Effect of Combining Fungal and Flame-Retardant Coatings on the Thermal Degradation of Spruce and Beech Wood Under Flame Loading

Abstract

1. Introduction

- Retarders releasing non-flammable gases;

- Heat-accumulating retardants;

- Intumescent retardants;

- Mechanical-type retardants.

- Inorganic salts;

- Alkaline earth metal hydroxides;

- Bromine compounds.

2. Materials and Methods

2.1. Experimental Samples of Spruce and Beech

- Norway Spruce (Picea abies (L.) Karst.)

- European Beech (Fagus sylvatica L.)

| Parameters | Spruce | Beech | |

|---|---|---|---|

| Fire-Technical Characteristics | |||

| Flash point [°C] | The stated values are valid at 15% moisture. | 350 ÷ 360 | 360–370 |

| Ignition temperature [°C] | 390 ÷ 400 | 400–410 | |

| Specific heat (calorific value) | 19.9 | 19.8 | |

| Mass loss rate [kg m−2] | 0.056 | 0.066 | |

| Physical properties | |||

| Wood density [kg m−3] | In absolutely dry state | 300–640 | 490–910 |

| Fresh | 740 | 990 | |

| Experimentally determined weight [kg] | 295.1 ± 11.2 | 421.17 ± 7.6 | |

| Mechanical properties | |||

| Tensile strength [MPa] | Parallel to the fibers | 90.0 | 135.0 |

| Perpendicular to the fibers | 2.7 | 10.7 | |

| Compressive strength [MPa] | Parallel to the fibers | 50.0 | 56.3 |

| Perpendicular to the fibers | 4.0 | 11.4 | |

2.2. Experimental Samples—Protective Coatings

2.3. Preparation of Samples for Flame Initiation Monitoring

- Conditioning and Drying: From 1 July 2020 to 15 July 2020, spruce (marked as SP) and beech (marked as BCH) samples were conditioned and then dried (drying plant, Airtechno, Nová Dubnica nad Váhom, Slovakia). The sample mass was measured using digital scales with an accuracy of 0.001 g (Mettler Toledo, Columbus, OH, USA).

- Sample Division and Coating: After mass stabilization, the samples were divided into three groups: the first group consisted of untreated samples, the second group was coated with a flame retardant (designated as FR), and the third group was successively treated with fungicidal coatings. The coatings, labelled FR, Bio, and Fun (Table 2), are water-dilutable (Table 3) and were applied in two coats. The drying time for the coatings was determined according to the manufacturers’ guidelines.

- Storage: All samples were stored for 10 days.

- Long-Term Storage: The samples were Then stored for 8 months, both indoors (lumber storage) and outdoors (wood storage shed), from August 2020 to March 2021.

- Mass Loss Rate Testing: Experimental determination of the mass loss rate began on 1 April 2021. In Table 4 are intentionally highlighted samples that were actually exposed to the flame; SP (spruce) wood samples are green and BCH (beech) wood samples are blue.

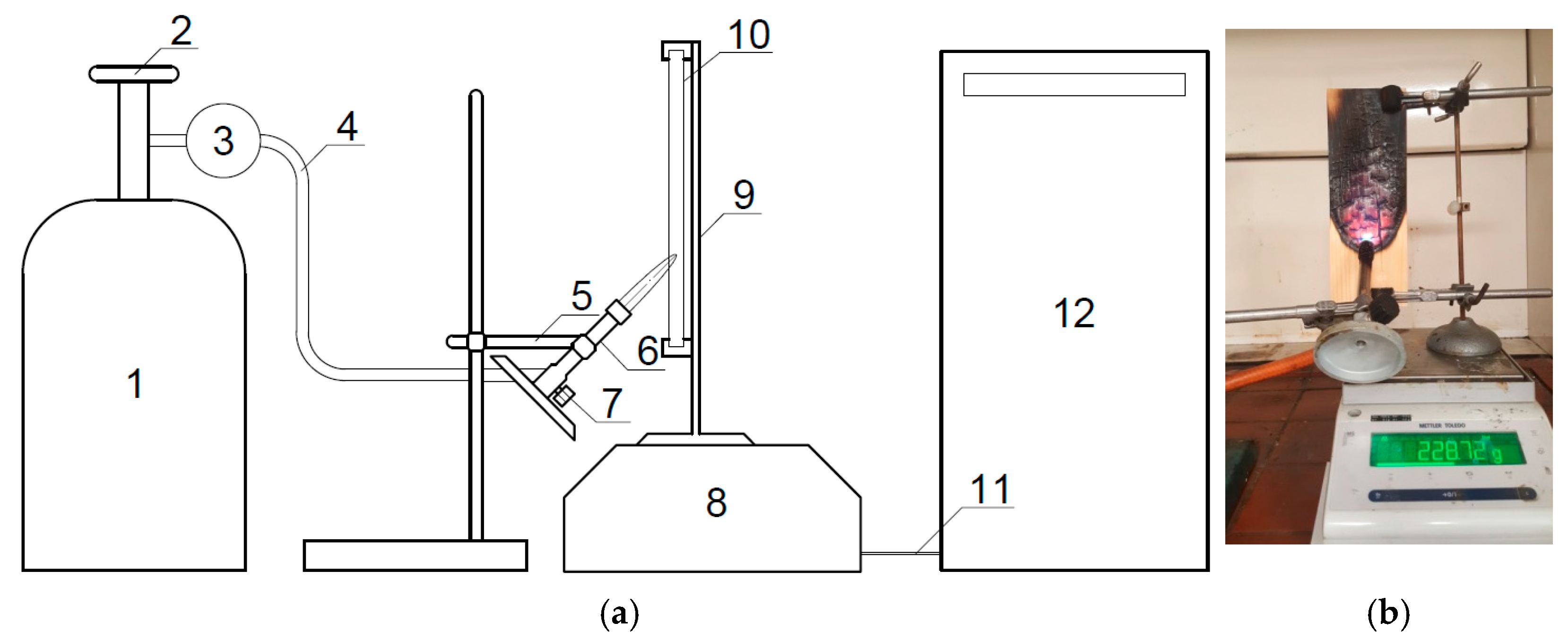

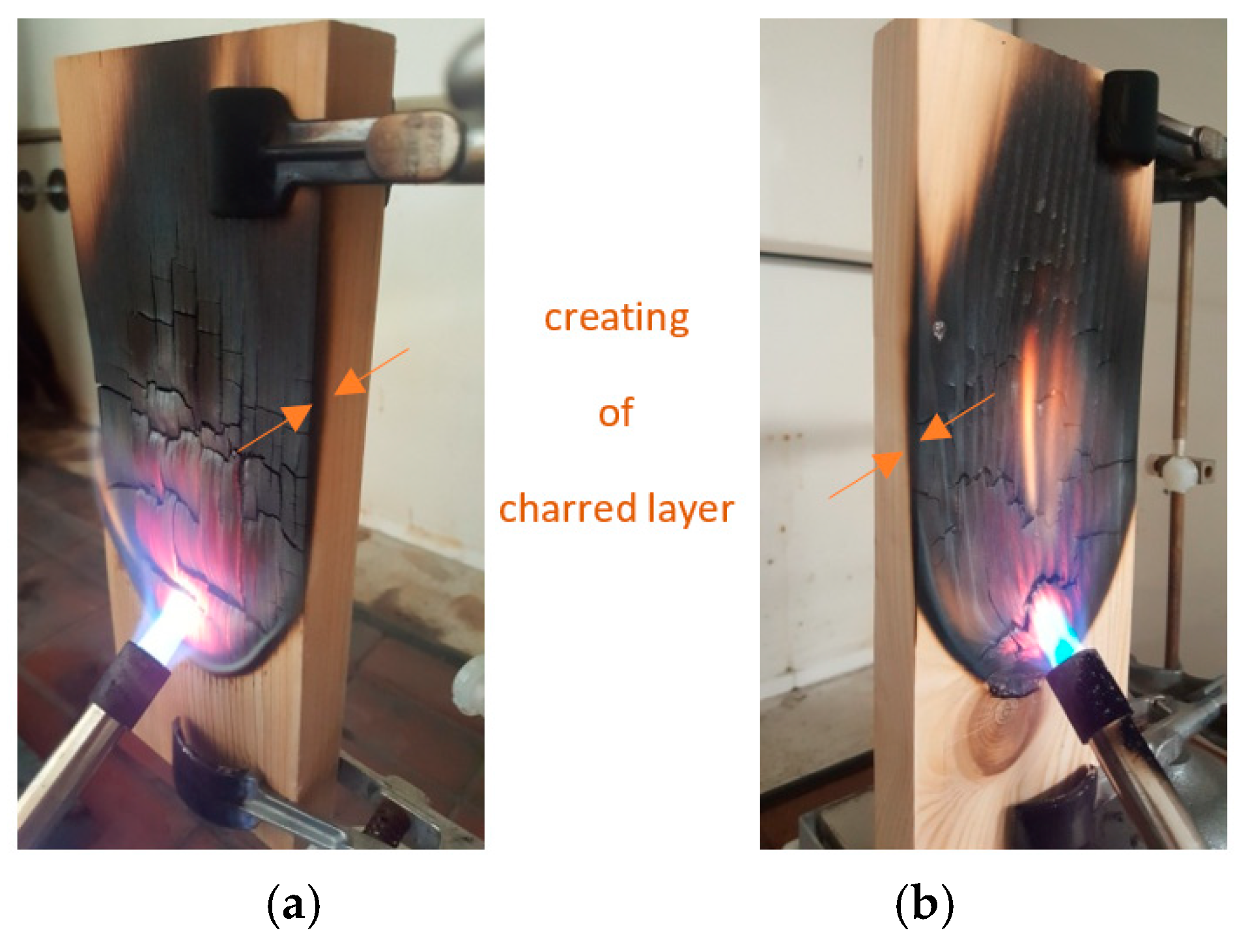

2.4. Experimental Determination of Mass Loss Rate Using a Small Ignition Source—Bunsen Burner

- Mass loss of the sample;

- Thickness of the charred layer;

- Temperature curve (temperatures were recorded every 30 s) of the sample mass loss as a function of the exposure time.

