Investigating the Influence of Flue Gas Induced by Coal Spontaneous Combustion on Methane Explosion Risk

Abstract

1. Introduction

2. Flue Gas Generation Characteristics during CSC

2.1. The Flue Gas Generation Characteristic Test Experiment of CSC

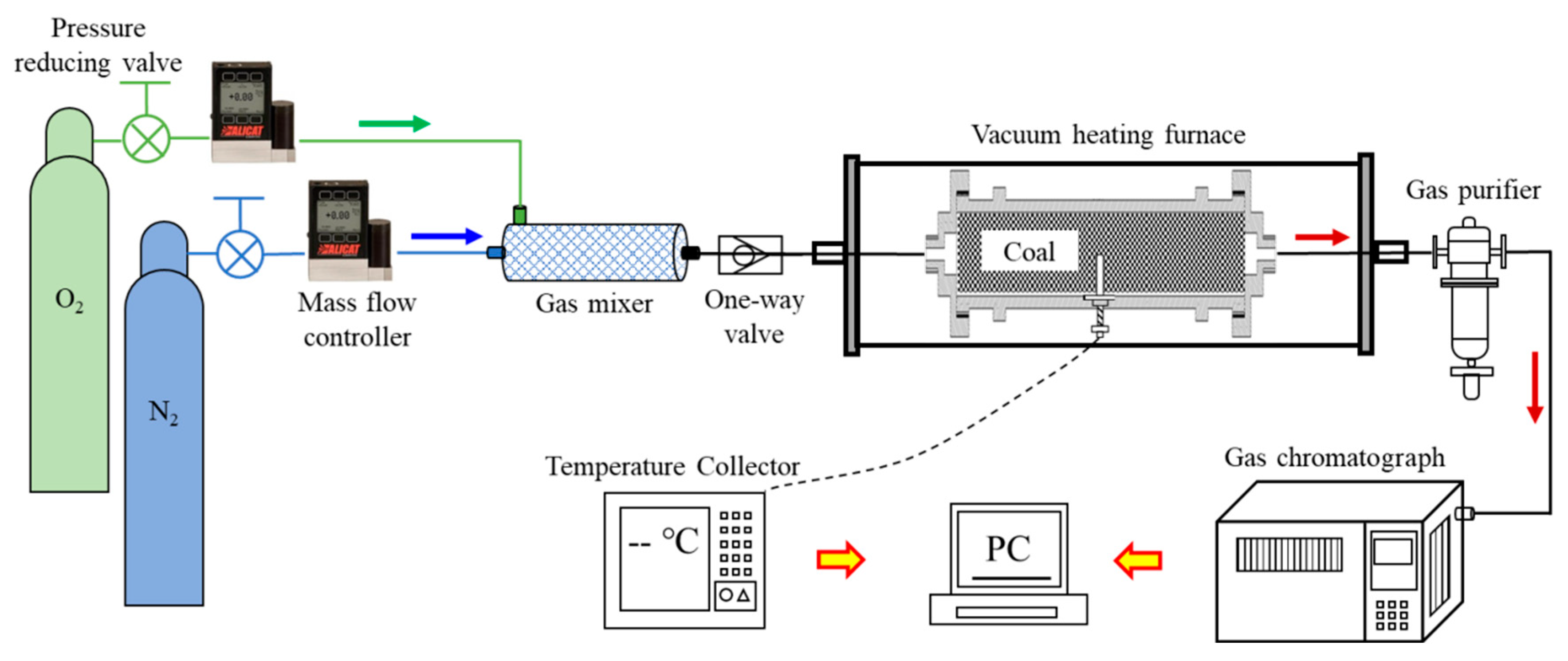

2.1.1. Experimental System

2.1.2. Experimental Process

- (1)

- Coal samples screening: The fresh coal samples taken from the site were removed by sandpaper, and then the coal samples were broken into different sizes by a crusher. Then, the coal samples were screened by a sieve with a screening range of 0.18–0.38 mm to obtain a coal sample with a particle size range of 40~80 mesh. Finally, 300 g coal samples were selected and placed in a vacuum-drying oven at 50 °C for 24 h to remove external moisture.

- (2)

- Heating pretreatment: After the dry coal samples were loaded into the coal sample container, N2 was first introduced into the furnace at a flow rate of 120 mL/min for about 10 min to drain the air in the tank. Subsequently, the furnace temperature was set at 30 °C and maintained for 30 min to make the initial temperature conditions of the experiment consistent.

- (3)

- Temperature programming: The flow controller was adjusted to supply gas to the coal sample tank at 300 mL/min, and the proportion of O2 in the supplied gas was 21%. At the same time, the flow and composition of the outlet gas were monitored. After the outlet gas was stable, the programmed temperature control system was turned on, and the heating rate was set to 2 °C/min, and the heating range was 30~710 °C.

- (4)

- Data collecting: After the temperature started to rise, the temperature acquisition instrument was opened, and the acquisition frequency was set to 1 time/s. At the same time, for every 20 °C increase in coal temperature, flue gas generated from coal spontaneous combustion was collected and stored separately in gas bags with a volume of 10 mL each. Subsequently, the flue gas in each gas bag was tested using the chromatograph.

