Integration of Phase-Change Materials in Ventilated Façades: A Review Regarding Fire Safety and Future Challenges

Abstract

1. Introduction

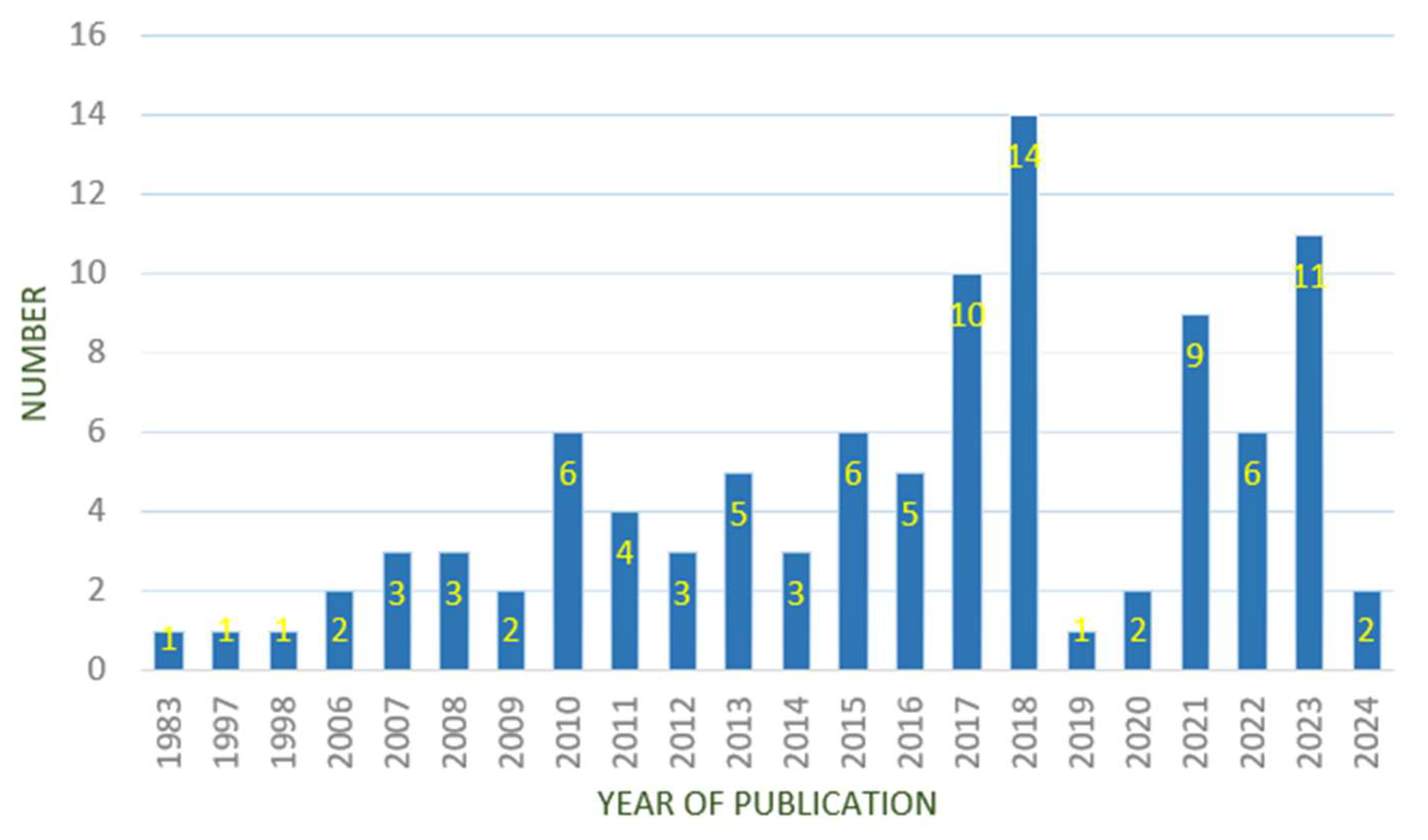

2. State of the Art

2.1. Ventilated Façades

2.2. Ventilated Façades with PCM Best-Practice Solutions

2.3. Fire Safety of Ventilated Façades

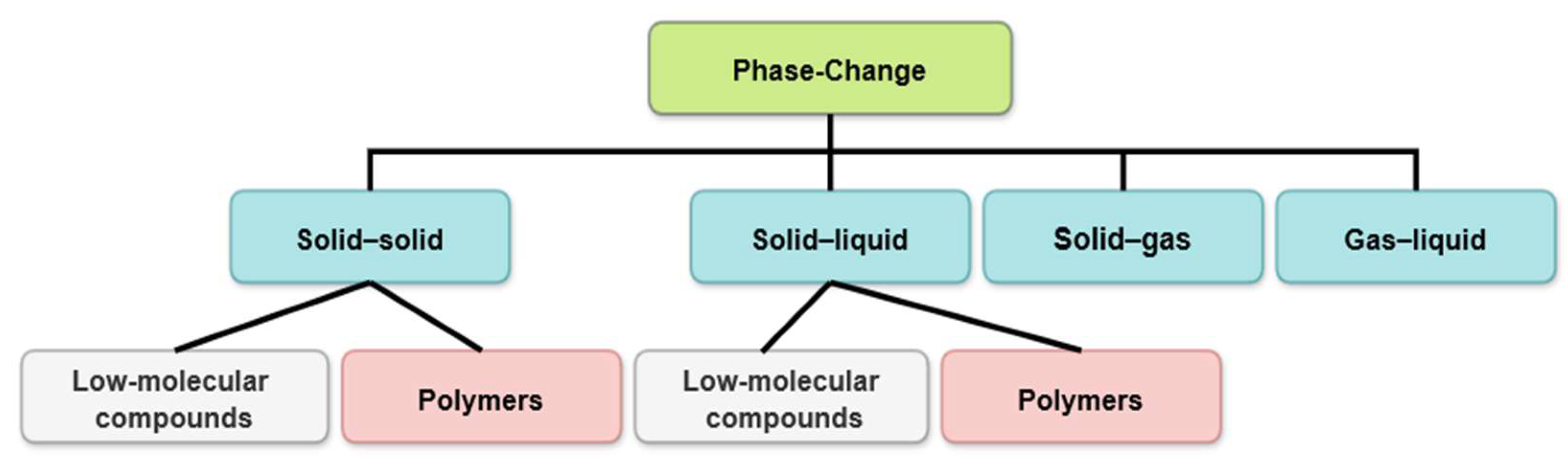

2.4. Fire Safety of Phase-Change Materials

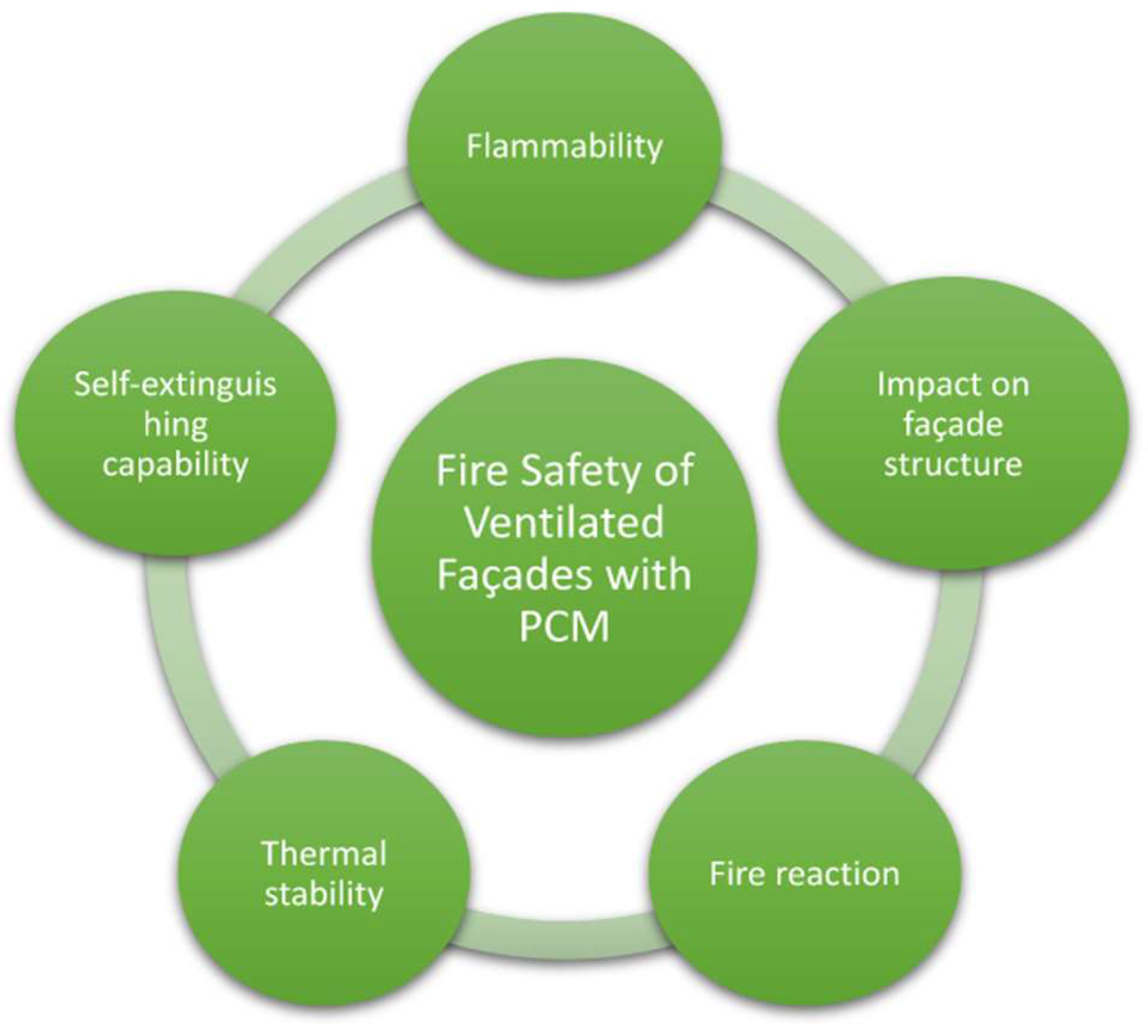

3. Fire Safety of Ventilated Façades with PCM

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Capros, P.; Mantzos, L.; Papandreou, V.; Tasios, N. Trends to 2030—Update 2007. Directorate-General for Energy and Transport; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- Directive of the European Parliament and of the Council on the Energy Performance of Buildings. 2024. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L_202401275&pk_keyword=Energy&pk_content=Directive (accessed on 1 May 2024).

- The EPBD Decrypted: A Treasure Chest of Opportunities to Accelerate Building Decarbonisation. Available online: https://www.bpie.eu/publication/the-epbd-decrypted-a-treasure-chest-of-opportunities-to-accelerate-building-decarbonisation/ (accessed on 1 May 2024).

