A Comparative Study of Fire Code Classifications of Building Materials

Abstract

1. Introduction

2. Overview of the Fire Classifications

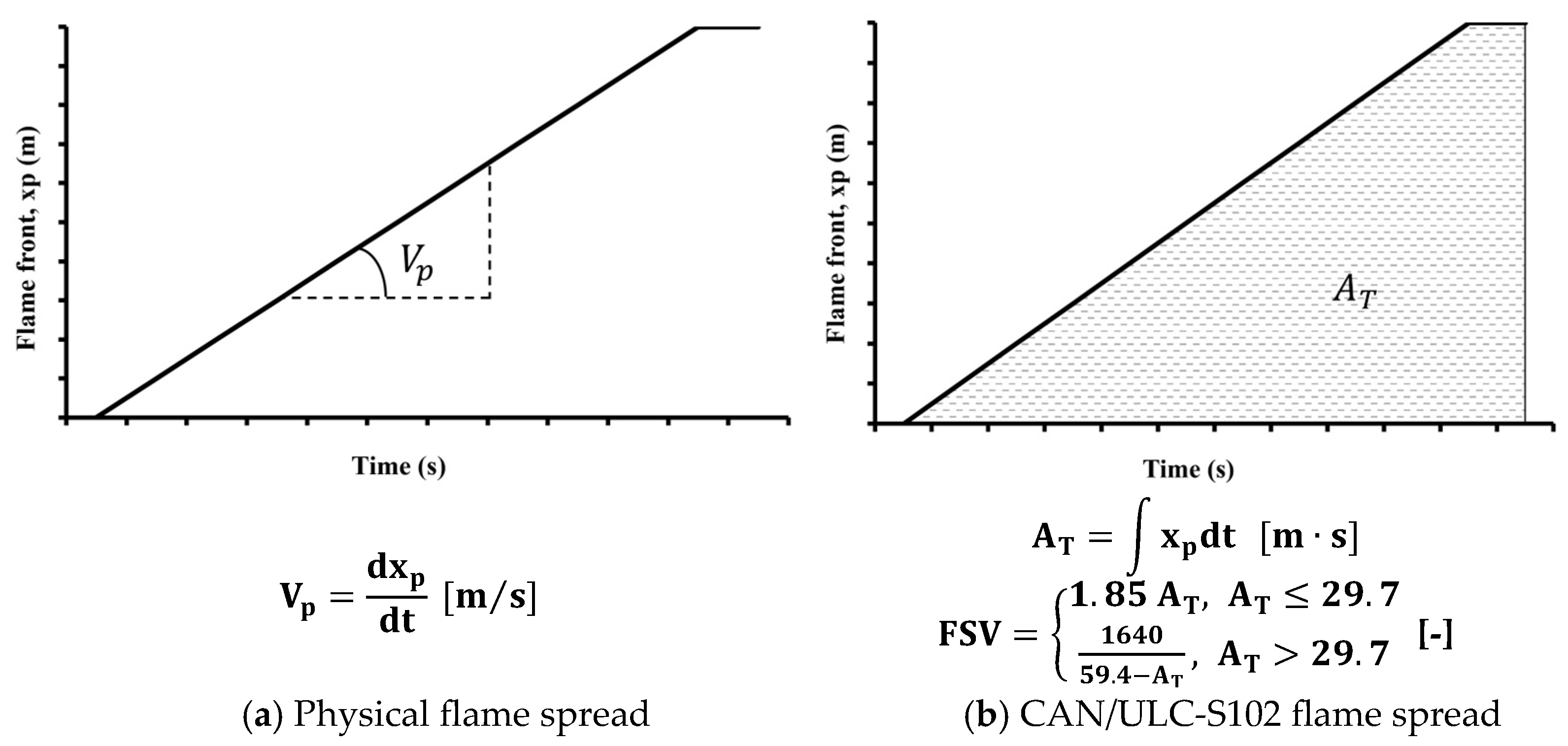

2.1. Canadian Fire Classification

2.2. Japanese Fire Classification

2.3. European Fire Classification

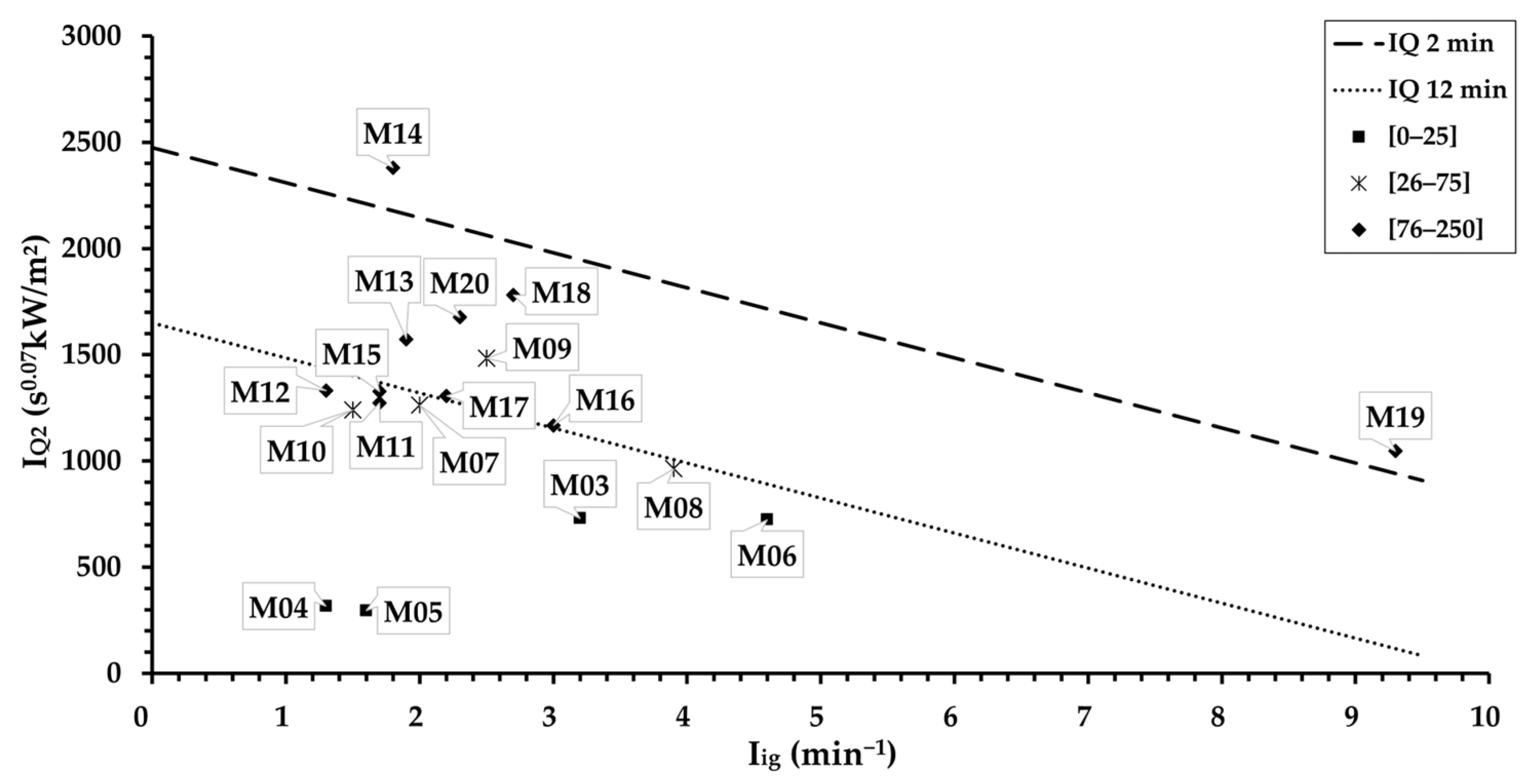

2.4. New Zealand Fire Classification

- Group number 1—no ignition exceeds 50 kW/m2 or and ;

- Group number 2 and ;

- Group number 3 and ;

- Group number 4 and .