3. Results

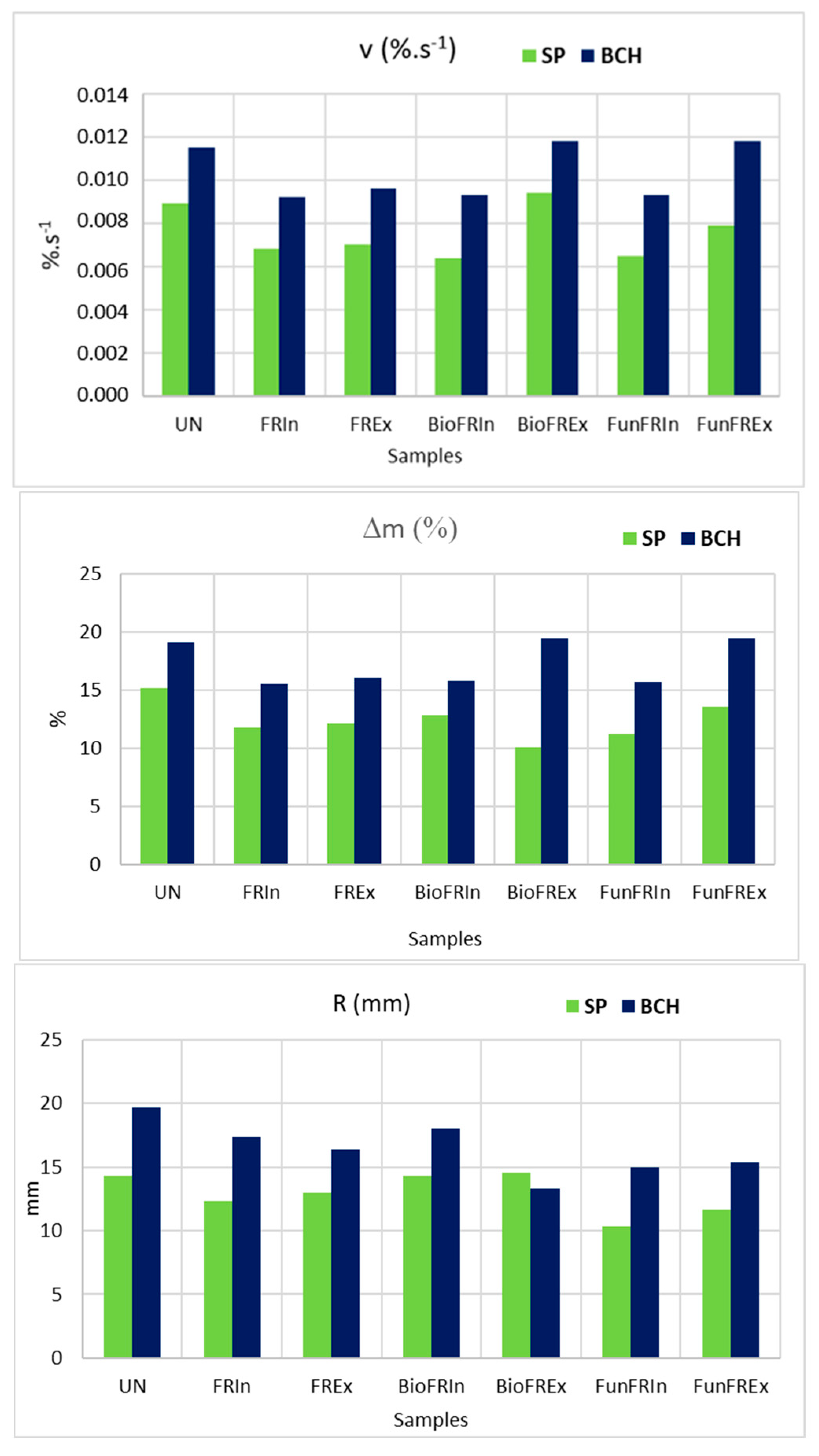

| Sample Treatment | Samples | |||||||

|---|---|---|---|---|---|---|---|---|

| Spruce | Beech | |||||||

| Designation | Δm (g) | v (%.s−1) | R (mm) | Designation | Δm (g) | v (%.s−1) | R (mm) | |

