Aspects Regarding the CO2 Footprint Developed by Marine Diesel Engines

Abstract

1. Introduction

- 1.

- To establish theoretical and practical methods for calculating and measuring the level of CO2 emitted by ship engines.

- 2.

- To compare the results of CO2 emission calculations based on theoretical methods with the results of real measurements.

- 3.

- To verify and assess the CO2 emission calculation methods compared to the emission measured in real conditions for diesel engines.

- 4.

- To conduct a comparative analysis of several methods for determining CO2 emissions, with the aim of obtaining much more accurate and conclusive results close to reality.

2. Literature Review

3. Materials and Methods of Research

- Determining CO2 emission mass flow rates: Establishing the mass flow rates of CO2 emissions across various sailing regimes using direct measurements.

- Analytical evaluation of CO2 emissions: Conducting analytical calculations to determine the CO2 emission mass flow rates for ship diesel engines at different working loads.

- Stoichiometric evaluation of CO2 emissions: Applying chemical equation to calculate the CO2 emission mass flow rates for reference ship diesel engines at different working loads.

- Comparison of methodologies: Analyzing the methods for determining CO2 emission mass flow rates by contrasting direct measurement results with the results obtained by the two methods: analytical and stoichiometric [16].

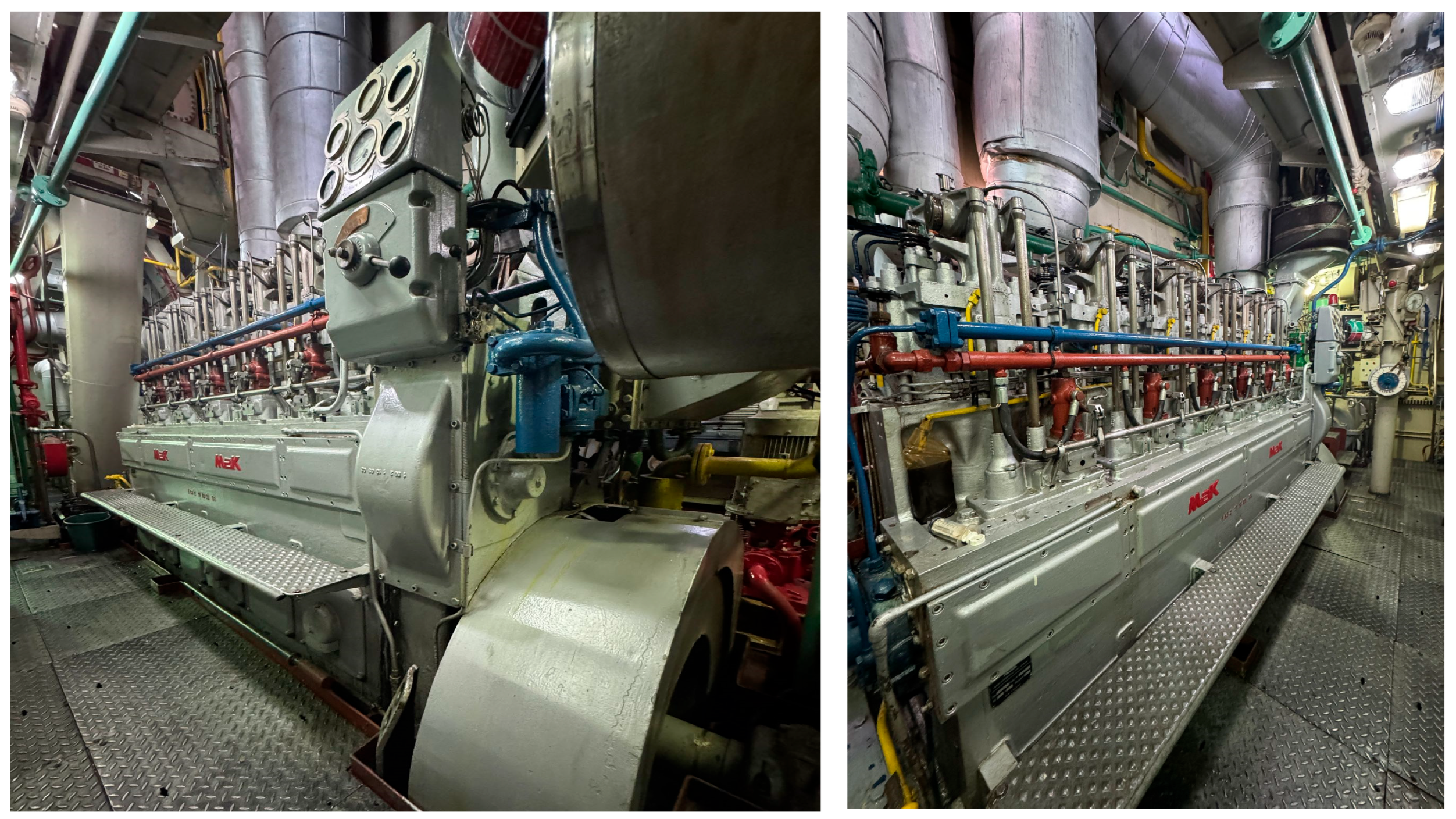

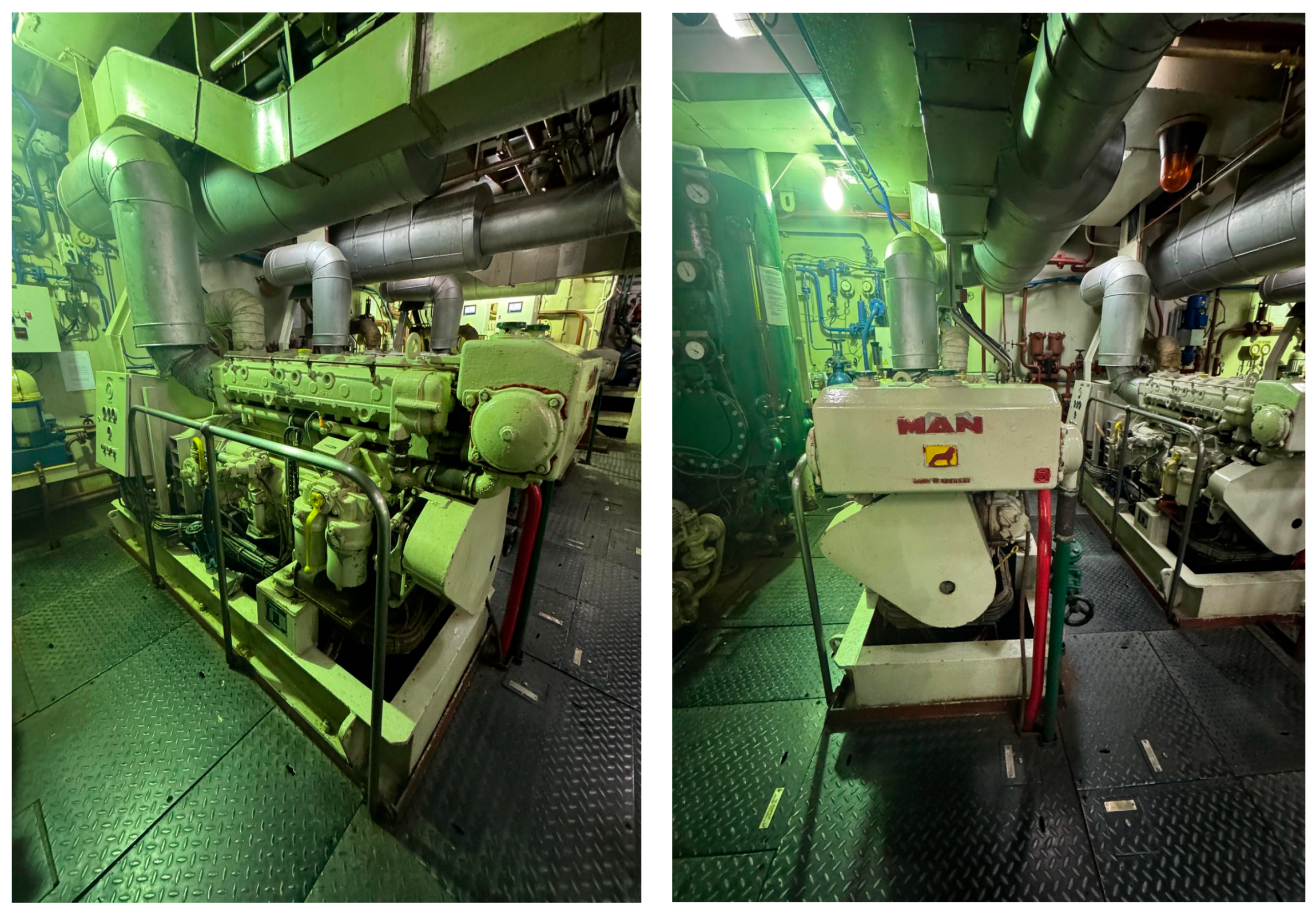

3.1. The Ship with Mechanical Equipment Onboard

- Main Engine—MAK 6 MU 451 main engine, providing the necessary power for the ship’s movement.

- Reducer (Gearbox)—Reduces the engine’s speed to an optimal level for the propeller. In this case, the speed is reduced from (main engine) 375 rpm to (propeller and shaft line) 250 rpm.

- Propeller Shaft—The shaft that transmits rotational motion from the gearbox to the propeller.

- Controllable-Pitch Propeller (CPP)—This type of propeller allows adjustment of the blade angles, optimizing propulsion efficiency based on navigation conditions and power requirements.

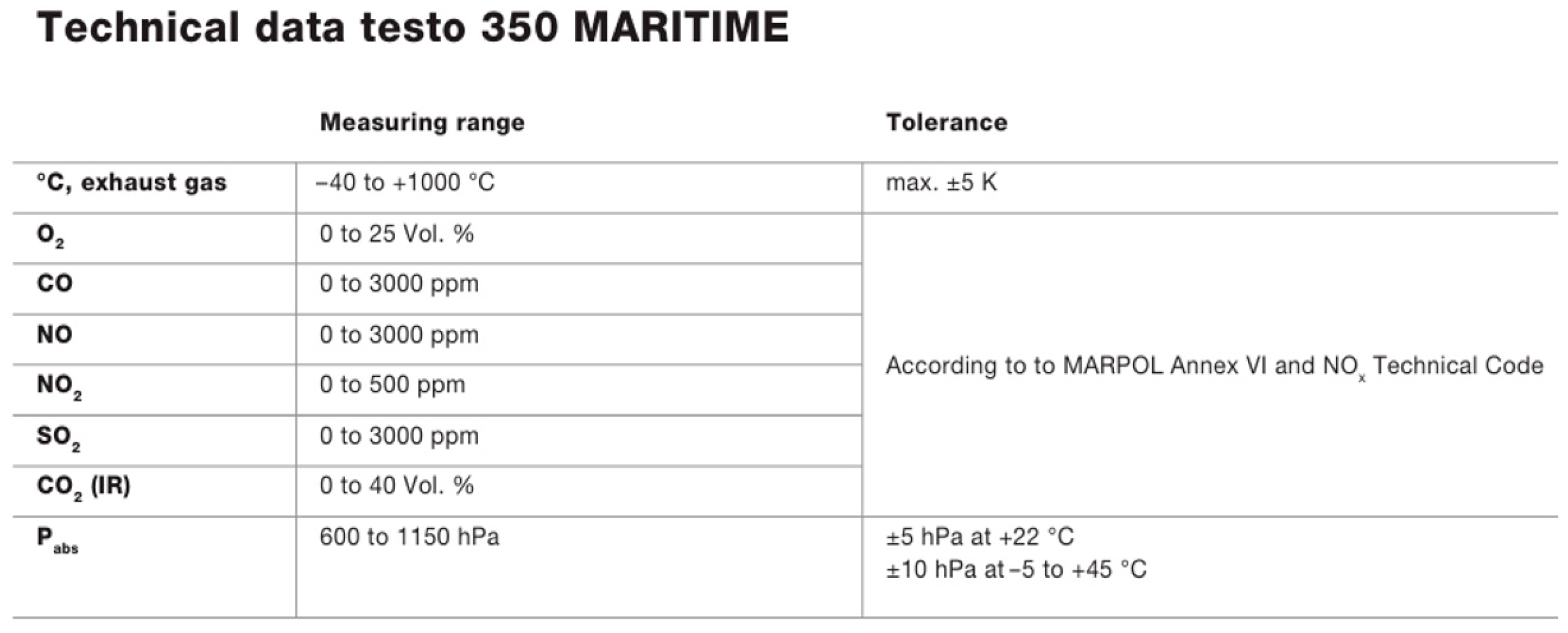

3.2. Methods of Measurements and Calculations

- The method of direct measurement of CO2 emissions (Section 4.1) use a specialized device (Figure 4) with an emission transducer mounted on the engine exhaust system. The carbon balance method (Section 3.3 and Section 4.2) is used to convert direct measurements values into mass flow rates.

- The analytical method (Section 3.4 and Section 4.3), using experimentally determined formulas, involves employing equations derived from experimental data to calculate CO2 emissions.

- The stoichiometric method (Section 3.5 and Section 4.4) for calculating the mass emissions of CO2 from the exhaust gases can be applied if the carbon content of the used fuel and the fuel consumption per hour are known.

