A Study on Prevention of Fire Proliferation in Building-Type Solar Modules

Abstract

1. Introduction

2. Materials and Methods

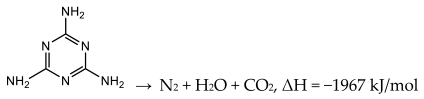

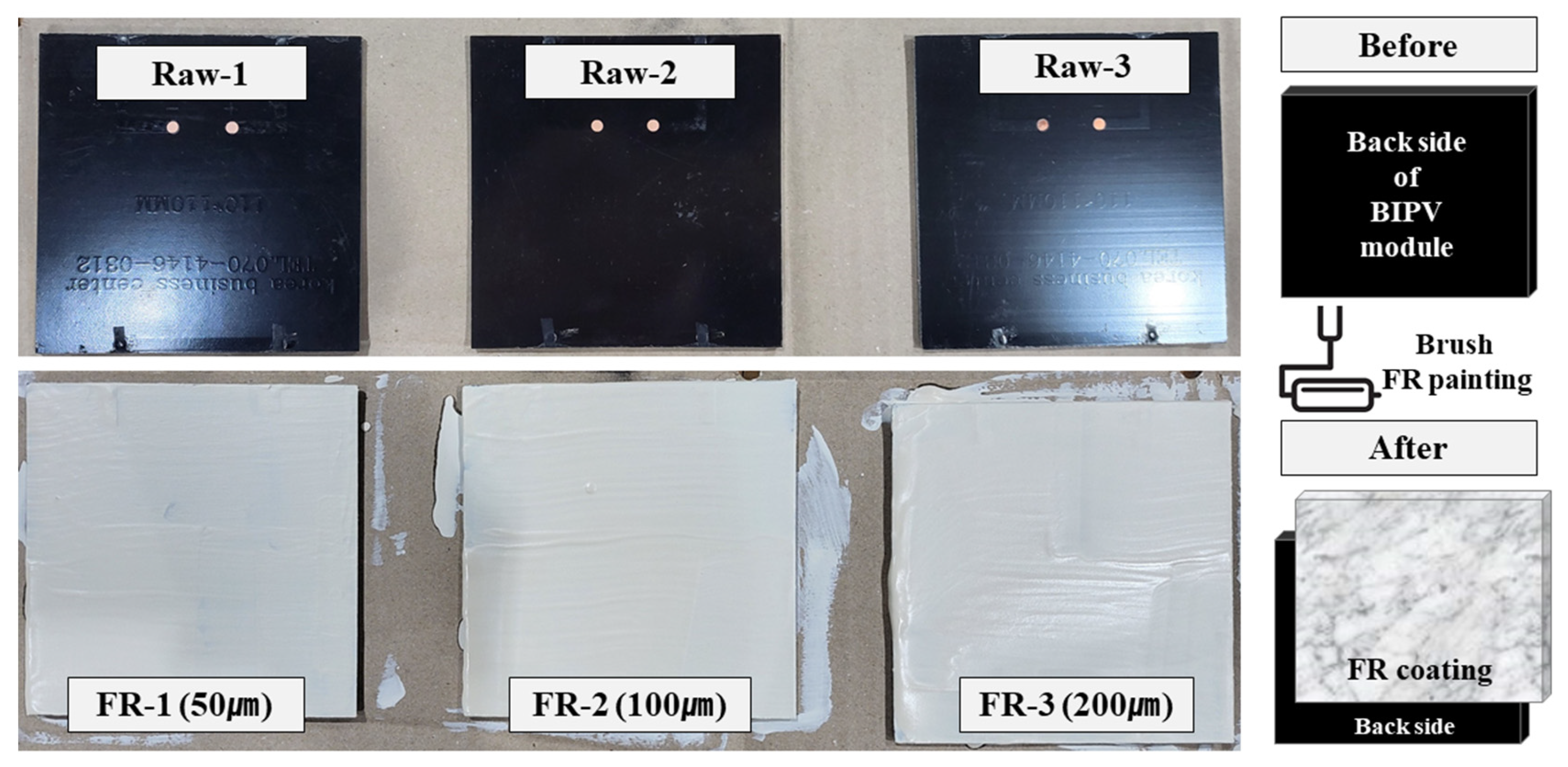

2.1. PV Module Specimens and FR Coating

- Power of the solar module: 1.6 W (270 mA, 6 V).

