A Device for Instantaneously Estimating Duff Moisture Content Is also Effective for Grassland Fuels

Abstract

1. Introduction

- Determine whether moisture content of samples collected for the DMM600 represent the moisture content of the broader grassland fuelbed,

- Determine efficacy and accuracy of the DMM600 in estimating grassland fuel moisture, and

- Fit an equation for calibrating the DMM600 to return grassland-specific moisture percentages.

2. Materials and Methods

2.1. Sample Collection

- A handful of sample material, collected as above, was clumped into a loose ball and stuffed into the DMM600 sample chamber, with no material allowed to hang over the edges.

- The top of the DMM600 was fixed into place, the device switched on, and the sample compressed via the screw.

- Once the device beeped, I recorded the freq and % VWC on the display.

- Number of rotations to decompress the sample were counted and recorded.

- The sample was put in a uniquely-identified envelope.

2.2. Data Analysis

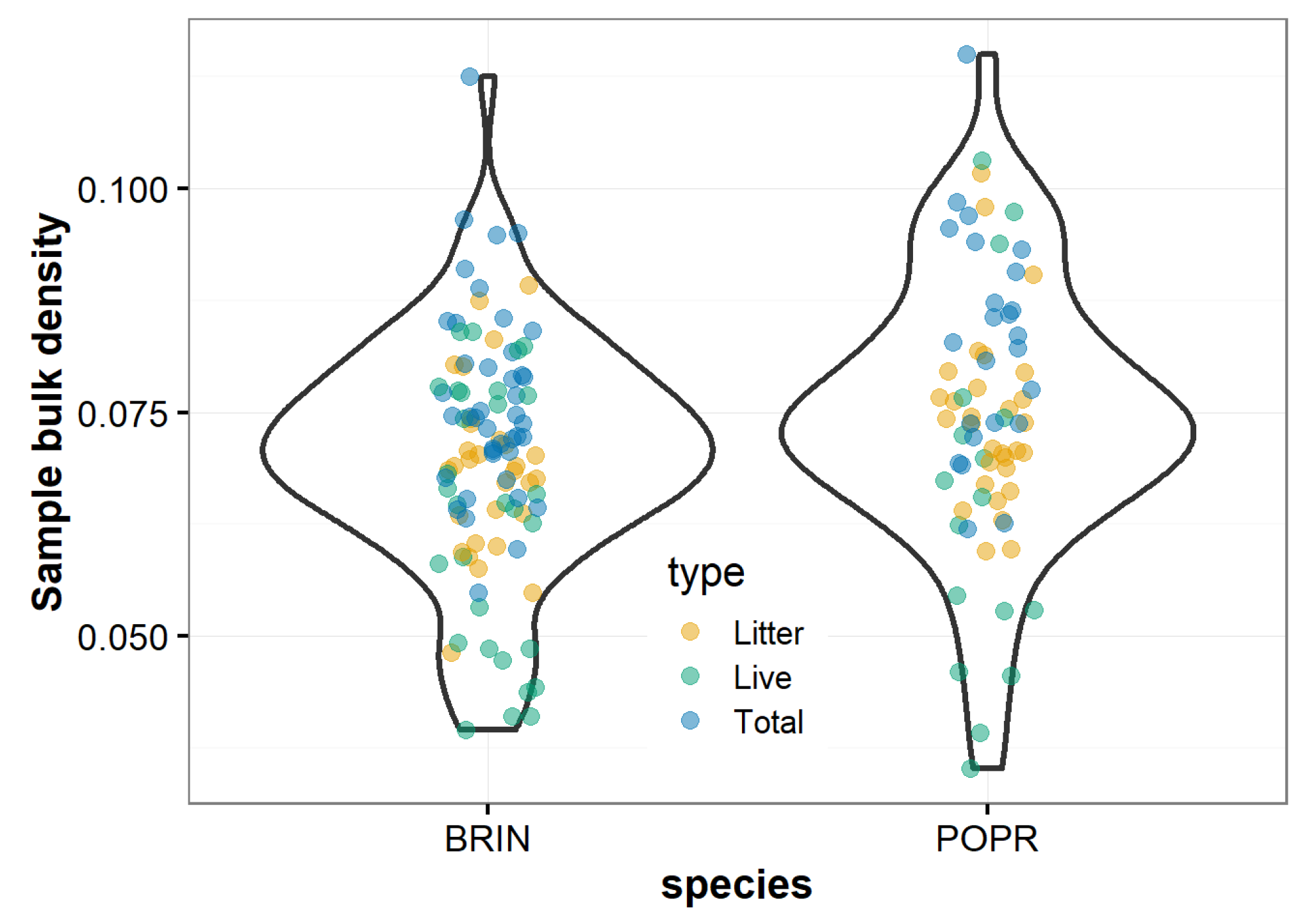

2.2.1. Calculating Bulk Density of Compressed Samples

2.2.2. Statistical Analysis

3. Results and Discussion

3.1. Duff Moisture Meter Performance

3.1.1. Samples Used in the DMM600 Represent the Grassland Fuelbed

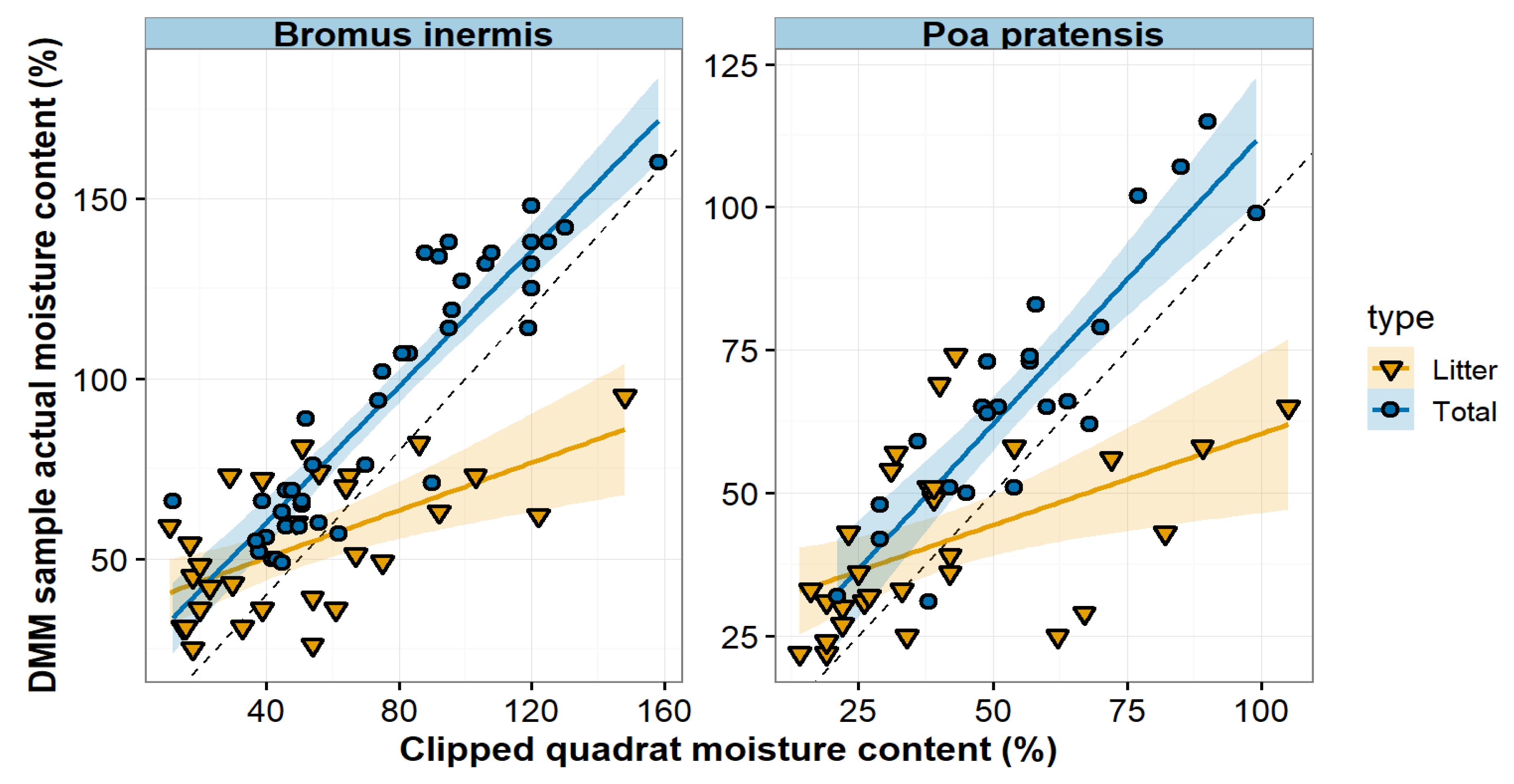

3.1.2. Dielectric Permittivity Correlates Well with Fine-Fuel Moisture Content

3.2. DMM600 Equations for Grassland Fuels

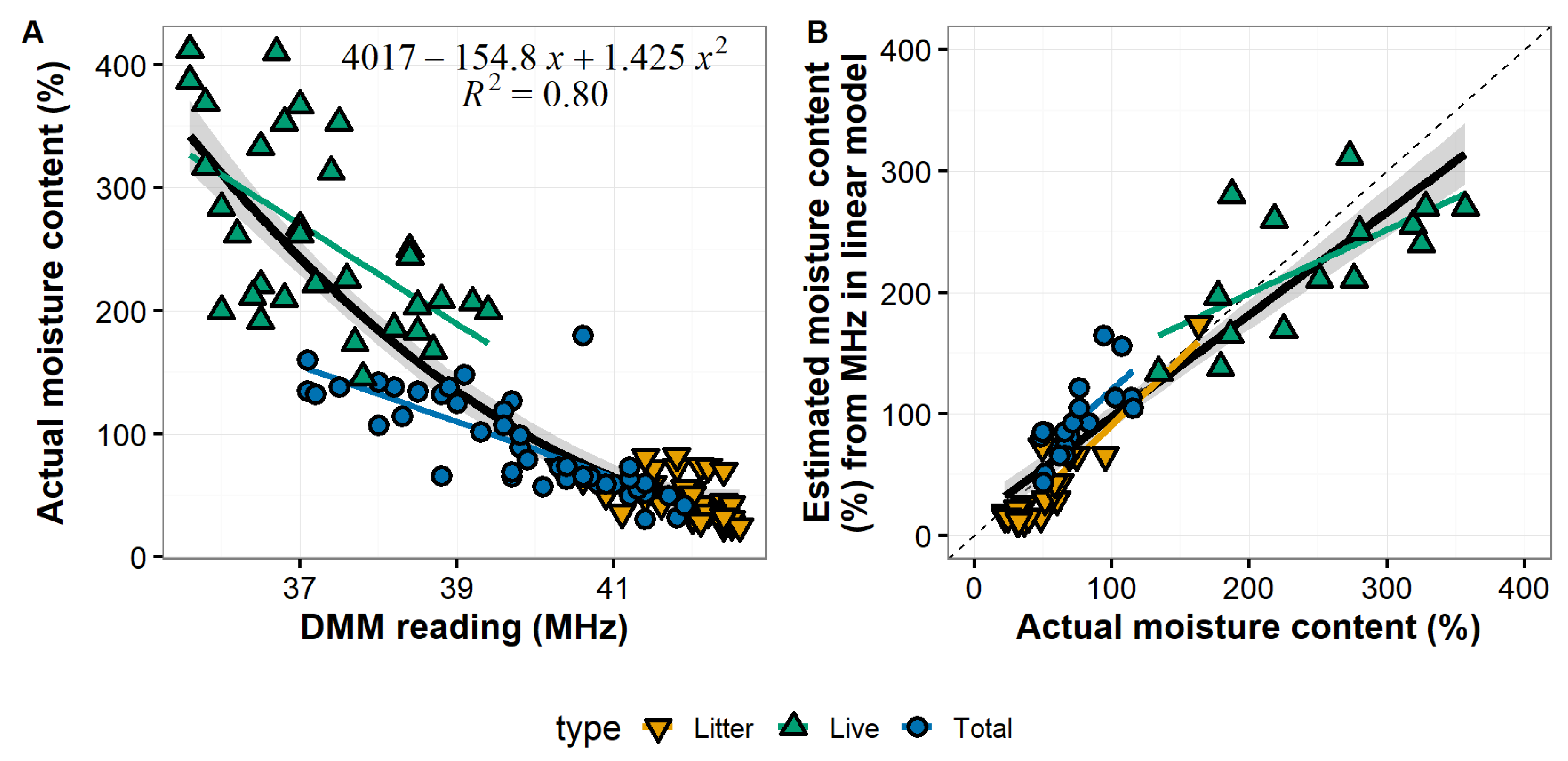

3.2.1. Using the Raw Dielectric Permittivity Values (freq)

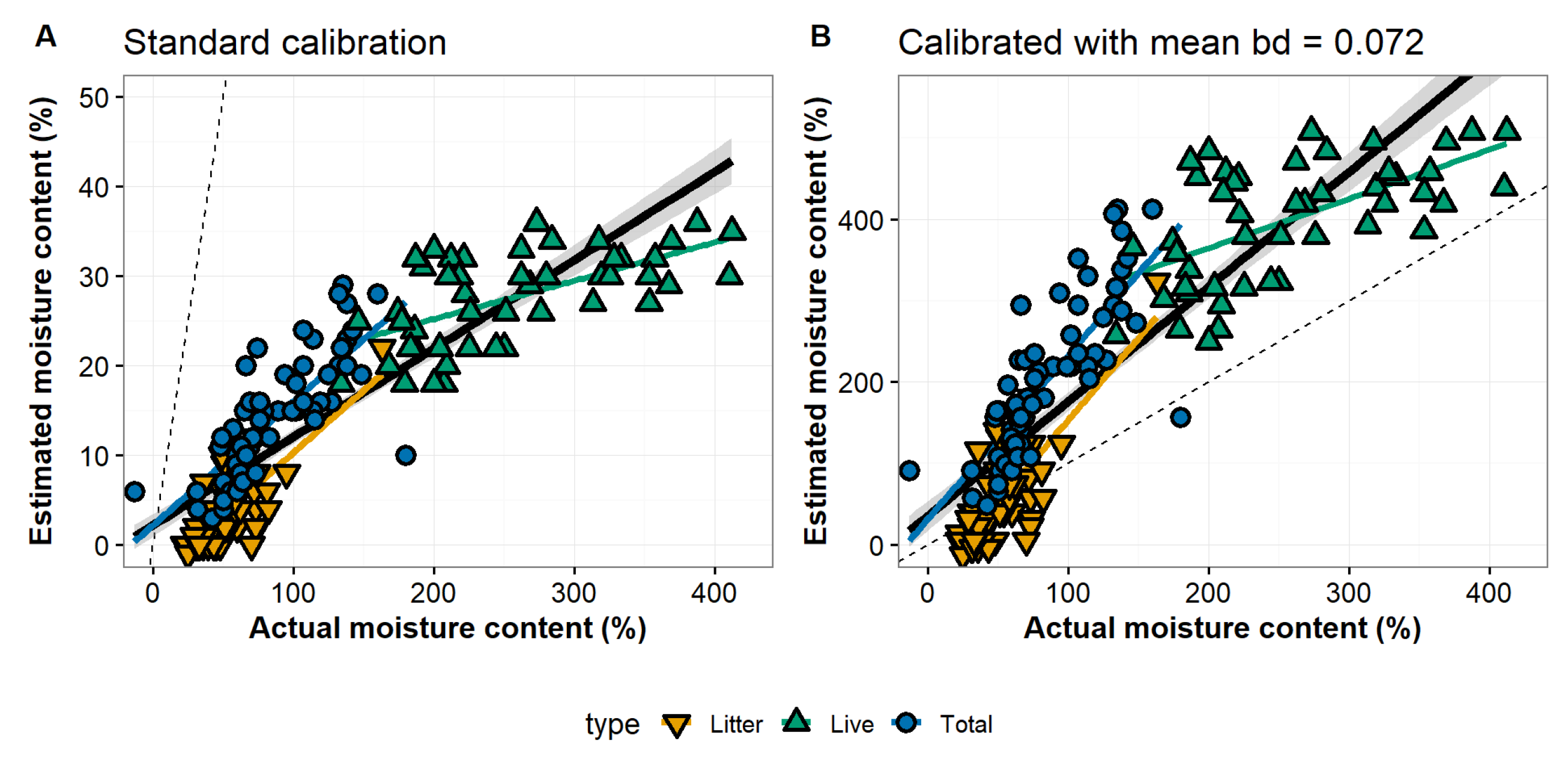

3.2.2. Programming a Custom Calibration Equation

3.2.3. So Which Calibration Approach Should One Use?

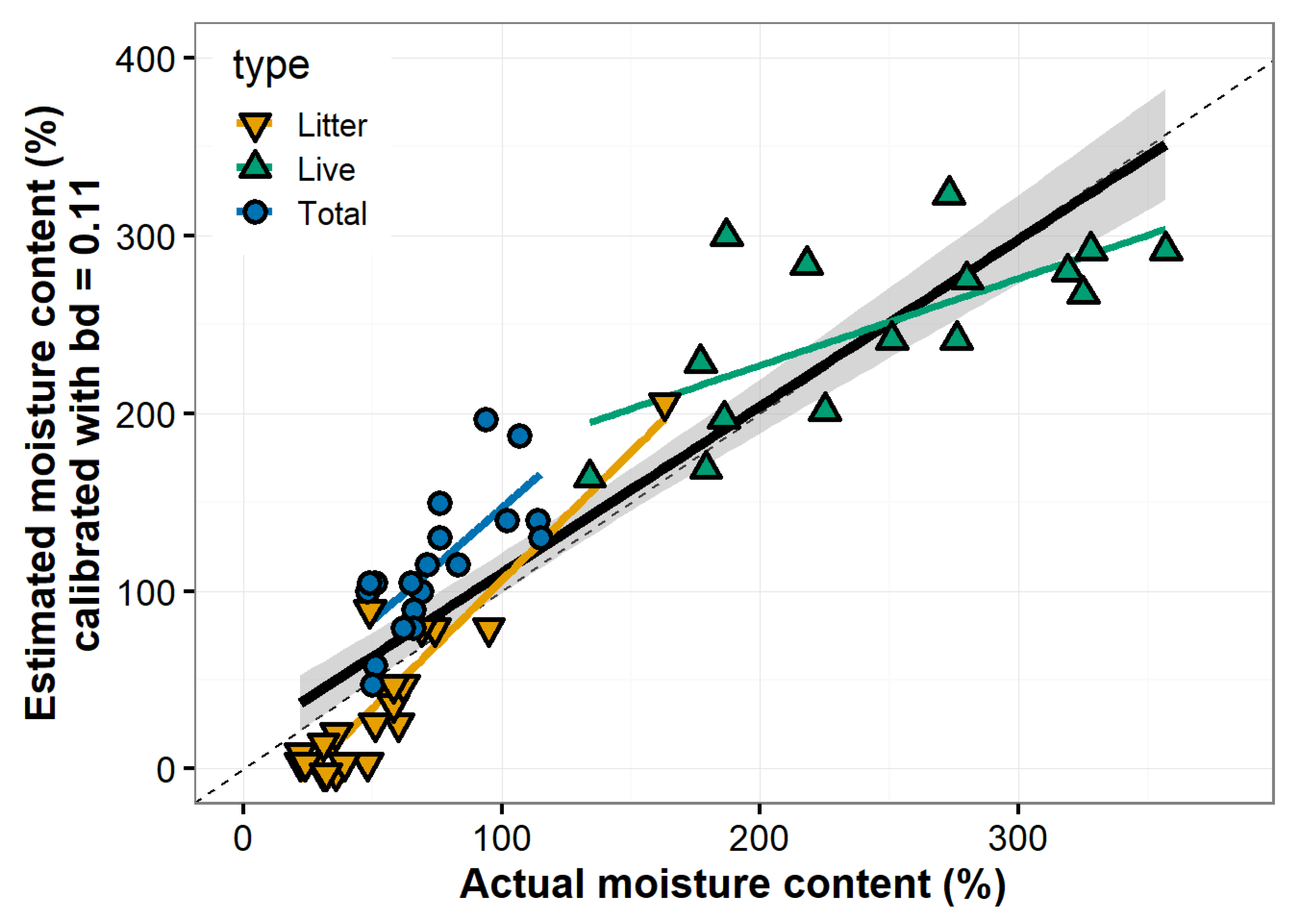