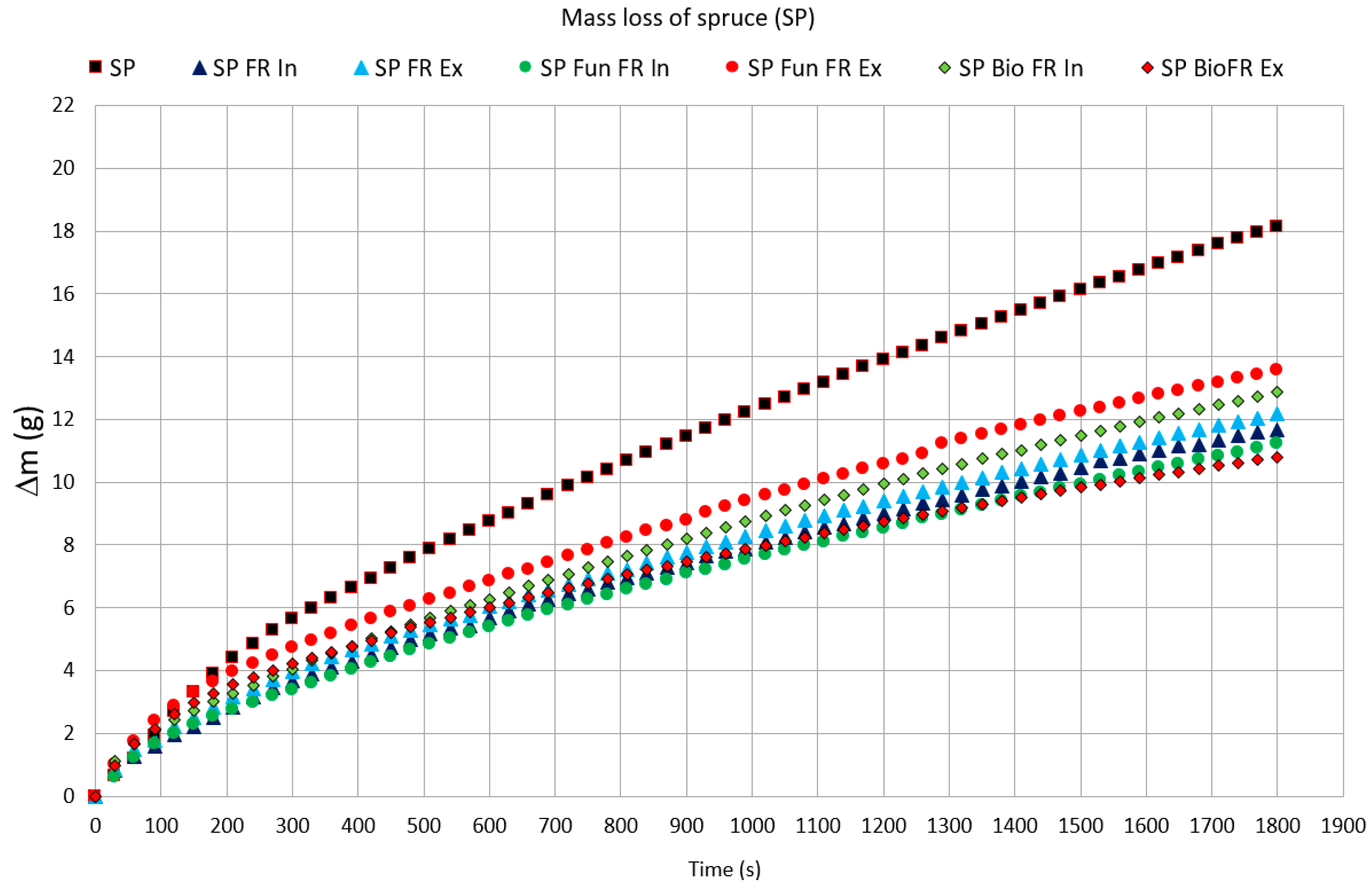

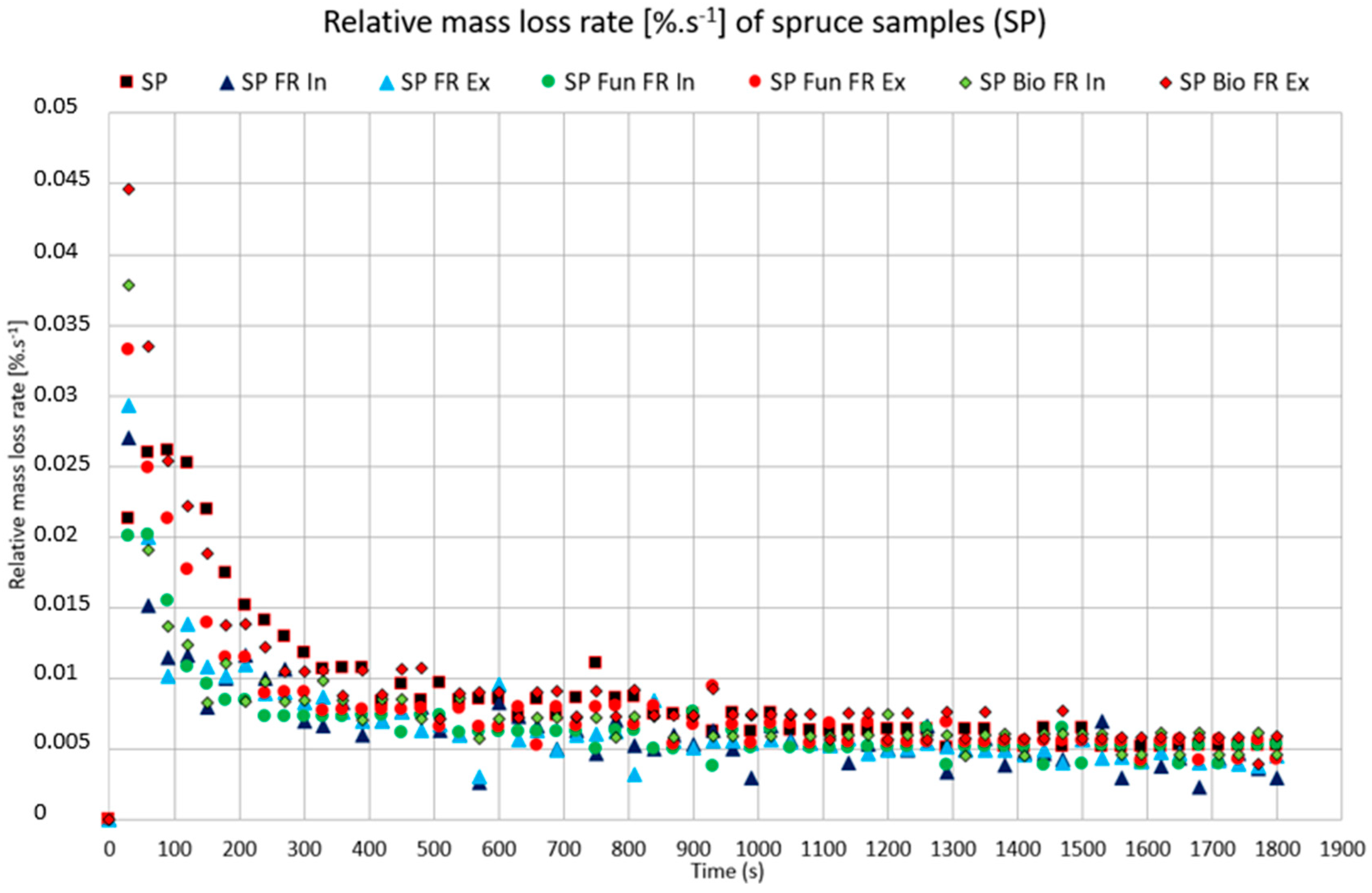

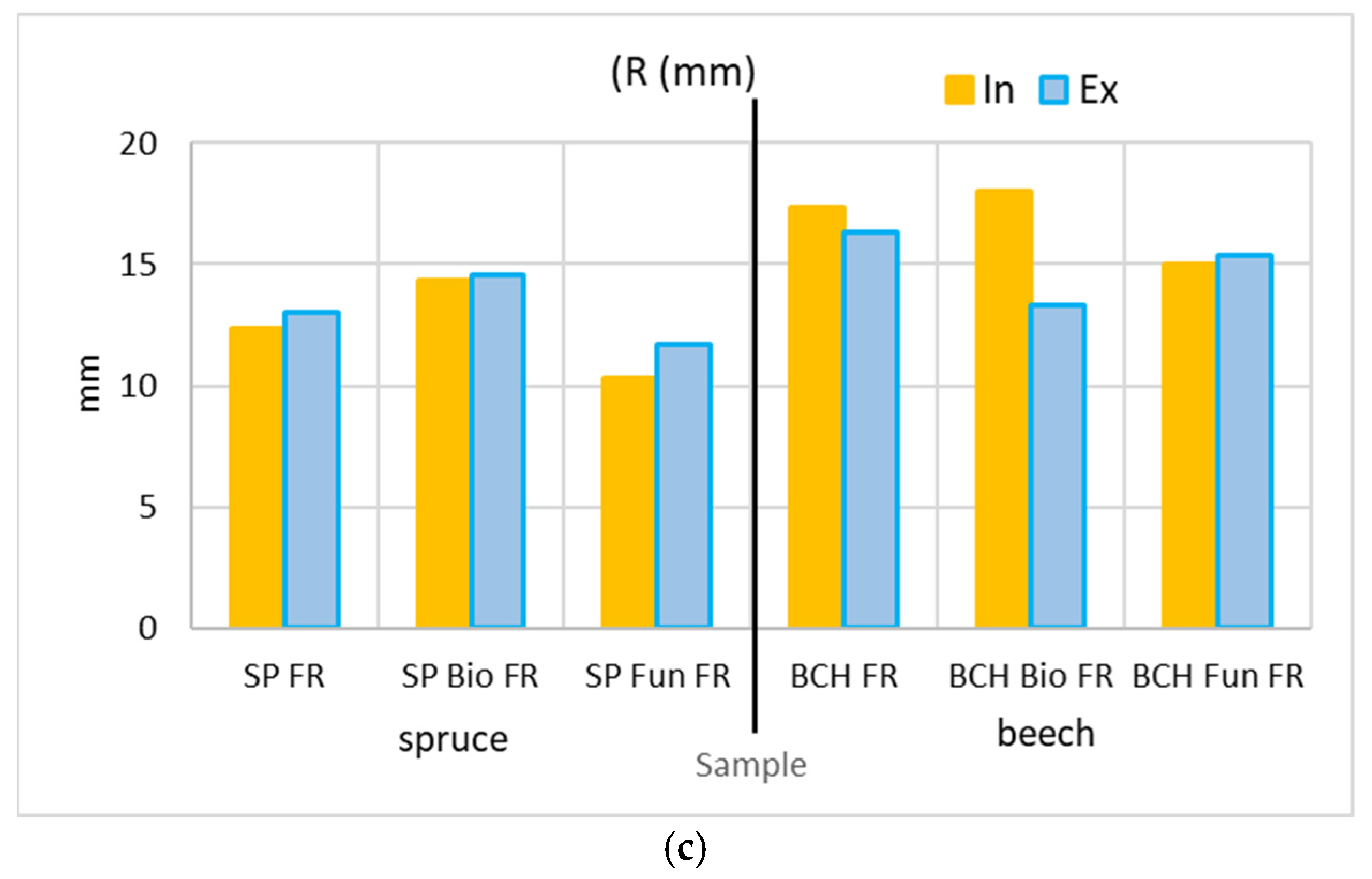

| Untreated | SP | 15.130 | 0.0089 | 14.34 | BCH | 19.086 | 0.0115 | 19.67 |

| Treated with fire retardant FR, stored indoors | SPFRIn | 11.746 | 0.0068 | 12.33 | BCHFRIn | 15.502 | 0.0092 | 17.34 |

| Treated with fire retardant FR, stored outdoors | SPFREx | 12.079 | 0.0070 | 13.00 | BCHFREx | 16.078 | 0.0096 | 16.34 |

| Treated with fungicide coating Bio and fire-retardant FR, stored indoors | SPBioFRIn | 12.859 | 0.0064 | 14.34 | BCHBioFRIn | 15.740 | 0.0093 | 18.00 |

| Treated with fungicide coating Bio and fire-retardant FR, stored outdoors | SPBioFREx | 10.081 | 0.0094 | 14.54 | BCHBioFREx | 19.461 | 0.0118 | 13.34 |

| Treated with fungicide coating Fun and fire-retardant FR, stored indoors | SPFunFRIn | 11.22 | 0.0065 | 10.30 | BCHFunFRIn | 15.671 | 0.0093 | 15.00 |

| Treated with fungicide coating Fun and fire-retardant FR, stored outdoors | SPFunFREx | 13.568 | 0.0079 | 11.67 | BCHFunFREx | 19.481 | 0.0118 | 15.34 |

