Application Development of Smoke Leakage Test Apparatus for Door Sets in the Field

Abstract

:1. Introduction

2. Experimental Plan

2.1. Scope and Conditions

2.1.1. Scope

2.1.2. Conditions

2.1.3. Terms and Definitions

- ①

- Door Assembly

- ②

- Ambient Temperature

- ③

- Leakage

2.1.4. Leakage Regulations

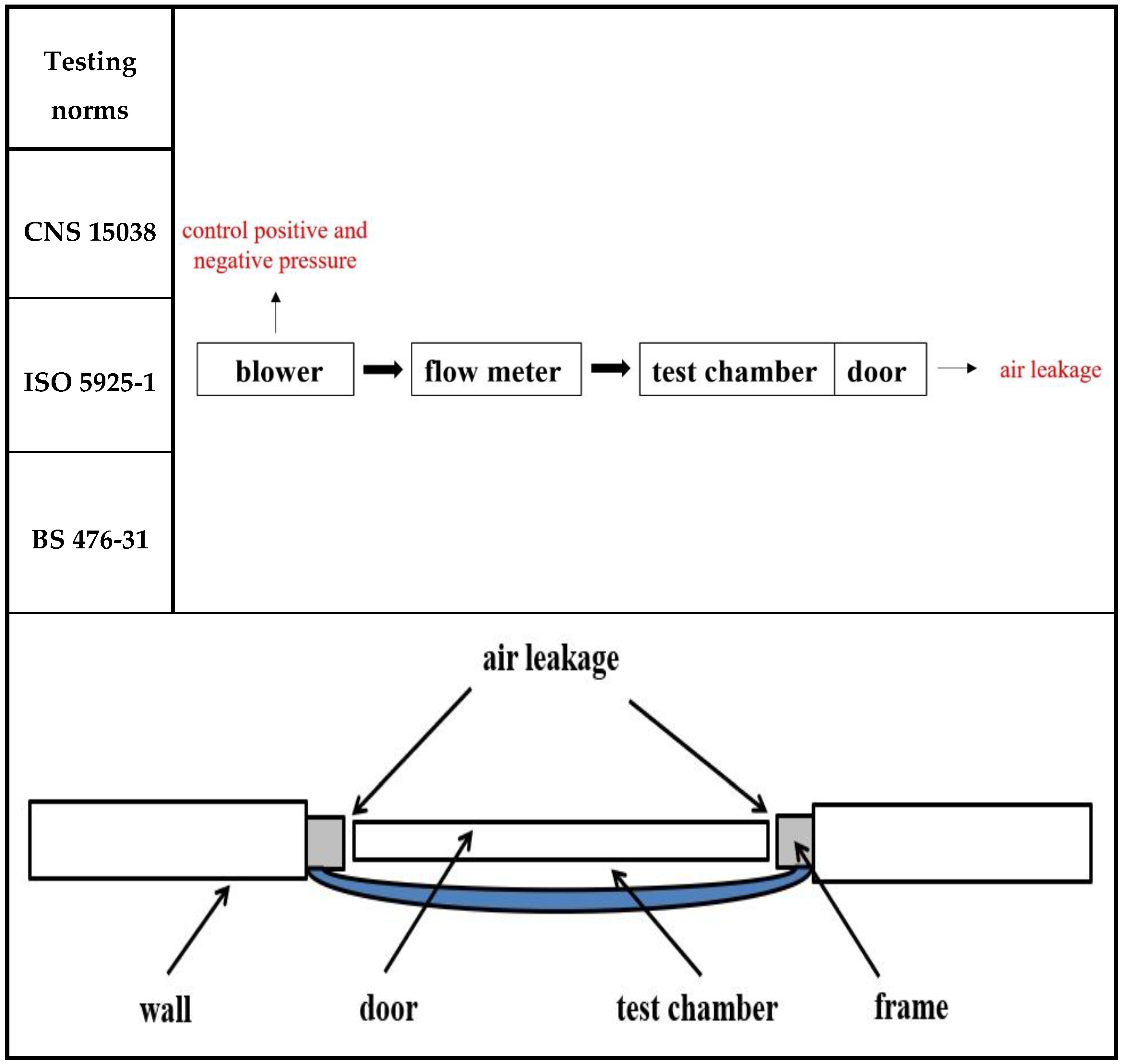

2.2. Experiment Apparatus

- Component 1—Test chamber:

- Component 2—Measurement system:

- ①

- Thermometer measurement range: −40 °C~+100 °C, with an accuracy of ±5%.

- ②

- Relative humidity meter measurement range: 0% RH~100% RH, with an accuracy of ±5%.

- ③

- Atmospheric pressure meter measurement range: 300 hPa~1200 hPa, with an accuracy of ±5%.