- Plant material type—litter vs. standing material vs. both combined—was a significant term in the model fitting estimated WC to actual WC using the bulk density-corrected equation. This suggests that the relationship could be less generalizeable, although the overall linear relationship still had a good fit (R2 = 0.85). Users do not likely need to account for these differences, however…

- There is a slight curvilinear pattern in the relationship between estimated WC and actual WC using the bulk density-corrected equation. It is quite apparent when the entire dataset is plotted (Figure A2B), and appears to be caused by a tendency for bulk density-derived WC estimations to slightly under-predict moisture content at low and high ends of the gradient. This curvilinear pattern is not apparent in WC estimations in the training dataset based on the empirically-derived equation (Equation (1)).

- The under-prediction by Equation (3) at the low end of the moisture gradient actually produces a few negative WC values (Figure 3). This is likely fine for users who only need a categorical determination of fuel moisture content in cured and partially-cured fuels, but such illogical values obviously create an issue for anyone who needs precise estimations.

3.3. How to Collect Good Samples for the DMM600

- Live fuel moisture—Simply cut enough live, green material to fill the sample chamber from as small of an area as possible, clipping tillers as low to the ground as possible.

- Litter moisture—Place random quadrats in areas of representative fuels. Cut and discard all live plants and woody or forb stems. Standing dead grass can be included or analyzed separately depending on intent. Clip remaining biomass to within 2 cm of mineral soil and collect in a bag (anything will do, but one that more or less holds itself open and will withstand repeated use makes life easier). Aggregate well. Grab a handful for the DMM600 chamber. Depending on the amount of biomass in the bag, one can repeat for added precision in fuel moisture estimation. Bear in mind that the DMM600 won’t work well on fully-cured stands, but why measure moisture if the stand is obviously cured?

- Overall stand fuel moisture—Place random quadrats in areas of representative fuels, cut and discard woody and forb stems, and clip and collect everything into the sample aggregation bag. Sub-sample handfuls for the DMM600. Again, don’t expect good results from the DMM600 on fully-cured fuels.

4. Conclusions

Funding

Conflicts of Interest

Abbreviations

| DMM600 | Campbell Scientific’s Duff Moisture Meter |

| LCD | Liquid Crystal Display |

| LMER | Linear Mixed-Effect Regression model, fit in R with lme4::lmer |

| freq | Shorthand for raw dielectic permittivity values given by the DMM600 as frequency (MHz) |

