Abstract

Storage tank fires can endanger society and the environment by generating intense heat radiation, rapidly spreading blazes, and cataclysmic explosions. Various types of foam and even two or more mixed foams are commonly used in storage tank fire disposal sites. This research aims to experimentally and analytically assess the efficacy of various and mixed forms of foam in putting out 120# gasoline pool fires. A series of foam fire extinguishing and re-ignition tests were conducted using a laboratory fire-extinguishing device that gently released low-expansion foam. In this work, a 2.4 m-diameter steel round tray was utilized to model the full-surface fire of an oilcan in a large oil depot base. The non-dimensional (T* = TExtinguishing/Tboiling point) average temperature of 0.62–0.66 is used in this study to represent the fire extinguishing temperatures of 120# gasoline fuel. The power law is still followed during the spreading phase as the length of the foam spreads further with time. When combined, 6% aqueous film-forming foam solution and alcohol-resistant aqueous film-forming foam solution (AFFF + AFFF/AR) have the highest flow velocity of 0.0189 m s−1. According to the results, synthesis foam solution combined with alcohol-resistant fluoroprotein foam (S + FP/AR) provided the greatest cooling effect, followed by S + S/AR (alcohol-resistant synthetic foam solution), AFFF/AR, S + AFFF, S/AR + AFFF, and finally S/AR + AFFF. According to the results, foam with an expansion ratio of 8.7:1 (FP (fluoroprotein foam solution) + AFFF/AR) has greater re-ignition resistance and burn-back protection. A referable tactic for choosing foam for liquid fire suppression is shown in this paper. The results suggested that FP and AFFF should be used for effective fire suppression in this hydrocarbon fuel fire rescue. Then, we can use synthetic foam and AR foams to provide continuous cooling and prevent the fire from re-igniting through efficient foam coverage.

1. Introduction

Hazardous fires in oil tanks may result in significant property loss and casualties along with unceasing industrialization development. Large amounts of flammable and volatile oil products are frequently stored in oil tanks, which are extremely susceptible to fire and even explosion, finally leading to serious tragedies. Due to the ineffectiveness of oil tank fire suppression, accidents may also result in secondary and derivative events such as reignition, boil over, oil tank explosions, etc. Aside from the fact that the types and properties of these fuels vary significantly, single foam or even mixed foams must be used to quench the flame. For example, the firefighting and rescue process of the “7.16” crude oil storage tank in Dalian, China, lasted 80 h, and more than 1000 tons of foam were used at the accident site. As a result of the rising public concern about liquid firefighting technology, there is an urgent need for a greener and more efficient method of dealing with fire explosions in oil tanks.

Generally, the extensive utilization of compressed air foam systems in industrial, military, and civilian sites attests to this technology’s ability to extinguish fires [1]. Foam extinguishing agents have been utilized for almost a century when Johnson [2] suggested that foam may be employed to quench the flame. Many experiments on the effect of foam on liquid pool fire suppression have been conducted. After that, the dominance of fire suppression, as well as the study and improvement of updated fire foam linked with fluid combustion, have been thoroughly investigated [3,4,5,6,7,8].

In a series of tests with three fuel pools, Hinnant et al. [9] found that both foams’ spreading coefficients of iso-negative octane and methylcyclohexane effectively put out a pool fire by both chemicals. Compared to film formation, foam degradation is more closely associated with the estimated fire extinction times. Several studies [10,11,12] indicated that aqueous film-forming foam solution (AFFF) with fluoronates surfactant is extremely effective in extinguishing fuel fires because it may produce a “water film” on the fuel layer to avoid fuel contact with the air.

Chen et al. [13] examined a variety of foam spraying rates on gasoline pool fires. They found that the flow velocity of fire foam is critical to the efficacy of pool fire suppression. As a consequence of the studies, the optimal expansion ratio of foam was calculated. Zhao et al. [14] investigated the extinguishing process and combined fluoroprotein foam with clean surfactants to increase fire extinguisher performance. Several tests [15] were conducted to assess the diffusion coverage effect and alcohol-resistant foam fire suppression performance on oil surfaces. It was found that AFFF/AR outperformed FP/AR in fire suppression under the same conditions. Multiple pool fire suppression studies were conducted by Su et al. [16] using three different combustibles. They created a model based on the way fire foam extinguishes a flame and the fuel’s combustion characteristics, obtaining the validity and dependability of several foam models for various fuels. In a series of diesel fire extinguishing experiments using a laboratory fire-extinguishing system, when Xu et al. [17] looked into how fire foam gas–liquid ratio affected the effectiveness of putting out diesel oil fires, they found that the main factor was the foam’s excellent refrigeration, covering, and suffocating characteristics against thermal transfer and air, which may have prevented the underneath oil from further igniting. These researchers [18] concentrated on the degradability of three perfluoro-carbons fire foams and the applicability of current reference measurements.

Scholars have recently concentrated on tactical firefighting strategies, spray angle and speed, and foam selection in firefighting and rescue. Wang et al. [19] studied the suppression performance of a heat-radiation-leading oilcan fire using self-built suppression equipment and developed a method for calculating the burn rate after foam discharge. According to Kang et al. [20], PF (protein foaming agent) with a 20:1 gas-to-liquid ratio and vertical incidence provides the greatest firefighting capability. Li et al. [21] used self-built foam extinguishing equipment to extinguish methanol/diesel pool fires to assess the diffusion rate of various foams on oil and the foam selection for different oil fire conditions.

To thoroughly investigate the fire suppression procedure, many case studies have long been employed in the field of fire foam. Nevertheless, the previous researchers were on a small scope and were inaccurate regarding the actual situation. The fire extinguishing impact of various fire foams would vary significantly depending on fireground circumstances, spraying methods, and oil types. Moreover, the fire grounds flame causes a drastic variation in the around flow field. Because medium and high expansion foam have little stability, they are easily destroyed by fire and influenced by external wind. Directly spraying to flames on the storage tank cannot adequately overlap the fuel surface owing to the fire smoke plume. Using a gentle application approach, this study simulated the fire suppression procedure once the foam impacted the wall of an oil tank. We also need to pay attention to the fact that in some large fires or emergency rescue, according to our investigation, it is too late to deploy the corresponding foam extinguishing agent, resulting in the mixed use of different types of foam at the fire rescue site. Furthermore, because there is no rigorous quantitative basis for optimizing the fire extinguishing foam, foam selection for firefighting and rescue is not targeted, and each foam’s firefighting performance is not entirely used.

