Study on the Prediction Model of Coal Spontaneous Combustion Limit Parameters and Its Application

Abstract

:1. Introduction

2. Optimized BP Neural Network Model

2.1. Sample Data

2.2. BP Neural Network

2.3. GA-BP Neural Network Model

- (1)

- Coding. Real coding is used to prevent falling into the local optimum with the mean square error as the evaluation index and the inverse of the mean square error 1/EMSE as the fitness function f. The smaller the loss is, the higher the fitness is, i.e.,where O is the model desired output, T is the mean, and N is the number of input samples.

- (2)

- Generating initial population. N individuals that are randomly generated form a population. The GA starts evolving continuously based on the initial point.

- (3)

- Selecting operator. The purpose of the selection operation is to pick the best individuals which can reproduce their offspring as parents, reflecting the idea of survival of the fittest. The probability of individual selection is based on a method of roulette wheel, that is, individuals that account for a larger proportion of fitness have a higher chance of being selected.where k represents individuals in the population.

- (4)

- Crossover operator. Crossover operation is a major genetic method of genetic algorithm, reflecting the idea of information exchange. The real coding method is adopted in this paper. The method of crossover is to take a (0, 1) random number m and a certain position (j) in the two chromosomes (ak and al) for crossover, combining to get two new chromosomes, i.e.,

- (5)

- Mutation operator. Mutation is the process of mutating selected individuals to form new individuals on the basis of a particular probability, which is to maintain the diversity of the population. Based on the random probability r (r (0, 1)), the yth gene of the xth chromosome is selected to mutate and the mutated chromosome a′xy is obtained with the expression:where amax and amin are the upper and lower bounds of gene axy, respectively, and f(t) = r1(1 − t/Gmax), where t is the current iteration number, Gmax is the maximum evolution number, and r1 is a random number of (0, 1).