| VWC | Volumetric Water Content |

| WC | metric Water Content |

| TDR/FDR | Time Domain Reflectometry/Frequency Domain Reflectometry |

Appendix A. Additional Data and Figures

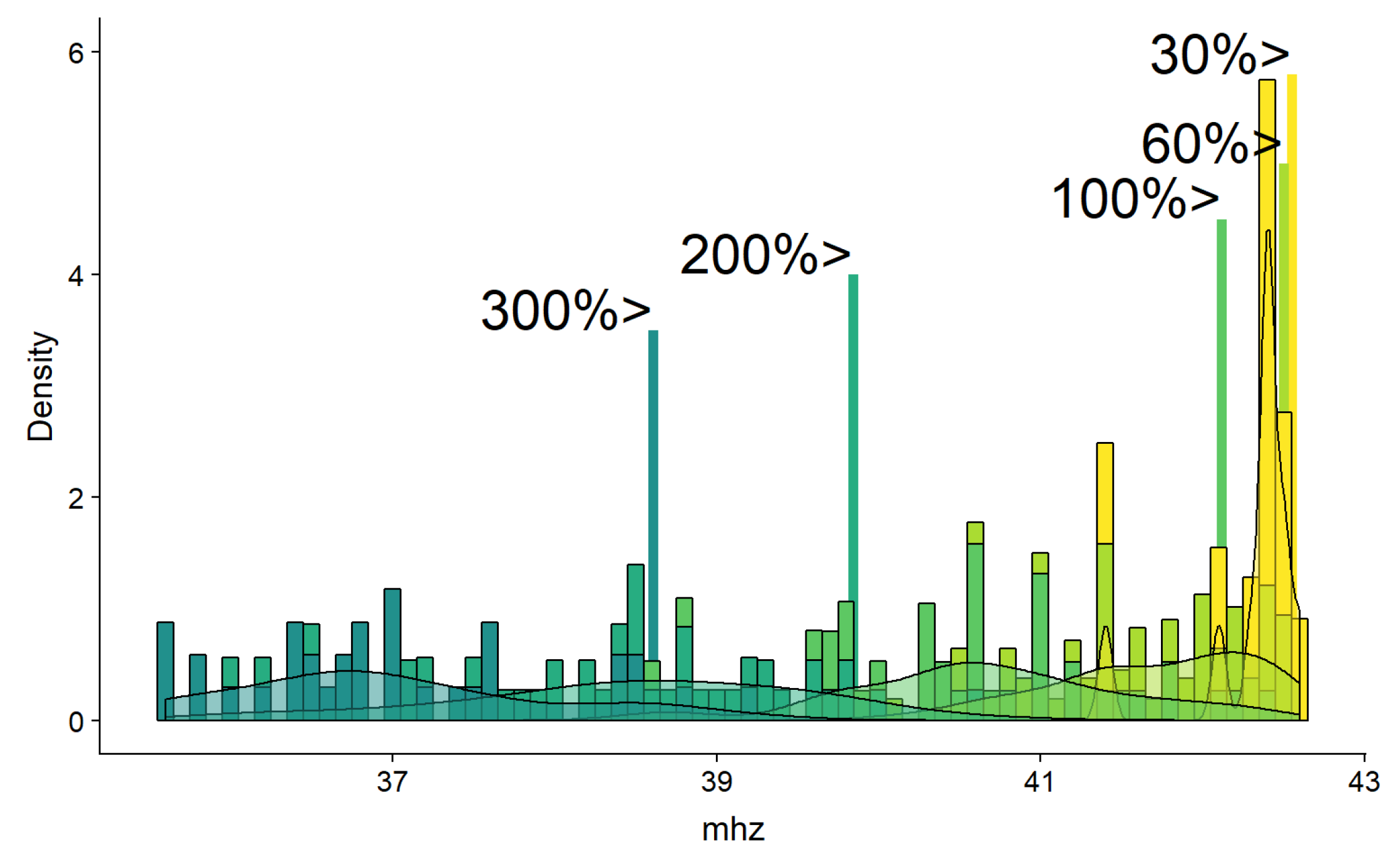

Appendix A.1. Data Distribution for Fuel Curing Categories

Appendix A.2. Performance of “Standard” DMM600 Calibration Equation Options

Appendix A.3. Bulk Density of Compressed Samples

References

- Parisien, M.A.; Moritz, M.A. Environmental Controls on the Distribution of Wildfire at Multiple Spatial Scales. Ecol. Monogr. 2009, 79, 127–154. [Google Scholar] [CrossRef]

- Rossa, C.G. A Generic Fuel Moisture Content Attenuation Factor for Fire Spread Rate Empirical Models. For. Syst. 2018, 27, e009. [Google Scholar] [CrossRef]

- Sullivan, A.L. Inside the Inferno: Fundamental Processes of Wildland Fire Behaviour: Part 2: Heat Transfer and Interactions. Curr. For. Rep. 2017, 3, 150–171. [Google Scholar] [CrossRef]

- Kreye, J.K.; Kobziar, L.N.; Zipperer, W.C. Effects of Fuel Load and Moisture Content on Fire Behaviour and Heating in Masticated Litter-Dominated Fuels. Int. J. Wildland Fire 2013, 22, 440. [Google Scholar] [CrossRef]

- Finney, M.A.; Cohen, J.D.; McAllister, S.S.; Jolly, W.M. On the Need for a Theory of Wildland Fire Spread. Int. J. Wildland Fire 2013, 22, 25–36. [Google Scholar] [CrossRef]

- Scott, J.H.; Burgan, R.E. Standard Fire Behavior Fuel Models: A Comprehensive Set for Use with Rothermel’s Surface Fire Spread Model; Technical Report General Technical Report RMRS-GTR-153; United States Department of Agriculture, Forest Service: Fort Collins, CO, USA, 2005; p. 66.

