Silicon-Based Solar Brick for Textile Ceramic Technology

Abstract

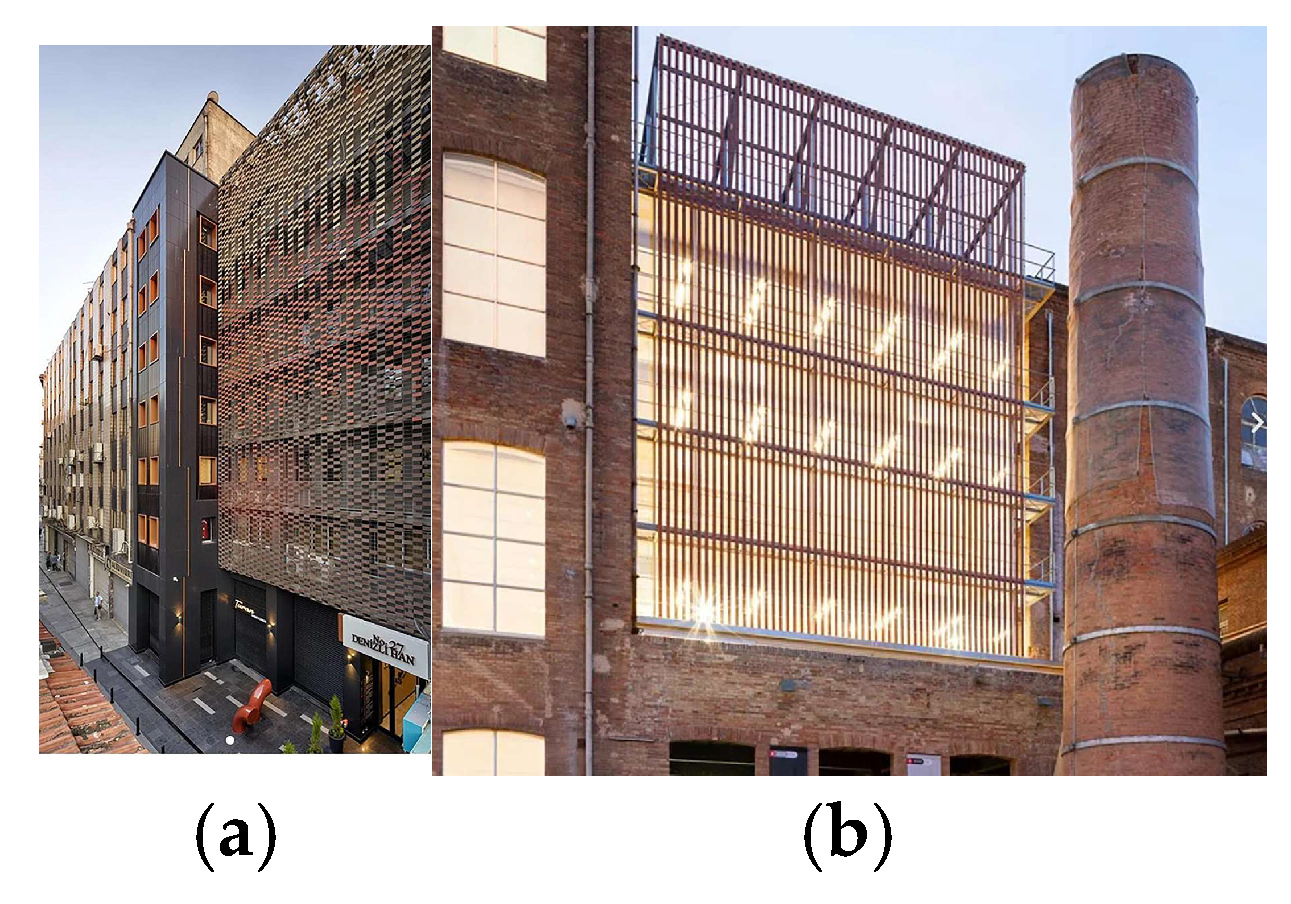

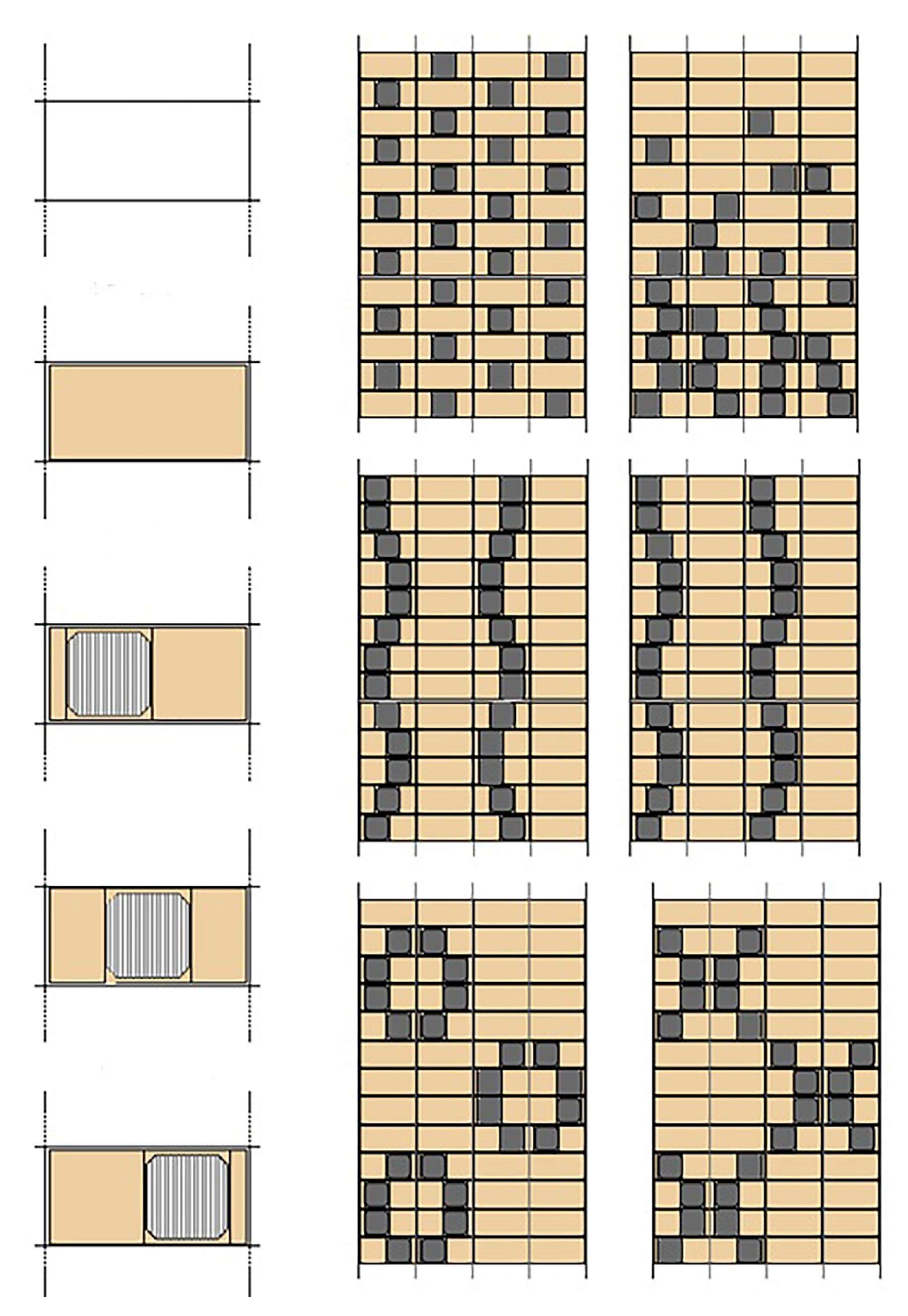