2.1.3. Experimental Samples

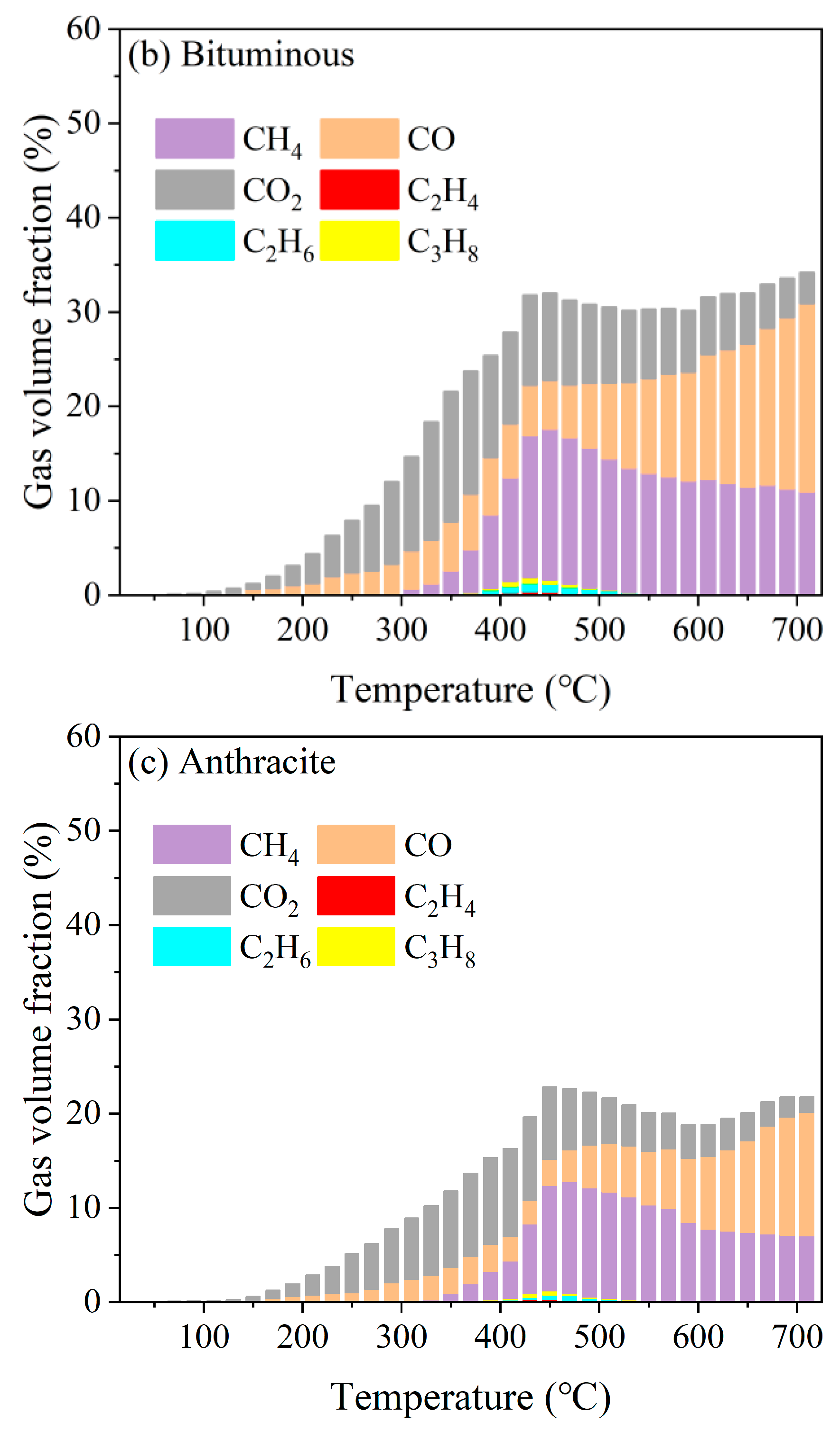

2.2. Flue Gas Generation Law of CSC

3. Influence of CSC Flue Gas on Methane Explosion Limit

3.1. Explosion Limit Test Experiment of Multi-Component Mixed Gas

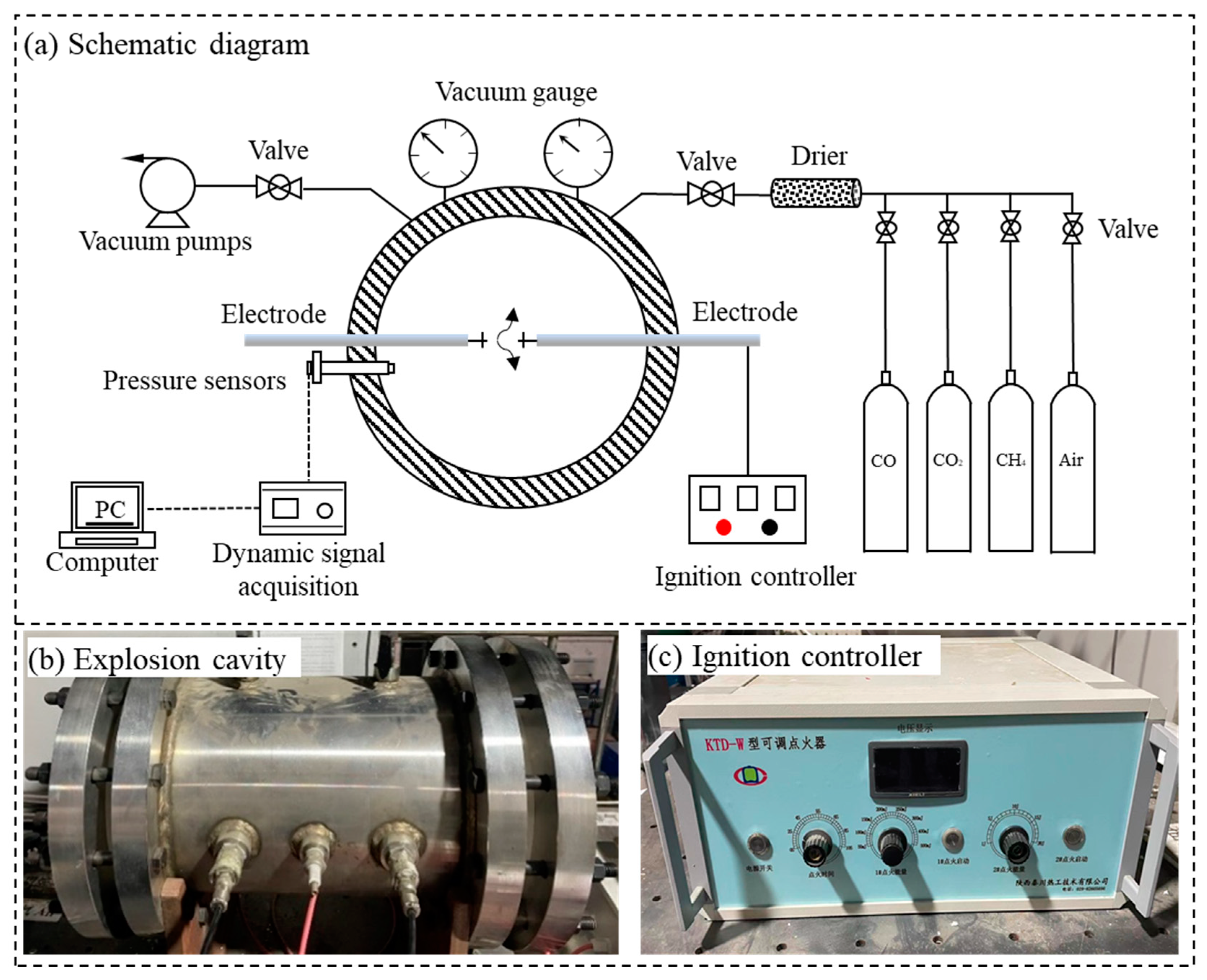

3.1.1. Experimental System

3.1.2. Experimental Process

- (1)

- Experimental preparation: Before the experiment, the line connections and the air tightness of the device were checked separately. The ignition system and explosion overpressure acquisition system were debugged under unpressurized conditions to ensure the normal operation of the testing apparatus.

- (2)

- Vacuuming: The intake valve was closed, the vacuum pump was turned on, the high-precision vacuum pressure gauge was observed, and once the pressure decreased to a stable level, the vacuuming valve was closed.

- (3)

- Gas supply: The partial pressure of each gas according to Dalton’s law was calculated, then sequentially the gas valve was opened and the concentration of each gas was controlled using the vacuum pressure gauge. After completion, the gases were allowed to stand for 10 min to ensure thorough mixing.

- (4)

- Ignition: The explosion overpressure signal acquisition was turned on, then the mixed gas was ignited using the igniter controller.

- (5)

- Exhaust the waste gas: After the explosion ended, the exhaust valve was opened and dry air was introduced into the explosion room via the intake pipe for 30 s to purge any remaining explosive gases inside the chamber.

