Thermal and Pyrolysis Kinetics Analysis of Glass Wool and XPS Insulation Materials Used in High-Rise Buildings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Simultaneous Thermal Analysis

2.3. Pyrolysis Kinetics Theory

2.4. Proposed Framework for Kinetics Data Extractions

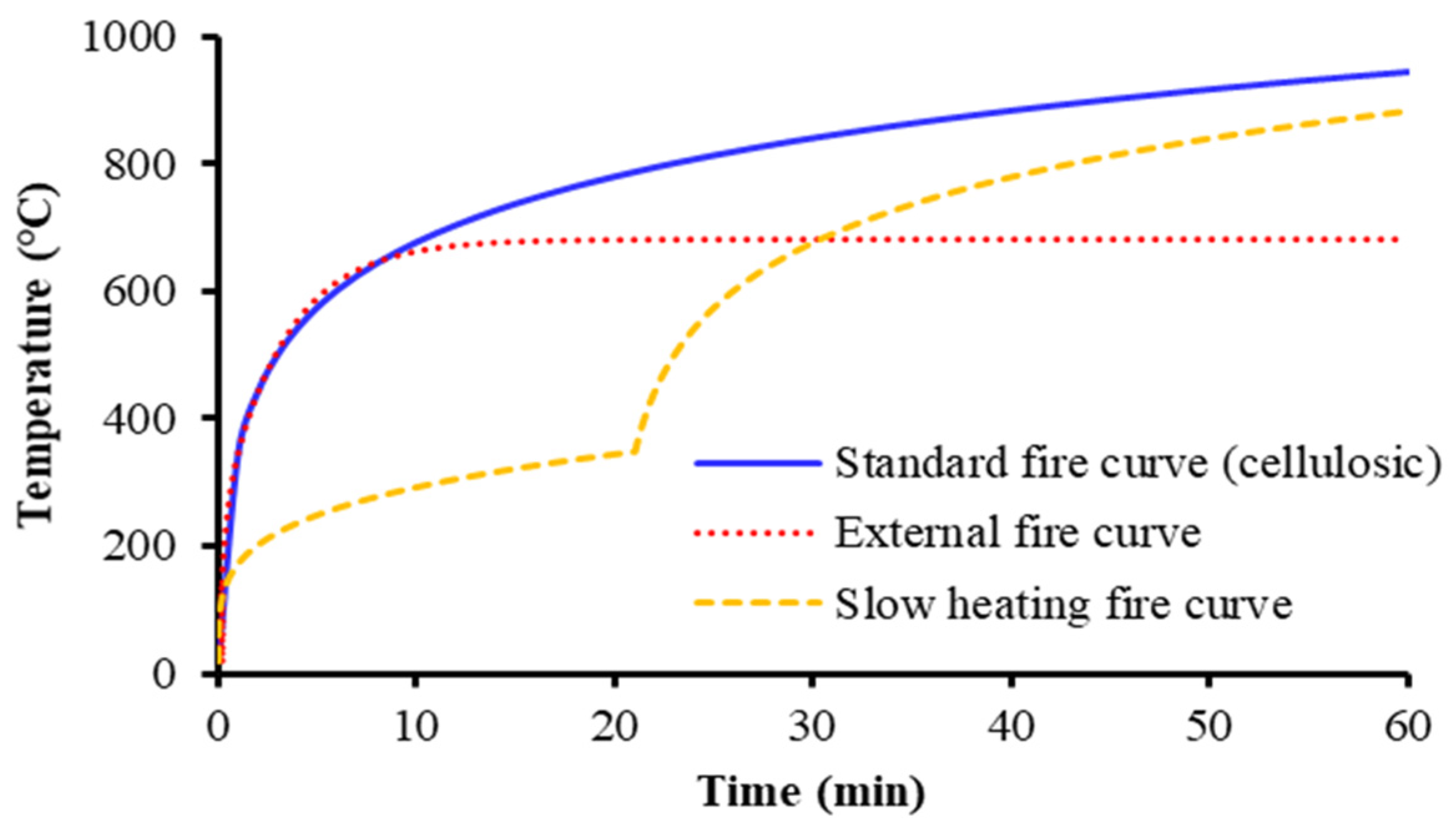

2.5. Fire Curves for Modelling

2.6. Microscopy Imaging and Elemental Microanalysis

3. Results and Discussion

3.1. Thermal Analysis

3.1.1. Extruded Polystyrene (XPS)

3.1.2. Glass Wool (GW)

3.2. Model Selections

3.3. Kinetics Analysis

3.3.1. Extruded Polystyrene (XPS)

3.3.2. Glass Wool (GW)

3.4. Mass Loss Prediction with Different Standard Fire Curves

4. Conclusions

- GW has lower mass loss than XPS, with an average residue of 95% and 3%, respectively;

- XPS has a single reaction step, while GW exhibits three reaction steps;

- The Friedman model fits XPS best (R2 = 0.99966) and the An model code fits GW best (R2 = 0.99961);

- Mass loss prediction shows consistent patterns, with a maximum mass loss around 2 min at 440 to 480 °C for cellulosic and external fires and around 23 min for slow-heating fires.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain, M.D.; Hassan, M.K.; Akl, M.; Pathirana, S.; Rahnamayiezekavat, P.; Douglas, G.; Bhat, T.; Saha, S. Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings. Fire 2022, 5, 81. [Google Scholar] [CrossRef]

- Zhang, W.; Jia, J.; Zhang, J.; Ding, Y.; Zhang, J.; Lu, K.; Mao, S. Pyrolysis and combustion characteristics of typical waste thermal insulation materials. Sci. Total Environ. 2022, 834, 155484. [Google Scholar] [CrossRef] [PubMed]

- Egbon, B.; Tomlinson, D. Experimental investigation of longitudinal shear transfer in insulated concrete wall panels with notched insulation. J. Build. Eng. 2021, 43, 103173. [Google Scholar] [CrossRef]

