Comparative Study of Temperature Distribution Characteristics of Ceiling Jets at Center and Edge Regions in Corridors

Abstract

1. Introduction

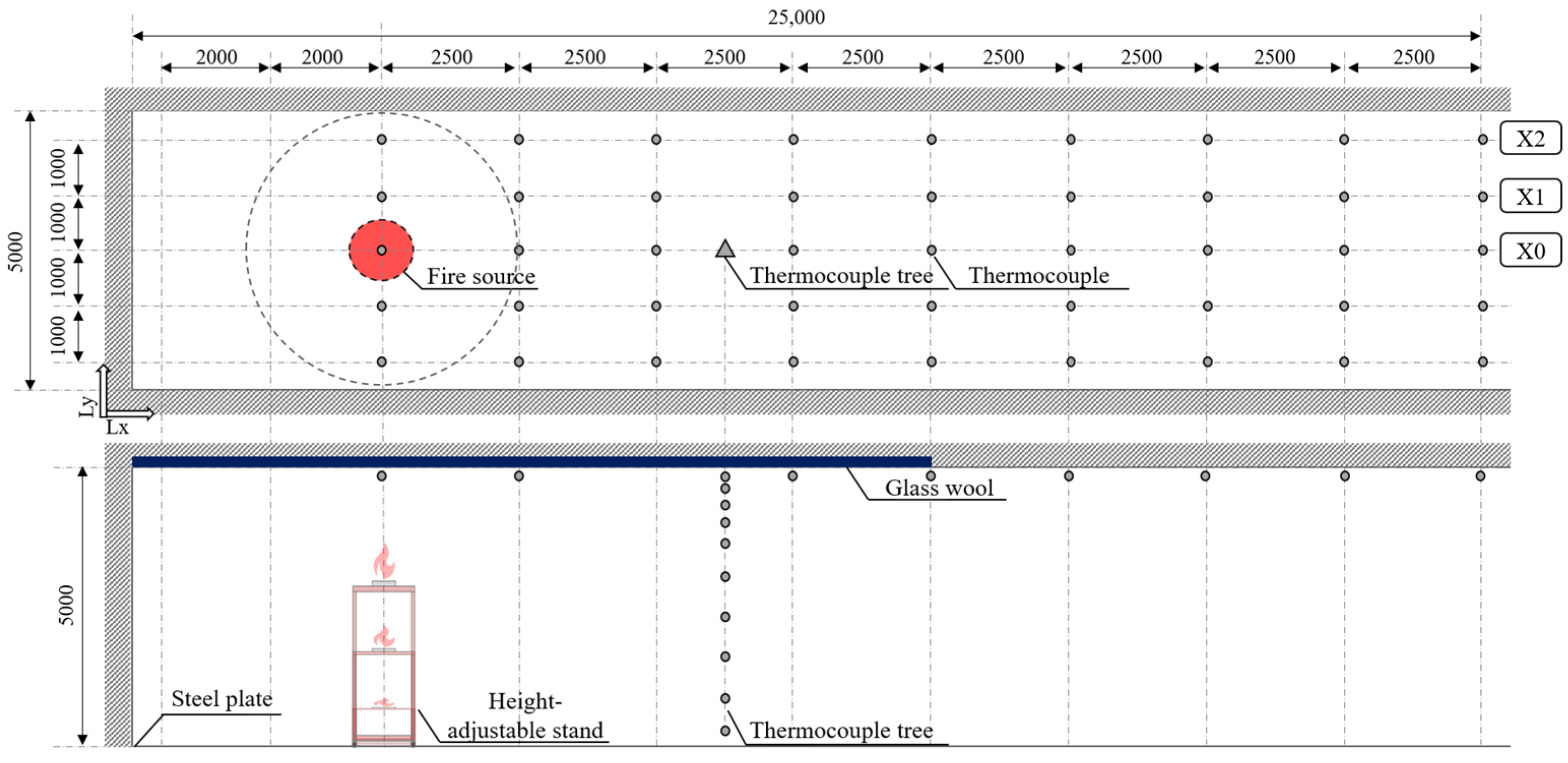

2. Experimental Overview

2.1. Experimental Setup

2.2. Measurement Items

2.3. Experimental Conditions

3. Experimental Results

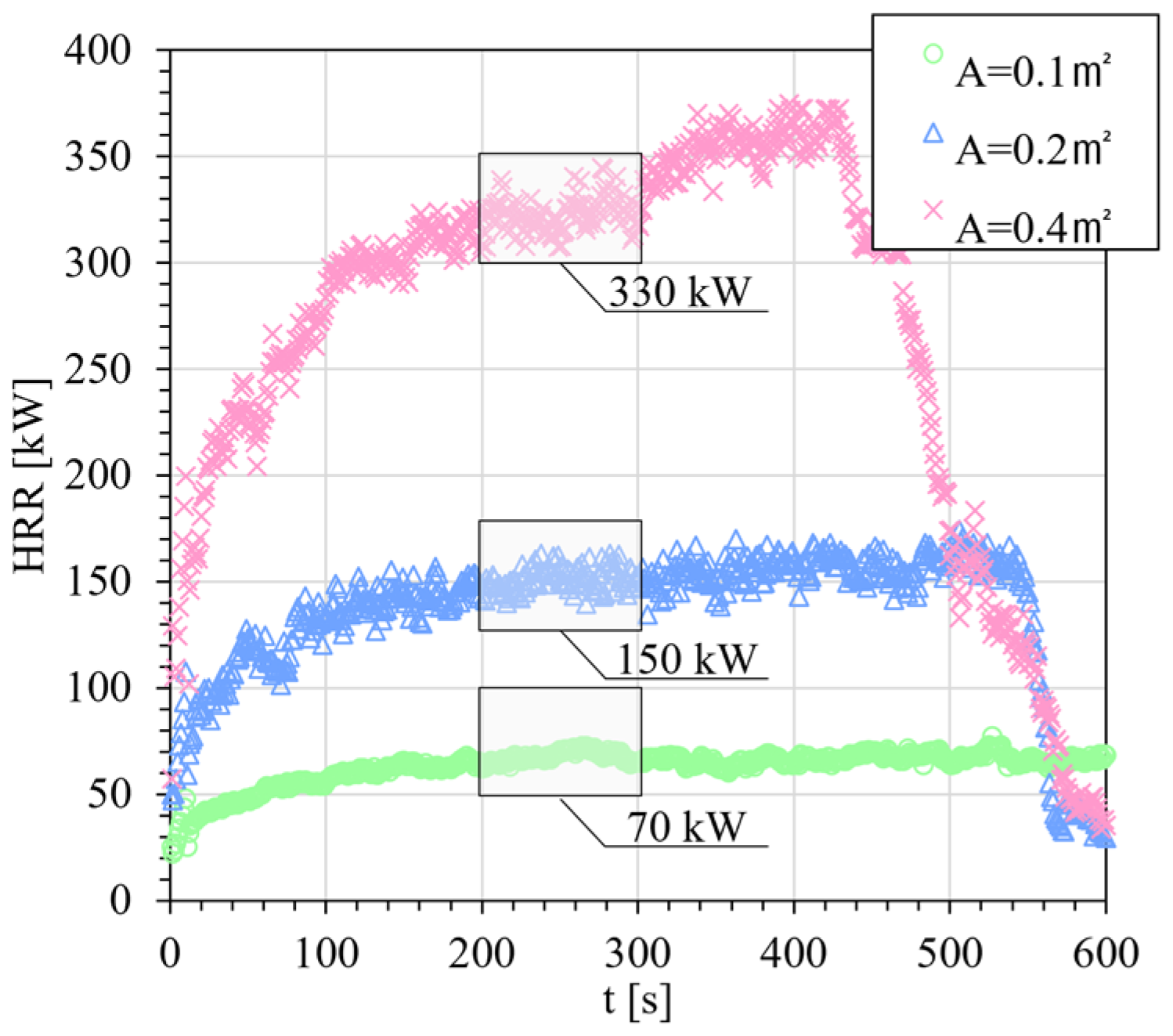

3.1. Heat Release Rate

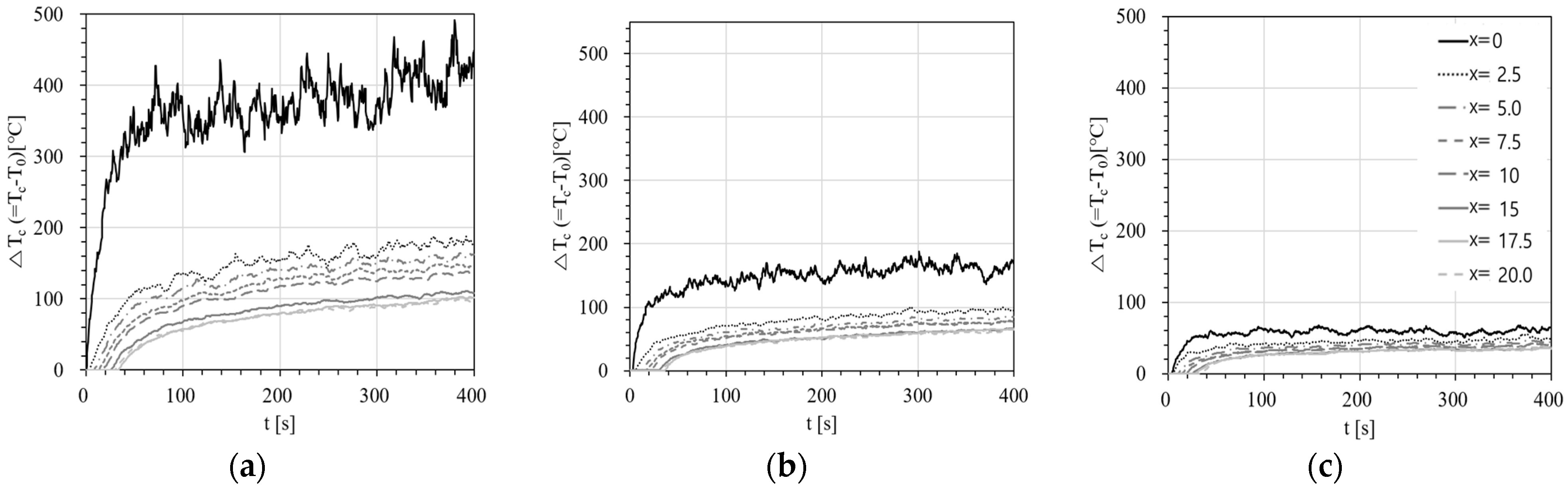

3.2. Variation in Temperature Rise over Time

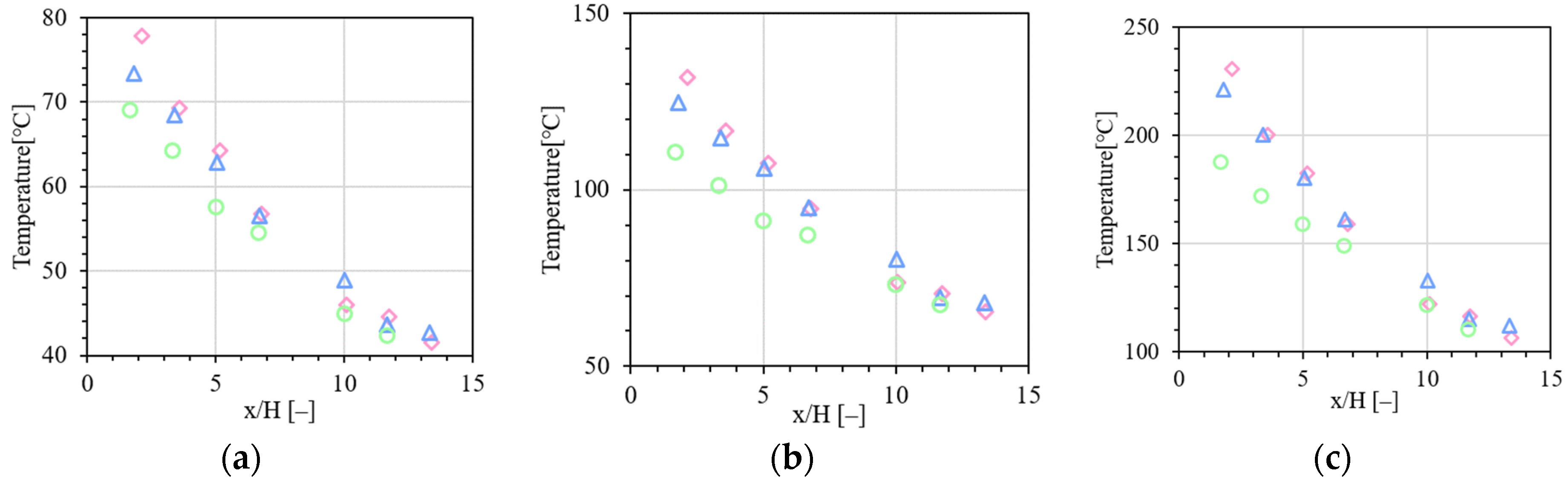