3.1.3. Experimental Design

3.2. Experiments

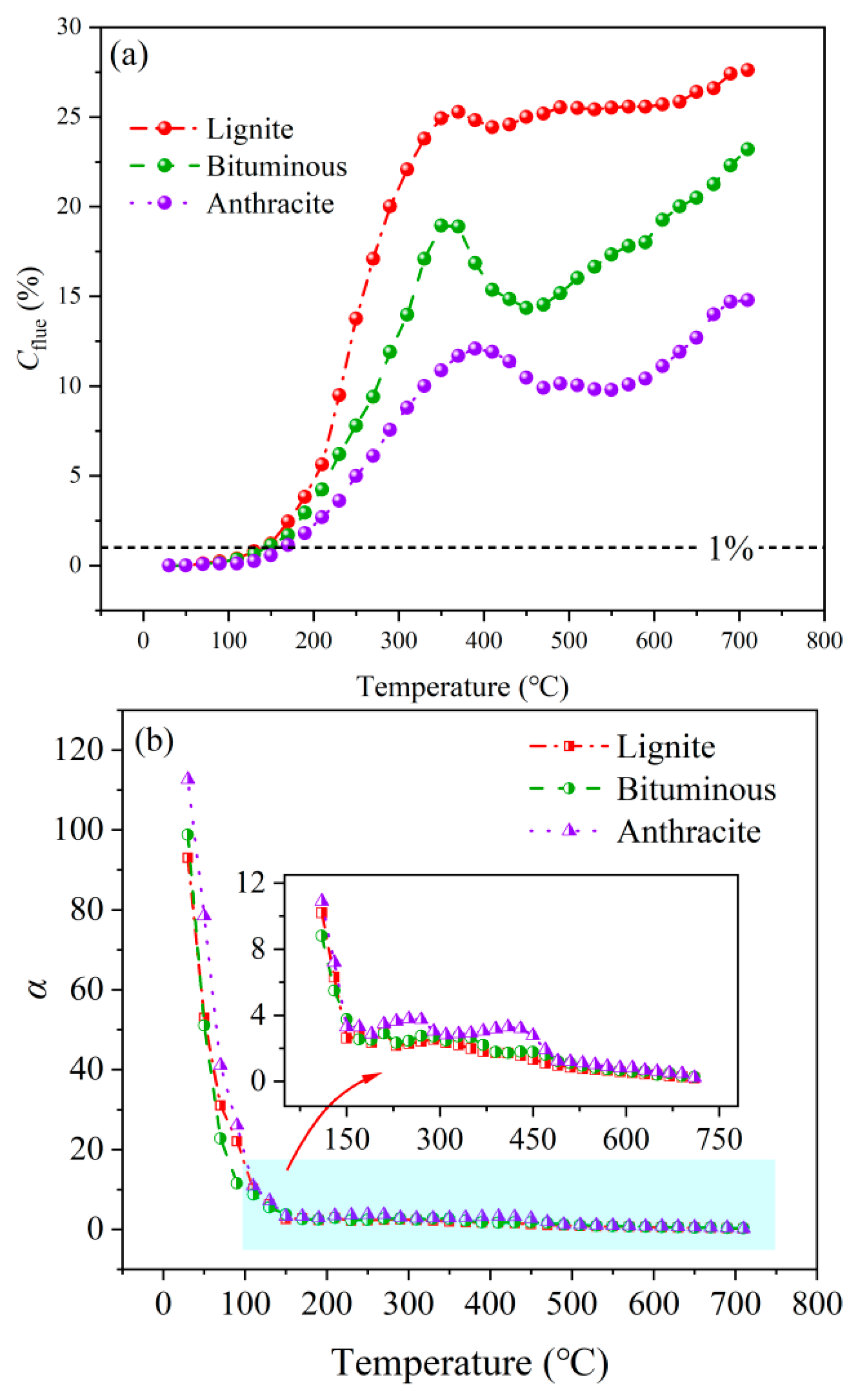

4. Influence of CSC Flue Gas on the Risk of Methane Explosion

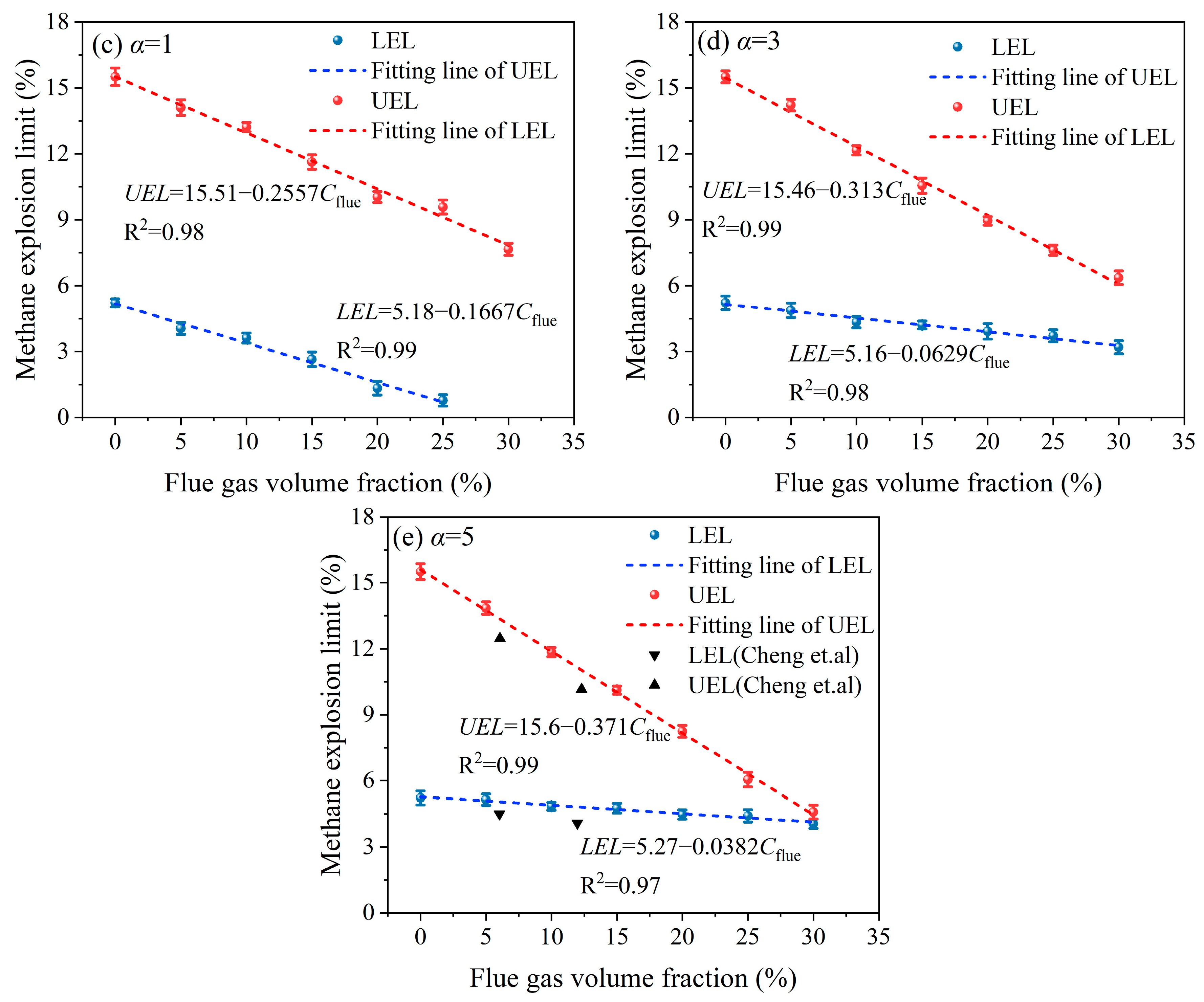

4.1. Influence of Flue Gas on Methane Explosion Limit Range

4.2. Variation Law of Methane Explosion Risk during the Temperature Increasing Process of CSC