- Awad, H.; Secchi, L.; Gül, M.; Ge, H.; Knudson, R.; Al-Hussein, M. Thermal resistance of multi-functional panels in cold-climate regions. J. Build. Eng. 2021, 33, 101838. [Google Scholar] [CrossRef]

- Kalhor, K.; Emaminejad, N. Qualitative and quantitative optimisation of thermal insulation materials: Insights from the market and energy codes. J. Build. Eng. 2020, 30, 101275. [Google Scholar] [CrossRef]

- Zhang, M.; Li, M.; Wang, Y.; Sun, J. Experimental study of thermal shrinkage and melt dripping properties of expanded polystyrene under various heat fluxes. J. Build. Eng. 2022, 60, 105179. [Google Scholar] [CrossRef]

- Yuan, R.; Zhang, Y.; Qiu, T.; Lu, S. Research on the effect of pyrolysis and melting on thermal insulation of glass fiber at multiple scales. J. Therm. Anal. Calorim. 2022, 147, 8009–8018. [Google Scholar] [CrossRef]

- BS 8414-1; Fire Performance of External Cladding Systems. Test Methods for Non-Loadbearing External Cladding Systems Applied to the Face of a Building. British Standards: London, UK, 2002.

- AS 5113:2016; Classification of External Walls of Buildings Based on Reaction-to-Fire Performance. Standards Australia: Sydney, Australia, 2016.

- Bakhtiyari, S.; Taghi-Akbari, L.; Ashtiani, M.J. Evaluation of thermal fire hazard of 10 polymeric building materials and proposing a classification method based on cone calorimeter results. Fire Mater. 2015, 39, 1–13. [Google Scholar] [CrossRef]

- Apte, V.B. Flammability Testing of Materials Used in Construction, Transport and Mining; Woodhead Publishing: Sawston, UK, 2006. [Google Scholar]

- Li, Y.; Wang, Z.; Huang, X. An exploration of equivalent scenarios for building facade fire standard tests. J. Build. Eng. 2022, 52, 104399. [Google Scholar] [CrossRef]

