Advanced Evaluation of Fire Resistance in Spruce Wood (Picea abies spp.) Treated with Innovative Surface Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood Samples

2.2. Applied Treatments

2.3. Testing Methods

2.3.1. Small Flame

2.3.2. Surface Roughness Measurement

2.3.3. Contact Angle Measurement

- Droplet size: 5 μL;

- Contact angles were recorded with a camera for 60 s.

2.3.4. Hyperspectral Imaging (HSI)

3. Results and Discussion

3.1. Fire Resistance

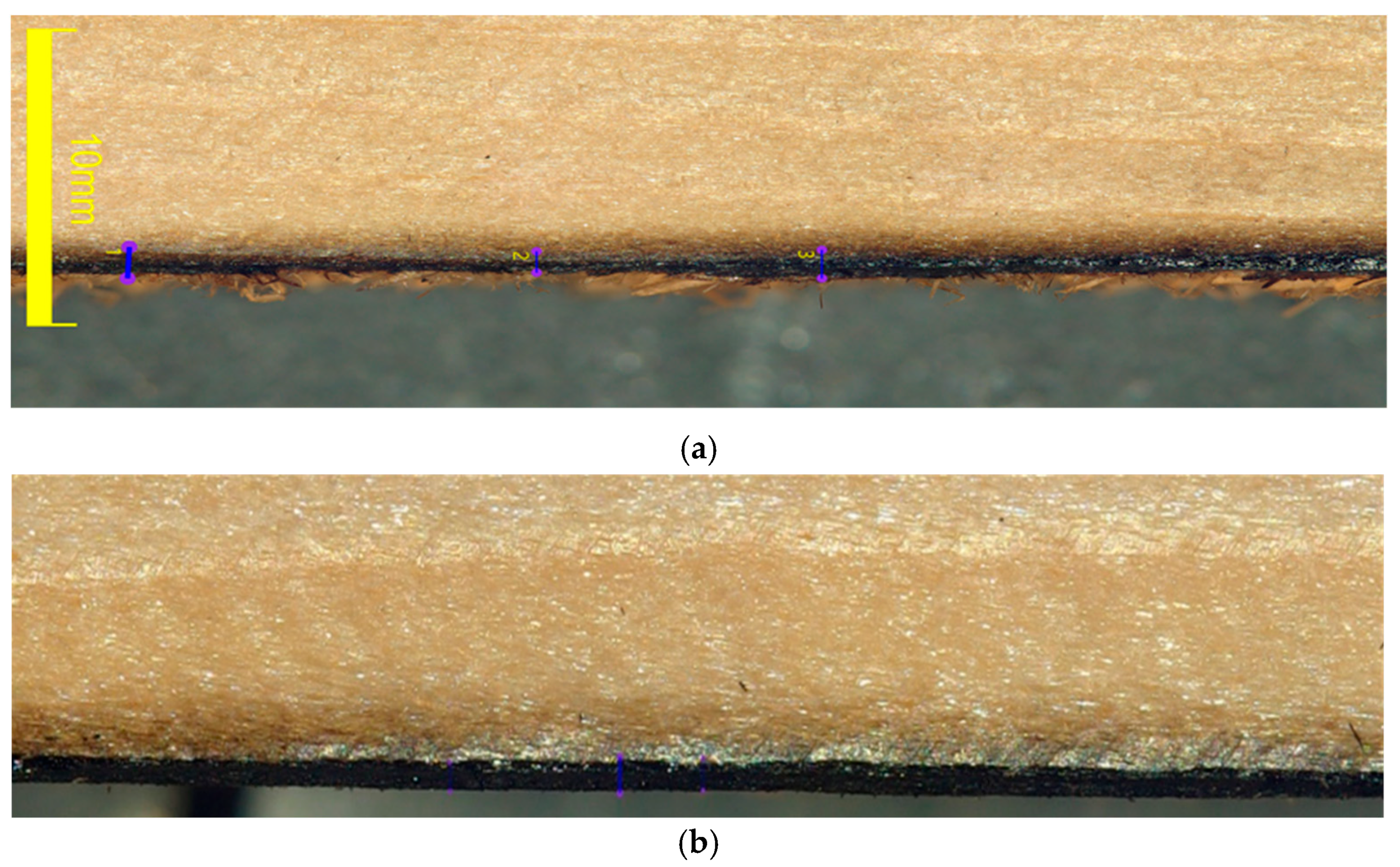

3.2. Analysis of Char Depth in Spruce Wood (Picea spp.) During Small Flame Test

3.3. Surface Roughness

3.4. Contact Angle