This study conducted experiments utilizing a laboratory fire suppression device with varied or mixed foams, as motivated by the preceding debates. The results of an experimental analysis of 120# gasoline (it is also called solvent gasolines) pool flames employing a gentle application of the low expansion foam spraying method are presented in this work. This study assessed the fire-extinguishing efficiency of several foams based on this. Furthermore, we attempt to compute the temperature range of fire extinguishment as well as the rate of foam flow distance on the oil surface. The analysis results provide extensive statistics, which could be utilized to build a fire suppression system and prospective application to aid in developing system codes and standards in an industrial district or oil tank.

2. Experimental Setup and Methodology

2.1. Experimental Setup

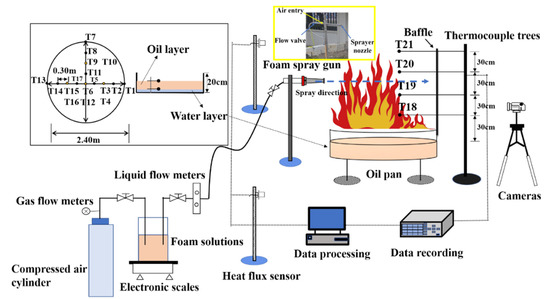

A 2.4 m in diameter and 200-mm-high steel circular fuel tray was built for the foam suppression experiments. Figure 1 depicts the laboratory foam suppression system, with the different components connected by plastic hoses with a layer of flame-retardant fabric laid outside the tube. The system comprises an air bottle, a vessel for holding the foam solutions, two flow meters to control the flow of pushing air and solutions, and a self-priming foam gun.

Figure 1.

Diagram of the fire suppression system.

The foam gun is 1.5 m away from the fuel tray’s edge. Place the foam gun directly opposite the iron baffle to guarantee the foam hits the middle of the baffle. According to GB15308 [22], the foam flows into the fuel tray after spraying under gentle application conditions, and the foam application rate is set to 11.4 L/min.

Temperature thermocouple were positioned perpendicularly and flatly in the fuel tray to measure the temperature fluctuations of the fuel while firing suppression. The eight thermocouples were set up at 1/2 the radius of the fuel tray (characterized by different colors in Figure 1), and measured changes in temperature just at the fuel surface and 5 mm below the top layer, respectively, to characterize the fire suppression and cooling effect of various or mixed types of fire foam.

Each temperature thermocouple was placed at a vertical interval of 30 cm. In addition, four temperature thermocouples were set at 30 cm above the tray’s high border in the direction of the vertical ground surface (T18–T21). A weighing scale calculated the volume of foam solutions used throughout the fire suppression procedure. Two thermal flow sensors were positioned around the fuel tray to monitor the heat radiation during the trials, 300(2.5D) and 600(5D) cm from the central location of the flame and 50 cm from the tray lip, respectively. A camcorder was also employed to capture the experiment and acquire exact fire extinguishing timings, and the data-collecting module was used to obtain actual time data for each apparatus.

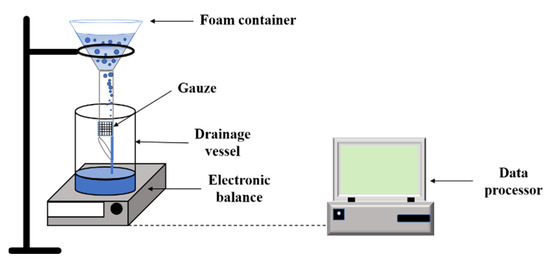

The test fuel that was utilized was 120# gasoline (flashpoint is 6 °C, boiling point ranges from 80 to 120 °C). All kinds of foam extinguishing agents selected in this paper are from the daily foam used by a fire rescue brigade in Guangdong, almost covering the range of common fires involved. The 6% low expansion foam aqueous was purchased from Longxing Fire Fighting Equipment Corporation, Guangdong province, China. A foam container, a foam drainage vessel, and a weighing scale are the main components of the measuring device for drainage characteristics, as shown in Figure 2. The basic parameters and main components of various foams are shown in Table 1 and Table 2.

Figure 2.

Diagram of drainage rate gaging apparatus.

Table 1.

Basic parameters of foam extinguishing agents.

Table 2.

Main components and application scenarios of foam extinguishing agents.

Where S stands for synthesized foam solution. AFFF stands for aqueous film-forming foam solution; FP stands for fluorine-protein foam solution. S/AR stands for alcohol-resistant synthesized foam solution; AFFF/AR stands for alcohol-resistant aqueous film-forming foam solution, and FP/AR stands for alcohol-resistant fluorine-protein foam solution.

Various gas–liquid ratios of foams were poured into a collector, and any foam that overflowed was removed. The foam receiver’s and foam’s overall mass quality were measured. Then, t25% was used to represent the difference in time necessary for 25% of the fluid to drain from the solution. The foaming times (E) and draining velocity (υ) may be calculated using the following expressions:

where E stands for the foaming ratio, V for the foam container’s volume (mL), m1 for the combined mass of the foam extinguishing agent container and the foam, m2 for the weight of the foam extinguishing agent container, and ρfoam for the solution’s density (which is assumed to be 1 g/mL).

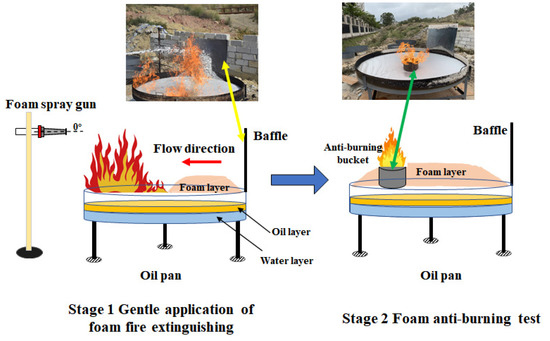

Before any test, the fuel tray was covered with a tiny amount of water, nearly 30 mm thick, then 120# gasoline was poured over the water’s surface to a thickness of 40 mm. Before the combustion, the fire extinguishing system, camcorder system, and data collection module were triggered. After the pool fire development stage, the foam was sprayed into the fuel tray with a rate of flow of 11.4 L/min in the gentle release when the burning was stable. The extinguishment time (99% flame control time) was measured until the visible fuel flame was put out. After 5 min, the re-ignition foam test was started, and the time to burn-back was recorded for 25% of the fuel tray area. After daily trials, the residual liquid mixture in the fuel tray was gathered and transferred to the recycling center for bio-safety treatment to limit pollution to the environment. The process of different stages of the experiment is shown in Figure 3. There were 21 combinations of foam working conditions, including 6 basic types of foam and 15 kinds of equivalent agents mixed in pairs (the mixture ratio of the mixed foam is 1:1).

