Abstract

The Wan’an Bridge, the longest wooden lounge bridge in China with a history of more than 900 years, was devastated by a catastrophic fire in 2022. This tragic event underscores the susceptibility of historical wooden structures to fire damage. In this article, the bridge’s intricate structure and the development of the fire incident are introduced in detail. To gain a deeper insight into the patterns of fire propagation across the bridge and assess the reliability of fire simulations in predicting fire spread in historical wooden structures, we utilized the Fire Dynamics Simulator (FDS), with a sophisticated pyrolysis model and thermal response parameters specifically tailored to ancient fir wood. The modeling results reveal that the FDS simulation reflects the actual fire spread process well. Both the investigation and simulation findings indicate that once the flame reaches above the bridge deck, it enters a rapid three-dimensional propagation phase that is exceptionally challenging to control. Furthermore, the modeling results suggest that the application of intumescent fire-retardant coatings can significantly delay fire spread, reduce heat release rates, and suppress smoke production, thereby making them an effective fire prevention measure for historical wooden buildings.

1. Introduction

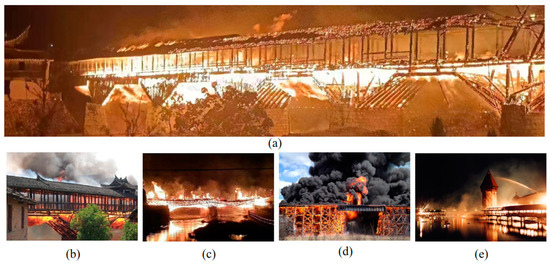

On the night of 6 August 2022, the Wan’an Bridge, the longest wooden arch bridge in China, was consumed by flames and ultimately collapsed [1]. The bridge was built in the Song Dynasty (960–1127) in Pingnan county in east China’s Fujian Province. It holds significant cultural value as it shows that ancient China possessed wisdom and ingenuity in wooden architecture designs, particularly considering the tremendous difficulty in building a prototype bridge of such a length. As illustrated in Figure 1, the Wan’an Bridge is not the only historic wooden bridge ravaged by fire in recent years. Worldwide, several other bridges rich in historical and cultural significance have also been destroyed by flames [2,3,4,5,6], resulting in significant losses of irreplaceable cultural heritage. These fires underline the vulnerability of historic wooden structures to fire damage and highlight the need for enhanced fire safety measures and conservation efforts to protect these invaluable cultural treasures.

Figure 1.

(a) Wan’an Bridge fire in Fujian, China, 2022 [1]; (b) Yuqing Bridge fire in Fujian, China, 2011 [2]; (c) Buyue Bridge fire in Fujian, China, 2019 [4]; (d) A wooden rail trestle bridge fire in Mayerthorpe, Canadian, 2016 [4]; (e) Chapel Bridge fire in Lucerne, Switzerland, 1993 [5].

Due to its prolonged exposure to the natural environment, the wood in ancient structures experiences irreversible changes, including photocatalytic degradation, moisture expansion, and shrinkage due to drying [7,8]. These alterations during the natural aging of wood lead to further transformations in both its macro-morphology and its micro-structure [9,10]. Additionally, there are changes in the moisture, lignin, and cellulose contents, which subsequently affect the thermal response of the wood and enhance the flammability of the timber structure [11].

To better safeguard vulnerable ancient wooden structures from fire in the future, fire case investigations and fire risk analyses are the most frequently utilized methods to identify existing problems and their corresponding countermeasures. Although experiments can be conducted to study the reaction of structures to fire, the unique and irreplaceable nature of ancient buildings renders experimental research nearly impossible. Consequently, numerical simulation has emerged as a desirable tool for fire safety assessments of wooden cultural heritages [12].

Currently, the most popular software used for fire simulations include FLUENT [13], OpenFOAM [14], and Fire Dynamics Simulator (FDS) [15]. Among these tools, FDS is the most frequently used numerical solver and has been applied to several ancient wooden buildings [16,17,18,19,20,21]. However, FDS has inherent shortcomings, such as a limited understanding of solid combustion mechanisms. Furthermore, there have been very few studies examining the thermal responses of ancient wood. All these issues cast doubt on the reliability of FDS in predicting the fire behavior of ancient wooden structures. Additionally, the absence of full-scale fire experiments further complicates the validation of the models. The surveillance video footage of Wan’an Bridge fire shows the fire’s progression, which can be used to validate the modeling outcomes.

The major objective of this study is to assess the reliability of the Fire Dynamics Simulator (FDS) in reconstructing the Wan’an Bridge fire and to obtain a deeper understanding of the propagation of flame across the bridge. To improve the accuracy of the simulation results, a sophisticated model that relies on pyrolysis parameters was employed, along with specifically tailored thermal response parameters for ancient fir wood. Additionally, the protection efficacy of intumescent flame-retardant (IFR) coatings was evaluated through modeling by incorporating temperature-dependent thermal conductivity and expansion coefficient.