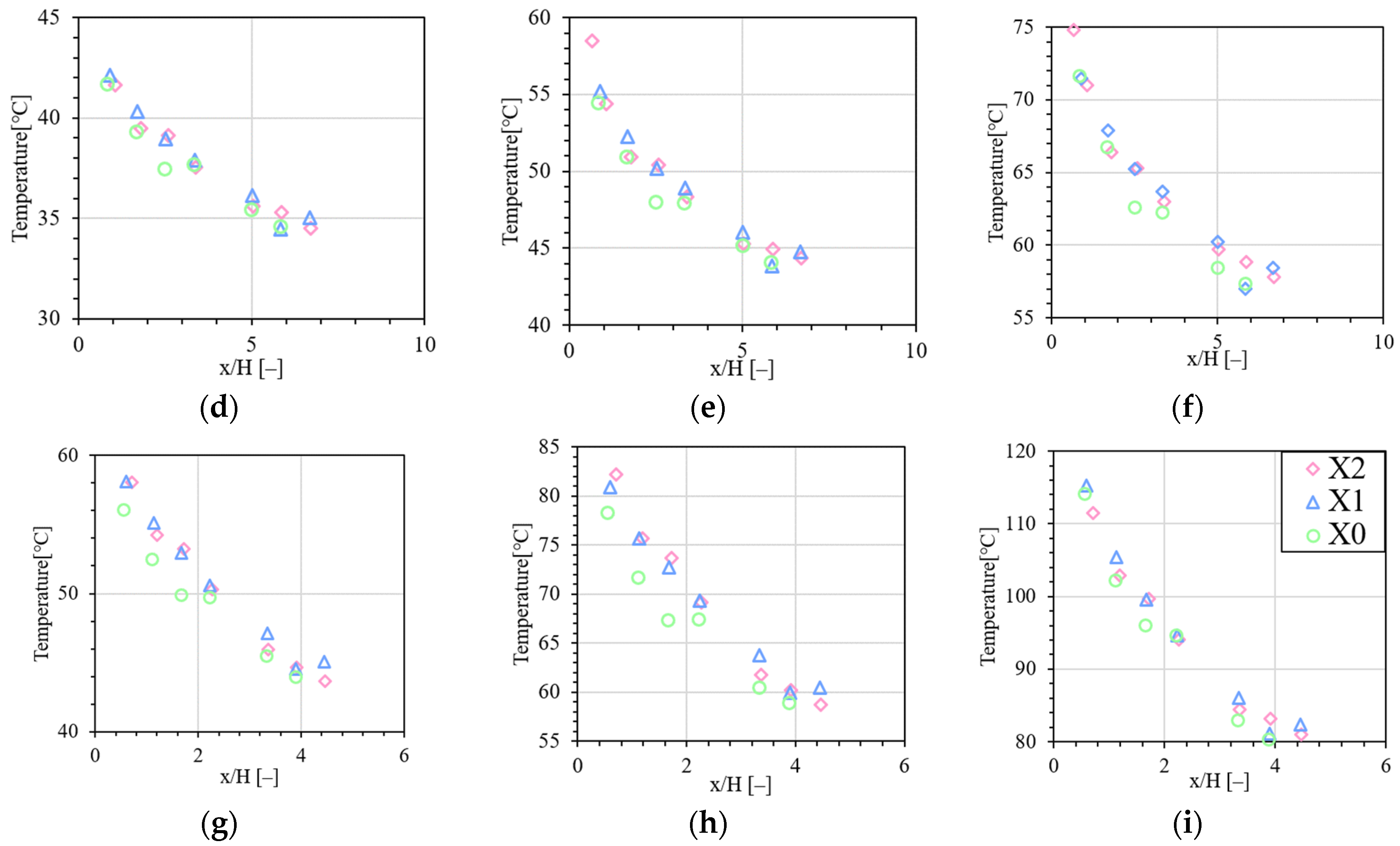

3.3. Horizontal Temperature Distribution

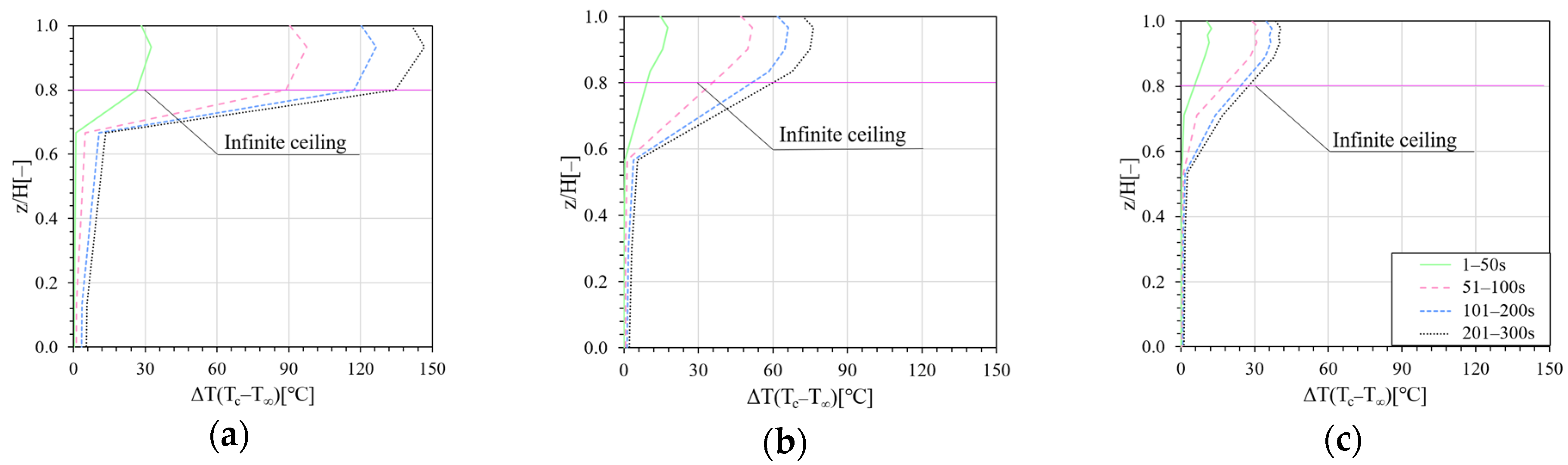

3.4. Vertical Temperature Distribution

4. Discussion

4.1. Temperature Prediction of Ceilling Flow During Smoke Inflow to the Lower Part

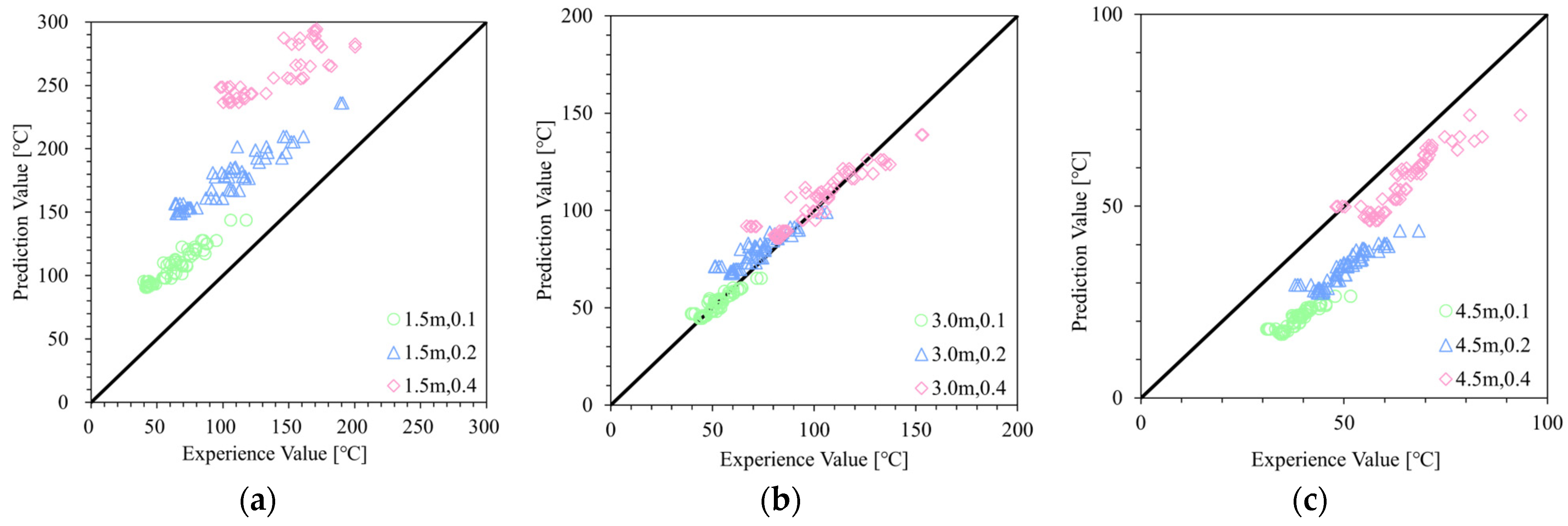

4.2. Review of Prediction Equation Through Conparison with Experimental Values

- Region 2:

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alpert, R.L. Turbulent Ceiling-Jet Induced by Large-Scale Fires. Combust. Sci. Technol. 1975, 11, 197–213. [Google Scholar] [CrossRef]