1. Introduction

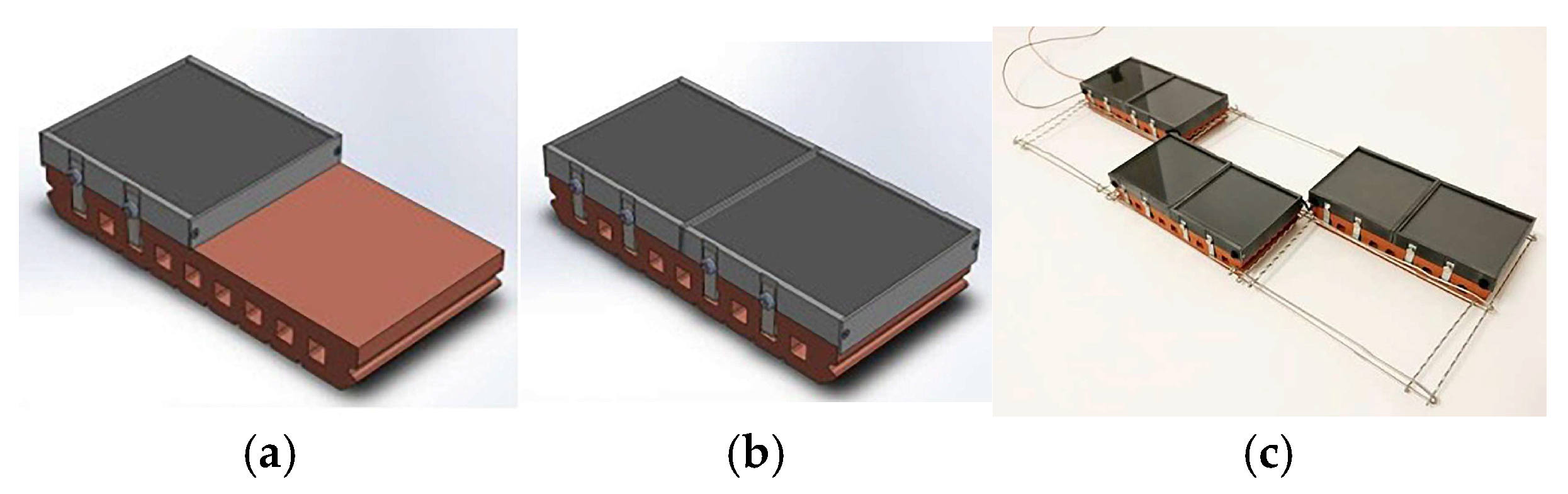

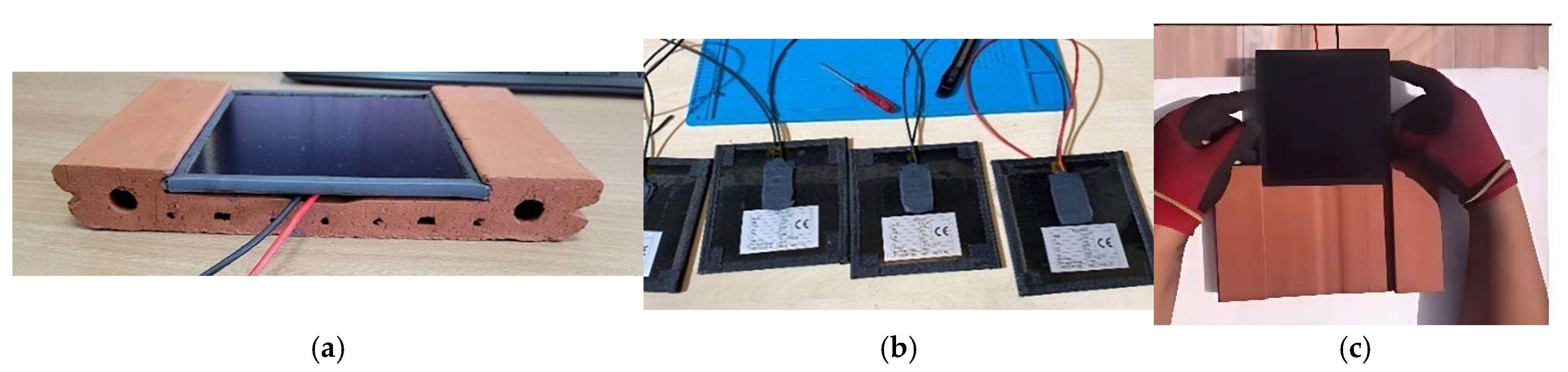

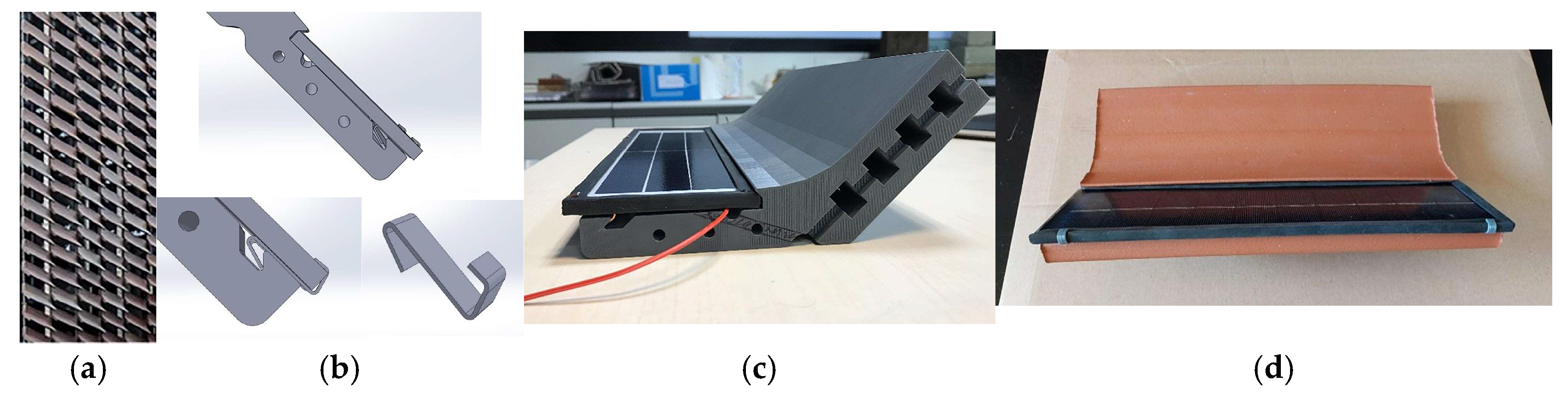