3. Materials and Methods

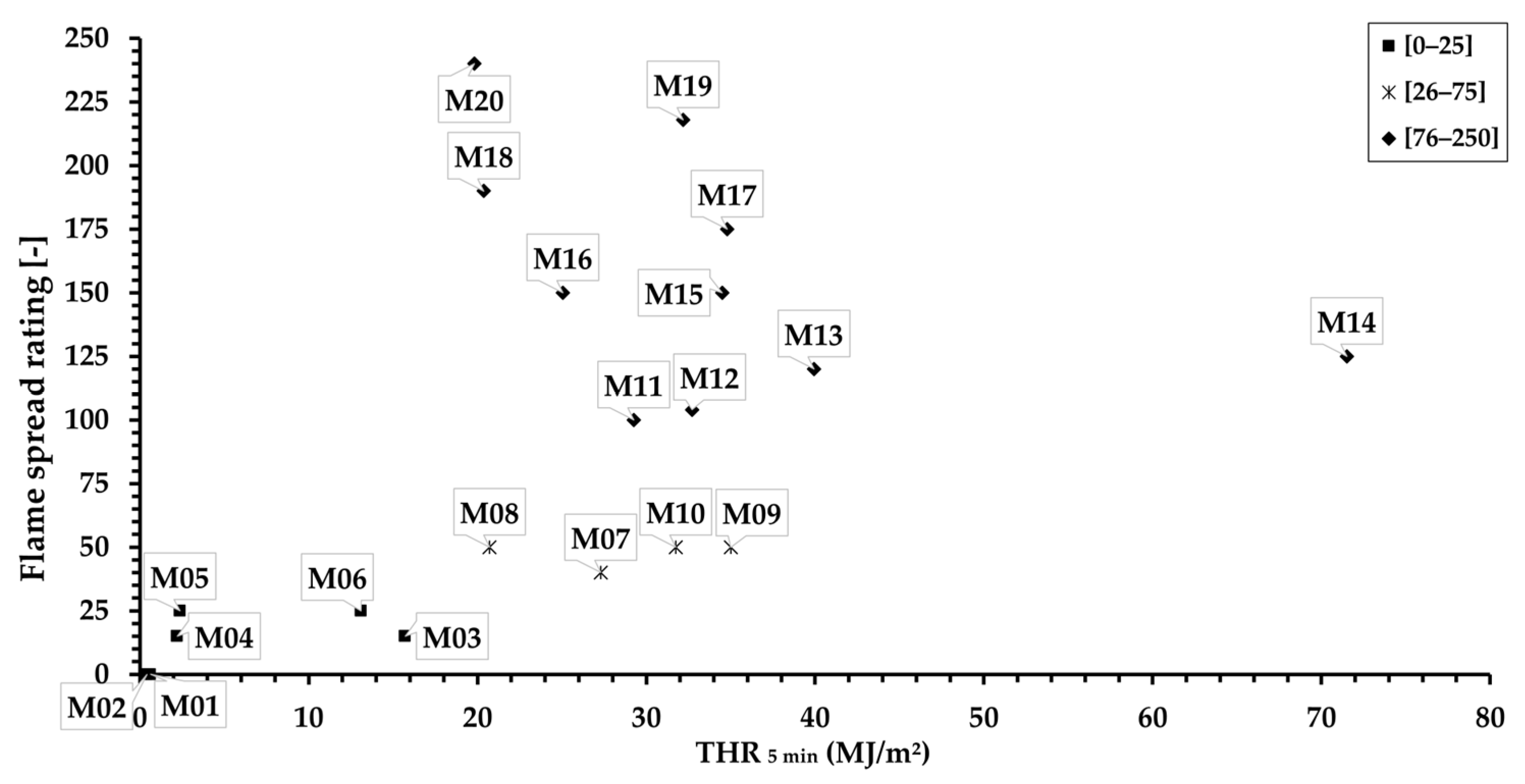

4. Results

4.1. Cone Calorimeter Test Results

4.2. Classification according to the Japanese and New Zealand Regulations

5. Discussion

5.1. Comparison of Fire Classifications of Materials

5.2. Comparison of Fire Reaction Tests

5.2.1. Scale

5.2.2. Cost and Size

5.2.3. Measurement

5.2.4. Performance

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Canadian Commission on Building and Fire Codes. National Building Code of Canada: 2020; National Research Council of Canada: Ottawa, ON, Canada, 2022.

- Janssens, M.L. Challenges in Fire Testing: A Tester’s Viewpoint. In Advances in Fire Retardant Materials; Woodhead Publishing: Amsterdam, The Netherlands, 2008; pp. 233–254. ISBN 978-1-84569-262-9. [Google Scholar]

- Hull, T.R. Challenges in Fire Testing: Reaction to Fire Tests and Assessment of Fire Toxicity. In Advances in Fire Retardant Materials; Woodhead Publishing: Amsterdam, The Netherlands, 2008; pp. 255–290. ISBN 978-1-84569-262-9. [Google Scholar]

- Janssens, M.; Östman, B. Reaction to Fire Performance. In Fire Safe Use of Wood in Buildings; CRC Press: Boca Raton, FL, USA, 2022; pp. 153–192. ISBN 978-1-00-319031-8. [Google Scholar]

- Karlsson, B. Performance-Based Test Methods for Material Flammability. In Fire Retardant Materials; Woodhead Publishing Limited: Sawston, UK, 2000; pp. 355–377. ISBN 978-1-85573-419-7. [Google Scholar]

- Dagenais, C.; Chen, Z.; Popovski, M. Performance-Based Approach to Support Tall and Large Wood Buildings: Fire and Seismic Performance; FPInnovations: Québec, QC, Canada, 2017; p. 48. [Google Scholar]

- Hadjisophocleous, G.V.; Benichou, N.; Tamim, A.S. Literature Review of Performance-Based Fire Codes and Design Environment. J. Fire Prot. Eng. 1998, 9, 12–40. [Google Scholar] [CrossRef]

- Troitzsch, J.; Antonatus, E. 9-International Standardization. In Plastics Flammability Handbook, 4th ed.; Troitzsch, J., Antonatus, E., Eds.; Hanser: Munich, Germany, 2021; pp. 257–286. ISBN 978-1-56990-762-7. [Google Scholar]

- Troitzsch, J.; Antonatus, E. 10-Building. In Plastics Flammability Handbook, 4th ed.; Troitzsch, J., Antonatus, E., Eds.; Hanser: Munich, Germany, 2021; pp. 287–535. ISBN 978-1-56990-762-7. [Google Scholar]