3.3. Carbon Balance Method for Calculating Emission Masses of CO2

3.4. Analytical Method for Calculating Emission Masses of CO2

3.5. Stoichiometric Method for Calculating Emission Masses of CO2

4. Results

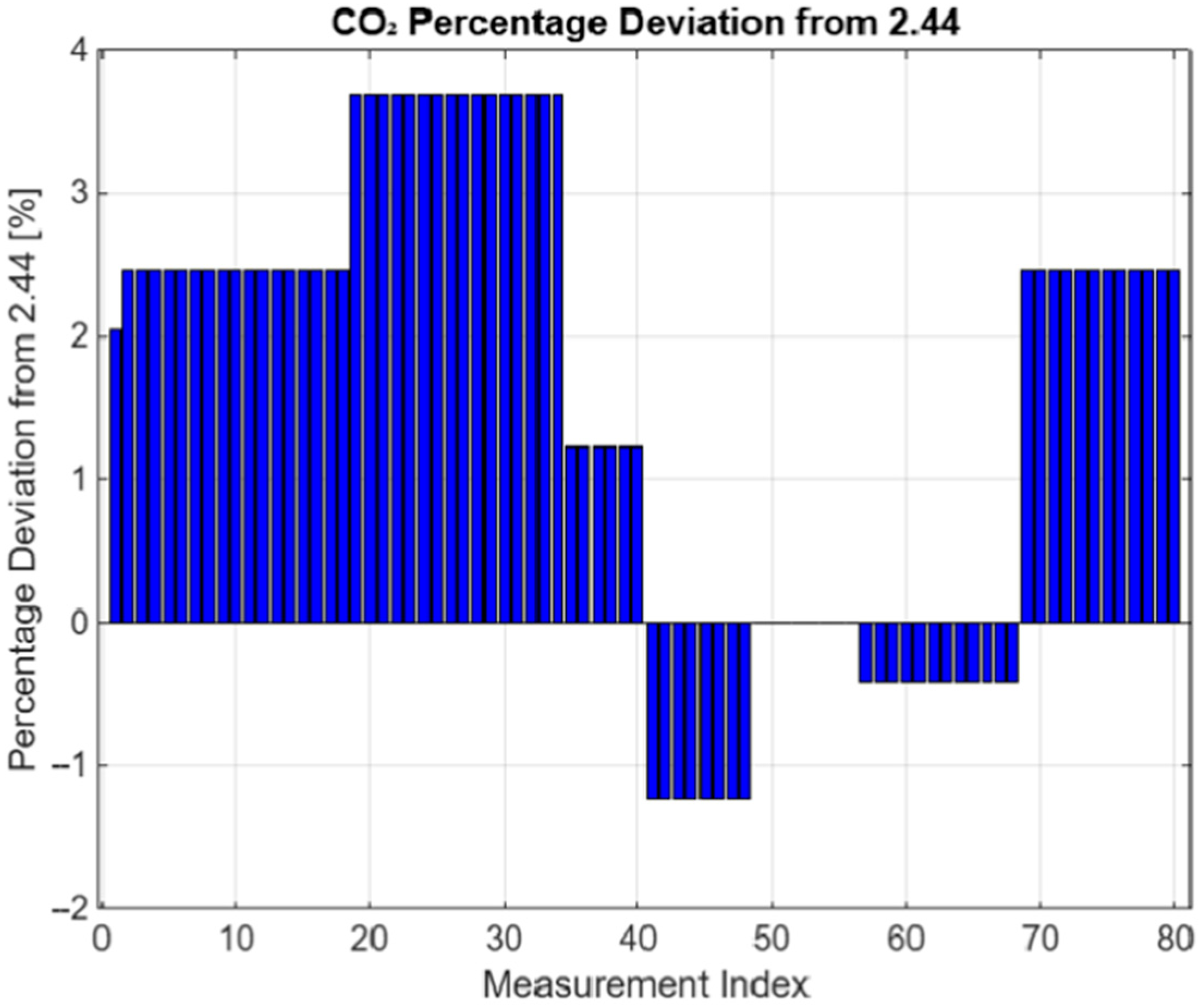

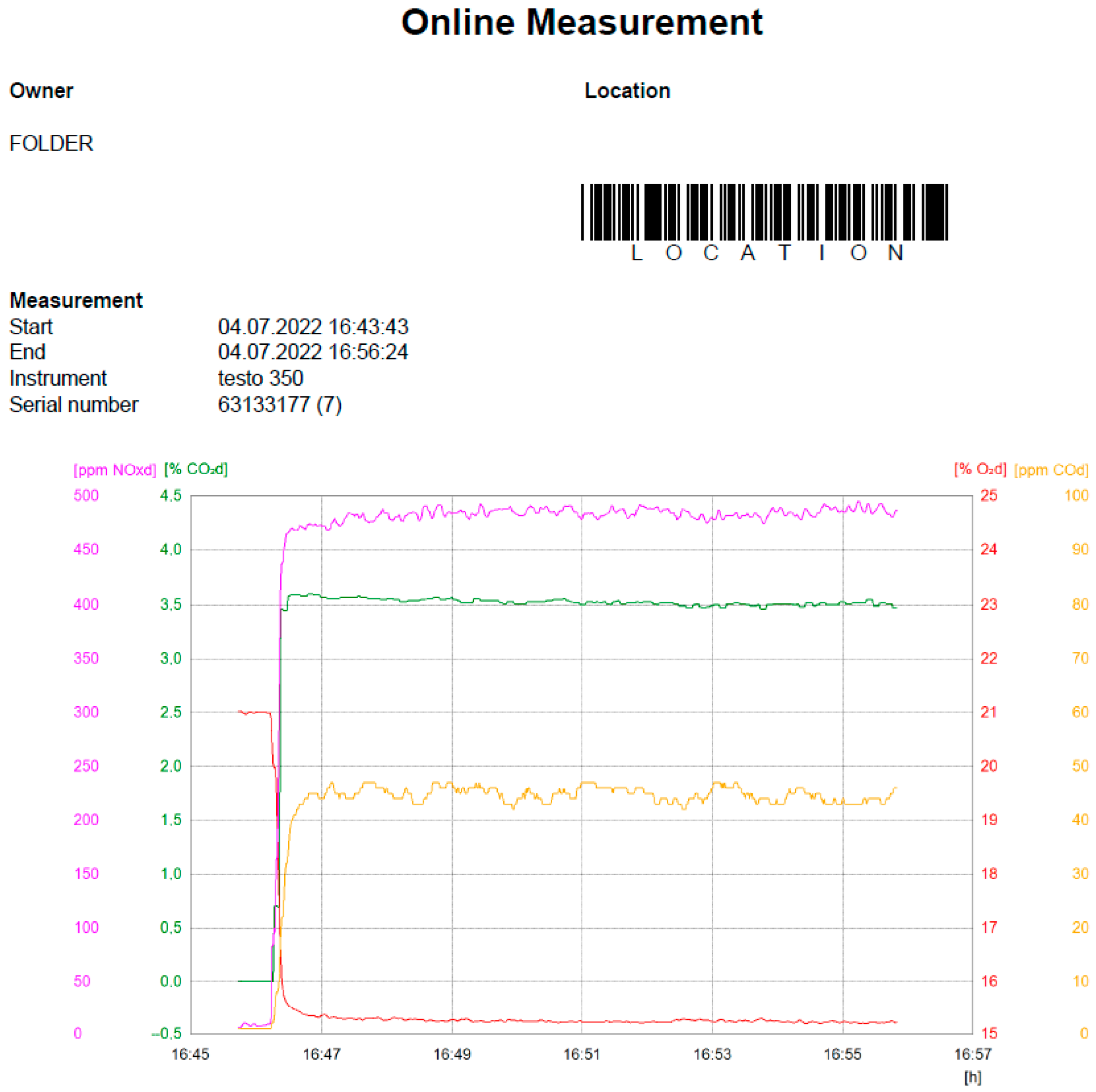

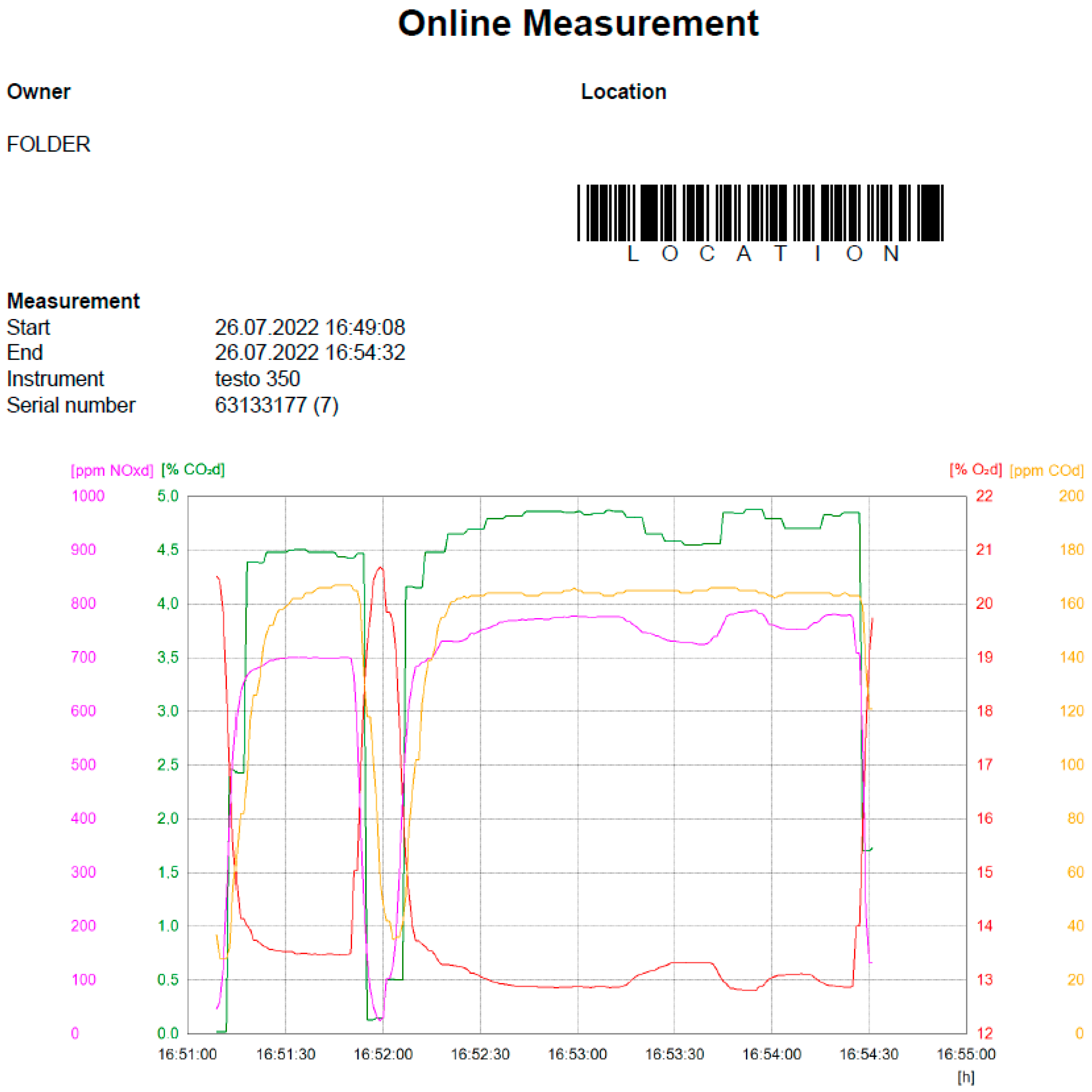

4.1. Measurement Performed Onboard the Ship

4.2. Results with Carbon Balance Method

4.3. Results with Analytical Method

4.4. Results with Stoichiometric Method

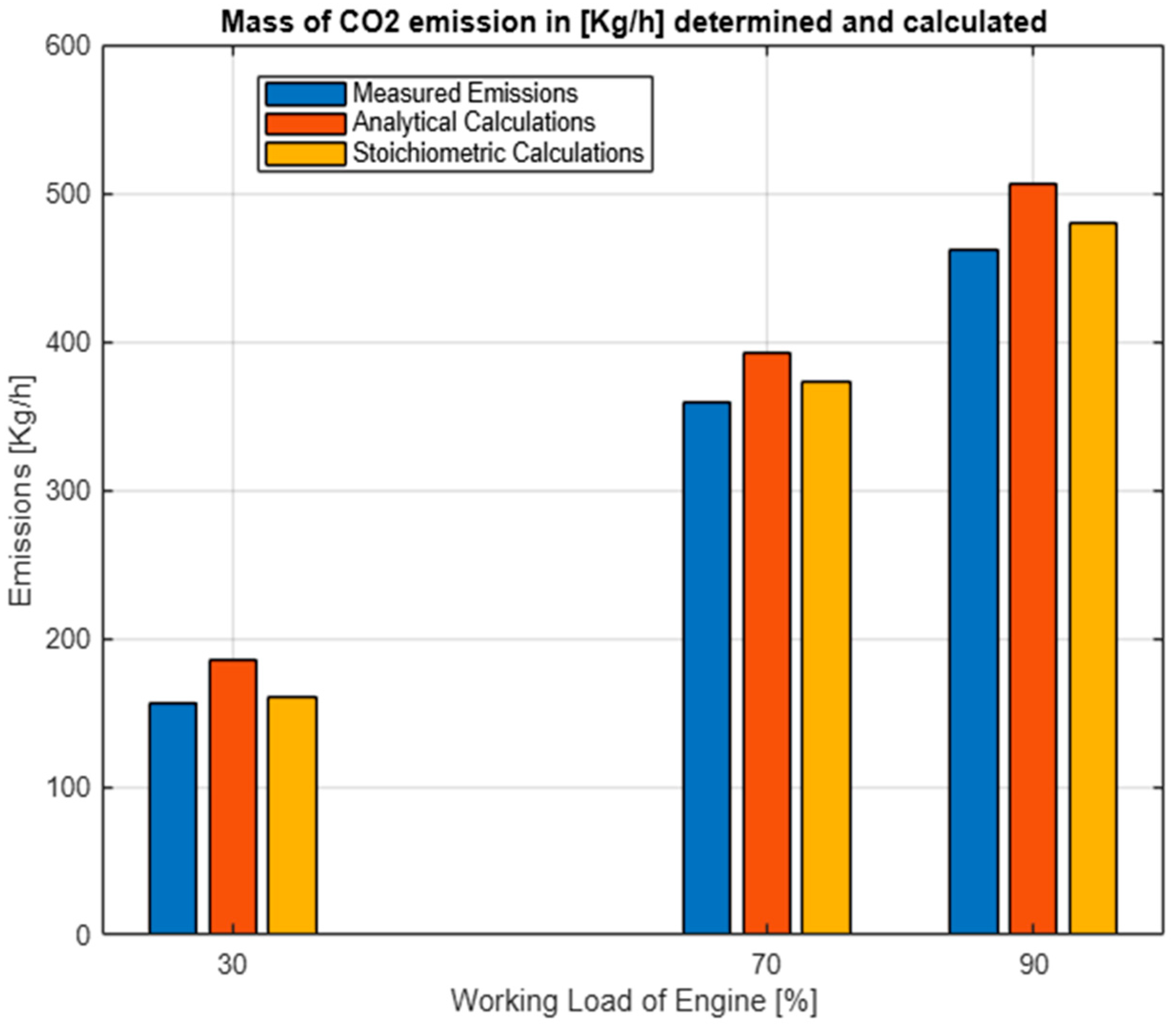

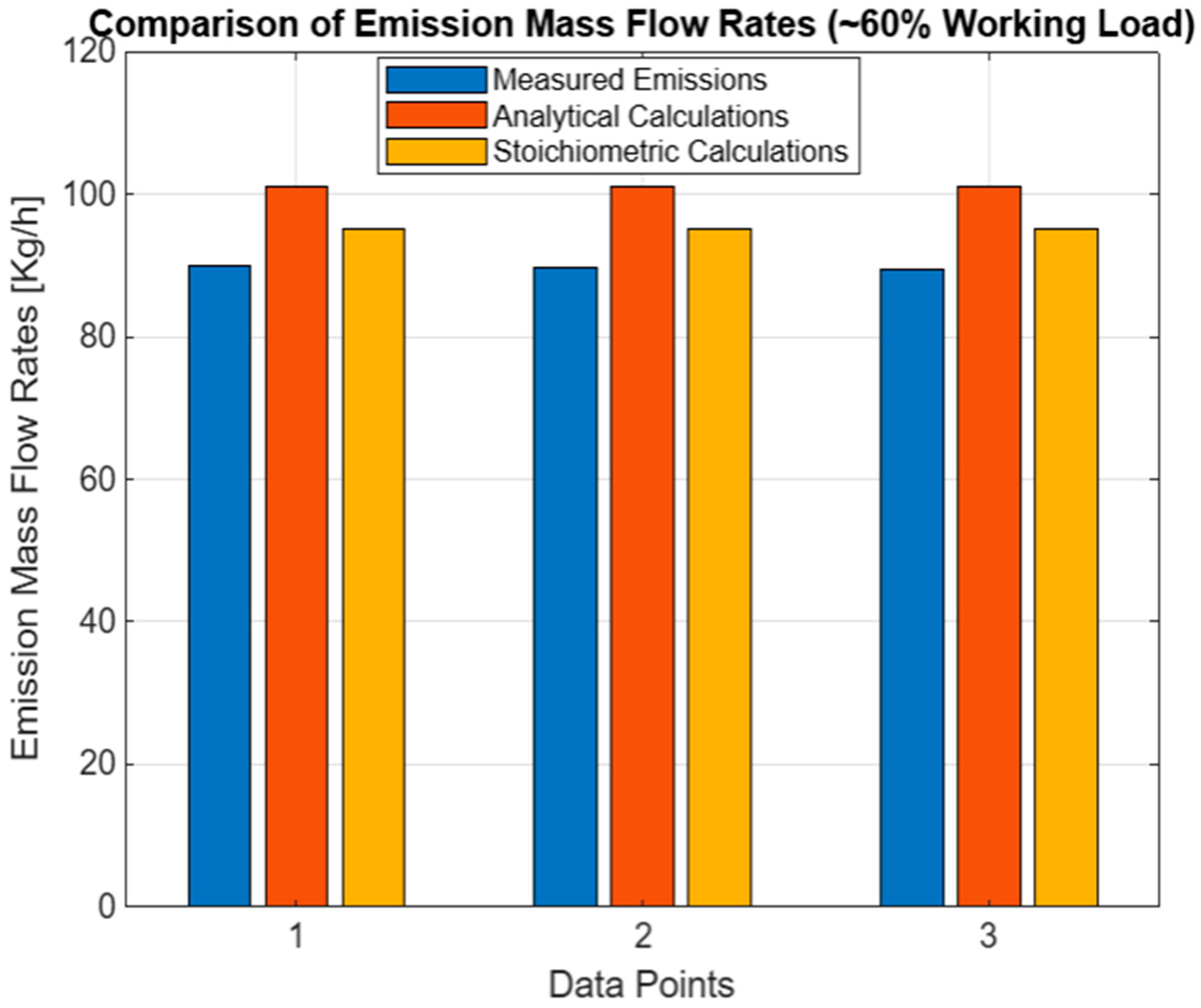

4.5. Comparative Results

- -

- The highest value results are those obtained from the theoretical (analytical and stoichiometric) calculation;

- -

- The lowest value results are those obtained from the measurements carried out onboard the ship.

- -

- The highest value results are those obtained from the theoretically (analytical and stoichiometric) calculation;

- -

- The lowest value results are those obtained from the measurements carried out onboard the ship.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CO2 | carbon dioxide |

| GHC | greenhouse gas |

| COP | Conference of the Parties |

| UNFCCC | United Nations Framework Convention on Climate Change |

| NDC | Nationally Determined Contributions |

| EU | European Union |

| ETS | Emissions Trading System |

| NGO | non-governmental organization |

| IMO | International Maritime Organization |

| NOx | nitrogen oxides |

| HDI | high-pressure direct injection |

| SFC | specific fuel consumption |