Figure 3.

Diagram of the experimental stages.

All tests were conducted outside, with wind speeds ranging from 0.3 to 3.0 m/s, no rainfall, and environmental temperature ranging from 20 to 25 °C. The repeatability of the results was ensured by conducting each experiment at least twice, and the data errors of the results were produced by averaging the data and represented by error bars in different figures.

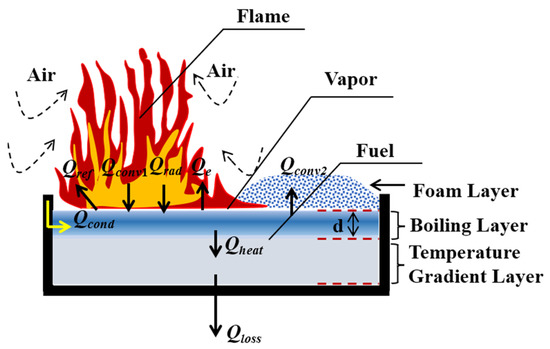

2.2. Models of Heat Transmission

Hamins et al. [23] updated the essential heat transmission theory for oil sheet burning fire suppression, which is shown in Figure 4. In addition, Vali’s study [24] indicates that the aqueous layer is composed of two distinct layers: the boiling layer (BL) and the temperature gradient layer (TGL).

Figure 4.

Diagram of the essential mechanisms of heat transport for thin oil layer combustion and the temperature composition of the aqueous layer.

Whenever gasoline evaporates at a high enough temperature to form a boiling layer, the rate of combustion is often characterized by the amount of heat absorbed by this layer. Based on the principle of energy conservation, Equation (3) calculates the heat obtainable to evaporate at any instant.

is the total net heat directly used to evaporate. Convective heat transfer from the oil sheet to the flame is denoted by , while the flame’s thermal flow to the aqueous layer is denoted by . The represents the conduction of heat from the adjacent wall to the liquid. The foam and fuel layers exchange heat through convection, denoted by . The represents the thermal conduction from the boiling layer to the gradient temperature layer. Heat flow reflected off the water’s surface is denoted by , whereas heat lost to the environment is denoted by .

In realistic calculations, is ignored. The cause of to is a tiny ratio (∼3–4%) [23]. This term is ignored in our trials since our burning area is big enough, and is only considered when the burning area is smaller than 0.01 m2, according to previous research [23,25,26]. As a result, Equation (4) may be used to rewrite the entire net heat of combustion in our experiments.

3. Results and Discussion

3.1. Applicability of Foam Extinguishing Agent

The foam selected in this paper comes from the type of foam extinguishing agent used by the fire rescue detachment in the experimental location. Combined with the practical experience of firefighting and rescue, the applicability of various extinguishing agents used in this paper to different types of fires is obtained. As shown in Table 3, for the gasoline fire extinguishing object in this paper, namely the fire of water-insoluble fuel, the selected six types of foam fire extinguishing did not appear inapplicable. The worst applicability of foam is that it is usually not used. In the actual rescue at the fire site, there will be a lack of fire extinguishing agent or an inappropriate situation. In combination with the experimental situation in this paper, each experiment ensures the accuracy of measurement data and eliminates errors. Each group of experiments shall be conducted at least twice. The experimental results in this paper have not failed to extinguish the fire completely. Therefore, the single type of foam selected in this experiment has good applicability, and combined with the actual situation of foam mixing in fire rescue, the single and mixed foam fire extinguishing experiment can provide some reference for fire rescue practice.

Table 3.

Applicability of various fire extinguishing agents used in the experiment to put out different types of fires.

3.2. Fire Suppression Procedure

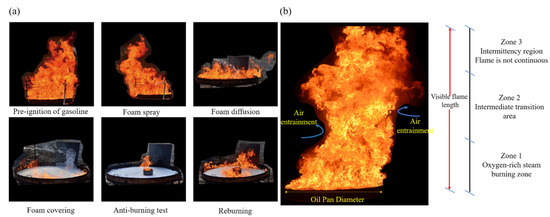

Figure 5 displays the actual flame morphology of a 120# gasoline pool fire as captured by consecutive transient flame pictures. Continuous combustion occurs at the gasoline’s surface. The fire continues to burn without external interference until the gasoline in the fuel tray has been used up.

Figure 5.

(a) Diagram of the fire suppression process; and (b) Flame shape.

Thermodynamics dictates that there are three distinct regions to a pool fire’s burning process. The first region would be mostly vapor. The fuel surface fire generates high temperatures, evaporates moisture, and boosts the ratio of vapor to airflow, all the while maintaining a steady flame. Unburned liquid gasoline vapor in this zone will rise because it has a lower density than air when it is being heated, creating an interstitial gap where the fire is kept burning low and air is drawn in. Consequently, an air-eddy and the air around the flame produce air entrainment. The residual unfired fuel vapor moves into the third zone, the intermittent area. The difference in air content in the burning region causes this intermittent zone of flame combustion, where stripped pieces of fuel vapor burn in random clumps.

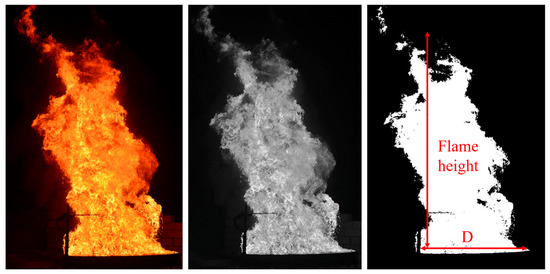

A well-established method utilized in previous works can be used to obtain the flame intermittency distribution and average values of consistent binary images. [27,28,29,30,31]. The mean flame length was determined based on a flame intermittency of 0.5. In this experiment, the height extraction process of flames is shown in Figure 6. The height of the stable combustion stage of 120# gasoline is about 5.0 m. From a different angle, the flame height can confirm that the pool fire combustion has reached a stable stage.