- Batra, U.; Singhal, S. Optimum level of insulation for energy efficient envelope of office buildings. Int. J. Environ. Sci. Technol. 2017, 14, 2389–2398. [Google Scholar] [CrossRef]

- Manioğlu, G.; Yılmaz, Z. Economic evaluation of the building envelope and operation period of heating system in terms of thermal comfort. Energy Build. 2006, 38, 266–272. [Google Scholar] [CrossRef]

- Pacheco, R.; Ordóñez, J.; Martínez, G. Energy efficient design of building: A review. Renew. Sustain. Energy Rev. 2012, 16, 3559–3573. [Google Scholar] [CrossRef]

- Baciu, I.-R.; Isopescu, D.N.; Lupu, M.L.; Maxineasa, S.G.; Plum, L.; Dan, S. Ventilated façade solutions. IOP Assoc. Prof. Ser. Mater. Sci. Eng. 2022, 1242, 012002. [Google Scholar] [CrossRef]

- Patania, F.; Gagliano, A.; Nocera, F.; Ferlito, A.; Galesi, A. Thermofluid-dynamic analysis of ventilated facades. Energy Build. 2010, 42, 1148–1155. [Google Scholar] [CrossRef]

- Seferis, P.; Strachan, P.; Dimoudi, A.; Androutsopoulos, A. Investigation of the performance of a ventilated wall. Energy Build. 2011, 43, 2167–2178. [Google Scholar] [CrossRef]

- Suresh, C.; Kumar Hotta, T.; Saha, S.K. Phase change material incorporation techniques in building envelopes for enhancing the building thermal comfort: A review. Energy Build. 2022, 268, 112225. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabo, M. Experimental study of PCM-enhanced building envelope towards energy-saving and decarbonisation in a severe hot climate. Energy Build. 2023, 279, 112680. [Google Scholar] [CrossRef]

- Diarce, G.; Urresti, A.; García-Romero, A.; Delgado, A.; Erkoreka, A.; Escudero, C.; Campos-Celador, Á. Ventilated Active Façades with PCM; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Bikas, D.; Tsikaloudaki, K.; Kontoleon, K.J.; Giarma, C.; Tsoka, S.; Tsirigoti, D. Ventilated Facades: Requirements and Specifications Across Europe. Procedia Environ. Sci. 2017, 38, 148–154. [Google Scholar] [CrossRef]

- Pastors, S.; Always, R.; Mazzucchelli, E.S.; Passoni, S.; Dotelli, G. Energy Performance Evaluation of a Ventilated Façade System through CFD Modeling and Comparison with International Standards. Energies 2023, 16, 2745. [Google Scholar]

- Mercader-Moyano, P.; Anaya-Durán, P.; Romero-Cortés, A. Eco-Efficient Ventilated Facades Based on Circular Economy for Residential Buildings as an Improvement of Energy Conditions. Energies 2021, 14, 7266. [Google Scholar] [CrossRef]

- Gracia, A.; Castell, A.; Medrano, M.; Cabeza, L.F. Dynamic thermal performance of alveolar brick construction system. Energy Convers. Manag. 2011, 52, 2495–2500. [Google Scholar] [CrossRef]

- Balaras, C.; Droutsa, K.; Dascalaki, E.; Kontoyiannidis, S. Heating energy consumption and resulting environmental impact of European apartment buildings. Energy Build. 1995, 37, 429–442. [Google Scholar] [CrossRef]

- Farid, M.M.; Behzadi, S. Energy storage for efficient energy utilization in buildings. In Proceedings of the 1st International High Performance Buildings Conference, West Lafayette, IN, USA, 12–15 July 2010. [Google Scholar]

- Cabeza, L.F.; Castell, A.; Barreneche, C.D.; De Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Croitoru, C.; Bode, F.; Cap, R.; Berville, C.; Georgescu, M. Harnessing Nanomaterials for Enhanced Energy Efficiency in Transpired Solar Collectors: A Review of Their Integration in Phase-Change Materials. Energies 2024, 17, 1239. [Google Scholar] [CrossRef]

- Gracia, A.; Navarro, L.; Castell, A.; Ruiz-Pardo, Á.; Alvárez, S.; Cabeza, L.F. Experimental study of a ventilated facade with PCM during winter period. Energy Build. 2013, 58, 324–332. [Google Scholar] [CrossRef]

- Gracia, A.; Navarro, L.; Castell, A.; Cabeza, L.F. Energy performance of a ventilated double skin facade with PCM under different climates. Energy Build. 2015, 91, 37–42. [Google Scholar] [CrossRef]

- ČurpekJ, J.; Hraska, J. Simulation Study on Thermal Performance of a Ventilated PV Façade Coupled with PCM. Appl. Mech. Mater. 2016, 861, 167–174. [Google Scholar] [CrossRef]

- Gracia, A.; Barzin, R.; Fernández, C.; Farid, M.M.; Cabeza, L.F. Control strategies comparison of a ventilated facade with PCM—Energy savings, cost reduction and CO2 mitigation. Energy Build. 2016, 130, 821–828. [Google Scholar] [CrossRef]

- Curpek, J.; Cekon, M.; Hraska, J. PCM Integrated in BiPV Ventilated Façade Concepts: Experimental Test Cell Platform and Initial Full-Scale Measurements. IOP Assoc. Ser. Earth Environ. 2019, 290, 012072. [Google Scholar] [CrossRef]

- Bejan, A.-S.; Croitoru, C.; Bode, F.; Theodosius, C.; Catalina, T. Experimental investigation of an enhanced transpired air solar collector with embodied phase changing materials. J. Clean. Prod. 2022, 336, 130398. [Google Scholar] [CrossRef]