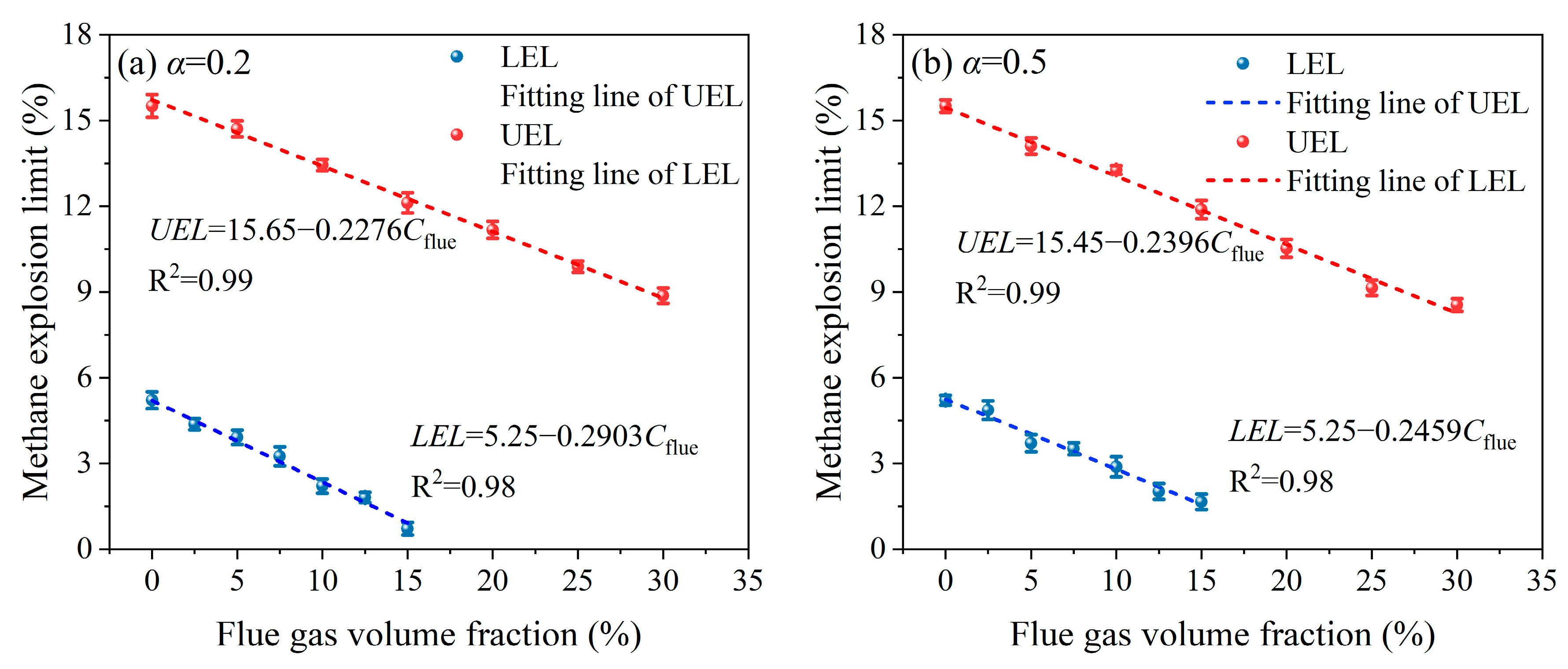

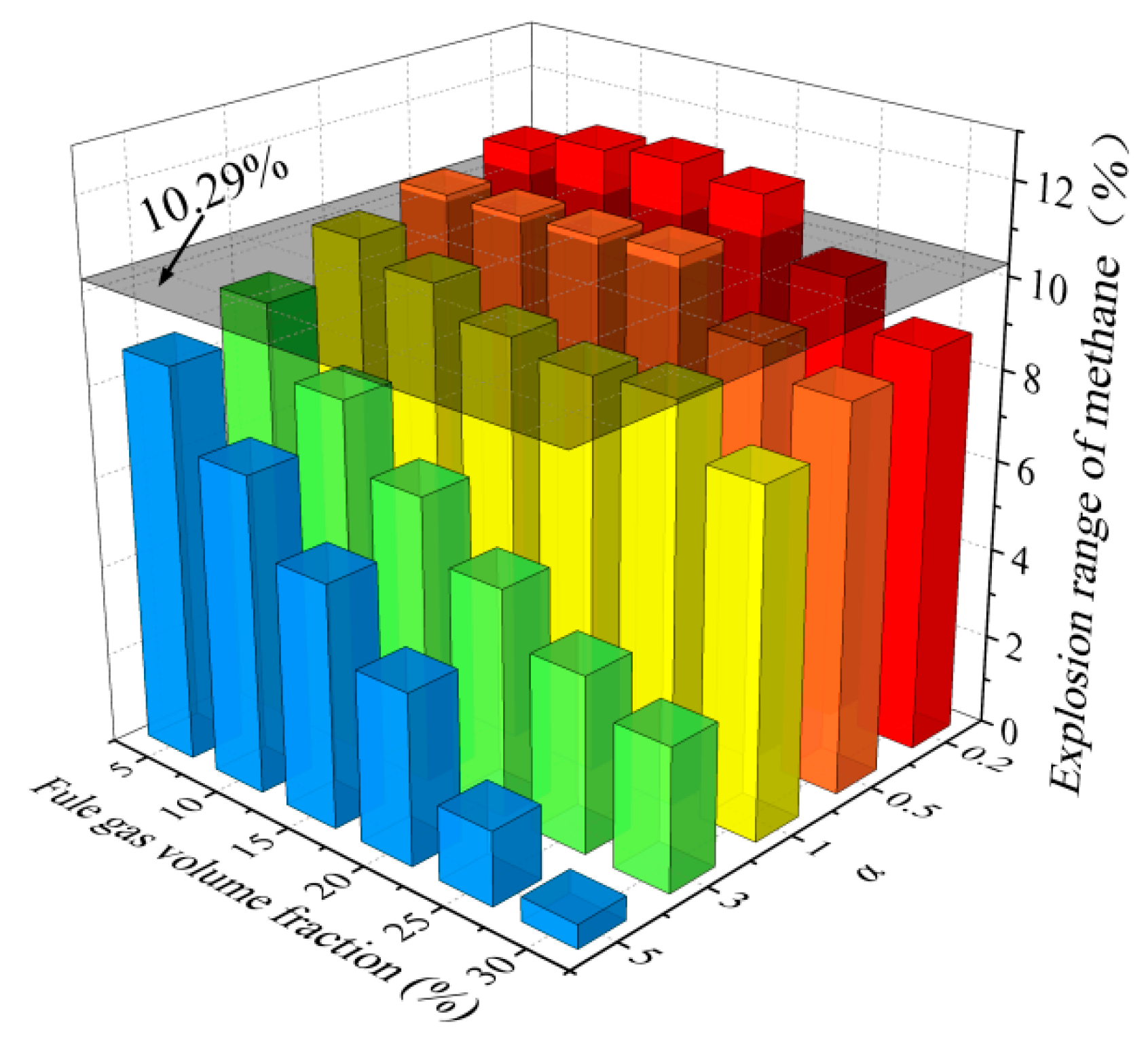

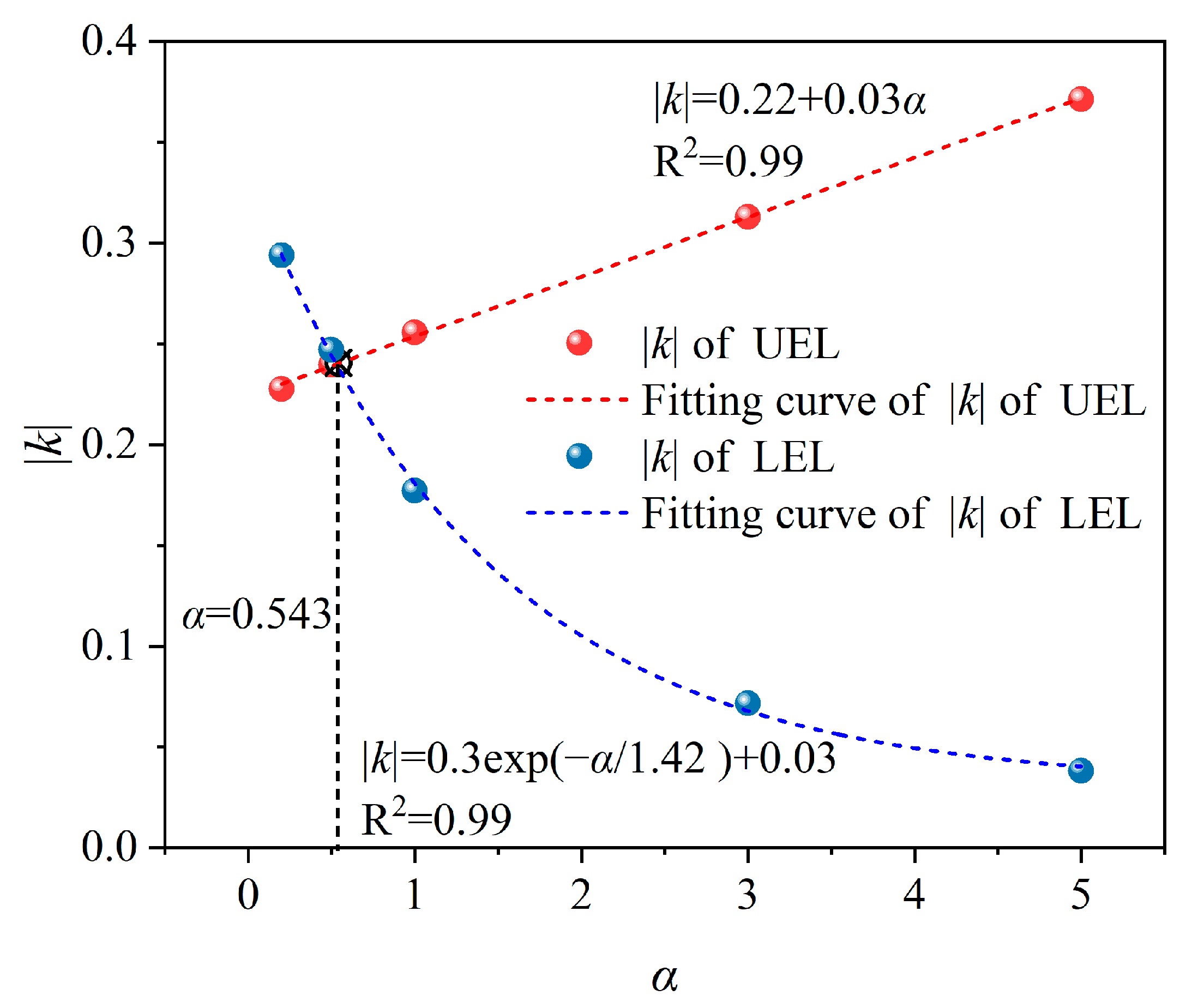

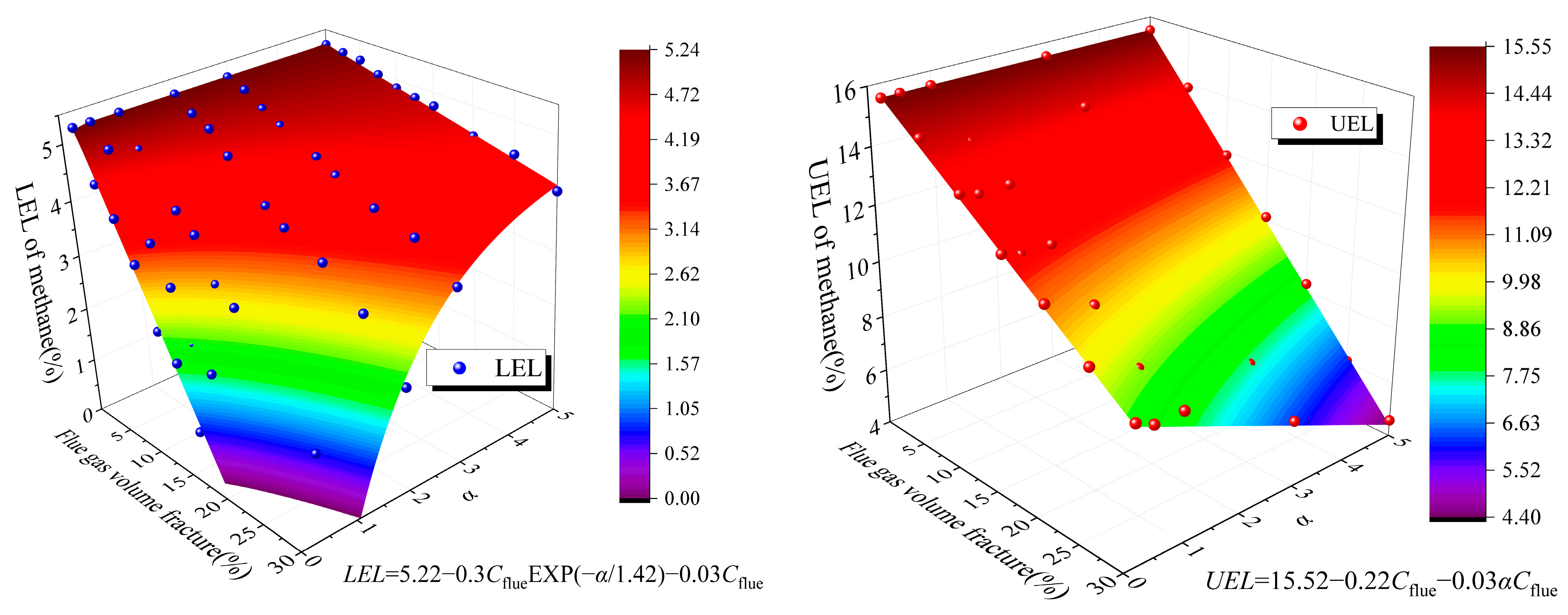

4.2.1. Fitting of Methane Explosion Limits under the Influence of Flue Gas

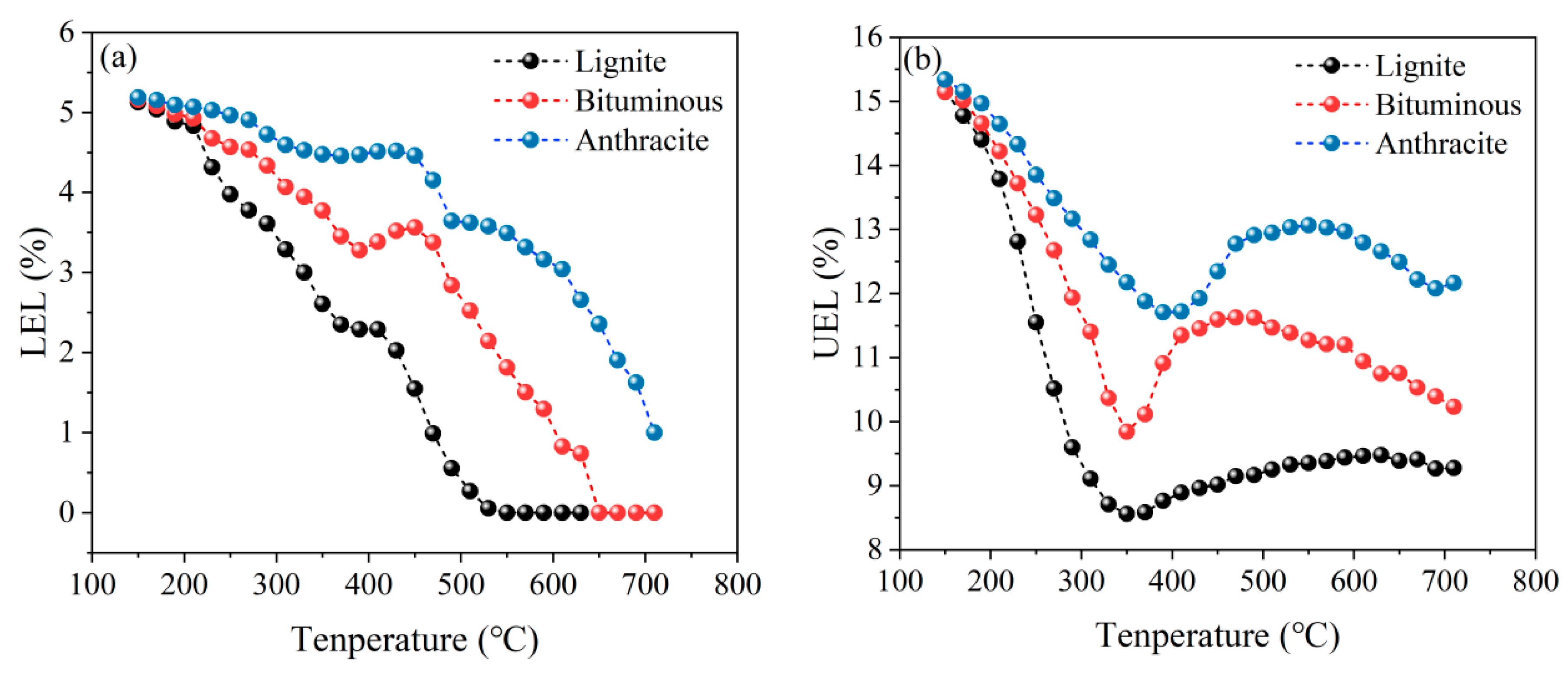

