Effectiveness of Surface Pre-Application of Compressed Air Foam in Delaying Combustion Spread to Adjacent Buildings

Abstract

1. Introduction

2. Experimental Methods

2.1. Experimental Structure

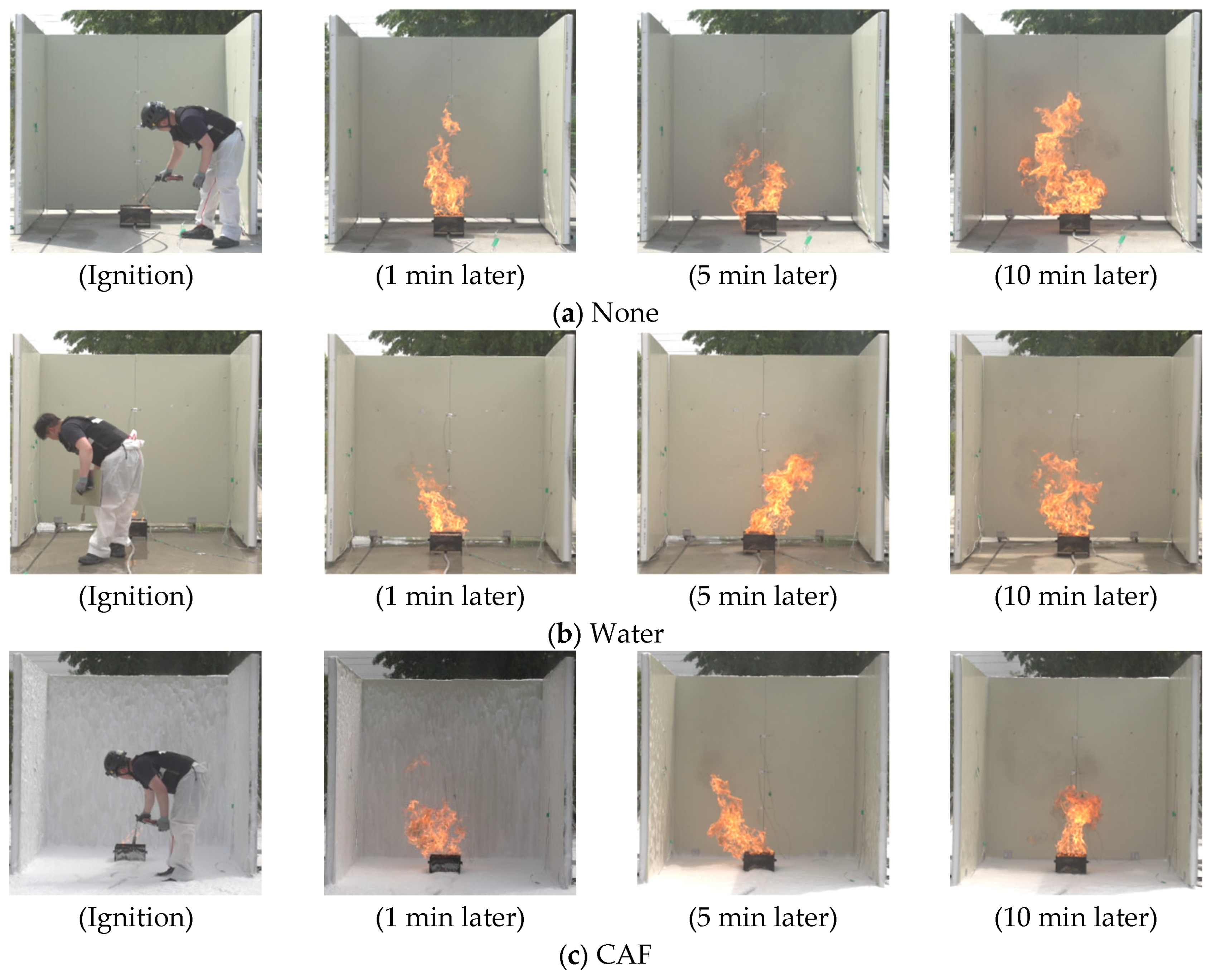

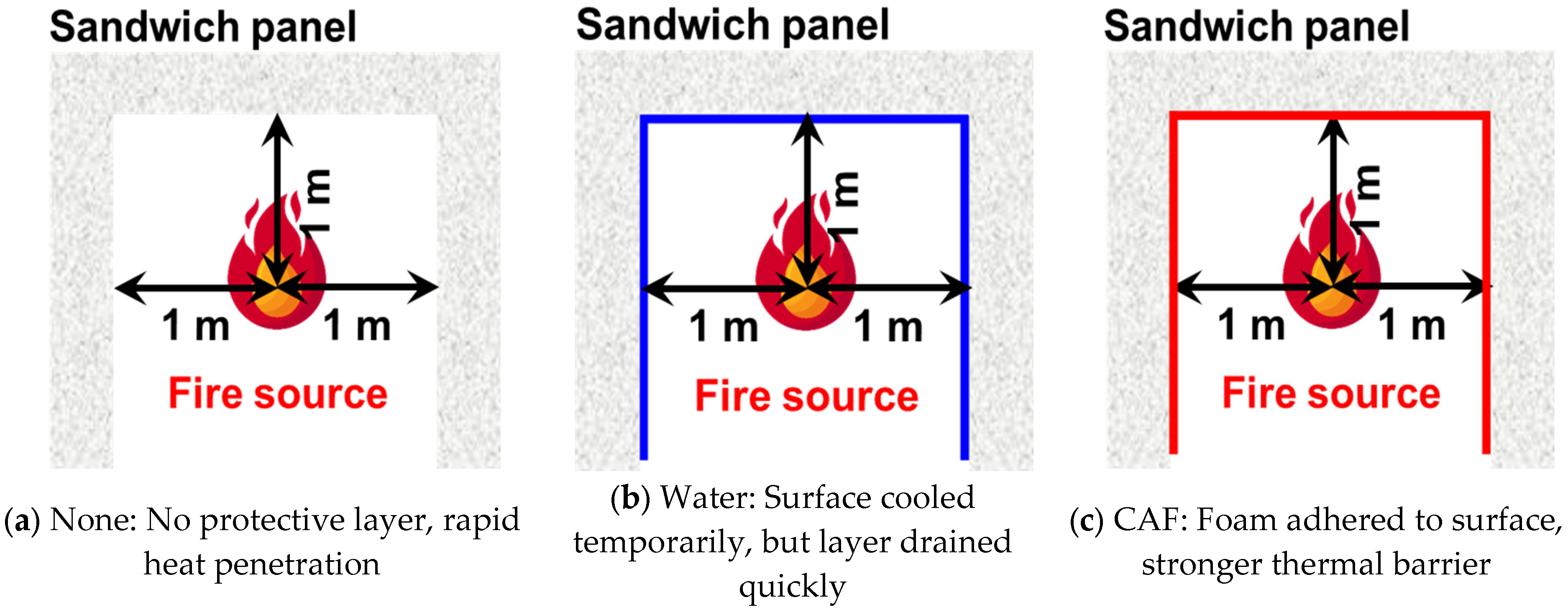

2.1.1. Pre-Experiments Structure

2.1.2. Main Experiments Structure

2.2. Experimental Procedure

2.2.1. Pre-Experiments Procedure

- Nothing pre-application at the surface: none.

- Water pre-application at the surface: water.

- Compressed air foam pre-application at surface: CAF.