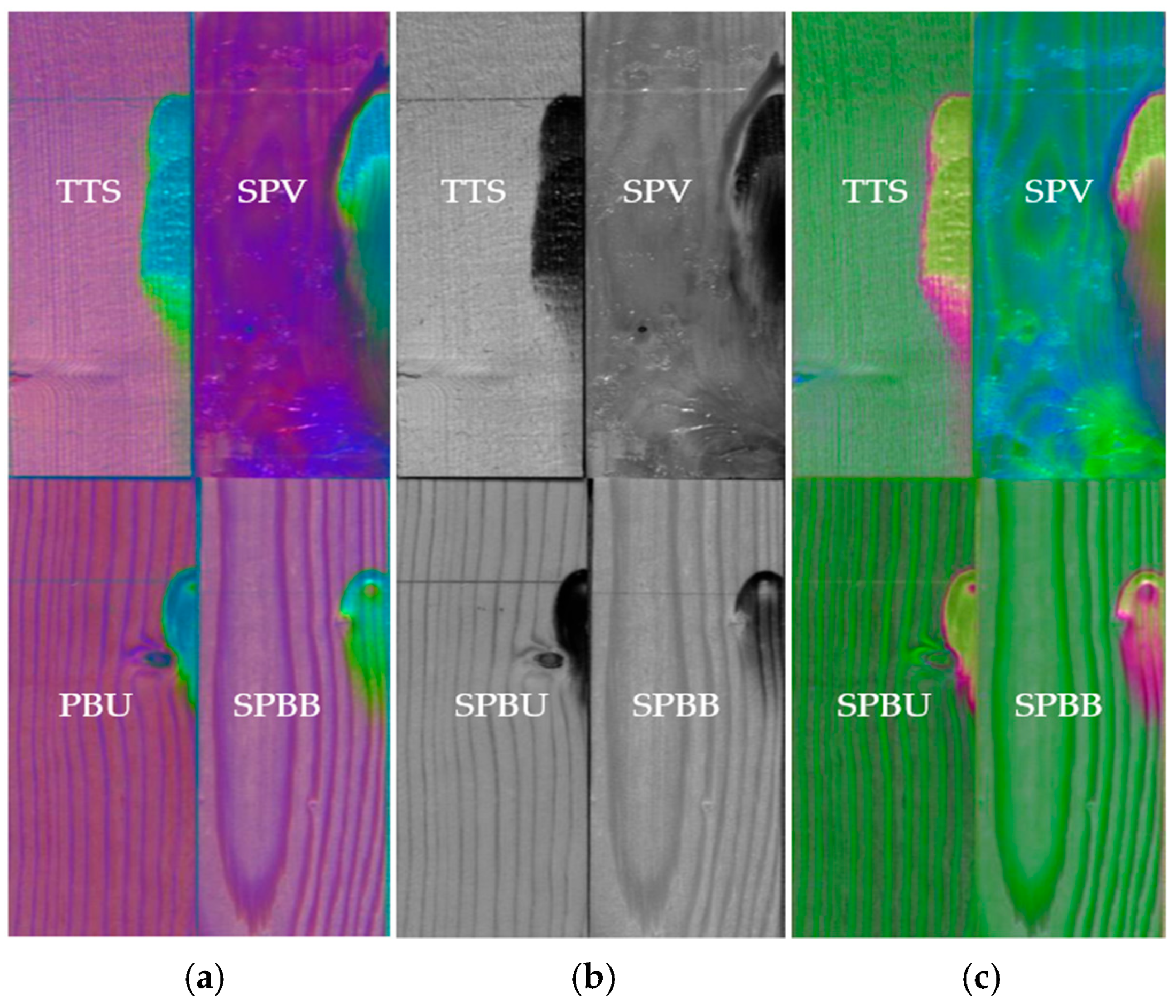

3.5. Hyperspectral Imaging

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barbu, M.C.; Tudor, E.M. State of the art of the Chinese forestry, wood industry and its markets. Wood Mater. Sci. Eng. 2021, 16, 1030–1039. [Google Scholar] [CrossRef]

- Netopilová, M.; Mikulenka, J.; Benešová, A. The development of composite building product and its fire technical characteristics. Adv. Mater. Res. 2014, 1001, 368–372. [Google Scholar] [CrossRef]

- Wu, X.F. Fire resistance of timber as a building material. Adv. Mater. Res. 2014, 1079–1080, 415–418. [Google Scholar] [CrossRef]