2. First Prototype

2.1. First Silicon-Based Solar Brick Prototype

2.2. Experimental Tests

2.2.1. Climatic Chamber

2.2.2. Outdoor Performance

2.3. Prototype 1: Conclusions

3. Second Prototype

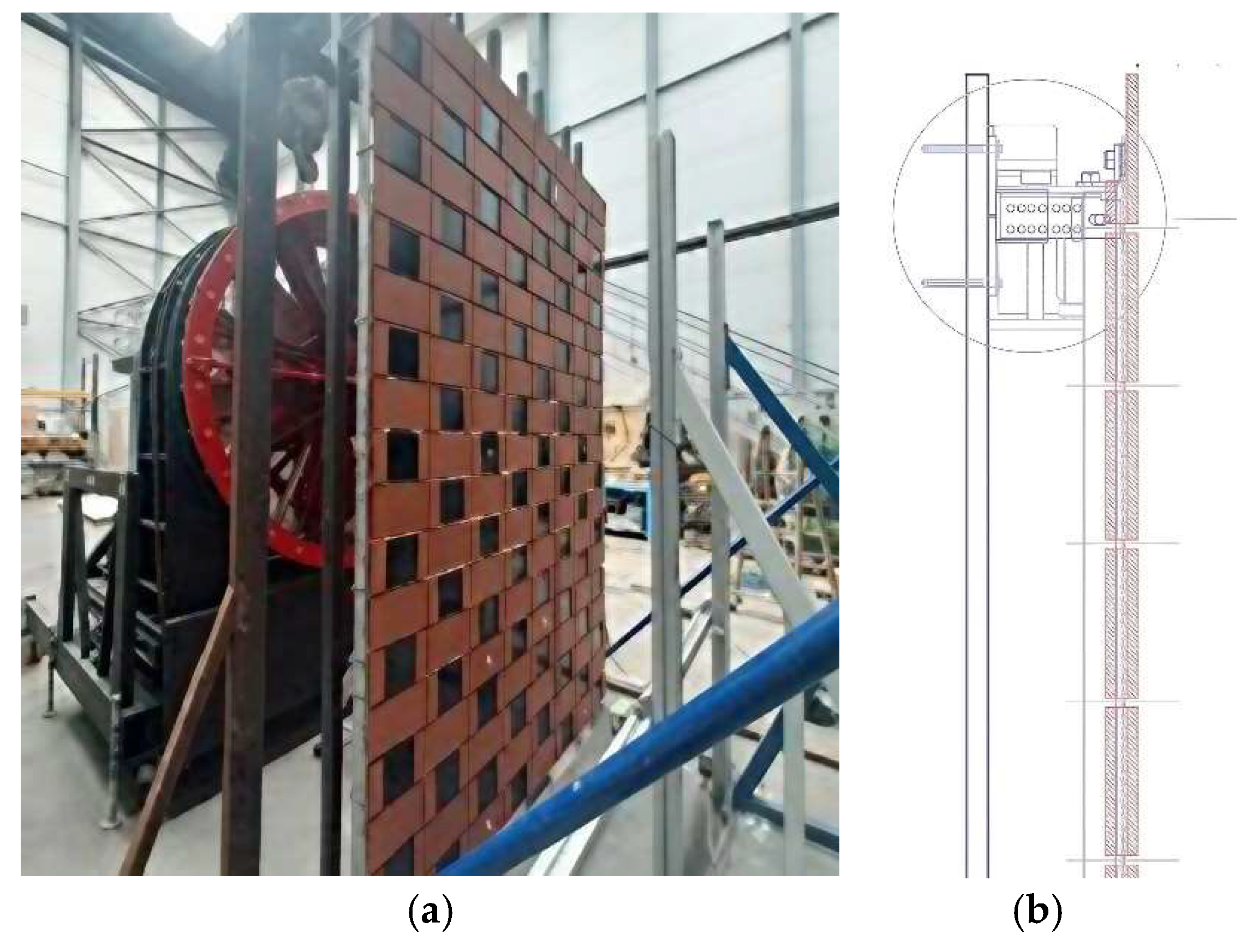

3.1. Second Silicon-Based Solar Brick Prototype

3.2. Experimental Tests