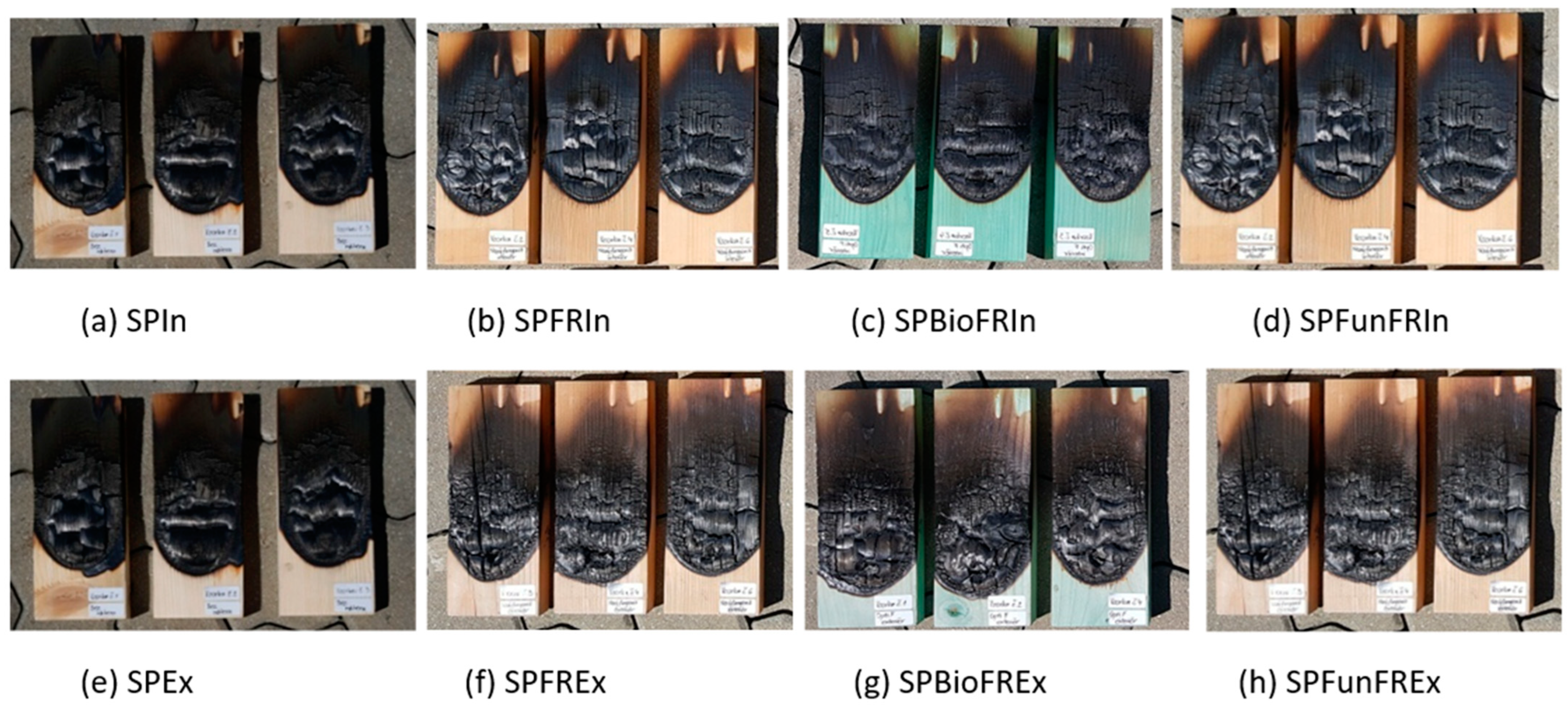

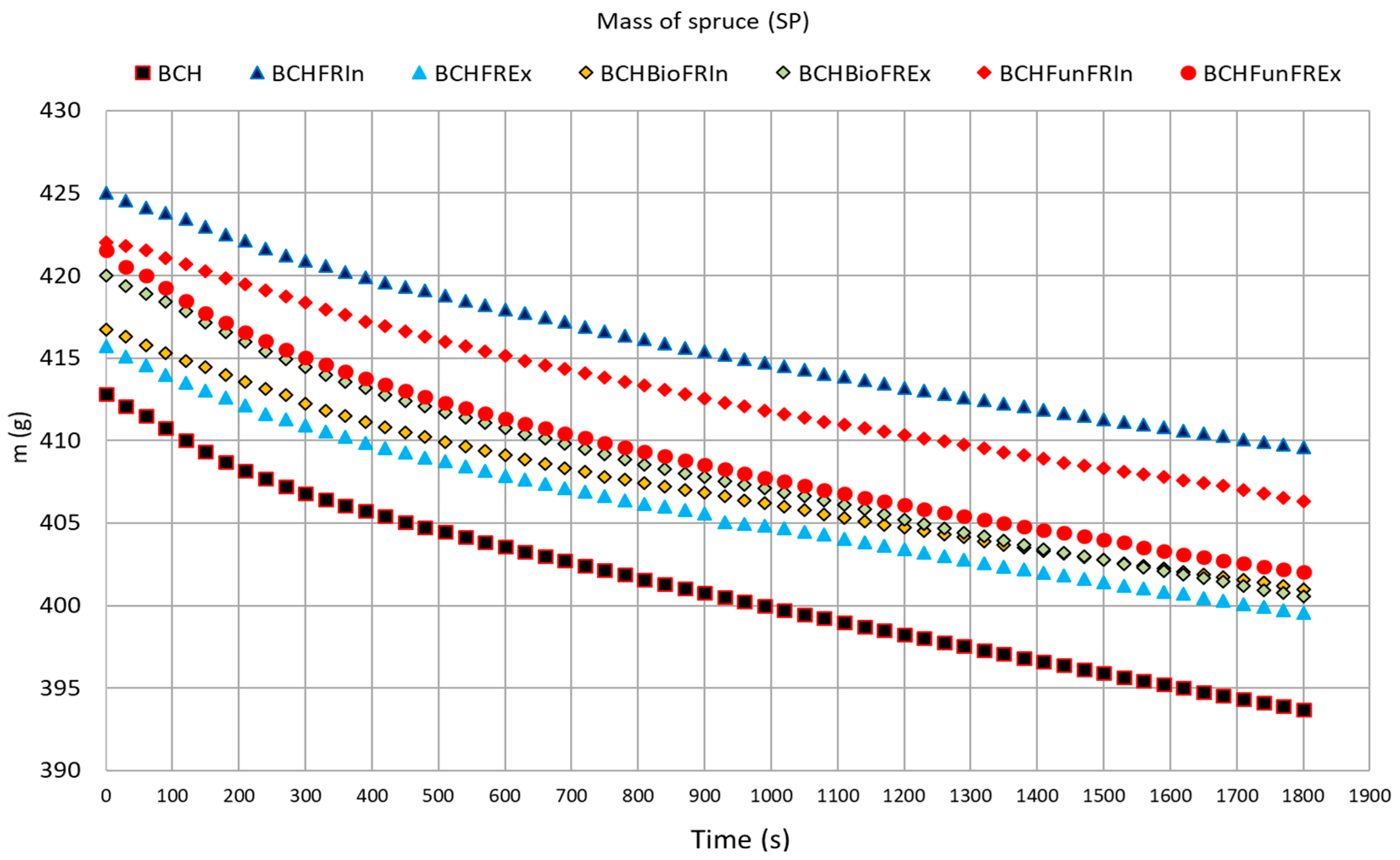

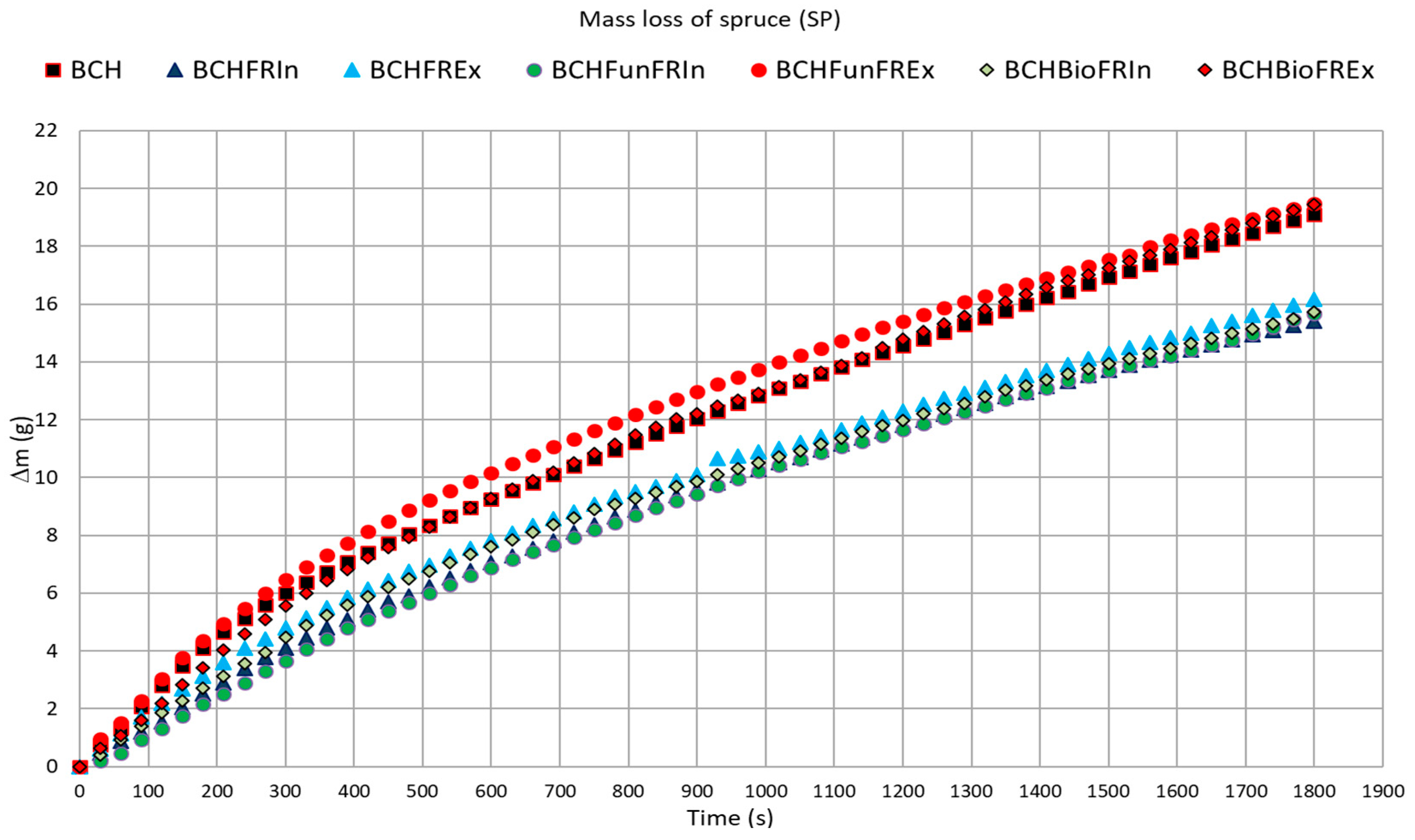

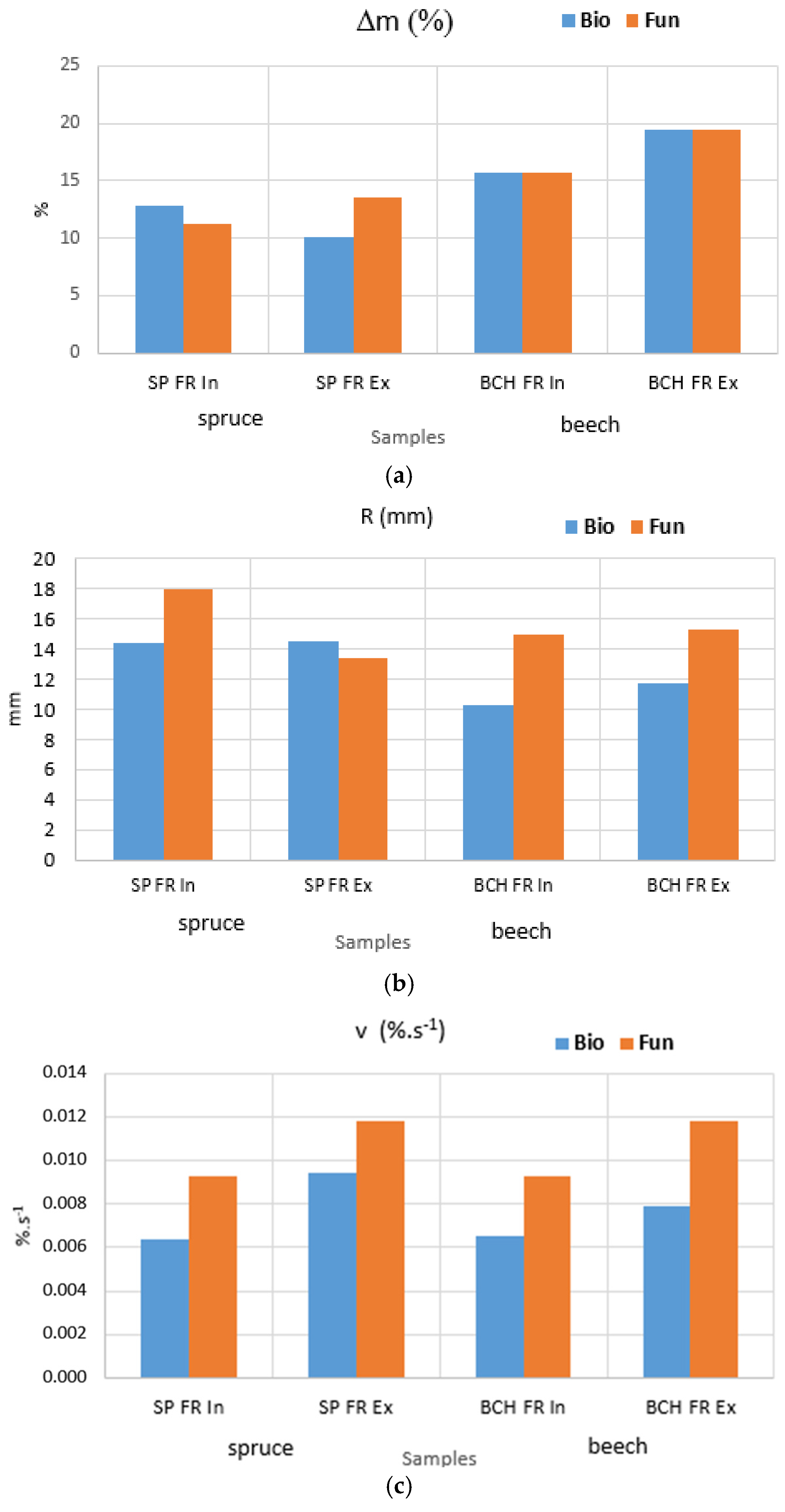

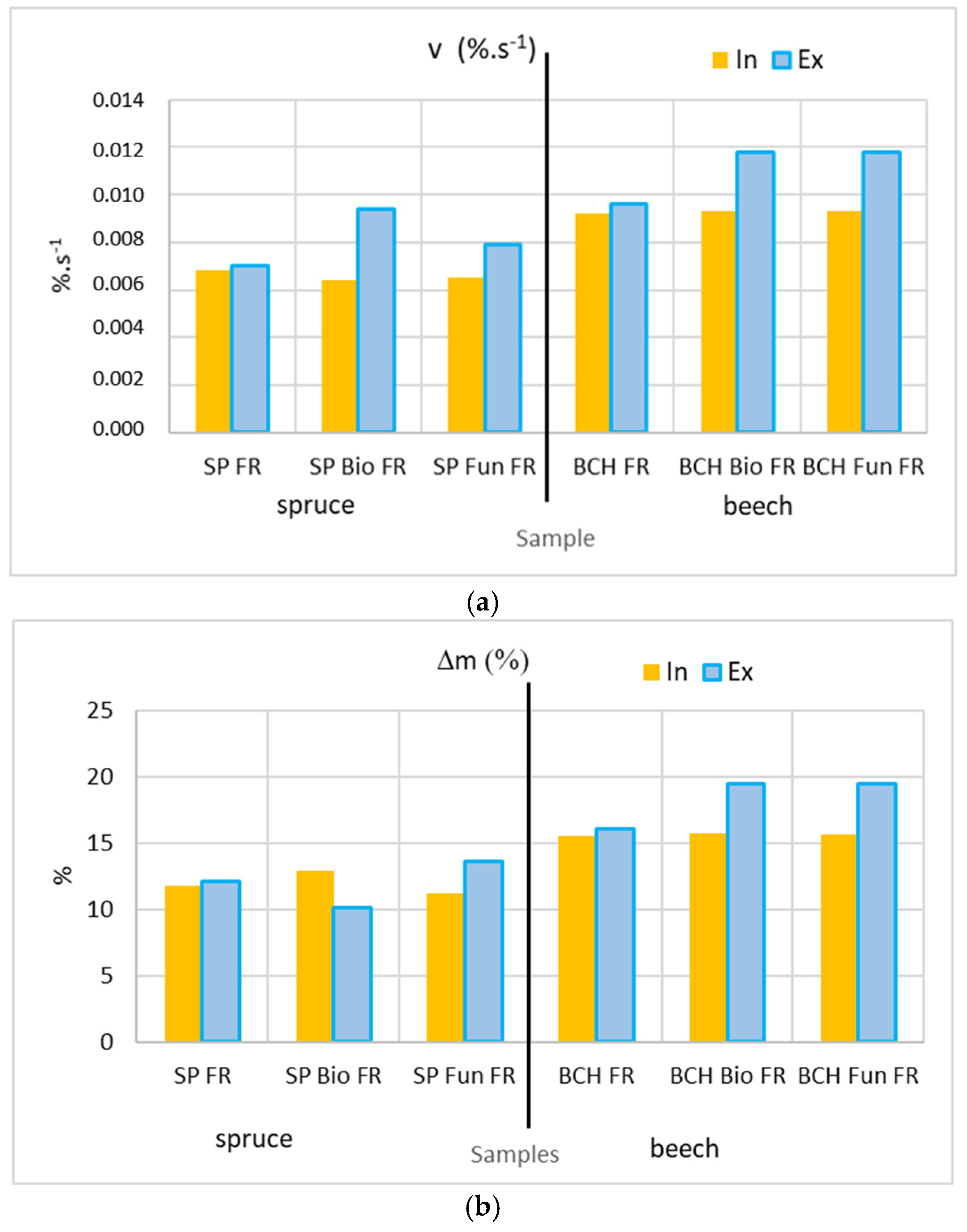

3.1. Results of the Thermal Degradation and Combustion Process of Spruce Samples

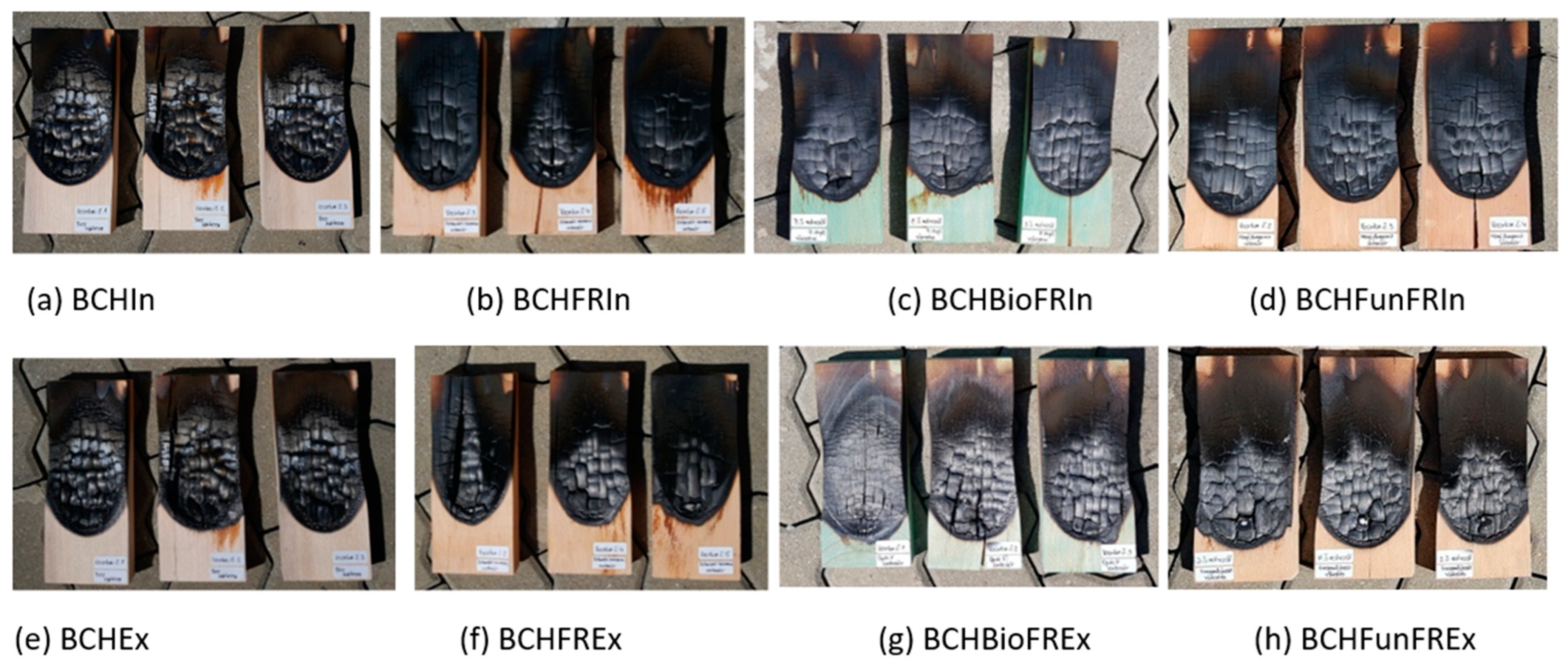

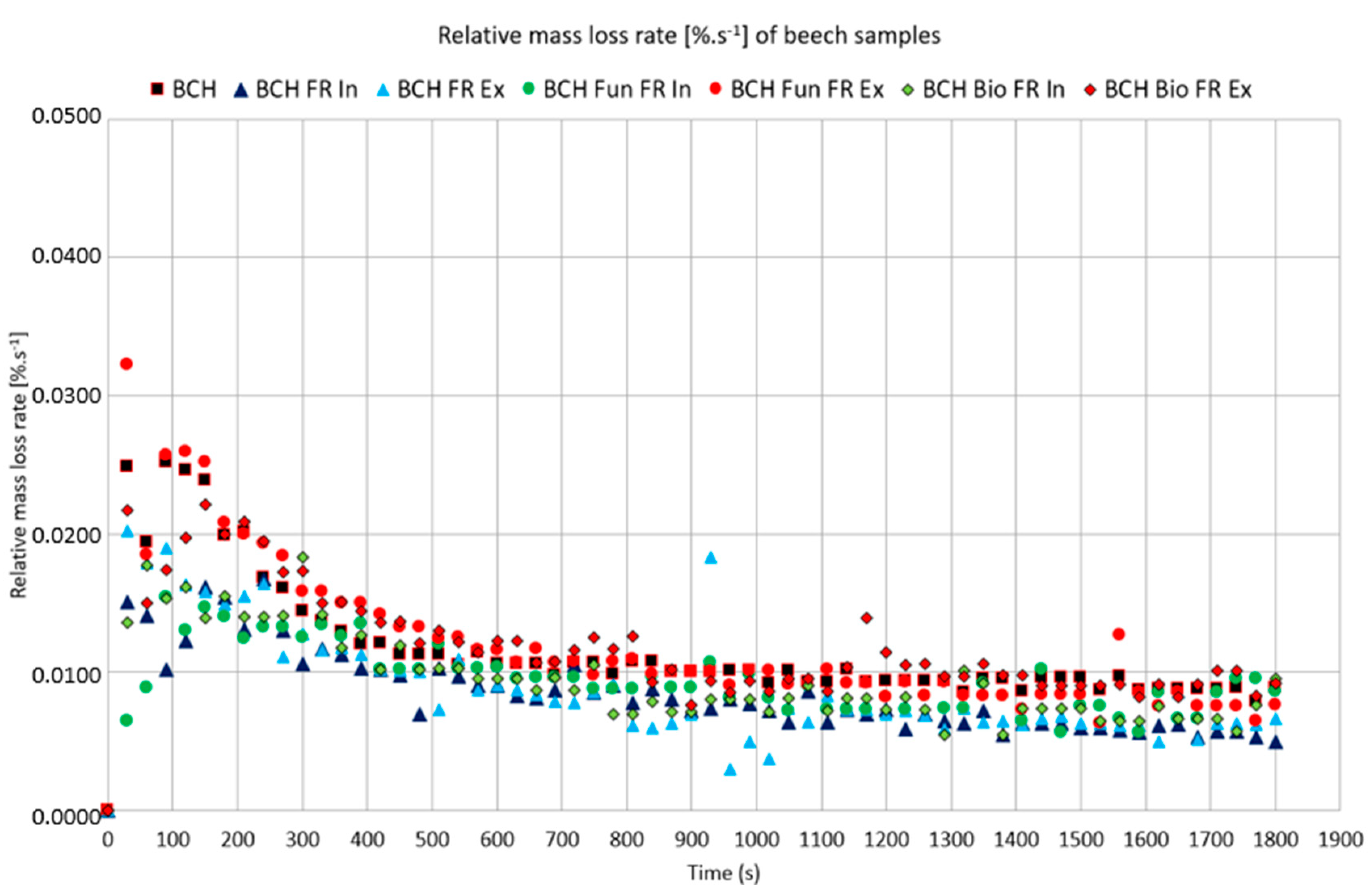

3.2. Results of Thermal Degradation and Combustion Process of Beech Samples

4. Discussion

5. Conclusions

- Impact of wood species: This has been confirmed. In all observed parameters, the beech samples exhibited worse results, including a higher mass loss, greater mass loss rates, and an increased charred depth. For spruce, the best variant was the combination of SPBioFRIn, while for beech, it was BCHFunFRIn.

- Impact of fire-retardant coating: Untreated samples demonstrated the fastest thermal degradation with the highest charred layer. The fire-retardant treatment (FR) reduced both the mass loss and charred layer thickness in spruce and beech samples. The combination of the Bio coating and FR improved the protective characteristics of the surface in beech wood.

- Impact of the combination of fungicidal coating and retardant: The results for the combination of FR + Fun were consistently higher, although a definitive conclusion cannot be drawn (Figure 12).

- Storage time: The differences were minimal; samples placed outdoors exhibited behavior and quantitative results (Δm and v) similar to those of the untreated samples.

- Location of use (outdoor and indoor): Better results were achieved by samples stored indoors, except for spruce samples treated with the Bio + FR coating. The assumption of the influence of external conditions on the quality (resistance to heat) of the protective coating was confirmed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wimmer, R.; Johansson, M. Effects of Reaction Wood on the Performance of Wood and Wood-Based Products. In The Biology of Reaction Wood, 1st ed.; Gardiner, B., Barnett, J., Saranpaa, P., Gril, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 225–248. [Google Scholar] [CrossRef]