- Leško, R.; Lopušniak, M. Determination of fire resistance of ceiling structure variant design on the basis of timber using numerical calculation methods. Appl. Mech. Mater. 2016, 820, 379–384. [Google Scholar] [CrossRef]

- Tatić, U.; Šubic, B.; Ugovšek, A.; Starman, N.; Gantar, U.; Lopatić, J. Development and testing of the reinforced wooden windows. Procedia Struct. Integr. 2018, 13, 496–502. [Google Scholar] [CrossRef]

- Zhou, X.; Carmeliet, J.; Derome, D. Assessment of moisture risk of wooden beam embedded in internally insulated masonry walls with 2D and 3D models. Build. Environ. 2021, 193, 107460. [Google Scholar] [CrossRef]

- Ovsyannikov, S.I.; Dyachenko, V.Y. Fire resistance evaluation of pressed straw building envelopes. Mater. Sci. Forum 2019, 974, 237–242. [Google Scholar] [CrossRef]

- Östman, B. Chapter 3—Flammability of wood products. In Flammability Testing of Materials Used in Construction, Transport and Mining, 2nd ed.; Vivek Apte: New Delhi, India, 2021; pp. 61–87. [Google Scholar]

- Tureková, I.; Turnova, Z.; Balog, K.; Pastier, M. Study of thermal degradation of polymers. Adv. Mater. Res. 2013, 652–654, 1664–1667. [Google Scholar] [CrossRef]

- Kucera, P.; Lokaj, A.; Vlcek, V. Behavior of the spruce and birch wood from the fire safety point of view. Adv. Mater. Res. 2013, 842, 725–728. [Google Scholar] [CrossRef]

- Rusinová, M.; Šlanhof, J. Fire safety of apartment buildings fabricated from glued sandwich panels compared with the more frequently used structural systems. Appl. Mech. Mater. 2016, 861, 104–111. [Google Scholar] [CrossRef]

- Rusinová, M.; Kalousek, M.; Šlanhof, J. Assessment of the dynamic temperature profile in fire loaded sandwich structures based on wood in comparison with conventional structural systems. Appl. Mech. Mater. 2019, 887, 98–105. [Google Scholar]

- Troitzsch, J.; Antonatus, E. Chapter 3—Flame retardants and flame-retarded plastics. In Plastics Flammability Handbook, 4th ed.; Carl Handes Verlag: München, Germany, 2021; pp. 53–128. [Google Scholar]

- Miklósiová, T. Damage of the wood by biological factors, fire and methods of its protection. Adv. Mater. Res. 2013, 855, 19–21. [Google Scholar]

- Li, X.; Zhang, Y. Fire Safety in Timber Structures: Advances in Fire-Retardant Treatments and Building Codes. Fire Saf. J. 2020, 114, 103124. [Google Scholar] [CrossRef]

- He, X.; Li, J.; Zhong, Z.; Mou, Q.; Yan, Y.; Chen, H.; Liu, L. Effectiveness of Impregnation of Ammonium Polyphosphate Fire Retardant in Poplar Wood Using Microwave Heating. Fire Mater. 2015, 40, 818–825. [Google Scholar] [CrossRef]

- Wypych, G. Chapter 6 Selection of flame retardants for different polymers. In Handbook of Flame Retardants; ChemTec Publishing: Toronto, ON, Canada, 2021; pp. 89–226. [Google Scholar]

- Wang, K.; Dong, Y.; Ling, Z.; Liu, X.; Shi, S.Q.; Li, G. Transparent wood developed by introducing epoxy vitrimers into a delignified wood template. Compos. Sci. Technol. 2021, 207, 108690. [Google Scholar]

- Tribulová, T.; Kačík, F.; Evtuguin, D.V.; Cabalová, I. Influence of chemical treatment on chemical changes of fir wood. Key Eng. Mater. 2016, 688, 38–43. [Google Scholar]

- Ni, J.; Song, L.; Hu, Y.; Zhang, P.; Xing, W. Preparation and Characterization of Microencapsulated Ammonium Polyphosphate with Polyurethane Shell by In Situ Polymerization and Its Flame Retardance in Polyurethane. Polym. Adv. Technol. 2008, 19, 1354–1360. [Google Scholar] [CrossRef]

- Wang, K.H.; Meng, D.; Wang, S.H.; Sun, J.; Li, H.F.; Gu, X.Y.; Zhang, S. Impregnation of Phytic Acid into the Delignified Wood to Realize Excellent Flame Retardant. Ind. Crops Prod. 2022, 176, 114364. [Google Scholar] [CrossRef]