| CPP | controllable peach propeller |

| CO | carbon monoxide |

| MDO | marine diesel oil |

| SO2 | sulfur dioxide |

| MCR | maximum continuous rating |

| O2 | oxygen |

| STOMIX | stoichiometric mixture requirement |

| EAFCDO | excess air factor from CO2 |

| HTCRAT | hydrogen-carbon ratio |

| AHA | absolute humidity of suction air |

| SFFW | specific fuel factor for wet base |

| FFF | specific fuel factor |

References

- Climate Change—NASA Science. Available online: https://science.nasa.gov/climate-change/ (accessed on 21 March 2025).

- The Paris Agreement|UNFCCC. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 21 March 2025).

- Yoro, K.O.; Daramola, M.O. CO2 Emission Sources, Greenhouse Gases, and the Global Warming Effect. In Advances in Carbon Capture: Methods, Technologies and Applications; Woodhead Publishing: Pretoria, South Africa, 2020; pp. 4–6. [Google Scholar] [CrossRef]

- Sustainable Maritime Fuels—‘Fit for 55′ package: The FuelEU Maritime proposal|Think Tank|European Parliament. Available online: https://www.europarl.europa.eu/thinktank/en/document/EPRS_BRI(2021)698808 (accessed on 21 March 2025).

- Global Warming of 1.5 °C. Available online: https://www.ipcc.ch/sr15/ (accessed on 21 March 2025).

- International Maritime Organization. Amendments to the Technical Code on Control of Emission of Nitrogen Oxides from Marine Diesel Engines (NOx Technical Code 2008). 2010. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.177(58).pdf (accessed on 2 April 2025).