- Guillaume, E.; Fateh, T.; Schillinger, R.; Chiva, R.; Ukleja, S.; Weghorst, R. Intermediate-Scale Tests of Ventilated Facades With Aluminium-Composite Claddings. J. Phys. Conf. Ser. 2018, 1107, 032007. [Google Scholar] [CrossRef]

- Yuen, A.; Chen, T.; Wang, C.; Wei, W.; Kabir, I.; Vargas, J.; Chan, Q.; Kook, S.; Yeoh, G. Utilising genetic algorithm to optimise pyrolysis kinetics for fire modelling and characterisation of chitosan/graphene oxide polyurethane composites. Compos. Part B Eng. 2020, 182, 107619. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Navaratnam, S.; Mendis, P.; Zhang, K.; Barnett, J.; Wang, H. Fire safety of composites in prefabricated buildings: From fibre reinforced polymer to textile reinforced concrete. Compos. Part B Eng. 2020, 187, 107815. [Google Scholar] [CrossRef]

- Oswald, D.; Moore, T.; Lockrey, S. Combustible costs! financial implications of flammable cladding for homeowners. Int. J. Hous. Policy 2022, 22, 225–250. [Google Scholar] [CrossRef]

- McKenna, S.T.; Jones, N.; Peck, G.; Dickens, K.; Pawelec, W.; Oradei, S.; Harris, S.; Stec, A.A.; Hull, T.R. Fire behaviour of modern façade materials–Understanding the Grenfell Tower fire. J. Hazard. Mater. 2019, 368, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Rogaume, T. Thermal decomposition and pyrolysis of solid fuels: Objectives, challenges and modelling. Fire Saf. J. 2019, 106, 177–188. [Google Scholar] [CrossRef]

- Hossain, M.D.; Hassan, M.K.; Yuen, A.C.Y.; He, Y.; Saha, S.; Hittini, W. Flame behaviour, fire hazard and fire testing approach for lightweight composite claddings—A review. J. Struct. Fire Eng. 2021, 12, 257–292. [Google Scholar] [CrossRef]

- Jiao, L.; Xu, G.; Wang, Q.; Xu, Q.; Sun, J. Kinetics and volatile products of thermal degradation of building insulation materials. Thermochim. Acta 2012, 547, 120–125. [Google Scholar] [CrossRef]

- Li, A.; Zhang, W.; Zhang, J.; Ding, Y.; Zhou, R. Pyrolysis kinetic properties of thermal insulation waste extruded polystyrene by multiple thermal analysis methods. Materials 2020, 13, 5595. [Google Scholar] [CrossRef]

- Hidalgo, J.P.; Torero, J.L.; Welch, S. Experimental characterisation of the fire behaviour of thermal insulation materials for a performance-based design methodology. Fire Technol. 2017, 53, 1201–1232. [Google Scholar] [CrossRef] [Green Version]

- Livkiss, K. Fires in Narrow Construction Cavities: Fire Dynamics and Material Fire Performance. Ph.D. Thesis, Lund University, Lund, Sweden, 2020. [Google Scholar]

- Stec, A.A.; Hull, T.R. Assessment of the fire toxicity of building insulation materials. Energy Build. 2011, 43, 498–506. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Yliniemi, J.; Nguyen, H.; Adesanya, E.; Tanskanen, P.; Kinnunen, P.; Roning, J.; Illikainen, M. Utilisation of glass wool waste and mine tailings in high performance building ceramics. J. Build. Eng. 2020, 31, 101383. [Google Scholar] [CrossRef]

- Torero, J. Flaming ignition of solid fuels. In SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 633–661. [Google Scholar]

- Liu, L.; Chen, T.B.Y.; Yuen, A.C.Y.; Doley, P.M.; Wang, C.; Lin, B.; Liang, J.; Yeoh, G.H. A systematic approach to formulate numerical kinetics for furnishing materials fire simulation with validation procedure using cone/FT-IR data. Heat Mass Transf. 2021, 1–19. [Google Scholar] [CrossRef]