4.2.2. Variation Law of Methane Explosion Limits during the Temperature Increasing Process of CSC

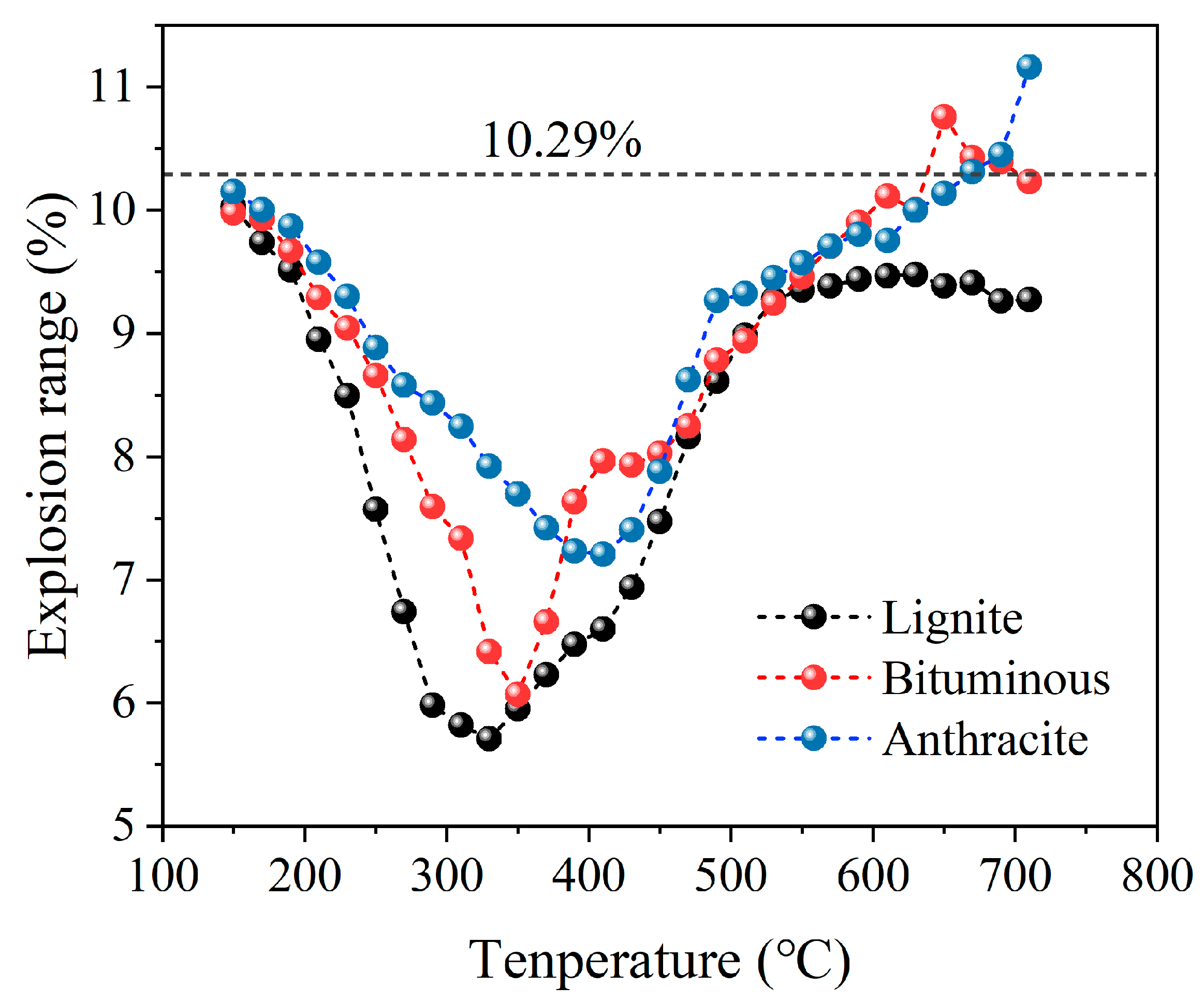

4.2.3. Variation Law of Methane Explosion Limits Range during the Temperature Increasing Process of CSC

5. Conclusions

- (1)

- Throughout the CSC temperature elevation process, CO, CO2, and CH4 are consistently generated in substantial quantities, constituting the primary components of CSC flue gas. They represent the predominant gases that influence the risk of methane explosions. Conversely, C2H4, C2H6, and C3H8 are produced only in minor quantities within the temperature range of 350~550 °C, and their impact on the risk of methane explosions remains limited.

