Experiments on a Mine System Subjected to Ascensional Airflow Fire and Countermeasures for Mine Fire Control

Abstract

1. Introduction

2. Theoretical Model of the Airflow Disaster Process in Underground Mine Fires

3. Experiment on Airflow System Disorder of Mine Fire

4. Experimental Results and Analysis

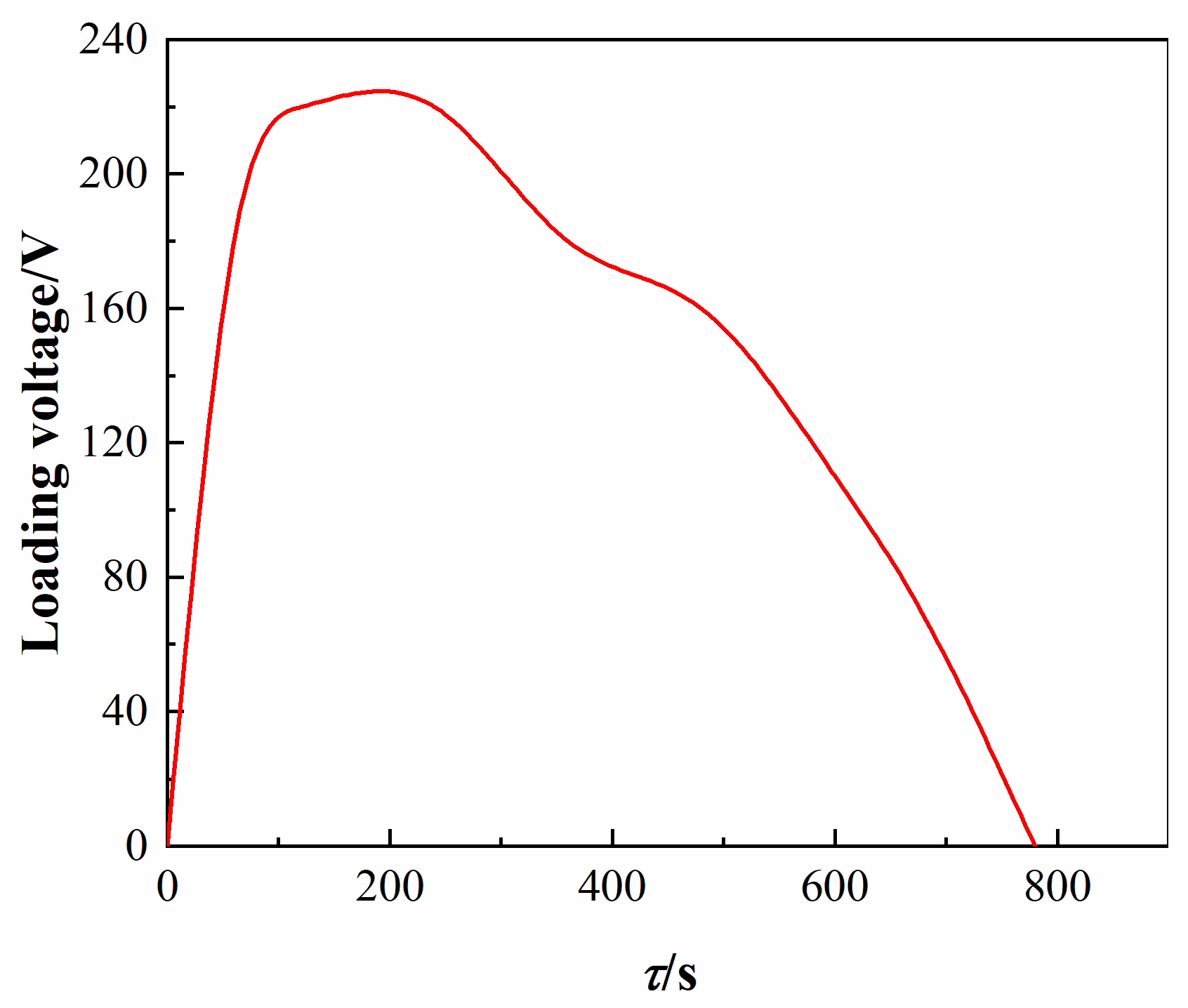

4.1. Airflow Disorder Characteristics in Ventilation System during Ascensional Airflow Fire

4.2. Variation Characteristics of Fire Heating Air Pressure and Ventilation Thermal Resistance

5. Simulation Analysis of the Disaster Evolution during the Period of Ascensional Airflow Fire in a Mine

5.1. Analysis of the Disaster Evolution during the Period of Ascensional Airflow Fire in a Mine

5.2. Analysis of Wind Flow Disorder Change Process in the Side Branch (Belt Uphill)

5.3. Emergency Planning Measures to Deal with the Reversal of Smoke Flow during Mine Fires

6. Conclusions

- (1)

- The experiments conducted in this study showed that, under the thermodynamic effect of fire and ascensional airflow fire period, the main wind duct air volume increased, the side branch air volume decreased, the airflow stagnated, and a reverse flow phenomenon occurred. When the fire development was strong, the fire heating air pressure caused the circulation of the airflow in the ventilation circuit, while the pipeline ventilation thermal resistance increased. Improving the air supply capacity of the ventilator could help overcome the retrograde of the wind flow of the fire side branch of the ascensional airflow and mitigate the disaster. The simulation results were in good agreement with previous experimental results, which were completely consistent with the airflow change law.