- Alpert, R.L. Calculation of Response Time of Ceiling-Mounted Fire Detectors. Fire Technol. 1972, 8, 181–195. [Google Scholar] [CrossRef]

- Suzuki, K. Extending of Ceiling Jet Model to Unsteady Cases in Large Spaces. J. Environ. Eng. 2012, 77, 223–230. [Google Scholar] [CrossRef]

- Quintiere, J.G.; Rinkinen, W.J.; Jones, W.W. The Effect of Room Openings on Fire Plume Entrainment. Combust. Sci. Technol. 1981, 26, 193–201. [Google Scholar] [CrossRef]

- Oka, Y.; Oka, H. Velocity and temperature attenuation of a ceiling-jet along a horizontal tunnel with a flat ceiling and natural ventilation. Tunn. Undergr. Space Technol. 2016, 56, 79–89. [Google Scholar] [CrossRef]

- Li, L.; Cheng, X.; Wang, X.; Zhang, H. Temperature distribution of fire-induced flow along tunnels under natural ventilation. J. Fire Sci. 2012, 30, 122–137. [Google Scholar] [CrossRef]

- Hu, L.H.; Huo, R.; Li, Y.Z.; Wang, H.B.; Chow, W.K. Full-scale burning tests on studying smoke temperature and velocity along a corridor. Tunn. Undergr. Space Technol. 