2. Wan’an Bridge Fire

2.1. Bridge Structure

As the longest wooden arch bridge in China, Wan’an Bridge boasted a length of 98.2 m and a width of 4.7 m. The bridge was constructed primarily from Chinese fir wood, a lightweight and naturally insect-resistant timber species that grows rapidly. As depicted in Figure 2, it comprised five boat-shaped stone piers and six wooden arches, with varying spans ranging from 10.6 to 15.2 m. The bridge featured 37 corridor houses and 156 pillars, offering a scenic walkway with a double-pitched roof and wooden benches along its sides [2]. To enhance its stability and strength, the wooden arches were interlocked with rows of three- and five-segmented beams. Additionally, clapboards covered the beams at both sides, creating a visually appealing facade. However, these designs introduced lots of gaps within the arch assemblies, which could easily trap weeds, leaves, and wooden debris, posing a significant fire hazard.

Figure 2.

Pre-fire photograph and detailed structural illustration of Wan’an Bridge.

2.2. Development of Fire

The fire was first observed at 19:12:37 on 6 August 2022, based on a video analysis of the Wan’an Bridge. Initially, a weak light was identified near the connection between the second pier and the adjacent clapboard, as highlighted by the red circle in Figure 3. This light disappeared immediately after its appearance. Subsequently, two more faint lights were observed at the same location at 19:15:41 and 20:41:24, respectively, and they also vanished rapidly. Continuous flashes of fire became visible after 21:02:20, followed by the flame propagating upwards and spreading beyond the bridge deck at 21:07:38. Although many individuals were walking on the bridge or resting on its benches, the fire was not detected for one hour and three quarters, until it burned through the bridge deck. Subsequently, the fire rapidly spread in different directions and reached the far end of the bridge at 21:18, as indicated in the investigation report. It took only approximately 12 min for the fire to engulf the entire wooden structure once it spread above the bridge deck. Minutes later, the burning components began to collapse.

Figure 3.

Surveillance video capturing the initial visible flame as indicated by the red circle.

2.3. Cause of Fire

According to the video analysis, local authorities reported that no one emerged from under the bridge on that day, while several people were smoking on the bridge that night. After ruling out all other potential causes, the fire investigation concluded that the most probable cause was a cigarette that smoldered and fell into the gaps between the pier and beams. This cigarette ignited the weeds, leaves, or debris trapped within the cavities. Due to the small ignition source, the fire initially grew slowly, and the clapboards’ shields delayed its detection. Simultaneously, the clapboards on both sides reduced heat loss, enabling heat to accumulate and sustain the burning or smoldering process. As the temperature gradually increased, the combustion intensified, releasing more heat. This continuous acceleration of heat release and temperature increase ultimately led to the ignition of the wooden beams.

3. Fire Simulation

In the present study, the Fire Dynamics Simulator (FDS) developed by the National Institute of Standards and Technology (NIST) was utilized. This simulator is a large-eddy simulation (LES) software, with a primary focus on smoke and heat transport from fires. In this study, the simulations of the Wan’an Bridge fire with and without IFR coatings were performed using PyroSim 2021, which is a graphical user interface for FDS version 6.7.5.

Wood comprises cellulose, hemicellulose, and lignin. In the absence of a flame-retardant coating, wood undergoes pyrolysis, resulting in the formation of char and various gaseous species upon exposure to heat. Subsequently, the char oxidizes, releasing heat, while certain gaseous species combust, producing carbon dioxide and water. To evaluate the protective performance of intumescent flame-retardant coatings under the simulated fire conditions, three established IFR coatings documented in the literature were selected: an epoxy resin coating [22], a vinyl acetate coating [23], and a water-based coating (FX100, Leighs Paints, Bolton, UK) [24,25]. These coatings were chosen because they are transparent, helping to preserve the original appearance of wooden cultural relics and ancient buildings. At elevated temperatures, a sequence of chemical reactions occurs within the IFR coating, leading to the formation of a porous, intumescent char layer [26,27,28]. This char layer typically exhibits low thermal conductivity, effectively insulating and safeguarding the substrate from fire.

3.1. Model Description

3.1.1. Complex Wood Pyrolysis Model

Without a layer of IFR coating, wood undergoes pyrolysis, yielding char and various gaseous species upon exposure to heat. The pyrolysis scheme of wood can be illustrated as follows:

where denotes the char yield.

To model the decomposition of wood, it is essential to consider both the reaction kinetics and the associated thermal response parameters. The pyrolysis of wood depends on pre-exponential factor () and activation energy (), which are often either unknown or difficult to directly obtain. Therefore, a sophisticated pyrolysis model, as demonstrated by Equations (1)–(3), was adopted and tailored to historic fir wood and its char layer to improve the modeling accuracy [29]. and can be derived from Equations (1)–(3), using reference temperature (), heating rate (), and pyrolysis range ():

To further enhance the reliability of the modeling results, the reference temperature (), heating rate (), and pyrolysis range () of Chinese fir naturally aged for 70 years, as reported by Huai-Lin Yan et al. [30] using an STA 449 thermal analyzer, were adopted in the simulation. These parameters were selected because Wan’an Bridge, reconstructed using fir wood in 1954 following a catastrophic flood in 1952, contained structural timber that had undergone approximately 70 years of natural aging by the time of the fire incident. Furthermore, the effective combustion heat, along with the mass remains of the fir wood, which were derived from Cone Calorimetry tests as documented in References [31,32], were utilized in our study. A comprehensive listing of all the pyrolysis parameters employed in the Wan’an Bridge fire simulation is presented in Table 1.