- Li, S.; Yu, L.; Xiong, J.; Xiong, Y.; Bi, S.; Quan, H. Facile Fabrication of Superhydrophobic and Flame-Retardant Coatings on Cotton Fabrics. Polymers 2022, 14, 5314. [Google Scholar] [CrossRef]

- Ma, T.; Li, L.; Liu, Z.; Zhang, J.; Guo, C.; Wang, Q. A facile strategy to construct vegetable oil-based, fire-retardant, transparent and mussel adhesive intumescent coating for wood substrates. Ind. Crops Prod. 2020, 154, 112628. [Google Scholar]

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Wang, S. The Flame-Retardant Mechanisms and Preparation of Polymer Composites and Their Potential Application in Construction Engineering. Polymers 2022, 14, 82. [Google Scholar] [CrossRef]

- Samanta, P.; Samanta, A.; Montanari, C.; Li, Y.Y.; Maddalena, L.; Carosio, F.; Berglund, L.A. Fire-retardant and transparent wood biocomposite based on commercial thermoset. Compos. Part A Appl. S. 2022, 156, 106863. [Google Scholar]

- Habibi, Y.; Lucia, L.; Rojas, O. Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [PubMed]

- Garg, M.; Linares, M.; Zozoulenko, I. Theoretical Rationalization of Self-Assembly of Cellulose Nanocrystals: Effect of Surface Modifications and Counterions. Biomacromolecules 2020, 21, 3069–3080. [Google Scholar]

- Zhu, B.; Johansen, V.E.; Kamita, G.; Guidetti, G.; Bay, M.M.; Parton, T.G.; Frka-Petesic, B.; Vignolini, S. Hyperspectral Imaging of Photonic Cellulose Nanocrystal Films: Structure of Local Defects and Implications for Self-Assembly Pathways. ACS Nano 2020, 14, 15361–15373. [Google Scholar]

- Leite, L.S.F.; Pham, C.; Bilatto, S.; Azeredo, H.M.; Cranston, E.D.; Moreira, F.K.; Mattoso, L.H.C.; Bras, J. Effect of Tannic Acid and Cellulose Nanocrystals on Antioxidant and Antimicrobial Properties of Gelatin Films. ACS Sustain. Chem. Eng. 2021, 9, 8539–8549. [Google Scholar]

- Gu, Z.; Lu, M.; Feng, K.; Jin, Z. The different composites of cellulose nanocrystals with d- or l-histidine. Nanoscale 2021, 13, 8174–8180. [Google Scholar]

- Pracella, M.; Mura, C.; Galli, G. Polyhydroxyalkanoate Nanocomposites with Cellulose Nanocrystals as Biodegradable Coating and Packaging Materials. ACS Appl. Nano Mater. 2021, 4, 260–270. [Google Scholar]

- Ferreira, E.S.; Rezende, C.A.; Cranston, E.D. Fundamentals of cellulose lightweight materials: Bio-based assemblies with tailored properties. Green Chem. 2021, 23, 3542–3568. [Google Scholar] [CrossRef]

- Ružinská, E.; Mitterová, I.; Zachar, M. The study of selected fire-technical characteristics of special wood products surface treatment by environmentally problematic coatings. Adv. Mater. Res. 2014, 1001, 373–378. [Google Scholar] [CrossRef]

- Orémusová, E.; Tutaj, M.; Dritomská, K. Effect of Fire Retardant Treatment on Flammability of Scots Pine Wood (Pinus sylvestris L.). In Heat–Fire–Materials 2019; Technical University in Zvolen: Zvolen, Slovakia, 2019; pp. 48–51. [Google Scholar]

- Gašparík, M.; Makovická Osvaldová, L.; Čekovská, H.; Potůček, D. Flammability characteristics of thermally modified oak wood treated with a fire retardant. Bioresources 2017, 12, 8451–8467. [Google Scholar]

- Sauerbier, P.; Mayer, A.K.; Emmerich, L.; Militz, H. Fire retardant treatment of wood–state of the art and future perspectives. In Wood & Fire Safety: Proceedings of the 9th International Conference on Wood & Fire Safety, Štrbské Pleso, Slovakia, 3–6 May 2020; Springer International Publishing: Cham, Switzerland, 2020; pp. 97–102. [Google Scholar]

- Popescu, C.-M.; Pfriem, A. Treatments and modification to improve the reaction to fire of wood and wood based products—An overview. Fire Mater. 2020, 44, 100–111. [Google Scholar]