- Netopilová, M.; Mikulenka, J.; Benešová, A. The Development of Composite Building Product and its Fire Technical Characteristics. Adv. Mater. Res. 2014, 1001, 368–372. [Google Scholar] [CrossRef]

- Barbu, M.C.; Tudor, E.M. State of the art of the Chinese forestry, wood industry and its markets. Wood Mater. Sci. Eng. 2021, 17, 1030–1039. [Google Scholar] [CrossRef]

- Kozlowski, R.; Muzyczek, M. Chapter 11—Smart environmentally friendly composite coatings for wood protection. In Woodhead Publishing Series in Composites Science and Engineering, Smart Composite Coatings and Membranes; Woodhead Publishing: Sawston, UK, 2016; pp. 293–325. [Google Scholar]

- Krišťak, L.; Kubovský, I.; Réh, R. New Challenges in Wood and Wood-Based Materials. Polymers 2021, 13, 2538. [Google Scholar] [CrossRef] [PubMed]

- Hrebenárová, E.; Wald, F. Comparison of mechanical properties of the eldest larch wood construction with oak wood and spruce wood. Wood Res. 2022, 67, 612–624. [Google Scholar] [CrossRef]

- Gryc, V.; Vavrčík, H. Structure of Wood [Anatomická stavba dřeva]; Mendel University in Brno: Brno, Czech Republic; Available online: https://doi.mendelu.cz/pdfs/doi/9900/04/4300.pdf (accessed on 11 September 2024). (In Czech)

- Čunderlík, I. Science of Wood [Náuka o dreve], 1st ed.; Technical University in Zvolen: Zvolen, Slovakia, 2009; p. 135. (In Slovak) [Google Scholar]

- Gašpercová, S.; Marková, I.; Vandlíčková, M.; Osvaldová, L.M.; Svetlík, J. Effect of Protective Coatings on Wooden Elements Exposed to a Small Ignition Initiator. Appl. Sci. 2023, 13, 3371. [Google Scholar] [CrossRef]