- (2)

- Increasing the ventilation fan speed was beneficial to divert the smoke from the mine fire. Using the TF1M3D platform simulation, the calculation mine ventilation fan was set at a speed of 540 r/min. After the occurrence of an ascensional airflow fire for 430 s, the airflow reversed in the side branch, and smoke flow circulation threatened the 401 intake roadway. After 4950 s, the fire strength was reduced, and the smoke flow caused a secondary attack at the side branch 402 working face. After increasing the fan speed to 740 r/min, the fire smoke diversion and disaster control were more favorable.

- (3)

- The TF1M3D software was found to be suitable for complex mine ventilation systems and can help simulate fires under real conditions in specific mines, providing auxiliary decision support for gaining disaster experience and developing fire emergency management plans. In future work, we will deeply study the ventilation law during the period of a mine disaster.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, F.-B.; Shi, B.-B.; Cheng, J.-W.; Ma, L.-J. A New Approach to Control a Serious Mine Fire with Using Liquid Nitrogen as Extinguishing Media. Fire Technol. 2013, 51, 325–334. [Google Scholar] [CrossRef]

- Dimitriadis, C.; Gao, C.X.; Ikin, J.F.; Wolfe, R.; Gabbe, B.J.; Sim, M.R.; Abramson, M.J.; Guo, Y. Exposure to mine fire related particulate matter and mortality: A time series analysis from the Hazelwood Health Study. Chemosphere 2021, 285, 131351. [Google Scholar] [CrossRef] [PubMed]

- Roy, D.; Singh, G.; Seo, Y.-C. Coal mine fire effects on carcinogenicity and non-carcinogenicity human health risks. Environ. Pollut. 2019, 254, 113091. [Google Scholar] [CrossRef]

- Lei, B.; He, B.; Xiao, B.; Du, P.; Wu, B. Comparative study of single inert gas in confined space inhibiting open flame coal combustion. Fuel 2020, 265, 116976. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, B.; Liu, S.-H.; Lei, B.; Zhao, J.; Zhao, Y. Thermal kinetics of nitrogen inhibiting spontaneous combustion of secondary oxidation coal and extinguishing effects. Fuel 2020, 278, 118223. [Google Scholar] [CrossRef]

- Yuan, L.; Zhou, L.; Smith, A.C. Modeling carbon monoxide spread in underground mine fires. Appl. Therm. Eng. 2016, 100, 1319–1326. [Google Scholar] [CrossRef]

- Li, Y.; Lei, B.; Ingason, H. Study of critical velocity and backlayering length in longitudinally ventilated tunnel fires. Fire Saf. J. 2010, 45, 361–370. [Google Scholar] [CrossRef]

- Wang, H. Numerical and theoretical evaluations of the propagation of smoke and fire in a full-scale tunnel. Fire Saf. J. 2012, 49, 10–21. [Google Scholar] [CrossRef]

- Litton, C.D.; Perera, I.E. Evaluation of criteria for the detection of fires in underground conveyor belt haulageways. Fire Saf. J. 2012, 51, 110–119. [Google Scholar] [CrossRef]

- Wan, H.; Gao, Z.; Ji, J.; Li, K.; Sun, J.; Zhang, Y. Experimental study on ceiling gas temperature and flame performances of two buoyancy-controlled propane burners located in a tunnel. Appl. Energy 2017, 185, 573–581. [Google Scholar] [CrossRef]

- Wang, J.; Fang, Z.; Tang, Z.; Yuan, J. Influence of longitudinal ventilation on the mass flow rate distribution of fire smoke flow in tunnels. Tunn. Undergr. Space Technol. 2021, 112, 103938. [Google Scholar] [CrossRef]

- Yuan, L.; Mainiero, R.J.; Rowland, J.H.; Thomas, R.A.; Smith, A.C. Numerical and experimental study on flame spread over conveyor belts in a large-scale tunnel. J. Loss Prev. Process Ind. 2014, 30, 55–62. [Google Scholar] [CrossRef]

