oxidation and Flame Heat Feedback on the Mass Loss Rate of Timber. Fire Saf. J. 2021, 120, 103058. [Google Scholar] [CrossRef]

- Kim, S.-C.; Nam, D.-G. Fire Characteristics of Flaming and Smoldering Combustion of Wood Combustibles Considering Thickness. Fire Sci. Eng. 2015, 29, 67–72. [Google Scholar] [CrossRef][Green Version]

- Sanned, E.; Mensah, R.A.; Försth, M.; Das, O. The Curious Case of the Second/End Peak in the Heat Release Rate of Wood: A Cone Calorimeter Investigation. Fire Mater. 2023, 47, 498–513. [Google Scholar] [CrossRef] [PubMed]

- Drysdale, D. An Introduction to Fire Dynamics, 3rd ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2011. [Google Scholar]

- Peng, L.; Wang, H.; Zhang, H.; Xin, Z.; Ke, D.; Lei, Z.; Ye, Q. Study of the Effect of Hole Defects on Wood Heat Transfer Based on Infrared Thermography. Int. J. Therm. Sci. 2023, 191, 108295. [Google Scholar] [CrossRef]

- Narang, A.; Kumar, R.; Dhiman, A.K.; Pandey, R.S.; Sharma, P.K. Study on the Influence of Vent Area on Porosity-Controlled Wood Crib Compartment Fires Prior to Flashover. J. Struct. Fire Eng. 2023, 15, 177–191. [Google Scholar] [CrossRef]

- Frangi, A.; Fontana, M.; Schleifer, V. Fire Behaviour of Timber Surfaces with Perforations. Fire Mater. 2005, 29, 127–146. [Google Scholar] [CrossRef]

- Couto, D.L.P.; Fonseca, E.M.M.; Piloto, P.A.G.; Meireles, J.M.; Barreira, L.M.S.; Ferreira, D.R.S.M. Perforated Cellular Wooden Slabs under Fire: Numerical and Experimental Approaches. J. Build. Eng. 2016, 8, 218–224. [Google Scholar] [CrossRef]

- Fonseca, E.; Meireles, J.; Piloto, P.; Ferreira, D. Fire Resistance of Wooden Cellular Slabs with Rectangular Perforations. In Proceedings of the IFireSS—International Fire Safety Symposium, Coimbra, Portugal, 20–22 April 2015; University of Coimbra: Coimbra, Portugal. [Google Scholar]

- Zhang, Z.; Ding, P.; Wang, S.; Huang, X. Smouldering-to-Flaming Transition on Wood Induced by Glowing Char Cracks and Cross Wind. Fuel 2023, 352, 129091. [Google Scholar] [CrossRef]

- Friquin, K.L. Material Properties and External Factors Influencing the Charring Rate of Solid Wood and Glue-Laminated Timber. Fire Mater. 2011, 35, 303–327. [Google Scholar] [CrossRef]

- Haddad, D.; Fonseca, E.M.M.; Lamri, B. Thermal Model for Charring Rate Calculation in Wooden Cellular Slabs under Fire. In Proceedings of the 7th International Conference on Safety and Durability of Structures ICOSADOS, Vila Real, Portugal, 10–12 May 2016; Universidade de Trás-os-Montes e Alto Douro: Vila Real, Portugal, 2016; Volume 7, p. 8. [Google Scholar]

- Lin, C.-F.; Zhang, C.; Karlsson, O.; Martinka, J.; Mantanis, G.I.; Rantuch, P.; Jones, D.; Sandberg, D. Phytic Acid-Silica System for Imparting Fire Retardancy in Wood Composites. Forests 2023, 14, 1021. [Google Scholar] [CrossRef]

- Marchoubeh, M.L.; Knight, H.; Horn, G.P. A Pyrolysis-Gas Chromatography/Mass Spectrometry Study of Volatile Compounds Produced by Wood-Based Materials. Fire Mater. 2024, 48, 542–550. [Google Scholar] [CrossRef]

- Fonseca, E.M.M.; Couto, D.; Piloto, P.A.G. Fire Safety in Perforated Wooden Slabs: A Numerical Approach. In Proceedings of the 5th International Conference on Safety and Security Engineering, Rome, Italy, 17–19 September 2013; WIT Press: Southampton, UK; pp. 577–584. [Google Scholar]

- Martinka, J.; Mantanis, G.I.; Lykidis, C.; Antov, P.; Rantuch, P. The Effect of Partial Substitution of Polyphosphates by Aluminium Hydroxide and Borates on the Technological and Fire Properties of Medium Density Fibreboard. Wood Mater. Sci. Eng. 2022, 17, 720–726. [Google Scholar] [CrossRef]