- Rashid, M.; Chetehouna, K.; Settar, A.; Rousseau, J.; Roudaut, C.; Lemée, L.; Aboura, Z. Kinetic analysis of the thermal degradation of an intumescent fire retardant coated green biocomposite. Thermochim. Acta 2022, 711, 179211. [Google Scholar] [CrossRef]

- Brown, M.E.; Dollimore, D.; Galwey, A.K. Reactions in the Solid State; Elsevier: Amsterdam, The Netherlands, 1980. [Google Scholar]

- Vyazovkin, S.; Chrissafis, K.; Di Lorenzo, M.L.; Koga, N.; Pijolat, M.; Roduit, B.; Sbirrazzuoli, N.; Suñol, J.J. ICTAC Kinetics Committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim. Acta 2014, 590, 1–23. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Thermal degradation kinetics of plastics and model selection. Thermochim. Acta 2017, 654, 191–202. [Google Scholar] [CrossRef]

- Mortezaeikia, V.; Tavakoli, O.; Khodaparasti, M.S. A review on kinetic study approach for pyrolysis of plastic wastes using thermogravimetric analysis. J. Anal. Appl. Pyrolysis 2021, 160, 105340. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Favergeon, L.; Koga, N.; Moukhina, E.; Pérez-Maqueda, L.A.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for analysis of multi-step kinetics. Thermochim. Acta 2020, 689, 178597. [Google Scholar] [CrossRef]

- NETZSCH. Model-Free (Isoconvertional) Analysis Methods in Kinetics Neo [Database on the Internet]. Available online: https://kinetics.netzsch.com/en/features/model-free-analysis (accessed on 4 July 2022).

- Manić, N.; Janković, B.; Dodevski, V. Model-free and model-based kinetic analysis of Poplar fluff (Populus alba) pyrolysis process under dynamic conditions. J. Therm. Anal. Calorim. 2021, 143, 3419–3438. [Google Scholar] [CrossRef]

- NETZSCH. Kinetics Neo. [Database on the Internet]. 2022. Available online: https://kinetics.netzsch.com/en (accessed on 4 July 2022).

- Di Bucchianico, A. Coefficient of determination (R2). Encycl. Stat. Qual. Reliab. 2008, 1. [Google Scholar] [CrossRef]

- EN 1363-2:1999; Fire Resistance Tests. Alternative and Additional Procedures. British Standards: London, UK, 1999.

- ISO 834-1; Fire-Resistance Tests—Elements of Building Construction—Part 1: General Requirements. ISO: Geneva, Switzerland, 1999.

- EN 1991-1-2; Eurocode 1: Actions on Structures—Part 1-2, General Actions—Action on structures Exposed to Fire. British Standards: London, UK, 2002; -2.

- Nyazika, T.; Jimenez, M.; Samyn, F.; Bourbigot, S. Pyrolysis modeling, sensitivity analysis, and optimisation techniques for combustible materials: A review. J. Fire Sci. 2019, 37, 377–433. [Google Scholar] [CrossRef]

- Yang, J.; Miranda, R.; Roy, C. Using the DTG curve fitting method to determine the apparent kinetic parameters of thermal decomposition of polymers. Polym. Degrad. Stab. 2001, 73, 455–461. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, D.; Li, M.; He, J.-J.; Gao, Z.-H.; Zhou, Y.; Sun, J.-H. Pyrolytic behavior of waste extruded polystyrene and rigid polyurethane by multi kinetics methods and Py-GC/MS. Fuel 2018, 222, 11–20. [Google Scholar] [CrossRef]

- Jiang, L.; Xiao, H.-H.; He, J.-J.; Sun, Q.; Gong, L.; Sun, J.-H. Application of genetic algorithm to pyrolysis of typical polymers. Fuel Process. Technol. 2015, 138, 48–55. [Google Scholar] [CrossRef]