- Östman, B.; Barber, D.; Dagenais, C.; Dunn, A.; Kagiya, K.; Mikkola, E.; Qiu, P.; Serkov, B.; Wade, C. Fire Safety Requirements in Different Regions. In Fire Safe Use of Wood in Buildings; CRC Press: Boca Raton, FL, USA, 2022; pp. 117–152. ISBN 978-1-00-319031-8. [Google Scholar]

- Sfpe, R.E.C. Fire Test Data and Building Design—Some Problem Areas. Fire Technol. 1965, 1, 295–302. [Google Scholar] [CrossRef]

- Babrauskas, V. Engineering Variables to Replace the Concept of ‘Noncombustibility’. Fire Technol. 2017, 53, 353–373. [Google Scholar] [CrossRef]

- Notarianni, K.A.; Parry, G.W. Uncertainty. In SFPE Handbook of Fire Protection Engineering; Hurley, M.J., Gottuk, D., Hall, J.R., Harada, K., Kuligowski, E., Puchovsky, M., Torero, J., Watts, J.M., Wieczorek, C., Eds.; Springer: New York, NY, USA, 2016; pp. 2992–3047. ISBN 978-1-4939-2564-3. [Google Scholar]

- Law, A.; Spinardi, G.; Bisby, L. A Taxonomy of UK Reaction-to-Fire Standard Testing: The Role of Black Boxing of Expertise. Fire Technol. 2024, 60, 1741–1767. [Google Scholar] [CrossRef]

- Law, A.; Spinardi, G.; Bisby, L. The Rise of the Euroclass: Inside the Black Box of Fire Test Standardisation. Fire Saf. J. 2023, 135, 103712. [Google Scholar] [CrossRef]

- Hirschler, M.M. Noncombustibility: Testing and Regulatory Requirements. Fire Mater. 2023, 47, 182–198. [Google Scholar] [CrossRef]

- Hirschler, M.M. Use of Heat Release Rate to Predict Whether Individual Furnishings Would Cause Self Propagating Fires. Fire Saf. J. 1999, 32, 273–296. [Google Scholar] [CrossRef]

- Grayson, S.; Hirschler, M. Comparison of ASTM Fire Standards with International Fire Standards for Buildings and Contents. In Fire Standards in the International Marketplace, ASTM STP 1163; Grand, A., Ed.; ASTM International: Philadelphia, PA, USA, 1995. [Google Scholar]

- Sadaoui, A.; Dagenais, C.; Blanchet, P.; Perez, C. The Evolution of Reaction to Fire Classification of Materials: A Case Study of Canada. Fire Mater. 2024, 1–15. [Google Scholar] [CrossRef]

- EN 13823; Reaction to Fire Tests for Building Products-Building Products Excluding Floorings Exposed to the Thermal Attack by a Single Burning Item. CEN: Brussels, Belgium, 2002.

