On the Large Eddy Simulation Modelling of Water Suppression Systems Droplet Impact and Coverage Area

Abstract

1. Introduction

- (i)

- Establish a predictive fire model to simulate sprinkler and water mist fire suppression system in a room fire scenario, and validate the model via comparison against referenced experimental data;

- (ii)

- Perform a series of numerical case studies by adjusting the fire location with different nozzle configurations;

- (iii)

- Compare the spray mechanisms and coverage area of water-mist against convention fire sprinkler systems;

- (iv)

- In-depth analysis of the fire suppression efficiency in terms of penetration capacity between the buoyant flaming fluid mixture and water droplets;

2. Computational Methods

2.1. Governing Equations, Turbulence Model

2.2. Combustion Model

2.3. Extinguishment and Evaporation

2.3.1. Extinction Model

2.3.2. Droplet Evaporation Models

3. Experiment and Numerical Configurations

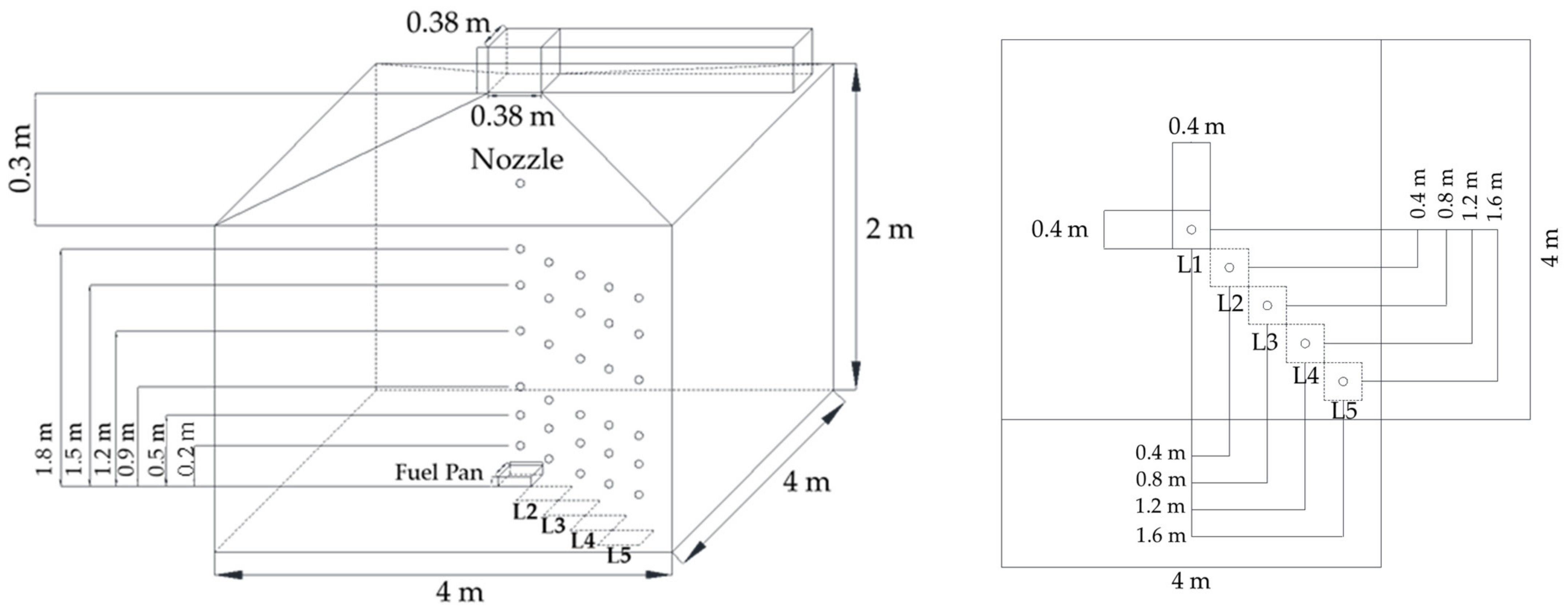

3.1. Compartment Geometry

3.2. Fuel Pan/Combustion Configuration and Measurement

3.3. Suppression Systems

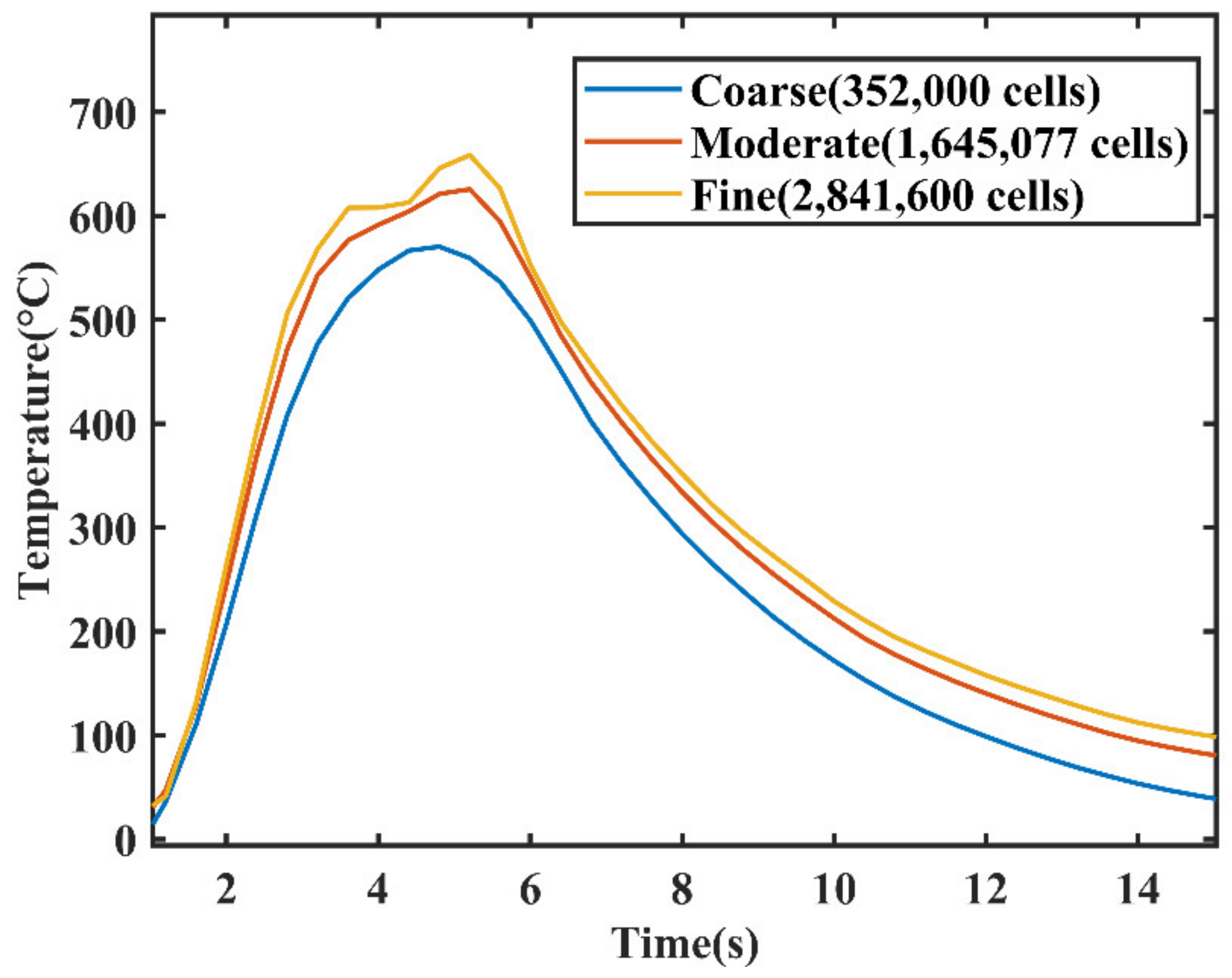

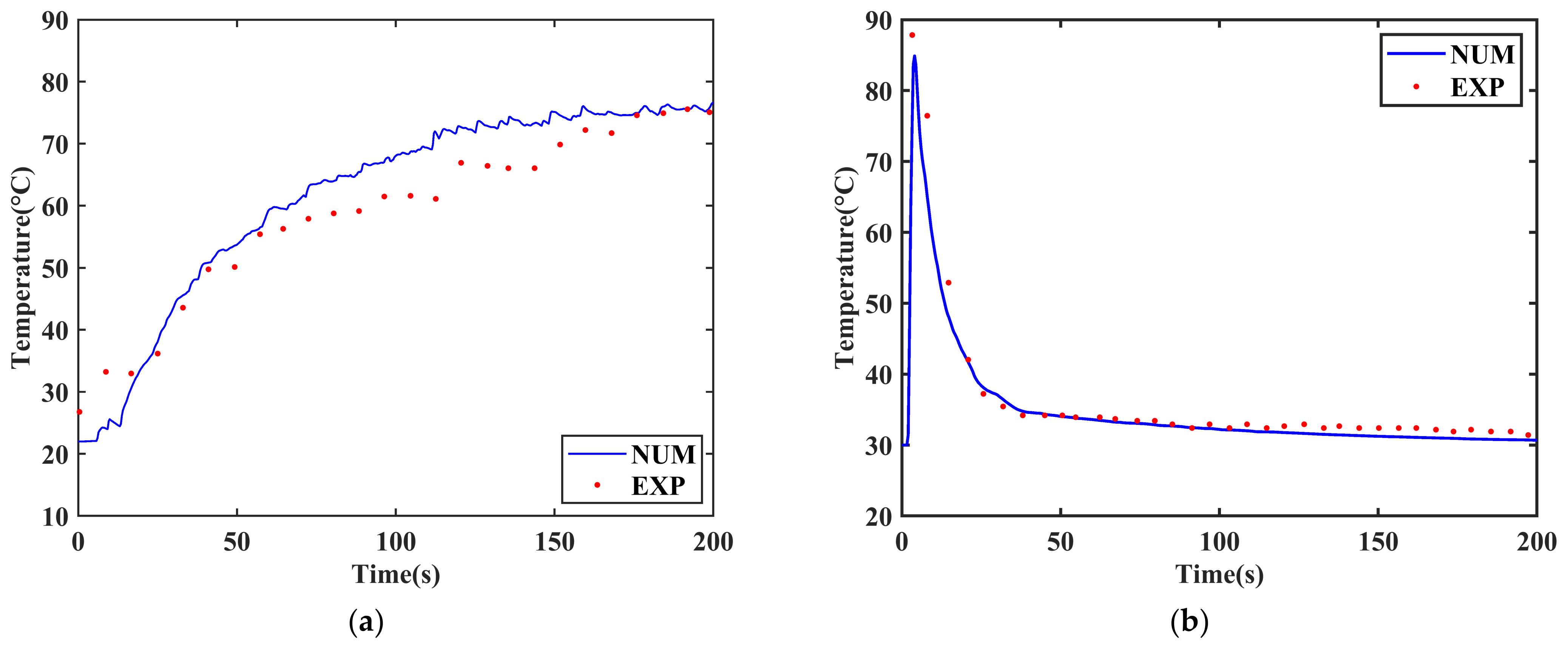

3.4. Mesh Independence and Validation

4. Results and Discussion

4.1. Fire Suppression Process Reflected by Heat Release Rate (HRR)

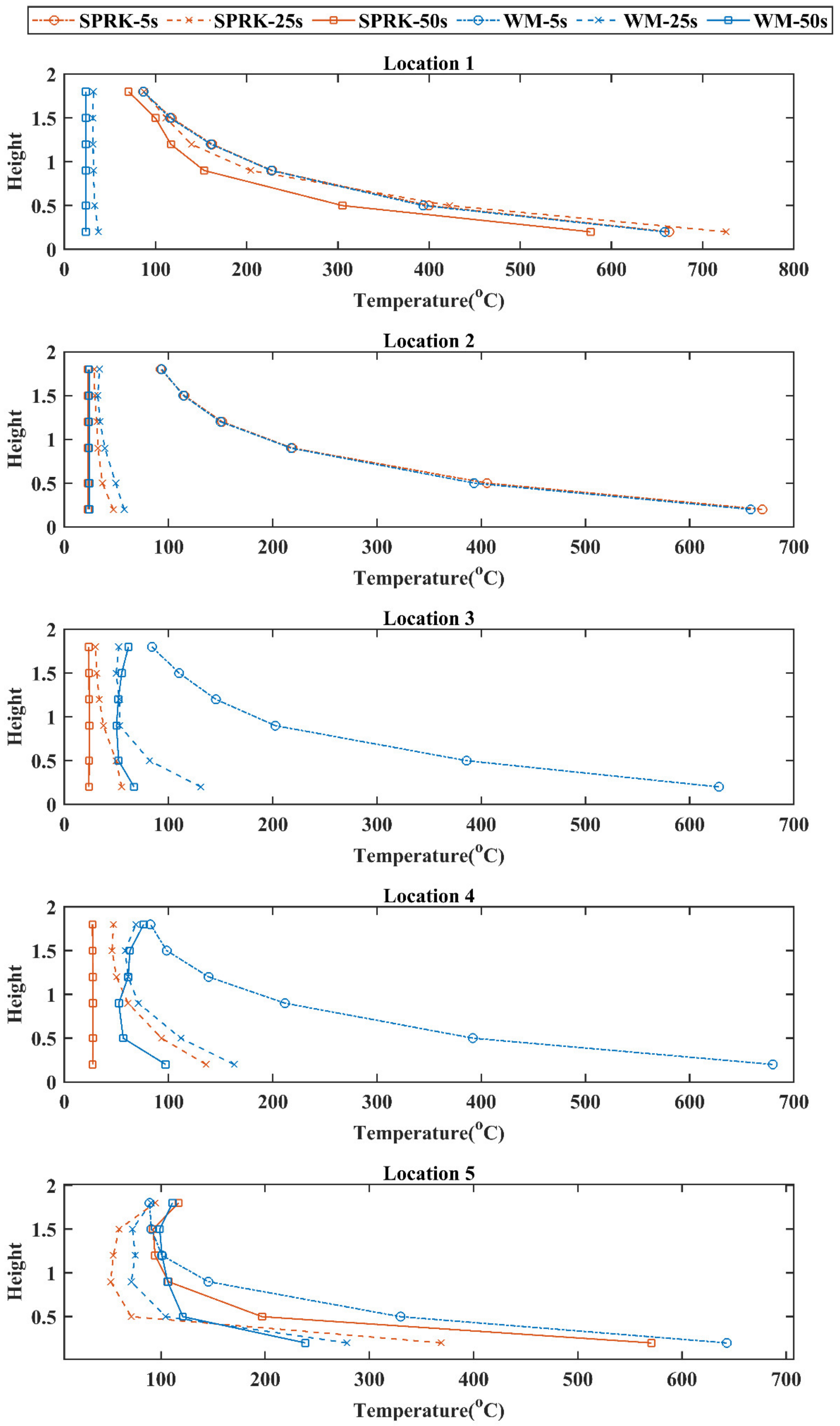

4.2. Cooling Effect Reflected by Local Temperature

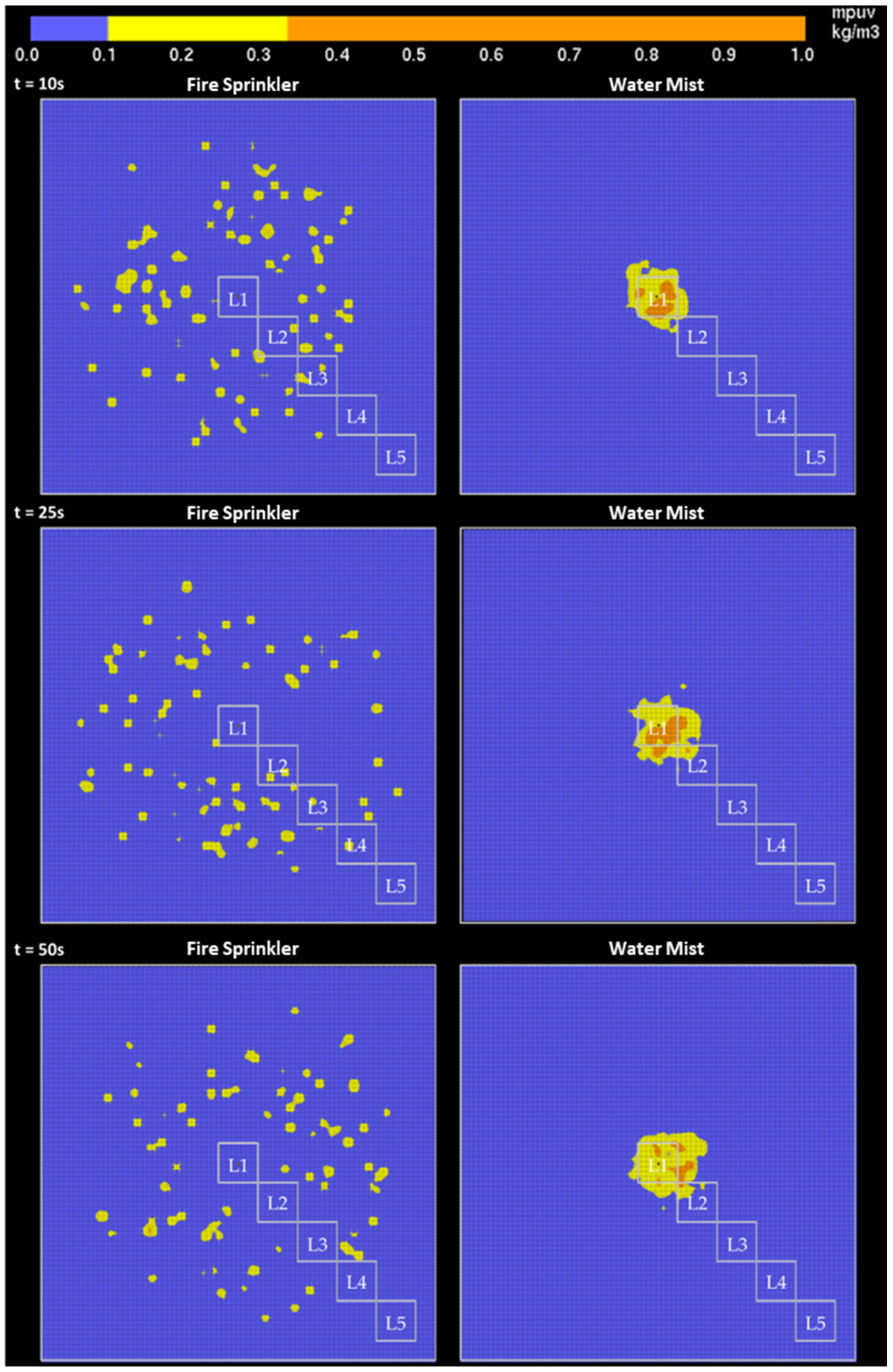

4.3. Fire Suppression Performance with Spray Coverage

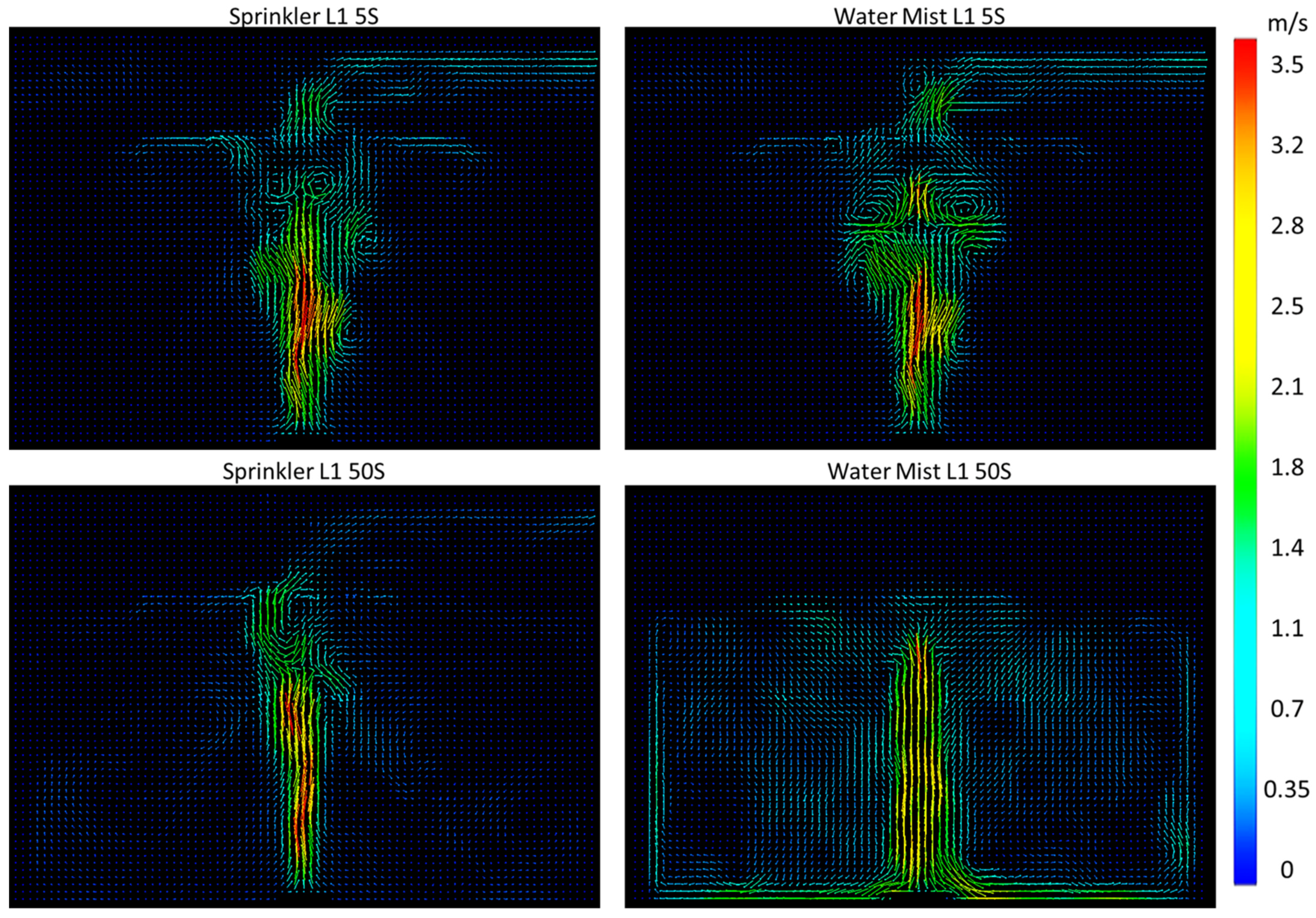