- Module dimensions: 110 × 110 mm2, thickness 2.8 mm.

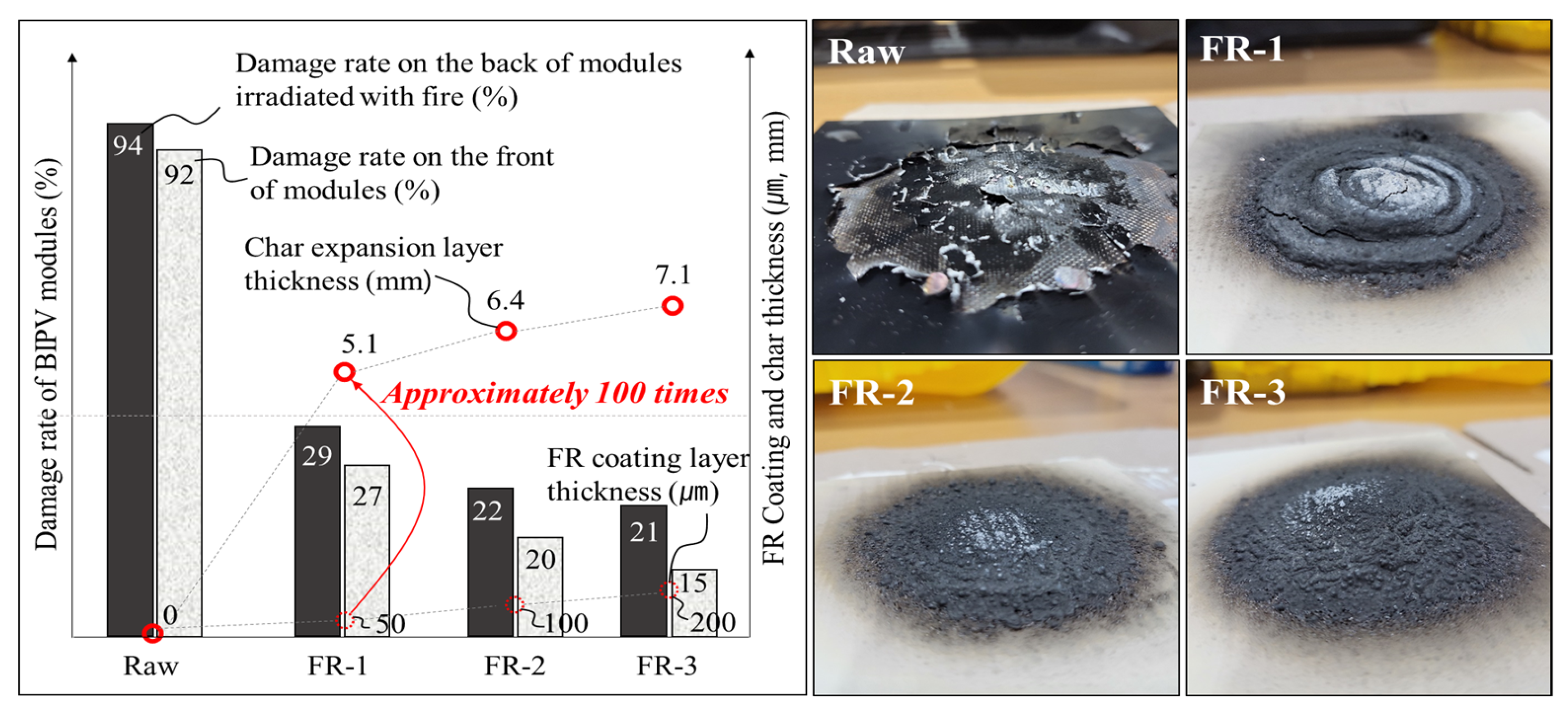

- FR coating thickness: 0 μm (Raw-1-3), 50 μm (FR-1), 100 μm (FR-2), 200 μm (FR-3).

- Microstructure analysis: DMi8 optical microscope (Leica Microsystems, Wetzlar, Germany); Merlin Compact scanning electron microscope with EDS (Carl Zeiss AG, Oberkochen, Germany).