2005, 20, 223–229. [Google Scholar] [CrossRef]

- Hu, L.H.; Huo, R.; Wang, H.B.; Li, Y.Z.; Yang, R.X.; He, W.H. Full scale experiments on studying smoke spread in a road tunnel. In Proceedings of the 8th International Symposium. International Association for Fire Safety Science, Beijing, China, 18–23 September 2005; pp. 1437–1447. [Google Scholar]

- Hu, L.H.; Huo, R.; Wang, H.B.; Li, Y.Z.; Yang, R.X. Experimental studies on fire- induced buoyant smoke temperature distribution along tunnel ceiling. Build. Environ. 2007, 42, 3905–3915. [Google Scholar] [CrossRef]

- Hu, L.H.; Chen, L.F.; Wu, L.; Li, Y.Z.; Zhand, J.Y.; Meng, N. An experimental investigation and correlation on buoyant gas temperature below ceiling in a slopping tunnel fire. Appl. Therm. Eng. 2013, 51, 246–254. [Google Scholar] [CrossRef]

- Li, S.; Zong, R.; Zhao, W.; Yan, Z.; Liao, G. Theoretical and experimental analysis of ceiling-jet flow in corridor fires. Tunneling Undergr. Space Technol. 2011, 26, 651–658. [Google Scholar] [CrossRef]