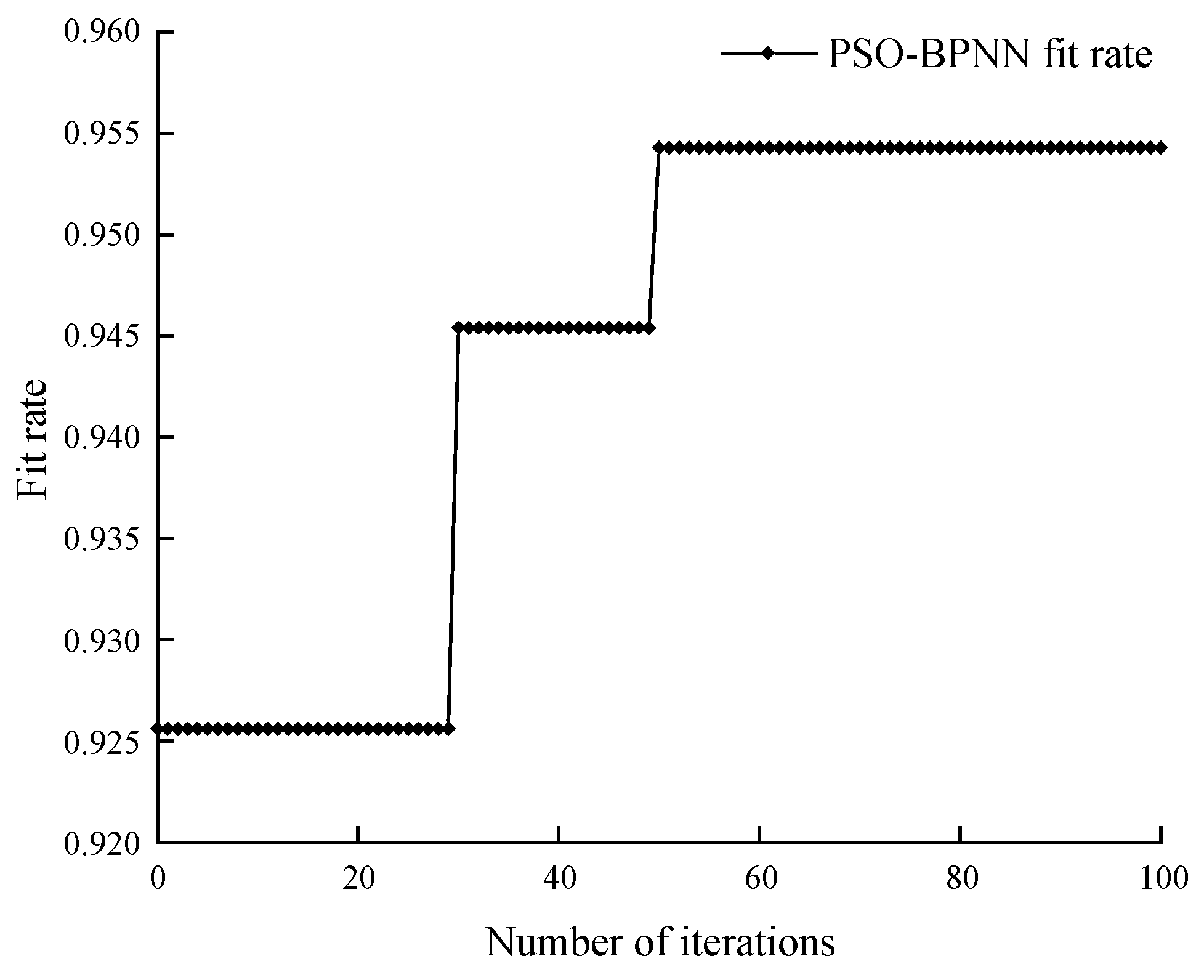

2.4. The PSO-BP Neural Network Model

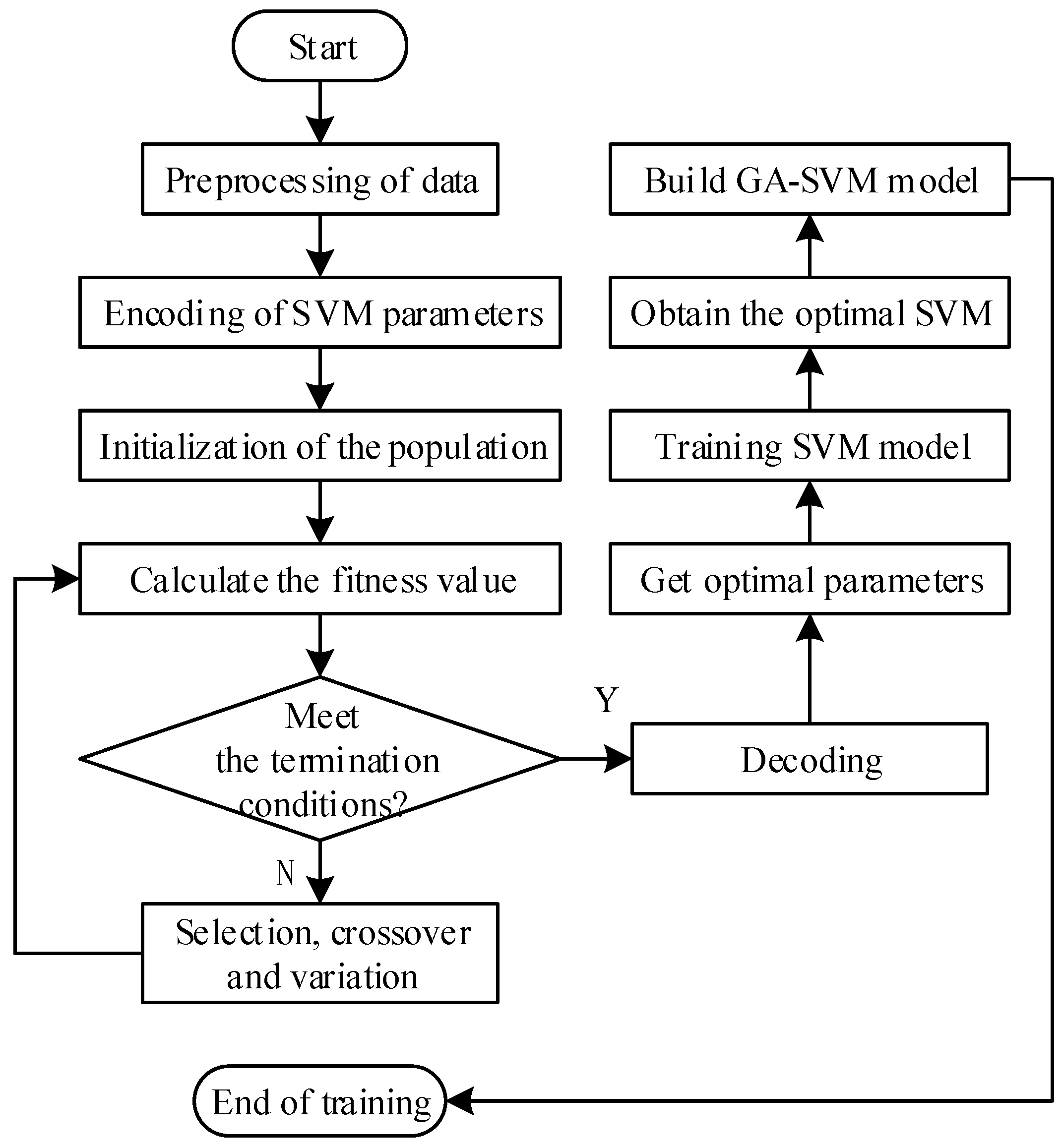

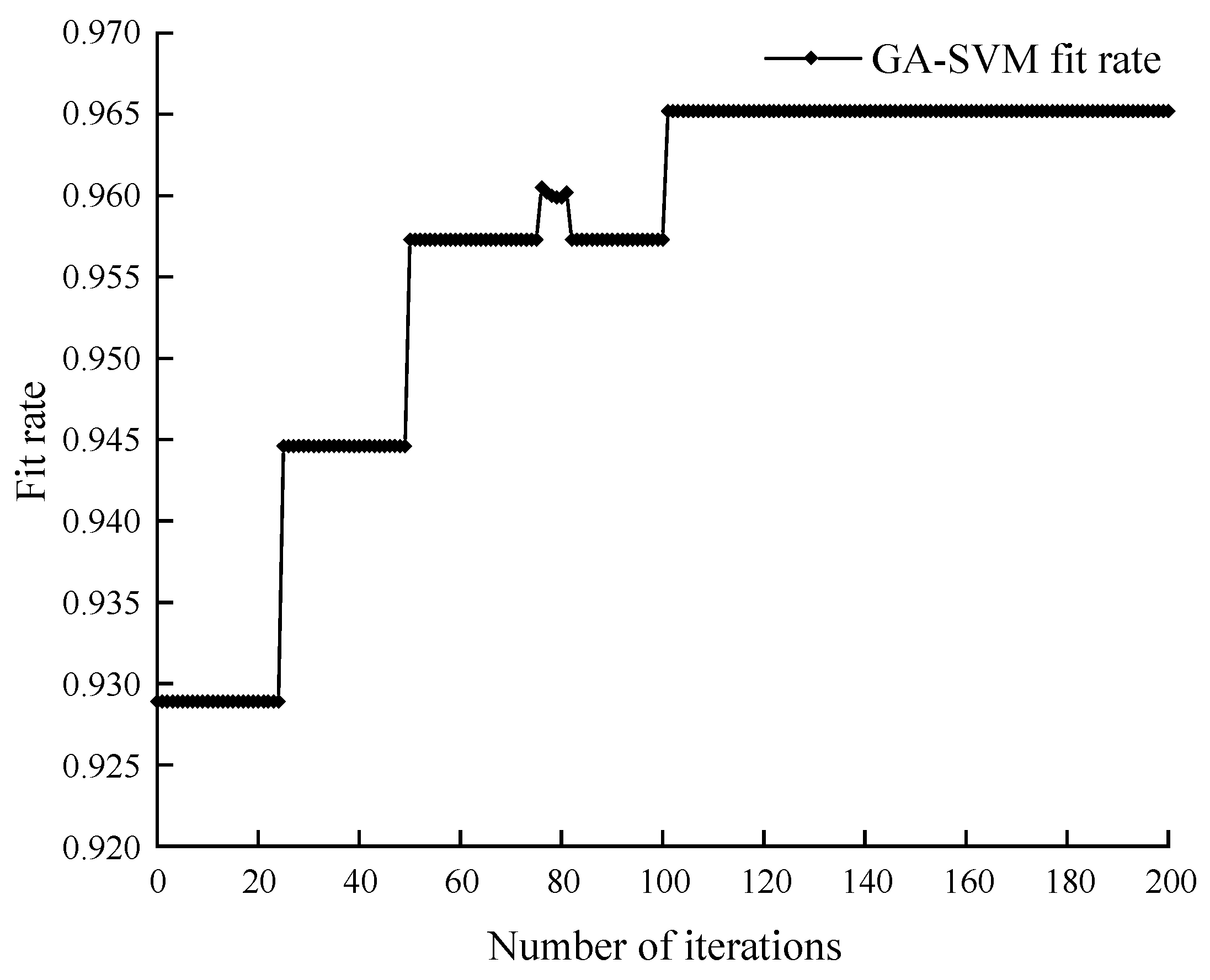

3. The GA-SVM Prediction Model

3.1. Support Vector Machine

3.2. Optimization of the SVM by the GA

- (1)

- Normalize the sample data and divide the training and test sets;

- (2)

- Encode the type of kernel function, kernel parameters, and penalty factors of the SVM in the binary coding manner and generate the initialization population,

- (3)

- Determine the fitness function and calculate the fitness value,

- (4)

- Determine whether the condition of termination is reached or not. If so, carry out the decoding operation; if not, perform selection, crossover, and mutation to form a new population and go to step (3), until the condition of termination is satisfied,

- (5)

- Train the SVM model by decoding to obtain the optimal parameters, and then train the GA-SVM model by obtaining the optimal SVM.