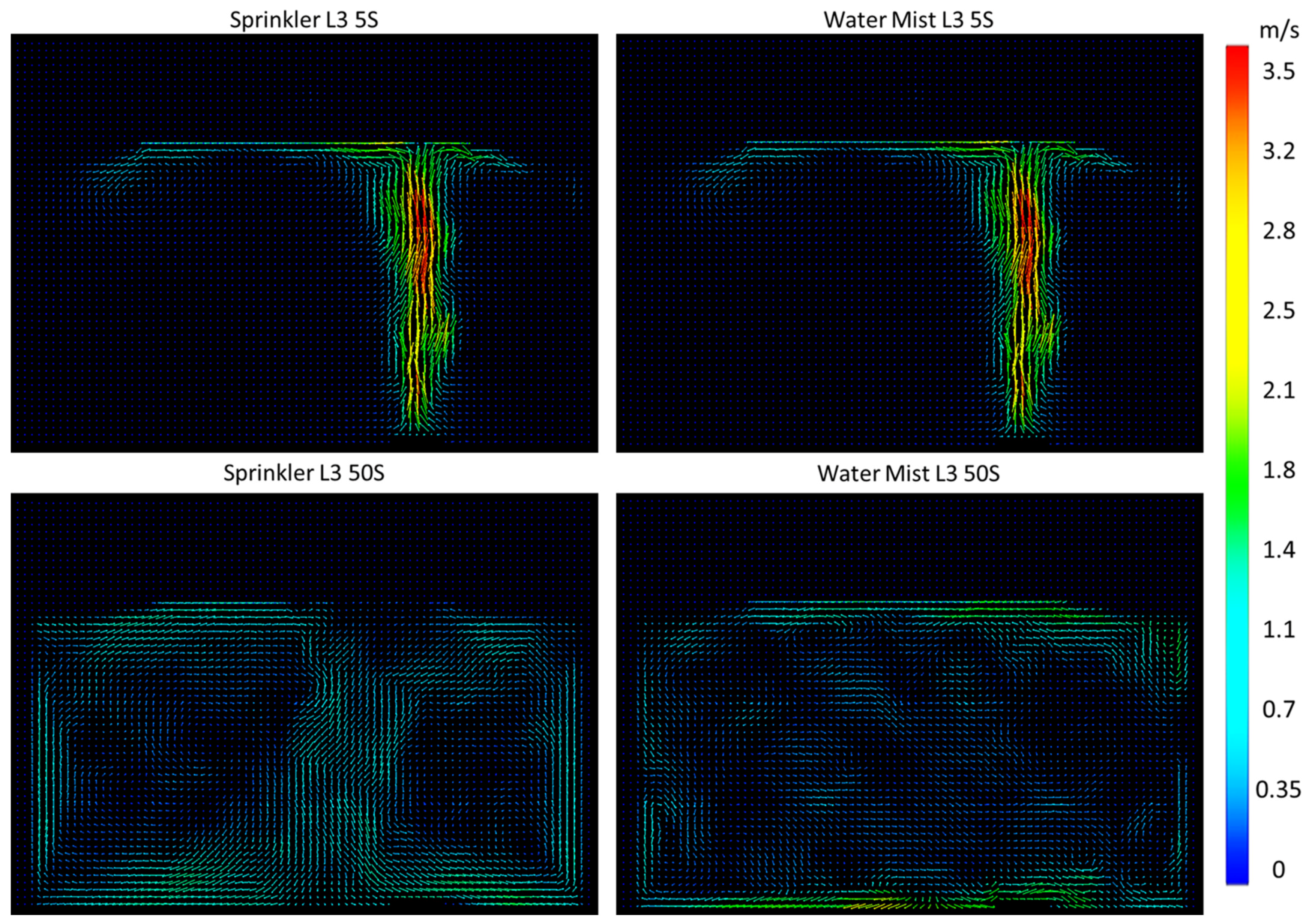

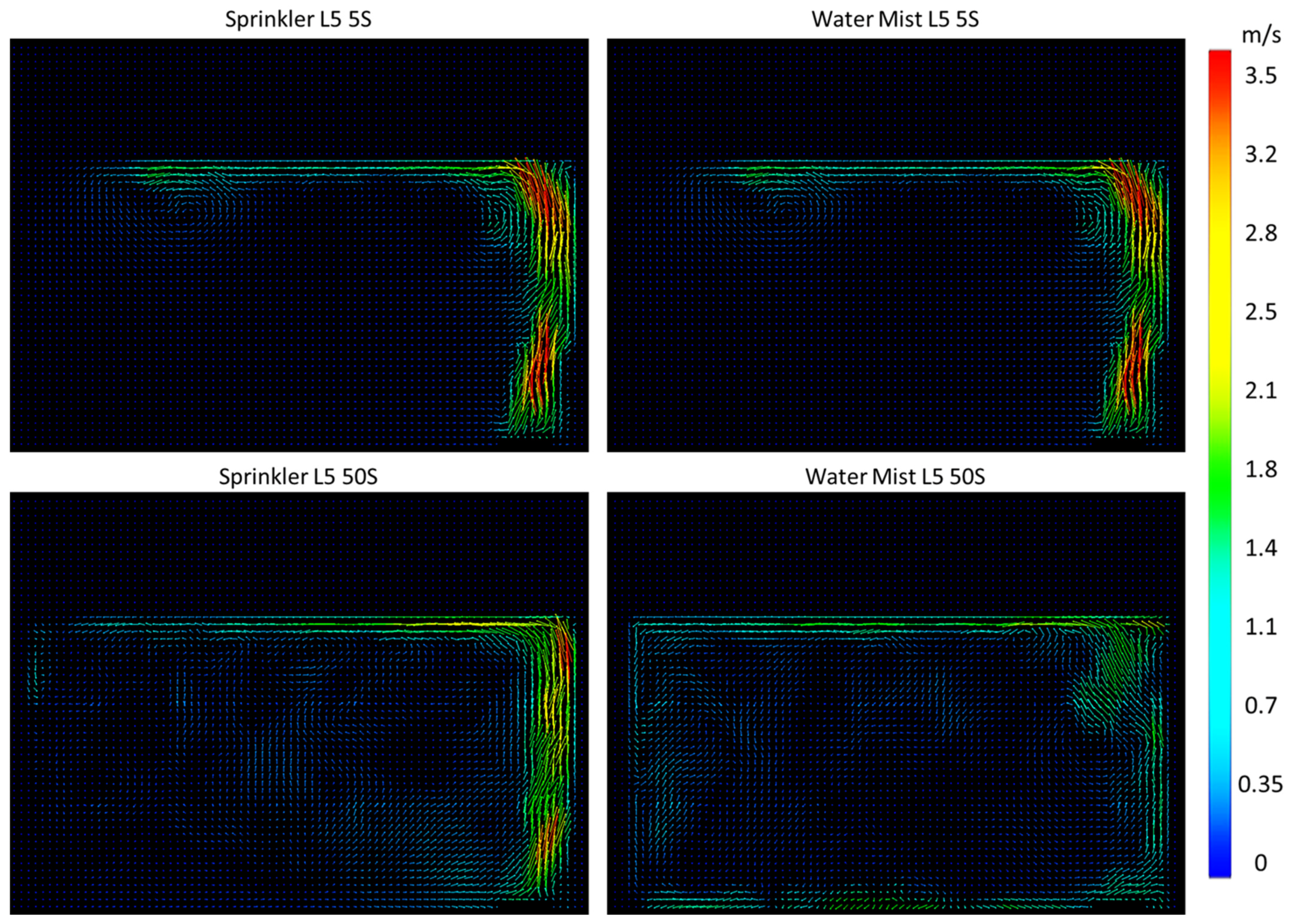

4.4. Velocity

5. Conclusions

- The fire sprinklers have exhibited significant fuel surface cooling effect that has suppressed the 50 kW HRR profiles effectively in from location 2–4 within 50 s. This can be attributed to the larger droplets (>1000 µm) sprayed from sprinklers carry more momentum and heat capacity, which forms a wide spray pattern that mainly covers locations 2 to 4 and provides better droplet penetrability toward the fire.

- Within the coverage area, the large droplets also evaporate slower than mist and create a downward velocity field against the flame plume. Despite the heat reduction from locations 2–4, the sprinklers are relatively weaker than water mist while the fuel pan was relocated at location 1 and 5, which is vertically below the nozzle and out of droplets coverage area.