- ④

- Gas volume flow meter: Honeywell (Honeywell International, Inc., Charlotte, NC, USA) intelligent differential pressure transmitter with flow meter. The measurement range is 0 m3/h ~75 m3/h; the accuracy is ±2.5%; the applicable fluid temperature is −10 °C~+60 °C; and humidity is below 90%. The flow meter has an inlet and outlet pipe diameter of 50 mm and is installed between the blower outlet and the test chamber.

- ⑤

- Differential pressure meter: Testo 510 (Testo SE & Co. KGaA, Titisee-Neustadt, Germany) pocket-type micro differential pressure meter, used to measure the difference in static pressure between the inside and outside of the test body; its measurement range is 0 hPa~100 hPa; its accuracy is ±0.03 hPa; and it is placed at 100 ± 10 cm from the surface of the test chamber in front.

- Component 3—Inflating system:

2.3. Test Principles

2.4. Test Procedure

- Step 1. Pre-test environmental assessment

- Step 2. Door functionality assessment

- Step 3. Trimming the plastic sheeting

- Step 4. Establishment of the test chamber

- Step 5. Equipment installation

- Step 6. Power on the equipment

- Step 7. Environmental testing

- Step 8. Testing and recording

- Step 9. Restoration of the field site

3. Results and Discussion

3.1. Confirmation of Device Function

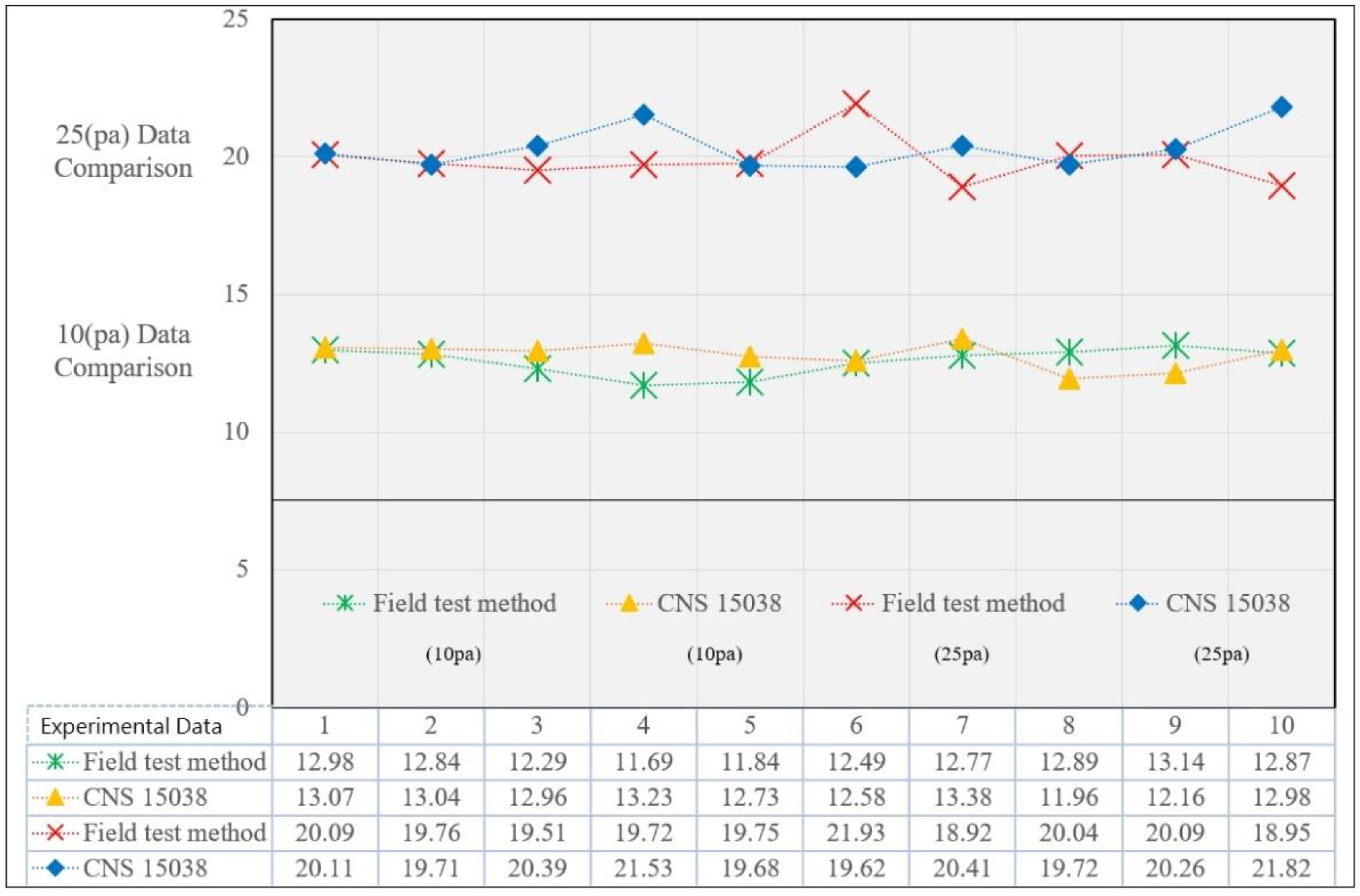

3.2. Flow Test Value Judgment

3.3. Test Method Verification

3.3.1. Levene’s Test

3.3.2. Independent Samples t-Test

3.3.3. Conclusions

3.4. Actual Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, S.C.; Lin, C.Y.; Chuang, Y.J.; Lin, Y.S. A Computer-Based Simulation and Evaluation: Applying an Automatic Sprinkler System for Extinguishing Scooter Fires in Arcade Areas. J. Eng. Res. 2021, 9, 14–24. [Google Scholar] [CrossRef]

- Clarke, F.B. Physiological Effects of Smoke: Managing Escape. ASHRAE J. 1997, 39, 47–56. [Google Scholar]

- CNS 15038Method of Test for Evaluating Smoke Control Performance of Doors, Bureau of Standard, Metrology and Inspection (BSMI): Taipei, Taiwan, 2009.

- JIS A1516Windows and Door Sets—Air Permeability Test, Japanese Industrial Standards: Tokyo, Japan, 1998.

- ISO 5925-1Fire Test-Evaluation of Performance of Smoke Control Door Assemblies-Part 1: Ambient Temperature Test, International Organization for Standardization (ISO): Geneva, Switzerland, 2007.