- Delichatsios, M.A. The flow of fire gases under a beamed ceiling. Combust. Flame 1981, 43, 1–10. [Google Scholar] [CrossRef]

- Haowen, T.; Zhisheng, X.; Dongmei, Z. Investigation of the Temperature Beneath Curved Tunnel Ceilings Induced by Fires with Natural Ventilation. Fire 2022, 5, 90. [Google Scholar] [CrossRef]

- Shenghao, Z.; Na, M. A Study on the Maximum Temperature of a Ceiling Jet of Asymmetric Dual Strong Plumes in a Naturally Ventilated Tunnel. Fire 2024, 7, 110. [Google Scholar] [CrossRef]

- Biteng, C.; Hong, L.; Rui, F.; Xiaoyu, J.; Lizhong, Y. Experimental and Theoretical Investigation of Longitudinal Temperature Attenuation and Smoke Movement in Urban Utility Tunnel Fires. Fire 2024, 7, 113. [Google Scholar] [CrossRef]

- Pittam, D.A.; Picher, G. Measurements of Heats of Combustion by Flame Calorimetry. Part 8.-Methane, Ethane, Propane, n-Butane and 2-Methylpropane. J. Chem. Soc. 1972, 68, 2224–2229. [Google Scholar] [CrossRef]

- Karlsson, B.; Quintiere, J.G. Enclosure Fire Dynamics; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Yamaguchi, J.; Muraoka, K. Method to Predict Smoke Diffusion Behavior in the Early Stage of a Fire. Rep. Obayashi Corp. Tech. Res. Inst. 2009, 73, 71–80. [Google Scholar]

- Tanaka, T. A Model Multiroom Fire Spread. Fire Sci. Technol. 1983, 3, 105–121. [Google Scholar] [CrossRef]

- Andoh, S.; Yamaguchi, J.; Muraoka, K.; Oka, Y. Experimental study on temperature property of ceiling jet Flowing Through the accumulated Thin Smoke Layer. J. Environ. Eng. AIJ 2013, 78, 307–315. [Google Scholar] [CrossRef]

- Muraoka, H.; Yamaguchi, J.; Oka, Y. Proceedings of JAFSE Annual Symposium. 2011. Available online: https://www.jafse.org/proceedings (accessed on 13 July 2024).

- Zukoski, E.E. Mass Flux In Fire Plumes. Fire Saf. Sci. 1994, 4, 137–147. [Google Scholar] [CrossRef]

- Heskestad, G.; Delichatsios, M.A. The Initial Convective Flow in Fire. Proc. Combust. Inst. 1979, 17, 1113–1123. [Google Scholar] [CrossRef]

- Zukoski, E.E.; Kubota, T.; Categen, B. Entrainment in fire plumes. Fire Saf. J. 1981, 3, 107–121. [Google Scholar] [CrossRef]

| Ceiling Height H [] | Fire Source Area A [] |

|---|---|

| 1.5 | 0.1/0.2/0.4 |

| 3.0 | 0.1/0.2/0.4 |

| 4.5 | 0.1/0.2/0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Kwon, Y.; Kang, H.; Kweon, O. Comparative Study of Temperature Distribution Characteristics of Ceiling Jets at Center and Edge Regions in Corridors. Fire 2025, 8, 181. https://doi.org/10.3390/fire8050181

Kim Y, Kwon Y, Kang H, Kweon O. Comparative Study of Temperature Distribution Characteristics of Ceiling Jets at Center and Edge Regions in Corridors. Fire. 2025; 8(5):181. https://doi.org/10.3390/fire8050181

Chicago/Turabian StyleKim, Yunseong, Youngjin Kwon, Hyun Kang, and Ohsang Kweon. 2025. "Comparative Study of Temperature Distribution Characteristics of Ceiling Jets at Center and Edge Regions in Corridors" Fire 8, no. 5: 181. https://doi.org/10.3390/fire8050181

APA StyleKim, Y., Kwon, Y., Kang, H., & Kweon, O. (2025). Comparative Study of Temperature Distribution Characteristics of Ceiling Jets at Center and Edge Regions in Corridors. Fire, 8(5), 181. https://doi.org/10.3390/fire8050181