- Regardless of fire suppression outcome (i.e., either fire has been fully suppressed or not), it can be seen that the water mist systems are able to rapidly cool down temperature near fuel source to a low value at all scenarios. Except for location 5, all the temperatures over 0.2 m above the fire have been suppressed below 100 °C within 20 s. This has exhibited the advantages of water mist, even though the mist droplets did not effectively reduce the HRR from locations 3–5 due to insufficient droplet transportation on the fuel surface, which can be attributed to small spray coverage or early droplet evaporation.

- Mist droplets often lose momentum after leaving the nozzle due to drag from air and buoyancy induced by fire; thus, the droplets are unable to travel along the intended trajectory with long horizontal distances. The water mist system can still eject micro-sized water droplets with rapid evaporation surrounding the flame and effectively stabilise the local temperature field at the fuel locations.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yuen, A.C.Y.; Yeoh, G.H.; Alexander, B.; Cook, M. Fire scene investigation of an arson fire incident using computational fluid dynamics based fire simulation. Build. Simul. 2014, 7, 477–487. [Google Scholar] [CrossRef]

- Hub, A.D.R.K. Fire-Urban-Quakers Hill Nursing Home, Sydney. Available online: https://knowledge.aidr.org.au/resources/fire-urban-quakers-hill-nursing-home-sydney-2011/ (accessed on 19 November 2022).