Table 1.

Pyrolysis parameters of Chinese fir.

3.1.2. Combustion Model

For large-scale fire simulations, we employ a simplified combustion model that assumes homogeneous fuel-mixing and instantaneous reactions to ensure computational efficiency. In this approach, pyrolyzed gaseous fuel (composed of C, H, O, and N) completely mixes with air and undergoes instantaneous combustion to form H2O, CO2, CO, N2, and soot. While neglecting intermediate reaction steps, this widely used model can effectively predict critical global parameters, including heat release rate (HRR), temperature distribution, and CO concentration at a minimal computational cost [33,34,35], making it particularly suitable for the Wan’an bridge fire simulation. The general chemical reaction for the combustion of gaseous fuel is represented by the following equation:

where denotes the stoichiometric coefficients.

In order to characterize the combustion properties, it is sufficient to provide the chemical formula of the fuel (), along with the associated yields of carbon monoxide () and soot (). Chinese fir is a type of low-density timber, whose chemical composition can be abbreviated as C48.7H6.1N0.1O45.1 according to elemental analysis [31]. Based on the same source, the yields of CO and flue gas are 0.0115 kg/kg and 0.0074 kg/kg, respectively. These values provide important insights into the combustion behavior of Chinese fir, which is crucial for accurate fire modeling.

3.1.3. Heat Transfer Model

The default radiation model was employed in the simulations, which computed the radiation intensity over 104 solid angles using a gray absorption coefficient and a radiative fraction of the local heat release rate equal to 0.35. Within the wood, heat transfer was calculated using one-dimensional heat conduction, as shown in Equations (4) and (5).

For the present simulation, the density and temperature-dependent thermal conductivity of dry fir reported in Reference [36], the specific heat capacity reported in Reference [37], and the thermal response parameters of the char formed during the combustion of Chinese fir reported in Reference [38] are utilized. These values are listed in Table 2 for reference.

Table 2.

Adopted thermal response parameters of dry Chinese fir and its char for simulation.

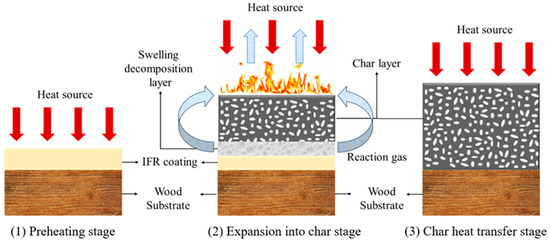

After the application of an IFR coating, the bridge components are regarded as multi-layered structures. This coating significantly impacts the heat transfer modes, altering the bridge’s thermal behavior. As demonstrated in Figure 4, the thermal protection process of the IFR coating exposed to the external heat flux undergoes three distinct stages: (1) preheating stage; (2) expansion into char stage; (3) char heat-transfer stage. The division is determined through the commencement of the coating decomposition and the cessation of flame combustion. During the preheating and char heat-transfer stage, heat is exclusively transferred via the coating or char layer. Conversely, during expansion into the char stage, the char layer, swelling decomposition layer, and coating co-exist, and heat is transferred through these three layers in turn [39]. To incorporate the changes in heat transfer throughout various stages of the expanding coating in a simple way, we utilized temperature-independent thermal conductivity and expansion ratio values, which were determined through a combination of thermal degradation experiments and mathematical models, as detailed in References [22,23,24,25], and summarized in Table 3.

Figure 4.

Thermal response of the IFR coating under exposure to external heat flux.

Table 3.

The temperature-independent thermal conductivity and expansion ratio of the IFR coatings.

Please note that the expansion ratio of intumescent coatings is temperature-dependent rather than a fixed value. The expansion ratio of the epoxy resin-based coating, measured using TGA at a heating rate of 10 °C/min, remained almost unchanged when the coating’s temperature increased from 400 °C to 800 °C [22]. The vinyl acetate-based coating’s expansion ratio was measured by a cone calorimeter under heat fluxes of 90 kW/m² and the coating temperatures reached above 550 °C [23]. The water-based coating’s expansion ratio was measured using a cone calorimeter under heat fluxes of 50 kW/m² and 65 kW/m². Based on the measured substrate temperature [24], the estimated final coating temperatures exceeded 400–500 °C. According to Reference [25], the expansion ratio of the water-based coating stabilizes when the temperature surpasses 400 °C. Therefore, the expansion ratios of the three IFR coatings are comparable.

In timber applications, a compatible primer is always applied before the fire-retardant coating to seal the substrate, improve adhesion, prevent interference from moisture/resin, and ensure uniform fire protection. Thus, its application to timber substrates does not affect the intumescent mechanism and has almost no impact on the thermal parameters, even though the three IFR fire-retardant coatings are generic fire-protection formulations designed for broad applications.