- Kidnie, S.; Cruz, M.G.; Gould, J.; Nichols, D.; Anderson, W.; Bessell, R. Effects of Curing on Grassfires: I. Fuel Dynamics in a Senescing Grassland. Int. J. Wildland Fire 2015, 24, 828–837. [Google Scholar] [CrossRef]

- Catchpole, E.A.; Catchpole, W.R.; Viney, N.R.; McCaw, W.L.; Marsden-Smedley, J.B. Estimating Fuel Response Time and Predicting Fuel Moisture Content from Field Data. Int. J. Wildland Fire 2001, 10, 215–222. [Google Scholar] [CrossRef]

- Fosberg, M.A. Theory of Precipitation Effects on Dead Cylindrical Fuels. For. Sci. 1972, 18, 98–108. [Google Scholar]

- Matthews, S. Dead Fuel Moisture Research: 1991–2012. Int. J. Wildland Fire 2014, 23, 78. [Google Scholar] [CrossRef]

- Marsden-Smedley, J.B.; Catchpole, W.R. Fire Modelling in Tasmanian Buttongrass Moorlands. III* Dead Fuel Moisture. Int. J. Wildland Fire 2001, 10, 241–253. [Google Scholar] [CrossRef]

- Jolly, W.M.; Hadlow, A.M.; Huguet, K. De-Coupling Seasonal Changes in Water Content and Dry Matter to Predict Live Conifer Foliar Moisture Content. Int. J. Wildland Fire 2014, 23, 480. [Google Scholar] [CrossRef]

- Qi, Y.; Dennison, P.E.; Spencer, J.; Riaño, D. Monitoring Live Fuel Moisture Using Soil Moisture and Remote Sensing Proxies. Fire Ecol. 2012, 8, 71–87. [Google Scholar] [CrossRef]

- Sow, M.; Mbow, C.; Hély, C.; Fensholt, R.; Sambou, B. Estimation of Herbaceous Fuel Moisture Content Using Vegetation Indices and Land Surface Temperature from MODIS Data. Remote Sens. 2013, 5, 2617–2638. [Google Scholar] [CrossRef]

- Krueger, E.S.; Ochsner, T.E.; Engle, D.M.; Carlson, J.; Twidwell, D.; Fuhlendorf, S.D. Soil Moisture Affects Growing-Season Wildfire Size in the Southern Great Plains. Soil Sci. Soc. Am. J. 2015, 79, 1567–1576. [Google Scholar] [CrossRef]

- Rossa, C.; Fernandes, P. Live Fuel Moisture Content: The ‘Pea Under the Mattress’ of Fire Spread Rate Modeling? Fire 2018, 1, 43. [Google Scholar] [CrossRef]

- Rossa, C.; Fernandes, P. An Empirical Model for the Effect of Wind on Fire Spread Rate. Fire 2018, 1, 31. [Google Scholar] [CrossRef]

- Engle, D.M.; Bidwell, T.G. The Response of Central North American Prairies to Seasonal Fire. J. Range Manag. 2001, 54, 2–10. [Google Scholar] [CrossRef]

- McGranahan, D.A.; Engle, D.M.; Fuhlendorf, S.D.; Miller, J.R.; Debinski, D.M. An Invasive Cool-Season Grass Complicates Prescribed Fire Management in a Native Warm-Season Grassland. Nat. Areas J. 2012, 32, 208–214. [Google Scholar]

- DeKeyser, E.S.; Meehan, M.; Clambey, G.; Krabbenhoft, K. Cool Season Invasive Grasses in Northern Great Plains Natural Areas. Nat. Areas J. 2013, 33, 81–90. [Google Scholar] [CrossRef]

- McGranahan, D.A.; Engle, D.M.; Miller, J.R.; Debinski, D.M. An Invasive Grass Increases Live Fuel Proportion and Reduces Fire Spread in a Simulated Grassland. Ecosystems 2013, 16, 158–169. [Google Scholar] [CrossRef]

- McGranahan, D.A.; Archibald, S.; Kirkman, K.P.; O’Connor, T.G. A Native C3 grass alters fuels and fire spread in montane grassland of South Africa. Plant Ecol. 2018, 219, 621–632. [Google Scholar] [CrossRef]

- Nyström, J.; Dahlquist, E. Methods for Determination of Moisture Content in Woodchips for Power Plants—A Review. Fuel 2004, 83, 773–779. [Google Scholar] [CrossRef]

- Anwar, S.I. Determination of Mositure Content of Bagasse of Jaggery Unit Using Microwave Oven. J. Eng. Sci. Technol. 2010, 5, 472–478. [Google Scholar]

- Nelson, S.; Soderholm, L.; Yung, F. Determining the Dielectric Properties of Grain. Agric. Eng. 1953, 34, 608–610. [Google Scholar]