- ISO 5925-2Fire Test-Smoke Control Door and Shutter Assemblies-Part 2: Commentary on Test Method and Test Data Application, International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- DIN 18095-1Smoke Control Doors; Concepts and Requirements, German National Standard: Berlin, Germany, 1988.

- DIN 18095-2Smoke Control Doors; Type Testing for Durability and Leakage, German National Standard: Berlin, Germany, 1991.

- UL 1784Air Leakage Tests of Door Assemblies, Underwriters Laboratories Inc. (UL): Northbrook, IL, USA, 1990.

- Lin, B.S.M.; Lin, C.Y.; Kung, C.W.; Lin, Y.J.; Chou, C.C.; Chuang, Y.J.; Hsiao, G.L.K. Wayfinding of Firefighters in Dark and Complex Environments. Int. J. Environ. Res. Public Health 2021, 18, 8014. [Google Scholar] [CrossRef] [PubMed]

- BS 476-31Methods for Measuring Smoke Penetration Through Door Sets and Shutter Assemblies, British Standards Institution (BSI): London, UK, 1983.

- Chuang, Y.H.; Chuang, Y.J.; Lin, C.Y. Using a New Testing Method to Measure Smoke Leakage of Existing Doors. J. Appl. Fire Sci. 2006, 16, 21–33. [Google Scholar] [CrossRef]

- Chuang, Y.J.; Luan, C.P.; Lin, C.Y.; Chen, P.H. Development and Application of Smoke Leakage Test Apparatus. J. Fire Sci. 2009, 27, 213–234. [Google Scholar] [CrossRef]

- Wu, C.W.; Lin, T.H.; Chen, C.J.; Tsai, M.J. Smoke Leakage Through Wall Openings in a Fire. Exp. Therm. Fluid Sci. 2007, 32, 29–37. [Google Scholar] [CrossRef]

- Tsai, T.H.; Kuo, S.Y.; Tseng, Y.T.; Tang, C.H.; Chuang, Y.J.; Lin, C.Y. Rates of Smoke Leakage Through Fire Stops. J. Eng. Res. 2013, 1, 231–250. [Google Scholar]

- Gross, D. Estimating Air Leakage Through Doors for Smoke Control. Fire Safety. J. 1991, 17, 171–177. [Google Scholar] [CrossRef]

- Kuo, S.Y.; Tseng, Y.T.; Chuang, Y.J. Comparison of Test Apparatus for Determining the Smoke Leakage Rate of Fire Doors. J. Food Agric. Environ. 2013, 11, 2831–2841. [Google Scholar]

- Rakic, J. The Performance of Unit Entry Doors when Exposed to Simulated Sprinkler Controlled Fires. Fire Australia. 24–28 February 2000. Available online: citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.527.1321&rep=rep1&type=pdf (accessed on 30 November 2021).