3.2. Numerical Setup

3.2.1. Architectural Model and Grid

The Wan’an Bridge architectural model is a full-scale replica based on the actual structure, strictly adhering to the spatial proportional relationships of the prototype. In response to the limitations of the FDS numerical simulation platform in modeling complex curved surfaces, a parameter equivalence method was employed to geometrically reconstruct the cylindrical members of the bridge. Specifically, cylindrical members were simplified as rectangular prismatic components, and the model was equivalently modified based on the measured surface area of the actual structure.

In the study, a computational domain measuring 12 m × 106 m × 10 m with grid cells of 0.4 m in cubic volume was utilized. The grid size was selected through the iterative testing of different grid configurations, aiming to achieve a balance between model precision and computational efficiency. Since the fire-development process employs a complex pyrolysis model (instead of directly predefining the heat release rate of materials), the heat release rate is a dynamic result calculated through the coupling of material pyrolysis kinetics and combustion reactions. This multi-physics coupling characteristic renders traditional grid validation formulas based on predefined heat release rates (such as empirical criteria based on flame characteristic scales) no longer applicable. Therefore, to balance computational efficiency and model accuracy, we conducted a systematic sensitivity analysis through comparative tests with four grid sizes (0.25 m, 0.3 m, 0.4 m, and 0.5 m). The results showed that when using a 0.4 m grid, key parameters (peak heat release rate and flame spread speed) achieved an error convergence within 8%, comparable to the results obtained with 0.25 m and 0.3 m grids. However, no ignition occurred above the bridge when employing a 0.5 m grid size. This demonstrates that the grid size of 0.4 m can accurately represent the simulation while improving computational efficiency. Cylindrical columns and beams on the bridge are represented as slender cuboids, with the side lengths determined using the measured surface area and diameter.

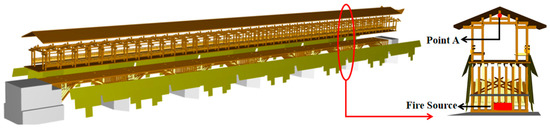

3.2.2. Fire Source

The location of the fire source, as shown in Figure 5, was determined based on the findings of the fire investigation. During the smoldering phase, estimating the fire source power is highly challenging. Based on video evidence, continuous flaming combustion was first observed at 21:02:20. The fire source’s power at this moment can be considered as the fire spread threshold. In the simulation sensitivity analysis, we evaluated fire source powers ranging from 300 kW to 800 kW. For each simulation scenario, the fire source power was maintained as a fixed input parameter. The results identified 500 kW as the critical threshold power required to initiate fire spread in the timber structure. Consequently, a 500 kW fire source power was adopted in the modeling. Subsequently, the actual fire event at 21:02:20 was deemed the start of the simulated fire scenario. To monitor the changes in temperature and smoke concentration throughout the fire’s progression, detectors were configured at Point A, as illustrated in Figure 5.

Figure 5.

The locations of fire source and detectors on the model of Wan’an Bridge.

3.2.3. Boundary and Initial Conditions

The accuracy of fire numerical simulations is highly dependent on the reasonable setting of boundary and initial conditions. This section clarifies the boundary conditions and initial parameters required for the simulation based on the actual environmental parameters during the Wan’an Bridge fire on 6 August 2022, as well as the experimental assumptions.

According to local meteorological records, the average ambient temperature on the day of the fire was approximately 25 °C. This temperature was used as the air temperature at the initial moment of the simulation, uniformly distributed within the computational domain, and it was assumed that the initial temperature of the bridge’s wooden materials was consistent with the ambient temperature. The relative humidity was set to 80% with reference to the humidity in Pingnan County in August. Humidity indirectly affects the combustion rate by influencing the moisture content of combustible materials. During the simulation, constant humidity conditions were adopted, and the minor disturbances to the fire caused by local evaporation effects were ignored.

To simplify the model and focus on the impact of the bridge structure on fire spread, the external wind speed was assumed to be 0 m/s (no wind conditions). The boundary ventilation was set to be dominated by natural convection, with the top and sides of the computational domain left open, and the pressure outlet boundary conditions following the Boussinesq buoyancy approximation. This assumption is consistent with eyewitness reports from the fire scene that there was “no significant wind interference”.

4. Results and Discussion

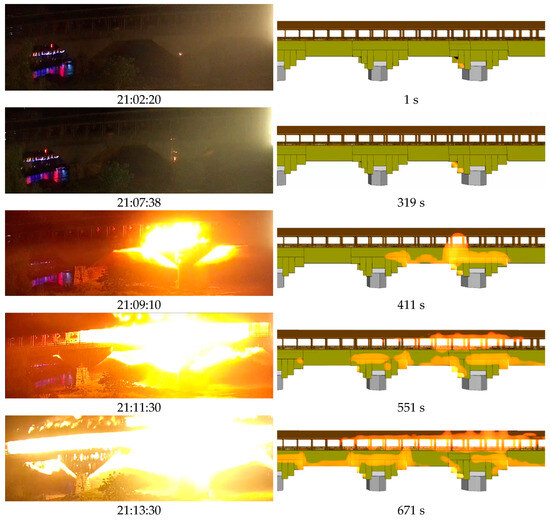

We used video footage from the Wan’an Bridge fire as qualitative validation when experimental data were unavailable due to the non-destructive requirements for cultural relics. The video snapshots of the Wan’an bridge, captured from the moment the first continuous flame was observed (designated as the onset of the fire) until the flame reached the deck, ceiling, and the tops of the first and second left piers, are presented in Figure 6. Parallel to these real-time observations, simulated fire scenarios at corresponding time intervals are also exhibited. Limited by the camera’s field of view, our comparison focuses solely on the initial 11 min, during which the fire’s spread remained within the monitored perimeter. According to Figure 6, the predicted fire growth reflects the real fire development well, although the modeled fire propagates slightly slower than the actual case. This finding is rationalized by the fact that the smoldering and small flames, concealed by clapboards, persisted for approximately 2 h, gradually heating the adjacent wooden components and thereby facilitating the accelerated spread of the fire.