- Yuen, A.C.Y.; Chen, T.B.Y.; Li, A.; De Cachinho Cordeiro, I.M.; Liu, L.; Liu, H.; Lo, A.L.P.; Chan, Q.N.; Yeoh, G.H. Evaluating the fire risk associated with cladding panels: An overview of fire incidents, policies, and future perspective in fire standards. Fire Mater. 2021, 45, 663–689. [Google Scholar] [CrossRef]

- Cao, R.F.; Lee, E.W.M.; Yuen, A.C.Y.; Chen, T.B.Y.; De Cordeiro, I.M.C.; Shi, M.; Wei, X.; Yeoh, G.H. Simulation of competitive and cooperative egress movements on the crowd emergency evacuation. Simul. Model. Pract. Theory 2021, 109, 102309. [Google Scholar] [CrossRef]

- Hall, J.R.; Ahrens, M.; Evarts, B. Sprinkler Impact on Fire Injury; Fire Protection Research Foundation: Quincy, MA, USA, 2012. [Google Scholar]

- Hoffmann, N.A.; Galea, E.R. An extension of the fire-field modelling technique to include fire-sprinkler interaction—I. The mathematical basis. Int. J. Heat Mass Transf. 1993, 36, 1435–1444. [Google Scholar] [CrossRef]

- Zlatanovic, L.; Vreeburg, J.; van der Hoek, J.P.; Poznakovs, I. An experimental study on the spray characteristics of residential sprinklers under low-flow and low-pressure conditions. Fire Saf. J. 2014, 68, 30–40. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Gong, J.; Zhang, X.; Fan, C.; Wang, X. Assessment of a clean and efficient fire-extinguishing technique: Continuous and cycling discharge water mist system. J. Clean. Prod. 2018, 182, 682–693. [Google Scholar] [CrossRef]

- Chow, W.K.; Yao, B.; Ng, M.Y. Application of Water Mist Fire Suppression Systems in Small Retail Shops. J. Fire Sci. 2002, 20, 479–503. [Google Scholar] [CrossRef]

- Liu, J. Progress in research and application of water mist fire sup-pression technology. Chin. Sci. Bull. 2003, 48, 718–725. [Google Scholar] [CrossRef]

- Chow, W.K.; Shek, L.C. Physical Properties of a Sprinkler Water Spray. Fire Mater. 1993, 17, 279–292. [Google Scholar] [CrossRef]

- Chen, B.; Lu, S.-X.; Li, C.-H.; Kang, Q.-S.; Lecoustre, V. Initial fuel temperature effects on burning rate of pool fire. J. Hazard. Mater. 2011, 188, 369–374. [Google Scholar] [CrossRef]

- Fan, X.; Wang, C.; Guo, F. Experimental study of flame expansion induced by water droplet impact on the burning cooking oil. Fuel 2020, 270, 117497. [Google Scholar] [CrossRef]

- Kim, S.C.; Ryou, H.S. An experimental and numerical study on fire suppression using a water mist in an enclosure. Build. Environ. 2003, 38, 1309–1316. [Google Scholar] [CrossRef]

- Abdulrahman, S.A.; Chetehouna, K.; Cablé, A.; Skreiberg, Ø.; Kadoche, M. A review on fire suppression by fire sprinklers. J. Fire Sci. 2021, 39, 512–551. [Google Scholar] [CrossRef]

- Yao, C.; Kalelkar, A.S. Effect of drop size on sprinkler performance. Fire Technol. 1970, 6, 254–268. [Google Scholar] [CrossRef]

- Gupta, M.; Pasi, A.; Ray, A.; Kale, S.R. An experimental study of the effects of water mist characteristics on pool fire suppression. Exp. Therm. Fluid Sci. 2013, 44, 768–778. [Google Scholar] [CrossRef]

- Ferng, Y.-M.; Liu, C.-H. Numerically investigating fire suppression mechanisms for the water mist with various droplet sizes through FDS code. Nucl. Eng. Des. 2011, 241, 3142–3148. [Google Scholar] [CrossRef]

- Hua, J.; Kumar, K.; Khoo, B.C.; Xue, H. A numerical study of the interaction of water spray with a fire plume. Fire Saf. J. 2002, 37, 631–657. [Google Scholar] [CrossRef]

- Alpert, R.L. Numerical modeling of the interaction between automatic sprinkler sprays and fire plumes. Fire Saf. J. 1985, 9, 157–163. [Google Scholar] [CrossRef]

- Nam, S. Numerical simulation of the penetration capability of sprinkler sprays. Fire Saf. J. 1999, 32, 307–329. [Google Scholar] [CrossRef]

- Chow, W.K.; Fong, N.K. Numerical simulation on cooling of the fire-induced air flow by sprinkler water sprays. Fire Saf. J. 1991, 17, 263–290. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, W.; Wang, Q. Optimization of water mist droplet size by using CFD modeling for fire suppressions. J. Loss Prev. Process Ind. 2016, 44, 626–632. [Google Scholar] [CrossRef]

- Liu, H.; Wang, C.; De Cachinho Cordeiro, I.M.; Yuen, A.C.Y.; Chen, Q.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Critical assessment on operating water droplet sizes for fire sprinkler and water mist systems. J. Build. Eng. 2020, 28, 100999. [Google Scholar] [CrossRef]

- Mahmud, H.; Thorpe, G.; Moinuddin, K.A. The Behaviour of Water-Mists in Hot Air Induced by a Room Fire: Effect of the Initial Size of Droplets. Fire 2022, 5, 116. [Google Scholar] [CrossRef]

- Mahmud, H.I.; Moinuddin, K.A.; Thorpe, G.R. Experimental and numerical study of high-pressure water-mist nozzle sprays. Fire Saf. J. 2016, 81, 109–117. [Google Scholar] [CrossRef]

- Yu, H.-Z.; Kasiski, R.; Daelhousen, M. Characterization of twin-fluid (water mist and inert gas) fire extinguishing systems by testing and modeling. Fire Technol. 2015, 51, 923–950. [Google Scholar] [CrossRef]

- Sikanen, T.; Vaari, J.; Hostikka, S.; Paajanen, A. Modeling and simulation of high pressure water mist systems. Fire Technol. 2014, 50, 483–504. [Google Scholar] [CrossRef]

- Gui, J.; Wang, D.; Jiang, Y.; Liu, J.; Yang, L. Study on the Protection Effect of Sprinklers on Glass by Fire Scale in Building Fires. Fire 2022, 5, 100. [Google Scholar] [CrossRef]

- Nmira, F.; Consalvi, J.-L.; Kaiss, A.; Fernandez-Pello, A.; Porterie, B. A numerical study of water mist mitigation of tunnel fires. Fire Saf. J. 2009, 44, 198–211. [Google Scholar] [CrossRef]

- Lee, J.; Moon, J. Numerical analysis of the effect of horizontal distance between a water mist nozzle and ignition source on reduction in heat release rate. Ann. Nucl. Energy 2020, 144, 107560. [Google Scholar] [CrossRef]

- Kim, S.C.; Ryou, H.S. The effect of water mist on burning rates of pool fire. J. Fire Sci. 2004, 22, 305–323. [Google Scholar] [CrossRef]

- Frank, K.; Gravestock, N.; Spearpoint, M.; Fleischmann, C. A review of sprinkler system effectiveness studies. Fire Sci. Rev. 2013, 2, 6. [Google Scholar] [CrossRef]