- Chuang, Y.J.; Tsai, T.H.; Chuang, Y.-H.; Lin, C.Y.; Huang, C.H.; Chen, P.H. Performance Assessment of Single-Leaf Timber Door in a Smoke Leakage Test. J. Appl. Fire Sci. 2006, 16, 101–114. [Google Scholar] [CrossRef]

- Liu, F.; Gong, N.; Yan, Z.J. Opening Flow Coefficient and Its Effect on Fire Smoke Flow. J. Chongqing Jianzhu Univ. 2000, 22, 86–92. [Google Scholar]

- CNS 15038Method of Test for Evaluating Smoke Control Performance of Doors, Bureau of Standard, Metrology and Inspection (BSMI): Taipei, Taiwan, 2002.

- ISO 5925-1Fire Test-Evaluation of Performance of Smoke Control Door Assemblies-Part 1: Ambient Temperature Test, International Organization for Standardization (ISO): Geneva, Switzerland, 1981.

- ISO 5925-2Fire Test-Smoke Control Door and Shutter Assemblies-Part 2: Commentary on Test Method and Test Data Application, International Organization for Standardization (ISO): Geneva, Switzerland, 1997.

- Tamura, G.T. Fire Tower Tests on Vestibule Pressurization for Protection of Stair Shafts. ASHRAE Trans. 1994, 100, 981–989. [Google Scholar]

- Tamura, G.T. Stair Pressurization Systems for Smoke. Control: Design Considerations. ASHRAE Trans. 1989, 95, 184–192. [Google Scholar]

- Hewitt, P.G. Bernoulli’s Principle Understanding Bernoulli’s Principle as it Applies to Aerodynamic Lift. Natl. Sci. Teach. Assoc. 2004, 71, 51–55. [Google Scholar]

- Chou, T.L.; Tang, C.H.; Chuang, Y.J.; Lin, C.Y. Study on Smoke Leakage Performance of Suspended Ceiling System. Sustainability 2020, 12, 7244. [Google Scholar] [CrossRef]

- Klote, J.H. Smoke Movement Through a Suspended Ceiling System; NBSIR-81-2444; Center for Fire Research, National Bureau of Standards, NIST Interagency: Washington, DC, USA, 1982. [Google Scholar]

- Allen, P.; Bennett, K.; Heritage, B. SPSS Statistics Version 22: A Practical Guide; Cengage Learning Australia: Victoria, Australia, 2014. [Google Scholar]

| Differential Pressure | 10 Pa | 25 Pa | 50 Pa | |

|---|---|---|---|---|

| Flow Coefficient | ||||

| 0.60 | 2.79 m3/h | 4.41 m3/h | 6.24 m3/h | |

| 0.70 | 3.33 m3/h | 5.27 m3/h | 7.46 m3/h | |

| Differential Pressure | Testing Methodology | Levene’s Test | Independent Samples t-Test | ||||||

|---|---|---|---|---|---|---|---|---|---|

| F | p-Value | t | Degree of Freedom | p-Value (Two-Tailed) | Mean Difference | SD Difference | CI 95% | ||

| 10 Pa | Equal Variance | 0.131 | 0.722 | −1.077 | 18 | 0.296 | −0.229 | 0.21257 | Lower Limit −0.6756 Upper Limit 0.2176 |

| Unequal Variance | −1.077 | 17.895 | 0.296 | −0.229 | 0.21257 | Lower Limit −0.67579 Upper Limit 0.21779 | |||

| 25 Pa | Equal Variance | 0.134 | 0.718 | −1.467 | 18 | 0.160 | −0.536 | 0.36530 | Lower Limit −1.30346 Upper Limit 0.23146 |

| Unequal Variance | −1.467 | 17.958 | 0.160 | −0.536 | 0.36530 | Lower Limit −1.30359 Upper Limit 0.23159 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, H.-Y.; Lin, C.-Y.; Chuang, Y.-J.; Luan, C.-P. Application Development of Smoke Leakage Test Apparatus for Door Sets in the Field. Fire 2022, 5, 12. https://doi.org/10.3390/fire5010012

Hung H-Y, Lin C-Y, Chuang Y-J, Luan C-P. Application Development of Smoke Leakage Test Apparatus for Door Sets in the Field. Fire. 2022; 5(1):12. https://doi.org/10.3390/fire5010012

Chicago/Turabian StyleHung, Hsuan-Yu, Ching-Yuan Lin, Ying-Ji Chuang, and Chung-Pi Luan. 2022. "Application Development of Smoke Leakage Test Apparatus for Door Sets in the Field" Fire 5, no. 1: 12. https://doi.org/10.3390/fire5010012

APA StyleHung, H.-Y., Lin, C.-Y., Chuang, Y.-J., & Luan, C.-P. (2022). Application Development of Smoke Leakage Test Apparatus for Door Sets in the Field. Fire, 5(1), 12. https://doi.org/10.3390/fire5010012