Figure 6.

Comparison of the recorded (left) and simulated (right) fire scenarios.

4.1. Simulation Results Without Flame-Retardant Coatings

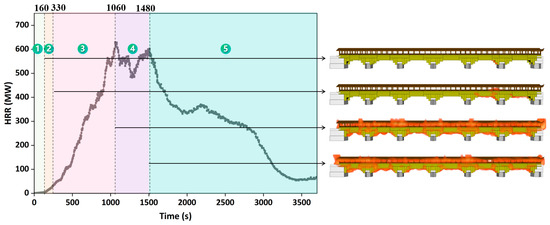

The modeled HRR of the Wan’an bridge fire without flame-retardant coatings is presented in Figure 7. The fire’s development is divided into five stages based on the fire growth rate, as shown in Figure 7, and the instantaneous flame contours at the end of different stages are indicated by dashed lines.

Figure 7.

HRR profile and snapshots of simulated Wan’an Bridge fire without flame-retardant coatings.

During Stage 1, the fire grows vertically within the arch and the HRR increases slowly. At the end of this stage (160 s), the bottom surface of the bridge deck located above the ignition source is ignited. In Stage 2, the fire mainly spreads horizontally along the first and second bridge arches, while the HRR increases almost linearly. At 330 s, the flame begins to emerge on the top of the bridge deck. Afterwards, the fire development enters a rapid growth phase, as also verified by the video snapshots. Stage 3 continues for about 750 s, during which the fire spreads horizontally above and below the deck at the same time. Meanwhile, the HRR growth rate is much faster than that of the second stage. By 1060 s, the flame reaches the left end of the bridge. In Stage 4, the bridge continues to burn fiercely and the peak HRR of 630 MW occurs at 1060 s. As the fire propagates, the initially ignited bridge sections begin to decay while newly ignited areas continue to develop. This dynamic interaction between decaying and growing fire zones collectively influences the HRR, resulting in non-monotonic variations. Consequently, Figure 7 demonstrates a characteristic trough between two HRR peaks, occurring at approximately 1250 s. At approximately 1480 s, the fire enters Stage 5 and begins to decay due to the consumption of fuel and formation of a carbonaceous protective layer over the wood, which slows the burning process.

The simulation became unreliable after 1600 s because the bridge began to collapse almost 5 min after the whole construction was on fire and the caving-in behavior changed the fuel configuration, which cannot be simulated by FDS.

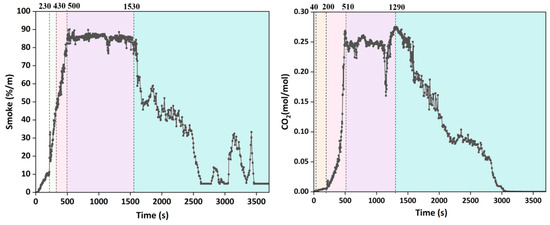

Since smoke and CO2 concentrations significantly affect evacuation, and as many villagers were present on the bridge during the Wan’an Bridge fire, the variations in smoke and CO2 concentration at Point A are presented in Figure 8. The smoke curve exhibits two distinct growth phases, where the growth rate is noticeably lower during the first 200 s compared to between 200 and 510 s. Hereafter, the smoke concentration remains stable at around 85%/m. The growth in the CO2 concentration can be largely divided into three stages and the growth rate of each stage gradually increases until the concentration reaches a peak value of 0.25 mol/mol at around 500 s. Afterwards, the CO2 concentration remains relatively steady before the final decline.

Figure 8.

Smoke and CO2 concentration profile at Point A without flame-retardant coatings.

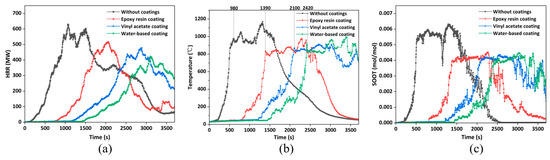

4.2. Simulation Results with Flame-Retardant Coatings

Figure 9 shows the HRR of the Wan’an Bridge fire simulation with and without flame-retardant coatings. All three flame-retardants demonstrate significant suppressing effects on the fire development, including a delayed ignition time, reduced fire growth rate, and decreased peak HRR, as illustrated in Table 4. For example, the water-based one delayed the time to ignition () by 1280 s, reduced the peak HRR () by 34%, delayed the time to PHRR () by 2080 s, and lowered the peak smoke production rate (PSPR) by 30%.

Figure 9.