4. Forecast Results and Example Analysis

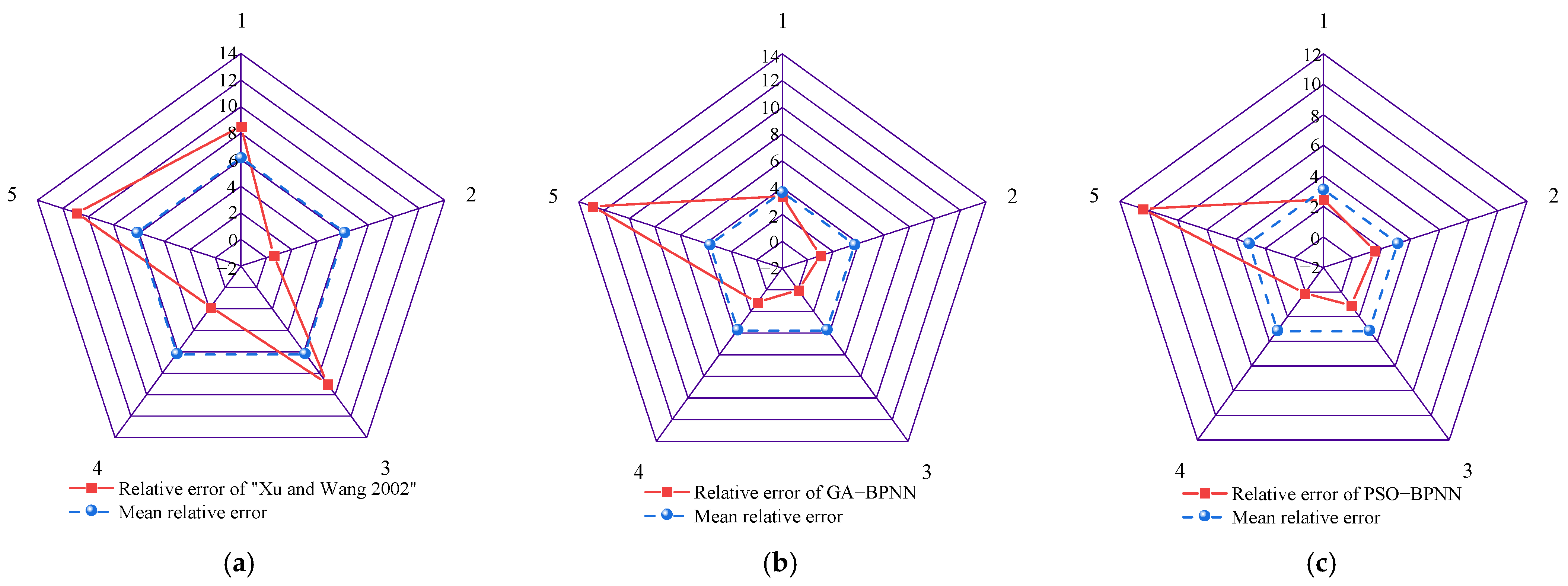

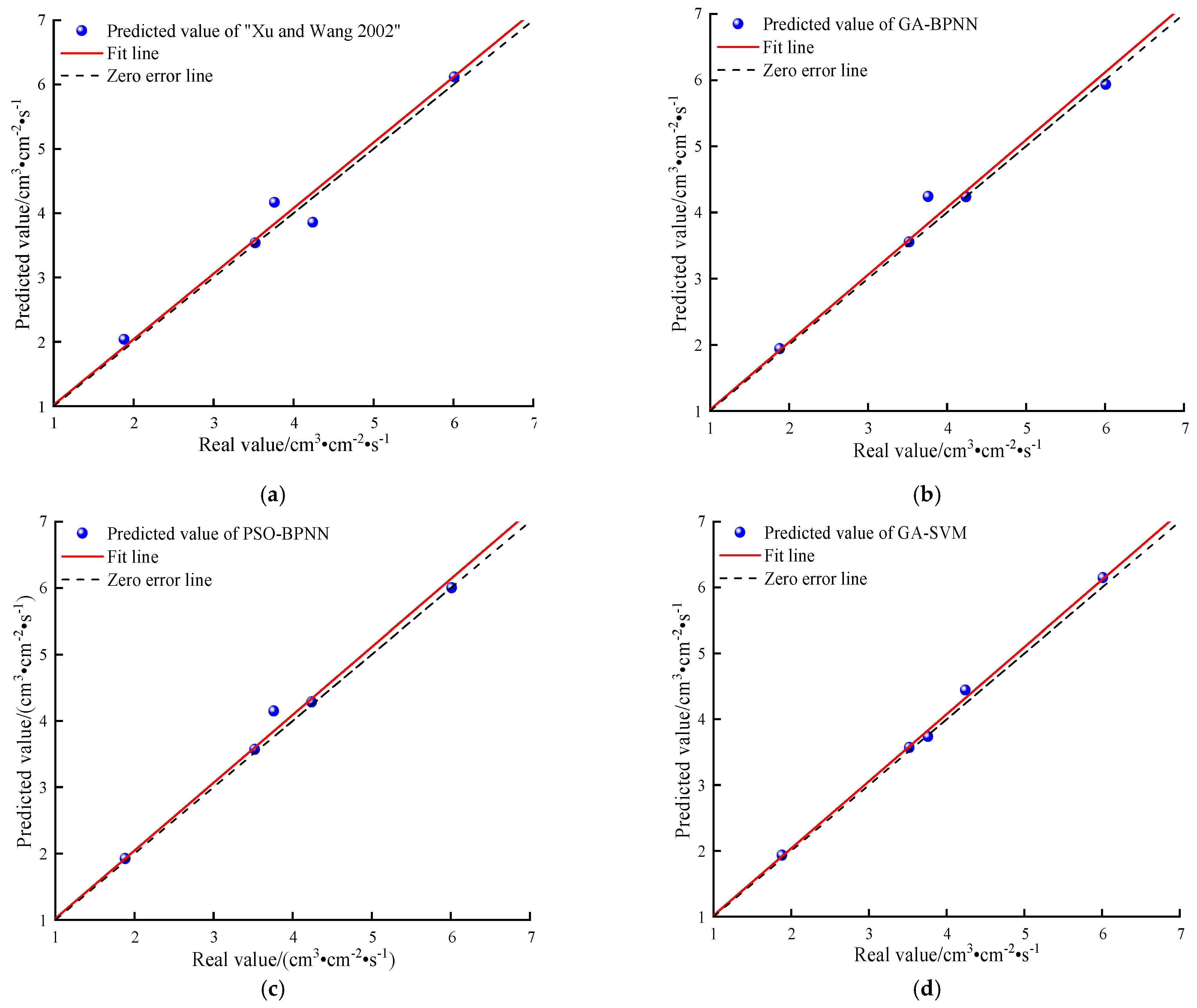

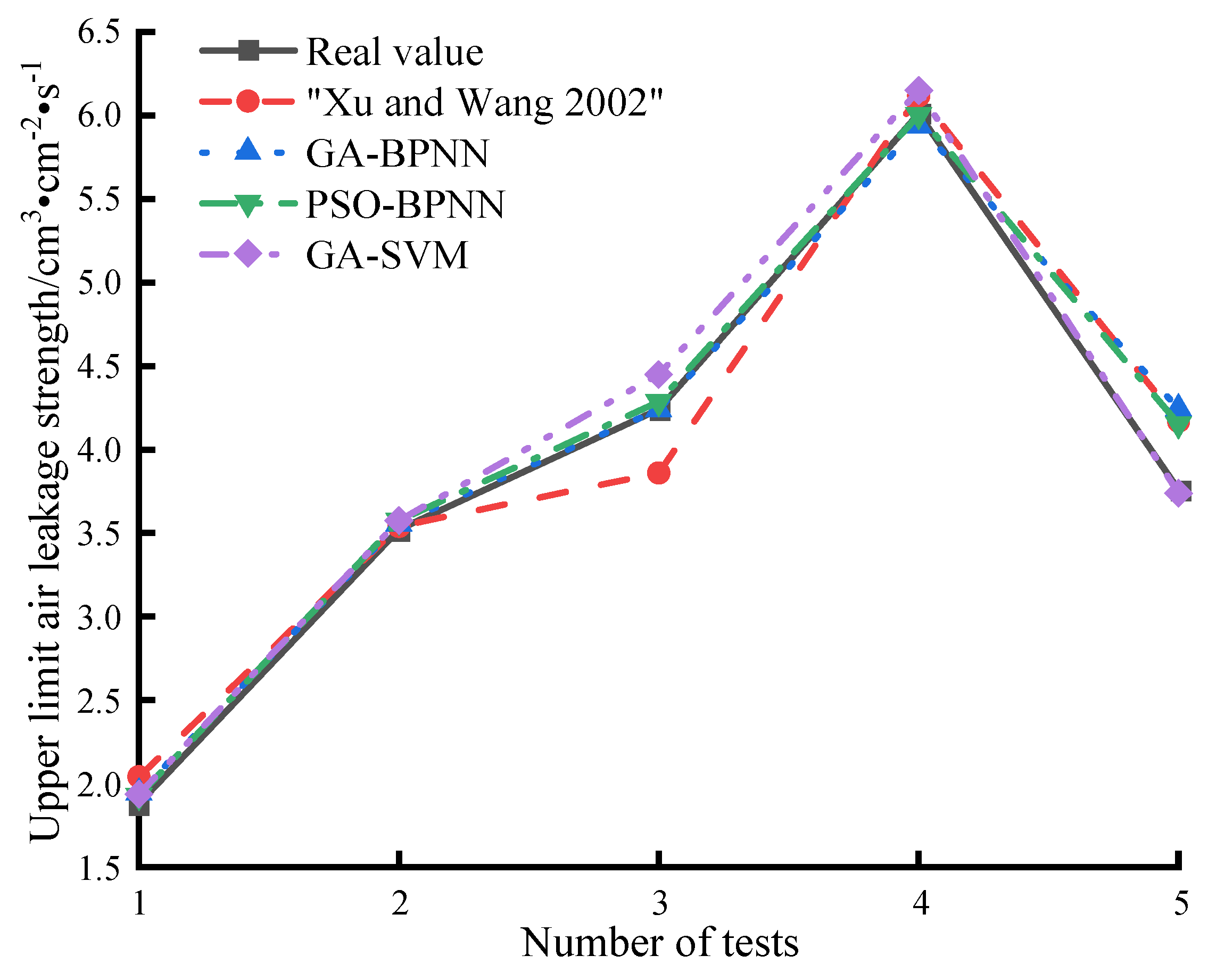

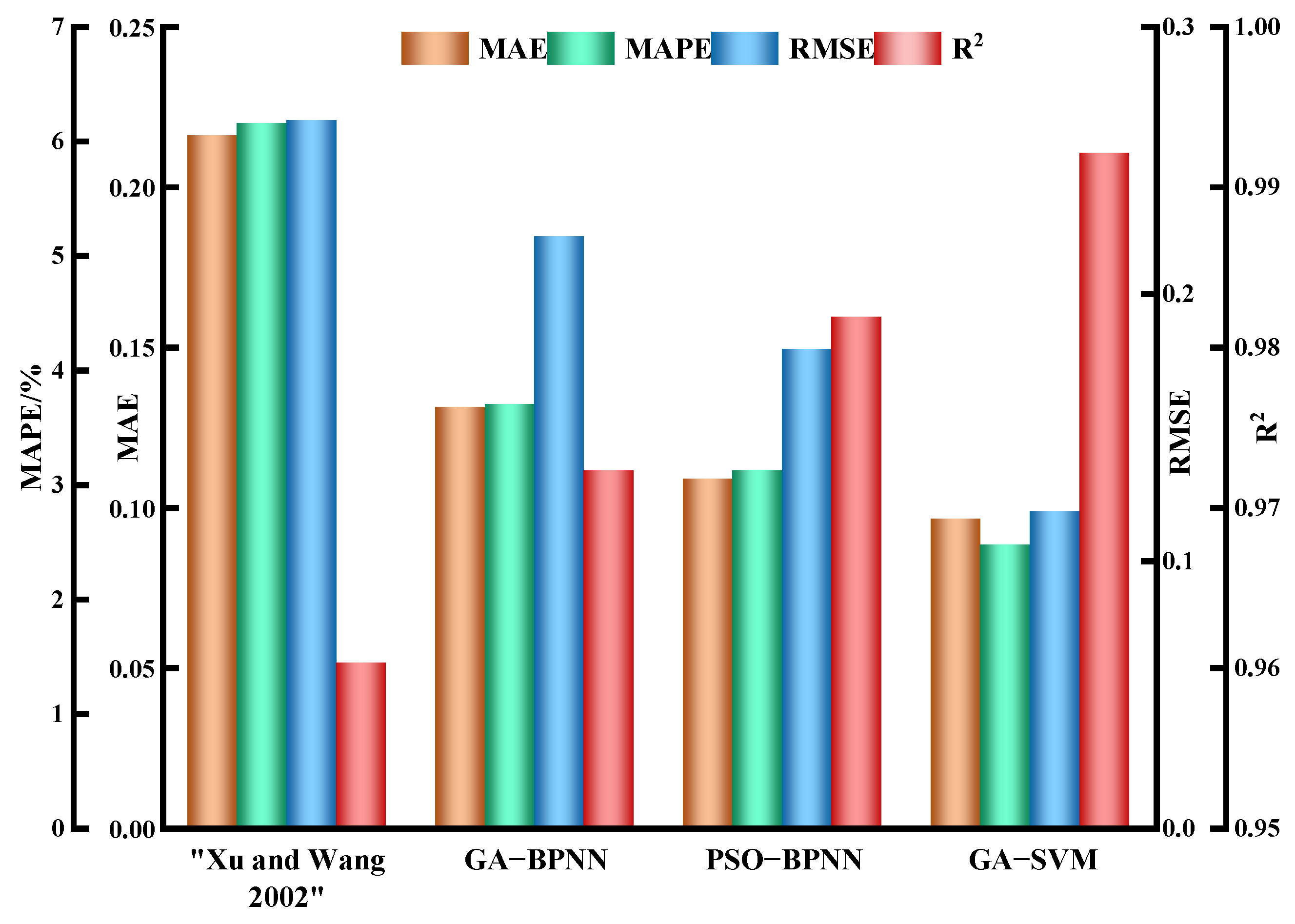

4.1. Analysis of Results

4.2. Example Applications

5. Conclusions

- (1)

- A coal spontaneous combustion limit parameter prediction model is proposed based on BP neural network. Two optimization algorithms, GA and PSO, are applied to improve the BP neural network, respectively. The results show as follows: after optimization of the GA and the PSO, the BP neural network overcomes the shortcomings, such as slow convergence and local optimum. The prediction results of the BP neural network optimized by the PSO are better than those optimized by the GA;

- (2)

- Comparing the prediction results of each prediction model with those in the reference [9], the results show the following: the MAE, MAPE, and RMSE of the GA-SVM model are reduced by 0.0126, 0.65%, and 0.0609 than the PSO-BPNN model, respectively; the R2 is increased by 0.0103 than the PSO-BPNN model. Compared with the GA-BPNN model, the MAE, MAPE, and RMSE were reduced by 0.0349, 1.23%, and 0.1032, respectively, with R2 increasing by 0.0199. Compared to reference [9], the MAE, MAPE, and RMSE were reduced by 0.12, 3.70%, and 0.1468, respectively, with R2 increasing by 0.0319. Therefore, the prediction results of the GA-SVM model are