2.2. Combustion Test

3. Results

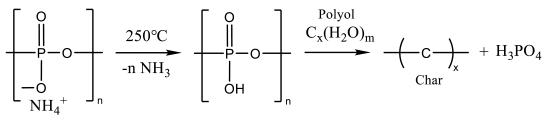

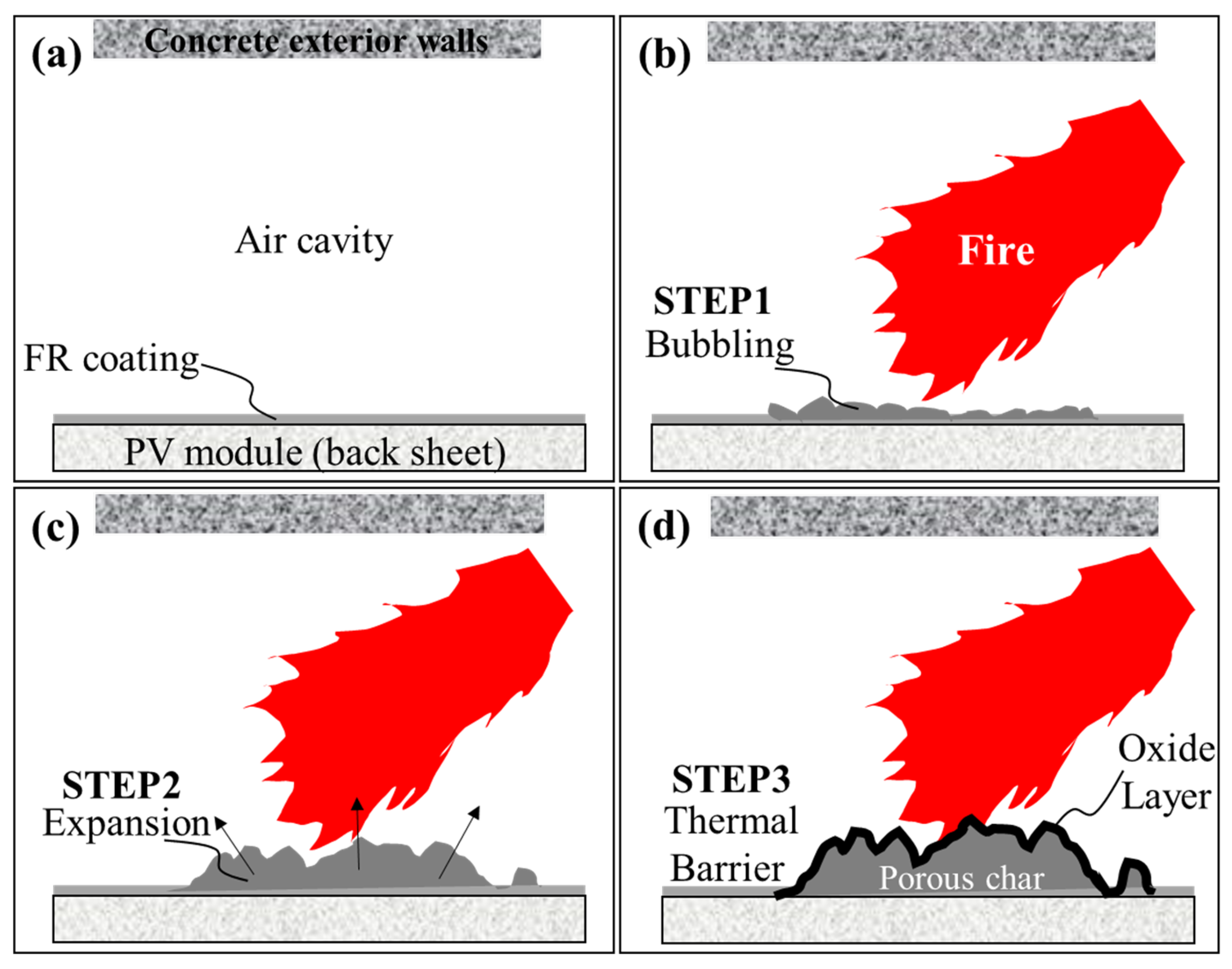

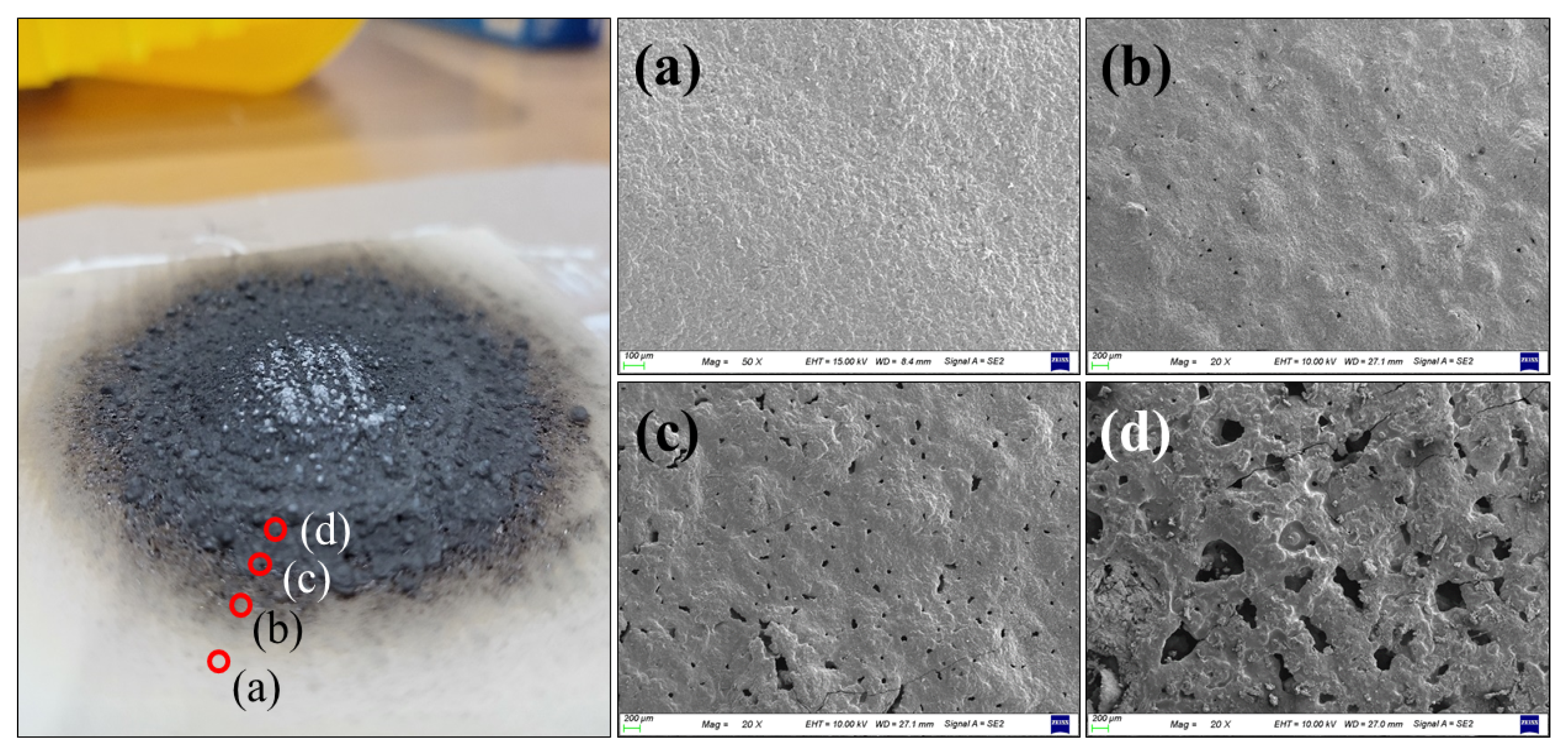