HRR profile (a), along with the temperature (b) and soot concentration (c) measured at Point A.

Table 4.

Key parameters of Wan’an Bridge fire with and without flame-retardant coatings.

As illustrated in Figure 9b, it takes much longer for the temperature at Point A to reach a stable stage, as indicated by the dashed line, after the application of flame-retardant coatings. At the same time, the peak and average temperatures during the steady burning stage are 11–17% lower than those obtained without coatings. Among the three fire-resistant coatings, the water-based one shows the largest delay in temperature growth and smoke production. The maximum soot concentrations obtained with the three types of flame-retardant coatings are similar and approximately 30% lower than that of the case without coatings.

The effect of the flame-retardant coatings can be attributed to the barrier formed by the carbon layer and the gas generated by the coating during the combustion process, providing highly effective heat insulation. This layer prevents rapid temperature increases on the surface of the combustible material, resulting in a significant reduction in the thermal decomposition rate of wood. The layer also impedes the mass transfer of the pyrolysis gases and ambient air, leading to a lower combustion speed and lower heat release rate.

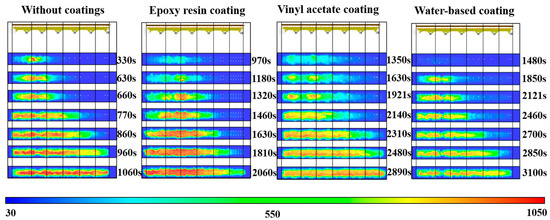

Figure 10 shows the temperature slices on the bridge deck when the fire spreads to different bridge arches while using different treatment methods. It can be seen from the figure that the use of fire-retardant paint has a significant impact on the position at which the fire spreads to the bridge deck. When there is no fire-retardant paint, the position at which the fire spreads to the bridge deck is directly above the fire source. When fire retardant paint is added, the fire spreads to the middle part of the arch, where there is more combustible wood under the bridge. It can also be seen from the temperature distribution that the water-based fire-retardant coating has the best effect on hindering the fire.

Figure 10.

Temperature slice on the bridge slab.

It can be seen from Table 4 and Figure 9 that the water-based coating exhibits the best flame-resistant performance among the three cases. When considering the effectiveness of the expandable flame-retardant coatings, the expansion ratio plays a crucial role. The expansion ratios of the epoxy resin, vinyl acetate, and water-based flame-retardant coatings are 6.4, 20, and 20, respectively. In addition, the char produced by the water-based agent has a lower thermal conductivity compared to that of the vinyl acetate coating, so the water-based painting exhibits the best fire-resistance among the three agents.

From the above discussion, it is evident that the IFR coatings demonstrated an excellent fire-protection performance for Wan’an bridge, significantly delaying ignition, reducing peak heat release rate, and lowering fire temperatures and soot concentrations. The increased expansion ratio and reduced thermal conductivity of IFR coatings can significantly enhance the effectiveness of their protection. These findings underscore the potential of transparent IFR coatings in safeguarding historic timber structures, effectively balancing fire safety with minimal intervention, which is a key requirement in heritage conservation.

The major limitations of the study’s use of FDS for the Wan’an Bridge fire simulation include the following: (1) the necessary structural simplifications that omitted detailed architectural features of the complex bridge structure, potentially affecting simulation accuracy; (2) the inherent constraints in FDS’s capacity to model coupled structural failure processes, particularly deformation and collapse mechanisms; and (3) the dependence on a video-based qualitative validation of fire spread patterns, lacking complementary quantitative measurements such as temperature distributions and smoke concentration data for full validation because the irreplaceable nature of cultural relics precludes destructive testing.

5. Conclusions

This study employed a Fire Dynamics Simulator (FDS) to investigate the fire behavior of China’s longest wooden arch bridge, Wan’an Bridge. Given that video footage provide the only data available for the Wan’an Bridge fire, comparisons between simulations and actual events were necessarily limited to the range of fire spread. Through these comparisons, FDS demonstrated its effectiveness in analyzing fire progression using customized pyrolysis and combustion models, albeit with a slight underestimation of the fire spread speed due to concealed smoldering. The simulations provided valuable insights into flame propagation and thermal dynamics across the bridge.

Furthermore, the study evaluated the performance of three types of intumescent flame-retardant coatings. The results indicated that IFR coatings significantly enhanced the bridge’s fire resistance, with the water-based coating exhibiting the most pronounced effects due to its high expansion ratio and low thermal conductivity. These coatings delayed ignition, mitigated fire growth, and decreased peak heat release rates.

The irreplaceable nature of cultural relics precludes destructive testing, necessitating reliance on simulation-based predictive frameworks. Although only video footage of the Wan’an Bridge fire was available for validation, the simulation results still contribute to fire safety knowledge through the application of FDS in simulating historic wooden construction fires, and provide actionable insights for fire prevention strategies in comparable structures.

Author Contributions

Conceptualization, H.J. and L.Z.; methodology, H.J.; software, J.T.; validation, J.T. and D.W.; formal analysis, J.T. and D.W.; investigation, J.T.; resources, H.J.; data curation, J.T.; writing—original draft preparation, J.T. and Y.C.; writing—review and editing, L.Z.; supervision, L.Z.; project administration, H.J.; funding acquisition, H.J. and L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Science and Technology of the People’s Republic of China (Grant No. 2021YFC1523504) and Beijing Municipal Natural Science Foundation (Grant No. 8222021).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on reasonable request.