- Drysdale, D. An Introduction to Fire Dynamics, 3rd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011; ISBN 978-0-470-31903-1. [Google Scholar]

- NFPA 550; Guide to the Fire Safety Concepts Tree. National Fire Protection Association: Boston, MA, USA, 2022.

- Babrauskas, V.; Peacock, R.D. Heat Release Rate: The Single Most Important Variable in Fire Hazard. Fire Saf. J. 1992, 18, 255–272. [Google Scholar] [CrossRef]

- Janssens, M. Calorimetry. In SFPE Handbook of Fire Protection Engineering; Hurley, M.J., Gottuk, D., Hall, J.R., Harada, K., Kuligowski, E., Puchovsky, M., Torero, J., Watts, J.M., Wieczorek, C., Eds.; Springer: New York, NY, USA, 2016; pp. 905–951. ISBN 978-1-4939-2565-0. [Google Scholar]

- Thornton, W.M. XV. The Relation of Oxygen to the Heat of Combustion of Organic Compounds. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1917, 33, 196–203. [Google Scholar] [CrossRef]

- Huggett, C. Estimation of Rate of Heat Release by Means of Oxygen Consumption Measurements. Fire Mater. 1980, 4, 61–65. [Google Scholar] [CrossRef]

- ISO 5660-1; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method). International Organization for Standardization: Geneva, Switzerland, 2002.

- ISO 9705; Fire Tests-Full-Scale Room Test for Surface Products. International Organization for Standardization: Geneva, Switzerland, 1993.

- ASTM E2257; Test Method for Room Fire Test of Wall and Ceiling Materials and Assemblies. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- CAN/ULC-S114; Standard Method of Test for Determination of Noncombustibility in Building Materials. Underwriters Laboratories of Canada: Scarborough, ON, USA, 2018.

- ASTM E136; Test Method for Assessing Combustibility of Materials Using a Vertical Tube Furnace at 750C. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- CAN/ULC-S135; Standard Test Method for the Determination of Combustibility Parameters of Building Materials Using an Oxygen Consumption Calorimeter (Cone Calorimeter). Underwriters Laboratories of Canada: Toronto, ON, Canada, 2022.

- ASTM E1354; Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption Calorimeter. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM E2965; Standard Test Method for Determination of Low Levels of Heat Release Rate for Materials and Products Using an Oxygen Consumption Calorimeter. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- CAN/ULC-S102; Method of Test for Surface Burning Characteristics of Building Materials and Assemblies. Underwriters Laboratories of Canada: Toronto, ON, Canada, 2019.

- ASTM E84; Standard Test Method for Surface Burning Characteristics of Building Materials. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Hasemi, Y. Surface Flame Spread. In SFPE Handbook of Fire Protection Engineering; Hurley, M.J., Gottuk, D., Hall, J.R., Harada, K., Kuligowski, E., Puchovsky, M., Torero, J., Watts, J.M., Wieczorek, C., Eds.; Springer: New York, NY, USA, 2016; pp. 705–723. ISBN 978-1-4939-2565-0. [Google Scholar]

- Eickner, H.W. Surface Flammability Measurements for Building Materials and Related Products. In Treatise on Analytical Chemistry; Kolthoff., I.M., Elving, P.J., Stross, F.H., Eds.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1977; Volume 4, ISBN 978-0-471-49966-4. [Google Scholar]

- UL 723; Test for Surface Burning Characteristics of Building Materials. UL Standard: Northbrook, IL, USA, 2018.

- NFPA 255; Standard Method of Test of Surface Burning Characteristics of Building Materials. National Fire Protection Association: Boston, MA, USA, 2005.

- CAN/ULC-S102.2; Standard Method of Test for Surface Burning Characteristics of Flooring, Floor Coverings, and Miscellaneous Materials and Assemblies. Underwriters Laboratories of Canada: Toronto, ON, Canada, 2019.

- Hakkarainen, T.; Hayashi, Y. Comparison of Japanese and European Fire Classification Systems for Surface Linings. Fire Sci. Technol. 2001, 21, 19–42. [Google Scholar] [CrossRef]

- ISO 1182; Reaction to Fire Tests for Products—Non-Combustibility Test. International Organization for Standardization: Geneva, Switzerland, 2010.

- ISO/TS 17431; Fire Tests—Reduced-Scale Model Box Test. International Organization for Standardization: Geneva, Switzerland, 2006.

- European Commission. Commission Delegated Regulation (EU) 2016/364 of 1 July 2015 on the classification of the reaction to fire performance of construction products pursuant to Regulation (EU) No 305/2011 of the European Parliament and of the Council (Text with EEA relevance). Official Journal of the European Union. 2016. Available online: http://data.europa.eu/eli/reg_del/2016/364/oj (accessed on 14 July 2024).

- EN 13501-1; Fire Classification of Construction Products and Building Elements. Part 1: Classification Using Data from Reaction to Fire Tests. CEN: Brussels, Belgium, 2018.