superior to all other models, followed by the PSO-BPNN model, with reference [9] bringing up the rear, which indicates that the GA-SVM model can effectively improve the accuracy of the prediction of the parameters of the spontaneous combustion limit of coal;

- (3)

- To further verify the universality and stability of the GA-SVM model, it is applied to the prediction of the minimum coal thickness in the goaf of a coal mine in Shanxi. Compared with other prediction models, the results show that the prediction effect of the GA-SVM model is optimal over the other models, indicating that the GA-SVM model is more accurate in predicting the parameters of the spontaneous combustion limit of coal.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Niu, K.; Du, W.; Zhang, J.; Wang, H.; Zhang, J. A method to identify coal spontaneous combustion—Proneregions based on goaf flow field under dynamic porosity. Fuel 2021, 288, 119690. [Google Scholar] [CrossRef]

- Wang, W.; Qi, Y.; Jia, B.; Yao, Y. Dynamic prediction model of spontaneous combustion risk in goaf based on improved CRITIC-G2-TOPSIS method and its application. PLoS ONE 2021, 16, e0257499. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Xu, K.; Xue, G.; Liu, J.; Xu, Z. Prediction of coal spontaneous combustion temperature based on improved grey wolf optimizer algorithm and support vector regression. Fuel 2022, 324 Pt B, 124670. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, W.; Qi, Q.; Ning, Z.; Yao, Y. Distribution of spontaneous combustion three zones and optimization of nitrogen injection location in the goaf of a fully mechanized top coal caving face. PLoS ONE 2021, 16, e0256911. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-C.; Zhong, K.-Q.; Xiao, Y.; Lai, X.-P.; Li, Q.-W. Determining the Spontaneous Combustion Period and Limit Parameters of Coal: A Large-Scale Furnace Experiment. Combust. Sci. Technol. 2023, 195, 494–507. [Google Scholar] [CrossRef]

- Wang, W.; Qi, Y.; Liu, J. Study on multi field coupling numerical simulation of nitrogen injection in goaf and fire-fighting technology. Sci. Rep. 2022, 12, 17399. [Google Scholar] [CrossRef]

- Qiao, M.; Ren, T.; Roberts, J.; Yang, X.; Li, Z.; Wu, J. New insight into proactive goaf inertisation for spontaneous combustion management and control. Process Saf. Environ. Prot. 2022, 161, 739–757. [Google Scholar] [CrossRef]

- Yan, H.; Nie, B.; Kong, F.; Liu, Y.; Liu, P.; Wang, Y.; Chen, Z.; Yin, F.; Gong, J.; Lin, S.; et al. Experimental investigation of coal particle size on the kinetic properties of coal oxidation and spontaneous combustion limit parameters. Energy 2023, 270, 126890. [Google Scholar] [CrossRef]

- Xu, J.; Wang, H. The neural network prediction method for the limit parameters of coal self-ignition. J. China Coal Soc. 2002, 27, 366–370. [Google Scholar] [CrossRef]