Figure 6.

Flame height extraction process.

The experimental data of 120# gasoline are classified by time, as indicated in Table 4.

Table 4.

Results of foam suppression 120# gasoline pool fire.

According to the fire extinguishing time data in Table 4, we found that the AFFF has an excellent fire extinguishing efficiency, followed by fluoroprotein foam, and then synthetic foam. In terms of time alone, without considering the interaction of components, the mixed foam with the same quality shows better fire extinguishing efficiency than the single foam. The experimental results can basically reflect the respective advantages of the two types of foam after mixing, for example, the stability of anti-soluble foam is not easy to re-ignite; moreover, the cooling effect of aqueous film forming and fluoroprotein foam.

3.3. Temperature Analysis of Foam Extinguishing

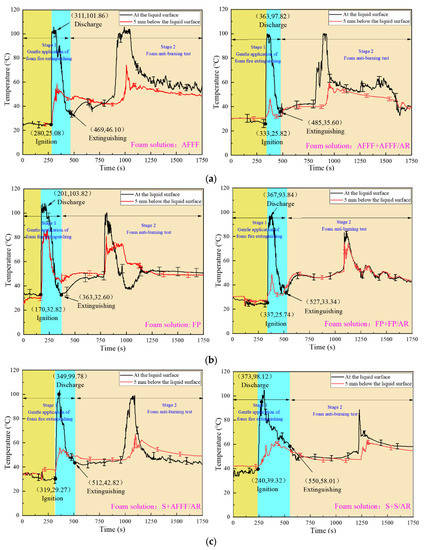

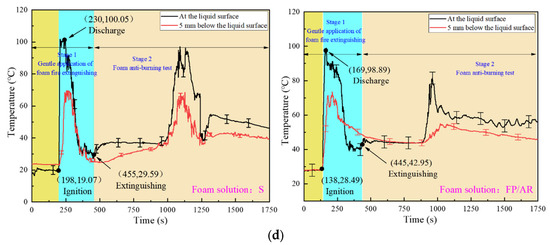

While the blaze is being suppressed, the value of the T-6 and T-12 temperature thermocouples in the middle of the fuel tray is recorded as such a typical temperature. To measure temperature differences throughout the fire suppression process, temperature thermocouples were positioned near the oil–blaze contact and 0.5 cm just under the fuel surface in the fuel tray. The cooling impact of the foam cover, in particular, clearly illustrates the difficulty of re-igniting residual gasoline in the fuel tray. The study uses the eight foams listed below as examples. Figure 7a–d depicts temperature curves for several types of foam suppression procedures. The data in Table 5 are the temperatures of various types of foam when extinguishing oil fires and 200 s after extinguishing.

Figure 7.

(a) The temp (°C) of T-6 & T-12 temperature thermocouples using AFFF and AFFF + AFFF/AR in the 120# gasoline pool fire; (b) The temp (°C) of T-6 and T-12 temperature thermocouples using FP and FP + FP/AR in the 120# gasoline pool fire; (c) The temp (°C) of T-6 and T-12 temperature thermocouples using S + AFFF/AR and S + S/AR in the 120# gasoline pool fire; (d) The temp (°C) of T-6 and T-12 temperature thermocouples using S and FP/AR in the 120# gasoline pool fire.

Table 5.

Fuel surface temperature when the foam is used to put out the fire and after 200 s of putting out the fire with different and mixed kinds of foam solution.

When the oil is ignited, the fire is far less intense. Soon, the oil’s surface will absorb enough heat to boil, forming a boiling layer that will be several millimeters thick. The surface of the burning fuel is susceptible to the transmission of heat through conduction and radiation from the wall, as well as convection and radiation from the flame itself. At the same time, the temperature gradient layer under the oil’s surface is steadily raised by the boiling layer’s continued heating. The addition of foam solution to the pool will cause the fire to gradually diminish since the foam will inhibit the evaporation of fuel. Because of this, the flame will not grow as tall. On the flip side, the foam will prevent the oil’s surface from re-absorbing heat that is radiated from the flame. Therefore, the feedback from the flame’s thermal flow to the fuel surface will keep going down. It is worth noting that the amount of convection heat transfer between the foam layer and the fuel surface increases as the foam expands to cover more area. This means that the oil is losing heat at an alarming rate. It is crucial to note that the temperature of the layer under the oil’s surface progressively increased throughout the fire extinguishment phase, eventually reaching the same level as the oil’s surface. It is still possible for heat to be transferred from the top layer of boiling oil to the layer with a temperature differential because the flames have not been completely suppressed.

The data points of the curves depict the three phases of extinguishing a foam fire. It has been shown that the growth of a flame is assisted along with the pre-igniting fuel during foam suppression. When the fire foam is ejected, the temperature of oil surface soon reaches its maximum (about 100 °C, which is close to the boiling point of 120# gasoline), which is almost identical to the boiling temperatures of the fuel. The fuel tray air is short to be completely encased in foam, creating an environment that is both flammable and coboiling. In addition, the rise or fall in surface temperature has a direct impact on the underlying temperature of the liquid.

Due to the foam’s outstanding chilling and enveloping capabilities, the temperature decreases significantly when the spraying process is constant. The surface temperatures of 120# gasoline oil drop to roughly 40 °C throughout the suppression and extinguishment phase. This study attempts to provide fire extinguishing temperatures for 120# gasoline using video contents and curves. We find that curve temperatures will drop dramatically or that curve gradients will show a striking propensity to shift. According to our research, the optimal temperature range for extinguishing fires is between 62 and 66 degrees Celsius. In this article, we use the non-dimensionalized method of describing the foam suppression temperature as the specific value of the mean extinguishing temperature to the boiling point of gasoline (θ* = θExtinguishing/θboiling point). Non-dimensional mean fire extinguishing temperatures for 120# gasoline is calculated to be between 0.62 and 0.66.