- Zhong, J.; Huang, Y.; Chen, Y.; Li, L.; Guo, C. Synthesis of eugenol-modified epoxy resin and application on wood flame retardant coating. Ind. Crops Prod. 2022, 183, 114979. [Google Scholar] [CrossRef]

- Kozlowski, R.; Muzyczek, M. Chapter 11 Smart environmentally friendly composite coatings for wood protection. In Woodhead Publishing Series in Composites Science and Engineering, Smart Composite Coatings and Membranes; Woodhead Publishing: Sawston, UK, 2016; pp. 293–325. [Google Scholar]

- Tanasă, F.; Teacă, C.A.; Zănoagă, M. Chapter 6 Protective coatings for wood. In Handbook of Modern Coating Technologies; Elsevier: New York, NY, USA, 2021; pp. 175–267. [Google Scholar]

- Makovická Osvaldová, L.; Osvald, A. Flame retardation of wood. Adv. Mater. Res. 2013, 690–693, 1331–1334. [Google Scholar] [CrossRef]

- Gaff, M.; Kačík, F.; Gašparík, M.; Todaro, L.; Jones, D.; Corleto, R.; Makovická Osvaldová, L.; Cekovská, H. The effect of synthetic and natural fire-retardants on burning and chemical characteristics of thermally modified teak (Tectona grandis L. f.) wood. Constr. Build. Mater. 2019, 200, 551–558. [Google Scholar]

- Deng, C.; Ji, Y.; Zhu, M.; Liang, Y.; Jian, H.; Yan, Z.; Wen, M.; Park, H. Preparation of Organic-Inorganic Phosphorus-Nitrogen-Based Flame Retardants and Their Application to Plywood. Polymers 2023, 15, 3112. [Google Scholar] [CrossRef]

- Hao, X.H.; Li, M.L.; Huang, Y.S.; Sun, Y.H.; Zhang, K.X.; Guo, C.G. High-Strength, Dimensionally Stable, and Flame-Retardant Fast-Growing Poplar Prepared by Ammonium Polyphosphate-Waterborne Epoxy Impregnation. ACS Appl. Polym. Mater. 2022, 4, 1305–1313. [Google Scholar] [CrossRef]

- Malucelli, G. Biomacromolecules and Bio-Sourced Products for the Design of Flame Retarded Fabrics: Current State of the Art and Future Perspectives. Molecules 2019, 24, 3774. [Google Scholar] [CrossRef]

- Elvira-León, J.; Chimenos, J.M.; Isábal, C.; Monton, J.; Formosa, J.; Haurie, L. Epsomite as flame retardant treatment for wood: Preliminary study. Constr. Build. Mater. 2016, 126, 936–942. [Google Scholar]

- Kim, J.-H.; Kwon, D.-J.; Shin, P.-S.; Baek, Y.-M.; Park, H.-S.; DeVries, K.L.; Park, J.-M. The evaluation of the interfacial and flame retardant properties of glass fiber/unsaturated polyester composites with ammonium dihydrogen phosphate. Compos. Part B Eng. 2019, 167, 221–230. [Google Scholar] [CrossRef]

- Rep, G.; Pohleven, F.; Kosmerl, S. Development of the Industrial Kiln for Thermal Wood Modification by a Procedure with an Initial Vacuum and Commercialisation of Modified Silvapro Wood. In Proceedings of the 6th European Conference on Wood Modification, Ljubljana, Slovenia, 17–18 September 2012; pp. 11–17. [Google Scholar]

- Chu, D.; Hasanagić, R.; Hodžić, A.; Kržišnik, D.; Hodžić, D.; Bahmani, M.; Petrič, M.; Humar, M. Application of Temperature and Process Duration as a Method for Predicting the Mechanical Properties of Thermally Modified Timber. Forests 2022, 13, 217. [Google Scholar] [CrossRef]

- KGM. Tikovo Ulje za Tvrdo Drvo. Available online: https://www.kgm.hr/proizvod/tikovo-ulje-za-tvrdo-drvo/ (accessed on 27 February 2025).

- Hi-Glitz. Teak and Hardwood Oil. Available online: https://www.hi-glitz.com/wp-content/uploads/2022/11/Teak-and-Hardwood-Oil.png (accessed on 27 February 2025).

- Belinka. Belinka Oil Exterier. Available online: https://www.belinka.com/hr/proizvodi/belinka-oil-exterier/ (accessed on 27 February 2025).