- Deng, J.; Ren, S.; Ren, L.; Wang, C.; Li, Q. Hazard indicators and limit parameters of coal spontaneous combustion in Eastern Sichan. J. Xi’an Univ. Sci. Technol. 2021, 42, 196–202. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, H.; Wang, Y.; Zhou, Y. Predicting limit parameters of coal self-ignition based on support vector machine. J. China Coal Soc. 2009, 34, 1489–1493. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, X.; Bai, Z.; Deng, J.; Shu, C.-M.; Zhang, M. Comprehensive index evaluation of the spontaneous combustion capability of different ranks of coal. Fuel 2021, 291, 120087. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Li, Y.; Li, Q.; Zhang, J.; Yang, C. Study on the characteristics of coal spontaneous combustion during the development and decaying processes. Process Saf. Environ. Prot. 2020, 138, 9–17. [Google Scholar] [CrossRef]

- Zhang, F. Limit parameter changes and hazardous area determination of residual coal spontaneous combustion in compound goaf. Min. Saf. Environ. Prot. 2020, 41, 66–72. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Zou, Z.; Liu, Q. Study on spontaneous combustion characteristics and limit parameters of coal in high geothermal mine. Coal Technol. 2020, 39, 90–93. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, H.; An, Q.; Li, X.; Cheng, W.; Dou, K. Analysis on limit parameters of coal spontaneous combustion in goaf of Kaida coal mine. J. Saf. Sci. Technol. 2021, 17, 86–92. [Google Scholar] [CrossRef]

- Wang, J.; Su, H.; Li, J.; Zou, L.; Ren, L. Effect of sulfur content on characteristics and limiting parameters of coal spontaneous combustion. Saf. Coal Mines 2020, 51, 43–48. [Google Scholar] [CrossRef]

- Zhou, X.; Niu, T.; Bai, G.; Li, A.; Wang, C. Study on influence of air supply on limit parameters of spontaneous combustion of lignite. J. Saf. Sci. Technol. 2018, 14, 82–86. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Will, S. Fintech model: The random neural network with genetic algorithm. Procedia Comput. Sci. 2018, 126, 537–546. [Google Scholar] [CrossRef]

- Mahya, M.; Alireza, A.; Masoud, R. Transmission and generation expansion planning of energy hub by an improved genetic algorithm. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 3112–3126. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, L.M.; Qin, Y. Modified constriction particle swarm optimization algorithm. J. Syst. Eng. Electron. 2015, 26, 1107–1113. [Google Scholar] [CrossRef]

- Cao, Y.; Yin, K.; Zhou, C.; Ahmed, B. Establishment of landslide groundwater level prediction model based on GA-SVM and influencing factor analysis. Sensors 2020, 20, 845. [Google Scholar] [CrossRef] [PubMed]

| No. | Distance/m | Oxygen Concentration/% | Coal Temperature/°C | Heat Liberation Intensity/105 J·s−1·cm−3 | Thickness of Residual Coal/m | Upper Limit Air Leakage Intensity/cm3·cm−2·s−1 |

|---|---|---|---|---|---|---|

| 1 | 1.7 | 20.60 | 19.60 | 0.87 | 0.7 | 0.70 |

| 2 | 2.5 | 20.04 | 20.30 | 1.04 | 0.6 | 0.83 |

| 3 | 4.7 | 19.88 | 22.00 | 1.27 | 0.5 | 1.08 |

| 4 | 7.6 | 19.03 | 22.50 | 1.34 | 0.4 | 1.56 |

| 5 | 16.3 | 18.21 | 24.20 | 1.43 | 0.2 | 2.35 |

| 6 | 20.5 | 17.99 | 25.60 | 1.51 | 0.3 | 2.58 |

| 7 | 25.2 | 17.60 | 26.70 | 1.58 | 0.4 | 2.88 |

| 8 | 29.1 | 17.36 | 26.80 | 1.58 | 0.3 | 3.17 |

| 9 | 36.4 | 16.90 | 27.50 | 1.62 | 0.2 | 3.43 |

| 10 | 43.9 | 15.74 | 28.30 | 1.67 | 0.3 | 3.87 |

| 11 | 44.3 | 15.68 | 28.60 | 1.69 | 0.4 | 3.92 |

| 12 | 47.0 | 14.91 | 28.10 | 1.66 | 0.5 | 4.12 |

| 13 | 53.7 | 13.77 | 25.13 | 1.49 | 0.7 | 5.60 |

| 14 | 56.4 | 13.09 | 24.80 | 1.47 | 0.6 | 5.77 |

| 15 | 59.0 | 12.44 | 24.30 | 1.43 | 0.5 | 6.00 |

| 16 | 61.2 | 11.93 | 23.60 | 1.40 | 0.4 | 6.53 |

| 17 | 70.6 | 10.78 | 24.67 | 1.46 | 0.2 | 5.39 |

| 18 | 74.3 | 9.81 | 26.30 | 1.55 | 0.2 | 4.18 |

| 19 | 78.0 | 8.85 | 27.80 | 1.61 | 0.3 | 3.76 |

| 20 | 89.2 | 7.14 | 30.40 | 1.79 | 0.3 | 2.89 |

| No. | Distance/m | Oxygen Concentration/% | Coal Temperature/°C | Heat Liberation Intensity/105 J·s−1·cm−3 | Thickness of Residual Coal/m | Upper Limit Air Leakage Intensity/cm3·cm−2·s−1 |