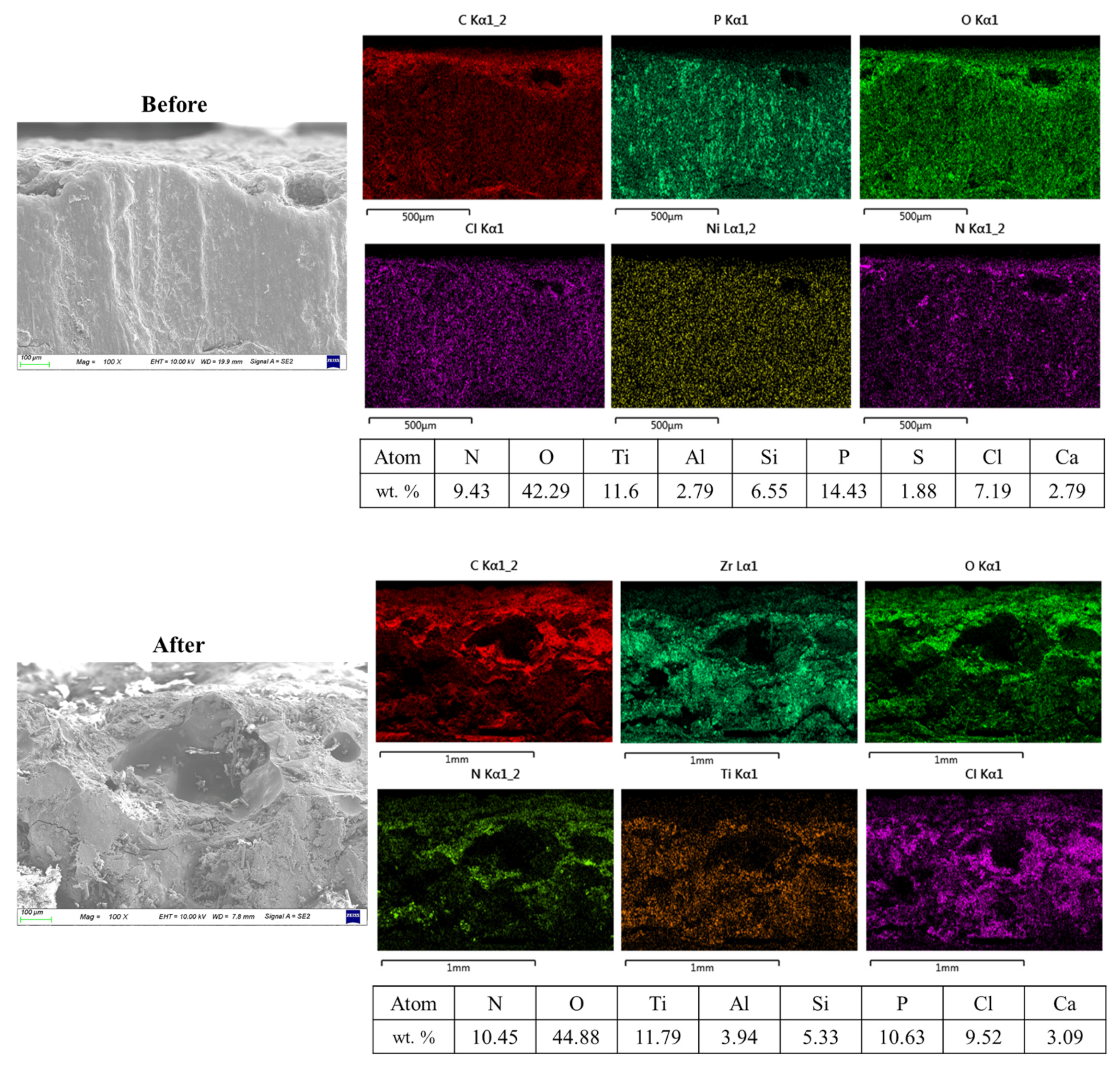

3.1. FR Coating Reaction Mechanism

- 1st step (FR coating): application of FR coating on the bottom of the back sheet of PV panel.

- 2nd step (chemical reaction): melting of FR coating by flame and initiation of chemical reaction.

- 3rd step (char expansion): release of N2 gas from melamine and formation of porous char.