- United Nations. The 17 GOALS. Sustainable Development. Goal 11; Department of Economic and Social Affairs, United Nations: New York, NY, USA, 2024. [Google Scholar]

- Sun, J.; Hu, L.; Zhang, Y. A review on research of fire dynamics in high-rise buildings. Theor. Appl. Mech. Lett. 2013, 3, 042001. [Google Scholar] [CrossRef]

- Hu, L.; Milke, J.A.; Merci, B. Special issue on fire safety of high-rise buildings. Fire Technol. 2017, 53, 1–3. [Google Scholar] [CrossRef]

- Ronchi, E.; Nilsson, D. Fire evacuation in high-rise buildings: A review of human behaviour and modelling research. Fire Sci. Rev. 2013, 2, 7. [Google Scholar] [CrossRef]

- Ahrens, M. High-Rise Building Fires; National Fire Protection Association: Quincy, MA, USA, 2016. [Google Scholar]

- Sharma, A. Experimental and Numerical Investigations on External and Internal Fire Files in High-Rise Buildings. Ph.D. Thesis, Indian Institute of Technology Roorkee, Haridwar, India, 2021. [Google Scholar]

- Bonner, M.; Rein, G. Flammability and multi-objective performance of building façades: Towards optimum design. Int. J. High-Rise Build. 2018, 7, 363–374. [Google Scholar]

- Anderson, J.; Boström, L.; Jansson McNamee, R.; Milovanović, B. Experimental comparisons in façade fire testing considering SP Fire 105 and the BS 8414-1. Fire Mater. 2018, 42, 484–492. [Google Scholar] [CrossRef]

- Gandhi, P.; Jagdish, V.; Karthikeyan, G.; Chakravarthy, A.; Nakrani, D.; Ghoroi, C.; Srivastava, G. Performance of glass-ACP façade system in a full-scale real fire test in a G+2 structure. Procedia Eng. 2017, 210, 512–519. [Google Scholar] [CrossRef]

- Sharma, A.; Zhang, T.; Dwivedi, G. Façade Fires in High-Rise Buildings: Challenges and Artificial Intelligence Solutions; Springer International Publishing: Cham, Switzerland, 2024. [Google Scholar]

- The Guideline Design and Installation of Rear-Ventilated Rainscreen Façades. 2018. Available online: https://www.emimar.lv/pdfdwg/pdf_catalogs/FVHF-Facades_180306_EN.pdf (accessed on 1 May 2024).

- DIN 18516-1:2010-06; Cladding for External Walls, Ventilated at Rear—Part 1: Requirements, Principles of Testing. German Institute for Standardisation (Deutsches Institut für Normung): Berlin, Germany, 2010.

- Huang, X.; Alva, G.; Jia, Y.; Fang, G. Morphological characterization and applications of phase change materials in thermal energy storage: A review. Renew. Sustain. Energy Rev. 2017, 72, 128–145. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles—An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Nandy, A.; Houl, Y.; Zhao, W.; D’Souza, N.A. Thermal heat transfer and energy modeling through incorporation of phase change materials (PCMs) into polyurethane foam. Renew. Sustain. Energy Rev. 2023, 182, 113410. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Mahmood, D.M.N.; Sopian, K. A Review of Recent Improvements, Developments, and Effects of Using Phase—Change Materials in Buildings to Store Thermal Energy. Designs 2023, 7, 90. [Google Scholar] [CrossRef]

- Motahar, S. Experimental study and ANN-based prediction of melting heat trans-fer in a uniform heat flux PCM enclosure. J. Energy Storage 2020, 30, 101535. [Google Scholar] [CrossRef]

- Venkitaraj, K.P.; Sivan, S.; Pillai, P.B.; Nair, S.C. Experimental heat transfer analysis of macro packed neopentylglycol with CuO nano additives for building cooling applications. J. Energy Storage 2018, 17, 1–10. [Google Scholar] [CrossRef]

- Mourid, A.; El Alami, M.; Kuznik, F. Experimental investigation on thermal behavior and reduction of energy consumption in a real scale building by using phase change materials on its envelope. Sustain. Cities Soc. 2018, 41, 35–43. [Google Scholar] [CrossRef]

- Kalnæs, S.E.; Jelle, B.P. Phase change materials and products for building applications: A state-of-the-art review and future research opportunities. Energy Build. 2015, 94, 150–176. [Google Scholar] [CrossRef]

- Zalba, B.; Marín, J.M.; Cabeza, L.F.; Mehling, H. Review on Thermal Energy Storage with Phase Change: Materials, Heat Transfer Analysis and Applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Tyagi, V.; Kaushik, S.; Tyagi, S.; Akiyama, T. Development of phase change materials based microencapsulated technology for buildings: A review. Renew. Sustain. Energy Rev. 2012, 15, 1373–1391. [Google Scholar] [CrossRef]

- Pielichowska, K.; Paprota, N. Fire Retardant Phase Change Materials—Recent Developments and Future Perspectives. Materials 2023, 16, 4391. [Google Scholar] [CrossRef] [PubMed]

- Dash, L.; Mahanwar, P. A Review on Organic Phase Change Materials and Their Applications. Int. J. Eng. Appl. Sci. Technol. 2021, 5, 45–52. [Google Scholar] [CrossRef]

- Liu, Z.; Zang, C.; Zhang, Y.; Jiang, J.; Yuan, Z.; Liu, G.; Li, H. Mechanical properties and antifreeze performance of cement-based composites with liquid paraffin/diatomite capsule low-temperature phase change. Constr. Build. Mater. 2022, 341, 127773. [Google Scholar] [CrossRef]

