Fire Performances of SFRC-Insulated Panels and Slabs for Modular Construction: An Experimental Study

Abstract

1. Introduction

2. Materials Properties

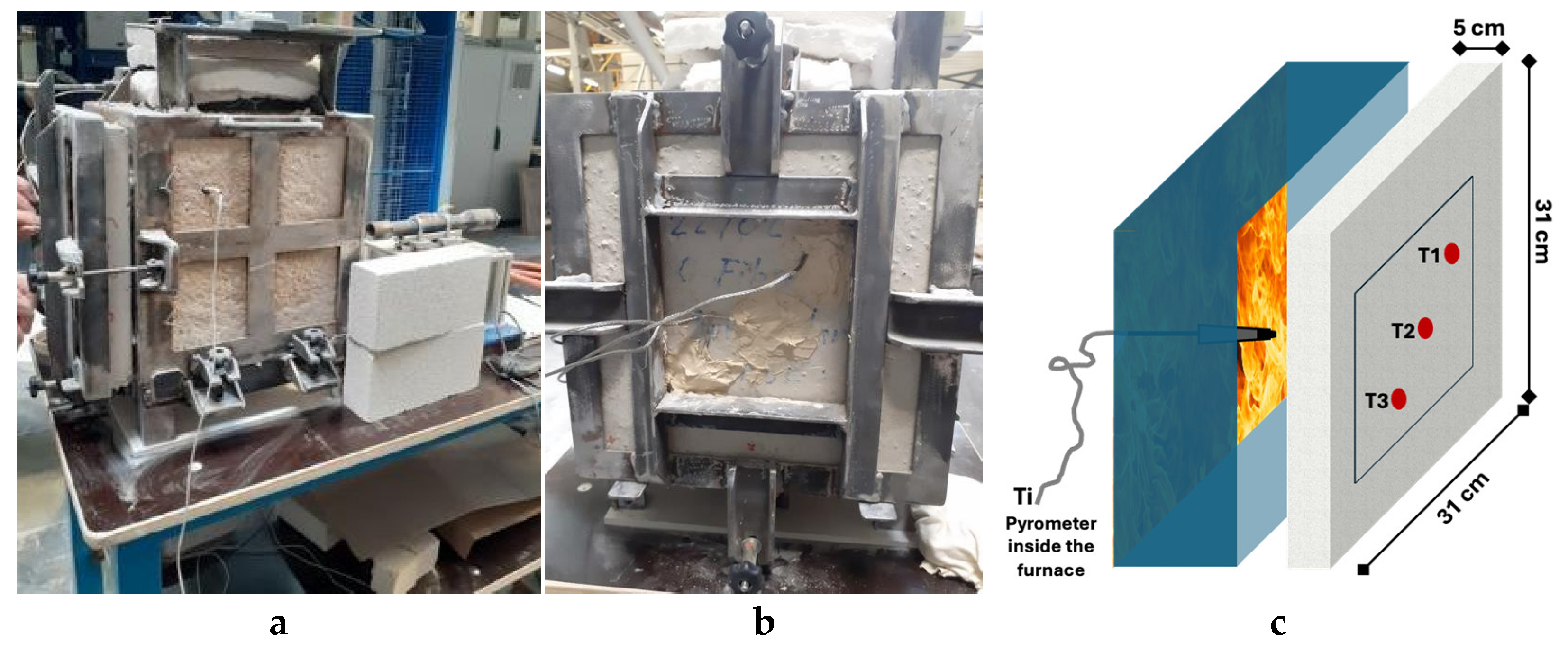

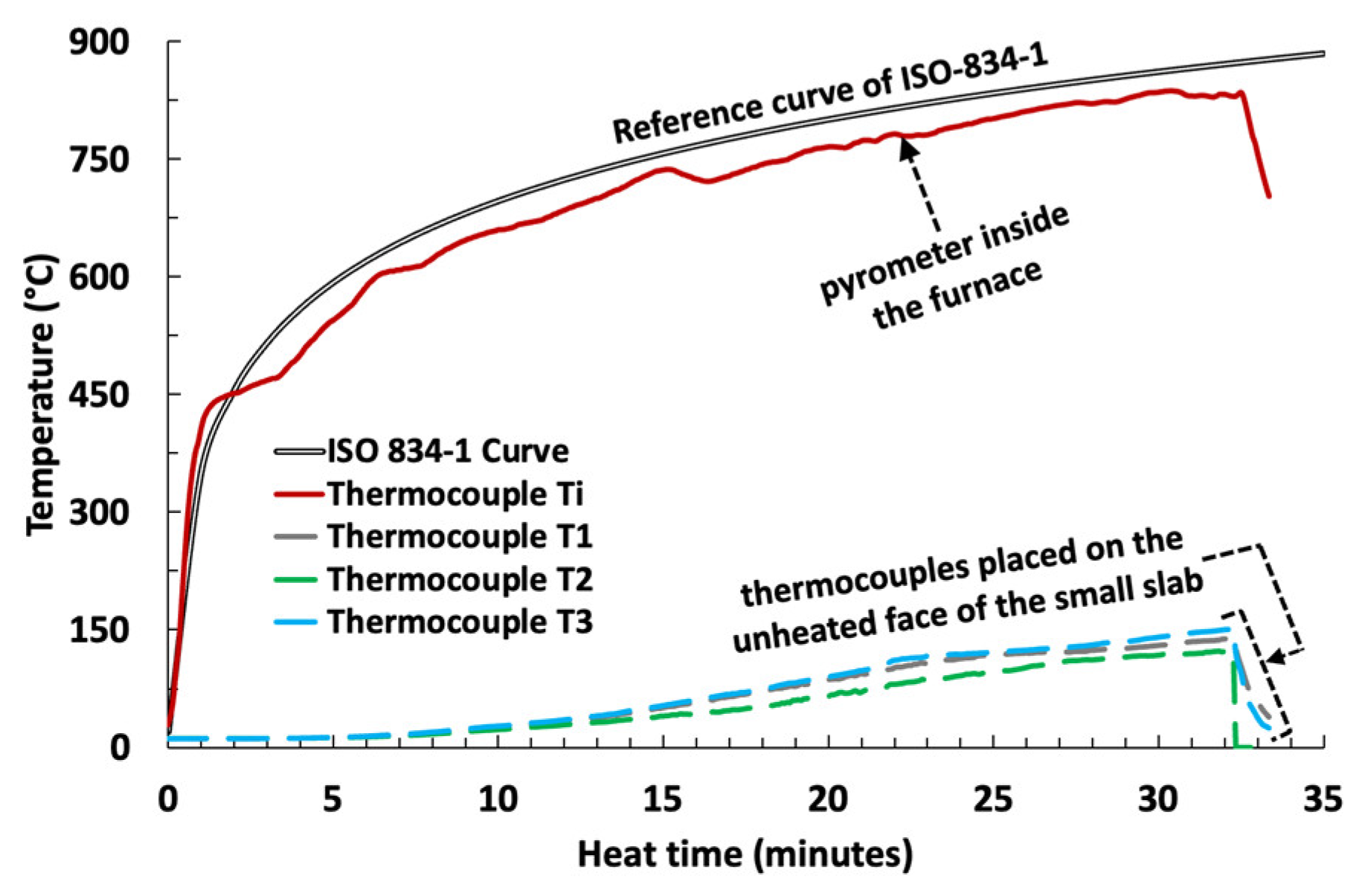

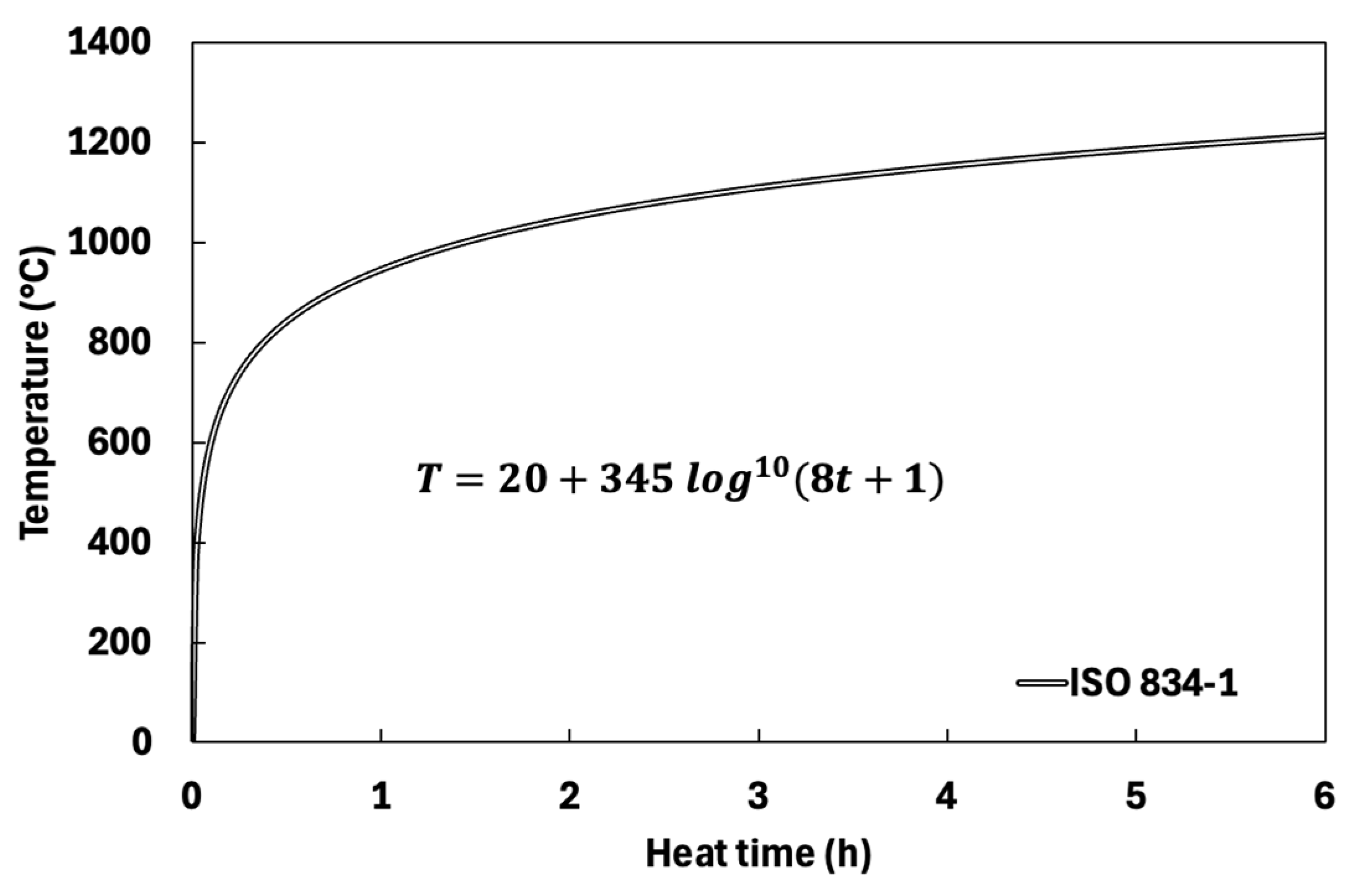

3. Relevance of Preliminary Small-Scale Fire Tests

4. Test Specimens: Wall and Slab Details

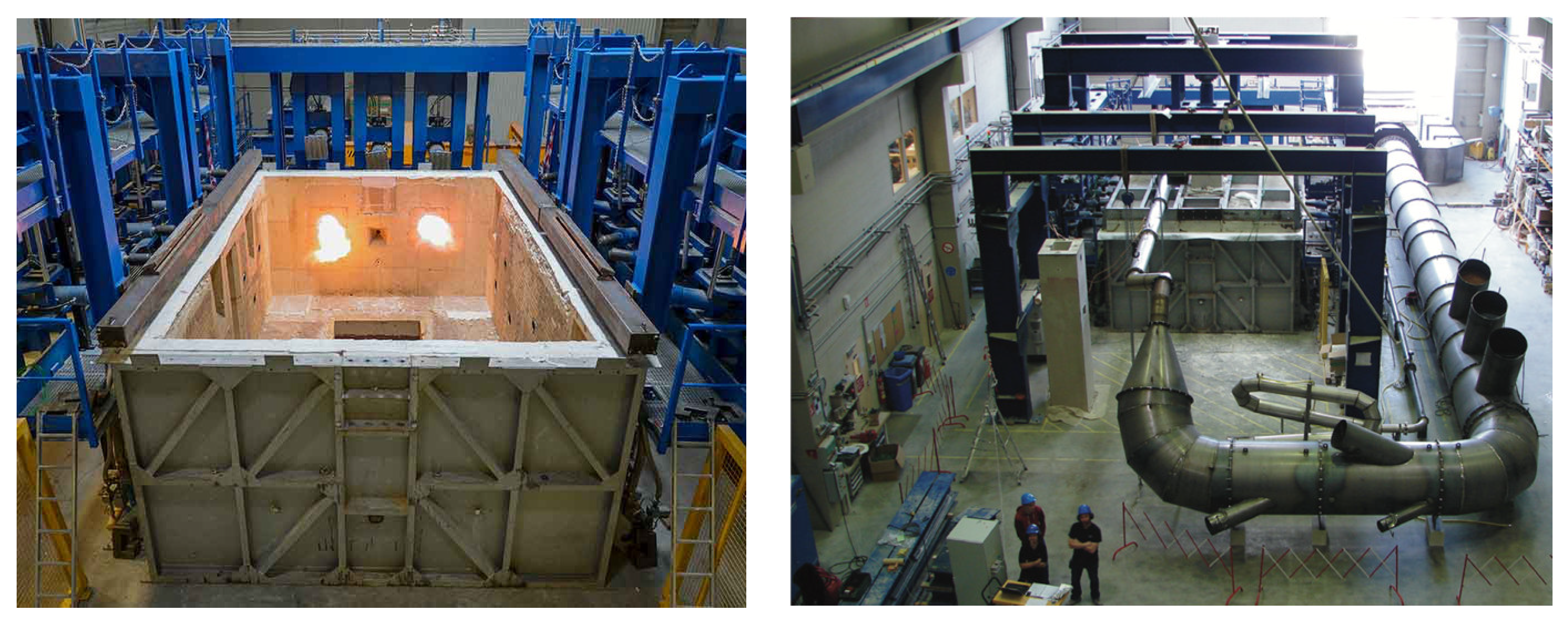

5. Fire Tests

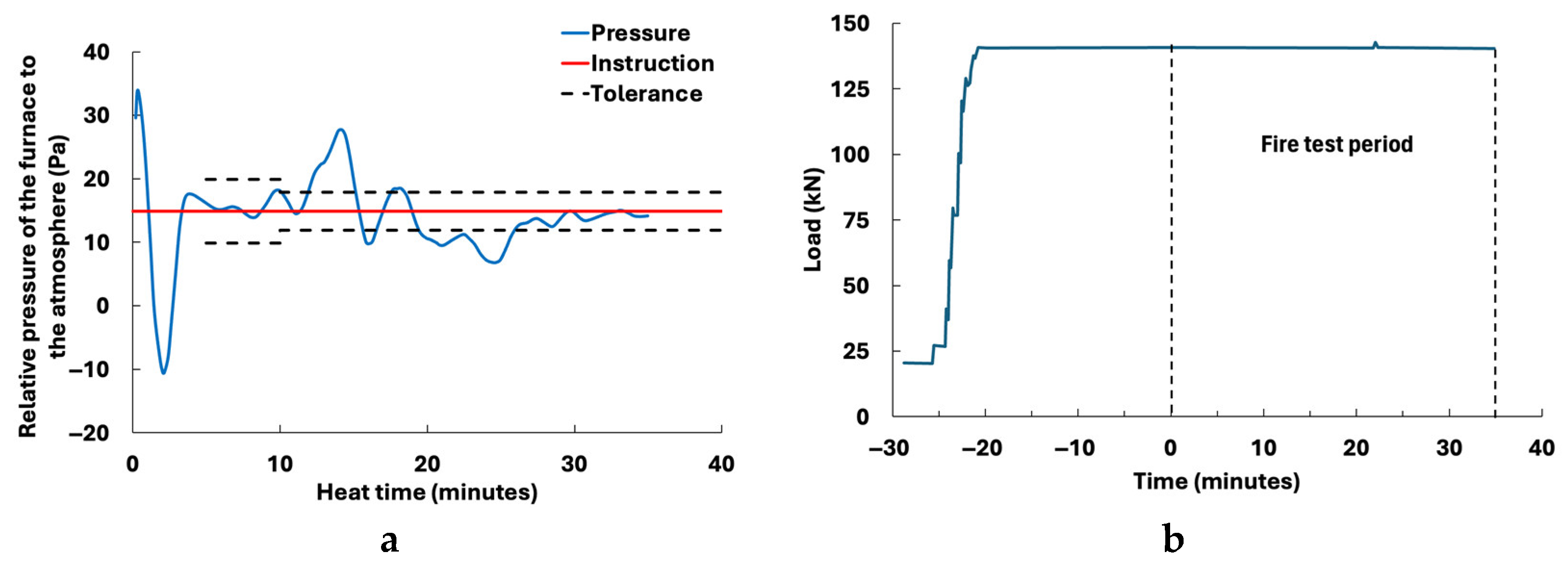

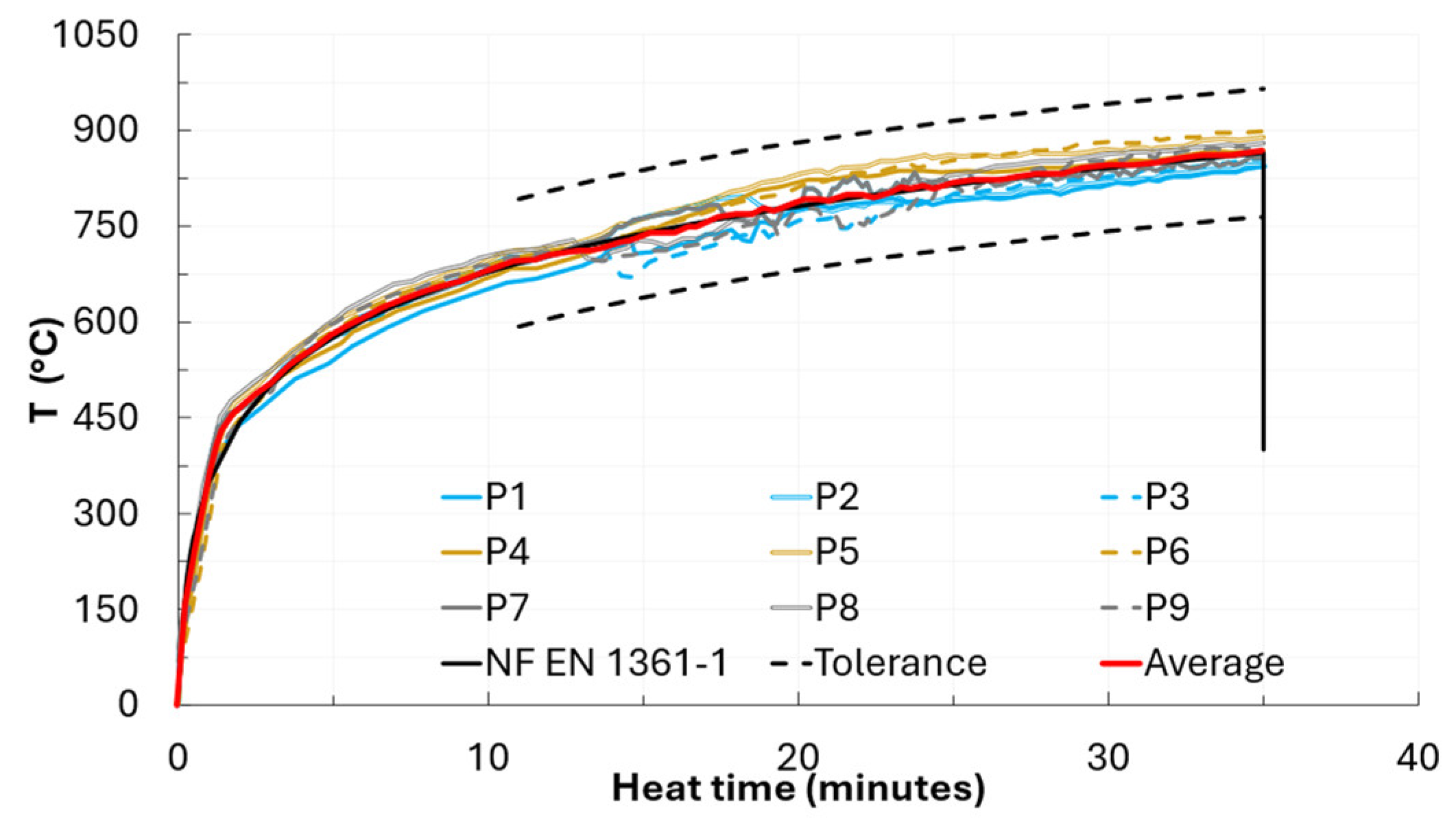

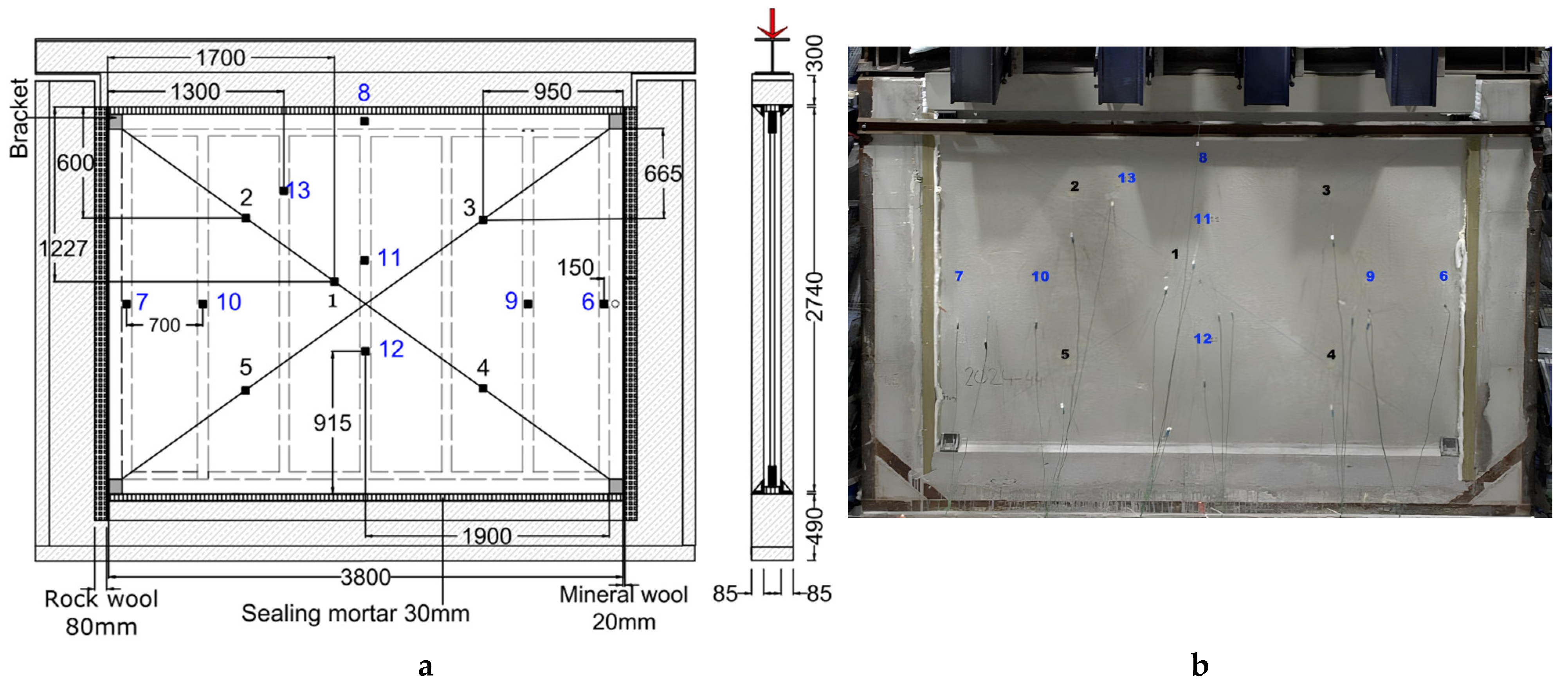

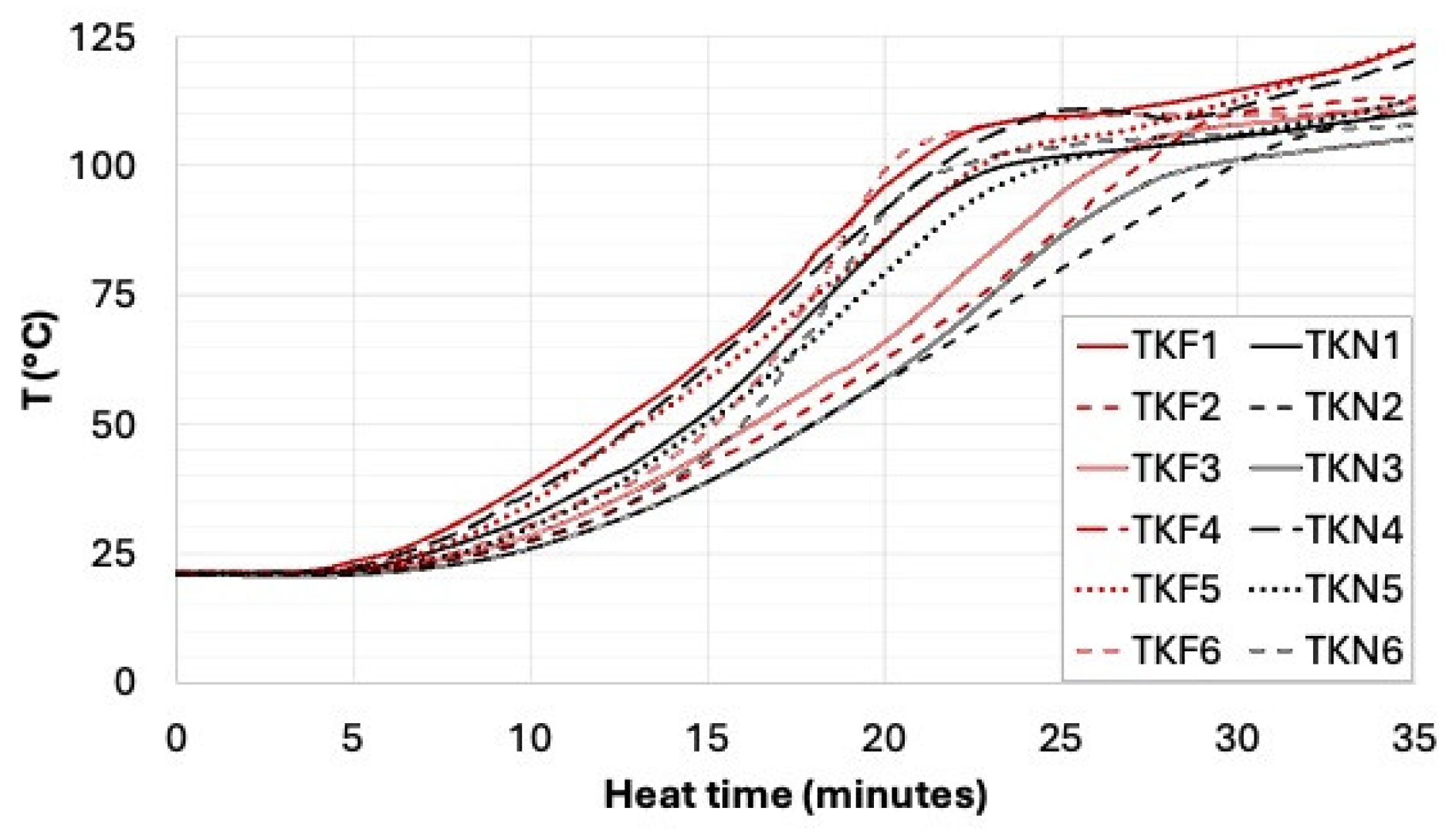

5.1. Stiffened Load-Bearing Wall

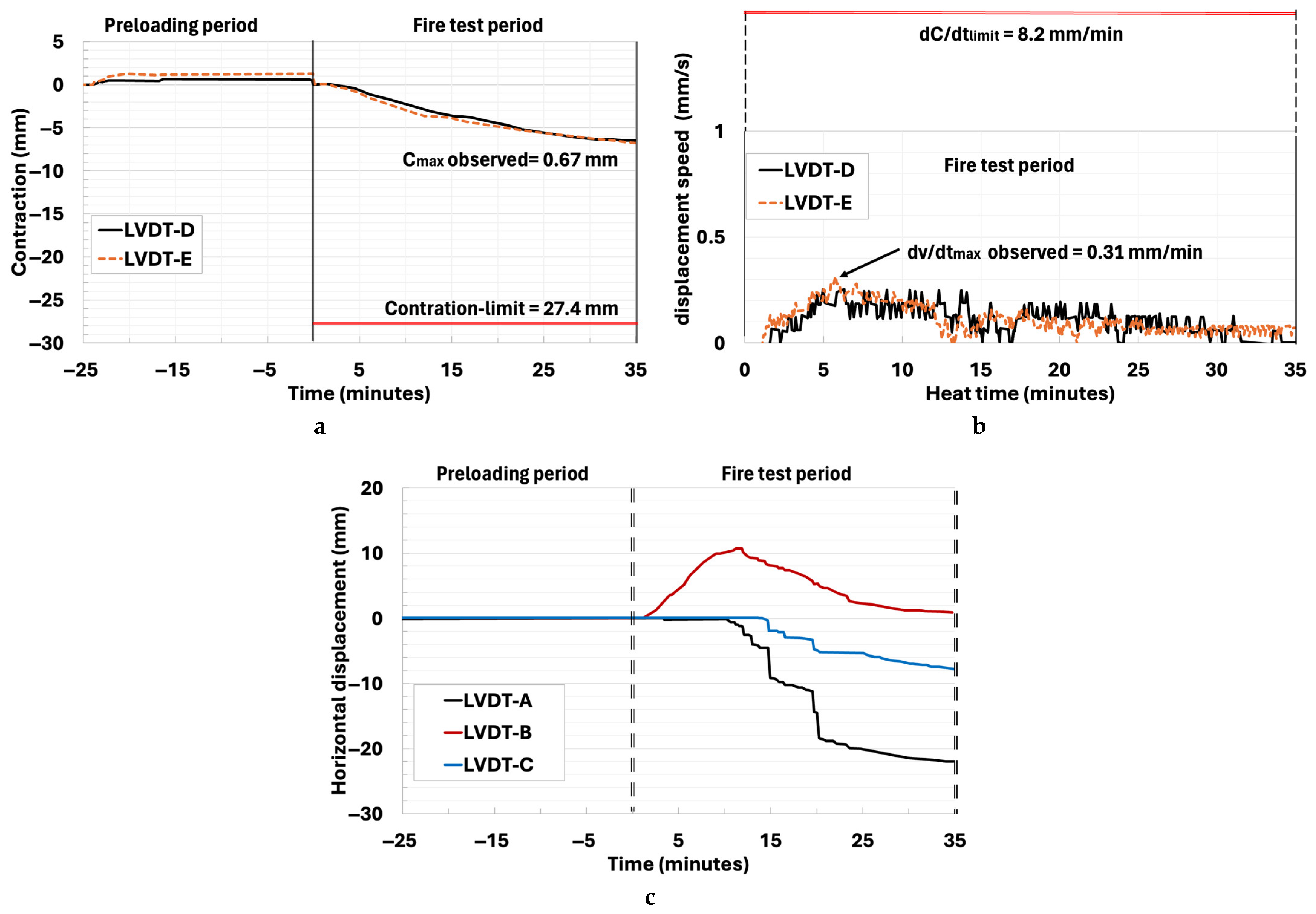

5.1.1. Test Description

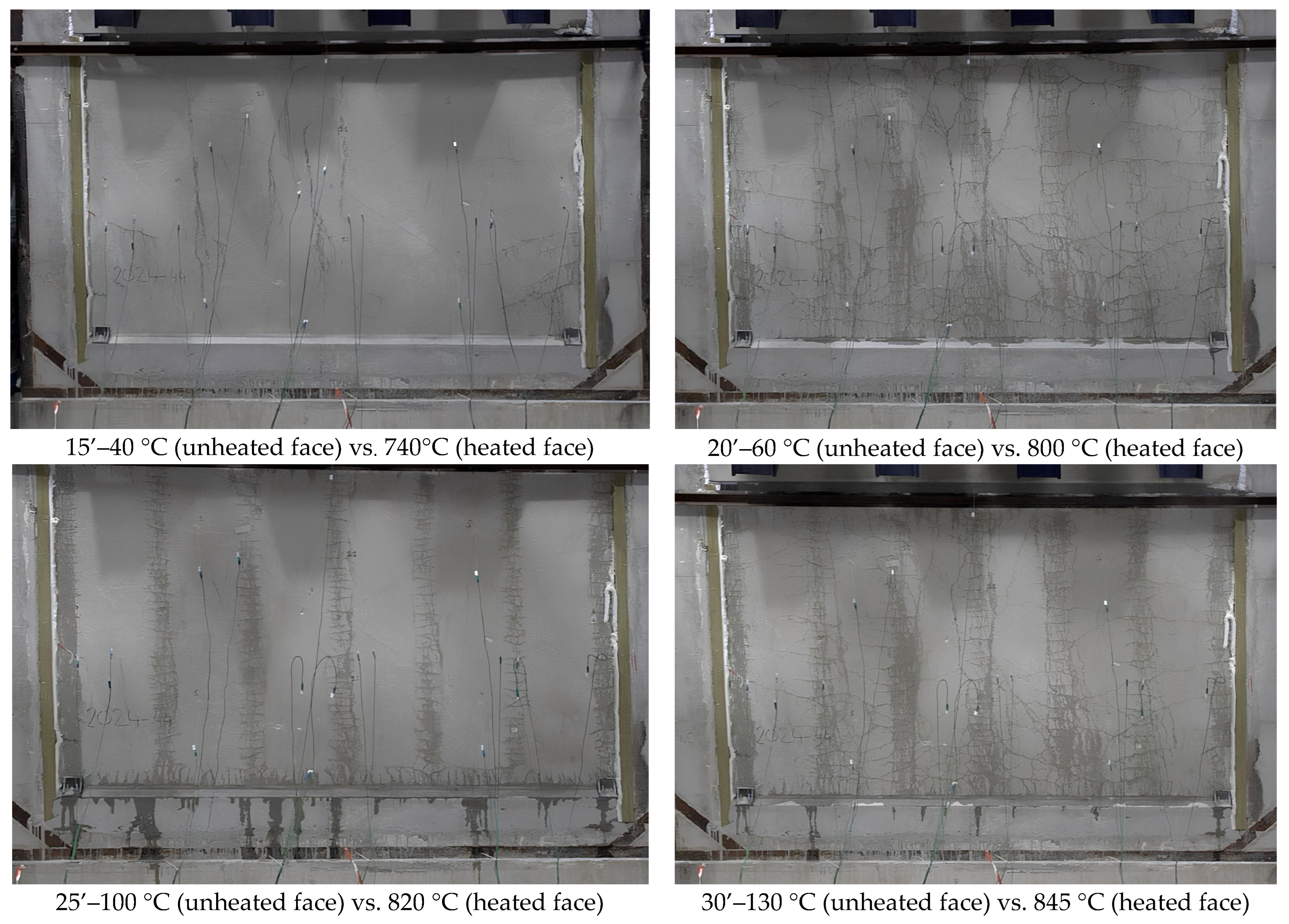

5.1.2. Results and Analysis

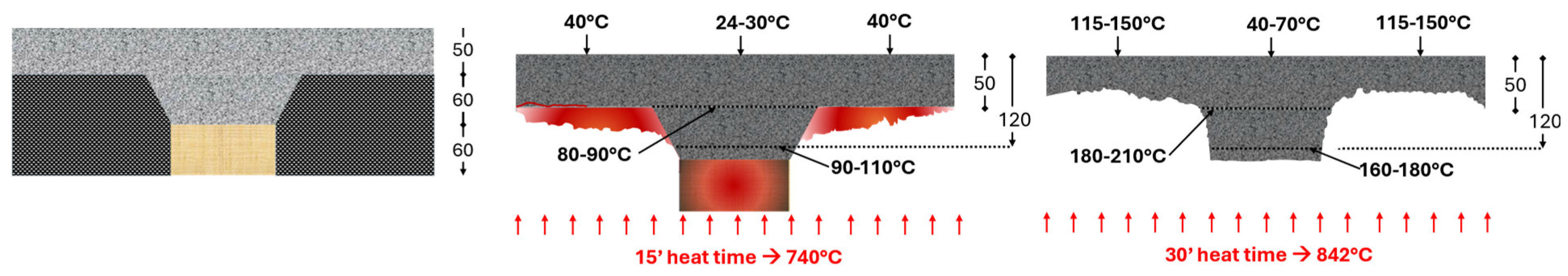