- (2)

- Both the LEL and UEL of methane demonstrate a linear decline with increasing Cflue. The UEL of explosion diminishes with escalating α, whereas the LEL increases with α.

- (3)

- Flue gas characterized by lower α values facilitates an expansion of the range of methane explosion limits, whereas flue gas with higher α values constrains the range of methane explosion limits. α = 0.543 marks the critical threshold at which flue gas transitions from promoting to inhibiting the explosion limit range of methane.

- (4)

- At lower coal temperatures, the influence of flue gas on methane LEL is minimal, while the explosion range is inhibited, culminating in a reduced risk of methane explosion. However, once the coal temperature surpasses 330~410 °C, the risk of methane explosion continues to escalate under the dual effects of a rapid decline in LEL and a continuous increase in the explosion limit range.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alshehry, A.; Belloumi, M. The Symmetric and Asymmetric Impacts of Energy Consumption and Economic Growth on Environmental Sustainability. Sustainability 2024, 16, 205. [Google Scholar] [CrossRef]

- Fouquet, R. The Digitalisation, Dematerialisation and Decarbonisation of the Global Economy in Historical Perspective: The Relationship Between Energy and Information Since 1850. Environ. Res. Lett. 2024, 19, 014043. [Google Scholar] [CrossRef]

- Wang, X.; Lu, Y.; Chen, C.; Yi, X.; Cui, H. Total-factor Energy Efficiency of Ten Major Global Energy-consuming Countries. J. Environ. Sci. 2024, 137, 41–52. [Google Scholar] [CrossRef]

- Zhang, X.; Jian, S.; Lin, B.; Zhu, C. Study on the Influence of Different-voltage Plasma Breakdowns on Functional Group Structures in Coal. Energy 2023, 284, 128768. [Google Scholar] [CrossRef]

- Liu, T.; Li, M.; Zou, Q.; Li, J.; Lin, M.; Lin, B. Crack Instability in Deep Coal Seam Induced By the Coupling of Mining Unloading and Gas Driving and Transformation of Failure Mode. Int. J. Rock Mech. Min. Sci. 2023, 170, 105526. [Google Scholar] [CrossRef]

- Li, B.; Wang, E.; Li, Z.; Cao, X.; Liu, X.; Zhang, M. Automatic Recognition of Effective and Interference Signals Based on Machine Learning: A Case Study of Acoustic Emission and Electromagnetic Radiation. Int. J. Rock Mech. Min. Sci. 2023, 170, 105505. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, S.; Xue, S.; Jiang, B.; Ren, B.; Zhao, Y. Study on the Evolution Characteristics of Coal Spontaneous Combustion and Gas Coupling Disaster Region in Goaf. Fuel 2023, 349, 128505. [Google Scholar] [CrossRef]

- Duan, H.; Zhao, L.; Yang, H.; Zhang, Y.; Xia, H. Development of 3D Top Coal Caving Angle Model for Fully Mechanized Extra-thick Coal Seam Mining. Int. J. Min. Sci. Technol. 2022, 32, 1145–1152. [Google Scholar] [CrossRef]

- Liu, Q.; Lin, B.; Zhou, Y.; Li, Y. Permeability and Inertial Resistance Coefficient Correction Model of Broken Rocks in Coal Mine Goaf. Powder Technol. 2021, 384, 247–257. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Q.; Zhu, P.; Li, X.; Zhang, G.; Ma, X.; Zhao, Y. Study on Multi-field Evolution and Influencing Factors of Coal Spontaneous Combustion in Goaf. Combust. Sci. Technol. 2023, 195, 247–264. [Google Scholar] [CrossRef]

- Ma, D.; Qin, B.; Li, L.; Gao, A.; Gao, Y. Study on the Methane Explosion Regions Induced By Spontaneous Combustion of Coal in Longwall Gobs Using a Scaled-down Experiment Set-up. Fuel 2019, 254, 115547. [Google Scholar] [CrossRef]

- Gao, A.; Qin, B.; Zhang, L.; Ma, D.; Li, L. Experimental Study on Gas Migration Laws at Return Air Side of Goaf Under High-temperature Conditions. Combust. Sci. Technol. 2023, 195, 1930–1944. [Google Scholar] [CrossRef]

- Bai, G.; Li, X.; Zhou, X.; Wang, J.; Linghu, J. Evaluation of Lignite Combustion Characteristics and Gas Explosion Risks Under Different Air Volumes. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–15, 1770375. [Google Scholar] [CrossRef]

- Ma, D.; Qin, B.; Zhong, X.; Sheng, P.; Yin, C. Effect of Flammable Gases Produced From Spontaneous Smoldering Combustion of Coal on Methane Explosion in Coal Mines. Energy 2023, 279, 128125. [Google Scholar] [CrossRef]

- Zhuo, H.; Qin, B.; Qin, Q. The Impact of Surface Air Leakage on Coal Spontaneous Combustion Hazardous Zone in Gob of Shallow Coal Seams: A Case Study of Bulianta Mine, China. Fuel 2021, 295, 120636. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Liu, C.; Zhang, N. Study on the Air Leakage Characteristics of a Goaf in a Shallow Coal Seam and Spontaneous Combustion Prevention and Control Strategies for Residual Coal. PLoS ONE 2022, 17, e0269822. [Google Scholar]

- Yang, Y.; Fei, J.; Luo, Z.; Wen, H.; Wang, H. Experimental Study on Characteristic Temperature of Coal Spontaneous Combustion. J. Therm. Anal. Calorim. 2023, 148, 10011–10019. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Y.; Dai, L.; Wang, K.; Cheng, G. Mechanisms of CO and CO2 Production During the Low-temperature Oxidation of Coal: Molecular Simulations and Experimental Research. Fire 2023, 6, 475. [Google Scholar] [CrossRef]

- Hao, Q.; Luo, Z.; Wang, T.; Xie, C.; Zhang, S.; Bi, M.; Deng, J. The Flammability Limits and Explosion Behaviours of Hydrogen-enriched Methane-air Mixtures. Exp. Therm. Fluid Sci. 2021, 126, 110395. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, X.; Bai, G.; Li, C. Influence of CO on Explosion Limits and Characteristics of the CH4/air Mixture. ACS Omega 2022, 7, 24766–24776. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Shan, Q. Influence of Gas From Long-flame Coal Spontaneous Combustion on Gas Explosion Limit. Int. J. Chem. Eng. 2023, 2023, 5096109. [Google Scholar] [CrossRef]