After then, the temperature begins to rise again. The fire is extinguished, the foam spray ending, and the complex physicochemical interactions between the layer of foam and the gasoline surface all contribute to the bubble dissolving and the temperature increasing. Ultimately, temperatures remain rather stable both below the oil’s surface and at the fuel’s surface.

When the fire suppression time and the other results from Table 4 are analyzed, it is found that the FP and AFFF are pretty effective at putting out flames caused by 120# gasoline. The AFFF has a similar effect on the fluorine-containing surfactant in FP. The foam expands on the gasoline surface and forms a “moisture” that restricts fuel from evaporating while also lowering the gasoline surface temperature and isolating the air, thereby effectively controlling the flame.

This is because the foam extinguishing agent and the moisture that drains from the layer of the foam have an effect of temp-decrease, and the active components in two distinct foams are largely hydrocarbon surface activators. The fuel is protected from the combustible air and vapor by a blanket of foam extinguishing agent that has been spread. The water reduces the amount of oxygen available in the fire’s combustion zone, which in turn lowers the flame temperature, and the temperature of the gasoline, and ultimately puts out the fire.

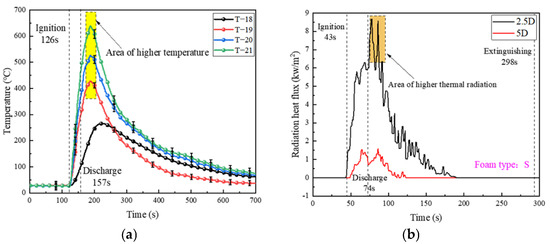

3.4. Flame Temperature and Heat Flow in Erectly

The video imaging process revealed flame amplification at the onset of foam release, as well as the rapid growth of fire, which extended in the flame’s upper part. Figure 8 shows that at the beginning of the foam spraying, there is a pronounced peak in temperature and radiation (for instance, synthetic foam), corroborating the occurrence of co-boiling. When the foam comes into contact with the surface of the burning fuel, the vapor pressure at the liquid’s surface increases, causing a substantial concentration of combustible gases to form at the flame’s epicenter. The combustion equilibrium is disturbed by co-boiling, and the high moisture level of the sprayed foam extinguishing agent enhances the air entrainment effect, which increases the contact area between the flammable gas and the air at the flame’s center. Additionally, under more intense flame radiation circumstances, the air bubbles in the foam rupture release air. Because of this, the flame’s core will become very hot, improving combustion efficiency [19]. Foam gradually forms an effective blanket and spreads across the fuel surface as moisture in the foam works on the heating element to decrease the burning zone and flame temperature. When the additional foam is released, the fire in the pool is extinguished because the rate at which the combustible liquid evaporates is slowed, effectively isolating the flame from the burning surface. It is possible that the foam barrier may prevent the fire from spreading further and the fuel from rekindling after the fire has been put out.

Figure 8.

(a) Temperatures at the vertical direction in 120# gasoline pool fire; and (b) Variations in the radiative heat flux for synthetic foam.

3.5. Flow Velocity of Foam on the Oil-Water Mixed Liquids Surface

According to the observations, the foam first gathers around the baffle, just as it was shown in the video showing the process of putting out a fire. After that, the foam swiftly spreads out in a normal arc-shaped pattern. As the amount of the layer of foam that is produced expands, the propagation of foam across the surface of the liquid passes through different phases. These phases are referred to as the gravity–inertia regime, the gravity–viscous regime, and the surface–tension–viscous regime [32]. The critical thickness of the foam layer, TF, is defined as the boundary between the gravity domain and the surface tension domain in the SFPE Handbook [32].

where Δ = (ρfuel − ρfoam)/ρfuel, g is the acceleration of gravity (981 cm/s2). The coefficient of spread (Dyn/cm) sa/b is given by sa/b =γb − γa − γl, where γb is the surface tension of the lower moisture layer of a water-insoluble gasoline (Dyn/cm), γa is the surface tension of the top layer of foam solutions (Dyn/cm), and γl is the interfacial tension between the two layers. According to the published literature [32], the coefficient of spread of foam solution over gasoline is around −7.8. Thus, the critical thickness of the foam layer determined by our studies using Equation (5) is around 0.02 cm. Thus, the diffusion is in a viscous dominant area of surface tension because the foam’s thickness is greater than the foam’s critical value. Therefore, the fuel surface spreading length is determined by

IF represents the length of fire foam spreading in the fuel tray, and υ stands for the kinematic viscosity of the fuel measured in centimeters per second. Spreading distance is directly proportional to the power of time and inversely proportional to viscosity, as seen in Equation (6). It is also clear that the viscosity of the foam reduces and the foam spreads more quickly as the temperature increases.

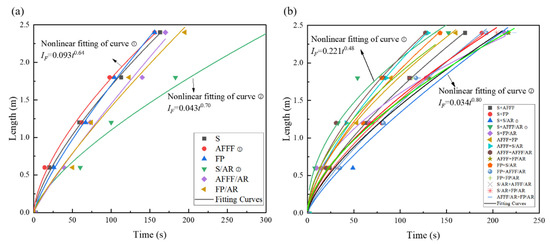

It should be emphasized that Equation (6) was originally formulated for oil spread over water, and that its application to foam spread on a fuel surface relies on this assumption. On the fire scene, however, the foam is constantly evolving. The foam extinguishing agent never stops receiving heat feedback from the flame and the tray wall during the whole duration of the process of putting out the fire. As a direct consequence of this, the foam’s viscosity is reduced, and the rate at which it propagates is quickened [33]. As a direct result of this, the results with various types of foam extinguishing agent and fuel are modeled by applying an exponential connection, which was published by Wang et al. [20]. This correlation is indicated by the equation IF = a × tn, and it can be found in Figure 9. By doing so, we can estimate how far a foam in a liquid pool fire will travel.

Figure 9.

Variations in foam spreading length (m) for (a) 6 basic foam and (b) 15 types of mixed foam in a 120# gasoline pool fire.