- Jun, H.-C.; Oh, S.C.; Lee, H.P.; Kim, H.T. A kinetic analysis of the thermal-oxidative decomposition of expandable polystyrene. Korean J. Chem. Eng. 2006, 23, 761–766. [Google Scholar] [CrossRef]

- Ashraf, A.; Sattar, H.; Munir, S. A comparative applicability study of model-fitting and model-free kinetic analysis approaches to non-isothermal pyrolysis of coal and agricultural residues. Fuel 2019, 240, 326–333. [Google Scholar] [CrossRef]

- Kinetic Analysis—Selection of Suitable Kinetic Methods & Models by Means of Kinetics Neo Software. 2022. [Database on the Internet]. 2022. Available online: https://www.youtube.com/watch?v=tKi70BAz3z8 (accessed on 4 February 2023).

- Mandal, S.; Mohalik, N.K.; Ray, S.K.; Khan, A.M.; Mishra, D.; Pandey, J.K. A comparative kinetic study between TGA & DSC techniques using model-free and model-based analyses to assess spontaneous combustion propensity of Indian coals. Process Saf. Environ. Prot. 2022, 159, 1113–1126. [Google Scholar]

- Šimon, P.; Thomas, P.; Dubaj, T.; Cibulková, Z.; Peller, A.; Veverka, M. The mathematical incorrectness of the integral isoconversional methods in case of variable activation energy and the consequences. J. Therm. Anal. Calorim. 2014, 115, 853–859. [Google Scholar] [CrossRef]

- Jiao, L.-L.; Sun, J.-H. A thermal degradation study of insulation materials extruded polystyrene. Procedia Eng. 2014, 71, 622–628. [Google Scholar] [CrossRef] [Green Version]

- Livkiss, K.; Andres, B.; Bhargava, A.; van Hees, P. Characterization of stone wool properties for fire safety engineering calculations. J. Fire Sci. 2018, 36, 202–223. [Google Scholar] [CrossRef]

- Sammler, A. Comprehensive Overview of the Thermal Properties of Ceramics; NETZSCH: Selb, Germany, 2021; pp. 1–20. [Google Scholar]

- Khan, A.A.; Lin, S.; Huang, X.; Usmani, A. Facade fire hazards of bench-scale aluminum composite panel with flame-retardant core. Fire Technol. 2021, 59, 5–28. [Google Scholar] [CrossRef]

- Bisby, L.A. Grenfell Tower Inquiry: Phase 1-Final Expert Report. [Database on the Internet]. 2018. Available online: https://www.research.ed.ac.uk/en/publications/grenfell-tower-inquiry-phase-1-final-expert-report (accessed on 4 July 2022).

- Yuen, A.C.Y.; Chen, T.B.Y.; Li, A.; De Cachinho Cordeiro, I.M.; Liu, L.; Liu, H.; Lo, A.L.P.; Chan, Q.N.; Yeoh, G.H. Evaluating the fire risk associated with cladding panels: An overview of fire incidents, policies, and future perspective in fire standards. Fire Mater. 2021, 45, 663–689. [Google Scholar] [CrossRef]

| Sample Code | Material Types | b (mm) | ρ (kg/m3) | k (W/mK) | CP (Jg−1 K−1) | Ref. |

|---|---|---|---|---|---|---|

| XPS | Extruded polystyrene | 25 | 28 | 0.025 | 1.712 | [1] |

| GW | Glass wool | 30 | 45 | 0.032 | 0.855 | [7] |

| Methods | Expression | Types |

|---|---|---|

| Friedman (FR) | Differential | |

| Ozawa–Flynn–Wall (OFW) | Integral | |

| Kissinger–Akahira–Sunose (KAS) | Integral | |

| Vyazovkin (VA) | Where | Integral |

| Code | Function | Type of Reaction |

|---|---|---|

| Fn | Reaction of nth order | |

| Cn | ) | Reaction of nth order with autocatalysis by product |

| Cnm | ) | Reaction of nth order with m-Power autocatalysis by product |

| An | n-dimensional nucleation according to Avrami−Erofeev | |

| KS | Kamal–Sourur equation |

| Material | Temperature Range (°C) | β (K/min) | To (°C) | Te (°C) | Mass Residual % | ||