2.2.2. Main Experiments Procedure

2.2.3. Limitations

3. Results

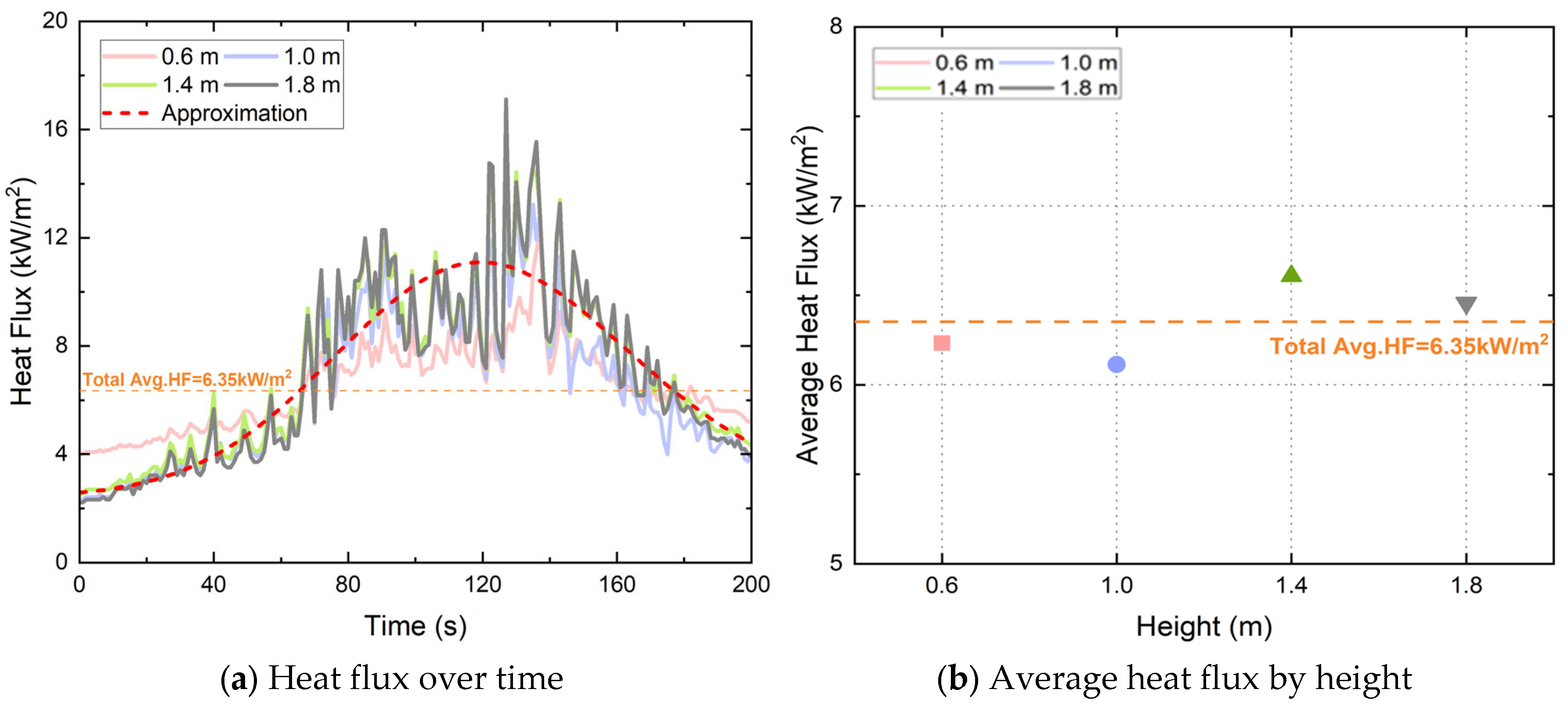

3.1. Pre-Experiments Results

3.2. Main Experiments Results

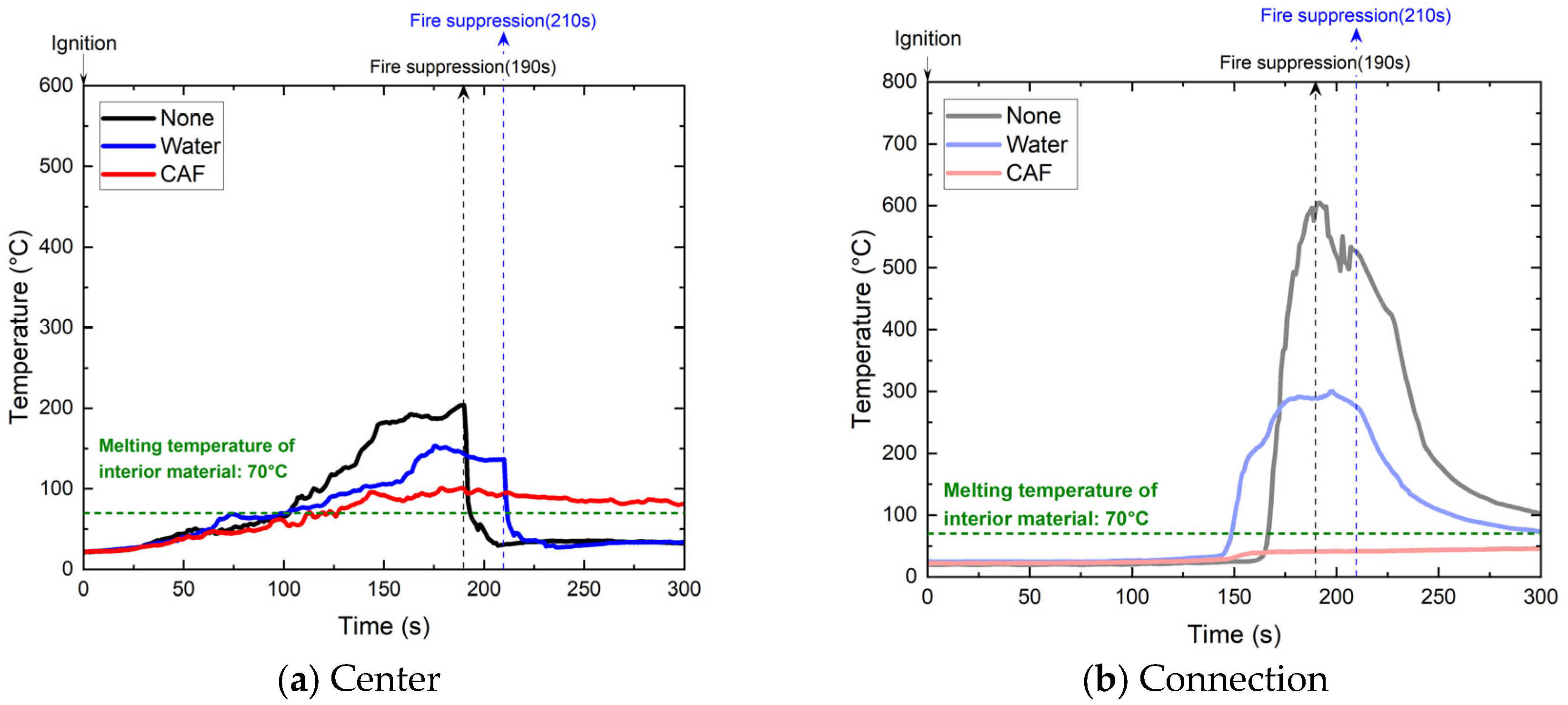

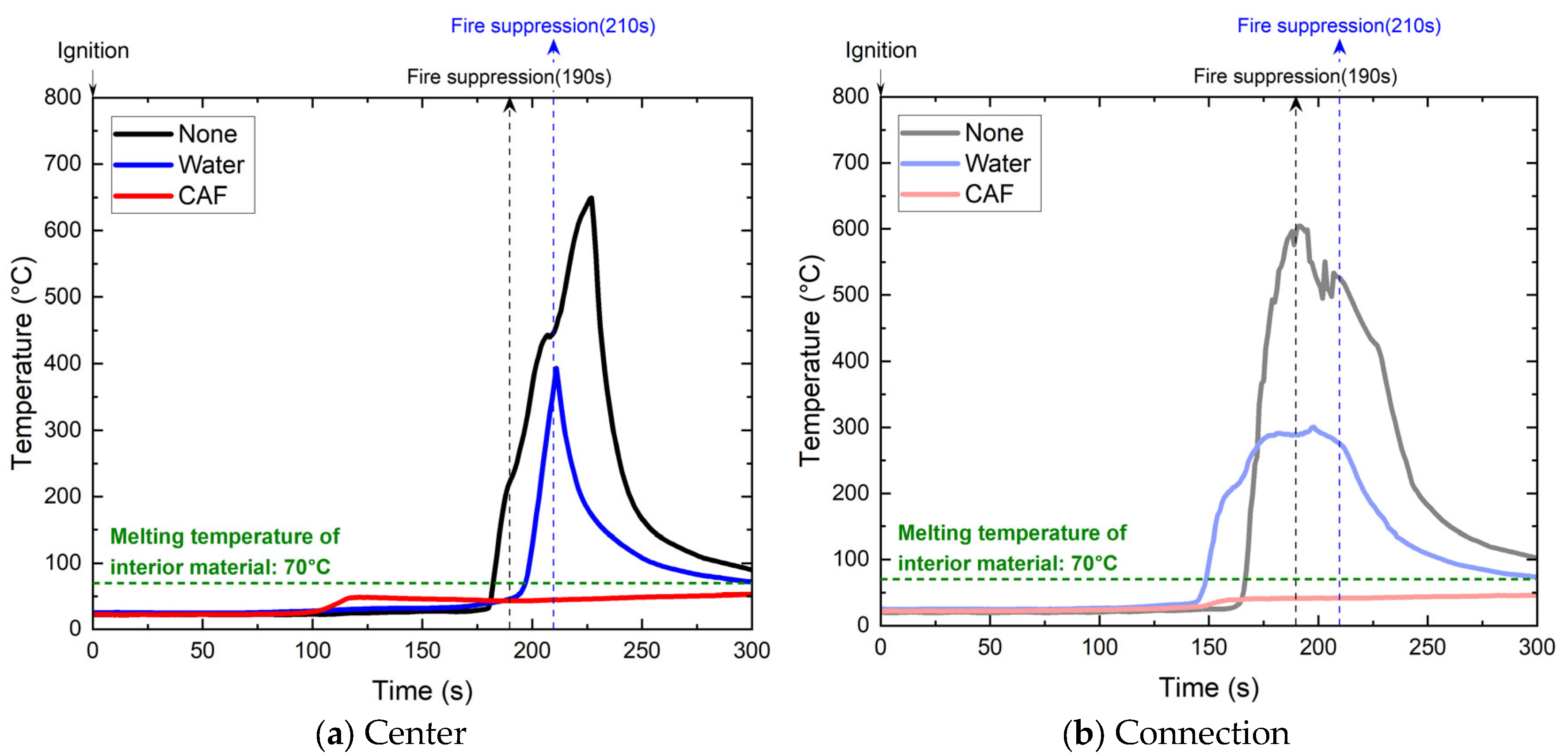

3.2.1. Surface Temperature

3.2.2. Core Temperature

3.2.3. Inner Temperature

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Glossary

- CAF, compressed air foam

- Pre-application

- Class A fire

- Heat blocking rate

- Radiant heat flux

- Connection (joint) area

- Melting point of insulation

- Dry foam (CAF application)

References

- ASM International. ASM Handbook, Volume 1: Properties and Selection—Irons, Steels, and High-Performance Alloys; ASM International: Materials Park, OH, USA, 1990. [Google Scholar] [CrossRef]

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 10th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2020; Available online: https://books.google.co.kr/books?id=dmoTEQAAQBAJ (accessed on 15 August 2025).

- Chen, J.; Hamed, E.; Gilbert, R.I. Structural Performance of Concrete Sandwich Panels under Fire. Fire Saf. J. 2021, 121, 103293. [Google Scholar] [CrossRef]

- Campbell, R.B. Structure Fires in Warehouse Properties; National Fire Protection Association, Fire Analysis and Research Division: Quincy, MA, USA, 2016; Available online: https://www.nfpa.org/education-and-research/research/nfpa-research/fire-statistical-reports/warehouse-structure-fires (accessed on 15 August 2025).

- CFPA-E. Fire Safety in Warehouses. CFPA-E Guideline No. 35. 2017. Available online: https://cfpa-e.eu/app/uploads/2022/04/CFPA_E_Guideline_No_35_2017_F.pdf (accessed on 15 August 2025).