- ISO 1716; Reaction to Fire Tests for Products—Determination of the Gross Heat of Combustion (Calorific Value). International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 11925-2; Reaction to Fire Tests—Ignitability of Products Subjected to Direct Impingement of Flame Part 2: Single-Flame Source Test. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 9239-1; Reaction to Fire Tests for Floorings—Part 1: Determination of the Burning Behaviour Using a Radiant Heat Source. International Organization for Standardization: Geneva, Switzerland, 2010.

- Wade, C. Fire Performance of External Wall Claddings under a Performance-Based Building Code. Fire Mater. 1995, 19, 127–132. [Google Scholar] [CrossRef]

- C/AS2 Acceptable Solution for Buildings Other than Risk Group SH: For New Zealand Building Code Clauses C1-C6 Protection from Fire, 1st ed.; Ministry of Business, Innovation & Employment, Hīkina Whakatutuki: Wellington, New Zealand, 2019; ISBN 978-1-988570-08-2.

- Innovation & Employment Ministry of Business. Department of Building and Housing C1-C6 Protection from Fire Acceptable Solution C/AS1: Protection from Fire for Buildings with Sleeping (Residential) and Outbuildings (Risk Group SH), 2nd ed.; Ministry of Business, Innovation and Employment: Wellington, New Zealand, 2023; ISBN 978-1-991092-92-2.

- Innovation & Employment Ministry of Business. Department of Building and Housing. In C/VM2 Framework for Fire Safety Design for New Zealand Building Code Clauses C1-C6 Protection from Fire; Ministry of Business, Innovation and Employment: Wellington, New Zealand, 2012; ISBN 978-0-478-38165-8. [Google Scholar]

- Dowling, V.P.; Blackmore, J.M. Project 2: Fire Performance of Wall and Ceiling Linings; CSIRO Building, Construction and Engineering for Fire Code Reform Centre Ltd.: Sydney, Australia, 1998; p. 176. [Google Scholar]

- Collier, P.C.R.; Whiting, P.N.; Wade, C.A. Fire Properties of Wall and Ceiling Linings: Investigation of Fire Test Methods for Use in NZBC Compliance Documents. BRANZ Ltd Study Report No. 160; BRANZ Ltd.: Judgeford, New Zealand, 2006. [Google Scholar]

- Kokkala, M.A.; Thomas, P.H.; Karlsson, B. Rate of Heat Release and Ignitability Indices for Surface Linings. Fire Mater. 1993, 17, 209–216. [Google Scholar] [CrossRef]

- Canadian Wood Council. CWC Fire Fact Sheet: Surface Flammability and Flame-Spread Ratings. Canadian Wood Council: Ottawa, Ontario, Canada. 2020. Available online: https://cwc.ca/wp-content/uploads/2020/09/Fact-Sheets-Surface-Flammability-and-Flame-spread-Ratings.pdf (accessed on 14 July 2024).

- American Wood Council. Fire Design Specification (FDS) for Wood Construction; American Wood Council: Leesburg, VA, USA, 2022; ISBN 978-1-940383-54-5. [Google Scholar]

- Wade, C.; Baker, G. Fire Hazard Assessment of Wall and Ceiling Fire Spread in Rooms. In Flammability Testing of Materials Used in Construction, Transport and Mining; Elsevier: Amsterdam, The Netherlands, 2022; pp. 127–156. ISBN 978-0-08-102801-8. [Google Scholar]

- Sundström, B.; Van Hees, P.; Thureson, P. Sveriges provnings-och forskningsinstitut. In Results and Analysis from Fire Tests of Building Products in ISO 9705, the Room/Corner Test; SP-RAPP-; Swedish National Testing and Research Institute: Borås, Sweden, 1998; ISBN 91-7848-716-1. [Google Scholar]

- White, R.H.; Dietenberger, M.A.; Tran, H.; Grexa, O.; Richardson, L.; Sumathipala, K.; Janssens, M. Comparison of Test Protocols for the Standard Room/Corner Test. Fire Mater. 1999, 23, 139–146. [Google Scholar] [CrossRef]

- Babrauskas, V. Editorial 2. Fire Saf. J. 1997, 29, ix. [Google Scholar] [CrossRef]

- Östman, B. Acceptance Criteria for Products According to the Cone Calorimeter. Fire Mater. 2023, 47, 848–850. [Google Scholar] [CrossRef]

- Sanned, E.; Mensah, R.A.; Försth, M.; Das, O. The Curious Case of the Second/End Peak in the Heat Release Rate of Wood: A Cone Calorimeter Investigation. Fire Mater. 2023, 47, 498–513. [Google Scholar] [CrossRef]

- Babrauskas, V. Comments on “The Curious Case of the Second/End Peak in the Heat Release Rate of Wood: A Cone Calorimeter Investigation,” by Sanned et Al. Fire Mater. 2023, 47, 733–734. [Google Scholar] [CrossRef]

- Karlsson, B.; Quintiere, J.G. Enclosure Fire Dynamics; Environmental and Energy Engineering Series; CRC Press: Boca Raton, FL, USA, 2000; ISBN 978-0-8493-1300-4. [Google Scholar]

- van Mierlo, R.; Bart, S. The Single Burning Item (SBI) Test Method—A Decade of Development and Plans for the near Future. Heron 2005, 50, 191–207. [Google Scholar]

- Messerschmidt, B. The Capabilities and Limitations of the Single Burning Item (SBI) Test. In Fire & Building Safety in the Single European Market; Carvel, R., Ed.; School of Engineering and Electronics, University of Edinburgh: Edinburgh, UK, 2008; ISBN 978-0-9557497-3-5. [Google Scholar]

- Östman, B.A.-L.; Tsantaridis, L.D. Correlation between Cone Calorimeter Data and Time to Flashover in the Room Fire Test. Fire Mater. 1994, 18, 205–209. [Google Scholar] [CrossRef]

