Incentives and Barriers to Adopting Fluorine-Free Foams (FFFs) in Fire Training Facilities: Results of the First North American Survey

Abstract

1. Introduction

2. Methods

2.1. Survey Development

2.2. Survey Administration

2.3. Survey Data Analysis

3. Results

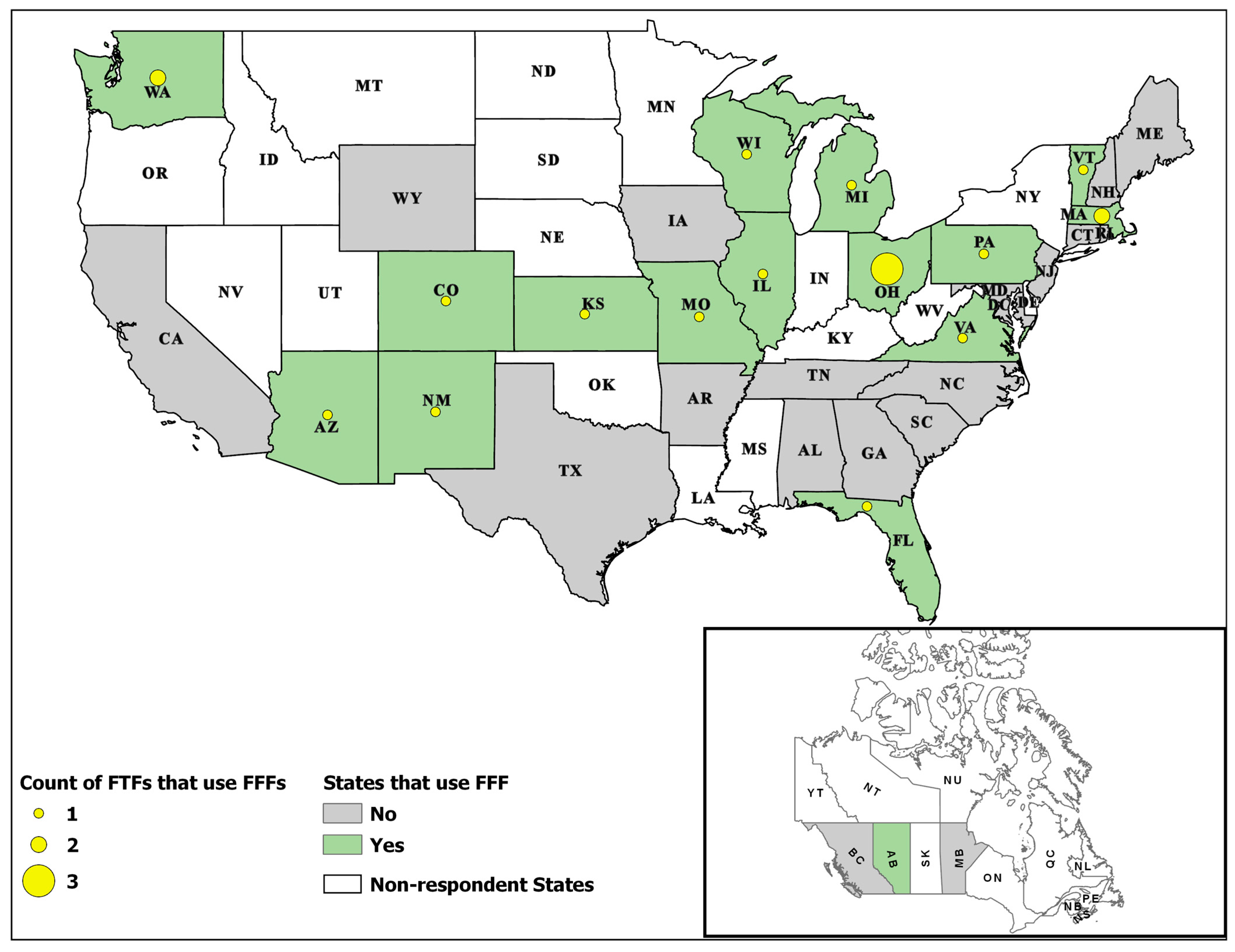

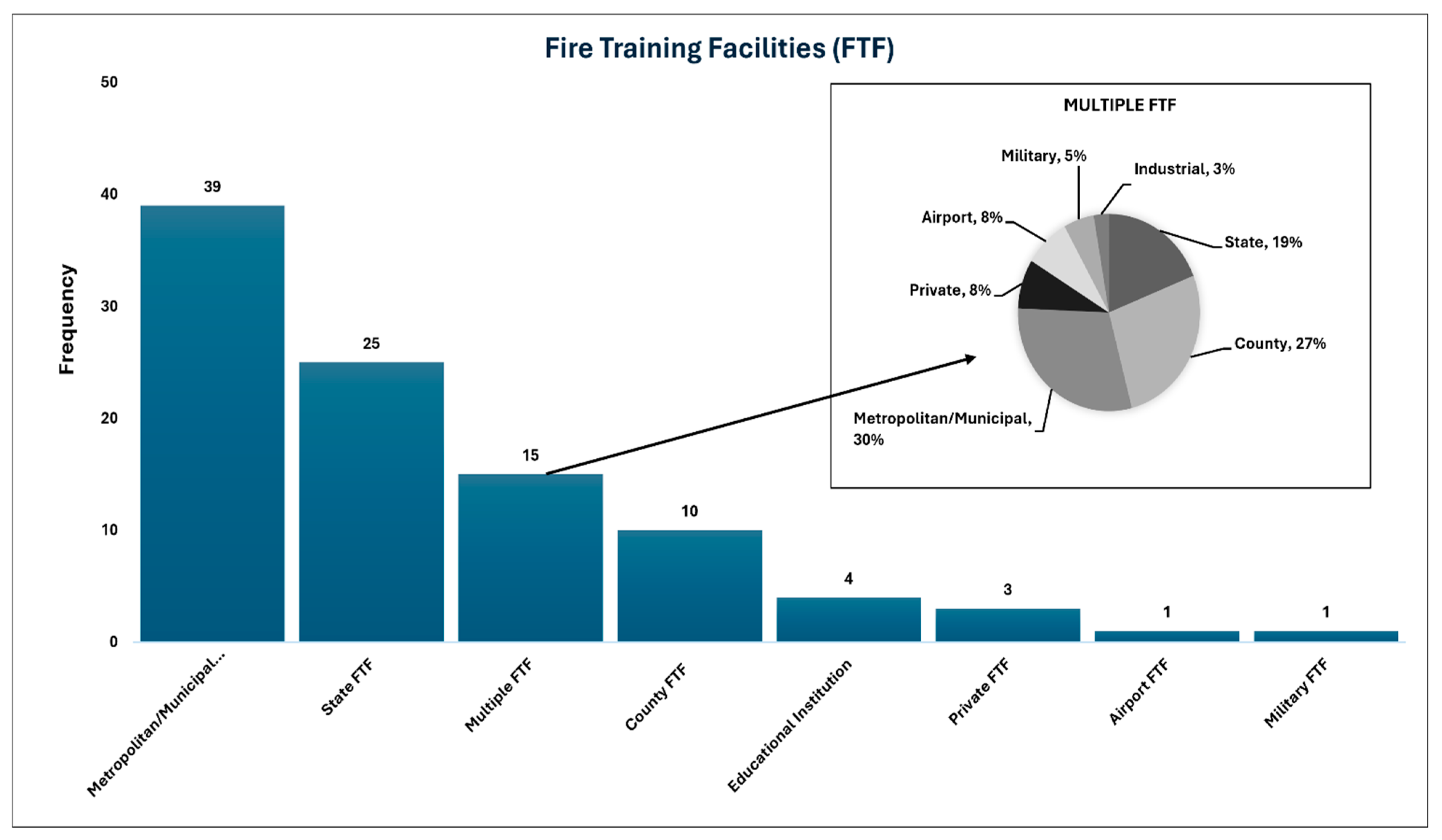

3.1. Characteristics of FTFs That Responded to the Survey

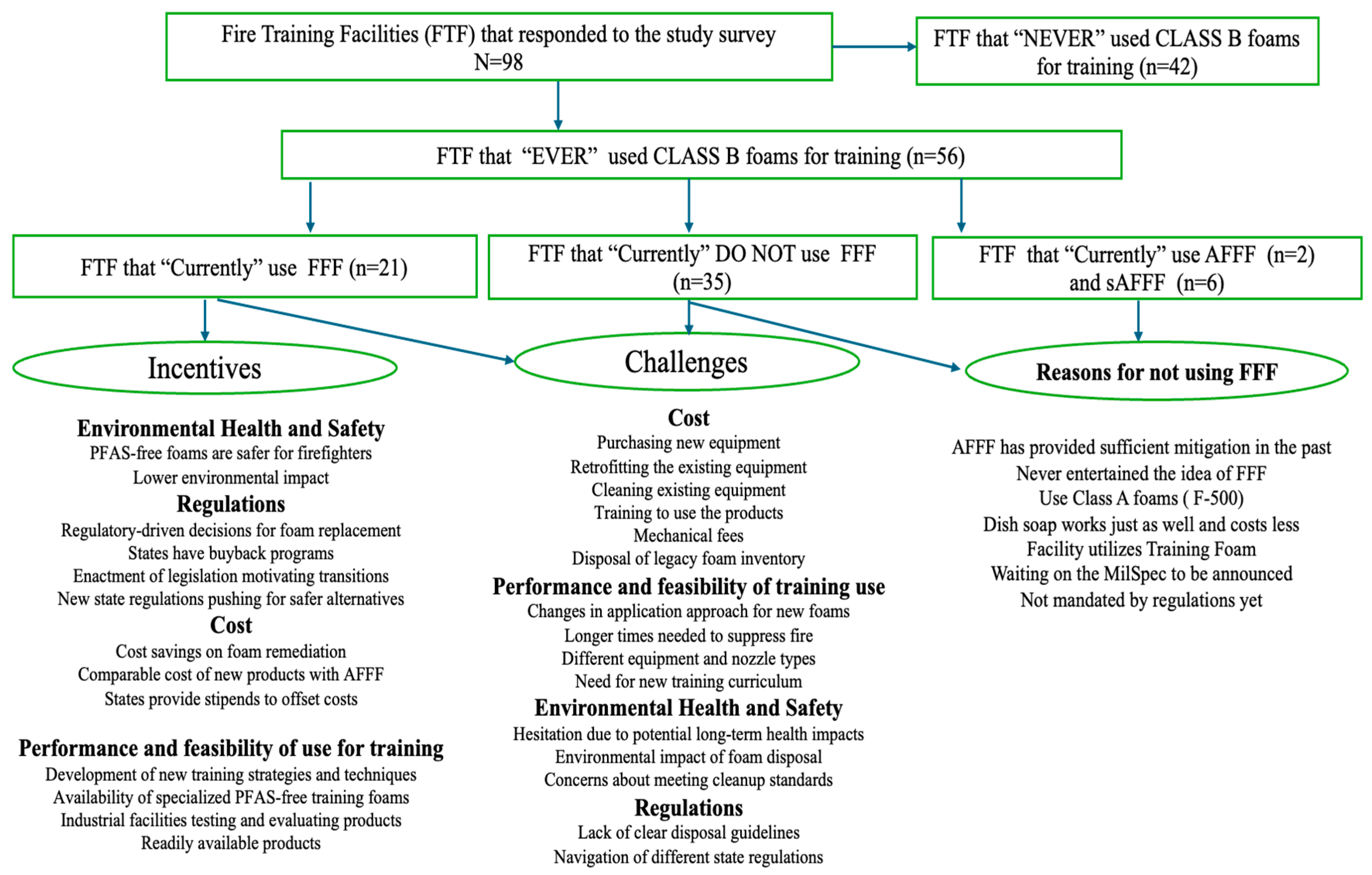

3.2. Training with Class B Foams