- Kim, J.Y. Conduct Planning Research of Evacuation Improvement and Risk-Based Management for Fire Safety of Storage Facilities; Ministry of Land, Infrastructure, and Transport: Sejong, Republic of Korea, 2021; Available online: https://www.codil.or.kr/viewDtlConRpt.do?gubun=rpt&pMetaCode=OTKCRK220002 (accessed on 15 August 2025).

- Grant, G.; Brenton, J.; Drysdale, D. Fire Suppression by Water Sprays. Prog. Energy Combust. Sci. 2000, 26, 79–130. [Google Scholar] [CrossRef]

- Nam, S.W. Design & Construction of Fire Protection Systems; Sungandang: Seoul, Republic of Korea, 2018; Available online: https://www.cyber.co.kr/book/item/8480 (accessed on 15 August 2025).

- Kwon, J.-S.; Park, T.-H.; Shin, Y.M.; Lim, Y.R.; Lee, J.H. An Experimental Study on Fire Prevention in Buildings Using Emergency Extinguishing Equipment in the Presence of Flying Sparks from Wildfires. Fire Sci. Eng. 2022, 36, 114–121. [Google Scholar] [CrossRef]

- Kim, H.S.; Hwang, I.J.; Kim, Y.J. Thermal Characteristics of Fire-Protection Foams Exposed to Radiant Heating. In Proceedings of the Korean Society of Mechanical Engineers Spring and Autumn Conference, Daejon, Republic of Korea, 3–5 November 2004; Available online: https://koreascience.or.kr/article/CFKO200433239309636.page (accessed on 15 August 2025).

- Taylor, R.G. Compressed Air Foam Systems in Limited Staffing Conditions; National Fire Academy: Emmitsburg, MD, USA, 1997. Available online: https://apps.usfa.fema.gov/pdf/efop/efo27966.pdf (accessed on 15 August 2025).

- Magrabi, S.A.; Dlugogorski, B.Z.; Jameson, G.J. The Performance of Aged Aqueous Foams for Mitigation of Thermal Radiation. Dev. Chem. Eng. Miner. Process. 2000, 8, 93–112. [Google Scholar] [CrossRef]

- Boyd, C.F.; Marzo, M.D. The Behavior of a Fire-Protection Foam Exposed to Radiant Heating. Int. J. Heat Mass Transf. 1998, 41, 1719–1728. [Google Scholar] [CrossRef]

- National Fire Protection Association (NFPA). Standard for Low-, Medium-, and High Expansion Foam (NFPA 11); NFPA: Quincy, MA, USA, 2021; Available online: https://www.nfpa.org/codes-and-standards/nfpa-11-standard-development/11 (accessed on 15 August 2025).

- Feng, D.Y. Analysis on Influencing Factors of the Gas-Liquid Mixing Effect of Compressed Air Foam Systems. Procedia Eng. 2013, 52, 105–111. [Google Scholar] [CrossRef]

- Zhang, J.; Delichatsios, M.; O’Neillet, A. Assessment of Gas Cooling Capabilities of Compressed Air Foam Systems in Fuel- and Ventilation-Controlled Compartment Fires. J. Fire Sci. 2011, 29, 543–554. [Google Scholar] [CrossRef]

- Kim, T.-S.; Park, T.-H.; Park, J.-H.; Yang, J.-H.; Han, D.-H.; Lee, B.-C.; Kwon, J.-S. Thermal Characteristics of Fire Extinguishing Agents in Compartment Fire Suppression. Sci. Prog. 2024, 107, 00368504241263435. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, J.S. The Feasibility Study of Extinguishing Oil Tank Fire by Using Compressed Air Foam System. Procedia Eng. 2016, 135, 61–66. [Google Scholar] [CrossRef]

- Rappsilber, T.; Krüger, S. Design Fires with Mixed-Material Burning Cribs to Determine the Extinguishing Effects of Compressed Air Foams. Fire Saf. J. 2018, 98, 3–14. [Google Scholar] [CrossRef]

- Kim, A.K.; Crampton, G.P. Evaluation of the Fire Suppression Effectiveness of Manually Applied Compressed-Air-Foam (CAF) System. Fire Technol. 2012, 48, 549–564. [Google Scholar] [CrossRef]

- Madrzykowski, D. Study of the Ignition Inhibiting Properties of Compressed Air Foam; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1988; NISTIR 88–3880. Available online: https://www.govinfo.gov/content/pkg/GOVPUB-C13-59e80dc51906e3bbe9774e103f1170c0/pdf/GOVPUB-C13-59e80dc51906e3bbe9774e103f1170c0.pdf (accessed on 15 August 2025).