- Kabdrakhmanova, M.; Memon, S.A.; Saurbayeva, A. Implementation of the panel data regression analysis in PCM integrated buildings located in a humid subtropical cli-mate. Energy 2021, 237, 121651. [Google Scholar] [CrossRef]

- Islam, M.N.; Ahmed, D.H. Delaying the temperature fluctuations through PCM inte-grated building walls—Room conditions, PCM placement, and temperature of the heat sources. Energy Storage 2021, 3, e245. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM thermal storage in buildings: A state of art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Jelle, B.P.; Kalnæs, S.E. Phase Change Materials for Application in Energy-Efficient Buildings; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Nader, N.A.; Bulshlaibi, B.; Jamil, M.; Suwaiyah, M.; Uzair, M. Application of Phase-Change Materials in Buildings. Am. J. Energy Eng. 2015, 3, 46–52. [Google Scholar] [CrossRef]

- Fang, X.; Fan, L.; Ding, Q.; Yao, X.; Wu, Y.; Hou, J.; Wang, X.; Yu, Z.; Cheng, G.; Hu, Y. Thermal energy storage performance of paraffin-based composite phase change materials filled with hexagonal boron nitride nanosheets. Energy Convers. Manag. 2014, 80, 103–109. [Google Scholar] [CrossRef]

- Png, Z.M.; Soo, X.Y.D.; Chua, M.H.; Ong, P.J.; Suwardi, A.; Tan, C.K.I.; Xu, J.; Zhu, Q. Strategies to reduce the flammability of organic phase change Materials: A review. Sol. Energy 2022, 231, 115–128. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, Y.; Song, L.; Ni, J.; Xing, W.; Wang, J. Effect of expanded graphite on properties of high-density polyeth lene/paraffin composite with intumescent flame retardant as a shape-stabilized phase change material. Sol. Energy Mater. Sol. Cells. 2010, 94, 360–365. [Google Scholar] [CrossRef]

- Zhang, P.; Kang, M.; Hu, Y. Influence of layered zinc hydroxide nitrate on thermal properties of paraffin/intumescent flame retardant as a phase change material. J. Therm. Anal. Calorim. 2013, 112, 1199–1205. [Google Scholar] [CrossRef]

- Palacios, A.; De Gracia, A.; Haurie, L.; Cabeza, L.F.; Fernández, A.I.; Barreneche, C. Study of the Thermal Properties and the Fire Performance of Flame RetardantOrganic PCM in Bulk Form. Materials 2018, 11, 117. [Google Scholar] [CrossRef]

- An, W.; Sun, J.; Liew, K.M.; Zhu, G. Flammability and safety design of thermal insulation materials comprising PS foams and fire barrier materials. Mater. Des. 2016, 99, 500–508. [Google Scholar] [CrossRef]

- Inaba, H.; Tu, P. Evaluation of thermophysical characteristics on shape-stabilized paraffin as a solid-liquid phase change material. Heat Mass Transf. 1997, 32, 307–312. [Google Scholar] [CrossRef]

- Zhao, Y.; Min, X.; Huang, Z.; Liu, Y.; Wu, X.; Fang, M. Honeycomb-like structured biological porous carbon encapsulating PEG: A shape-stable phase change material with enhanced thermal conductivity for thermal energy storage. Energy Build. 2018, 158, 1049–1062. [Google Scholar] [CrossRef]

- Cai, Y.; Hu, Y.; Song, L.; Tang, Y.; Yang, R.; Zhang, Y.; Chen, Z.; Fan, W. Flammability and thermal properties of high density polyethylene/paraffin hybrid as a form-stable phase change material. J. Appl. Polym. Sci. 2006, 99, 1320–1327. [Google Scholar] [CrossRef]

- Cai, Y.; Hu, Y.; Song, L.; Kong, Q.; Yang, R.; Zhang, Y.; Chen, Z.; Fan, W. Preparation and flammability of high density polyethylene/paraffin/organophilic montmorillonite hybrids as a form stable phase change material. Energy Converse. Manag. 2007, 48, 462–469. [Google Scholar] [CrossRef]

- Cai, Y.; Wei, Q.; Huang, F.; Lin, S.; Chen, F.; Gao, W. Thermal stability, latent heat and flame retardant properties of the thermal energy storage phase change materials based on paraffin/high density polyethylene composites. Renew. Energy 2009, 34, 2117–2123. [Google Scholar] [CrossRef]

- Hu, Y.; Song, L.; Xu, J.; Yang, L.; Chen, Z.; Fan, W. Synthesis of polyurethane/clay intercalated nanocomposites. Colloid Polym. Sci. 2001, 279, 819–822. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Konuklu, Y.; Fernández, A.I. Preparation and exhaustive characterization of paraffin or palmitic acid microcapsules as novel phase change material. Sol. Energy 2015, 112, 300–309. [Google Scholar] [CrossRef]

- Li, W.; Song, G.; Tang, G.; Chu, X.; Ma, S.; Liu, C. Morphology, structure and thermal stability of microencapsulated phase change material with copolymer shell. Energy 2011, 36, 785–791. [Google Scholar] [CrossRef]

- Li, M.; Chen, M.; Wu, Z. Enhancement in thermal property and mechanical property of phase change microcapsule with modified carbon nanotube. Appl. Energy 2014, 127, 166–171. [Google Scholar] [CrossRef]

- Qiu, X.; Li, W.; Song, G.; Chu, X.; Tang, G. Fabrication and characterization of microencapsulated n-octadecane with different crosslinked methylmethacrylatebased polymer shells. Sol. Energy Mater. Sol. Cells 2012, 98, 283–293. [Google Scholar] [CrossRef]