|---|---|---|---|---|---|---|

| 21 | 11.0 | 18.59 | 23.40 | 1.39 | 0.3 | 1.88 |

| 22 | 39.7 | 16.50 | 27.90 | 1.64 | 0.2 | 3.52 |

| 23 | 50.4 | 14.36 | 28.20 | 1.66 | 0.6 | 4.24 |

| 24 | 66.8 | 11.18 | 24.20 | 1.43 | 0.3 | 6.01 |

| 25 | 83.5 | 7.97 | 28.10 | 1.66 | 0.4 | 3.76 |

| Parameter | Specific Values |

|---|---|

| Genetic generations | 50 |

| Population size | 5 |

| Maximum number of iterations | 1000 |

| Learning rate | 0.01 |

| Error threshold | 0.0000001 |

| No. | True Values /cm3·cm−2·s−1 | Prediction Values /cm3·cm−2·s−1 | Absolute Error | Relative Error/% |

|---|---|---|---|---|

| 1 | 1.88 | 1.9433 | 0.0633 | 3.37 |

| 2 | 3.52 | 3.5554 | 0.0354 | 1.00 |

| 3 | 4.24 | 4.2388 | 0.0012 | 0.03 |

| 4 | 6.01 | 5.9394 | 0.0706 | 1.17 |

| 5 | 3.76 | 4.2442 | 0.4842 | 12.88 |

| Parameter | Specific Values |

|---|---|

| Population size | 5 |

| Maximum number of iterations | 1000 |

| Learning rate | 0.01 |

| Error threshold | 0.0000001 |

| Learning factors | 2 |

| Number of population updates | 30 |

| No. | True Values /cm3·cm−2·s−1 | Prediction Values /cm3·cm−2·s−1 | Absolute Error | Relative Error/% |

|---|---|---|---|---|

| 1 | 1.88 | 1.9263 | 0.0463 | 2.46 |

| 2 | 3.52 | 3.5737 | 0.0537 | 1.53 |

| 3 | 4.24 | 4.2859 | 0.0459 | 1.08 |

| 4 | 6.01 | 6.0041 | 0.0059 | 0.10 |

| 5 | 3.76 | 4.1511 | 0.3911 | 10.40 |

| Parameter | Specific Values |

|---|---|

| Maximum evolutionary generations of the genetic algorithm | 200 |

| Population size | 20 |

| Number of cross-validations | 5 |

| Penalty coefficient | [0.1, 100] |

| Radius of the Gaussian kernel function | [0.01, 1000] |

| No. | True Values /cm3·cm−2·s−1 | Prediction Values /cm3·cm−2·s−1 | Absolute Error | Relative Error /% |

|---|---|---|---|---|

| 1 | 1.88 | 1.9354 | 0.0554 | 2.94 |

| 2 | 3.52 | 3.5748 | 0.0548 | 1.56 |

| 3 | 4.24 | 4.4483 | 0.2083 | 4.91 |

| 4 | 6.01 | 6.1503 | 0.1403 | 2.33 |

| 5 | 3.76 | 3.7386 | 0.0214 | 0.57 |

| Name of the Method | Duration of the Analysis/s |

|---|---|

| GA-BPNN | 8.35 |

| PSO-BPNN | 5.61 |

| GA-SVM | 4.11 |

| Models | Performance Index | |||

|---|---|---|---|---|

| MAE | MAPE/% | RMSE | R2 | |

| Reference [9] | 0.2160 | 6.16 | 0.2648 | 0.9602 |

| GA-BPNN | 0.1309 | 3.69 | 0.2212 | 0.9722 |

| PSO-BPNN | 0.1086 | 3.11 | 0.1789 | 0.9818 |

| GA-SVM | 0.0960 | 2.46 | 0.1180 | 0.9921 |

| No. | True Values/m | BPNN | GA-BPNN | PSO-BPNN | GA-SVM | ||||

|---|---|---|---|---|---|---|---|---|---|

| Prediction Values/m | Relative Error/% | Prediction Values/m | Relative Error/% | Prediction Values/m | Relative Error/% | Prediction Values/m | Relative Error/% | ||

| 1 | 0.53 | 0.56 | 5.66 | 0.4747 | 10.44 | 0.5095 | 3.86 | 0.5101 | 3.76 |

| 2 | 0.77 | 0.74 | 3.90 | 0.7706 | 0.08 | 0.7664 | 0.47 | 0.7834 | 1.75 |

| 3 | 0.84 | 0.90 | 7.14 | 0.8546 | 1.74 | 0.8353 | 0.56 | 0.8534 | 1.59 |

| 4 | 0.73 | 0.68 | 6.85 | 0.7163 | 1.88 | 0.7173 | 1.74 | 0.7417 | 1.60 |

| 5 | 1.11 | 1.14 | 2.70 | 1.0981 | 1.07 | 1.1592 | 4.43 | 1.0878 | 2.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Liang, R.; Qi, Y.; Cui, X.; Liu, J.; Xue, K. Study on the Prediction Model of Coal Spontaneous Combustion Limit Parameters and Its Application. Fire 2023, 6, 381. https://doi.org/10.3390/fire6100381

Wang W, Liang R, Qi Y, Cui X, Liu J, Xue K. Study on the Prediction Model of Coal Spontaneous Combustion Limit Parameters and Its Application. Fire. 2023; 6(10):381. https://doi.org/10.3390/fire6100381

Chicago/Turabian StyleWang, Wei, Ran Liang, Yun Qi, Xinchao Cui, Jiao Liu, and Kailong Xue. 2023. "Study on the Prediction Model of Coal Spontaneous Combustion Limit Parameters and Its Application" Fire 6, no. 10: 381. https://doi.org/10.3390/fire6100381

APA StyleWang, W., Liang, R., Qi, Y., Cui, X., Liu, J., & Xue, K. (2023). Study on the Prediction Model of Coal Spontaneous Combustion Limit Parameters and Its Application. Fire, 6(10), 381. https://doi.org/10.3390/fire6100381