3.3. Current Use of AFFFs and Short-Chain PFAS Replacement Foams (sAFFFs)

3.4. Current Use of FFFs in Fire Training Facilities

3.5. Incentives and Challenges Associated with the Use of FFFs in Fire Training Facilities

3.5.1. Cost Associated with the Transition to FFFs

3.5.2. Feasibility of FFF Use in Training

3.5.3. Environmental Health and Safety

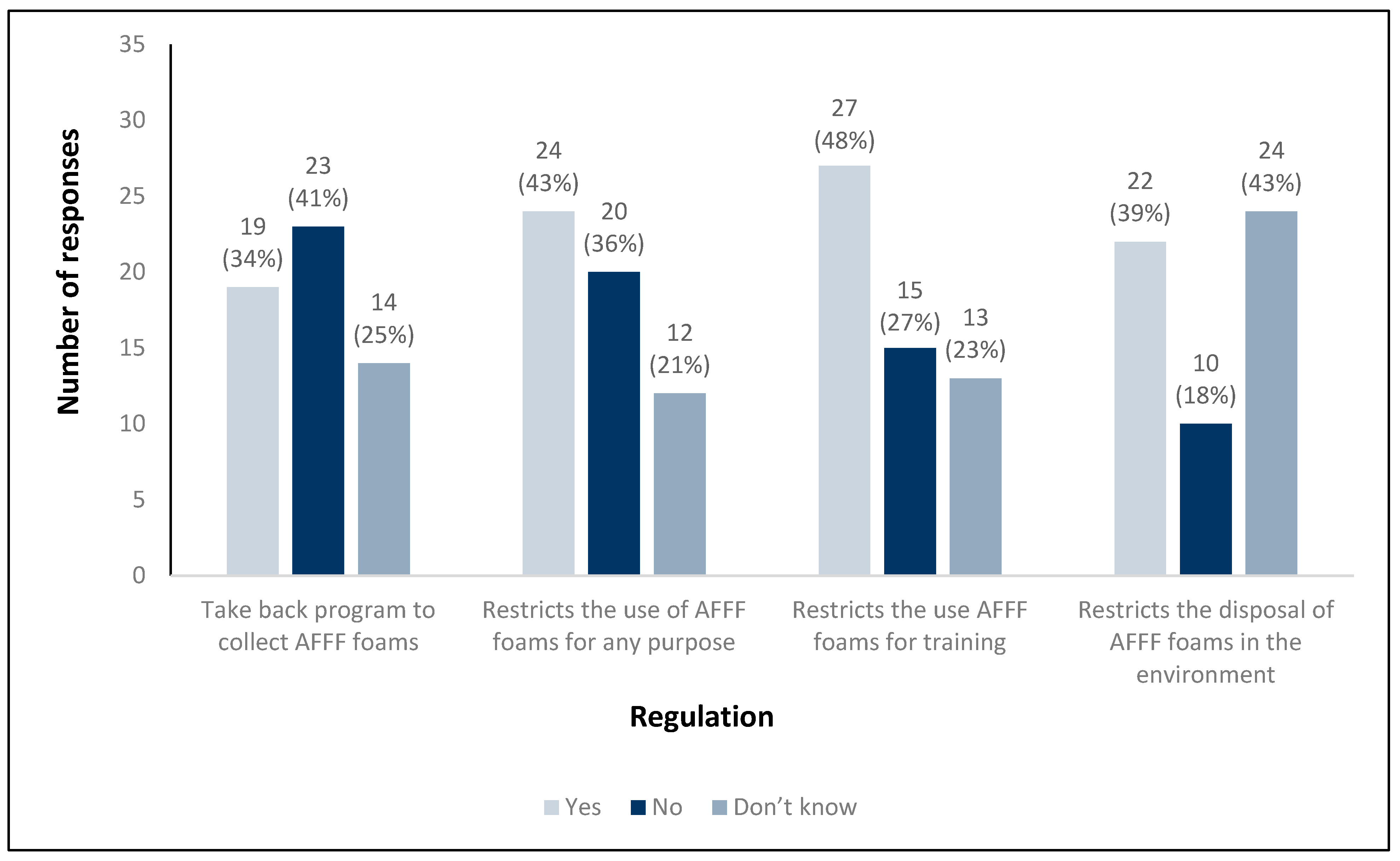

3.6. Existing Enforceable Laws or Regulations

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AFFF | Aqueous Film-Forming Foam |