- Janssens, M. Calorimetry. In SFPE Handbook of Fire Protection Engineering; Hurley, M.J., Gottuk, D., Hall, J.R., Harada, K., Kuligowski, E., Puchovsky, M., Torero, J., Watts, J.M., Wieczorek, C., Eds.; Springer: New York, NY, USA, 2016; pp. 905–951. [Google Scholar]

- Ira, J.; Hasalová, L.; Šálek, V.; Jahoda, M.; Vystrčil, V. Thermal Analysis and Cone Calorimeter Study of Engineered Wood with an Emphasis on Fire Modelling. Fire Technol. 2020, 56, 1099–1132. [Google Scholar] [CrossRef]

- Xu, B.; Chen, Q.; Zhang, R.; Wang, Z. Fire Performance Comparison of Bamboo-Wood Composite and Spruce-Pine-Fir Cross-Laminated Timber Panels. Cellulose 2025, 32, 7911–7928. [Google Scholar] [CrossRef]

- Jin, E.; Chung, Y.-J. Combustive Properties of Medium Density Fibreboard (MDF) Specimens Treated with Alkylenediaminoalkyl-Bis-Phosphonic Acid Derivatives. Fire Sci. Eng. 2014, 28, 57–63. [Google Scholar] [CrossRef]

- Lee, M.; Lee, S.-M.; Kang, E.-C.; Son, D.-W. Combustibility and Characteristics of Wood-Fiber Insulation Boards Prepared with Four Different Adhesives. BioResources 2019, 14, 6316–6330. [Google Scholar] [CrossRef]

- Gałaj, J.; Gruszczyński, P. Analysis of Ignitability and Combustion Rate of Selected Interior Furnishing Materials. Zesz. Nauk. SGSP/Szkoła Główna Służby Pożarniczej 2024, 1, 59–74. [Google Scholar] [CrossRef]

- Franke, T.; Volkmer, T. Thermal Behaviour and Reaction to Fire of Three Various Hardwood Species Mineralized with Calcium Oxalate. In Proceedings of the 10th European Conference on Wood Modification, Nancy, France, 25–26 April 2022; Université de Lorraine: Nancy, France, 2022; p. 125. [Google Scholar]

- Gašpercová, S.; Osvaldová, L.M. Influence of Surface Treatment of Wood to the Flame Length and Weight Loss under Load Single-Flame Source. Key Eng. Mater. 2017, 755, 353–359. [Google Scholar] [CrossRef]

- Chanda, A.; Kim, N.K.; Wijaya, W.; Bhattacharyya, D. Fire Reaction of Sandwich Panels with Corrugated and Honeycomb Cores Made from Natural Materials. J. Sandw. Struct. Mater. 2021, 23, 4196–4217. [Google Scholar] [CrossRef]

- Kmet’ová, E.; Zachar, M.; Kačíková, D. The Progressive Test Method for Assessing the Thermal Resistance of Spruce Wood. Acta Fac. Xylologiae Zvolen Res. Publica Slovaca 2022, 64, 29–36. [Google Scholar]

- Awad, A. Effect of Fire Retardant Painting Product on Smoke Optical Density of Burning Natural Wood Samples. World Acad. Sci. Eng. Technol. Int. J. Electr. Comput. Energetic Electron. Commun. Eng. 2020, 11, 1028–1037. [Google Scholar]

- Tissot, J.; Talbaut, M.; Yon, J.; Coppalle, A.; Bescond, A. Spectral Study of the Smoke Optical Density in Non-Flaming Condition. Procedia Eng. 2013, 62, 821–828. [Google Scholar] [CrossRef]

- Jaskolowski, W.; Łukaszek-Chmielewska, A.; Ogrodnik, P.; Sobczak, T. Evaluation of Maximum Specific Optical Density for Selected Wood Based Materials Using PN-EN ISO 5659:2017 Method. Ann. Wars. Univ. Life Sci.–SGGW 2017, 100, 18–22. [Google Scholar]

- Park, H.-J.; Jian, H.; Wen, M.; Jo, S.-U. Toxic Gas and Smoke Generation and Flammability of Flame-Retardant Plywood. Polymers 2024, 16, 507. [Google Scholar] [CrossRef] [PubMed]