|---|---|---|---|---|---|---|---|

| R1 | R2 | ||||||

| XPS | 25–600 | 5 | 390 | 408 | - | 430 | 3.32 |

| XPS | 25–600 | 10 | 390 | 418 | - | 453 | 3.63 |

| XPS | 25–600 | 15 | 407 | 428 | - | 460 | 2.48 |

| XPS | 25–600 | 20 | 411 | 435 | - | 469 | 2.42 |

| GW | 25–1000 | 5 | 242 | 295 | 745 | 819 | 95.12 |

| GW | 25–1000 | 10 | 246 | 300 | 750 | 820 | 95.48 |

| GW | 25–1000 | 15 | 256 | 320 | 754 | 877 | 95.89 |

| GW | 25–1000 | 20 | 260 | 335 | 775 | 986 | 95.45 |

| Material | Types of Method | Model/Code | R2 | Sum of Deviated Squares | Mean Residual | F-Test |

|---|---|---|---|---|---|---|

| Glass wool (GW) | Model-based | An | 0.99961 | 1.30 | 0.03 | 1.00 |

| Cn | 0.99870 | 4.33 | 0.06 | 3.35 | ||

| Cnm | 0.99891 | 3.64 | 0.05 | 2.82 | ||

| Fn | 0.99874 | 4.22 | 0.06 | 3.26 | ||

| KS | 0.99948 | 1.73 | 0.04 | 1.35 | ||

| XPS | Model-free | Friedman | 0.99981 | 781.80 | 0.60 | α |

| NOA | 0.99985 | 626.856 | 0.544 | α | ||

| OFW | 0.99734 | 10,861.58 | 2.024 | α | ||

| Vyazovkin | 0.99955 | 1854.16 | 0.885 | α |

| Material | Model | Ea (kJ/mol) | log A (A/1/s) | ni | ci |

|---|---|---|---|---|---|

| Glass wool (GW) | An | R1 = 106.96 | R1 = 6.88 | R1 = 0.33 | R1 = 0.47 |

| R2 = 89.27 | R2 = 1.88 | R2 = 0.27 | R2 = 0.31 | ||

| R3 = 361.89 | R3 = 16.40 | R3 = 0.06 | R3 = 0.22 | ||

| XPS | Friedman | R1 = 159.89 | R1 = 9.927 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, M.D.; Hassan, M.K.; Saha, S.; Yuen, A.C.Y.; Wang, C.; George, L.; Wuhrer, R. Thermal and Pyrolysis Kinetics Analysis of Glass Wool and XPS Insulation Materials Used in High-Rise Buildings. Fire 2023, 6, 231. https://doi.org/10.3390/fire6060231

Hossain MD, Hassan MK, Saha S, Yuen ACY, Wang C, George L, Wuhrer R. Thermal and Pyrolysis Kinetics Analysis of Glass Wool and XPS Insulation Materials Used in High-Rise Buildings. Fire. 2023; 6(6):231. https://doi.org/10.3390/fire6060231

Chicago/Turabian StyleHossain, Md Delwar, Md Kamrul Hassan, Swapan Saha, Anthony Chun Yin Yuen, Cheng Wang, Laurel George, and Richard Wuhrer. 2023. "Thermal and Pyrolysis Kinetics Analysis of Glass Wool and XPS Insulation Materials Used in High-Rise Buildings" Fire 6, no. 6: 231. https://doi.org/10.3390/fire6060231

APA StyleHossain, M. D., Hassan, M. K., Saha, S., Yuen, A. C. Y., Wang, C., George, L., & Wuhrer, R. (2023). Thermal and Pyrolysis Kinetics Analysis of Glass Wool and XPS Insulation Materials Used in High-Rise Buildings. Fire, 6(6), 231. https://doi.org/10.3390/fire6060231