- Damp-Heat Test (DH1000)

- Dynamic Wind Load Test (WIND)

- Hail Impact Test

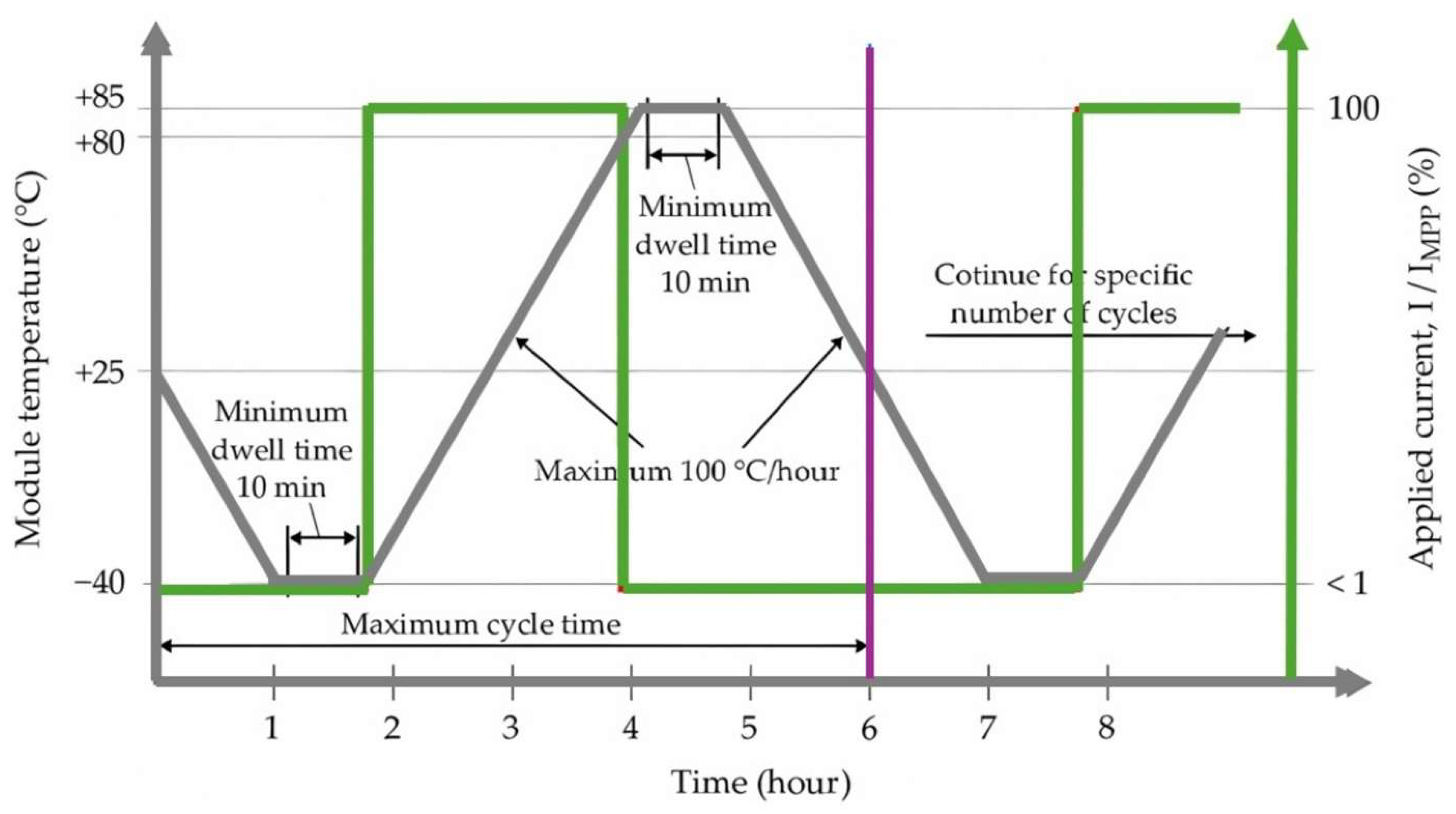

- Thermal Cycling Test (TC50)