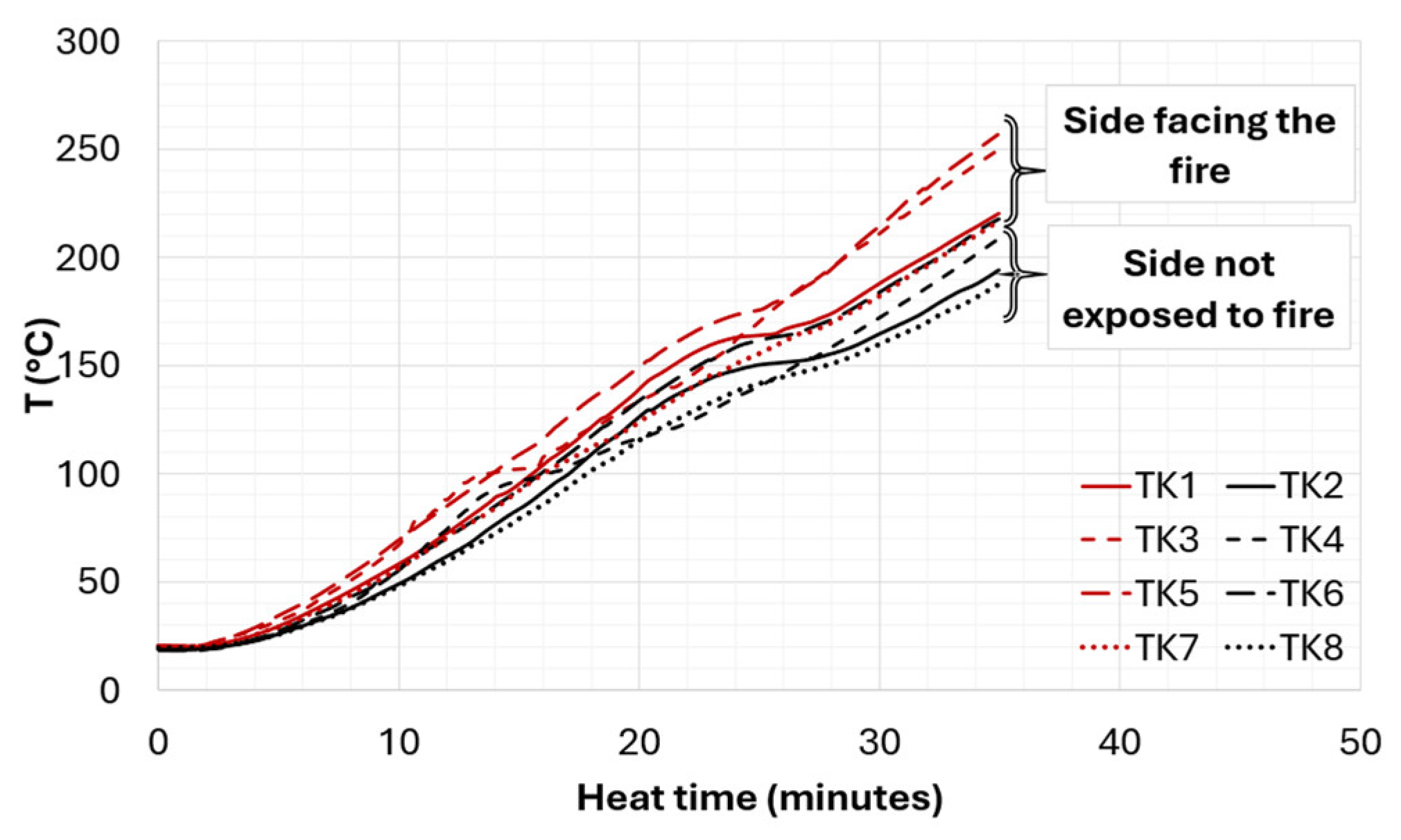

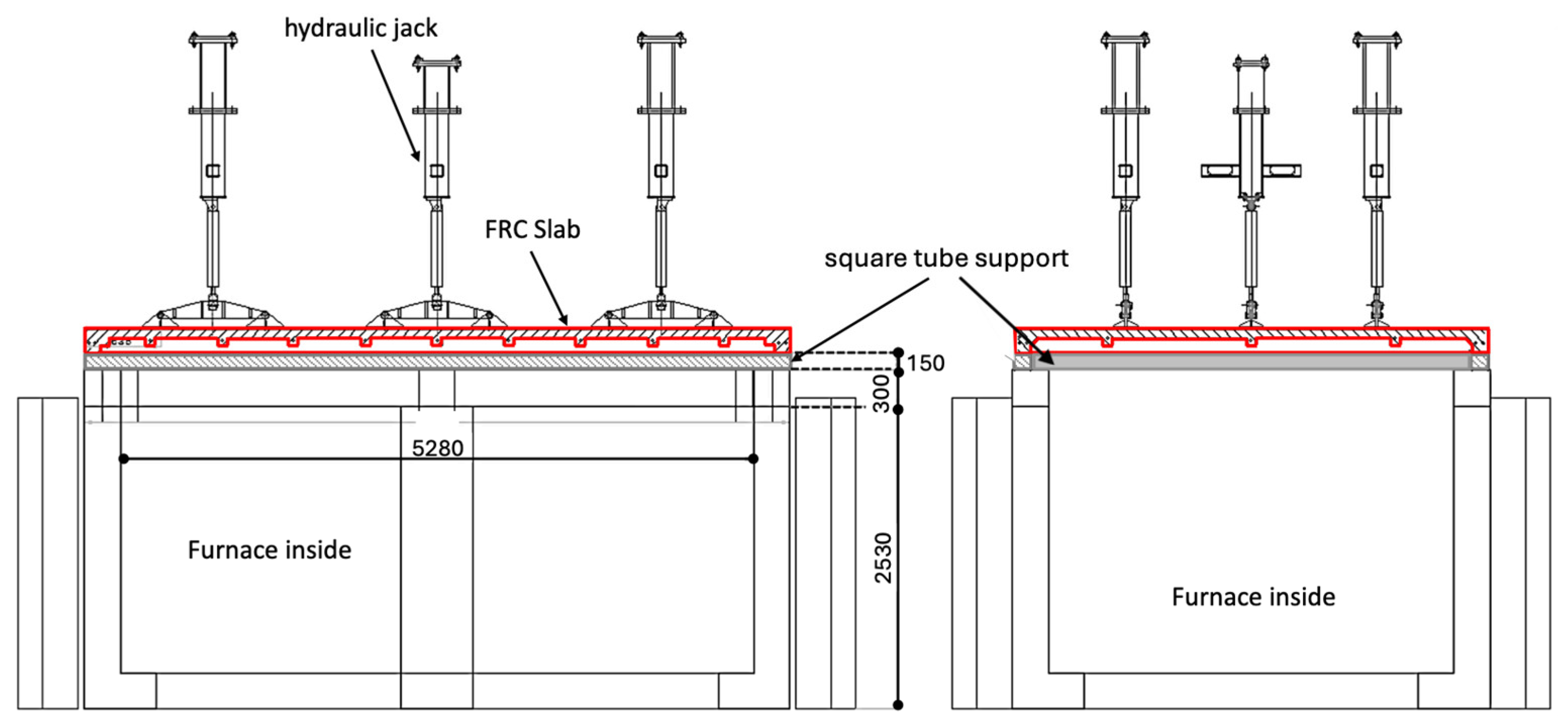

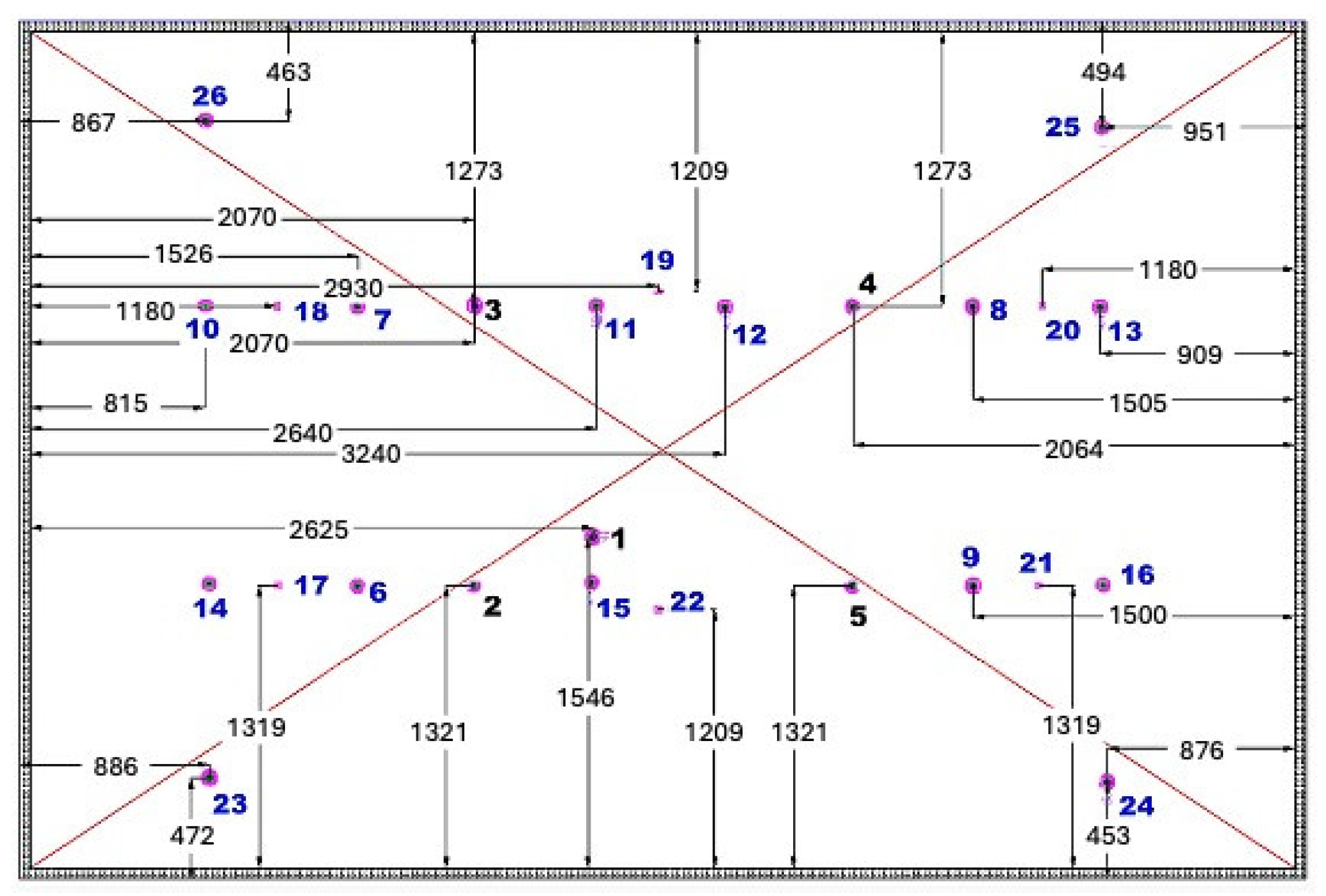

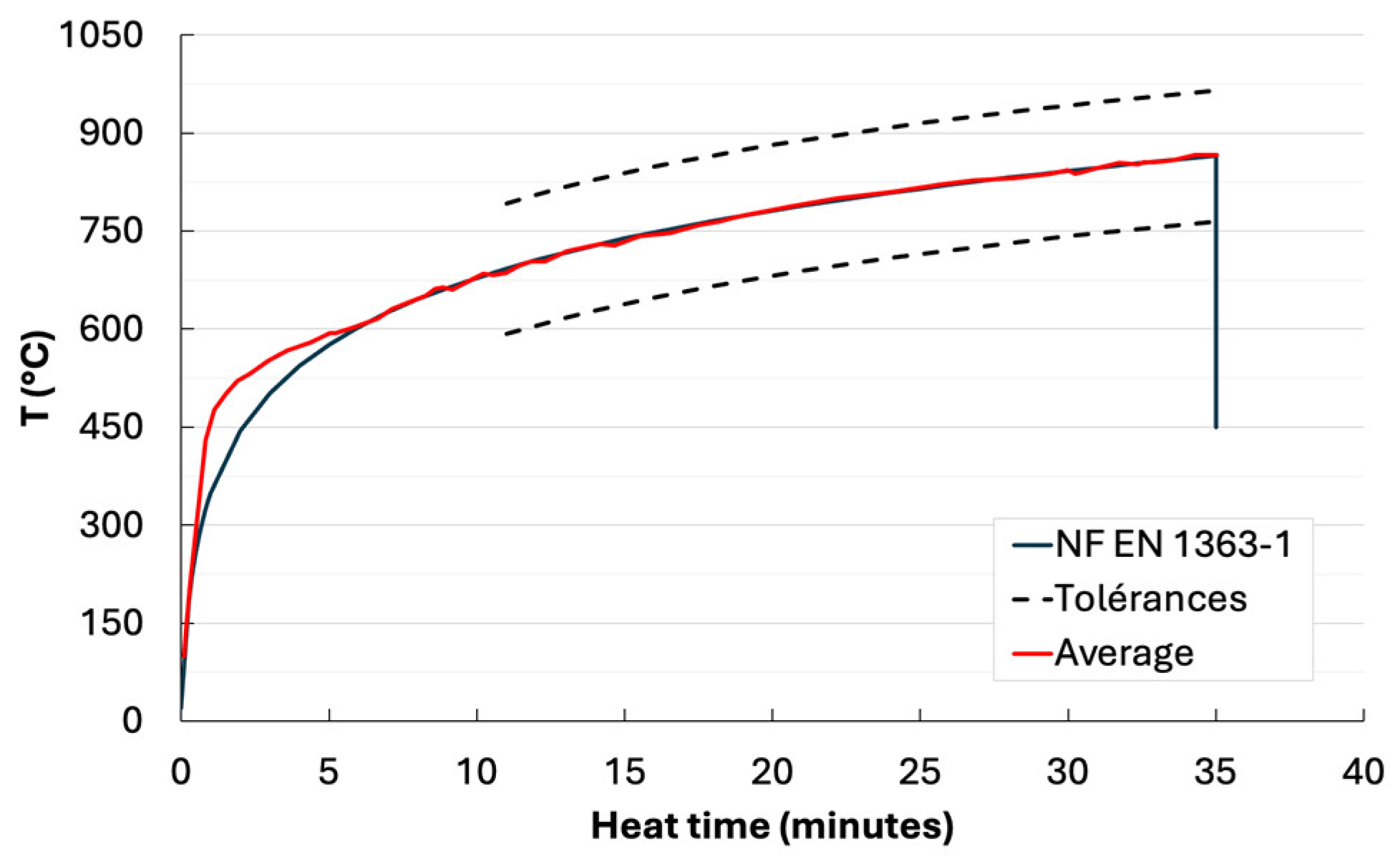

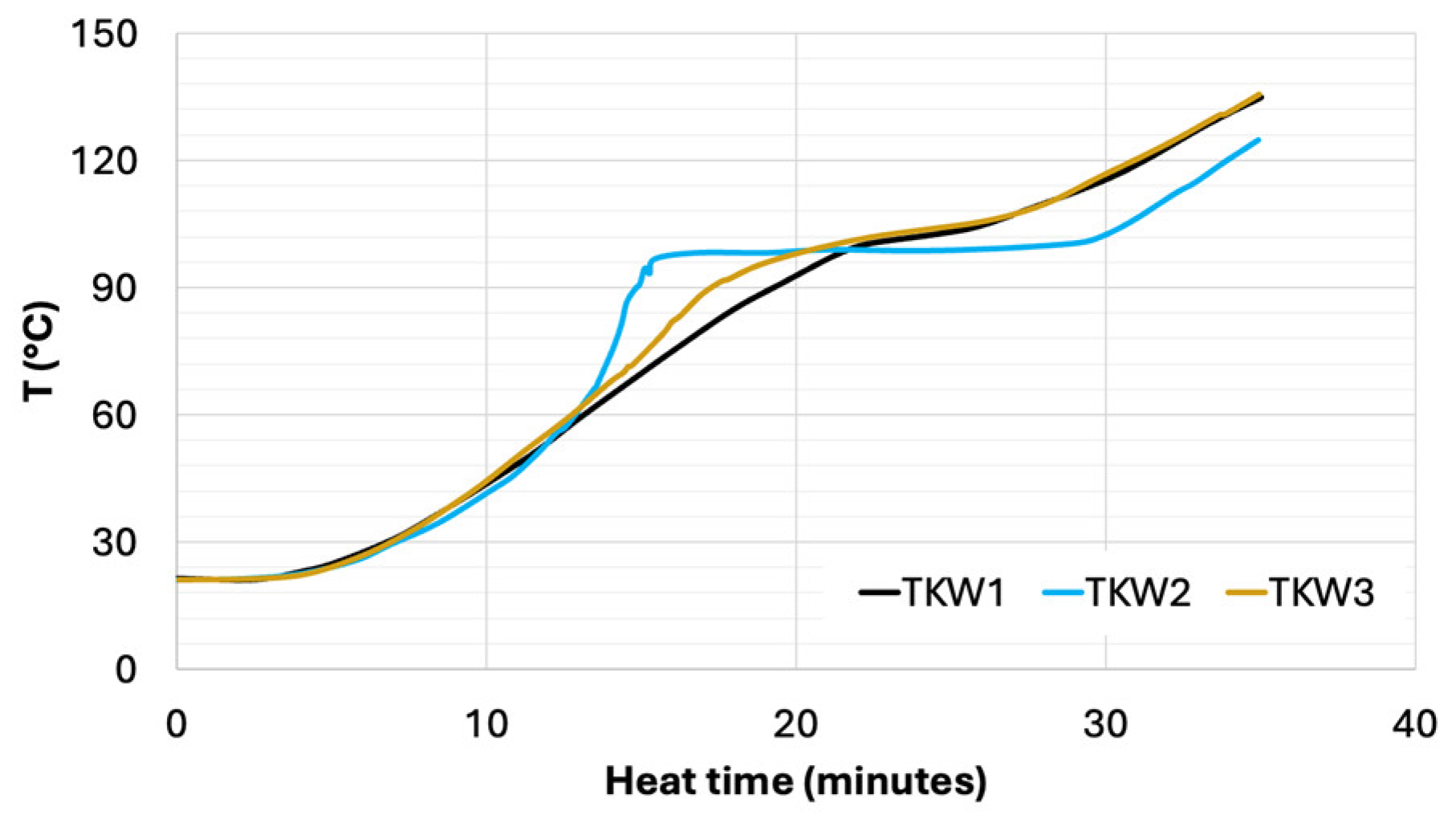

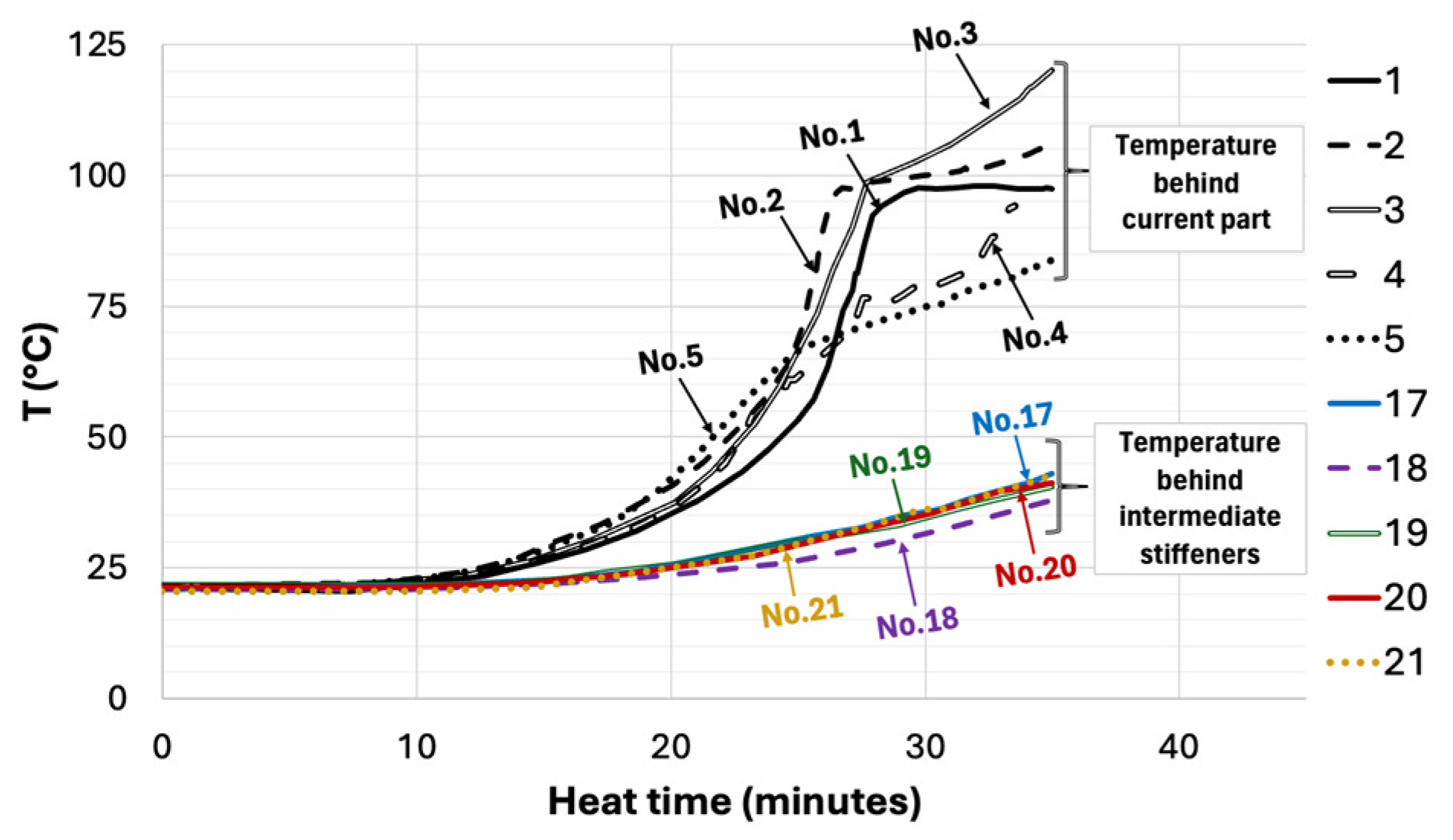

5.2. Stiffened Slab

5.2.1. Test Description

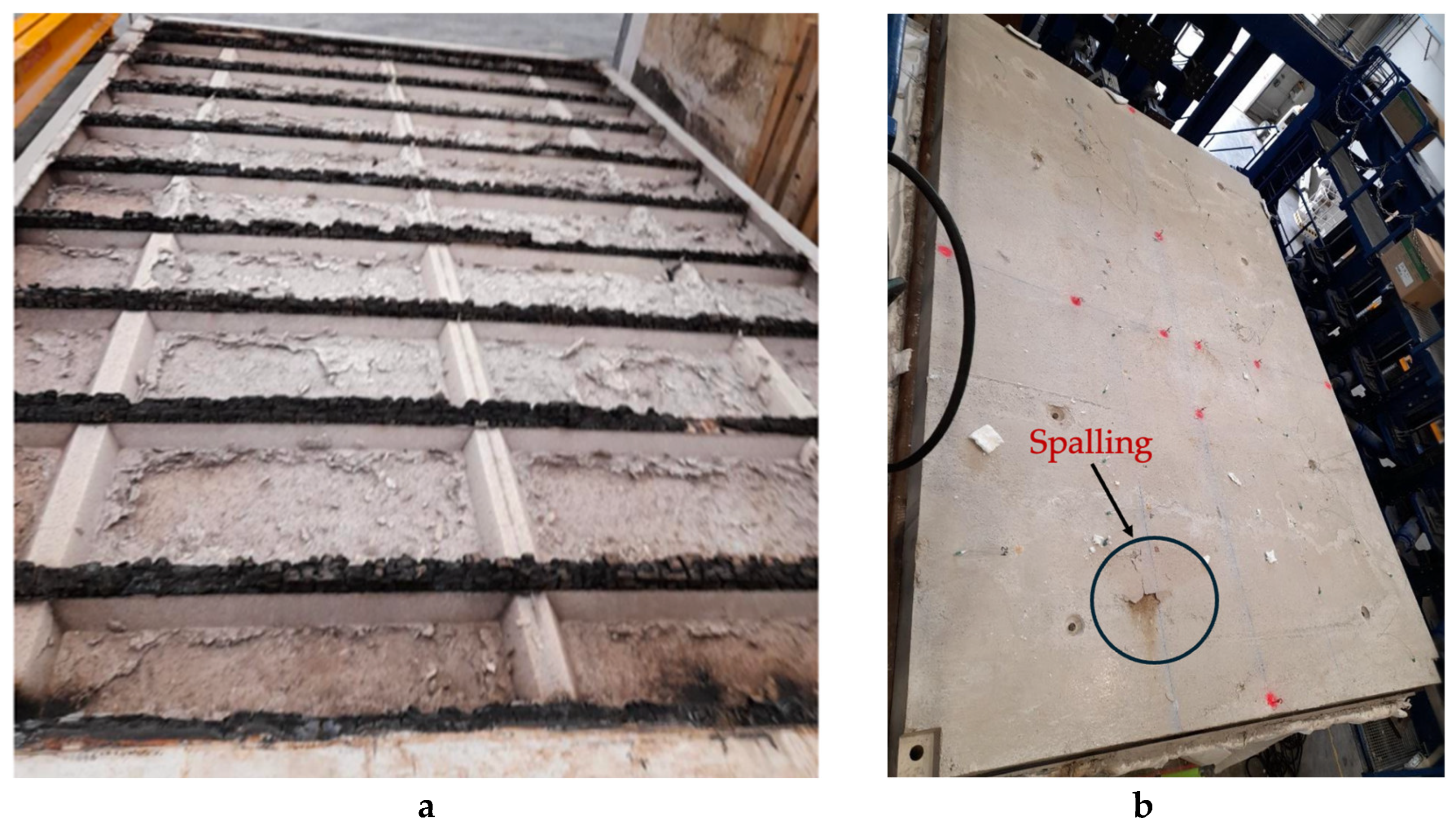

5.2.2. Degradation Mechanism

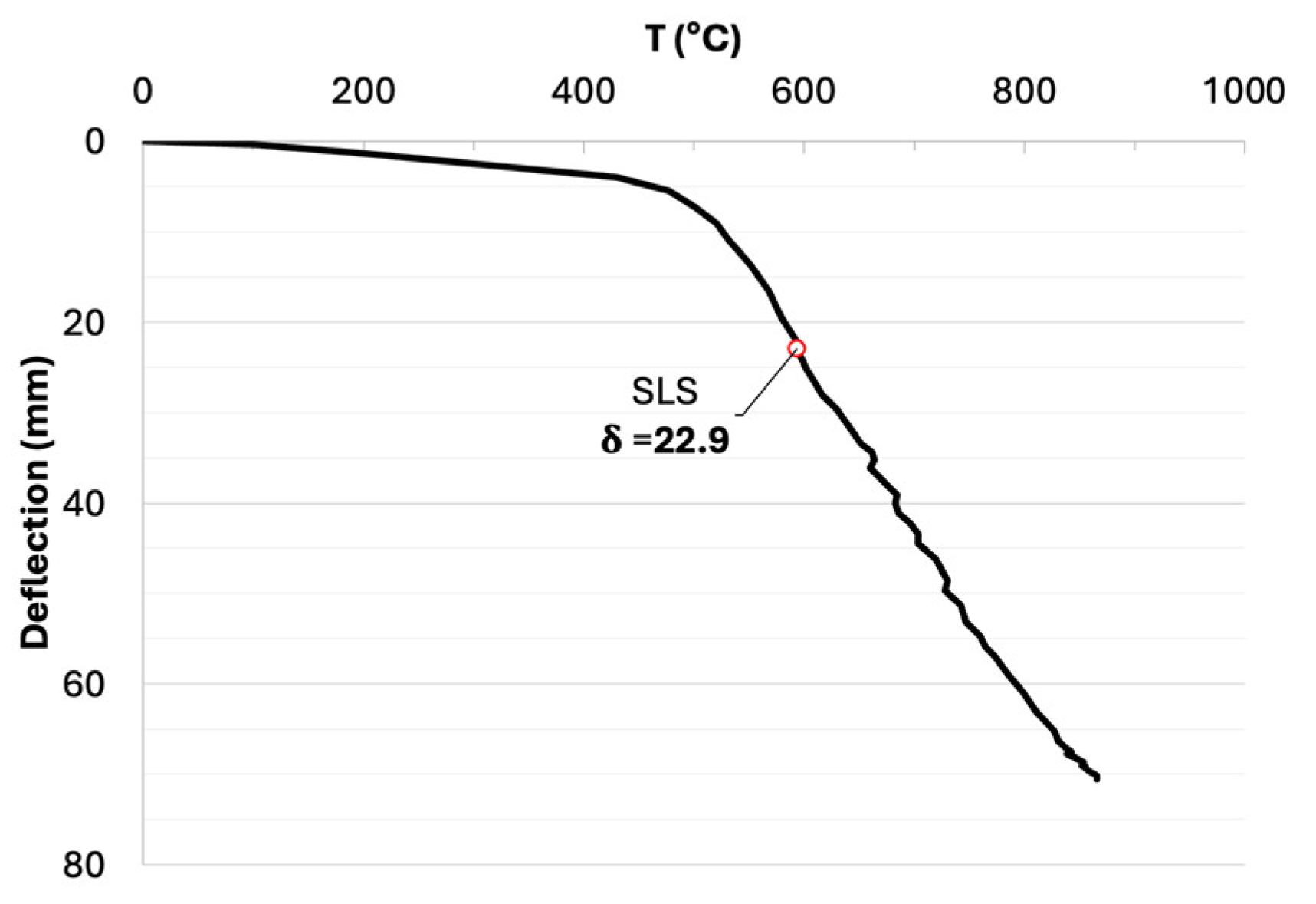

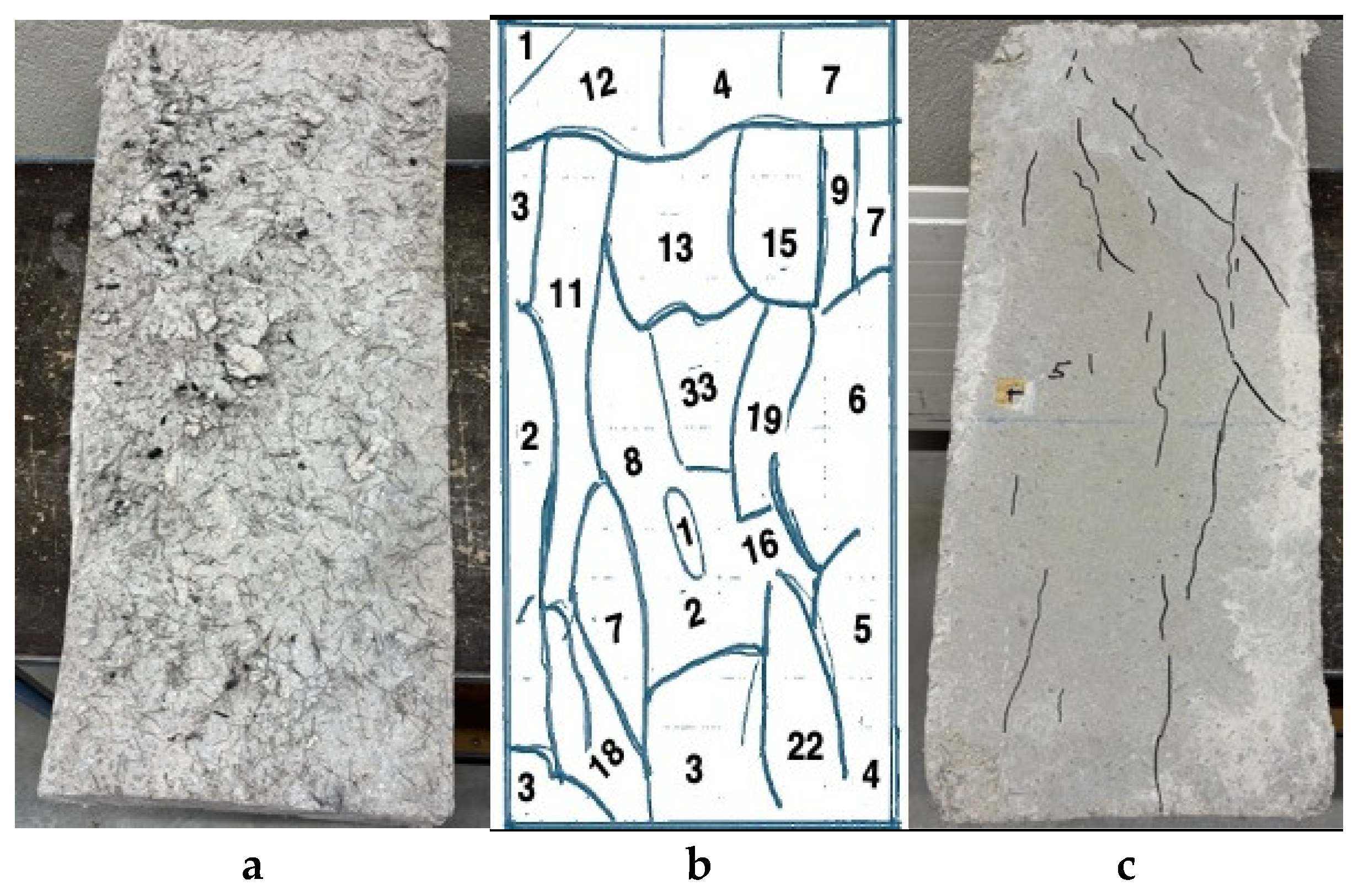

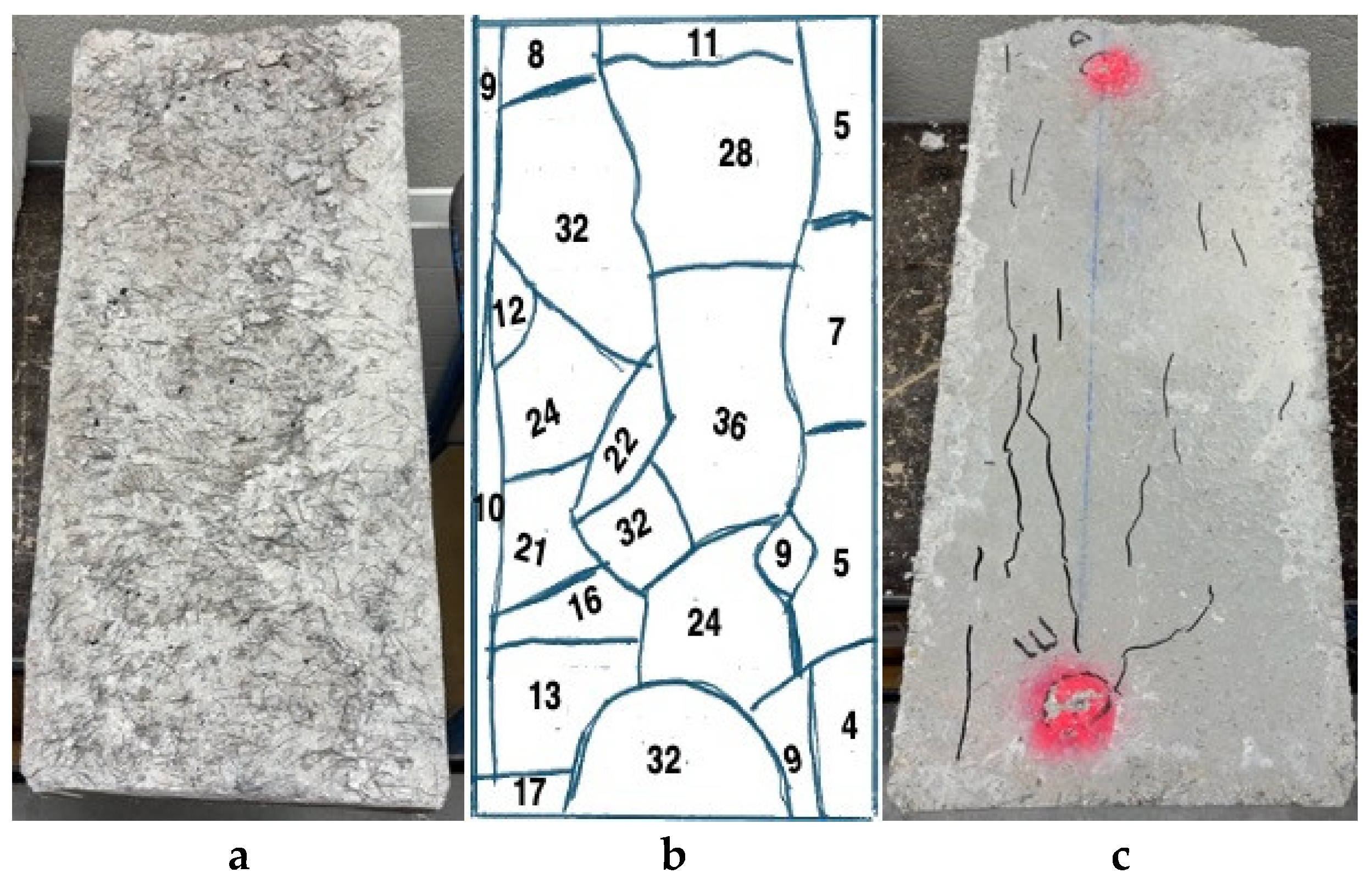

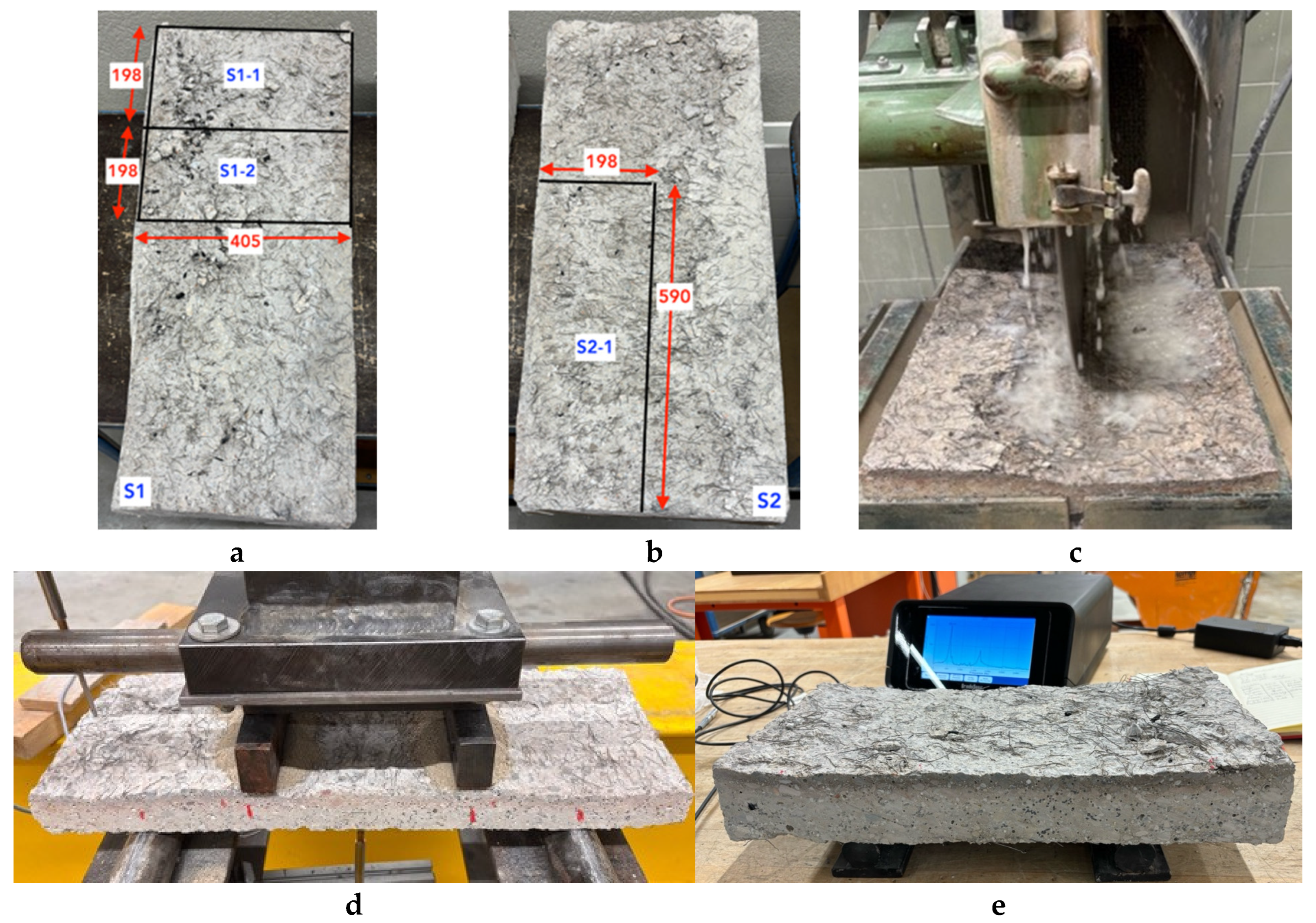

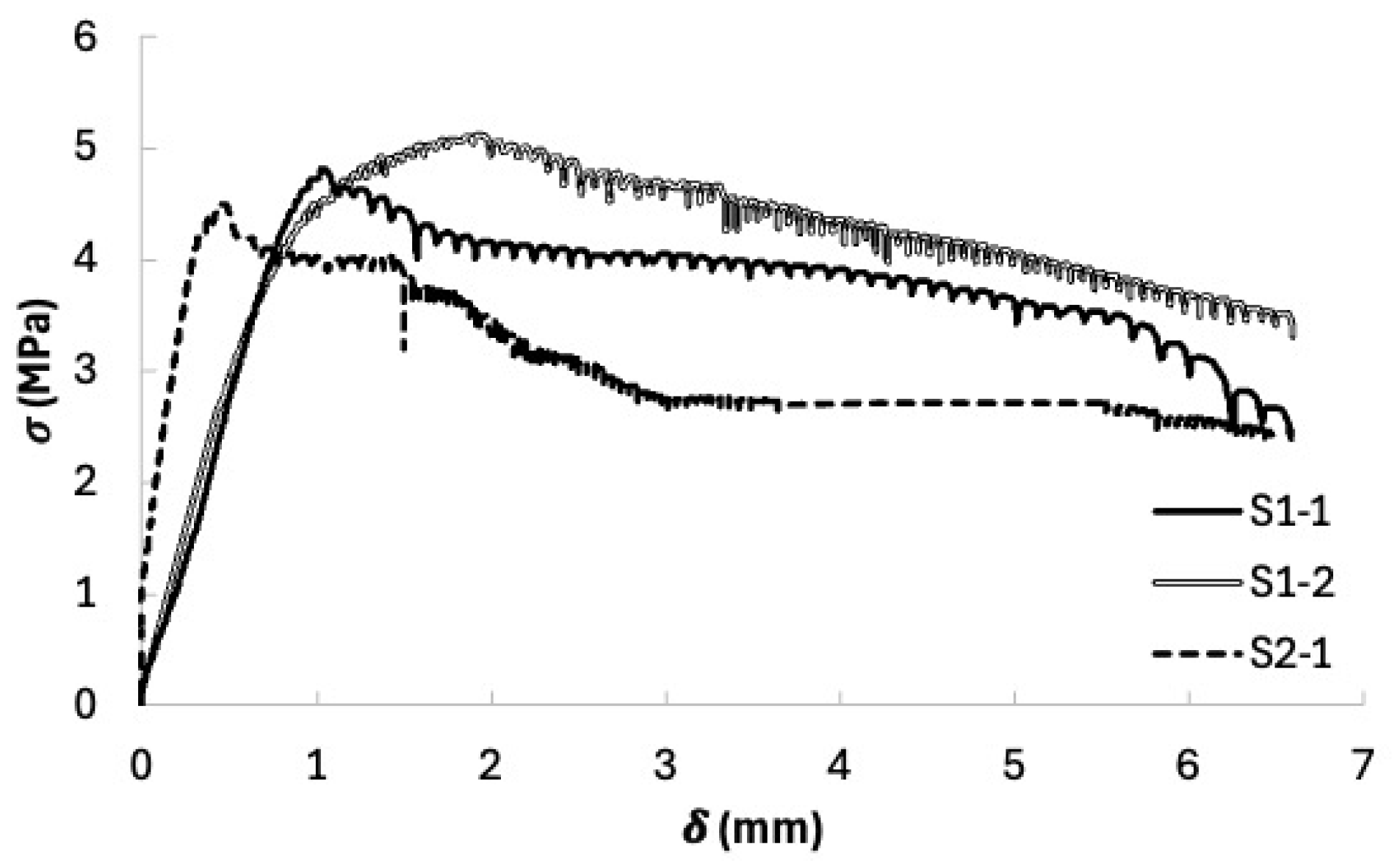

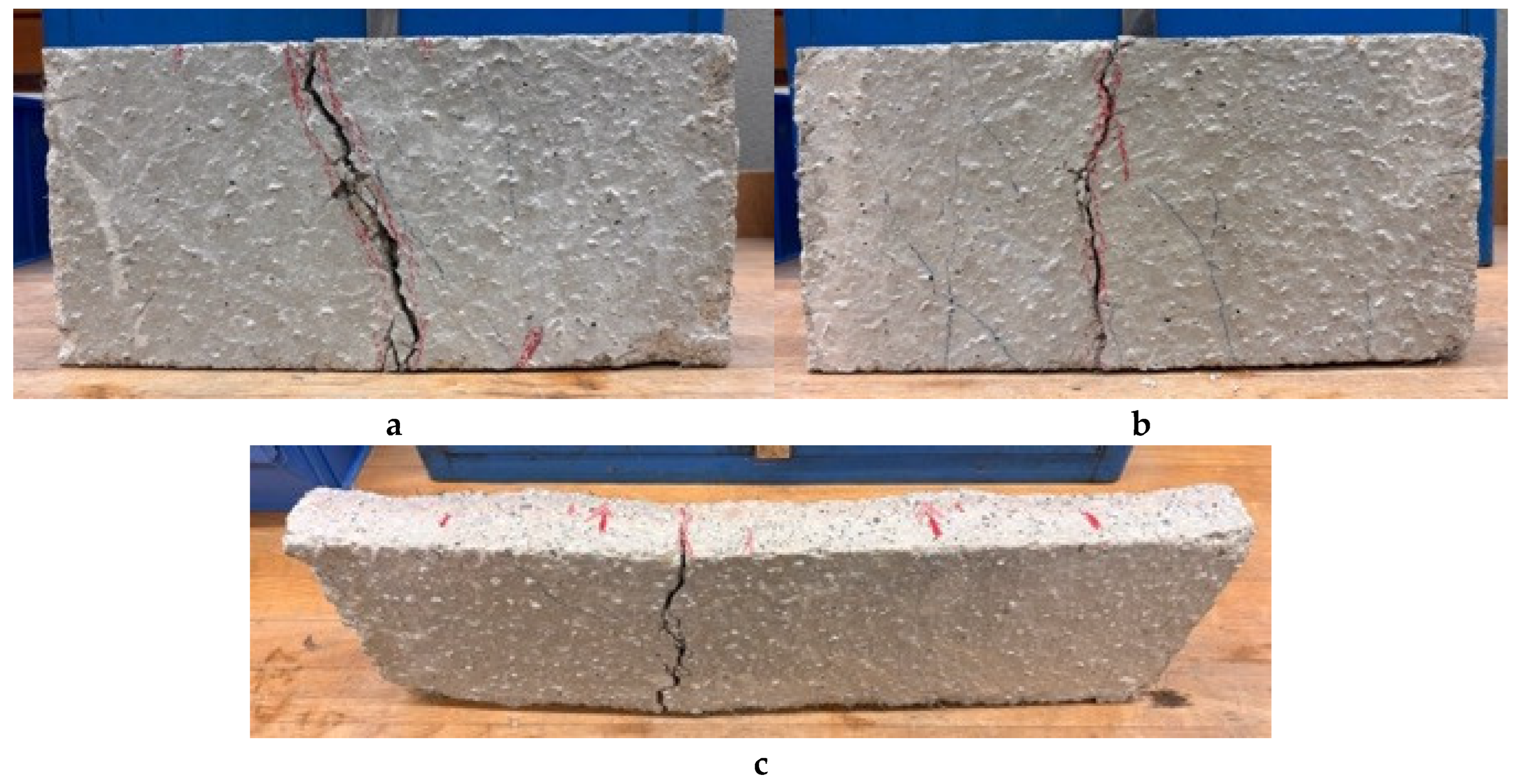

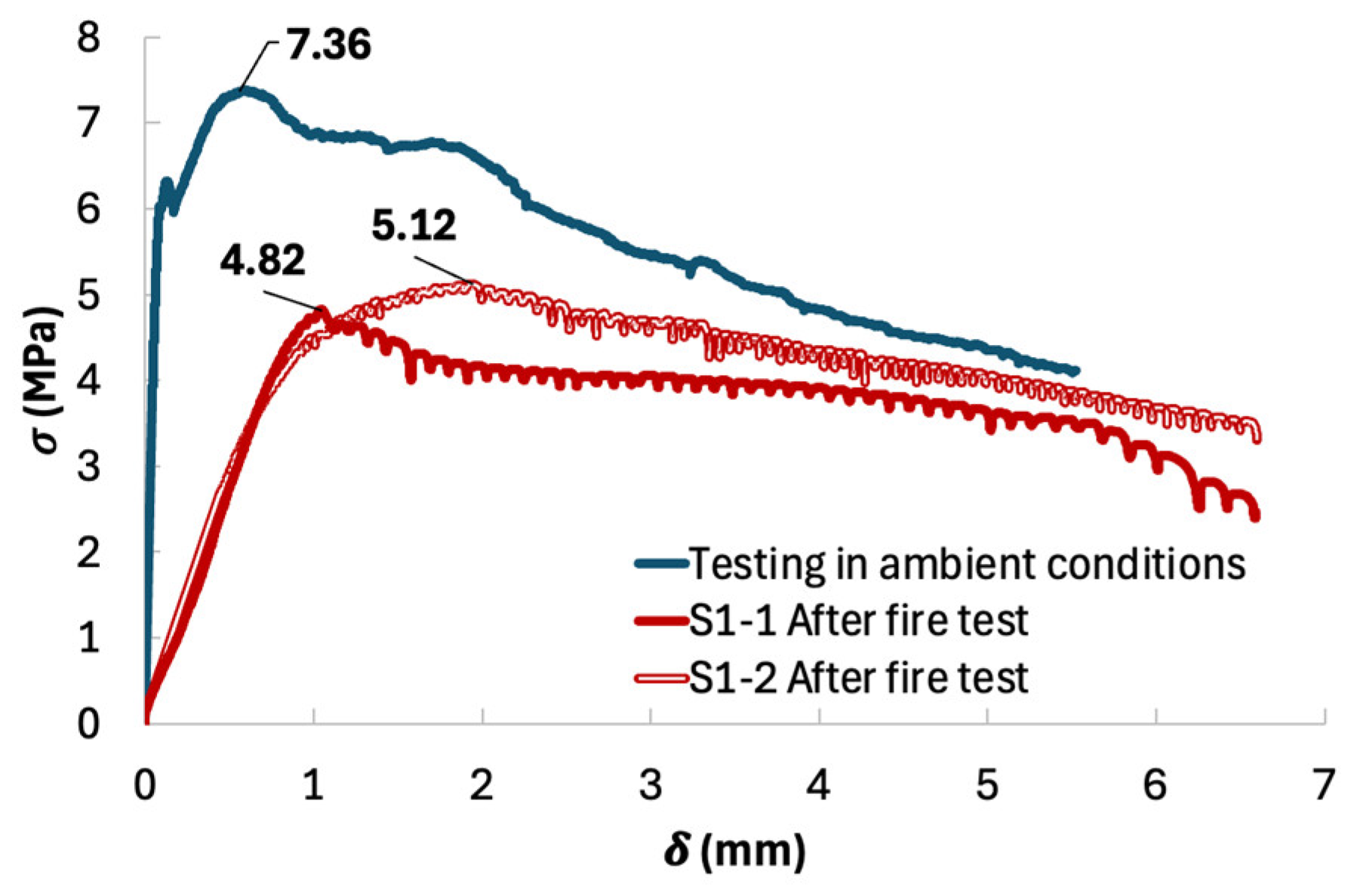

5.2.3. Post-Fire Damage and Residual Strength of Slabs