- ROMONTA—Wachs und Mehr. The Company. Available online: https://www.romonta.de/ (accessed on 27 February 2025).

- Wikipedia. Borna Kiselina. Available online: https://sh.wikipedia.org/wiki/Borna_kiselina (accessed on 27 February 2025).

- Zorka Color. Decolux, Slika. Available online: https://www.zorkacolor.com/Files/Products/3579_1_34_Thumb.jpg (accessed on 27 February 2025).

- Grube.ba. Vosak za Drvo Brunonia. Available online: https://www.grube.ba/product/vosak-za-drvo-brunonia/ (accessed on 27 February 2025).

- Grube.ba. Vosak Brunonia, Slika. Available online: https://www.grube.ba/wp-content/uploads/2019/04/b_51-059_j15_2560x2560.jpg (accessed on 27 February 2025).

- Burnblock. How It Works. Available online: https://burnblock.com/products/how-it-works/ (accessed on 27 February 2025).

- EN ISO 11925-2:2020; Reaction to Fire Tests Ignitability of Products Subjected to Direct Impingement of Flame Part 2: Single-Flame Source Test, Test Method. European Committee for Standardization: Brussels, Belgium, 2011.

- Gašpercová, S.; Marková, I.; Vandlíčková, M.; Osvaldová, L.M.; Svetlík, J. Effect of Protective Coatings on Wooden Elements Exposed to a Small Ignition Initiator. Appl. Sci. 2023, 13, 3371. [Google Scholar] [CrossRef]

- Mao, N.; Jiang, L.; Li, X.; Gao, Y.; Zang, Z.; Peng, S.; Ji, L.; Lv, C.; Guo, J.; Wang, H.; et al. Core-shell ammonium polyphosphate@nanoscopicaluminum hydroxide microcapsules: Preparation, characterisation, and its flame retardancy performance on woodpulp paper. Chem. Eng. J. Adv. 2021, 6, 100096. [Google Scholar] [CrossRef]

- Zhang, M.F.; Wang, D.; Li, T.; Jiang, J.; Bai, H.Y.; Wang, S.B.; Wang, Y.; Dong, W.F. Multifunctional Flame-Retardant, Thermal Insulation, and Antimicrobial Wood-Based Composites. Biomacromolecules 2023, 24, 957–966. [Google Scholar]

- Lainioti, G.C.; Koukoumtzis, V.; Andrikopoulos, K.S.; Tsantaridis, L.; Ostman, B.; Voyiatzis, G.A.; Kallitsis, J.K. Environmentally friendly hybrid organic–inorganic halogen-free coatings for wood fire-retardant applications. Polymers 2022, 14, 4959. [Google Scholar] [CrossRef] [PubMed]

- Leitner, B.; Gašpercová, S.; Marková, I.; Tureková, I. Effect of Combining Fungal and Flame-Retardant Coatings on the Thermal Degradation of Spruce and Beech Wood Under Flame Loading. Fire 2024, 7, 463. [Google Scholar] [CrossRef]

- Čekovská, H.; Gaff, M.; Osvald, A.; Kačík, F.; Kubš, J.; Kaplan, L. Fire Resistance of Thermally Modified Spruce Wood. BioResources 2017, 12, 947–959. [Google Scholar]

- Mandraveli, E.; Mitani, A.; Terzopoulou, P.; Koutsianitis, D. Oil Heat Treatment of Wood—A Comprehensive Analysis of Physical, Chemical, and Mechanical Modifications. Materials 2024, 17, 2394. [Google Scholar] [CrossRef]

- Ali, S.; Hussain, S.A.; Mohd Tohir, M.Z. Fire Test and Effects of Fire Retardant on the Natural Ability of Timber: A Review. Pertanika J. Sci. Technol. 2019, 27, 673–688. Available online: https://www.researchgate.net/publication/332754332_Fire_Test_and_Effects_of_Fire_Retardant_on_the_Natural_Ability_of_Timber_A_Review (accessed on 12 March 2025).