- Republic of Korea. Civil Act, Article 242: Construction near Boundary Line. 2025. Available online: https://elaw.klri.re.kr/eng_service/lawView.do?hseq=29453&lang=ENG (accessed on 15 August 2025).

- Chen, Y.; Li, X.; Wang, H.; Zhang, Y.; Liu, J. Multi-Scale Experimental Study on Properties of Compressed Air Foam and Pressure Drop in the Long-Distance Vertical Pipe. J. Build. Eng. 2024, 96, 110397. [Google Scholar] [CrossRef]

- Park, T.-H.; Park, J.-H.; Yang, J.-H.; Lee, B.-C.; Kim, T.-D.; Kim, B.-J.; Kwon, J.-S. Experiments on the Application of Class A and B Fires to Derive the Optimum Air Ratio of Compressed Air Foam Systems. Fire Sci. Eng. 2023, 37, 38–43. [Google Scholar] [CrossRef]

- Kim, A.K.; Dlugogorski, B.Z.; Mawhinney, J.R. Effect of Foam Additives on the Fire Suppression Efficiency of Water Mist. In Proceedings of the Halon Options Technical Working Conference, Albuquerque, NM, USA, 3–5 May 1994; pp. 347–358. Available online: https://www.nist.gov/system/files/documents/el/fire_research/R9402226.pdf (accessed on 15 August 2025).

- Hipkins, D.B. Class A Foam Water Sprinkler Systems; University of Canterbury: Christchurch, New Zealand, 1999; Available online: https://ir.canterbury.ac.nz/server/api/core/bitstreams/4df3b805-9337-441a-8c8c-623b6197a623/content (accessed on 15 August 2025).

- Hurley, M.J.; Gottuk, D.T.; Hall, J.R., Jr.; Harada, K.; Kuligowski, E.D.; Puchovsky, M.; Torero, J.L.; Watts, J.M., Jr.; Wieczorek, C.J. SFPE Handbook of Fire Protection Engineering, 5th ed.; Springer: New York, NY, USA, 2015; Available online: https://www.sfpe.org/publications/handbooks/sfpehandbook (accessed on 15 August 2025).

- Ahn, J.K. Technology Development Trends of Sandwich Panel Fireproof Wall for Architecture; Korea Institute of Construction Technology: Goyang-si, Republic of Korea, 2021; Available online: https://www.xn--z69aksb59ee70eilbh1mizbn16d.kr/board.es?mid=a10105070000&bid=cntrbclmn&list_no=17138 (accessed on 15 August 2025).

- Boyd, W.K.; Marzo, R.J. Evaluation of Class A Foams for Structural Firefighting. Fire Technol. 1998, 34, 123–138. [Google Scholar]

- Back, G.G.; Beyler, C.L. Flammability of Class A Foam Solution and Water Mist. Fire Saf. J. 1995, 24, 125–150. [Google Scholar]

- Lattimer, B.Y.; Trelles, J.P.; Roby, R.J. Heat Transfer from Fires to Fuel Surfaces Covered with Firefighting Foams. Fire Saf. J. 2004, 39, 241–268. [Google Scholar] [CrossRef]

| Heat Flux (kW/m2) | Damaged Equipment |

|---|---|

| 12.5 | Minimum energy required to ignite wood by flame |

| 25.0 | Minimum energy required to ignite wood through prolonged exposure without flame |