- Nelson, S.O. Dielectric Properties of Agricultural Products-Measurements and Applications. IEEE Trans. Electr. Insul. 1991, 26, 845–869. [Google Scholar] [CrossRef]

- Nelson, S.; Kraszewski, A.; Trabelsi, S.; Lawrence, K. Using Cereal Grain Permittivity for Sensing Moisture Content. IEEE Trans. Instrum. Meas. 2000, 49, 470–475. [Google Scholar] [CrossRef]

- Robichaud, P.R.; Gasvoda, D.S.; Hungerford, R.D.; Bilskie, J.; Ashmun, L.E.; Reardon, J. Measuring Duff Moisture Content in the Field Using a Portable Meter Sensitive to Dielectric Permittivity. Int. J. Wildland Fire 2004, 13, 343–353. [Google Scholar] [CrossRef]

- Engber, E.A.; Varner, J.M.; Dugaw, C.J.; Quinn-Davidson, L.N.; Hiers, J.K. Utility of an Instantaneous Moisture Meter for Duff Moisture Prediction in Long-Unburned Longleaf Pine Forests. South. J. Appl. For. 2013, 37, 13–17. [Google Scholar] [CrossRef]

- Matthews, S. Effect of Drying Temperature on Fuel Moisture Content Measurements. Int. J. Wildland Fire 2010, 19, 800–802. [Google Scholar] [CrossRef]

- Jolly, W.M.; Hadlow, A.M. A Comparison of Two Methods for Estimating Conifer Live Foliar Moisture Content. Int. J. Wildland Fire 2012, 21, 180–185. [Google Scholar] [CrossRef]

- Gillen, R.L.; Tate, K.W. The Constituent Differential Method for Determining Live and Dead Herbage. J. Range Manag. 1993, 46, 142–147. [Google Scholar] [CrossRef]

- Vermeire, L.T.; Ganguli, A.C.; Gillen, R.L. A Robust Model for Estimating Standing Crop across Vegetation Types. J. Range Manag. 2002, 55, 494–497. [Google Scholar] [CrossRef]

- Starns, H.D.; Fuhlendorf, S.D.; Elmore, R.D.; Twidwell, D.; Thacker, E.T.; Hovick, T.J.; Luttbeg, B. Recoupling Fire and Grazing Reduces Wildland Fuel Loads on Rangelands. Ecosphere 2019, 10, e02578. [Google Scholar] [CrossRef]

- Kohavi, R. A Study of Cross-Validation and Bootstrap for Accuracy Estimation and Model Selection. In Proceedings of the International Joint Conference on Artificial Intelligence, Montreal, QC, Canada, 20–25 August 1995; Volume 14, pp. 1137–1145. [Google Scholar]

- Bates, D.; Mächler, M.; Bolker, B.; Walker, S. Fitting Linear Mixed-Effects Models Using Lme4. J. Stat. Softw. 2015, 67, 1–48. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2017. [Google Scholar]

- Fox, J.; Weisberg, S. An R Companion to Applied Regression, 2nd ed.; Sage: Thousand Oaks, CA, USA, 2011. [Google Scholar]

- Barton, K. MuMIn: Multi-Model Inference, R package version 1.42.1; R Package: Boston, MA, USA, 2018. [Google Scholar]

- Twidwell, D.; Fuhlendorf, S.D.; Taylor, C.A.; Rogers, W.E. Refining Thresholds in Coupled Fire-Vegetation Models to Improve Management of Encroaching Woody Plants in Grasslands. J. Appl. Ecol. 2013, 50, 603–613. [Google Scholar] [CrossRef]

| Moisture Content (%) | DMM600 Reading (MHz) | Vegetative Development Stage |

|---|---|---|

| 300 | 38.6 | Fresh foliage. Early in the growing cycle. |

| 200 | 39.8 | Maturing foliage. Still developing, full turgor. |

| 100 | 42.1 | Mature foliage. New growth |

| complete & similar to old growth. | ||

| 60 | 42.5 | Partially cured. Entering dormancy. |

| 30 | 42.6 | Fully cured. Treat as fine dead fuel. |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

McGranahan, D.A. A Device for Instantaneously Estimating Duff Moisture Content Is also Effective for Grassland Fuels. Fire 2019, 2, 12. https://doi.org/10.3390/fire2010012

McGranahan DA. A Device for Instantaneously Estimating Duff Moisture Content Is also Effective for Grassland Fuels. Fire. 2019; 2(1):12. https://doi.org/10.3390/fire2010012

Chicago/Turabian StyleMcGranahan, Devan Allen. 2019. "A Device for Instantaneously Estimating Duff Moisture Content Is also Effective for Grassland Fuels" Fire 2, no. 1: 12. https://doi.org/10.3390/fire2010012

APA StyleMcGranahan, D. A. (2019). A Device for Instantaneously Estimating Duff Moisture Content Is also Effective for Grassland Fuels. Fire, 2(1), 12. https://doi.org/10.3390/fire2010012