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, L.; Huang, Z.; Pan, W.; Su, R.K.L.; Zhong, Y.; Zhang, Y. Low carbon concrete for prefabricated modular construction in circular economy: An integrated approach towards sustainability, durability, cost, and mechanical performances. J. Build. Eng. 2024, 90, 109368. [Google Scholar] [CrossRef]

- NF EN 1992-1-2; Eurocode 2: Design of Concrete Structures—Part 1–2: General Rules—Structural Fire Design. Association Francaise de Normalisation (AFNOR): La Plaine Saint-Denis, France, 2005.

- Fire Design of Concrete Structures; fib Bulletin, No. 38; The International Federation for Structural Concrete: Lausanne, Switzerland, 2007. [CrossRef]

- NF P92-701: FB Calculation Method—Calculation Method Used for Forecasting the Fire Resistance of Concrete Structures, AFNOR, 45 p 1993. Available online: https://www.boutique.afnor.org/en-gb/standard/p92701/fb-calculation-method-calculation-method-used-for-forecasting-the-fire-resi/fa036571/275 (accessed on 24 November 2025).

- Lyu, X.; Wang, W.; Xu, Q.; Wu, F.; Yi, S.; Yu, Y. Post-fire behaviors of stiffened concrete-filled thin-walled square steel tubular slender columns: Experimental and numerical investigations. Structures 2025, 78, 109348. [Google Scholar] [CrossRef]

- Heo, Y.-S.; Sanjayan, J.G.; Han, C.-G.; Han, M.-C. Limited effect of diameter of fibres on spalling protection of concrete in fire. Mater. Struct. 2012, 45, 325–335. [Google Scholar] [CrossRef]

- Liu, X.; Ye, G.; De Schutter, G.; Yuan, Y.; Taerwe, L. On the mechanism of polypropylene fibres in preventing fire spalling in self-compacting and high-performance cement paste. Cem. Concr. Res. 2008, 38, 487–499. [Google Scholar] [CrossRef]