- Varada Rajulu, C.K.; Nandanwar, A.; Chandroji Rao, K. Evaluation of Smoke Density on Combustion of Wood Based Panel Products. Int. J. Mater. Chem. 2013, 2, 225–228. [Google Scholar] [CrossRef][Green Version]

- Półka, M.; Białek, J. The Smoke Emission Properties of Selected Elements of Furnishing Apartments in the Building. In Proceedings of the 13th International Scientific Conference “Modern Building Materials, Structures and Techniques”, Vilnius, Lithuania, 16–17 May 2019; Vilnius Gediminas Technical University: Vilnius, Lithuania, 2019. [Google Scholar]

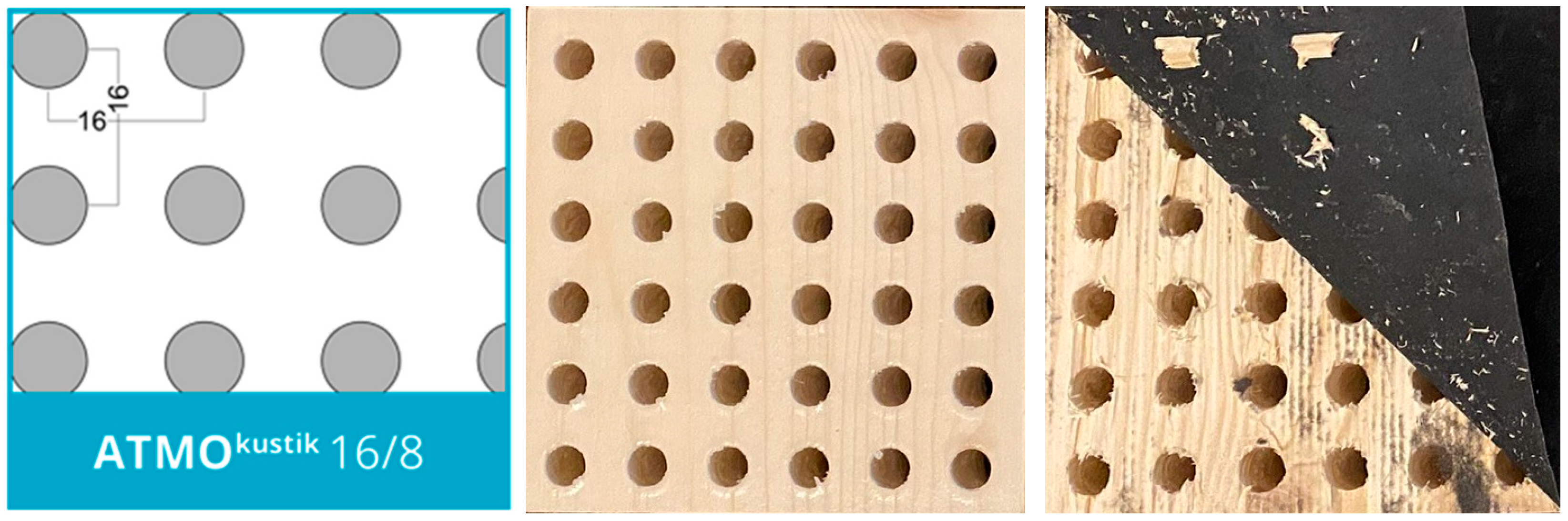

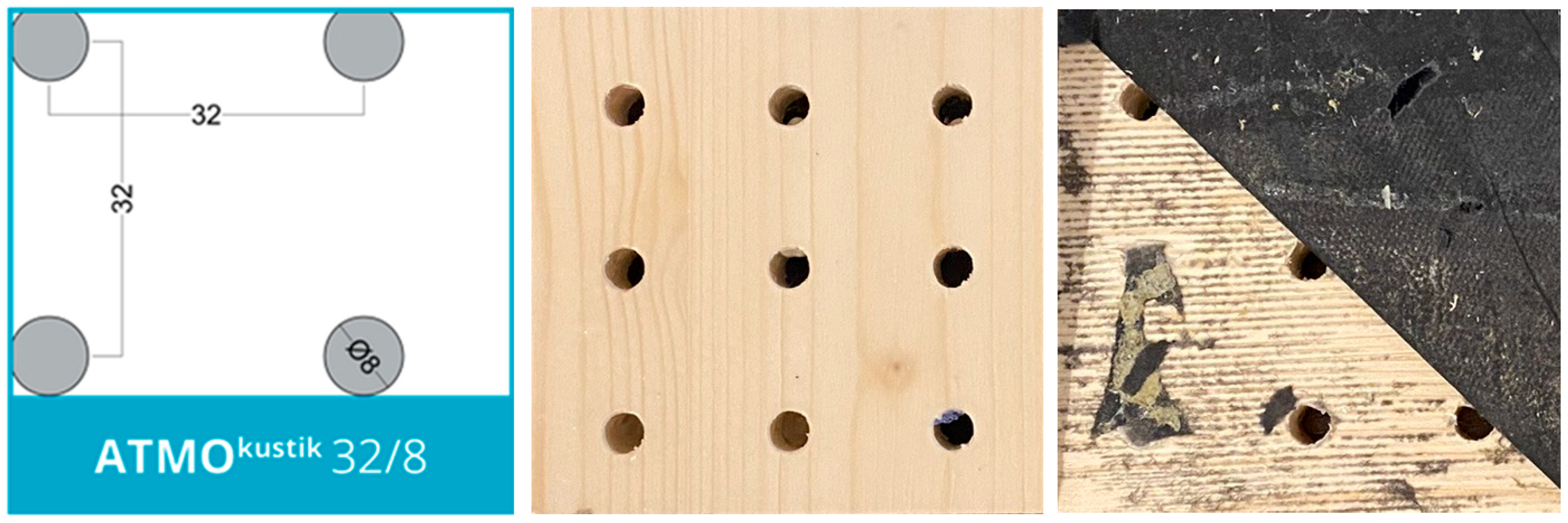

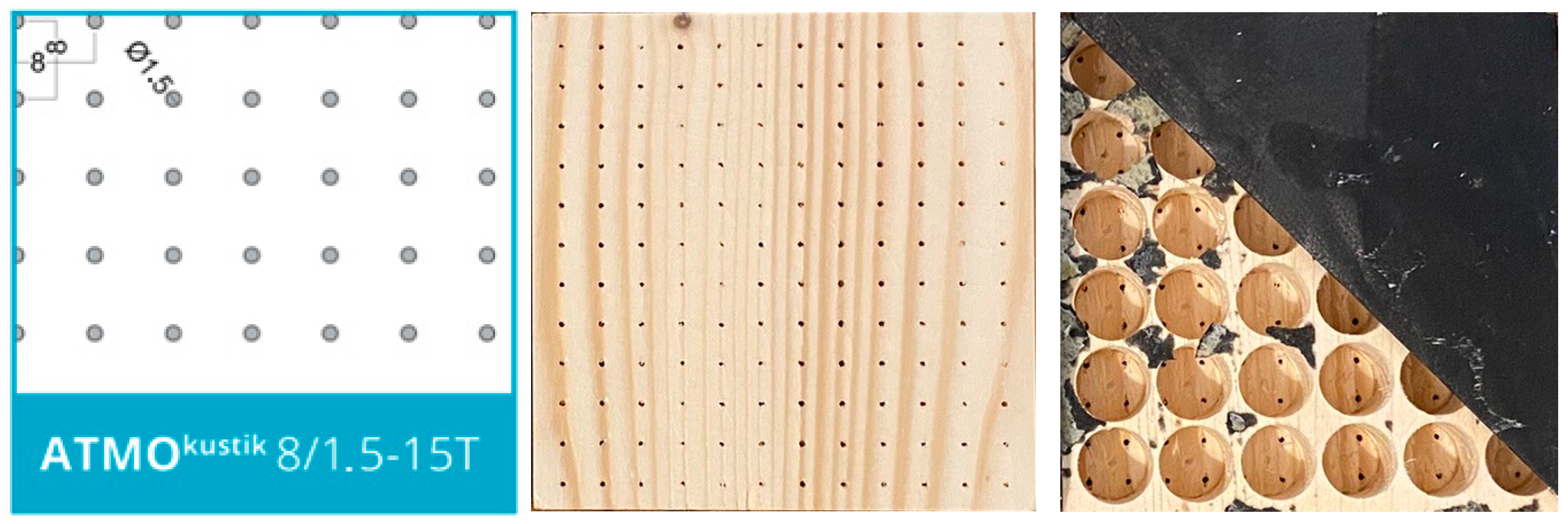

| Acoustic Surface Treatment | No. of Holes/ Grooves per Sample | Sample Surface [cm2] | Flat Surface [cm2] | Hollow Surface [cm2] | Difference [%] | Flat Surface After 5 mm Burning [cm2] | Hollow Surface After 5 mm Burning [cm2] | Difference After 5 mm Burning [%] |