- 4th step (surface oxidation): stabilization of porous char and thermal barrier oxidation layer.

|

|

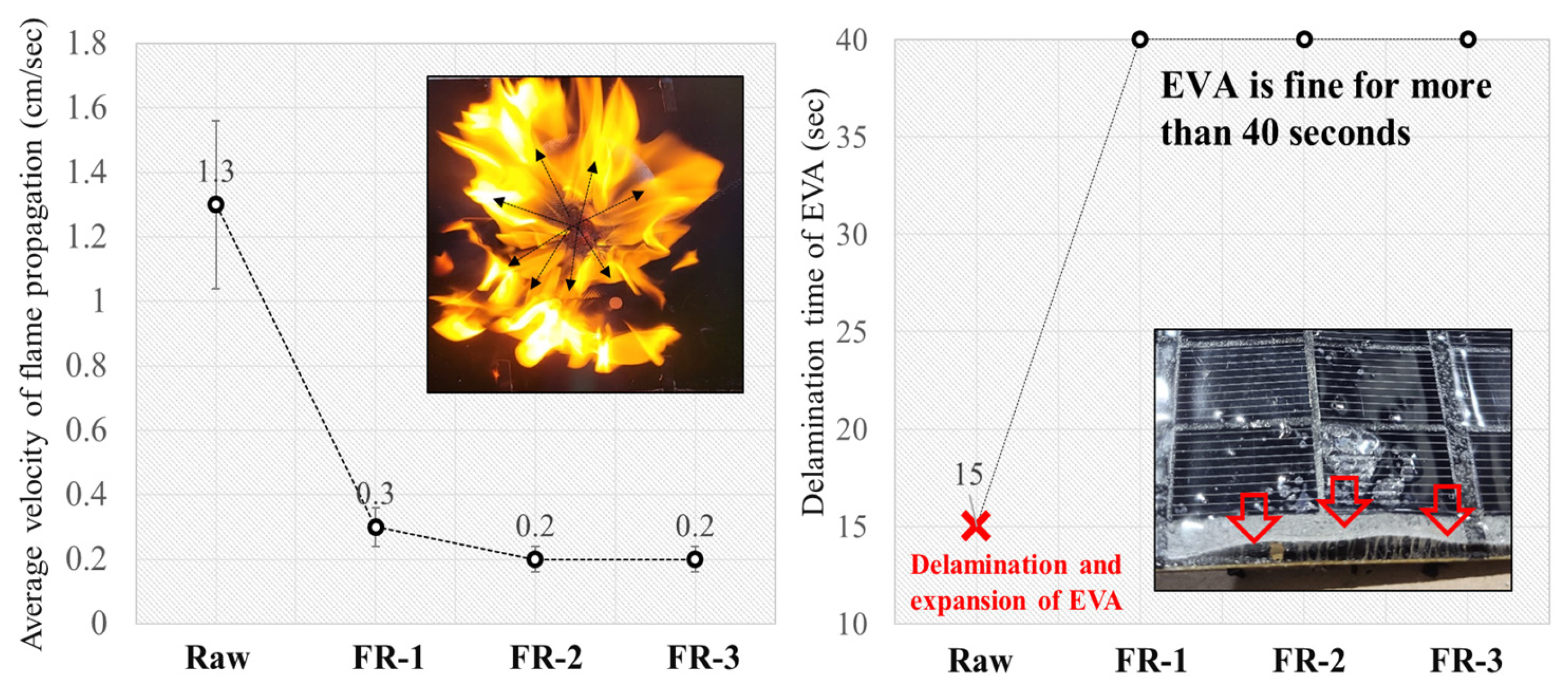

3.2. Combustion Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yonhap News. Ulsan 33rd Floor Samhwan Art Nouveau Apartment Building Large Fire. Available online: https://www.youtube.com/watch?v=bgjtnCBiR2w (accessed on 9 September 2020).

- Yonhap News. High-Rise Apartment Fire in Haeundae, Busan. Available online: https://www.yna.co.kr/view/AKR20101001133000051 (accessed on 1 October 2010).

- National Fire Evaluation Agency. Understanding the Stack Effect, the Main Culprit of Smoke Diffusion. Available online: https://firesafety.tistory.com/63 (accessed on 12 April 2024).