- International Maritime Organization. Guidelines on the Method of Calculation of the Attained Energy Efficiency Design Index (eedi) for New Ships. 2012. p. 2. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.212(63).pdf (accessed on 2 April 2025).

- Coşofreţ, D.; Bunea, M.; Popa, C. The Computing Methods for CO2 Emissions in Maritime Transports. Int. Conf. Knowl.-Based Organ. 2016, 22, 622–627. [Google Scholar] [CrossRef]

- MARPOOL. NOx Technical Code (2008). Technical Code on Control of Emission of Nitrogen Oxides from Marine Diesel Engines. 2008. Available online: https://media.liscr.com/marketing/liscr/media/liscr/online%20library/maritime/nox%20technical%20code%202008,%20as%20amended.pdf (accessed on 8 May 2025).

- Fourth Greenhouse Gas Study 2020. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Fourth-IMO-Greenhouse-Gas-Study-2020.aspx (accessed on 21 March 2025).

- Xin, R.; Zhai, J.; Liao, C.; Wang, Z.; Zhang, J.; Bazari, Z.; Ji, Y. Simulation Study on the Performance and Emission Parameters of a Marine Diesel Engine. J. Mar. Sci. Eng. 2022, 10, 985. [Google Scholar] [CrossRef]

- Lim, S.; Park, J.; Lee, J.; Lee, D.; Oh, J. Carbon Dioxide Emission Characteristics and Operation Condition Optimization for Slow-Speed and High-Speed Ship Engines. Appl. Sci. 2024, 14, 6134. [Google Scholar] [CrossRef]

- Salehin, L.; Limon, M.M.I.; Mehedi, I. A Comparison of CO2 Emission between Diesel-Fueled and Dual-Fueled Marine Engines. Available online: https://www.researchgate.net/publication/384695125_A_Comparison_of_CO2_Emission_between_Diesel-Fueled_and_Dual-Fueled_Marine_Engines (accessed on 2 June 2025).