- Hansen, A.S.; Hovde, P.J. Prediction of Time to Flashover in the ISO 9705 Room Corner Test Based on Cone Calorimeter Test Results. Fire Mater. 2002, 26, 77–86. [Google Scholar] [CrossRef]

| Class | CAN/ULC-S114 | CAN/ULC-S135 | CAN/ULC-S102/S102.2 |

|---|---|---|---|

| Noncombustible | T ≤ 36 °C m ≤ 20% Duration of 15 min (1) | THR ≤ 3 MJ/m2 TSEA ≤ 1 m2 Duration of 15 min (2) | - |

| Combustible | - | - | Flame spread rating (3) Smoke production classification (3) |

| Class | Method 1 | Method 2 | |

|---|---|---|---|

| ISO 5660-1 (1) | ISO 1182 | ISO 17431 | |

| Noncombustible | THR ≤ 8 MJ m−2 HRRmax ≤ 200 kW m−2 (2) Duration of 20 min | T ≤ 30 K (3) m ≤ 50% | - |

| Quasi-noncombustible | THR ≤ 8 MJ m−2 HRRmax ≤ 200 kW m−2 (2) Duration of 10 min | - | THR ≤ 50 MJ (4) HRRmax ≤ 140 kW (2)(4) Duration of 10 min |

| Fire-retardant materials | THR ≤ 8 MJ m−2 HRRmax ≤ 200 kW m−2 (2) Duration of 5 min | - | THR ≤ 40 MJ (4) HRRmax ≤ 140 kW m−2 (2)(4) Duration of 5 min |

| Class | Test Standard | Criteria | Additional |

|---|---|---|---|

| A1: Noncombustible No contribution | EN ISO 1182 (1) and | T ≤ 30 °C; and m ≤ 50%; and tf = 0 s (no sustained flaming) | — |

| EN ISO 1716 | PCS ≤ 2.0 MJkg−1 (1); and PCS ≤ 2.0 MJkg−1 (2) (2a); and PCS ≤ 1.4 MJm−2 (3); and PCS ≤ 2.0 MJkg−1 (4) | — | |

| A2: Noncombustible Limited contribution | EN ISO 1182 (1) or | T ≤ 50 °C; and m ≤ 50%; and tf = 20 s | — |

| EN ISO 1716 and | PCS ≤ 3.0 MJkg−1 (1); and PCS ≤ 4.0 MJkg−1 (2); and PCS ≤ 4.0 MJm−2 (3); and PCS ≤ 3.0 MJkg−1 (4) | Smoke production (5); and flaming droplets/particles (6) | |

| EN 13823 (SBI) | FIGRA ≤ 120 Ws−1; and LFS < edge of specimen; and THR600s ≤ 7.5 MJ | ||

| B: Combustible Limited contribution | EN 13823 (SBI) and | FIGRA ≤ 120 Ws−1; and LFS < edge of the specimen; and THR600s ≤ 7.5 MJ | Smoke production (5); and flaming droplets/particles (6) |

| EN ISO 11925-2 (8) Exposure = 30 s | Fs ≤ 150 mm within 60 s | ||

| C: Combustible Low contribution | EN 13823 (SBI) and | FIGRA ≤ 250 Ws−1; and LFS < edge of specimen; and THR600s ≤ 15 MJ | |

| EN ISO 11925-2 (8) Exposure = 30 s | Fs ≤ 150 mm within 60 s | ||

| D: Combustible Medium contribution | EN 13823 (SBI) and | FIGRA ≤ 750 Ws−1 | |

| EN ISO 11925-2 (8) Exposure = 30 s | Fs ≤ 150 mm within 60 s | ||

| E: Combustible High contribution | EN ISO 11925-2 (8) Exposure = 15 s | Fs ≤ 150 mm within 20 s | Flaming droplets/particles (7) |

| F: Combustible Very high contribution or unclassified | EN ISO 11925-2 (8) Exposure = 15 s | Fs > 150 mm within 20 s |

| Group Number | Exposition | Criteria |

|---|---|---|

| 1 | 100 kW for 10 min, then 300 kW for 10 min | THR < 1 MW |

| 1-S | 100 kW for 10 min, then 300 kW for 10 min | THR < 1 MW SPR < 5 m2/s, from 0 to 20 min |