- Bangi, M.R.; Horiguchi, T. Effect of fibre type and geometry on maximum pore pressures in fibre-reinforced high strength concrete at elevated temperatures. Cem. Concr. Res. 2012, 42, 459–466. [Google Scholar] [CrossRef]

- Maluk, C.; Bisby, L.; Terrasi, G.P. Effects of polypropylene fibre type and dose on the propensity for heat-induced concrete spalling. Eng. Struct. 2017, 141, 584–595. [Google Scholar] [CrossRef]

- Hiremath, P.N.; Yaragal, S.C. Performance evaluation of reactive powder concrete with polypropylene fibers at elevated temperatures. Constr. Build. Mater. 2018, 169, 499–512. [Google Scholar] [CrossRef]

- Li, S.; Gondokusumo, G.S.; Venkateshwaran, A.; Liew, J.Y.R. Structural behaviour of steel fibre-reinforced concrete floor system for modular construction. Eng. Struct. 2023, 291, 116437. [Google Scholar] [CrossRef]

- Yermak, N.; Pliya, P.; Beaucour, A.-L.; Simon, A.; Noumowé, A. Influence of steel and/or polypropylene fibres on the behaviour of concrete at high temperature: Spalling, transfer and mechanical properties. Constr. Build. Mater. 2017, 132, 240–250. [Google Scholar] [CrossRef]

- Zeiml, M.; Leithner, D.; Lackner, R.; Mang, H.A. How do polypropylene fibers improve the spalling behavior of in-situ concrete? Cem. Concr. Res. 2006, 36, 929–942. [Google Scholar] [CrossRef]

- Lee, W.M.; Fragomeni, S.; Monckton, H.; Guerrieri, M. A review of test Methods, issues and challenges of Large-Scale fire testing of concrete tunnel linings. Constr. Build. Mater. 2023, 392, 131901. [Google Scholar] [CrossRef]

- Serafini, R.; Dantas, S.R.A.; Agra, R.R.; de la Fuente, A.; Berto, A.F.; de Figueiredo, A.D. Design-oriented assessment of the residual post-fire bearing capacity of precast fiber reinforced concrete tunnel linings. Fire Saf. J. 2022, 127, 103503. [Google Scholar] [CrossRef]

- Tatnall, P.C. Shotcrete in Fires: Effects of Fibers on Explosive Spalling. Shotcrete 2002, 4, 10–12. [Google Scholar]

- Kalifa, P.; Chéné, G.; Gallé, C. High-temperature behaviour of HPC with polypropylene fibres: From spalling to microstructure. Cem. Concr. Res. 2001, 31, 1487–1499. [Google Scholar] [CrossRef]

- Serrano, R.; Cobo, A.; Prieto, M.I.; González, M.d.l.N. Analysis of fire resistance of concrete with polypropylene or steel fibers. Constr. Build. Mater. 2016, 122, 302–309. [Google Scholar] [CrossRef]

- McNamee, R.; Sjöström, J.; Boström, L. Reduction of fire spalling of concrete with small doses of polypropylene fibres. Fire Mater. 2021, 45, 943–951. [Google Scholar] [CrossRef]