- Luo, Z.; Liang, H.; Wang, T.; Cheng, F.; Su, B.; Liu, L.; Liu, B. Evaluating the Effect of Multiple Flammable Gases on the Flammability Limit of CH4: Experimental Study and Theoretical Calculation. Process Saf. Environ. Prot. 2021, 146, 369–376. [Google Scholar] [CrossRef]

- Li, H.; Chen, X.; Shu, C.M.; Wang, Q.; Ma, T.; Bin, L. Effects of Oxygen Concentration on the Macroscopic Characteristic Indexes of High-temperature Oxidation of Coal. J. Energy Inst. 2019, 92, 554–566. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, T.; Deng, J.; Shu, C.M.; Zeng, Q.; Guo, T.; Zhang, Y. Microcharacteristic Analysis of CH4 Emissions Under Different Conditions During Coal Spontaneous Combustion with High-temperature Oxidation and in Situ Ftir. Energy 2020, 209, 118494. [Google Scholar] [CrossRef]

- Robinson, C.; Smith, D.B. The Auto-ignition Temperature of Methane. J. Hazard. Mater. 1984, 8, 199–203. [Google Scholar] [CrossRef]

- Wang, K. An Approach for Evaluation of Grading Forecasting Index of Coal Spontaneous Combustion By Temperature-programmed Analysis. Environ. Sci. Pollut. Res. 2023, 30, 3970–3979. [Google Scholar] [CrossRef] [PubMed]

- Ji, W.; Wang, Y.; Yang, J.; He, J.; Wen, X. Methods to Predict Variations of Lower Explosion Limit Associated with Hybrid Mixtures of Flammable Gas and Dust. Fuel 2022, 310, 122138. [Google Scholar] [CrossRef]

- Wang, G.; Shi, G.; Yang, Y.; Liu, S. Experimental Study on the Exogenous Fire Evolution and Flue Gas Migration During the Fire Zone Sealing Period of the Coal Mining Face. Fuel 2022, 320, 123879. [Google Scholar] [CrossRef]

- Nie, B.; Peng, C.; Gong, J.; Yin, F.; Wang, K. Explosion Characteristics and Energy Utilisation of Coal Mine Ultra-lean Methane. Combust. Theory Model. 2021, 25, 73–95. [Google Scholar] [CrossRef]

- Jiao, F.; Zhang, H.; Li, W.; Zhao, Y.; Guo, J.; Zhang, X.; Zhang, Y. Experimental and Numerical Study of the Influence of Initial Temperature on Explosion Limits and Explosion Process of Syngas-air Mixtures. Int. J. Hydrogen Energy 2022, 47, 22261–22272. [Google Scholar] [CrossRef]

- European Committee for Standardisation. Determination of Explosion Limits of Gases and Vapours: BS EN 1839:2012 [S]; BIS Standards Publication: Brussels, Belgium, 2012; p. 7. [Google Scholar]

- Zhu, X.; Zhou, J.; Guo, Z.; Zhang, X. CO2 Suppression of Methane/air Explosion Flame and Pressure Coupling Analysis. Fresenius Environ. Bull. 2022, 31, 4995–5003. [Google Scholar]

- Luo, Z.; Su, Y.; Li, R.; Chen, X.; Wang, T. Effect of Inert Gas CO2 on Deflagration Pressure of CH4/CO. ACS Omega 2020, 5, 23002–23008. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.; Cheng, F.; Song, Y.; Luo, Z.; Zhang, Y. Experimental and Simulation Studies on the Influence of Carbon Monoxide on Explosion Characteristics of Methane. J. Loss Prev. Process Ind. 2015, 36, 45–53. [Google Scholar] [CrossRef]

- Cheng, F.; Deng, J. Experimental study on the influence of carbon monoxide on carbon dioxide-inerted methane explosion. Xian Univ. Sci. Technol. 2016, 36, 315–319. [Google Scholar]

- Wang, T.; Zhou, Y.; Luo, Z.; Wen, H.; Zhao, J.; Su, B.; Deng, J. Flammability Limit Behavior of Methane with the Addition of Gaseous Fuel at Various Relative Humidities. Process Saf. Environ. Prot. 2020, 140, 178–189. [Google Scholar] [CrossRef]

- Sun, Y.; Qian, X.; Yuan, M.; Zhang, Q.; Li, Z. Investigation on the Explosion Limits and Flame Propagation Characteristics of Premixed Methanol-gasoline Blends. Case Stud. Therm. Eng. 2021, 26, 101000. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Chen, C.; Wang, P.; Xu, L. Experimental Study to Assess the Explosion Hazard of CH4/coal Dust Mixtures Induced by High-temperature Source Surface. Process Saf. Environ. Prot. 2021, 154, 60–71. [Google Scholar] [CrossRef]

- Li, L.; Liu, T.; Li, Z.; Chen, X.; Wang, L.; Feng, S. Different Prevention Effects of Ventilation Dilution on Methane Accumulation at High Temperature Zone in Coal Mine Goafs. Energies 2023, 16, 3168. [Google Scholar] [CrossRef]

- Deng, L.; Lei, C.; Xiao, Y.; Cao, K.; Ma, L.; Wang, W.; Bin, L. Determination and Prediction on “three Zones” of Coal Spontaneous Combustion in a Gob of Fully Mechanized Caving Face. Fuel 2018, 211, 458–470. [Google Scholar] [CrossRef]

- Ma, D.; Qin, B.; Gao, Y.; Jiang, J.; Feng, B. An Experimental Study on the Methane Migration Induced By Spontaneous Combustion of Coal in Longwall Gobs. Process Saf. Environ. Prot. 2021, 147, 292–299. [Google Scholar] [CrossRef]

| Coal Samples | Proximate Analysis (w/w %) | Vitrinite Reflectance R0, max (%) | |||

|---|---|---|---|---|---|

| Mad | Aad | Vdaf | FCad | ||

| Lignite | 11.37 | 14.63 | 53.41 | 20.59 | 0.32 |

| Bituminous | 1.16 | 9.37 | 24.60 | 64.87 | 1.22 |

| Anthracite | 2.18 | 15.45 | 6.64 | 75.73 | 3.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Li, Y.; Zhu, C.; Lin, B.; Li, Q.; Li, B.; Huang, Z. Investigating the Influence of Flue Gas Induced by Coal Spontaneous Combustion on Methane Explosion Risk. Fire 2024, 7, 105. https://doi.org/10.3390/fire7040105

Hu S, Li Y, Zhu C, Lin B, Li Q, Li B, Huang Z. Investigating the Influence of Flue Gas Induced by Coal Spontaneous Combustion on Methane Explosion Risk. Fire. 2024; 7(4):105. https://doi.org/10.3390/fire7040105

Chicago/Turabian StyleHu, Sijia, Yanjun Li, Chuanjie Zhu, Baiquan Lin, Qingzhao Li, Baolin Li, and Zichao Huang. 2024. "Investigating the Influence of Flue Gas Induced by Coal Spontaneous Combustion on Methane Explosion Risk" Fire 7, no. 4: 105. https://doi.org/10.3390/fire7040105

APA StyleHu, S., Li, Y., Zhu, C., Lin, B., Li, Q., Li, B., & Huang, Z. (2024). Investigating the Influence of Flue Gas Induced by Coal Spontaneous Combustion on Methane Explosion Risk. Fire, 7(4), 105. https://doi.org/10.3390/fire7040105