The length of the foam’s spreading was calculated using video footage captured using a camcorder. In Figure 9, we can observe that the incline of the increasing length gradually decreases with time. Therefore, the gradient of the curve may be utilized to estimate the instantaneous flow speed of the foam extinguishing agent. We calculated the exact amount of time that the foam blanket spent moving in a horizontal path over the fuel container (see Figure 9). It is important to note that the flow time did not match the time required to put out the fire, as shown in Table 4. In conclusion, the firefighting and the progress of the flow were both initiated by the spraying and forward movement of the foam. When considering the method by which foam is dispersed, it is possible that the difference results from foam accumulation and the effect of temp-decrease at the start of the release. Until the foam extinguishing agent builds up to a certain thickness, it is unable to advance at this time.

According to Table 6, we can use the flow time to obtain the average of the different foam flow velocities over the surface of the burning fuel. With 6% AFFF + AFFF/AR, the fastest flow speed was 0.0189 m s−1, and the foam extinguishing agent release rate was 11.4 L/min, while fighting a 120# gasoline pool fire. At the outset of extinguishing a 120# gasoline pool fire, non-AR foam (AFFF > S > FP) spreads more quickly. AR-foam, on the other hand, does not spread as quickly as 120# gasoline in a pool fire. Because of its high gas concentration, alcohol-resistant foam is more stable and expands faster than conventional foam; yet, its density makes it difficult to deal with. Moreover, according to Table 6, AFFF mixed with AFFF/AR foams performed better than other foams when coupled with them. Due to increasing heat feedback from the wall of the fuel tray and the flame, the foam’s viscosity reduces and its spread rate rises during fire suppression. The application of an oleophobic fluorine-containing surfactant helps to reduce spreading efficiency while boosting foam boundary thickness. This, in turn, reduces the efficiency of fuel combustion and has a linked physical chemistry suppression effect, contributing to the extinguishment of the fire.

Table 6.

Velocities of different foam flows were determined using a curve-fitting method.

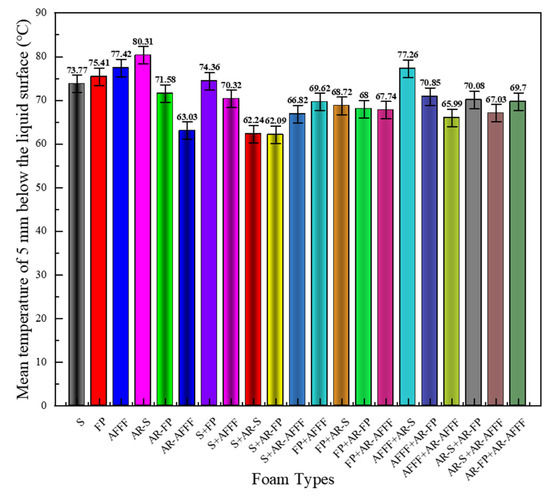

3.6. Temperature Analysis under the Gasoline Surface of Several foam Extinguishing Agents

It was discovered that the cooling impact of various foam extinguishing agents varies to diverse degrees. It has been discovered that the cooling performance of the foam extinguishing agents is as follows: S + FP/AR > S + S/AR > AFFF/AR > AFFF + AFFF/AR > S + AFFF/AR > S/AR + AFFF/AR for a 120# gasoline pool fire.

Figure 10 demonstrates the foam’s noticeable cooling effect beneath the 120# fuel surface. Fuel-burning causes a more pronounced rise under the liquid surface because the temperature of the liquid surface is around 100 °C.

Figure 10.

Bar chart of the mean temperature below the fuel surface.

As a result, while putting out a fire started with 120# gasoline, we need first to take into account the cooling impact of foam to lower the flame temperature before reducing radiation to put out the fire. This explains why the 120# gasoline pool fire took the longest to put out with S/AR in this study. We discovered that the S/AR expansion rate (9.3) is considerably larger, which is consistent with the foam’s gas concentration. The foam’s fragmented air bubbles increase the combustion rate at the expense of cooling effectiveness. The findings of the foam’s cooling capabilities also show that synthetic foam and AFFF/AR combined with other AR foams have better cooling outcomes. This exemplifies the covering resilience of AR-foams and the thermal insulation characteristics of synthetic foam.

The cooling impact of the foam is the most important aspect in 120# gasoline pool fires. FP foam and AFFF should be employed for efficient fire suppression in this type of hydrocarbon fuel fire rescue, according to the trial results. Then, we may utilize synthetic foam and AR-foams to effectively cover the fire with foam to offer continual cooling and stop it from re-igniting.

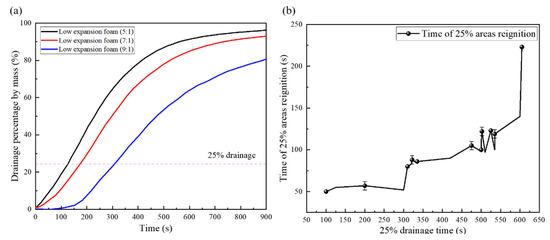

3.7. The Foam Stability

Foams, whether low-expansion or high-expansion, are thermodynamically unstable because of the substantial interfacial free energy they possess. Foam bubbles and their agglomerations are constantly being broken down by liquid drainage or foam film fracturing, and they never reach equilibrium. Foam-producing procedures and foam types have the most impact on foam stability, which is represented by foam drainage time [34,35,36]. Figure 11a demonstrates how the producing method and foam expansion affect how long foam drains. A typical air-foam cannon produces the low expansion foam (5:1, 7:1, and 9:1) at a rate of flow of 11.4 L/min.

Figure 11.

The link between: (a) Different foam expansion rates; (b) Foam burn-back time at 25% and foam drainage percentage.

The drainage procedures are largely the same for different foam expansions. The stationary phase, which is the period before the foam starts to drain liquid, lasts for a while. Foams with expansion ratios of 5:1 or higher, such as compressed air foam, have the longest stationary phase times. During the drainage phase, low-expansion foam performs better than compressed air foam. As a foam expands, its ability to drain water slows down. According to the results, compressed air foam is more stable than low-expansion foam and more stable than greater-expansion compressed air foam within a specific range.

The results indicate that foam with an expansion ratio of 8.7:1 (FP + AFFF/AR) offers better burn-back protection and re-ignition resistance. High-expansion compressed air foam, on the other hand, does not encourage the formation of a water film when the drainage period is very long. Because of this, the high-expansion compressed air foam was not always effective at controlling or putting out fires quickly. According to Figure 11b, the foam’s resistance to re-ignition increases with draining time in a given range. Foam stability consequently has a big impact on burn-back protection, re-ignition resistance, and firefighting foam extinguishing performance.