|---|---|---|---|---|---|---|---|---|

| Reference | 0 | 100.00 | 100.00 | 0.00 | 0.00 | 100.00 | 0.00 | 0.00 |

| 16/8 mm | 36 | 100.00 | 81.91 | 18.09 | 22.08 | 81.91 | 18.09 | 22.08 |

| 32/8 mm | 9 | 100.00 | 95.48 | 4.52 | 4.74 | 95.48 | 4.52 | 4.74 |

| 8/1.5–15T | 144 | 100.00 | 89.83 | 10.17 | 11.33 | 36.42 | 63.58 | 174.61 |

| 14/2 extra | 18/6 | 100.00 | 88.00 | 12.00 | 13.64 | 88.55 | 11.45 | 12.92 |

| Primary Material | Acoustic Surface Treatment | Mean Starting Weight [g] | Mean Weight After Burning [g] | Unburned Fraction of Starting Weight [%] | Mass Loss [g/m2] |

|---|---|---|---|---|---|

| Solid wood panel | Reference | 85.7 | 8.12 | 9.47 | 7852 |

| 16/8 mm | 64.2 | 3.4 | 5.30 | 6015 | |

| 32/8 mm | 81.8 | 8.29 | 10.13 | 7416 | |

| 8/1.5–15T | 43.2 | 2.5 | 5.79 | 4322 | |

| 14/2 extra | 80.2 | 7.17 | 8.94 | 7339 | |

| Plywood | Reference | 118.2 | 16.75 | 14.17 | 10,255 |

| 16/8 mm | 95.1 | 14.59 | 15.34 | 8201 | |

| 32/8 mm | 113.1 | 17.64 | 15.60 | 9709 | |

| 8/1.5–15T | 58.9 | 3.66 | 6.21 | 5656 | |

| 14/2 extra | 130.1 | 17.31 | 13.31 | 8732 | |

| MDF | Reference | 133.8 | 45.8 | 34.23 | 8984 |

| 16/8 mm | 105.7 | 31.28 | 29.59 | 7610 | |

| 32/8 mm | 128.4 | 40.56 | 31.59 | 8983 | |

| 8/1.5–15T | 56.2 | 2.51 | 4.47 | 5452 | |

| 14/2 extra | 100.7 | 14.37 | 14.27 | 8764 |

| Primary Material of Acoustic Panel | Acoustic Surface Treatment | HRR (kW/m2) | MLR (g/m2s) | MARHE (kW/m2) | EHC (MJ/kg) | TTI (s) | |