- Cao, L.; Tang, F.; Fang, G. Preparation and characteristics of microencapsulated palmitic acid with TiO2 shell as shape-stabilized thermal energy storage materials. Sol. Energy Mater. Sol. Cells 2014, 123, 183–188. [Google Scholar] [CrossRef]

- Sun, X.; Wang, S.; Du, Z.; Cheng, X.; Wang, H. Preparation and characterization of flame-retardant nanoencapsulated phase change materials with poly(methylmethacrylate) shells for thermal energy storage. J. Mater. Chem. A 2018, 6, 17519–17529. [Google Scholar]

- Yang, Z.; Sun, Z.; Li, G.; Li, Z.; Liu, Y. Preparation of Flame Retardant Phase Change Microcapsules and Ink Application; Part of the book series: Lecture Notes in Electrical Engineering (LNEE, Volume 991); Springer: Berlin/Heidelberg, Germany, 2023; pp. 514–519. ISSN 1876-1119. [Google Scholar]

- Szczotok, A.M.; Carmona, M.; Serrano, A.; Kjøniksen, A.L.; Rodriguez, J.F. Development of thermoregulating microcapsules with cyclotriphosphazene as a flame-retardant agent. IOP Assoc. Prof. Ser. Mater. Sci. Eng. 2017, 251, 12120. [Google Scholar] [CrossRef]

- Jiang, Y.; Yan, P.; Wang, Y.; Zhou, C.; Lei, J. Form-stable phase change materials with enhanced thermal stability and fire resistance via the incorporation of phosphorus and silicon. Mater. Des. 2018, 160, 763–771. [Google Scholar] [CrossRef]

- Chen, R.; Huang, X.; Zheng, R.; Xie, D.; Mei, Y.; Zou, R. Flame-retardancy and thermal properties of a novel phosphorus-modified PCM for thermal energy storage. Chem. Eng. J. 2020, 380, 122500. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, B.; Wang, L.; Lu, R.; Zhao, D.; Zhang, S. Novel hybrid form-stable polyether phase change materials with good fire resistance. Energy Storage Mater. 2017, 6, 46–52. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Yang, R. A new flame retardance strategy for shape stabilized phase change materials by surface coating. Sol. Energy Mater. Sol. Cells 2017, 170, 87–94. [Google Scholar] [CrossRef]

- Gao, C.; Kuklane, K.; Holmér, I. Cooling vests with phase change material packs: The effects of temperature gradient, mass and covering area. Ergonomics 2010, 53, 716–723. [Google Scholar] [CrossRef]

- Shaid, A.; Wang, L.; Fergusson, S.M.; Padhye, R. Effect of Aerogel Incorporation in PCM-Containing Thermal Liner of Firefighting Garment. Cloth. Text. Res. J. 2018, 36, 151–164. [Google Scholar] [CrossRef]

- McLaggan, M.S.; Hadden, R.M.; Gillie, M. Fire Performance of Phase Change Material Enhanced Plasterboard. Fire Technol. 2018, 54, 117–134. [Google Scholar] [CrossRef]

- McLaggan, M.S.; Hadden, R.M.; Gillie, M. Flammability assessment of phase change material wall lining and insulation materials with different weight fractions. Energy Build. 2017, 153, 439–447. [Google Scholar] [CrossRef]

- ISO 13785-2:2002; Reaction-to-Fire Tests for Façades. Available online: https://www.iso.org/standard/22928.html#:~:text=ISO%2013785%2D2%3A2002%20specifies,impinging%20directly%20on%20the%20fa%C3%A7ade (accessed on 15 April 2024).

- Ferrarini, G.; Agresti, F.; Barison, S.; Bison, P.; Cadelano, G.; Bortolin, A.; Fedele, L.; Rossi, S.; Scattolini, M. Thermal investigation of Phase Change Materials (PCM) by infrared thermography. In Thermosense: Thermal Infrared Applications XLV; SPIE: Bellingham, WA, USA, 2023; Volume 12536, p. 125360. [Google Scholar]

- Gonçalves, M.C.; Coelho, A.L. State-of-the-Art and Future Insights into the Material’s Fire Behaviour Tests. In Advances on Testing and Experimentation in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1–16. [Google Scholar]

- Garg, K.; Singh, S.; Rokade, M.; Singh, S. The Behavior of Passive Fire Protection Materials Used for Fire Protection of Steel Structures in Standard, Hydrocarbon, and Jet Fire Exposure. Fire Technol. 2023, 59, 2517–2541. [Google Scholar] [CrossRef]

- Amaral, C.; Gomez, F.; Moreira, M.; Silva, T.; Vicente, R. Thermal Performance of Multifunctional Facade Solution Containing Phase Change Materials: Experimental and Numerical Analysis. Polymers 2023, 15, 2971. [Google Scholar] [CrossRef] [PubMed]

- Alkhazaleh, A. Thermal and Flammability Properties of Flame Retardant Phase Change Material for Buildings Applications. Mater. Sci. Forum 2023, 1082, 284–289. [Google Scholar] [CrossRef]

- Yang, Y.; Pang, Y.; Liu, Y.; Guo, H. Preparation and thermal properties of polyethylene glycol/expanded graphite as novel form-stable phase change material for indoor energy saving. Mater. Lett. 2018, 216, 72–75. [Google Scholar] [CrossRef]

- Kürklü, A. Energy storage applications in greenhouses by means of phase change materials (PCMs): A review. Renew. Energy 1998, 13, 89–103. [Google Scholar] [CrossRef]