Acknowledgments

Not applicable.

Conflicts of Interest

Author Dong Wang was employed by the company China Railway Construction Group Co. Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Nomenclature

| Symbol | Description | Unit |

| Activation energy | ||

| Peak reaction rate | ||

| Frequency factor | ||

| Gas constant | ||

| Mass fraction of reacting material | ||

| Temperature | ||

| Peak temperature | ||

| Heating rate | ||

| Temperature difference | ||

| Yield of solid residue | ||

| Density of the material | ||

| Specific heat capacity of the material | ||

| Thermal conductivity of the material | ||

| Temperature of the solid | ||

| Time | ||

| Heat production rate | ||

| Convective heat flux | ||

| Radiative heat flux |

References

- The Wan’an Bridge—The Longest Wooden Arched Corridor Bridge in China Originally Built During the Northern Song Dynasty Was Destroyed by Fire. Available online: http://finance.sina.com.cn/jjxw/2022-08-07/doc-imizmscv5170237.shtml (accessed on 28 April 2025). (In Chinese).

- Wan’an Bridge. Available online: https://baike.baidu.com/item/%E4%B8%87%E5%AE%89%E6%A1%A5/5149574?fr=aladdin (accessed on 28 April 2025). (In Chinese).

- Wuyishan Yuqing Bridge Fire Incident. Available online: https://news.ifeng.com/c/7fZm9at4PzN (accessed on 28 April 2025). (In Chinese).

- The 500-Year-Old Buyue Bridge in Jianou, Fujian Province, Was Burned Down, the Cause of the Fire Is Under Investigation. Available online: https://www.thepaper.cn/newsDetail_forward_2939781 (accessed on 28 April 2025). (In Chinese).

- Chongqing Qianjiang Zhuoshui Ancient Town’s Fengyu Covered Bridge Destroyed by Fire. Available online: https://war.163.com/photoview/00AP0001/40509.html#p=9EPDNBJ200AP0001 (accessed on 28 April 2025). (In Chinese).

- Canadian Wooden Trestle Bridge Destroyed in Spectacular Fire in Alberta’s Mayerthorpe. Available online: https://www.abc.net.au/news/2016-04-28/wooden-trestle-bridge-destroyed-in-spectacular-fire/7365688 (accessed on 28 April 2025).

- Wells, N.; Moon, R.E. Wood Swelling: Pressures exerted from saturated wood materials. In Forensic Engineering; American Society of Civil Engineers: Reston, VA, USA, 2015; pp. 209–218. [Google Scholar] [CrossRef]

- Tolvaj, L.; Varga, D. Photodegradation of timber of three hardwood species caused by different light sources. Acta Silv. Lignaria Hung. 2012, 8, 145–156. [Google Scholar] [CrossRef]

- Zborowska, M.; Niedzielski, P.; Budka, A.; Enenche, J.; Mleczek, M. Content of elements in contemporary and archaeological wood as a marker of possible change in physico-chemical parameters. J. Cult. Herit. 2023, 63, 90–100. [Google Scholar] [CrossRef]

- Borgin, K.; Parameswaran, N.; Liese, W. The effect of aging on the ultrastructure of wood. Wood Sci. Technol. 1975, 9, 87–98. [Google Scholar] [CrossRef]

- Lowden, L.A.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef]

- Guibaud, A.; Mindeguia, J.C.; Albuerne, A.; Parent, T.; Torero, J. Notre-Dame de Paris as a validation case to improve fire safety modelling in historic buildings. J. Cult. Herit. 2023, 65, 145–154. [Google Scholar] [CrossRef]

- You, D.; Wang, X.Z.; Chen, W.J.; Wu, G.X. Numerical simulation analysis of smoke control and flow for large building fire. Appl. Mech. Mater. 2014, 608–609, 61–65. [Google Scholar] [CrossRef]

- Binbin, W. Comparative research on fluent and fds’s numerical simulation of smoke spread in subway platform fire. Procedia Eng. 2011, 26, 1065–1075. [Google Scholar] [CrossRef]

- Mohan, R.; Sundararaj, S.; Thiagarajan, K.B. Numerical simulation of flow over buildings using OpenFOAM®. AIP Conf. Proc 2019, 2112, 020149. [Google Scholar] [CrossRef]

- Shen, T.; Huang, Y.; Chien, S. Using fire dynamic simulation (FDS) to reconstruct an arson fire scene. Bldg. Environ. 2008, 43, 1036–1045. [Google Scholar] [CrossRef]

- Chang, W.Y.; Tang, C.H.; Lin, C.Y. Estimation of magnitude and heat release rate of fires occurring in historic buildings-taking churches as an example. Sustainability 2021, 13, 91–93. [Google Scholar] [CrossRef]

- Wang, X.Y.; Wang, J.; Wang, J.H.; Sheng, G.H. Experimental and numerical simulation analyses of flame spread behaviour over wood treated with flame retardant in ancient buildings of fuling mausoleum, China. Fire Technol. 2022, 61, 1053–1077. [Google Scholar] [CrossRef]