| AA | Alternatives Assessment |

| ARFF | Aircraft Rescue and Firefighting |

| ATSDR | Agency for Toxic Substances and Disease Registry |

| DoD | Department of Defense |

| FAA | Federal Aviation Administration |

| FFF | Fluorine-Free Foam |

| FPRF | Fire Protection Research Foundation |

| FTF | Fire Training Facility |

| GIS | Geographic Information System |

| IARC | International Agency for Research on Cancer |

| ISFSI | International Society of Fire Service Instructors |

| IPSDI | International Public Safety Data Institute |

| MilSpec | Military Specification |

| NAFTD | North American Fire Training Directors |

| NDAA | National Defense Authorization Act |

| PFAS | Per- and Polyfluoroalkyl Substances |

| PFEtS | Perfluoroethane Sulfonate |

| PFHxA | Perfluorohexanoic Acid |

| PFHxS | Perfluorohexane Sulfonate |

| PFOS | Perfluorooctane Sulfonate |

| PFOA | Perfluorooctanoic Acid |

| PFPrS | Perfluoropropane Sulfonate |

| PPE | Personal Protective Equipment |

| QPL | Qualified Products List |

| REDCap | Research Electronic Data Capture |

| sAFFF | Short-Chain Aqueous Film-Forming Foam |

| SCBA | Self-Contained Breathing Apparatus |

| SDS | Safety Data Sheet |

| TAP | Technical Advisory Panel |

References

- National Academies of Sciences Engineering and Medicine. Use and Potential Impacts of AFFF Containing PFASs at Airports; The National Academies Press: Washington, DC, USA, 2017. [Google Scholar] [CrossRef]

- European Commission DG Environment. The Use of PFAS And Fluorine-Free Alternatives in Fire-Fighting Foams; Stakeholder Workshop Background Paper; European Chemicals Agency (ECHA): Helsinki, Finland, 2019.

- Trowbridge, J.; Gerona, R.R.; Lin, T.; Rudel, R.A.; Bessonneau, V.; Buren, H.; Morello-Frosch, R. Exposure to Perfluoroalkyl Substances in a Cohort of Women Firefighters and Office Workers in San Francisco. Environ. Sci. Technol. 2020, 54, 3363–3374. [Google Scholar] [CrossRef] [PubMed]

- Rotander, A.; Toms, L.-M.L.; Aylward, L.; Kay, M.; Mueller, J.F. Elevated levels of PFOS and PFHxS in firefighters exposed to aqueous film forming foam (AFFF). Environ. Int. 2015, 82, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Leary, D.B.; Takazawa, M.; Kannan, K.; Khalil, N. Perfluoroalkyl Substances and Metabolic Syndrome in Firefighters: A Pilot Study. J. Occup. Environ. Med. 2020, 62, 52–57. [Google Scholar] [CrossRef] [PubMed]

- Burgess, J.L.; Fisher, J.M.; Nematollahi, A.; Jung, A.M.; Calkins, M.M.; Graber, J.M.; Grant, C.C.; Beitel, S.C.; Littau, S.R.; Gulotta, J.J. Serum per-and polyfluoroalkyl substance concentrations in four municipal us fire departments. Am. J. Ind. Med. 2023, 66, 411–423. [Google Scholar] [CrossRef] [PubMed]

- Purdue, M.P.; Rhee, J.; Denic-Roberts, H.; McGlynn, K.A.; Byrne, C.; Sampson, J.; Botelho, J.C.; Calafat, A.M.; Rusiecki, J. A Nested Case-Control Study of Serum Per- and Polyfluoroalkyl Substances and Testicular Germ Cell Tumors among U.S. Air Force Servicemen. Environ. Health Perspect. 2023, 131, 77007. [Google Scholar] [CrossRef] [PubMed]

- Agency for Toxic Substances and Disease Registry. Toxicological Profile for Perfluoroalkyls; Agency for Toxic Substances and Disease Registry, U.S. Department of Health and Human Services, Public Health Service: Atlanta, GA, USA, 2021.

- Fenton, S.E.; Ducatman, A.; Boobis, A.; DeWitt, J.C.; Lau, C.; Ng, C.; Smith, J.S.; Roberts, S.M. Per- and Polyfluoroalkyl Substance Toxicity and Human Health Review: Current State of Knowledge and Strategies for Informing Future Research. Environ. Toxicol. Chem. 2021, 40, 606–630. [Google Scholar] [CrossRef]

- Daniels, R.D.; Bertke, S.; Dahm, M.M.; Yiin, J.H.; Kubale, T.L.; Hales, T.R.; Baris, D.; Zahm, S.H.; Beaumont, J.J.; Waters, K.M.; et al. Exposure-response relationships for select cancer and non-cancer health outcomes in a cohort of U.S. firefighters from San Francisco, Chicago and Philadelphia (1950–2009). Occup. Environ. Med. 2015, 72, 699–706. [Google Scholar] [CrossRef] [PubMed]