| 2 | 100 kW for 10 min | THR < 1 MW |

| 2-S | 100 kW for 10 min | THR < 1 MW |

| 3 | 100 kW for 2 min | SPR < 5 m2/s, from 0 to 20 min |

| 4 | 100 kW for 2 min | THR < 1 MW |

| N° | Material | Thickness (mm) | Density (kg/m³) | Combustible (Y/N) | FSR |

|---|---|---|---|---|---|

| M01 | Rock fiber insulation | 36.6 | 128 | N | 0 (1) |

| M02 | Fibreglass insulation | 50.0 | 12.8 | N | 0 (1) |

| M03 | Polyvinyl chloride board (PVC) | 19.2 | 557 | Y | 15 (1) |

| M04 | Gypsum board (Type X) | 15.9 | 673 | N | 15 (1) |

| M05 | Gypsum board (regular) | 12.7 | 614 | N | 25 (1) |

| M06 | Fire-retardant treated plywood (Douglas fir) | 11.6 | 535 | Y | 25 (1) |

| M07 | Douglas fir (Pseudotsuga menziesii) | 19.1 | 561 | Y | 40 (2) |

| M08 | White spruce (Picea glauca) | 15.2 | 349 | Y | 50 (2) |

| M09 | Parallel strand lumber (PSL) | 31.9 | 680 | Y | 50 (1) |

| M10 | Laminated veneer lumber (LVL) | 24.4 | 599 | Y | 50 (1) |

| M11 | Red oak (Quercus rubra) | 22.4 | 764 | Y | 100 (2) |

| M12 | Sugar maple (Acer saccharum) | 20.3 | 780 | Y | 104 (2) |

| M13 | Medium-density fibreboard (MDF) | 16.2 | 766 | Y | 120 (3) |

| M14 | Wood–plastic composite (WPC) | 19.0 | 1022 | Y | 125 (1) |

| M15 | Particleboard | 16.5 | 607 | Y | 150 (3) |

| M16 | Spruce plywood | 12.9 | 501 | Y | 150 (1) |

| M17 | Oriented strand board (OSB) | 15.0 | 620 | Y | 175 (3) |

| M18 | Extruded polystyrene insulation (XPS) | 24.2 | 25 | Y | 190 (1) |

| M19 | Wood fiber insulation (WFI) | 12.8 | 232 | Y | 218 (1) |

| M20 | Expanded polystyrene insulation (EPS) | 25.0 | 24 | Y | 240 (1) |

| New Zealand Criteria | Japanese Criteria | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| N° | min−1 | s0.66kW/m2 | s0.07kW/m2 | s0.66kW/m2 | s0.07kW/m2 | s0.07kW/m2 | kW/m2 | MJ/m2 | MJ/m2 | MJ/m2 |

| M01 | NI | NI | NI | NI | NI | NI | 13 ± 3 | 0.6 ± 0.1 | - | - |

| M02 | NI | NI | NI | NI | NI | NI | 11 ± 1 | 0.4 ± 0.1 | - | - |

| M03 | 3.2 ± 0.5 | 8607 ± 482 | 730 ± 24 | 5076 ± 257 | 1948 ± 78 | 1123 ± 78 | 175 ± 8 | 15.7 ± 2.0 | - | - |

| M04 | 1.3 ± 0.1 | 897 ± 15 | 316 ± 10 | 6124 ± 38 | 2268 ± 12 | 1443 ± 12 | 99 ± 4 | 2.2 ± 0.1 | - | - |

| M05 | 1.6 ± 0.0 | 795 ± 323 | 258 ± 110 | 5924 ± 0 | 2207 ± 0 | 1382 ± 0 | 106 ± 29 | 2.4 ± 0.2 | - | - |

| M06 | 4.6 ± 0.8 | 6607 ± 171 | 724 ± 5 | 4327 ± 416 | 1719 ± 127 | 894 ± 127 | 149 ± 16 | 13.1 ± 1.0 | 32.7 ± 0.6 | - |

| M07 | 2.0 ± 0.4 | 12,982 ± 289 | 1263 ± 71 | 5731 ± 204 | 2148 ± 62 | 1323 ± 62 | 244 ± 23 | 27.3 ± 0.8 | 51.0 ± 1.5 | 115 ± 3 |

| M08 | 3.9 ± 1.4 | 10,274 ± 70 | 963 ± 44 | 4692 ± 757 | 1831 ± 231 | 1006 ± 231 | 184 ± 8 | 20.7 ± 0.8 | 43.8 ± 1.8 | - |

| M09 | 2.5 ± 0.9 | 14,797 ± 335 | 1483 ± 158 | 5427 ± 471 | 2056 ± 144 | 1231 ± 144 | 280 ± 54 | 35.0 ± 0.7 | 61.3 ± 0.6 | 114 ± 2 |

| M10 | 1.5 ± 0.9 | 15,417 ± 336 | 1239 ± 571 | 5979 ± 511 | 2224 ± 156 | 1399 ± 156 | 308 ± 55 | 31.8 ± 1.8 | 61.2 ± 1.5 | 142 ± 3 |

| M11 | 1.7 ± 0.1 | 13,512 ± 199 | 1273 ± 76 | 5898 ± 50 | 2199 ± 15 | 1374 ± 15 | 245 ± 19 | 29.3 ± 0.9 | 52.6 ± 0.9 | 116 ± 1 |

| M12 | 1.3 ± 0.2 | 16,003 ± 458 | 1331 ± 37 | 6074 ± 81 | 2253 ± 25 | 1428 ± 25 | 207 ± 10 | 32.7 ± 1.0 | 63.6 ± 2.3 | 162 ± 4 |

| M13 | 1.9 ± 0.1 | 19,352 ± 342 | 1572 ± 8 | 5795 ± 67 | 2168 ± 20 | 1343 ± 20 | 291 ± 1 | 39.9 ± 0.7 | 67.6 ± 1.1 | - |

| M14 | 1.8 ± 0.1 | 28,068 ± 538 | 2380 ± 48 | 5856 ± 32 | 2186 ± 10 | 1361 ± 10 | 710 ± 13 | 71.5 ± 1.0 | 112.0 ± 2.4 | - |

| M15 | 1.7 ± 0.2 | 15,193 ± 229 | 1327 ± 14 | 5860 ± 92 | 2188 ± 28 | 1363 ± 28 | 249 ± 10 | 34.5 ± 0.1 | 57.4 ± 0.1 | - |

| M16 | 3.0 ± 0.5 | 12,163 ± 599 | 1167 ± 76 | 5175 ± 278 | 1978 ± 85 | 1153 ± 85 | 220 ± 2 | 25.1 ± 2.6 | 62.4 ± 3.4 | - |