- Mitrenga, P.; Vandlíčková, M.; Konárik, M. Experimental Investigation of Fire—Technical Characteristics of Selected Flame Retardants for the Protection of Wooden Structures. Coatings 2025, 15, 193. [Google Scholar] [CrossRef]

- Lin, S.; Qin, Y.; Huang, X.; Gollner, M. Use of Pre-Charred Surfaces to Improve Fire Performance of Wood. Fire Saf. J. 2023, 136, 103745. [Google Scholar] [CrossRef]

- Mohebby, B.; Kevily, H.; Kazemi-Najafi, S. Oleothermal Modification of Fir Wood with a Combination of Soybean Oil and Maleic Anhydride and Its Effects on Physico-Mechanical Properties of Treated Wood. Wood Sci. Technol. 2014, 48, 797–809. [Google Scholar] [CrossRef]

- Cheng, D.; Chen, L.; Jiang, S.; Zhang, Q. Oil uptake percentage in oil-heat-treated wood, its determination by Soxhlet extraction, and its effects on wood compression strength parallel to the grain. BioResources 2013, 9, 120–131. [Google Scholar] [CrossRef]

| N | Material | Abbreviation | Specification |

|---|---|---|---|

| 1 | Natural Spruce—Sawing | SPRP | Untreated, natural spruce wood. |

| 2 | Natural Spruce—Planed Samples | SPBU | Smooth surface due to planning, natural state. |

| 3 | Burnblock Spray | SPBB | Fire-retardant spray, reduces flammability and flame spread. |

| 4 | Boric Acid | SPBK | Antiseptic, insecticidal properties, fire retardant. |

| 5 | Chromos Svjetlost | SPPCS | Protective coating, weather-resistant, prevents moisture absorption. |

| 6 | Belinka Oil | SPUB | Plant-based oil, enhances durability, water-repellent. |

| 7 | Wax Slovenia | SPV | Protective wax layer, enhances water resistance, adds shine. |

| 8 | Thermally Treated Spruce | TTS | Enhanced dimensional stability, reduced moisture absorption. |

| 9 | Caparol Coating | SPPC | Protective coating, UV-resistant, weatherproof. |

| 10 | Wepos Oil | SPUW | Protective oil, moisture-resistant, maintains wood texture. |

| 11 | Schacht Wax | SPVS | Forms a protective layer, increases shine, repels water. |

| 12 | Ekotep Oil | SPUE | Protective oil, reduces moisture absorption, enhances wood colour. |

| 13 | Decolux Coating | SPPD | Protective coating, enhances surface durability, prevents moisture damage. |

| Material Type | Appearance | Density (g/cm3) | Component | Amount (%) |

|---|---|---|---|---|

| Ekotep (Oil) | Transparent liquid | 0.91 | Natural oils, fatty acids | <100 |

| Wepos (Oil) | Transparent liquid | 0.92 | Natural and synthetic oils, fatty acids | <100 |

| Belinka (Oil) | Transparent liquid | 0.91 | Natural oils, resins, fatty acids | <100 |

| Montan Wax | White, solid | 0.90 | Montan wax, paraffin | <100 |

| Schacht Wax | White, solid | 0.92 | Paraffin wax, microcrystalline wax | <100 |

| Boric Acid (Chemical Agent) | White powder | 1.43 | Boric acid | 100 |

| Chromos Svjetlost (Coating) | Glossy, liquid | 1.03 | Synthetic resins, pigments, solvents | <50 |

| Decolux (Coating) | Glossy, liquid | 1.05 | Synthetic resins, pigments, additives | <50 |

| Caparol (Coating) | Glossy, liquid | 1.10 | Synthetic resins, pigments, additives | <50 |

| Burnblock (Fire-Retardant Spray) | Transparent liquid | 1.08 | Natural substances, non-toxic compounds | <100 |

| Material Description | Flame Occurrence After 30 s | Small Flame Duration (s) | Avg Flame Height (cm) | St Deviation. |

|---|---|---|---|---|

| SPRP | YES | 30 | 9.34 | 2.19 |

| SPBU | YES/NO | 30 | 7.42 | 1.49 |

| SPBB | NO | 30 | 6.57 | 0.30 |

| SPBK | YES | 30 | 12.18 | 3.70 |

| SPPCS | YES/NO | 30 | 6.98 | 0.87 |

| SPUB | YES | 30 | 9.40 | 2.09 |

| SPV | YES | 30 | 8.02 | 1.57 |

| TTS | YES | 30 | 10.97 | 3.62 |

| SPPC | NO | 30 | 6.95 | 0.55 |

| SPUW | YES | 30 | 8.88 | 1.05 |

| SPVS | YES/NO | 30 | 7.29 | 2.86 |

| SPUE | YES | 30 | 11.44 | 2.64 |

| SPPD | YES/NO | 30 | 6.82 | 1.35 |

| Samples | Measurement 1 Sa (µm) | Measurement 2 Sa (µm) | Measurement 3 Sa (µm) | Measurement 4 Sa (µm) | Measurement 5 Sa (µm) | Measurement 6 Sa (µm) | Avg | StdDev |