- Beji, T.; Zadeh, S.E.; Maragkos, G.; Merci, B. Influence of the particle injection rate, droplet size distribution and volume flux angular distribution on the results and computational time of water spray CFD simulations. Fire Saf. J. 2017, 91, 586–595. [Google Scholar] [CrossRef]

- Sumon, S.M.; Sang-Wook, L. Efficiency of water mist on fire suppression: A numerical study. In Proceedings of the International Forum on Strategic Technology 2010, Ulsan, Korea, 13–15 October 2010; pp. 10–14. [Google Scholar]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Numerical model for evaluating thermal performance of residential building roof integrated with inclined phase change material (PCM) layer. J. Build. Eng. 2020, 28, 101018. [Google Scholar] [CrossRef]

- De Cachinho Cordeiro, I.M.; Liu, H.; Yuen, A.C.Y.; Chen, T.B.Y.; Li, A.; Cao, R.F.; Yeoh, G.H. Numerical investigation of expandable graphite suppression on metal-based fire. Heat Mass Transf. 2022, 58, 65–81. [Google Scholar] [CrossRef]

- Li, A.; Yuen, A.C.Y.; Wang, W.; Chen, T.B.Y.; Lai, C.S.; Yang, W.; Wu, W.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Integration of Computational Fluid Dynamics and Artificial Neural Network for Optimization Design of Battery Thermal Management System. Batteries 2022, 8, 69. [Google Scholar] [CrossRef]

- Duny, M.; Dhima, D.; Garo, J.P.; Wang, H.Y. Numerical investigation on window ejected facade flames. J. Build. Eng. 2016, 8, 305–312. [Google Scholar] [CrossRef]

- Yuen, A.C.Y.; Chen, T.B.Y.; Yang, W.; Wang, C.; Li, A.; Yeoh, G.H.; Chan, Q.N.; Chan, M.C. Natural ventilated smoke control simulation case study using different settings of smoke vents and curtains in a large Atrium. Fire 2019, 2, 7. [Google Scholar] [CrossRef]

- Chen, T.B.Y.; Yuen, A.C.Y.; Yeoh, G.H.; Yang, W.; Chan, Q.N. Fire risk assessment of combustible exterior cladding using a collective numerical database. Fire 2019, 2, 11. [Google Scholar] [CrossRef]

- Yuen, A.C.Y.; De Cachinho Cordeiro, I.M.; Chen, T.B.Y.; Chen, Q.; Liu, H.; Yeoh, G.H. Multiphase CFD modelling for enclosure fires—A review on past studies and future perspectives. Exp. Comput. Multiph. Flow 2021, 4, 1–25. [Google Scholar] [CrossRef]

- Rehm, R.G.; Baum, H.R. The equations of motion for thermally driven buoyant flows. J. Res. NBS 1978, 83, 297–308. [Google Scholar] [CrossRef]

- Nicoud, F.; Ducros, F. Subgrid-Scale Stress Modelling Based on the Square of the Velocity Gradient Tensor. Flow Turbul. Combust. 1999, 62, 183–200. [Google Scholar] [CrossRef]

- Chen, T.B.Y.; De Cachinho Cordeiro, I.M.; Yuen, A.C.Y.; Yang, W.; Chan, Q.N.; Zhang, J.; Cheung, S.C.P.; Yeoh, G.H. An Investigation towards Coupling Molecular Dynamics with Computational Fluid Dynamics for Modelling Polymer Pyrolysis. Molecules 2022, 27, 292. [Google Scholar] [CrossRef]

- Yuen, A.C.Y.; Chen, T.B.Y.; De Cachinho Cordeiro, I.M.; Liu, H.; Li, A.; Yang, W.; Cheung, S.C.P.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Developing a solid decomposition kinetics extraction framework for detailed chemistry pyrolysis and combustion modelling of building polymer composites. J. Anal. Appl. Pyrolysis 2022, 163, 105500. [Google Scholar] [CrossRef]

- De Cachinho Cordeiro, I.M.; Chen, T.B.Y.; Yuen, A.C.Y.; Wang, C.; Chan, Q.N.; Zhang, J.; Yeoh, G.H. Pyrolysis and combustion characterisation of HDPE/APP composites via molecular dynamics and CFD simulations. J. Anal. Appl. Pyrolysis 2022, 163, 105499. [Google Scholar] [CrossRef]

- Li, A.; Yuen, A.C.Y.; Wang, W.; Weng, J.; Yeoh, G.H. Numerical investigation on the thermal management of lithium-ion battery system and cooling effect optimization. Appl. Therm. Eng. 2022, 215, 118966. [Google Scholar] [CrossRef]

- Cheremisinoff, N.P. Encyclopedia of Fluid Mechanics. Volume 3: Gas-Liquid Flows; Gulf Publishing: Houston, TX, USA, 1986. [Google Scholar]

- Yu, H.-z.; Lee, J.L.; Kung, H.-C.; Brown, W. Suppression of rack-storage fires by water. Fire Saf. Sci. 1994, 4, 901–912. [Google Scholar] [CrossRef]

- Hamins, A.; McGrattan, K.B. Reduced-Scale Experiments to Characterize the Suppression of Rack-Storage Commodity Fires; NIST Interagency/Internal Report (NISTIR), National Institute of Standards and Technology: Gaithersburg, MD, USA, 1999.

- Lee, J. Numerical analysis on the rapid fire suppression using a water mist nozzle in a fire compartment with a door opening. Nucl. Eng. Technol. 2019, 51, 410–423. [Google Scholar] [CrossRef]

- Beyler, C. Chapter 7: Flammability Limits of Premixed and Diffusion Flames. In Section Two, SFPE Handbook of Fire Protection Engineering, 3rd ed.; National Fire Protection Association: Quincy, MA, USA, 2002. [Google Scholar]

- Liu, H.; Cachinho Cordeiro, I.M.D.; Yin Yuen, A.C.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Application of multi-parametric characterization to water-based fire suppression systems in compartment fire scenarios. Numer. Heat Transf. Part A Appl. 2022, 1–19. [Google Scholar] [CrossRef]

- Liu, H.; Yuen, A.C.Y.; De Cachinho Cordeiro, I.M.; Han, Y.; Yuan Chen, T.B.; Chan, Q.N.; Kook, S.; Yeoh, G.H. A novel stochastic approach to study water droplet/flame interaction of water mist systems. Numer. Heat Transf. Part A Appl. 2021, 79, 1–27. [Google Scholar] [CrossRef]

- Bourque, M.J.; Svirsky, T.A. Computational Modeling of Fire Sprinkler Spray Characteristics Using the Fire Dynamics Simulator. Bachelor’s Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2013. [Google Scholar]

- Lehtimäki, M. Simulation of Water Cooling in Fires. Master’s Thesis, Aalto University, Espoo, Finland, 2017. [Google Scholar]