- Chivu, R.M.; Martins, J.; Popescu, F.; Gonçalves, M.; Uzuneanu, K.; Frătița, M.; Brito, F.P. Assessment of Engine Performance and Emissions with Eucalyptus Oil and Diesel Blends. Energies 2024, 17, 3528. [Google Scholar] [CrossRef]

- Skoko, I.; Stanivuk, T.; Franic, B.; Bozic, D. Comparative Analysis of CO2 Emissions, Fuel Consumption, and Fuel Costs of Diesel and Hybrid Dredger Ship Engines. J. Mar. Sci. Eng. 2024, 12, 999. [Google Scholar] [CrossRef]

- Yuksel, O.; Pamik, M.; Bayraktar, M. The assessment of alternative fuel and engine power limitation utilisation in hybrid marine propulsion systems regarding energy efficiency metrics. J. Mar. Eng. Technol. 2025, 1–15. [Google Scholar] [CrossRef]

- Forțele Navale Române. Available online: https://www.navy.ro/despre/bric/caract_nava.php (accessed on 13 June 2025).

- Bhalothia, D.; Beniwal, A.; Bagaria, A.; Chen, T.-Y. Promoting CO2 Methanation Performance over NiO@TiO2 Nanoparticles via Oxygen Vacancies Enriched Fe-Oxide Modifiers Assisted Surface and Interface Engineering. Processes 2025, 13, 834. [Google Scholar] [CrossRef]

- The Automotive Research Association of India. Chapter 8 Calculation of the Mass Emissions of Pollutants. DOC. No.: MoRTH/CMVR/TAP-115/116, no. Issue No. 4, 2010. Available online: https://www.araiindia.com/CMVR_TAP_Documents/Part-14/Part-14_Chapter08.pdf (accessed on 22 March 2025).

- FPC International. Inc. Fuel Performance Catalyst—Technical Bulletins. Available online: https://www.fpc1.com/sci_cmb_fuel.php (accessed on 6 April 2025).

- Sagin, S.; Haichenia, O.; Karianskyi, S.; Kuropyatnyk, O.; Razinkin, R.; Sagin, A.; Volkov, O. Improving Green Shipping by Using Alternative Fuels in Ship Diesel Engines. J. Mar. Sci. Eng. 2025, 13, 589. [Google Scholar] [CrossRef]

- Third IMO GHG Study 2014 Executive Summary and Final Report. pp. 177–178, 2015. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/Third%20Greenhouse%20Gas%20Study/GHG3%20Executive%20Summary%20and%20Report.pdf (accessed on 2 April 2025).

- International Association of Classification Societies. Procedure for Calculation and Verification of the Energy Efficiency Design Index (EEDI). no. IACS Proc Req. 2013/Rev.3 2021. Available online: https://www.classnk.or.jp/hp/pdf/activities/statutory/eedi/16_pr38rev3.pdf (accessed on 22 March 2025).

- Sadloe, A.; Rahnama, P.; Novella, R.; Somers, B. A Combined 1D/3D Method to Accurately Model Fuel Stratification in an Advanced Combustion Engine. Fire 2025, 8, 117. [Google Scholar] [CrossRef]

- MATLAB Online, “MATLAB Home”. Available online: https://matlab.mathworks.com/?elqsid=vy8forrnvn46js7qemo6 (accessed on 1 April 2025).

- Reitmayr, C.; Hofmann, P. Strategies to Increase Hydrogen Energy Share of a Dual-Fuel Hydrogen–Kerosene Engine for Sustainable General Aviation. Hydrogen 2025, 6, 17. [Google Scholar] [CrossRef]

- Stipanov, M.; Dujmović, J.; Pelić, V.; Radonja, R. Simulation Approach as an Educational Tool for Comparing NOx Emission Reductions in Two-Stroke Marine Diesel Engines During Low-Load Operation: Water–Fuel Emulsion vs. Late Injection. Sustainability 2024, 16, 10833. [Google Scholar] [CrossRef]

| Characteristics | Value |

|---|---|

| Maximum length | 81.36 [m] |

| Draft 1 | 5.35 [m] |

| Maximum speed | 9.5 [knots] |

| Deadweight | 1840 [tones] |

| Characteristics | Value |

|---|---|

| Engine type | 4-stroke, diesel |

| Engine power | 810 [kW] |

| Speed | 375 [rpm] |

| Fuel type | Marine diesel oil |

| Specific fuel consumption | 215 [g/kWh] |

| Year of manufacture | 1969 |

| Year of last major overhaul | 2020 |

| Characteristics | Value |

|---|---|

| Engine type | 4-stroke, diesel |

| Engine nominal power | 125 [kW] |

| Speed | 1500 [rpm] |

| Fuel type | Marine diesel oil |

| Specific fuel consumption | 207 [g/kWh] |

| Year of manufacture | 1995 |

| Year of installation onboard | 1997 |

| Year of last major overhaul | 2020 |

| Parameter | Main Engine Load 30% 20 June 2022 | Main Engine Load 70% 9 June 2022 | Main Engine Load 90% 4 July 2022 |

|---|---|---|---|

| Engine telegraph | Slow ahead | Half ahead | Full ahead |

| CPP angle [degree] | 6 | 15 | 20 |

| Engine speed [rpm] | 350 | 355 | 365 |

| Engine power [kW] | 243 | 567 | 729 |

| Fuel consumption [kg fuel/h] | 52.245 | 121.905 | 156.735 |

| CO2 [%] | |||

| O2 [%] | 17.05 | 15.07 | 15.30 |

| NOx [ppm] | 353.2 | 516 | 478 |

| CO [ppm] | 31.96 | 47.74 | 45 |

| SO2 [ppm] | 25.34 | 29.22 | 27 |

| Air temperature [°C] | 25 | 25 | 25 |

| Atmospheric pressure [hPa] | 1018 | 1018 | 1018 |

| Relative humidity [%] | 50 | 50 | 50 |

| Exhaust gas temperature [°C] | 134.6 | 230.5 | 282.7 |

| Fuel Sulphur quantity [%] | 0.2 | 0.1 | 0.1 |

| Parameter | Load Approx. 60% 26 July 2022 16:52 | Load Approx. 60% 26 July 2022 16:53 | Load Approx. 60% 26 July 2022 16:54 |

|---|---|---|---|

| Engine speed [rpm] | 1500 | 1500 | 1500 |

| Engine power [kW] | 150 | 150 | 150 |

| Fuel consumption [kg fuel/h] | 31.05 | 31.05 | 31.05 |

| CO2 [%] | |||

| O2 [%] | 13.29 | 13.25 | 14.00 |

| NOx [ppm] | 731 | 736 | 709 |

| CO [ppm] | 155 | 165 | 163 |

| SO2 [ppm] | 43 | 39 | 41 |

| Air temperature [°C] | 25 | 25 | 25 |

| Atmospheric pressure [hPa] | 1018 | 1018 | 1018 |

| Relative humidity [%] | 50 | 50 | 50 |

| Exhaust gas temperature [°C] | 204.6 | 266.6 | 269.5 |

| Fuel Sulphur quantity [%] | 0.1 | 0.2 | 0.2 |

| Parameter | Unit | Load 30% | Load 70% | Load 90% |

|---|---|---|---|---|

| Carbon content of fuel MDO | [%] | 83.51 | 83.51 | 83.51 |

| Hydrogen content of fuel MDO | [%] | 13.30 | 13.30 | 13.30 |

| Sulphur content of fuel MDO | [%] | 0.077 | 0.077 | 0.077 |

| Nitrogen content of fuel MDO | [%] | 0.00 | 0.00 | 0.00 |

| Oxygen content of fuel MDO | [%] | 2.96 | 2.96 | 2.96 |

| Molar mass of carbon | [kg/kmole] | 12.011 | 12.011 | 12.011 |

| Molar mass of hydrogen | [kg/kmole] | 1.00797 | 1.00797 | 1.00797 |

| Molar mass of sulfur | [kg/kmole] | 32.060 | 32.060 | 32.060 |

| Molar mass of oxygen | [kg/kmole] | 31.999 | 31.999 | 31.999 |

| Molar mass of air from oxygen | [kg/kmole] | 23.15 | 23.15 | 23.15 |

| Stoichiometric mixture requirement (STOIMIX)/100 | [kg/kg] | 0.1417 | 0.1417 | 0.1417 |