- Huang, Y.H. The use of parallel computing to accelerate fire simulations for cultural heritage buildings. Sustainability 2020, 12, 10005. [Google Scholar] [CrossRef]

- Zhou, B.; Zhou, X.M.; Chao, M.Y. Fire protection of historic buildings: A case study of group-living yard in Tianjin. J. Cult. Herit. 2012, 13, 389–396. [Google Scholar] [CrossRef]

- Zhang, F.; Shi, L.; Liu, S.; Shi, J.; Shi, C.; Xiang, T. CFD-based fire risk assessment and control at the historic dong wind and rain bridges in the western Hunan region: The case of Huilong bridge. Sustainability 2022, 14, 12271. [Google Scholar] [CrossRef]

- Gomez Mares, M.; Tugnoli, A.; Landucci, G.; Barontini, F.; Cozzani, V. Behavior of intumescent epoxy resins in fireproofing applications. J. Anal. Appl. Pyrol. 2012, 97, 99–108. [Google Scholar] [CrossRef]

- Griffin, G.J. The modeling of heat transfer across intumescent polymer coatings. J. Fire Sci. 2010, 28, 249–277. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.C.; Bailey, C.C.; Taylor, A.P. Global modelling of fire protection performance of an intumescent coating under different furnace fire conditions. Fire Saf. J. 2012, 31, 51–72. [Google Scholar] [CrossRef]

- Cirpici, B.K.; Wang, Y.C.; Rogers, B. Assessment of the thermal conductivity of intumescent coatings in fire. Fire Saf. J. 2016, 81, 74–84. [Google Scholar] [CrossRef]

- Hao, J.; Chow, W.K. A brief review of intumescent fire retardant coatings. Archit. Sci. Rev. 2003, 46, 89–95. [Google Scholar] [CrossRef]

- Bar, M.; Alagirusamy, R.; Das, A. Flame retardant polymer composites. Fibers Polym. 2015, 16, 705–717. [Google Scholar] [CrossRef]

- Mohd Sabee, M.M.S.; Itam, Z.; Beddu, S.; Zahari, N.M.; Mohd Kamal, N.L.; Mohamad, D.; Zulkepli, N.A.; Shafiq, M.D.; Abdul Hamid, Z.A. Flame retardant coatings: Additives, binders, and fillers. Polymer 2022, 14, 2911. [Google Scholar] [CrossRef] [PubMed]

- McGrattan, K.; McDermott, R.; Weinschenk, C.; Forney, G. Fire Dynamics Simulator Users Guide, 6th ed.; Special Publication (NIST SP); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013. [CrossRef]

- Yan, H.; Zhu, G.; Zhao, Y. Study on pyrolysis characteristics of Chinese fir under different natural aging times. Fire 2022, 5, 161. [Google Scholar] [CrossRef]

- Yue, K.; Wu, J.; Xu, L.; Tang, Z.; Chen, Z.; Liu, W.; Wang, L. Use impregnation and densification to improve mechanical properties and combustion performance of Chinese fir. Constr. Build. Mater. 2020, 241, 118101. [Google Scholar] [CrossRef]

- Ira, J.; Hasalová, L.; Šálek, V.; Jahoda, M.; Vystrčil, V. Thermal analysis and cone calorimeter study of engineered wood with an emphasis on fire modelling. Fire Technol. 2020, 56, 1099–1132. [Google Scholar] [CrossRef]

- Koraïem, M.; Assanis, D. Wood stove combustion modeling and simulation: Technical review and recommendations. Int. Commun. Heat. Mass. 2021, 127, 105423. [Google Scholar] [CrossRef]

- Dai, X.; Gamba, A.; Liu, C.; Anderson, J.; Charlier, M.; Rush, D.; Welch, S. An engineering CFD model for fire spread on wood cribs for travelling fires. Adv. Eng. Softw. 2022, 173, 103213. [Google Scholar] [CrossRef]

- Yang, D.; Hu, L.H.; Jiang, Y.Q.; Huo, R.; Zhu, S.; Zhao, X.Y. Comparison of FDS predictions by different combustion models with measured data for enclosure fires. Fire Saf. J. 2010, 45, 298–313. [Google Scholar] [CrossRef]

- Yu, Z.; Xu, X.; Fan, L.; Hu, Y.; Cen, K. Experimental measurements of thermal conductivity of wood species in China: Effects of density, temperature, and moisture content. For. Prod. J. 2011, 61, 130–135. [Google Scholar] [CrossRef]

- Wang, J.; Hou, S.; Shen, Z.; Wen, J.; Qi, C. Thermal characteristics and simulation of enzymatic lignin isolated from Chinese fir and birch. Forests 2022, 13, 914. [Google Scholar] [CrossRef]

- Shi, L.; Chew, M.Y.L. A review of thermal properties of timber and char at elevated temperatures. Indoor Built Environ. 2023, 32, 9–24. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, F.; Xing, L.; Xie, W.; Cheng, Y. Construction and verification of a heat transfer model for intumescent coatings. Prog. Org. Coat. 2022, 167, 106868. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).