- Abhat, A. Low temperature latent heat thermal energy storage: Heat storage materials. Sol. Energy 1983, 30, 313–332. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, N. Thermal Energy Storage and Energy Conversion Engineering; Chemical Industry Press: Beijing, China, 2001. [Google Scholar]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM: An up to Date Introduction into Basics and Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Keshavarz, M.H. Combustible Organic Materials: Determination and Prediction of Combustion Properties; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2022. [Google Scholar]

| Incident | Location | Year | Details |

|---|---|---|---|

| Grenfell Tower Fire | London, UK | 2017 | A tragic and widely publicized fire where the ventilated façade contributed to the rapid spread of fire throughout the 24-storey building, resulting in 72 fatalities and prompting extensive reviews of building safety regulations. |

| Torre Windsor Fire | Madrid, Spain | 2005 | The fire illustrated how a ventilated façade can facilitate the rapid spread of fire in high-rise buildings. The 32-storey building was nearly completely destroyed due to the flammable material used in its ventilated cladding. |

| The Address Downtown Fire | Dubai, UAE | 2015 | The New Year’s Eve fire affected a 63-storey building with a ventilated façade. While there were no fatalities, the fire highlighted the risks associated with using flammable materials in tall buildings. |

| Lacrosse Building Fire | Melbourne, Australia | 2014 | The fire demonstrated the negative impact of flammable materials. |

| Type of Façade | PCM Used | Conclusion | Results | Reference |

|---|---|---|---|---|

| Ventilated Façade | SP-22 from Rubitherm | Improved thermal performance and energy efficiency by integrating PCM into the façade’s air cavity. | Reduced HVAC electric consumption, enhanced thermal comfort, and adaptable PCM usage under different conditions. | [21] |

| Ventilated Double-Skin Façade (VDSF) | SP-22 from Rubitherm | Effective in reducing energy consumption by absorbing and releasing heat based on temperature variations. | Significant energy savings, particularly in cold seasons, are adaptable to various climates and building types. | [22] |

| Ventilated PV Façade | Not specified | Integration of PCM and PV can enhance thermal performance and delay peak temperatures. | Lowered PV panel temperatures by over 20 °C; delayed peak temperatures by more than 5 h. | [23] |

| Ventilated Façade | Not specified | Optimizing control strategies for PCM-ventilated façades can maximize energy savings and reduce CO2 emissions. | Achieved average savings of 4.3%, 7.8%, and 16.7% in energy, cost, and CO2 emissions, respectively. | [24] |

| BiPV Ventilated Façade | Not specified | PCM can mitigate overheating and improve temperature management, thereby enhancing energy efficiency and thermal comfort. | Lower operating temperatures of PV modules, efficient heat storage, and maximized solar energy utilization. | [25] |

| Solar Collectors | RT35 (paraffin) | Integration of PCM enhances efficiency and operational duration of solar collectors. | Increased maximum temperature by 8.8%, improved coefficient of performance by 10.6%, and extended operational time by 110%. | [26] |

| Problem | Citation: | Result | References |

|---|---|---|---|

| Bulk PCM flammability | Incorporation of flame retardants in bulk PCMs | Reduction in flammability | [58,59,60,61] |

| Stabilization of PCM shape | Incorporation of flame retardants in shape-stabilized PCMs | Shaped-stabilized PCMs and flame protection | [62,63,64,65,66,67,68] |

| Flame propagation in microencapsulated PCMs | Incorporation of flame retardants in microencapsulated PCMs | Additional flame protection, prevention of fire spread | [69,70,71,72,73,74,75] |

| PCM flammability | Chemical transformations to reduce flammability | Reduction in flammability through chemical modifications | [76,77,78] |

| Surface flammability of PCMs | Surface coating for reducing flammability | Additional surface flame protection | [79,80] |

| Practical applicability of PCMs | Use of flame-retardant PCMs for practical applications | Safe and efficient PCMs for practical uses | [81,82,83,84] |