- Mazumder, N.U.; Hossain, M.T.; Jahura, F.T.; Girase, A.; Hall, A.S.; Lu, J.; Ormond, R.B. Firefighters’ exposure to per-and polyfluoroalkyl substances (PFAS) as an occupational hazard: A review. Front. Mater. 2023, 10, 1143411. [Google Scholar] [CrossRef]

- Jalilian, H.; Ziaei, M.; Weiderpass, E.; Rueegg, C.S.; Khosravi, Y.; Kjaerheim, K. Cancer incidence and mortality among firefighters. Int. J. Cancer 2019, 145, 2639–2646. [Google Scholar] [CrossRef] [PubMed]

- Demers, P.A.; DeMarini, D.M.; Fent, K.W.; Glass, D.C.; Hansen, J.; Adetona, O.; Andersen, M.H.; Freeman, L.E.B.; Caban-Martinez, A.J.; Daniels, R.D.; et al. Carcinogenicity of occupational exposure as a firefighter. Lancet Oncol. 2022, 23, 985–986. [Google Scholar] [CrossRef] [PubMed]

- International Agency for Research on Cancer. Monographs on the Identification of Carcinogenic Hazards to Humans. In Perfluorooctanoic Acid (PFOA) and Perfluorooctanesulfonic Acid (PFOS); International Agency for Research on Cancer: Lyon, France, 2025. [Google Scholar]

- International Agency for Research on Cancer. Occupational Exposure as a Firefighter; Working Group on the Identification of Carcinogenic Hazards to Humans; International Agency for Research on Cancer: Lyon, France, 2023. [Google Scholar]

- New York State Pollution Prevention Institute. Per- and Polyfluorinated Substances in Firefighting Foam; Rochester Institute of Technology: Rochester, NY, USA, 2019. [Google Scholar]

- Environmental Protection Agency. PFAS Strategic Roadmap: EPA’s Commitments to Action 2021–2024. 2021. Available online: https://www.epa.gov/pfas/pfas-strategic-roadmap-epas-commitments-action-2021-2024 (accessed on 29 September 2025).

- Barzen-Hanson, K.A.; Field, J.A. Discovery and Implications of C2 and C3 Perfluoroalkyl Sulfonates in Aqueous Film-Forming Foams and Groundwater. Environ. Sci. Technol. Lett. 2015, 2, 95–99. [Google Scholar] [CrossRef]

- Rice, P.A.; Aungst, J.; Cooper, J.; Bandele, O.; Kabadi, S.V. Comparative analysis of the toxicological databases for 6:2 fluorotelomer alcohol (6:2 FTOH) and perfluorohexanoic acid (PFHxA). Food Chem. Toxicol. 2020, 138, 111210. [Google Scholar] [CrossRef] [PubMed]

- National Institute for Occupational Safety and Health. Hierarchy of Controls. 2021. Available online: https://www.cdc.gov/niosh/learning/safetyculturehc/module-3/2.html (accessed on 29 September 2025).

- Geiser, K.; Tickner, J.; Edwards, S.; Rossi, M. The Architecture of Chemical Alternatives Assessment. Risk Anal. 2015, 35, 2152–2161. [Google Scholar] [CrossRef]

- National Academies of Sciences Engineering and Medicine. A Framework to Guide Selection of Chemical Alternatives; National Academies of Sciences Engineering and Medicine: Washington, DC, USA, 2014. [Google Scholar]

- US Government Accountability Office. Firefighting foam: DOD Is Working to Address Challenges to Transitioning to PFAS-Free Alternatives; Report to Congressional Requesters (GAO-24-107322); US Government Accountability Office: Washington, DC, USA, 2024; p. 27.

- Bello, D.; Biswas, K.; Bhandari, S.; Ross, M.B.; Wang, C.; Sahabandu, C.; Liu, P.; Bello, A. Thermal Degradation Behavior of Aqueous Film Forming Foams (AFFF) and Health Implications. In Proceedings of the Military Health System Research Symposium, Kissimmee, FL, USA, 4–7 August 2025. [Google Scholar]

- Federal Aviation Administration. Fluorine-Free Foam Testing; Federal Aviation Administration; William J. Hughes Technical Center; Aviation Research Division, Atlantic City International Airport: Egg Harbor Township, NJ, USA, 2022.