| Molar volume of CO2 | [dm3/mole] | 22.262 | 22.262 | 22.262 |

| Oxygen density | [kg/m3] | 1.429 | 1.429 | 1.429 |

| Molar volume of SO2 | [dm3/mole] | 21.891 | 21.891 | 21.891 |

| Molar mass of nitrogen from air | [kg/kmole] | 0.769 | 0.769 | 0.769 |

| Nitrogen density | [kg/m3] | 1.250 | 1.250 | 1.250 |

| Excess air factor from CO2 (EAFCDO) | - | 3.544 | 2.919 | 2.776 |

| Hydrogen-carbon ratio (HTCRAT) | - | 1.898 | 1.898 | 1.898 |

| Suction air vapor pressure | [kPa] | 3.17 | 3.17 | 3.17 |

| Barometric pressure | [kPa] | 101.3 | 101.3 | 101.3 |

| Absolute humidity of suction air (AHA) | [g/kg] | 9.88 | 9.88 | 9.88 |

| Specific fuel factor for wet base (SFFW) | - | 0.760106 | 0.760106 | 0.760106 |

| Dry Air flow (Qmad) | [kg/h] | 1749.65 | 5043.31 | 6166.82 |

| H2 concentration | [%] | 0.001045 | 0.001298 | 0.001488 |

| Intake air temperature at air filter inlet (Ta) | [K] | 298.15 | 298.15 | 298.15 |

| Charge air temperature (T_sc) | [K] | 298.75 | 298.75 | 298.75 |

| Charge air temperature at each mode point corresponding to a seawater temperature of 25 °C (Specified by manufacturer) (T_SCRef) | [K] | 296.75 | 296.75 | 296.75 |

| Humidity correction factor for NOx for compression ignition engine (k_hd) | - | 0.9844 | 0.9844 | 0.9844 |

| Humidity correction factor for NOx for compression ignition engine with intercooler (k_hd) | - | 0.9850 | 0.9850 | 0.9850 |

| Charge air pressure (p_c) | [kPa] | 10,130 | 10,130 | 10,130 |

| Charge air vapor pressure (p_sc) | [kPa] | 3.2822 | 3.2822 | 3.2822 |

| Humidity of charging air | [g/kg] | 0.2015956 | 0.2016 | 0.2016 |

| Specific fuel factor (FFF) | 0.0106571 | 0.0113605 | 0.0112089 | |

| CO2 concentration in ambient air | [%] | 0.03 | 0.03 | 0.03 |

| Carbon factor | 1.3511 | 1.7869 | 1,9287 | |

| Specific fuel constant for dry exhaust (f_fd) | 0.7601 | 0.7601 | 0.7601 | |

| Mass gas exhaust rate (q_mew) | [kg/h] | 2766.5 | 7295.9 | 8680.9 |

| Wet concentration—NOx | [ppm] | 350.56 | 505.94 | 469.42 |

| Wet concentration—O2 | [%] | 16.92 | 14.81 | 15.03 |

| Wet concentration—CO | [ppm] | 31.72 | 46.90 | 44.19 |

| Wet concentration—CO2 | [%] | 2.42 | 3.47 | 3.51 |

| Wet concentration—SO2 | [ppm] | 23.82 | 30.45 | 26.52 |

| Density—NOx | [kg/m3] | 2.053 | 2.053 | 2.053 |

| Density—CO | [kg/m3] | 1.25 | 1.25 | 1.25 |

| Density—CO2 | [kg/m3] | 1.9636 | 1.9636 | 1.9636 |

| Density—O2 | [kg/m3] | 1.4277 | 1.4277 | 1.4277 |

| Density—HC | [kg/m3] | 0.62 | 0.62 | 0.62 |

| Density—SO2 | [kg/m3] | 2.855 | 2.855 | 2.855 |

| Density—exhaust gas | [kg/m3] | 1.2943 | 1.2943 | 1.2943 |

| Ratio NOx density/exhaust gas density | - | 0.000966 | 0.000966 | 0.000966 |

| Ratio CO density/exhaust gas density | - | 0.000479 | 0.000479 | 0.000479 |

| Ratio HC density/exhaust gas density | - | 0.001517 | 0.001517 | 0.001517 |

| Ratio CO2 density/exhaust gas density | - | 0.001103 | 0.001103 | 0.001103 |

| Ratio O2 density/exhaust gas density | - | 0.002206 | 0.002206 | 0.002206 |

| Ratio SO2 density/exhaust gas density | - | 0.000966 | 0.000966 | 0.000966 |

| Mass flow—NOx | [kg/h] | 2.3394 | 5.3987 | 6.3668 |

| Mass flow—O2 | [Kg/h] | 79.7349 | 111.5392 | 143.8859 |

| Mass flow—CO | [Kg/h] | 0.130859 | 0.309364 | 0.370521 |

| Mass flow—CO2 | [Kg/h] | 156.9387 | 359.3395 | 461.7545 |

| Mass flow—SO2 | [kg/h] | 0.2244 | 0.4588 | 0.5078 |

| Mass flow—wet air | [kg/h] | 4.2193 | 6.7080 | 8.5247 |

| Parameter | Unit | Load 60% | Load 60% | Load 60% |

|---|---|---|---|---|

| Carbon content of fuel MDO | [%] | 83.51 | 83.51 | 83.51 |

| Hydrogen content of fuel MDO | [%] | 13.30 | 13.30 | 13.30 |

| Sulphur content of fuel MDO | [%] | 0.077 | 0.077 | 0.077 |

| Nitrogen content of fuel MDO | [%] | 0.00 | 0.00 | 0.00 |

| Oxygen content of fuel MDO | [%] | 2.96 | 2.96 | 2.96 |

| Molar mass of carbon | [kg/kmole] | 12.011 | 12.011 | 12.011 |

| Molar mass of hydrogen | [kg/kmole] | 1.00797 | 1.00797 | 1.00797 |

| Molar mass of sulfur | [kg/kmole] | 32.060 | 32.060 | 32.060 |

| Molar mass of oxygen | [kg/kmole] | 31.999 | 31.999 | 31.999 |

| Molar mass of air from oxygen | [kg/kmole] | 23.15 | 23.15 | 23.15 |

| Stoichiometric mixture requirement (STOIMIX)/100 | [kg/kg] | 0.1417 | 0.1417 | 0.1417 |