| M17 | 2.2 ± 0.0 | 15,395 ± 159 | 1306 ± 42 | 5614 ± 25 | 2113 ± 8 | 1288 ± 8 | 211 ± 4 | 34.8 ± 0.7 | 65.8 ± 2.6 | - |

| M18 | 2.7 ± 0.4 | 7697 ± 75 | 1781 ± 8 | 5366 ± 241 | 2037 ± 74 | 1212 ± 74 | 697 ± 8 | 20.4 ± 0.3 | - | - |

| M19 | 9.3 ± 1.0 | 8120 ± 133 | 1046 ± 34 | 1786 ± 545 | 943 ± 167 | 118 ± 167 | 209 ± 4 | 32.2 ± 0.1 | - | - |

| M20 | 2.3 ± 0.1 | 7285 ± 161 | 1676 ± 94 | 5584 ± 51 | 2103 ± 16 | 1278 ± 16 | 541 ± 59 | 19.8 ± 0.4 | - | - |

| N° | CAN/ULC-S114 | CAN/ULC-S102 | Japanese Class | Euroclass | New Zealand Group |

|---|---|---|---|---|---|

| M01 | Noncombustible | 0 | NC | A1 | 1 |

| M02 | Noncombustible | 0 | NC | A1 | 1 |

| M03 | Combustible | 15 | UC | Bfl 2 | 3 |

| M04 | Noncombustible | 15 | NC | A2 | 1 |

| M05 | Noncombustible | 25 | NC | A2 | 1 |

| M06 | Combustible | 25 | UC | B 1 | 3 |

| M07 | Combustible | 40 | UC | D | 3 |

| M08 | Combustible | 50 | UC | D | 3 |

| M09 | Combustible | 50 | UC | D 1 | 3 |

| M10 | Combustible | 50 | UC | D | 3 |

| M11 | Combustible | 100 | UC | D | 3 |

| M12 | Combustible | 104 | UC | D | 3 |

| M13 | Combustible | 120 | UC | D | 3 |

| M14 | Combustible | 125 | UC | Efl 2 | 4 |

| M15 | Combustible | 150 | UC | D | 3 |

| M16 | Combustible | 150 | UC | D | 3 |

| M17 | Combustible | 175 | UC | D | 3 |

| M18 | Combustible | 190 3 | UC | E | 3 |

| M19 | Combustible | 218 | UC | E | 4 |

| M20 | Combustible | 240 4 | UC | E | 3 |

| New Zealand Groups | |||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||||

| Japan | NC (1) | M01, M02, M04, M05 | - | - | - | NC (1) | Canada |

| QC (2) | - | - | - | - | |||

| FR (3) | - | - | - | - | |||

| C (4) | - | - | M03, M06, M07, M08, M09, M10, M11, M12, M13, M15, M16, M17, M18, M20 | M14, M19 | C (4) | ||

| New Zealand Groups | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Flame spread rating | [0–25] | M01, M02, M04, M05 | - | M03, M06 | - |

| [26–75] | - | - | M07, M08, M09, M10 | - | |

| [76–250] | - | - | M11, M12, M13, M15, M16, M17, M18, M20 | M14, M19 | |

| Test | Advantage | Disadvantage |

|---|---|---|

| Vertical tube furnace “Unrepresentative tests” | Controlled test environment Insights into material properties (temperature rise, mass loss, and ignition time) Low cost Material representativeness Repeatability and reproducibility | Binary result (pass/fail) Absence of fire dynamics Sensitivity to heterogeneous and/or composite materials Exposure of all faces System representativeness Product representativeness Absence of fire effluent measurements (smoke and toxicity) |

| ISO 1716 “Unrepresentative tests” | Controlled test environment Material representativeness Insights into material properties (gross heat of combustion) Repeatability and reproducibility Low cost | Absence of fire dynamics System representativeness Product representativeness Absence of fire effluent measurements (smoke and toxicity) Product representativeness |

| ISO 5660 “Unrepresentative tests” | Controlled test environment Low cost Insights into material properties (HRR, fire effluents, ignition, mass loss, etc.) Repeatability and reproducibility Material representativeness | No classification criteria Thickness limitation Constant radiant heat flux exposure Sensitivity to material emissivity Product representativeness |

| CAN/ULC-S102/S102.2 “Model tests” | Accounts for thermal inertia Material representativeness Comparative test Model tests | Influenced by airflow turbulence Controlled test environment Unrealistic fire scenario Absence of fuel input Relevance of FSR and SDC ratings Sensitivity to material type Repeatability and reproducibility Test not recommended on its own Cost Product representativeness |

| EN 13823 “Model tests” | Sample representativeness Controlled test environment Material representativeness | Cost Absence of ceiling influence System effect Unrealistic scenario Correlation with ISO 9705 (around 90%) Product representativeness |

| ISO 9705 “Technological proof tests” | Controlled test environment Reference scenario test Product representativeness | Cost Bidirectional flow on opening System effect Representative of one fire scenario Material representativeness |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadaoui, A.; Dagenais, C.; Blanchet, P. A Comparative Study of Fire Code Classifications of Building Materials. Fire 2024, 7, 252. https://doi.org/10.3390/fire7070252

Sadaoui A, Dagenais C, Blanchet P. A Comparative Study of Fire Code Classifications of Building Materials. Fire. 2024; 7(7):252. https://doi.org/10.3390/fire7070252

Chicago/Turabian StyleSadaoui, Amirouche, Christian Dagenais, and Pierre Blanchet. 2024. "A Comparative Study of Fire Code Classifications of Building Materials" Fire 7, no. 7: 252. https://doi.org/10.3390/fire7070252

APA StyleSadaoui, A., Dagenais, C., & Blanchet, P. (2024). A Comparative Study of Fire Code Classifications of Building Materials. Fire, 7(7), 252. https://doi.org/10.3390/fire7070252