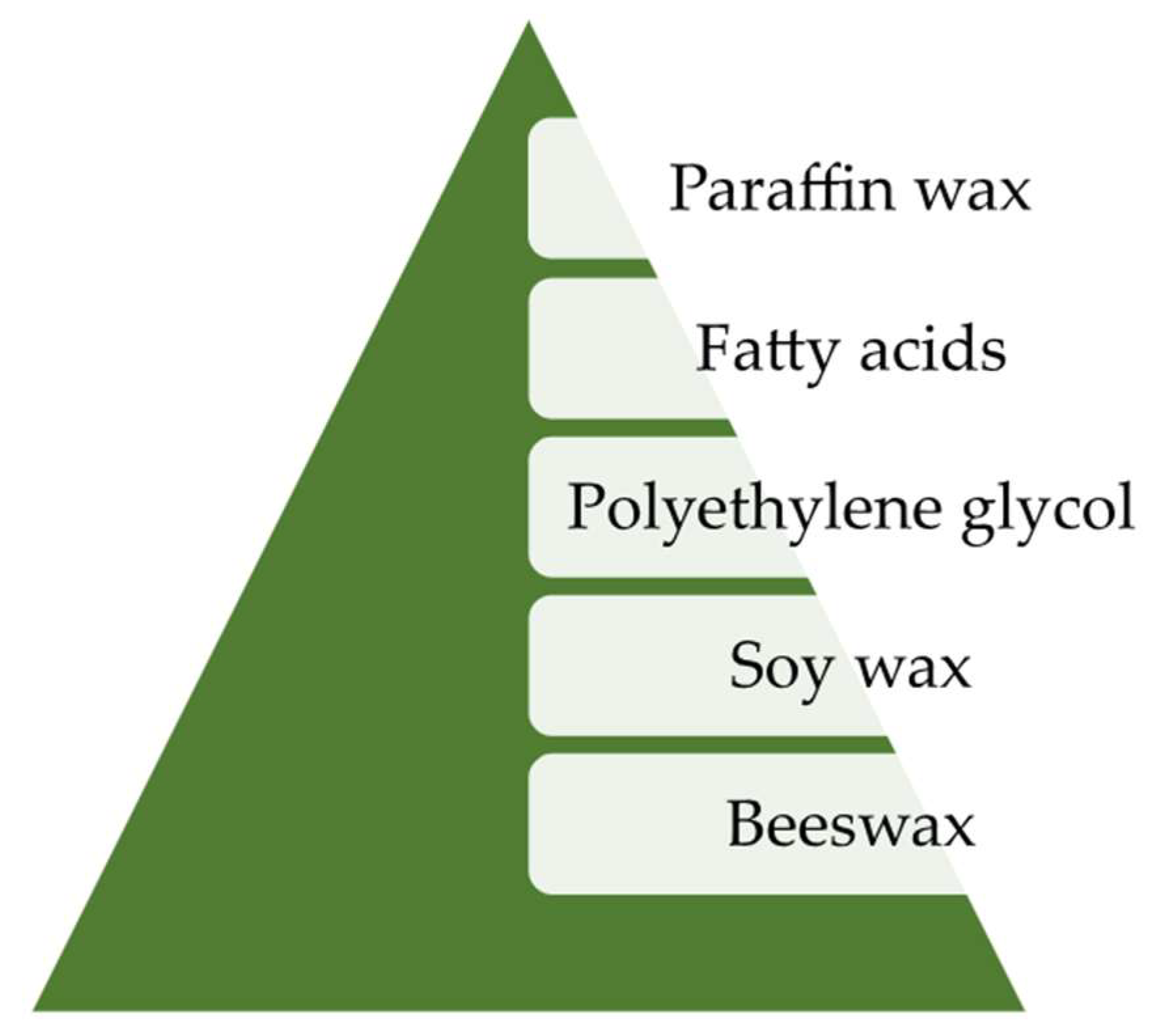

| PCM Type | Material | Heat of Combustion | Ignition Temperature | Fire Risk | Other Fire-Related Properties |

|---|---|---|---|---|---|

| Organic PCMs | Paraffin wax | ~42 | 220–250 | High | Low flash point, fast burning rate, produces significant heat when burning. |

| Organic PCMs | Fatty acids (e.g., stearic acid) | ~39 | ~250 | High | Relatively low ignition temperatures, high heat of combustion. |

| Organic PCMs | Polyethylene glycol (PEG) | ~30 | ~300 | Moderate to high | Combustible with higher ignition temperature than paraffin. |

| Inorganic PCMs | Salt hydrates (e.g., sodium sulfate decahydrate) | N/A | N/A | Low | Non-combustible, minimal fire risk. |

| Inorganic PCMs | Calcium chloride hexahydrate | N/A | N/A | Low | Similar to other salt hydrates, this material is non-combustible. |

| Biobased PCMs | Soy wax | ~40 | 200–230 | High | Flammable with low ignition temperature, high heat of combustion. |

| Biobased PCMs | Beeswax | ~39 | 204–226 | High | Flammable, similar heat of combustion and ignition temperature to soy wax. |

| Problem Identified | Percent | Proposed Measures for Improvement | Recommended Research Directions |

|---|---|---|---|

| Insufficient presence of PCMs in legislation | 35% | Update fire safety regulations to include specific requirements for PCMs | Study of the behavior of PCMs under fire conditions through experimental research and simulations |

| Lack of standardization tests for PCMs | 25% | Implementation of standardization tests to evaluate the behavior of PCMs in fire conditions | Development of PCMs with improved performance and flame-retardant properties |

| The need for integrated design solutions | 40% | Development of integrated design solutions that include fire barriers and flame-retardant materials | Design and testing of safe façade systems that integrate PCMs efficiently and safely |

| Limited awareness | 20% | Conduct workshops and training sessions to educate stakeholders about the benefits and risks of PCM-integrated façade systems | Research on effective communication strategies to increase awareness and understanding of PCM technologies among stakeholders |

| High initial costs of PCM-integrated façade systems | 30% | Invest in cost–benefit analysis and financial incentives to make PCM integration more economically viable for building projects | Development of cost-effective manufacturing processes and materials for PCM integration in façade systems |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ovadiuc, E.-P.; Calotă, R.; Năstase, I.; Bode, F. Integration of Phase-Change Materials in Ventilated Façades: A Review Regarding Fire Safety and Future Challenges. Fire 2024, 7, 244. https://doi.org/10.3390/fire7070244

Ovadiuc E-P, Calotă R, Năstase I, Bode F. Integration of Phase-Change Materials in Ventilated Façades: A Review Regarding Fire Safety and Future Challenges. Fire. 2024; 7(7):244. https://doi.org/10.3390/fire7070244

Chicago/Turabian StyleOvadiuc, Emanuil-Petru, Răzvan Calotă, Ilinca Năstase, and Florin Bode. 2024. "Integration of Phase-Change Materials in Ventilated Façades: A Review Regarding Fire Safety and Future Challenges" Fire 7, no. 7: 244. https://doi.org/10.3390/fire7070244

APA StyleOvadiuc, E.-P., Calotă, R., Năstase, I., & Bode, F. (2024). Integration of Phase-Change Materials in Ventilated Façades: A Review Regarding Fire Safety and Future Challenges. Fire, 7(7), 244. https://doi.org/10.3390/fire7070244