|---|---|---|---|---|---|---|---|---|

| SPRP | 16.705 | 9.276 | 11.322 | 16.766 | 12.299 | 11.106 | 12.912 | 3.119 |

| SPBU | 5.399 | 5.081 | 4.212 | 2.956 | 5.504 | 4.608 | 4.627 | 0.952 |

| SPBB | 14.235 | 14.453 | 7.318 | 6.406 | 5.791 | 5.346 | 8.925 | 4.250 |

| SPBK | 16.559 | 11.659 | 12.502 | 9.863 | 8.975 | 8.662 | 11.370 | 2.954 |

| SPPCS | 7.491 | 10.062 | 9.094 | 9.198 | 10.282 | 8.909 | 9.173 | 0.993 |

| SPUB | 9.826 | 10.294 | 3.319 | 5.153 | 6.456 | 6.524 | 6.929 | 2.694 |

| SPV | 17.883 | 1.588 | 6.25 | 12.917 | 9.762 | 10.548 | 9.825 | 5.579 |

| TTS | 5.778 | 7.971 | 7.013 | 7.238 | 7.373 | 3.757 | 6.522 | 1.535 |

| SPPC | 7.553 | 5.915 | 6.916 | 5.456 | 6.827 | 5.664 | 6.389 | 0.830 |

| SPUW | 6.131 | 6.687 | 5.521 | 5.664 | 3.893 | 6.595 | 5.749 | 1.024 |

| SPVS | 2.61 | 5.22 | 1.985 | 3.087 | 13.325 | 2.493 | 4.787 | 4.332 |

| SPUE | 3.097 | 3.077 | 5.582 | 3.63 | 7.361 | 4.279 | 4.504 | 1.683 |

| SPPD | 5.16 | 3.946 | 4.235 | 4.052 | 3.558 | 5.133 | 4.347 | 0.658 |

| Wetting Time (min) | SPRP | SPBU | SPBB | SPBK | SPPCS | SPUB | SPV1 | TTS | SPPC | SPUW | SPVS | SPUE | SPPD |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 121.4 | 89.5 | 88.5 | 138.3 | 131.8 | 114.2 | 135.2 | 129 | 114.6 | 121.4 | 109 | 118.1 | 83.1 |

| 10 | 98.6 | 63.4 | 58.9 | 139.6 | 128.8 | 116.7 | 135.3 | 124.6 | 111.5 | 120.7 | 109.1 | 117.5 | 88.9 |

| 30 | 120.6 | 52.6 | 44.3 | 137.4 | 128.5 | 112.4 | 134.8 | 124.6 | 115.1 | 120 | 109.4 | 116.2 | 72.1 |

| 55 | 94 | 39 | 38.4 | 122.1 | 121.7 | 113.5 | 87.2 | 124 | 111 | 120.7 | 84.4 | 115.3 | 84.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasanagić, R.; Mujanić, S.; Keržič, E.; Fathi, L.; Bahmani, M.; Dahmardeh Ghalehno, M.; Lesar, B.; Humar, M. Advanced Evaluation of Fire Resistance in Spruce Wood (Picea abies spp.) Treated with Innovative Surface Coatings. Fire 2025, 8, 120. https://doi.org/10.3390/fire8040120

Hasanagić R, Mujanić S, Keržič E, Fathi L, Bahmani M, Dahmardeh Ghalehno M, Lesar B, Humar M. Advanced Evaluation of Fire Resistance in Spruce Wood (Picea abies spp.) Treated with Innovative Surface Coatings. Fire. 2025; 8(4):120. https://doi.org/10.3390/fire8040120

Chicago/Turabian StyleHasanagić, Redžo, Selma Mujanić, Eli Keržič, Leila Fathi, Mohsen Bahmani, Mohammad Dahmardeh Ghalehno, Boštjan Lesar, and Miha Humar. 2025. "Advanced Evaluation of Fire Resistance in Spruce Wood (Picea abies spp.) Treated with Innovative Surface Coatings" Fire 8, no. 4: 120. https://doi.org/10.3390/fire8040120

APA StyleHasanagić, R., Mujanić, S., Keržič, E., Fathi, L., Bahmani, M., Dahmardeh Ghalehno, M., Lesar, B., & Humar, M. (2025). Advanced Evaluation of Fire Resistance in Spruce Wood (Picea abies spp.) Treated with Innovative Surface Coatings. Fire, 8(4), 120. https://doi.org/10.3390/fire8040120