4. Conclusions

This investigation used a laboratory foam extinguishing device to compare the efficacy of several foams in putting out a 120# gasoline pool fire. It should be noted that the effectiveness of various foams may vary depending on factors such as the size of the tank fire, the amount of foam discharged, the kind of gasoline used, and other initial conditions. To examine more intricate situations, however, we may broaden our experimental and theoretical approach. It has been shown that significant phenomena, such as the cooling effect that occurs after foam discharge and the spreading rate of distinct foam on the surface of gasoline, continue to occur in extensive oilcan fire accidents.

- (1)

- The instantaneous increase in flame temperature caused by discharging the foam poses a significant risk in actual rescue situations. Time required to put out a fire depends on the fuel’s surface temperature, as we saw above. The findings show that FP foam and AFFF are more effective than water on a 120# gasoline pool fire, and that the cooling performance was noticeable on the fire’s surface. Our video imaging procedure and the resulting curves are an attempt to provide safe temperatures for extinguishing fires with 120# gasoline. In this study, the extinguishing temperatures of 120# gasoline fuel were determined to be in the non-dimensional range of 0.62 to 0.66;

- (2)

- Foam suppression highlights the foam’s cooling function. According to the findings, the order of the foams’ cooling effectiveness in the 120# gasoline pool fire is as follows: S + FP/AR > S + S/AR > AFFF/AR > AFFF + AFFF/AR > S + AFFF/AR > S/AR + AFFF/AR;

- (3)

- According to the results, foam with an expansion ratio of 8.7:1 (FP + AFFF/AR) has greater re-ignition resistance and burn-back protection;

- (4)

- The research presented herein offers a useful framework for selecting foam for liquid fire suppression. The cooling impact of the foam is the most important aspect in the event of 120# gasoline pool fires. Based on the findings of the experiments, FP foam and AFFF are recommended for use in hydrocarbon fuel fire rescues for successful fire suppression. Then, we may utilize synthetic foam and AR-foams to effectively douse the flames with foam and keep the area cold for as long as possible.

Author Contributions

Conceptualization, Z.L.; methodology, Z.L.; software, C.T. and J.Z.; validation, H.Z. and F.Q.; formal analysis, Z.L.; investigation, Z.L.; resources, H.Z., F.Q., C.T. and J.Z.; data curation, Z.L., C.T. and J.Z.; writing—original draft preparation, Z.L.; writing—review and editing, H.Z. and F.Q.; visualization, Z.L., C.T. and J.Z.; supervision, H.Z. and F.Q.; project administration, H.Z. and F.Q.; funding acquisition, H.Z. and F.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No. 51774290). And The APC was funded by Hongqing Zhu.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors declare that the data supporting the findings of this study are available within the article.

Acknowledgments

This study was made possible thanks to funding from the National Natural Science Foundation of China (No.51774290). The authors would like to extend their gratitude to the editor, as well as the anonymous reviewers, whose in-depth critiques and perceptive comments significantly contributed to the overall improvement in the quality of the completed paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, A.K.; Dlugogorski, B.Z. Multipurpose Overhead Compressed-Air Foam System and Its Fire Suppression Performance. J. Fire Prot. Eng. 1996, 8, 133–150. [Google Scholar] [CrossRef]

- Hill, C.; Eastoe, J. Foams: From nature to industry. Adv. Colloid Interface Sci. 2017, 247, 496–513. [Google Scholar] [CrossRef]

- Hill, C.; Czajka, A.; Hazell, G.; Grillo, I.; Rogers, S.E.; Skoda, M.W.; Joslin, N.; Payne, J.; Eastoe, J. Surface and bulk properties of surfactants used in fire-fighting. J. Colloid Interface Sci. 2018, 530, 686–694. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Jiang, N.; Miao, X.; Li, F.; Wang, J.; Zong, R.; Lu, S. Comparative studies on foam stability, oil-film interaction and fire extinguishing performance for fluorine-free and fluorinated foams. Process. Saf. Environ. Prot. 2019, 133, 201–215. [Google Scholar] [CrossRef]

- Ranjbar, H.; Shahraki, B.H. Effect of Aqueous Film-Forming Foams on the Evaporation Rate of Hydrocarbon Fuels. Chem. Eng. Technol. 2013, 36, 295–299. [Google Scholar] [CrossRef]

- Sontake, A.R.; Wagh, S.M. The phase-out of perfluorooctane sulfonate (PFOS) and the global future of aqueous film forming foam (AFFF), innovations in fire Fighting foam. Chem. Eng. Sci. 2014, 2, 11–14. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, J.-S. The Feasibility Study of Extinguishing Oil Tank Fire by Using Compressed Air Foam System. Procedia Eng. 2016, 135, 61–66. [Google Scholar] [CrossRef]

- Wang, K.; Fang, J.; Shah, H.R.; Lang, X.; Mu, S.; Zhang, Y.; Wang, J. Research on the influence of foaming gas in compressed air/nitrogen foam on extinguishing the n-heptane tank fire. J. Loss Prev. Process. Ind. 2021, 72, 104533. [Google Scholar] [CrossRef]

- Hinnant, K.; Button, M.; Giles, S.; Snow, A.; Ananth, R. Fuel effects on aqueous film formation and foam degradation and their impact on fire suppression by foams containing fluorosurfactants. Fire Mater. 2020, 45, 833–841. [Google Scholar] [CrossRef]

- Hinnant, K.M.; Giles, S.L.; Smith, E.P.; Snow, A.W.; Ananth, R. Characterizing the role of fluorocarbon and hydrocarbon surfactants in firefighting-foam formulations for fire-suppression. Fire Technol. 2019, 56, 1413–1441. [Google Scholar] [CrossRef]

- Laundess, A.J.; Rayson, M.S.; Dlugogorski, B.Z.; Kennedy, E.M. Small-scale test protocol for firefighting foams DEF (AUST) 5706: Effect of bubble size distribution and expansion ratio. Fire Technol. 2010, 47, 149–162. [Google Scholar] [CrossRef]

- Sheng, Y.; Jiang, N.; Sun, X.; Lu, S.; Li, C. Experimental study on effect of foam stabilizers on aqueous film-forming foam. Fire Technol. 2017, 54, 211–228. [Google Scholar] [CrossRef]