- Huang, L.-L.; Zhu, G.-Q.; Zhang, G.-W.; Yin, F. Research the Occupants Safe Egress of Underground Pedestrian Street based on the Analysis of Fire Smoke Movement. Procedia Eng. 2013, 52, 158–164. [Google Scholar] [CrossRef]

- Hansen, R. Modelling temperature distributions and flow conditions of fires in an underground mine drift. Geosyst. Eng. 2020, 23, 299–314. [Google Scholar] [CrossRef]

- Kalech, B.; Bouterra, M.; ElCafsi, A. Numerical analysis of smoke flow under the effect of longitudinal airflow in a tunnel fire. Fire Mater. 2020, 44, 1033–1043. [Google Scholar] [CrossRef]

- Kun, L.; Cui, D.; Changfu, Y. Influence of Ventilation Tube Rupture from Fires on Gas Distribution in Tunnel. Procedia Eng. 2011, 26, 1440–1446. [Google Scholar] [CrossRef]

- Hu, L.; Fong, N.; Yang, L.; Chow, W.; Li, Y.; Huo, R. Modeling fire-induced smoke spread and carbon monoxide transportation in a long channel: Fire Dynamics Simulator comparisons with measured data. J. Hazard. Mater. 2006, 140, 293–298. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Guo, S.; Wang, Y. Human evacuation affected by smoke movement in mine fires. Int. J. Coal Sci. Technol. 2016, 3, 28–34. [Google Scholar] [CrossRef]

- Ji, J.; Zhang, J.; Chen, J.; Wu, S. Computer simulation of evacuation in underground coal mines. Min. Sci. Technol. China 2010, 20, 677–681. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, S.; Ma, X.; Wu, Z.; Shao, H.; Zhang, W.; Cui, C. Information fusion of plume control and personnel escape during the emergency rescue of external-caused fire in a coal mine. Process Saf. Environ. Prot. 2016, 103, 46–59. [Google Scholar] [CrossRef]

- Adjiski, V.; Mirakovski, D.; Despodov, Z.; Mijalkovski, S. Simulation and optimization of evacuation routes in case of fire in underground mines. J. Sustain. Min. 2015, 14, 133–143. [Google Scholar] [CrossRef]

- Li, Z. Containing the source ventilation network model and its application. J. China Coal Soc. 2010, 35, 118–122. [Google Scholar] [CrossRef]

- Lei, B.; He, B.; Zhao, Z.; Xu, G.; Wu, B. A method for identifying the fire status through ventilation systems using tracer gas for improved rescue effectiveness in roadway drivage of coal mines. Process Saf. Environ. Prot. 2021, 151, 151–157. [Google Scholar] [CrossRef]

- Hu, D.; Li, Z.; Wang, H.; Xu, H.; Miao, C. Smoke dispersion test and emergency control plan of fire in mine roadway during downward ventilation. Sci. Rep. 2023, 13, 1–11. [Google Scholar] [CrossRef]

| Platform Element | Material | Size (Inner Diameters × Length)/mm |

|---|---|---|

| Total air inlet duct | Stainless steel | 50 × 700 |

| Main air duct | Quartz | 50 × 4800 |

| Side branch air duct | Stainless steel | 50 × 4800 |

| Total air outlet duct | Quartz | 50 × 400 |

| Order | Time/s | Location Node | Order | Time/s | Location Node |

|---|---|---|---|---|---|

| 1 | 45 | 7 | 9 | 2055 | 8 |

| 2 | 195 | 17 | 10 | 2070 | 5 |

| 3 | 300 | 81 | 11 | 2910 | 6 |

| 4 | 330 | 11 | 12 | 4575 | 6 |

| 5 | 480 | 21 | 13 | 5055 | 37 |

| 6 | 550 | 20 (Return air shaft entrance) | 14 | 5115 | 8 |

| 7 | 1635 | 37 | 15 | 5385 | 26 |

| 8 | 1920 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Li, Z. Experiments on a Mine System Subjected to Ascensional Airflow Fire and Countermeasures for Mine Fire Control. Fire 2024, 7, 223. https://doi.org/10.3390/fire7070223

Zhang M, Li Z. Experiments on a Mine System Subjected to Ascensional Airflow Fire and Countermeasures for Mine Fire Control. Fire. 2024; 7(7):223. https://doi.org/10.3390/fire7070223

Chicago/Turabian StyleZhang, Mingqian, and Zongxiang Li. 2024. "Experiments on a Mine System Subjected to Ascensional Airflow Fire and Countermeasures for Mine Fire Control" Fire 7, no. 7: 223. https://doi.org/10.3390/fire7070223

APA StyleZhang, M., & Li, Z. (2024). Experiments on a Mine System Subjected to Ascensional Airflow Fire and Countermeasures for Mine Fire Control. Fire, 7(7), 223. https://doi.org/10.3390/fire7070223