| Molar volume of CO2 | [dm3/mole] | 22.262 | 22.262 | 22.262 |

| Oxygen density | [kg/m3] | 1.429 | 1.429 | 1.429 |

| Molar volume of SO2 | [dm3/mole] | 21.891 | 21.891 | 21.891 |

| Molar mass of nitrogen from air | [kg/kmole] | 0.769 | 0.769 | 0.769 |

| Nitrogen density | [kg/m3] | 1.250 | 1.250 | 1.250 |

| Excess air factor from CO2 (EAFCDO) | - | 2.407 | 2.354 | 2.296 |

| Hydrogen-carbon ratio (HTCRAT) | - | 1.898 | 1.898 | 1.898 |

| Suction air vapor pressure | [kPa] | 3.17 | 3.17 | 3.17 |

| Barometric pressure | [kPa] | 101.3 | 101.3 | 101.3 |

| Absolute humidity of suction air (AHA) | [g/kg] | 9.88 | 9.88 | 9.88 |

| Specific fuel factor for wet base (SFFW) | - | 0.7601 | 0.7601 | 0.7601 |

| Dry air flow (Qmad) | [kg/h] | 1059.07 | 1035.74 | 1010.40 |

| H2 concentration | [%] | 0.004914 | 0.005231 | 0.005167 |

| Intake air temperature at air filter inlet (Ta) | [K] | 298.15 | 298.15 | 298.15 |

| Charge air temperature (T_sc) | [K] | 298.75 | 298.75 | 298.75 |

| Charge air temperature at each mode point corresponding to a seawater temperature of 25 °C (Specified by manufacturer) (T_SCRef) | [K] | 296.75 | 296.75 | 296.75 |

| Humidity correction factor for NOx for compression ignition engine (k_hd) | - | 0.9844 | 0.9844 | 0.9844 |

| Humidity correction factor for NOx for compression ignition engine with intercooler (k_hd) | - | 0.9850 | 0.9850 | 0.9850 |

| Charge air pressure (p_c) | [kPa] | 10130 | 10130 | 10130 |

| Charge air vapor pressure (p_sc) | [kPa] | 3.2822 | 3.2822 | 3.2822 |

| Humidity of charging Air | [g/kg] | 0.2015956 | 0.2016 | 0.2016 |

| Specific fuel factor (FFF) | 0.0110989 | 0.0110914 | 0.0110829 | |

| CO2 concentration in ambient air | [%] | 0.03 | 0.03 | 0.03 |

| Carbon factor | 2.4296 | 2.5227 | 2.6314 | |

| Specific fuel constant for dry exhaust (f_fd) | 0.7601 | 0.7601 | 0.7601 | |

| Mass gas exhaust rate (q_mew) | [kg/h] | 1359.7 | 1308.6 | 1253.4 |

| Wet concentration—NOx | [ppm] | 711.80 | 715.54 | 688.02 |

| Wet concentration—O2 | [%] | 12.94 | 11.91 | 13.59 |

| Wet concentration—CO | [ppm] | 150.93 | 160.41 | 158.18 |

| Wet concentration—CO2 | [%] | 4.36 | 4.52 | 4.71 |

| Wet concentration—SO2 | [ppm] | 41.87 | 37.92 | 39.79 |

| Density—NOx | [kg/m3] | 2.053 | 2.053 | 2.053 |

| Density—CO | [kg/m3] | 1.25 | 1.25 | 1.25 |

| Density—CO2 | [kg/m3] | 1.9636 | 1.9636 | 1.9636 |

| Density—O2 | [kg/m3] | 1.4277 | 1.4277 | 1.4277 |

| Density—HC | [kg/m3] | 0.620 | 0.620 | 0.620 |

| Density—SO2 | [kg/m3] | 2.855 | 2.855 | 2.855 |

| Density—exhaust gas | [kg/m3] | 1.2943 | 1.2943 | 1.2943 |

| Ratio NOx density/exhaust gas density | - | 0.001586 | 0.001586 | 0.001586 |

| Ratio CO density/exhaust gas density | - | 0.000966 | 0.000966 | 0.000966 |

| Ratio HC density/exhaust gas density | - | 0.000479 | 0.000479 | 0.000479 |

| Ratio CO2 density/exhaust gas density | - | 0.001517 | 0.001517 | 0.001517 |

| Ratio O2 density/exhaust gas density | - | 0.001103 | 0.001103 | 0.001103 |

| Ratio SO2 density/exhaust gas density | - | 0.002206 | 0.002206 | 0.002206 |

| Mass flow—NOx | [Kg/h] | 1.5120 | 1.4629 | 1.3473 |

| Mass flow—O2 | [Kg/h] | 19.4091 | 17.1906 | 18.7838 |

| Mass flow—CO | [Kg/h] | 0.198191 | 0.202727 | 0.191477 |

| Mass flow—CO2 | [Kg/h] | 89.9857 | 89.7476 | 89.4980 |

| Mass flow—SO2 | [kg/h] | 0.1256 | 0.1094 | 0.1100 |

| Mass flow—wet air | [kg/h] | 1.3286 | 1.2775 | 1.2224 |

| Working Load of Engine | |||

|---|---|---|---|

| Mass | Load 1 30% | Load 2 70% | Load 3 90% |

| Kg CO2/h | 185.2315 | 392.4171 | 506.3418 |

| Working Load of Engine | |

|---|---|

| Mass | Load Approx. 60% |

| Kg CO2/h | 101.13 |

| Working Load of Engine | |||

|---|---|---|---|

| Mass | Load 1 30% | Load 2 70% | Load 3 90% |

| Kg CO2/h | 160.6036 | 373.2771 | 479.9277 |

| Working Load of Engine | |

|---|---|

| Mass | Load Approx. 60% |

| Kg CO2/h | 95.076 |

| Working Load of Engine | Measured Emission Mass Flow Rates [kg CO2/h] | Analytical Calculated Emission Mass Flow Rates [kg CO2/h] | Stoichiometric Calculated Emission Mass Flow Rates [kg CO2/h] |

|---|---|---|---|

| 30% | 156.9387 | 185.2315 | 160.6036 |

| 70% | 359.3395 | 392.4171 | 373.2771 |

| 90% | 461.7545 | 506.3418 | 479.9277 |

| Working Load of Engine | Measured Emission Mass Flow Rates [kg CO2/h] | Analytical Calculated Emission Mass Flow Rates [kg CO2/h] | Stoichiometric Calculated Emission Mass Flow Rates [kg CO2/h] |

|---|---|---|---|

| Approx. 60% | 89.98 | 101.13 | 95.076 |

| Approx. 60% | 89.74 | 101.13 | 95.076 |

| Approx. 60% | 89.49 | 101.13 | 95.076 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Volintiru, O.N.; Mărășescu, D.; Coșofreț, D.; Popa, A. Aspects Regarding the CO2 Footprint Developed by Marine Diesel Engines. Fire 2025, 8, 240. https://doi.org/10.3390/fire8060240

Volintiru ON, Mărășescu D, Coșofreț D, Popa A. Aspects Regarding the CO2 Footprint Developed by Marine Diesel Engines. Fire. 2025; 8(6):240. https://doi.org/10.3390/fire8060240

Chicago/Turabian StyleVolintiru, Octavian Narcis, Daniel Mărășescu, Doru Coșofreț, and Adrian Popa. 2025. "Aspects Regarding the CO2 Footprint Developed by Marine Diesel Engines" Fire 8, no. 6: 240. https://doi.org/10.3390/fire8060240

APA StyleVolintiru, O. N., Mărășescu, D., Coșofreț, D., & Popa, A. (2025). Aspects Regarding the CO2 Footprint Developed by Marine Diesel Engines. Fire, 8(6), 240. https://doi.org/10.3390/fire8060240