- Li, Y.; Lattimer, B.Y.; Case, S.W. Measurement and modelling of thermal and physical properties of wood construction materials. Constr. Build. Mater. 2021, 284, 122780. [Google Scholar] [CrossRef]

- Li, X.J.; Cai, Z.Y.; Mou, Q.Y.; Wu, Y.Q.; Liu, Y. Effects of Heat Treatment on some Physical Properties of Douglas Fir (Pseudotsuga menziesii) Wood. Adv. Mater. Res. 2011, 197–198, 90–95. [Google Scholar] [CrossRef]

- Rosu, L.; Mustata, F.; Varganici, C.D.; Rosu, D.; Rusu, T.; Rosca, I. Thermal behaviour and fungi resistance of composites based on wood and natural and synthetic epoxy resins cured with maleopimaric acid. Polym. Degrad. Stab. 2019, 160, 148–161. [Google Scholar] [CrossRef]

- Mitrenga, P.; Vandlíčková, M.; Konárik, M.; Košútová, K. Impact of Heat Treatment of Spruce Wood on Its Fire-Technical Characteristics Based on Density and the Side Exposed to Fire. Appl. Sci. 2022, 12, 6452. [Google Scholar] [CrossRef]

- Gašpercová, S.; Osvaldová Makovická, L. Fire protection in various types of wooden structures. Civ. Environ. Eng. 2015, 11, 51–57. [Google Scholar] [CrossRef]

- Osvaldová Makovická, L.; Castellanos, J.R.S. Burning rate of selected hardwood tree species. Acta Fac. Xylologiae Zvolen 2019, 61, 91–97. [Google Scholar] [CrossRef]

- Mitrenga, P.; Osvald, A.; Dušková, M. Influence of sample preparation on output quality in assessing the effectiveness of wood burning retardants [Vplyv prípravy vzoriek na kvalitu výstupu pri hodnotení účinnosti retardérov horenia dreva]. In Proceedings of the 19th International Scientific Conference Crisis Situations Solution in Specific Environment, Faculty of Special Engineering UNIZA, Žilina, Slovakia, 21–22 May 2014. (In Slovak). [Google Scholar]

- Macroscopic Structure of Wood [Makroskopická Stavba Dřeva]. Available online: https://www.n-i-s.cz/cz/makroskopicka-stavba-dreva/page/318/ (accessed on 11 August 2024). (In Czech).