- DiNenno, P.J. SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

| Geometry | Compartment dimensions (m) | ||

| Computational domain size (m) | |||

| Grid sensitivity analysis | 352,000–2,841,600 cells | ||

| Final total number of cells | 1,645,077 cells | ||

| Boundary conditions | Fume hood, Ceiling | Open | |

| Combustions | Fuel pan size (m) | ||

| Fuel Type | Simple Chemistry: Methanol (CH3OH) | ||

| Mass loss Rate (kg/m2s) HRR per unit area (kW/m2) Heat of combustion (kJ/kg) | 0.0155 310.0 22,659.0 | ||

| Radiative Fraction | 0.36 | ||

| Soot Yield Oxygen index (XOI) Critical Flame Temperature (TOI) | 1.0 × 10-4 0.111 1257 | ||

| Simulations, Measurements | Fuel Location (m) | L1 (X: 0, Y: 0), L2 (X: 0.4, Y: 0.4), L3 (X: 0.8, Y: 0.8), L4 (X: 1.2, Y: 1.2), L5 (X: 1.6, Y: 1.6) | |

| Thermocouples, Gas Probe | Above each fuel location at 0.2 m, 0.5 m, 0.9 m, 1.2 m, 1.5 m and 1.8 m | ||

| Suppression System | Device | Sprinkler | Water Mist |

| Operating pressure (bar) | 0.48 | 7 | |

| K-Factor (L/min/) | 81 | 4.7 | |

| Flow rates (L/min) | 55.8 | 12 | |

| Spray Angle (°) | 10, 70 | 10, 70 | |

| Droplet Diameter (µm) | 1250 | 121 | |

| Activation control | Thermocouple 1.8 m above the fire reaches 85 °C | ||

| Location | Fire Sprinklers | Water Mist | |

|---|---|---|---|

| 1 | HRR Reduction | 100% | 100% |

| Suppression Time | 170.1 | 10 | |

| 2 | HRR Reduction | 100% | 100% |

| Suppression Time | 10.01 | 18.8 | |

| 3 | HRR Reduction | 100% | 68.2% |

| Suppression Time | 12.41 | 286 | |

| 4 | HRR Reduction | 100% | 0% |

| Suppression Time | 50.2 | / | |

| 5 | HRR Reduction | 0% | 0% |

| Suppression Time | / | / |

| Fire Sprinkler | Water Mist | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| THCP Height (m) | 0.2 | 0.5 | 1.2 | 0.2 | 0.5 | 1.2 | |||||||

| Location | t (s) | T (°C) | t (s) | T (°C) | t (s) | T (°C) | t (s) | T (°C) | t (s) | T (°C) | t (s) | T (°C) | |

| 1 | Growth | 10.0 | 765.7 | 3.6 | 492.8 | 3.6 | 195.8 | 5.6 | 674.8 | 3.6 | 492.8 | 3.6 | 195.8 |

| Reduction | 159.2 | 30.2 | 104.4 | 43.1 | 149.6 | 30.1 | 24 | 30.2 | 22.81 | 30.0 | 23.2 | 29.7 | |

| Δt | 149.2 | 100.8 | 146 | 18.4 | 19.2 | 19.6 | |||||||

| 2 | Growth | 5.6 | 676.8 | 3.6 | 443.1 | 3.6 | 160.9 | 5.2 | 658.6 | 3.6 | 443.1 | 3.6 | 160.9 |

| Reduction | 25.6 | 30.1 | 22.8 | 30.7 | 20.81 | 30.12 | 30.4 | 30.0 | 28.4 | 30.0 | 22.6 | 30.7 | |

| Δt | 20 | 19.2 | 27.21 | 25.2 | 24.8 | 19 | |||||||

| 3 | Growth | 6.4 | 696.6 | 3.6 | 460.4 | 6.4 | 155.9 | 6.4 | 697.5 | 3.6 | 460.4 | 6.4 | 155.9 |

| Reduction | 26.8 | 30.6 | 28.0 | 29.6 | 21.6 | 30.5 | 29.2 | 75.1 | 29.2 | 46.6 | 29.6 | 39.3 | |

| Δt | 20.4 | 24.4 | 15.2 | 22.8 | 25.6 | 23.2 | |||||||

| 4 | Growth | 4.4 | 695.3 | 3.6 | 438.7 | 4.4 | 141.7 | 4.4 | 695.3 | 3.6 | 438.7 | 4.4 | 141.7 |

| Reduction | 42.6 | 30.1 | 38.8 | 31.5 | 33.6 | 30.7 | 25.2 | 92.7 | 36.4 | 47.4 | 29.2 | 42.5 | |

| Δt | 38.2 | 35.2 | 29.2 | 20.8 | 32.8 | 24.8 | |||||||

| 5 | Growth | 4.8 | 647.6 | 4.0 | 362.8 | 4.4 | 104.1 | 4.8 | 647.6 | 4.0 | 362.8 | 4.4 | 104.1 |

| Reduction | / | / | / | / | / | / | 26.4 | 181.2 | 29.6 | 94.9 | 58.4 | 105.5 | |

| Δt | 21.6 | 25.6 | 54 | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Cachinho Cordeiro, I.M.; Liu, H.; Yuen, A.C.Y.; Chen, T.B.Y.; Li, A.; Wang, C.; Cao, R.; Yeoh, G.H. On the Large Eddy Simulation Modelling of Water Suppression Systems Droplet Impact and Coverage Area. Fire 2022, 5, 165. https://doi.org/10.3390/fire5050165

De Cachinho Cordeiro IM, Liu H, Yuen ACY, Chen TBY, Li A, Wang C, Cao R, Yeoh GH. On the Large Eddy Simulation Modelling of Water Suppression Systems Droplet Impact and Coverage Area. Fire. 2022; 5(5):165. https://doi.org/10.3390/fire5050165

Chicago/Turabian StyleDe Cachinho Cordeiro, Ivan Miguel, Hengrui Liu, Anthony Chun Yin Yuen, Timothy Bo Yuan Chen, Ao Li, Cheng Wang, Ruifeng Cao, and Guan Heng Yeoh. 2022. "On the Large Eddy Simulation Modelling of Water Suppression Systems Droplet Impact and Coverage Area" Fire 5, no. 5: 165. https://doi.org/10.3390/fire5050165

APA StyleDe Cachinho Cordeiro, I. M., Liu, H., Yuen, A. C. Y., Chen, T. B. Y., Li, A., Wang, C., Cao, R., & Yeoh, G. H. (2022). On the Large Eddy Simulation Modelling of Water Suppression Systems Droplet Impact and Coverage Area. Fire, 5(5), 165. https://doi.org/10.3390/fire5050165