- Chen, T.; Fu, X.-C.; Bao, Z.-M.; Xia, J.-J.; Wang, R.-J. Experimental study on the extinguishing efficiency of compressed air foam sprinkler system on oil pool fire. Procedia Eng. 2018, 211, 94–103. [Google Scholar] [CrossRef]

- Zhao, M.; Ni, X.; Zhang, S.; Cao, W.; Guan, Y.; Liang, C.; Wang, X.; Zhang, H. Improving the performance of fluoroprotein foam in extinguishing gasoline pool fires with addition of bromofluoropropene. Fire Mater. 2014, 40, 261–272. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, L.; Bi, Y.; Xu, D.; Zhi, H.; Qiu, P. Experimental investigation of foam spread and extinguishment of the large-scale methanol pool fire. J. Hazard. Mater. 2015, 287, 87–92. [Google Scholar] [CrossRef]

- Su, L.; Wang, L.J.; Wang, Z.H.; Zhang, J.; Tian, Y.X.; Yan, Y.G. Investigation on compressed air foams fire-extinguishing model for fuel tray fire. Procedia Eng. 2012, 45, 663–668. [Google Scholar] [CrossRef]

- Xu, Z.; Guo, X.; Yan, L.; Kang, W. Fire-extinguishing performance and mechanism of aqueous film-forming foam in diesel pool fire. Case Stud. Therm. Eng. 2019, 17, 100578. [Google Scholar] [CrossRef]

- Bourgeois, A.; Bergendahl, J.; Rangwala, A. Biodegradability of fluorinated fire-fighting foams in water. Chemosphere 2015, 131, 104–109. [Google Scholar] [CrossRef]

- Wang, K.; Fang, J.; Shah, H.R.; Mu, S.; Lang, X.; Wang, J.; Zhang, Y. A theoretical and experimental study of extinguishing compressed air foam on an n-heptane storage tank fire with variable fuel thickness. Process. Saf. Environ. Prot. 2020, 138, 117–129. [Google Scholar] [CrossRef]

- Kang, W.; Yan, L.; Ding, F.; Guo, X.; Xu, Z. Experimental study on fire-extinguishing efficiency of protein foam in diesel pool fire. Case Stud. Therm. Eng. 2019, 16, 100557. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, H.; Zhao, J.; Zhang, Y.; Hu, L. Experimental Research on the Effectiveness of Different Types of Foam of Extinguishing Methanol/Diesel Pool Fires. Combust. Sci. Technol. 2022, 1–19. [Google Scholar] [CrossRef]

- GB 15308; Foam Extinguishing Agent. Standards Press of China: Beijing, China, 2006.

- Hamins, A.; Kashiwagi, T.; Burch., R. Characteristics of pool fire burning. In Fire Resistance of Industrial Fluids; ASTM International: West Conshohocken, PA, USA, 1995. [Google Scholar]

- Vali, A. Investigation of the Transport Phenomena within the Liquid Phase of a Methanol Pool Fire. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2014. [Google Scholar]

- Zhao, J.; Huang, H.; Jomaas, G.; Zhong, M.; Yang, R. Experimental study of the burning behaviors of thin-layer pool fires. Combust. Flame 2018, 193, 327–334. [Google Scholar] [CrossRef]

- Drysdale, D. An Introduction to Fire Dynamics, 3rd ed.; John Wiley & Sons, Ltd.: New York, NY, USA, 2011. [Google Scholar]

- Fletcher, T.H.; Haycock, D.; Tollefsen, S.; Lignell, D.O. Merging of Horizontally and Vertically Separated Small-Scale Buoyant Flames. Fire 2021, 4, 51. [Google Scholar] [CrossRef]

- Tao, C.; He, Y.; Zhuang, Y.; Qian, Y.; Cheng, X.; Wang, X. The investigation of flame length of buoyancy-controlled gas fire bounded by wall and ceiling. Appl. Therm. Eng. 2017, 127, 1172–1183. [Google Scholar] [CrossRef]

- Wang, Y.; Vouros, A.; Zhang, J.; Delichatsios, M.A. Numerical and experimental validation study of flame extent of a pool fire under the ceiling. J. Loss Prev. Process. Ind. 2017, 49, 652–659. [Google Scholar] [CrossRef]

- He, P.X.; Wang, P.; Wang, K.; Liu, X.P.; Wang, C.M.; Tao, C.F.; Liu, Y.Q. The evolution on the behavior of flame height and air flow for double rectangular pool fires. Fuel 2019, 237, 486–493. [Google Scholar] [CrossRef]

- Liu, Q.; Du, B.; Yan, Q.; Shi, L.; Li, M.; Li, Z. Study on Coupled Combustion Behavior of Two Parallel Line Fires. Fire 2022, 5, 14. [Google Scholar] [CrossRef]

- Hurley, M.J.; Gottuk, D.; Hall, J.R., Jr.; Harada, K.; Kuligowski, E.; Puchovsky, M.; Torero, J.; Watts, J.M., Jr.; Wieeczrek, C. Foam Agents and AFFF System Design Considerations. In SFPE Handbook of Fire Protection Engineering; Scheffey, J.L., Ed.; Springer: New York, NY, USA, 2015; pp. 1658–1660. [Google Scholar]

- Nakakuki, A. Heat transfer in pool fires at a certain small lip height. Combust. Flame 2002, 131, 259–272. [Google Scholar] [CrossRef]

- Magrabi, S.; Dlugogorski, B.; Jameson, G. A comparative study of drainage characteristics in AFFF and FFFP compressed-air fire-fighting foams. Fire Saf. J. 2002, 37, 21–52. [Google Scholar] [CrossRef]

- Lunkenheimer, K.; Malysa, K.; Winsel, K.; Geggel, K.; Siegel, S. Novel method and parameters for testing and characterization of foam stability. Langmuir 2009, 26, 3883–3888. [Google Scholar] [CrossRef]

- Britan, A.; Ben-Dor, G.; Shapiro, H.; Liverts, M.; Shreiber, I. Drainage effects on shock wave propagating through aqueous foams. Colloids Surf. A Physicochem. Eng. Asp. 2007, 309, 137–150. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).