- Suandi, M.; Effendi, M.; Amlus, M.H.; Hemdi, A.R.; Abd Rahim, S.Z.; Ghazali, M.F.; Rahim, N.L. A Review on Sustainability Characteristics Development for Wooden Furniture Design. Sustainability 2022, 14, 8748. [Google Scholar] [CrossRef]

- Tanasă, F.; Teacă, C.A.; Zănoagă, M. Chapter 6 Protective coatings for wood. In Handbook of Modern Coating Technologies: Applications and Development, 1st ed.; Elsevier: New York, NY, USA, 2021; pp. 175–267. [Google Scholar] [CrossRef]

- Jellison, J.; Connolly, J.; Goodell, B.; Doyle, B.; Illman, B.; Fekete, F.; Ostrofsky, A. The role of cations in the biodegradation of wood by the brown rot fungi. Int. Biodeterior. Biodegrad. 1997, 39, 165–179. [Google Scholar] [CrossRef]

- Fransson, A.M.; Valeur, I.; Wallander, H. The wood-decaying fungus Hygrophoropsis aurantiaca increases P availability in acid forest humus soil, while N addition hampers this effect. Soil Biol. Biochem. 2004, 36, 1699–1705. [Google Scholar] [CrossRef]

- Osvaldová Makovická, L.; Osvald, A. Flame Retardation of Wood. Adv. Mater. Res. 2013, 690–693, 1331–1334. [Google Scholar] [CrossRef]

- Kadlicová, P.; Gašpercová, S.; Osvaldová Makovická, L. Monitoring of Weight Loss of Fibreboard during Influence of Flame. Procedia Eng. 2017, 192, 393–398. [Google Scholar] [CrossRef]

- Gašparík, M.; Osvaldová Makovická, L.; Čekovská, H.; Potůček, D. Flammability characteristics of thermally modified oak wood treated with a fire retardant. Bioresources 2017, 12, 8451–8467. [Google Scholar] [CrossRef]

- Taib, M.N.A.M.; Antov, P.; Savov, V.; Fatriasari, W.; Madyaratri, E.W.; Wirawan, R.; Osvaldová, L.M.; Hua, L.S.; Ghani, M.A.A.; Al Edrus, S.S.A.O.; et al. Current progress of biopolymer-based flame retardant. Polym. Degrad. Stab. 2022, 205, 110153. [Google Scholar] [CrossRef]

- Sivrikaya, H.; Kara, Ö. Airborne Fungi in Wood and Wood Based Board Factories. Indoor Built Environ. 2009, 18, 265–269. [Google Scholar] [CrossRef]

- Kim, N.K.; Park, J.Y.; Park, M.S.; Lee, H.; Cho, H.J.; Eimes, J.A.; Kim, C.; Lim, Y.W. Five New Wood Decay Fungi (Polyporales and Hymenochaetales) in Korea. Mycobiology 2016, 44, 146–154. [Google Scholar] [CrossRef]

- Andres, B.; Krajewski, K.J.; Betlej, I. Diversity of Indoor Wood Decaying Fungi in Poland. Bioresources 2022, 17, 4856–4869. [Google Scholar] [CrossRef]

- Hinçal, S.; Yalçin, M. Biological control of some wood-decay fungi with antagonistic fungi. Biodegradation 2023, 34, 597–607. [Google Scholar] [CrossRef] [PubMed]

- Mirski, R.; Kawalerczyk, J.; Dziurka, D.; Stuper-Szablewska, K.; Walkiewicz, J. Selected Chemical and Physical Properties of Pine Wood Chips Inoculated with Aspergillus and Penicillium Mold Fungi. Drv. Ind. 2023, 74, 317–326. [Google Scholar] [CrossRef]

- Lowden, L.; Hull, T. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 1–19. [Google Scholar] [CrossRef]

- Ružinská, E.; Mitterová, I.; Zachar, M. The Study of Selected Fire-Technical Characteristics of Special Wood Products Surface Treatment by Environmentally Problematic Coatings. Adv. Mater. Res. 2014, 1001, 373–378. [Google Scholar] [CrossRef]

- Ma, T.; Li, L.; Liu, Z.; Zhang, J.; Guo, C.; Wang, Q. A facile strategy to construct vegetable oil-based, fire-retardant, transparent and mussel adhesive intumescent coating for wood substrates. Ind. Crops Prod. 2020, 154, 112628. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, P.; Chen, Z.; Li, L.; Huang, Y. Flame retardancy, thermal stability, and hygroscopicity of wood materials modified with melamine and amino trimethylene phosphonic acid. Constr. Build. Mater. 2021, 267, 121042. [Google Scholar] [CrossRef]

- Mao, N.; Jiang, L.; Li, X.; Gao, Y.; Zang, Z.; Peng, S.; Ji, L.; Lv, C.; Guo, J.; Wang, H.; et al. Core-shell ammonium polyphosphate@nanoscopic aluminum hydroxide microcapsules: Preparation, characterization, and its flame retardancy performance on wood pulp paper. Chem. Eng. J. Adv. 2021, 6, 100096. [Google Scholar] [CrossRef]

- Gaff, M.; Kačík, F.; Gašparík, M.; Todaro, L.; Jones, D.; Corleto, R.; Osvaldová Makovická, L.; Čekovská, H. The effect of synthetic and natural fire-retardants on burning and chemical characteristics of thermally modified teak (Tectona grandis L. f.) wood. Constr. Build. Mater. 2019, 200, 551–558. [Google Scholar] [CrossRef]

- Troitzsch, J.; Antonatus, E. Chapter 3—Flame Retardants and Flame-Retarded Plastics. In Plastics Flammability Handbook, 1st ed.; Elsevier: Amsterdam, The Netherlands; ChemTec Publishing: Toronto, ON, Canada, 2021; pp. 53–128. [Google Scholar] [CrossRef]

- Fire Test and Effects of Fire Retardant on the Natural Ability of Timber: A Review. Available online: https://www.researchgate.net/publication/332754332_Fire_Test_and_Effects_of_Fire_Retardant_on_the_Natural_Ability_of_Timber_A_Review (accessed on 24 March 2021).

- Wypych, G. Chapter 6—Selection of flame retardants for different polymers. In Handbook of Flame Retardants, 1st ed.; Wypych, G., Ed.; ChemTec Publishing: Toronto, ON, Canada, 2021; pp. 89–226. [Google Scholar]

- Mitterová, I.; Zachar, M. Wood in historical buildings [Drevo v historických objektoch]. In Proceedings of the Fireco 2013, Trenčín, Slovakia, 2–4 May 2013. (In Slovak). [Google Scholar]

- Flame Retardants (ATH&MDH). Available online: https://www.mikrons.com.tr/en/product/detailmain/110 (accessed on 20 March 2024).

- Brominated Flame Retardants. Available online: https://www.efsa.europa.eu/en/topics/topic/brominated-flame-retardants (accessed on 20 March 2024).

- Brahmia, F.; Zsolt, K.; Horváth, P.; Alpár, T. Comparative study on fire retardancy of various wood species treated with PEG 400, phosphorus, and boron compounds for use in cement-bonded wood-based products. Surf. Interfaces 2020, 21, 100736. [Google Scholar] [CrossRef]

- Orémusová, E.; Tutaj, M.; Dritomská, K. Effect of Fire Retardant Treatment on Flammability of Scots Pine Wood (Pinus sylvestris L.). Fire Prot. Saf. Sci. J. 2019, 13, 86–90. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shaha, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Gejdoš, P. Analysis of performance improvement of wood processing companies in Slovakia and the Czech republic through the implementation of quality management systems. Acta Fac. Xylologiae Zvolen 2016, 58, 113–124. [Google Scholar] [CrossRef]

- Luptáková, J.; Kačík, F.; Mitterová, I.; Zachar, M. Influence of temperature of thermal modification on the fire-technical characteristics of spruce wood. BioRes 2019, 14, 3795–3807. [Google Scholar] [CrossRef]

- Zachar, M.; Čabalová, I.; Kačíková, D.; Zacharová, L. The influence of heat flow on the fire-technical and chemical properties of spruce wood (Picea abies L.) [Vplyv tepelného toku na požiarnotechnické a chemické vlastnosti smrekového dreva (Picea abies L.)]. Materials 2021, 14, 4989. (In Slovak) [Google Scholar] [CrossRef]

- Brunetti, M.; Nocetti, M.; Pizzo, B.; Aminti, G.; Cremonini, C.; Negro, F.; Zanuttini, R.; Romagnoli, M.; Mugnozza, G.S. Structural products made of beech wood: Quality assessment of the raw material. Eur. J. Wood Wood Prod. 2020, 78, 961–970. [Google Scholar] [CrossRef]

- Pöhler, E.; Klingner, R.; Künniger, T. Beech (Fagus sylvatica L.)—Technological properties, adhesion behaviour and colour stability with and without coatings of the red heartwood. Ann. For. Sci. 2006, 63, 12–137. [Google Scholar] [CrossRef][Green Version]

- Krügener, K.; Ornik, J.; Jachim, R.; Kietz, B.; Petersen, K.; Mittleman, D.M.; Koch, M.; Viöl, W. Monitoring fungus infestation of common beech wood using terahertz radiation. Holzforschung 2020, 74, 635–641. [Google Scholar] [CrossRef]

- STN EN 13183-1: 2002; Moisture Content of a Piece of Reacti—Part 1: Determination by Oven Dry Method. Slovak Standards Institute: Bratislava, Slovakia, 2002. (In Slovak)

- CEN Standard EN 323: 1993; Wood-Based Panels—Determination of Density. European Committe for Standartion: Brussels, Belgium, 1993.

- Lee, S.H.; Ashaari, Z.; Lum, W.C.; Abdul Halip, J.; Ang, A.F.; Tan, P.L.; Ling Chin, K.; MdTahir, P. Thermal treatment of wood using vegetable oils: A review. Constr. Build. Mater. 2018, 181, 408–419. [Google Scholar] [CrossRef]

- Kivader, M.; Klement, I. Determination of moisture content in spruce wood during high temperature drying process. Acta Fac. Xylologiae 2012, 51, 25–32. [Google Scholar]

- Mitrenga, P.; Osvaldová Makovická, L.; Konárik, M. Effect of Spruce Wood Density on Selected Fire-Technical Parameters during Thermal Loading. Appl. Sci. 2024, 14, 170. [Google Scholar] [CrossRef]

- Mitrenga, P.; Vandlíčková, M.; Dušková, M. Evaluation of the new fire retardants on wood by proposed testing method. In Proceedings of the International Conference on Engineering Science and Production Management (ESPM), Tatransk Strba, Slovakia, 16–17 April 2015. [Google Scholar]

- Pačaiová, H.; Nagyová, A.; Oravec, M. Risk-based thinking methodology and its influence on occupational health and safety proces. Adv. Intell. Syst. Comput. 2020, 967, 267–276. [Google Scholar] [CrossRef]

- Fungonit. Data Sheet. Available online: http://uloziste.primalex.cz/gallery/kbu-fungonit.pdf (accessed on 20 April 2024).

- Bochemit Opti F+. Data Sheet. Available online: https://www.bochemitshop.cz/index.php?controller=attachment&id_attachment=368&inline=1 (accessed on 20 April 2024).