| Measurement Height (m) | Heat Blocking Rate (%) | ||

|---|---|---|---|

| None/Water * | None/CAF ** | Water/CAF *** | |

| 0.6 | 31.8 | 22.5 | (−)12.0 |

| 1.0 | 33.9 | 35.5 | 2.5 |

| 1.4 | 27.3 | 38.1 | 17.5 |

| Conditions | Average and Maximum Temperature (°C) (Time to Reach Melting Temperature [s]) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| None | Water | CAF | |||||||

| Avg. (°C) | Max. (°C) | Time (s) | Avg. (°C) | Max. (°C) | Time (s) | Avg. (°C) | Max. (°C) | Time (s) | |

| Center | 92.7 | 204.1 | 103 | 80.3 | 153.6 | 102 | 69.4 | 101.2 | 113 |

| Connection | 166.6 | 457.7 | 97 | 108.4 | 236.6 | 101 | 75.0 | 100.5 | 109 |

| Differential | 73.9 | 253.6 | 6 | 28.1 | 83.1 | 1 | 5.7 | 0.7 | 4 |

| Measurement Points | Heat Blocking Rate (%) | ||

|---|---|---|---|

| None/Water * | None/CAF ** | Water/CAF *** | |

| Center | 13.5 | 25.2 | 13.6 |

| Connection | 35.0 | 55.0 | 30.8 |

| Measurement Points | Heat Blocking Rate (%) | ||

|---|---|---|---|

| None/Water * | None/Foam ** | Water/Foam *** | |

| Center | 42.1 | 67.4 | 43.7 |

| Connection | 32.1 | 78.0 | 67.5 |

| Conditions | Average and Maximum Temperature (°C) (Time to Reach Melting Temperature [s]) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| None | Water | CAF | |||||||

| Avg. (°C) | Max. (°C) | Time (s) | Avg. (°C) | Max. (°C) | Time (s) | Avg. (°C) | Max. (°C) | Time | |

| Center | 117.7 | 649.4 | 183.0 | 68.2 | 393.4 | 197.0 | 38.4 | 53.3 | - |

| Connection | 150.7 | 604.1 | 167.0 | 102.3 | 300.4 | 149.0 | 33.2 | 46.3 | - |

| Differential | 33.0 | −45.3 | −16.0 | 34.1 | −93.0 | −48.0 | −5.2 | −7.0 | - |

| Conditions | Rate of Temperature Rise (%) * | ||

|---|---|---|---|

| None | Water | CAF | |

| Center | 110.0 | 75.4 | 57.1 |

| Connection | 103.0 | 121.7 | 58.3 |

| Average | 106.5 | 98.6 | 57.7 |

| Conditions | Initial Temperature (°C) | Maximum Temperature (°C) | Temperature Increase Rate (%) * |

|---|---|---|---|

| None | 18.6 | 27.4 | 47.2 |

| Water | 20.8 | 23.0 | 10.7 |

| CAF | 21.8 | 22.3 | 2.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.-H.; Kim, T.-S.; Park, T.-H.; Kwon, J.-S. Effectiveness of Surface Pre-Application of Compressed Air Foam in Delaying Combustion Spread to Adjacent Buildings. Fire 2025, 8, 359. https://doi.org/10.3390/fire8090359

Yang J-H, Kim T-S, Park T-H, Kwon J-S. Effectiveness of Surface Pre-Application of Compressed Air Foam in Delaying Combustion Spread to Adjacent Buildings. Fire. 2025; 8(9):359. https://doi.org/10.3390/fire8090359

Chicago/Turabian StyleYang, Ji-Hyun, Tae-Sun Kim, Tae-Hee Park, and Jin-Suk Kwon. 2025. "Effectiveness of Surface Pre-Application of Compressed Air Foam in Delaying Combustion Spread to Adjacent Buildings" Fire 8, no. 9: 359. https://doi.org/10.3390/fire8090359

APA StyleYang, J.-H., Kim, T.-S., Park, T.-H., & Kwon, J.-S. (2025). Effectiveness of Surface Pre-Application of Compressed Air Foam in Delaying Combustion Spread to Adjacent Buildings. Fire, 8(9), 359. https://doi.org/10.3390/fire8090359