|---|---|---|---|---|---|---|---|

| Solid wood panel | Reference | Mean | 237.87 | 4.57 | 109.17 | 18.80 | 75.33 |

| SD | 14.35 | 0.15 | 11.16 | 1.88 | 2.52 | ||

| 16/8 mm | Mean | 283.67 | 3.50 | 168.57 | 34.39 | 76.00 | |

| SD | 35.40 | 0.20 | 9.65 | 3.91 | 2.65 | ||

| 32/8 mm | Mean | 218.13 | 4.30 | 133.70 | 35.05 | 77.67 | |

| SD | 6.30 | 0.10 | 9.40 | 1.49 | 2.31 | ||

| 8/1.5–15T | Mean | 317.50 | 2.50 | 153.20 | 44.86 | 81.00 | |

| SD | 57.30 | 0.10 | 11.53 | 4.96 | 3.00 | ||

| 14/2 extra | Mean | 292.47 | 4.23 | 157.83 | 36.35 | 81.33 | |

| SD | 23.55 | 0.21 | 5.78 | 3.72 | 4.16 | ||

| Plywood | Reference | Mean | 365.63 | 5.93 | 161.03 | 29.15 | 79.33 |

| SD | 27.20 | 0.15 | 13.23 | 3.43 | 2.08 | ||

| 16/8 mm | Mean | 595.03 | 4.73 | 235.17 | 37.45 | 81.33 | |

| SD | 38.22 | 0.29 | 18.13 | 3.16 | 1.15 | ||

| 32/8 mm | Mean | 411.70 | 5.63 | 202.50 | 42.25 | 83.67 | |

| SD | 13.06 | 0.06 | 5.20 | 7.04 | 2.08 | ||

| 8/1.5–15T | Mean | 481.80 | 3.30 | 197.37 | 35.25 | 81.33 | |

| SD | 44.48 | 0.30 | 2.85 | 3.42 | 1.53 | ||

| 14/2 extra | Mean | 537.63 | 5.23 | 225.43 | 43.54 | 81.67 | |

| SD | 8.32 | 0.12 | 4.48 | 3.41 | 1.15 | ||

| MDF | Reference | Mean | 156.57 | 5.20 | 56.77 | 16.38 | 78.67 |

| SD | 23.38 | 0.10 | 3.99 | 1.56 | 0.58 | ||

| 16/8 mm | Mean | 185.63 | 4.40 | 53.50 | 25.89 | 80.33 | |

| SD | 32.87 | 0.26 | 5.75 | 4.95 | 2.08 | ||

| 32/8 mm | Mean | 169.13 | 5.30 | 43.67 | 16.44 | 77.67 | |

| SD | 8.45 | 0.26 | 3.00 | 3.07 | 1.53 | ||

| 8/1.5–15T | Mean | 460.73 | 3.20 | 210.80 | 16.69 | 88.00 | |

| SD | 43.89 | 0.10 | 4.77 | 3.68 | 1.73 | ||

| 14/2 extra | Mean | 408.75 | 5.00 | 193.00 | 29.53 | 83.50 | |

| SD | 13.45 | 0.10 | 2.30 | 2.09 | 0.50 |

| Average Height of the Charred Area [mm] | Reaching the Upper Limit of 150 mm | Flaming Combustion | Flaming Droplets/ Particles | Filter Paper Ignition | ||

|---|---|---|---|---|---|---|

| Solid wood panel | reference | 76.47 | No | No | No | No |

| 16/8 | 100.53 | No | Yes. 19s | No | No | |

| 32/8 | 80.90 | No | Yes. 18s | No | No | |

| 8/1.5–15T | 87.80 | No | No | No | No | |

| 14/2 extra | 71.17 | No | Yes. 16s | No | No | |

| Plywood | reference | 33.40 | No | No | No | No |

| 16/8 | 48.23 | No | No | No | No | |

| 32/8 | 41.60 | No | Yes. 24s | No | No | |

| 8/1.5–15T | 37.47 | No | No | No | No | |

| 14/2 extra | 67.13 | No | No | No | No | |

| MDF | reference | 54.40 | No | Yes. 23s | No | No |

| 16/8 | 47.43 | No | No | No | No | |

| 32/8 | 45.57 | No | No | No | No | |

| 8/1.5–15T | 28.05 | No | No | No | No | |

| 14/2 extra | 76.63 | No | No | No | No | |

| Solid wood panels | |||||

| Time | reference | 16/8 | 32/8 | 8/1.5–15T | 14/2 extra |

| 4 min | 148.6 | 201.6 | 163.9 | 200.1 | 150.2 |

| 10 min | 420.5 | 488.3 | 405.3 | 563.0 | 431.2 |

| Max | 450.3 | 636.2 | 447.7 | 624.5 | 496.1 |

| Plywood | |||||

| Time | reference | 16/8 | 32/8 | 8/1.5–15T | 14/2 extra |

| 4 min | 128.8 | 232.3 | 164.6 | 247.9 | 216.7 |

| 10 min | 325.7 | 526.5 | 392.9 | 557.4 | 537.3 |

| Max | 375.9 | 651.8 | 485.6 | 680.8 | 641.3 |

| MDF | |||||

| Time | reference | 16/8 | 32/8 | 8/1.5–15T | 14/2 extra |

| 4 min | 162.1 | 135.2 | 135.4 | 295.0 | 322.6 |

| 10 min | 231.9 | 325.7 | 253.9 | 641.4 | 554.3 |

| Max | 284.5 | 396.8 | 316.1 | 650.2 | 621.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Gašparík, M.; Kytka, T.; Bezděková, M. Influence of Surface Treatment of Wood-Based Acoustic Panels on Their Fire Performance. Fire 2026, 9, 67. https://doi.org/10.3390/fire9020067

Gašparík M, Kytka T, Bezděková M. Influence of Surface Treatment of Wood-Based Acoustic Panels on Their Fire Performance. Fire. 2026; 9(2):67. https://doi.org/10.3390/fire9020067

Chicago/Turabian StyleGašparík, Miroslav, Tomáš Kytka, and Monika Bezděková. 2026. "Influence of Surface Treatment of Wood-Based Acoustic Panels on Their Fire Performance" Fire 9, no. 2: 67. https://doi.org/10.3390/fire9020067

APA StyleGašparík, M., Kytka, T., & Bezděková, M. (2026). Influence of Surface Treatment of Wood-Based Acoustic Panels on Their Fire Performance. Fire, 9(2), 67. https://doi.org/10.3390/fire9020067