- HR Prof. Data Sheet. Available online: https://colorcompany.sk/public/manager/source/DOKUMENTY/kbu-hr-prof.pdf (accessed on 22 April 2024).

- Reg. 401/2007 Col. on the Technical Conditions and Requirements for Fire Safety in the Use and Operation of Fuel Appliances, Electrothermal Appliances and Central Heating Devices and in the Construction and Operation of the Chimney and Flue, and on the Deadlines for Their Implementation and Inspection [Vyhláška MV SR č. 401/2007 Z.z. o Technických Podmienkach a Požiadavkách na Protipožiarnu Bezpečnosť pri Inštalácii a Prevádzkovaní Palivového Spotrebiča, Elektrotepelného Spotrebiča a Zariadenia Ústredného Vykurovania a pri Výstavbe a Používaní Komína a Dymovodu a o Lehotách ich Čistenia a Vykonávania Control]. Slovak Technical Standard. Bratislava. Slovakia. 2007. Available online: https://www.slov-lex.sk/ezbierky/pravne-predpisy/SK/ZZ/2007/401/20070901 (accessed on 21 April 2024).

- Kmeťová, E.; Kačíková, D.; Kačík, F. The Effect of Intumescent Coating Containing Expandable Graphite onto Spruce Wood. Coatings 2024, 14, 490. [Google Scholar] [CrossRef]

- Kmeťová, E.; Kačíková, D.; Jurczyková, T.; Kačík, F. The Influence of Different Types of Expandable Graphite on the Thermal Resistance of Spruce Wood. Coatings 2023, 13, 1181. [Google Scholar] [CrossRef]

- Repič, R.; Pondelak, A.; Kržišnik, D. Combining mineralisation and thermal modification to improve the fungal durability of selected wood species. J. Clean. Prod. 2022, 3511, 131530. [Google Scholar] [CrossRef]

- Hernandez, V.; Romero, R.; Arias, S. A Novel Method for Calcium Carbonate Deposition in Wood That Increases. Coatings 2022, 12, 72. [Google Scholar] [CrossRef]

- He, L.; Bao, G.; Yu, X. A green and eco-friendly method to enhance Bamboo flame resistance via calcium alginate assisted in-situ mineralization of hydroxyapatite. Chem. Eng. J. 2024, 485, 149765. [Google Scholar] [CrossRef]

- Repič, R.; Pondelak, A.; Kržišnik, D.; Humar, M.; Knez, N.; Knez, F.; Škapin, A. Environmentally friendly protection of European beech against fire and fungal decay using a combination of thermal modification and mineralisation. Wood Mater. Sci. Eng. 2024, 19, 33–44. [Google Scholar] [CrossRef]

- Lin, C.-F.; Karlsson, O.; Myronycheva, O.; Das, O.; Mensah, R.A.; Mantanis, G.I.; Jones, D.; Antzutkin, O.N.; Försth, M.; Sandberg, D. Phosphorylated and carbamylated Kraft lignin for improving fire-and biological-resistance of Scots pine wood. Int. J. Biol. Macromol. 2024, 276, 133734. [Google Scholar] [CrossRef]

- Underwriters Laboratories Inc. UL94. Tests for Flammability of Plastic Materials for Parts in Devices and Appliances. Last Revision: January 05, 2024. Standards & Endgagement. Woshington USA. 2024. Available online: https://www.shopulstandards.com/ProductDetail.aspx?productId=UL94 (accessed on 24 March 2024).

| Sample Name | Coating Composition | Treatment of Protected Coating | |

|---|---|---|---|

| Spruce | SP | Untreated | Untreated (conditioning and drying during 15th day) |

| Coated spruce (next 15th day) | SP FR SP FR In SP FR Ex | Treatment with retardant | First coat of paint layer FR and after 48 h continued with second coat of paint layer of FR Then stored for 8 months indoors Then stored for 8 months exterior |

| SP Bio SP Bio FR SP Bio FR In SP Bio FR Ex | Treatment with Fungicide—Bio Treatment with Fungicide Bio + Retardant FR | First coat of paint layer and after 48 h continued with second coat of paint layer Bio First coat of paint Bio and after 48 h continued with second coat of paint Bio, followed by 10 days of drying and was made First coat of paint FR and after 48 h continued with second coat of paint FR Then stored for 8 months indoors Then stored for 8 months exterior | |

| SP Fun SP Fun FR SP Fun FR In SP Fun FR Ex | Treatment with Fungicide 2—Fun Treatment with Fungicide Fun + Retardant FR | First coat of paint layer and after 48 h continued with second coat of paint First coat of paint Fun and after 48 h continued with second coat of paint Fun, followed by 10 days of drying and was then applied first coat of paint FR and after 48 h continued with second coat of paint FR Then stored for 8 months indoors Then stored for 8 months exterior | |

| Beech | BCH | Unterated | Untreated (conditioning and drying during 15th day |

| Coated beech (next 15th day) | BCH FR BCH FR In BCH FR Ex | Treatment with retardant | First coat of paint layer FR and after 48 h continued with second coat of paint layer Then stored for 8 months indoors Then stored for 8 months exterior |

| BCH Bio BCH Bio FR BCH Bio FR In BCH Bio FR Ex | Treatment with Fungicide 1—Bio Treatment with Fungicide Bio + Retardant FR | First coat of paint layer and after 48 h continued with second coat of paint layer Bio First coat of paint Bio and after 48 h continued with second coat of paint Bio, followed by 10 days of drying and was made First coat of paint FR and after 48 h continued with second coat of paint FR Then stored for 8 months indoors Then stored for 8 months exterior | |

| BCH Fun BCH Fun FR BCH Fun FR In BCH Fun FR Ex | Treatment with Fungicide 2—Fun Treatment with Fungicide Fun + Retardant FR | First coat of paint layer and after 48 h continued with second coat of paint layer Fun First coat of paint Fun and after 48 h continued with second coat of paint Fun, followed by 10 days of drying and was then applied first coat of paint FR and after 48 h continued with second coat of paint FR Then stored for 8 months indoors Then stored for 8 months exterior | |

| Atmospheric Conditions | Experimental Parameters | ||

|---|---|---|---|

| Air temperature [°C] | 20 | Flame angle [°] | 45 |

| Moisture [%] | 47 | Flame length [mm] | 50 |

| Pressure [hPa] | 980 | Duration of flame action [min] | 30 |

| Parameters | Fungicidal Protective Coatings | Fire-Resistant Coating | |

|---|---|---|---|

| Source | Bio [59] | Fungi [60] | FR [61] |

| Chemical composition | Alkyl (C12-16) dimethylbenzyl ammonium chloride, N-(3-aminopropyl)-N-dodecylpropane-1,3-diamine, propiconazole, tebuconazole and fenoxycarb | N-(3-aminopropyl)-N-dodecylpropane-1,3-diamine, lactic acid, 2,2′-oxydiethanol, amines, coco alkyldimethyl, N-oxides, propiconazole, cypermethrin. | Iron orthophosphate, citric acid, octadecan-1-ol, ethoxylated. |

| Appearance | Colorless transparent liquid | Colorless transparent liquid | Colorless transparent liquid |

| Relative density at 20 °C (g/m3) | 1.00–1.03 | 1.0 | 1.1 ± 0.05 |

| pH (at 20 °C) | 10.0–11.5 | 7.0–7.2 | 2.5 |

| Non-volatile substances (%hm) | 5.6 | - | 10 |

| Water solubility (%) | 100 | Yes, but the SDS does not list it. | 100 |

| Notes | Reaction to fire [7] B-s1, d0 | ||

| Sample Preparation Procedure | Sample Designation | |||

|---|---|---|---|---|

| Spruce | Beech | |||

| Untreated | SP | BCH | ||

| Treatment with fungicide preparation 1 (Bio) | SP Bio | BCH Bio | ||

| Treatment with fungicide preparation 2 | SP Fun | BCH Fun | ||

| Treatment with retardant (FR) | SP FR | BCH FR | ||

| Storage for 10 days | ||||

| Fungicide treatment 1 (Bio) | SP Bio | BCH Bio | ||

| Fungicide treatment 2 (Fun) | SP Fun | BCH Fun | ||

| Fire retardant application and storage for 8 months | ||||

| Storage location | Interior (lumber storage) | Exterior (wood storage shed) | Interior (lumber storage) | Exterior (wood storage shed) |

| Spruce/beech retardant treatment | SP FR In | SP FR Ex | BCH FR In | BCH FR Ex |

| Spruce/beech treatment with retardant and fungicide Bio | SP Bio FR In | SP Bio FR Ex | BCH Bio FR In | BCH Bio FR Ex |

| Spruce/beech treatment with retardant and fungicide Fun | SP Fun FR In | SP Fun FR Ex | BCH Fun FR In | BCH Fun FR Ex |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leitner, B.; Gašpercová, S.; Marková, I.; Tureková, I. Effect of Combining Fungal and Flame-Retardant Coatings on the Thermal Degradation of Spruce and Beech Wood Under Flame Loading. Fire 2024, 7, 463. https://doi.org/10.3390/fire7120463

Leitner B, Gašpercová S, Marková I, Tureková I. Effect of Combining Fungal and Flame-Retardant Coatings on the Thermal Degradation of Spruce and Beech Wood Under Flame Loading. Fire. 2024; 7(12):463. https://doi.org/10.3390/fire7120463

Chicago/Turabian StyleLeitner, Bohuš, Stanislava Gašpercová, Iveta Marková, and Ivana Tureková. 2024. "Effect of Combining Fungal and Flame-Retardant Coatings on the Thermal Degradation of Spruce and Beech Wood Under Flame Loading" Fire 7, no. 12: 463. https://doi.org/10.3390/fire7120463

APA StyleLeitner, B., Gašpercová, S., Marková, I., & Tureková, I. (2024). Effect of Combining Fungal and Flame-Retardant Coatings on the Thermal Degradation of Spruce and Beech Wood Under Flame Loading. Fire, 7(12), 463. https://doi.org/10.3390/fire7120463