- Aram, M. Fire Smoke Control for Building Integrated Photovoltaic (BIPV). ASHRAE Trans. 2021, 127, 14–16. [Google Scholar]

- Wu, Z.; Hu, Y.; Wen, J.X.; Zhou, F.; Ye, X. A review for solar panel fire accident prevention in large-scale PV applications. IEEE Access 2020, 8, 132466–132480. [Google Scholar] [CrossRef]

- Aram, M.; Zhang, X.; Qi, D.; Ko, Y. A state-of-the-art review of fire safety of photovoltaic systems in buildings. J. Clean. Prod. 2021, 308, 127239. [Google Scholar] [CrossRef]

- Wang, J.; Xue, L.; Zhao, B.; Lin, G.; Jin, X.; Liu, D.; Shang, K. Flame retardancy, fire behavior, and flame retardant mechanism of intumescent flame retardant EPDM containing ammonium polyphosphate/pentaerythrotol and expandable graphite. Material 2019, 12, 4035. [Google Scholar] [CrossRef] [PubMed]

- Kashiwagi, T. Polymer combustion and flammability—Role of the condensed phase. Symp. (Int.) Combust. 1994, 25, 1423–1437. [Google Scholar] [CrossRef]

- Salmeia, K.; Gaan, S.; Malucelli, G. Recent advances for flame retardancy of textiles based on phosphorus chemistry. Polymers 2016, 8, 319. [Google Scholar] [CrossRef] [PubMed]

- Lazar, S.T.; Kolibaba, T.J.; Grunlan, J.C. Flame-retardant surface treatments. Nat. Rev. 2020, 5, 259–275. [Google Scholar] [CrossRef]

- Pan, L.L.; Li, G.Y.; Su, Y.C.; Lian, J.S. Fire retardant mechanism analysis between ammonium polyphosphate and triphenyl phosphate in unsaturated polyester resin. Polym. Degrad. Stabil. 2012, 97, 1801–1806. [Google Scholar] [CrossRef]

- Fang, Y.; Cui, P.; Ding, Z.; Zhu, J.X. Properties of a magnesium phosphate cement-based fire-retardant coating containing glass fiber or glass fiber powder. Constr. Build. Mater. 2018, 162, 553–560. [Google Scholar] [CrossRef]

- Boryniec, S.; Przygocki, W. Polymer combustion process. 3. Flame retardants for polymeric materials. Prog. Rubber Plast. Technol. 2001, 17, 127–148. [Google Scholar] [CrossRef]

- Mazela, B.; Batista, A.; Grześkowiak, W. Expandable graphite as a fire retardant for cellulosic materials—A review. Forests 2020, 11, 755. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, T.; Luo, Y.; Wang, Y.; Li, J.; Ye, T.; Wang, H. Multifunctional polyurethane sponge coatings with excellent flame retardant, antibacterial, compressible, and recyclable properties. Compos. Part B Eng. 2021, 215, 108785. [Google Scholar] [CrossRef]

- Piperopoulos, E.; Scionti, G.; Atria, M.; Calabrese, L.; Proverbio, E. Flame-retardant performance evaluation of functional coatings filled with Mg(OH)2 and Al(OH)3. Polymers 2022, 14, 372. [Google Scholar] [CrossRef] [PubMed]

- Schartel, B. Phosphorus-based flame retardancy mechanisms—Old hat or a starting point for future development? Materials 2010, 3, 4710–4745. [Google Scholar] [CrossRef] [PubMed]

- Nabipour, H.; Wang, X.; Song, L.; Hu, Y. Metal-organic frameworks for flame retardant polymers application: A critical review. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106113. [Google Scholar] [CrossRef]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, Y.C.; Song, M.J.; Park, H.K.; Lee, M.C.; Lee, S.Y. A Study on Prevention of Fire Proliferation in Building-Type Solar Modules. Fire 2025, 8, 194. https://doi.org/10.3390/fire8050194

Jung YC, Song MJ, Park HK, Lee MC, Lee SY. A Study on Prevention of Fire Proliferation in Building-Type Solar Modules. Fire. 2025; 8(5):194. https://doi.org/10.3390/fire8050194

Chicago/Turabian StyleJung, Yong Chan, Min Ji Song, Hee Kyung Park, Min Chul Lee, and Soo Yeol Lee. 2025. "A Study on Prevention of Fire Proliferation in Building-Type Solar Modules" Fire 8, no. 5: 194. https://doi.org/10.3390/fire8050194

APA StyleJung, Y. C., Song, M. J., Park, H. K., Lee, M. C., & Lee, S. Y. (2025). A Study on Prevention of Fire Proliferation in Building-Type Solar Modules. Fire, 8(5), 194. https://doi.org/10.3390/fire8050194