- Back, G.G. An Evaluation of the Firefighting Effectiveness of Fluorine-Free Foams. Fire Technol. 2023, 59, 3107–3116. [Google Scholar] [CrossRef]

- MIL-PRF-32725; Performance Specification: Fire Extinguishing Agent, Fluorine-Free Foam (F3) Liquid Concentrate, For Land-Based, Fresh Water Applications. Department of Defense: Arlington, VA, USA, 2023.

- DOD. Qualified Products Database. 2024. Available online: https://qpldocs.dla.mil/search/parts.aspx?qpl=4513¶m=&type=32768 (accessed on 29 September 2025).

- Jacobs, M.; Tickner, J. Criteria for Safer: Alternatives to Aqueous Film, Forming Foam Products. In Sustainable Chemistry Catalyst; UMASS Lowell: Lowell, MA, USA, 2022. [Google Scholar]

| Information Collected | Number of Responses n (%) | Median Number (Range) |

|---|---|---|

| Fire departments trained per year | 96 (98.0%) | 10 (1–1000) |

| Firefighters trained per year | 96 (98.0%) | 450 (7–50,000) |

| Instructors in FTF | ||

| Full-time instructors (30 h a week/more) | 93 (94.9%) | 4 (1–650) |

| Part-time instructors (less than 30 h) | 85 (86.7%) | 25 (1–900) |

| Volunteer instructors | 79 (80.6%) | 6 (1–100) |

| Types of fire departments trained * | ||

| Career Volunteer Combination career/volunteer Wildland/Wildland Urban Interface Airport Military Industrial Other | 85 (86.7%) 62 (63.3%) 63 (64.3%) 16 (16.3%) 22 (22.4%) 22 (22.4%) 26 (26.5%) 11 (11.2%) | |

| Type of training | ||

| Fixed-schedule training | 6 (6.1%) | |

| Non-fixed-schedule training | 14 (14.3%) | |

| Both fixed schedule and non-fixed schedule | 79 (80.6%) | |

| Type of Facility | FTFs That Ever Used Class B Foams n (% of Total) | FTFs Currently Using FFFs 2 n (% Among Class B Foam Users) |

|---|---|---|

| Metropolitan/municipal FTF (n = 39) | 22 (56.4%) | 12 (54.5%) |

| State FTF (n = 25) | 13 (52.0%) | 5 (38.5%) |

| Multiple FTF (n = 15) | 10 (66.7%) | 3 (30.0%) |

| All others 1 (n = 19) | 11 (57.9%) | 2 (9.1%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bello, A.; Graber, J.M.; Ranganathan, S.; Oates, J.; Hubbard, L.; Campbell, R.; Ojo, A.; Bello, D. Incentives and Barriers to Adopting Fluorine-Free Foams (FFFs) in Fire Training Facilities: Results of the First North American Survey. Fire 2025, 8, 452. https://doi.org/10.3390/fire8120452

Bello A, Graber JM, Ranganathan S, Oates J, Hubbard L, Campbell R, Ojo A, Bello D. Incentives and Barriers to Adopting Fluorine-Free Foams (FFFs) in Fire Training Facilities: Results of the First North American Survey. Fire. 2025; 8(12):452. https://doi.org/10.3390/fire8120452

Chicago/Turabian StyleBello, Anila, Judith M. Graber, Sreenivasan Ranganathan, John Oates, Leigh Hubbard, Richard Campbell, Abimbola Ojo, and Dhimiter Bello. 2025. "Incentives and Barriers to Adopting Fluorine-Free Foams (FFFs) in Fire Training Facilities: Results of the First North American Survey" Fire 8, no. 12: 452. https://doi.org/10.3390/fire8120452

APA StyleBello, A., Graber, J. M., Ranganathan, S., Oates, J., Hubbard, L., Campbell, R., Ojo, A., & Bello, D. (2025). Incentives and Barriers to Adopting Fluorine-Free Foams (FFFs) in Fire Training Facilities: Results of the First North American Survey. Fire, 8(12), 452. https://doi.org/10.3390/fire8120452