- Khayat, K.H.; De Schutter, G. (Eds.) Mechanical Properties of Self-Compacting Concrete: State-of-the-Art Report of the RILEM Technical Committee 228-MPS on Mechanical Properties of Self-Compacting Concrete; RILEM State-of-the-Art Reports; Springer International Publishing: Cham, Switzerland, 2014; Volume 14. [Google Scholar] [CrossRef]

- Noumowé, A.; Carré, H.; Daoud, A.; Toutanji, H. High-Strength Self-Compacting Concrete Exposed to Fire Test. J. Mater. Civ. Eng. 2006, 18, 754–758. [Google Scholar] [CrossRef]

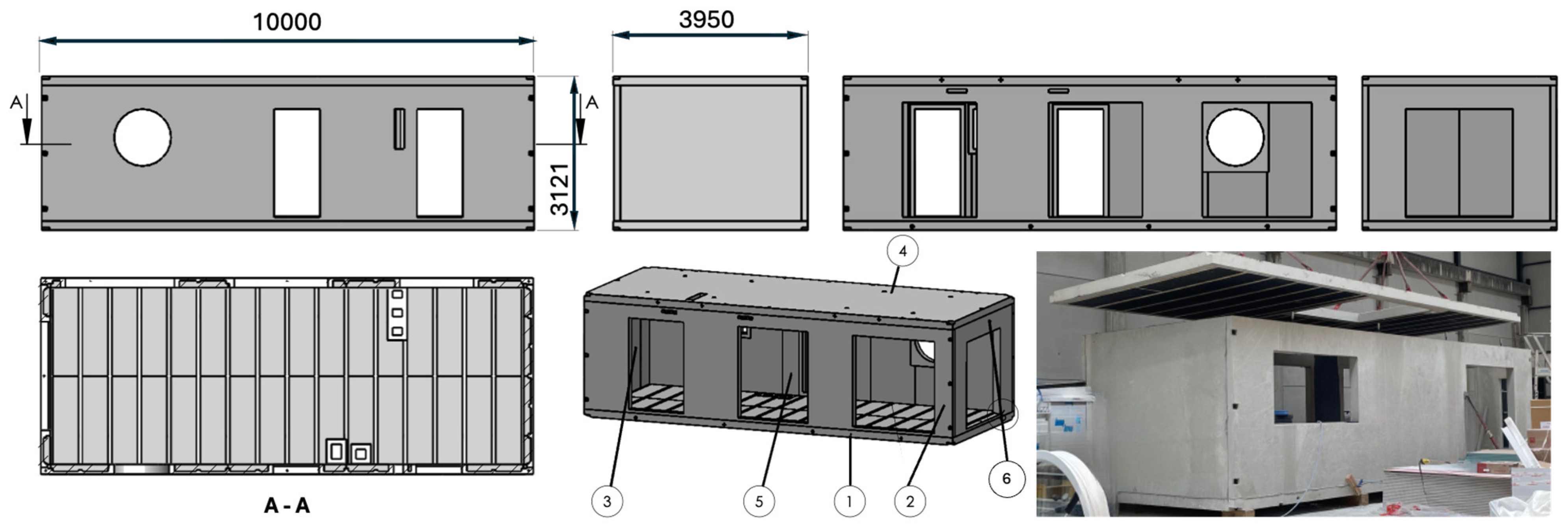

- Sawadogo, S.A.S.L.; Bui, T.T.; Bennani, A.; Al Galib, D.; Reynaud, P.; Limam, A. 3D Modular construction made of precast SFRC stiffened panels. Infrastructures 2025, 10, 176. [Google Scholar] [CrossRef]

- Xu, Y.; Yao, L.; Yu, X. Effect of polypropylene fibers on mechanical and wetting properties of overall superhydrophobic foamed concrete. Constr. Build. Mater. 2024, 448, 138207. [Google Scholar] [CrossRef]

- Pu, B.; Liu, B.; Li, L.; Pang, W.; Wan, Z. Influence of Polypropylene Fibre Factor on Flowability and Mechanical Properties of Self-Compacting Geopolymer. Materials 2021, 14, 5025. [Google Scholar] [CrossRef]

- Xia, Z.; Geng, J.; Zhou, Z.; Liu, G. Comparative analysis of polypropylene, basalt, and steel fibers in 3D printed concrete: Effects on flowability, printabiliy, rheology, and mechanical performance. Constr. Build. Mater. 2025, 465, 140098. [Google Scholar] [CrossRef]

- Osmanovic, Z.; Haračić, N.; Zelić, J. Properties of blastfurnace cements (CEM III/A, B, C) based on Portland cement clinker, blastfurnace slag and cement kiln dusts. Cem. Concr. Compos. 2018, 91, 189–197. [Google Scholar] [CrossRef]

- Konieczna, K.; Chilmon, K.; Jackiewicz-Rek, W. Investigation of Mechanical Properties, Durability and Microstructure of Low-Clinker High-Performance Concretes Incorporating Ground Granulated Blast Furnace Slag, Siliceous Fly Ash and Silica Fume. Appl. Sci. 2021, 11, 830. [Google Scholar] [CrossRef]

- Sawadogo, S.A.S.L.; Bui, T.T.; Bennani, A.; David, H.; Damichey, D.; Limam, A. Concrete Volumetric Building Units for Highly Environmental-Efficient Modular Houses. In Proceedings of the 7th International Conference on Geotechnics, Civil Engineering and Structures, CIGOS, Ho Chi Minh City, Vietnam, 4–5 April 2024; Ha-Minh, C., Pham, C.H., Vu, H.T.H., Huynh, D.V.K., Eds.; Springer Nature: Singapore, 2024; pp. 270–278. [Google Scholar]

- Pimienta, P.; McNamee, R.; Robert, F.; Boström, L.; Huang, S.-S.; Mróz, K.; Davie, C.; Mohaine, S.; Alonso, M.C.; Bodnarova, L.; et al. Recommendation of RILEM TC 256-SPF on fire spalling assessment during standardised fire resistance tests: Complementary guidance and requirements. Mater. Struct. 2023, 57, 3. [Google Scholar] [CrossRef]

- Pimienta, P.; McNamee, R.; Hager, I.; Mróz, K.; Boström, L.; Mohaine, S.; Huang, S.-S.; Mindeguia, J.-C.; Robert, F.; Davie, C.; et al. Recommendation of RILEM TC 256-SPF on the method of testing concrete spalling due to fire: Material screening test. Mater. Struct. 2023, 56, 164. [Google Scholar] [CrossRef]

- ISO 834-1; Fire-Resistance Tests—Elements of Building Construction—Part 1: General Requirements. ISO: Geneva, Switzerland, 1999.

- NF EN 1363-1; Fire Resistance Tests—Part 1: General Requirements. Association Francaise de Normalisation (AFNOR): La Plaine Saint-Denis, France, 2020.

- NF EN 1365-1; Fire Resistance Tests for Loadbearing Elements—Part 1: Walls. Association Francaise de Normalisation (AFNOR): La Plaine Saint-Denis, France, 2012.

- Yarmohammdian, R.; Felicetti, R.; Robert, F.; Mohaine, S.; Izoret, L. Crack instability of concrete in fire: A new small-scale screening test for spalling. Cem. Concr. Compos. 2024, 153, 105739. [Google Scholar] [CrossRef]

- Bastami, M.; Chaboki-Khiabani, A.; Baghbadrani, M.; Kordi, M. Performance of high strength concretes at elevated temperatures. Sci. Iran. 2011, 18, 1028–1036. [Google Scholar] [CrossRef]

- Gawin, D.; Pesavento, F.; Schrefler, B.A. Towards prediction of the thermal spalling risk through a multi-phase porous media model of concrete. Comput. Methods Appl. Mech. Eng. 2006, 195, 5707–5729. [Google Scholar] [CrossRef]

- Nassar, R.-U.-D.; Zaid, O.; Althoey, F.; Abuhussain, M.A.; Alashker, Y. Spalling behavior and performance of ultra-high-performance concrete subjected to elevated temperature: A review. Constr. Build. Mater. 2024, 411, 134489. [Google Scholar] [CrossRef]

- Maier, M.; Saxer, A.; Bergmeister, K.; Lackner, R. An experimental fire-spalling assessment procedure for concrete mixtures. Constr. Build. Mater. 2020, 232, 117172. [Google Scholar] [CrossRef]

- Mindeguia, J.-C.; Carré, H.; Pimienta, P.; Borderie, C.L. Experimental discussion on the mechanisms behind the fire spalling of concrete. Fire Mater. 2015, 39, 619–635. [Google Scholar] [CrossRef]

- Miah, M.J.; Kallel, H.; Carré, H.; Pimienta, P.; La Borderie, C. The effect of compressive loading on the residual gas permeability of concrete. Constr. Build. Mater. 2019, 217, 12–19. [Google Scholar] [CrossRef]

- Boström, L.; Wickström, U.; Adl-Zarrabi, B. Effect of specimen size and loading conditions on spalling of concrete. Fire Mater. 2007, 31, 173–186. [Google Scholar] [CrossRef]

- Jansson, R.; Boström, L. Factors influencing fire spalling of self compacting concrete. Mater. Struct. 2013, 46, 1683–1694. [Google Scholar] [CrossRef]

- NF EN 1365-2; Fire Resistance Tests for Loadbearing Elements—Part 2: Floors and Roofs. Association Francaise de Normalisation (AFNOR): La Plaine Saint-Denis, France, 2014.

- CERIB Centre Technique Industriel (CTI) en Recherches et en Innovation. Cerib. Available online: https://www.cerib-feu.com/en/cef/ (accessed on 24 November 2025).

- EN 1990:2002; Eurocode—Basis of Structural Design. European Committee for Standardization (CEN): Brussels, Belgium, 2003.

- EN 1991-1-5; Thermal Actions. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

| Type of Fiber | Dimensions Lf × df (mm) | Aspect Ratio Lf/df | Content (kg/m3) |

|---|---|---|---|

| SF: 3D Dramix 65/35GG | 35 × 0.55 | 65 | 80 |

| PPF: PB Eurofiber 506-20/6 | 6 × 0.0198 | 303 | 0.3 |

| Properties | Specimen Size | 28 Days | 2–3 Months | 4–6 Months |

|---|---|---|---|---|

| Cracking strength (3-point bending) | 70 × 70 × 280 mm | 7.69 → 8.61 MPa | ||

| Splitting tensile strength | 110 × 220 mm cylinder | 7.20 MPa | 8.74 MPa | |

| Compressive strength | 58.6 MPa | 76.5 → 78.9 MPa | ||

| Modulus of elasticity | 35.2 GPa | |||

| Density | 2400 kg/m3 |

| Mix Reference | Fibers | Moisture Condition Before Test | Spalling Behaviour |

|---|---|---|---|

| Slab No. P1 | 80 kg/m3 SF, no PPF | 3.78% | spalling at t = 32 min |

| Slab No. P2 | 80 kg/m3 SF + 0.3 kg/m3 PPF | 5.5% | no spalling up to t = 45 min |

| Type of Structure | Dimensions (mm) | Intermediate Stiffeners Width × Thickness (mm) | Peripheral Stiffeners Width × Thickness (mm) |

|---|---|---|---|

| Stiffened load-bearing wall | 2740 × 3800 × 50 | 60 × 110 | 130 × 130 |

| Stiffened slab | 5900 × 3900 × 70 | 80 × 130 | 190 × 190 |

| Specimens | Thickness (mm) | Specimens Age (Days) | (%) |

|---|---|---|---|

| Load-bearing wall (current part) | 50 | 124 | 4.0 |

| Load-bearing wall (intermediate stiffener) | 110 | 3.9 | |

| Large slab (current part) | 70 | 187 | 4.4 |

| Large slab (intermediate stiffener) | 130 | 4.5 |

| Specimens | Dimensions (mm) | Density (kg/m3) | Elastic Modulus (GPa) |

|---|---|---|---|

| S1 | 991 × 390 × 58.8 | 2189 | 8.80 |

| S2 | 991 × 515 × 56.7 | 2148 | 10.07 |

| Specimens | σmax (MPa) | δσmax (mm) | σδ = 5 mm (MPa) | Rate of Stress Decrease [σmax; σδ = 5 mm] (%) |

|---|---|---|---|---|

| S1-1 | 4.82 | 1.03 | 3.60 | 25.3 |

| S1-2 | 5.12 | 1.93 | 4.04 | 21.1 |

| S2-1 | 4.50 | 0.45 | 2.71 | 39.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sawadogo, S.A.S.L.; Bui, T.-T.; Bennani, A.; Damichey, D.; Limam, A. Fire Performances of SFRC-Insulated Panels and Slabs for Modular Construction: An Experimental Study. Fire 2025, 8, 458. https://doi.org/10.3390/fire8120458

Sawadogo SASL, Bui T-T, Bennani A, Damichey D, Limam A. Fire Performances of SFRC-Insulated Panels and Slabs for Modular Construction: An Experimental Study. Fire. 2025; 8(12):458. https://doi.org/10.3390/fire8120458

Chicago/Turabian StyleSawadogo, Sannem Ahmed Salim Landry, Tan-Trung Bui, Abdelkrim Bennani, David Damichey, and Ali Limam. 2025. "Fire Performances of SFRC-Insulated Panels and Slabs for Modular Construction: An Experimental Study" Fire 8, no. 12: 458. https://doi.org/10.3390/fire8120458

APA StyleSawadogo, S. A. S. L., Bui, T.-T., Bennani, A., Damichey, D., & Limam, A. (2025). Fire Performances of SFRC-Insulated Panels and Slabs for Modular Construction: An Experimental Study. Fire, 8(12), 458. https://doi.org/10.3390/fire8120458