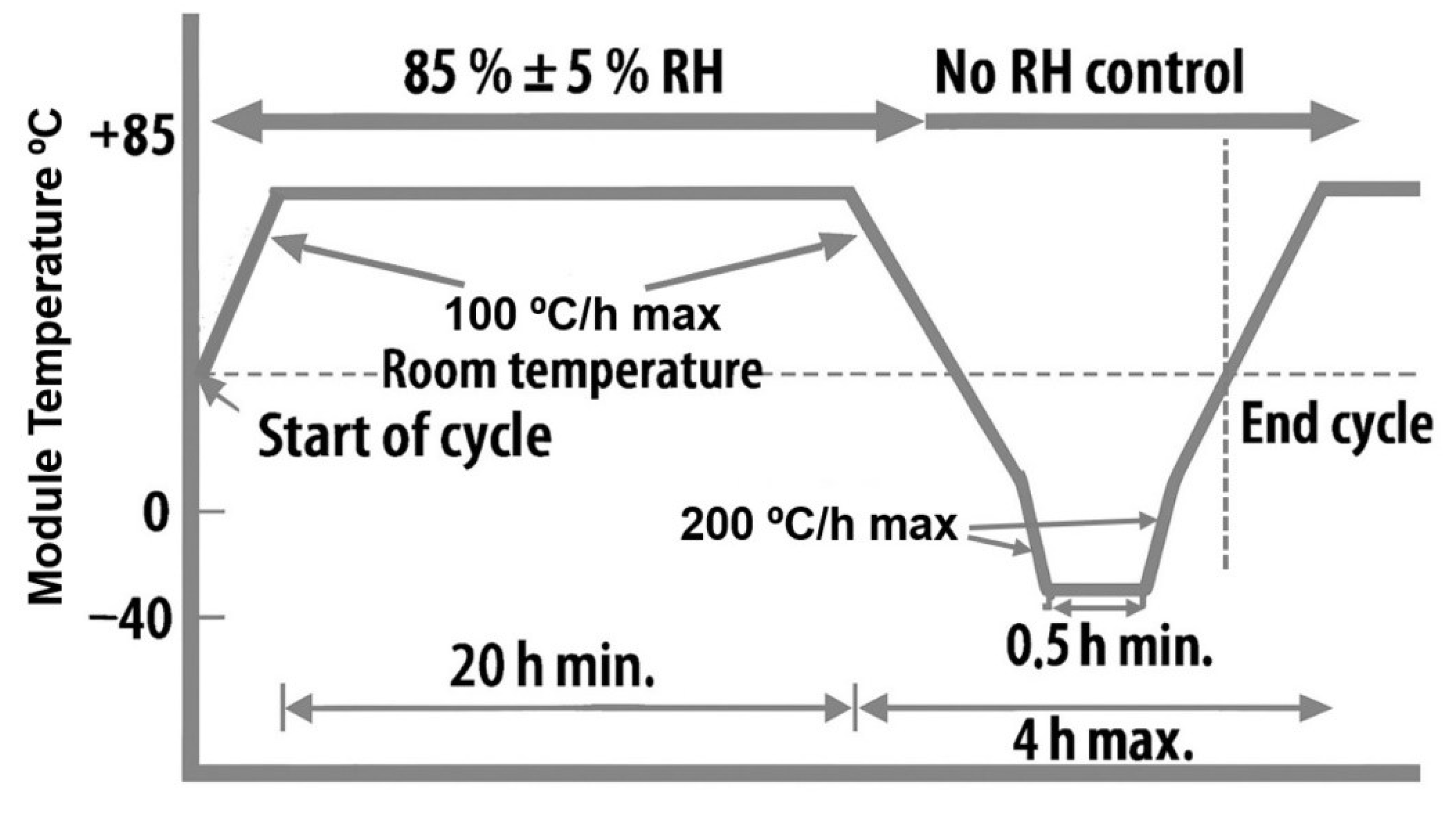

- Humidity Freeze Test (HF10)

3.2.1. Damp Heat Test

3.2.2. Dynamic Wind Load Test

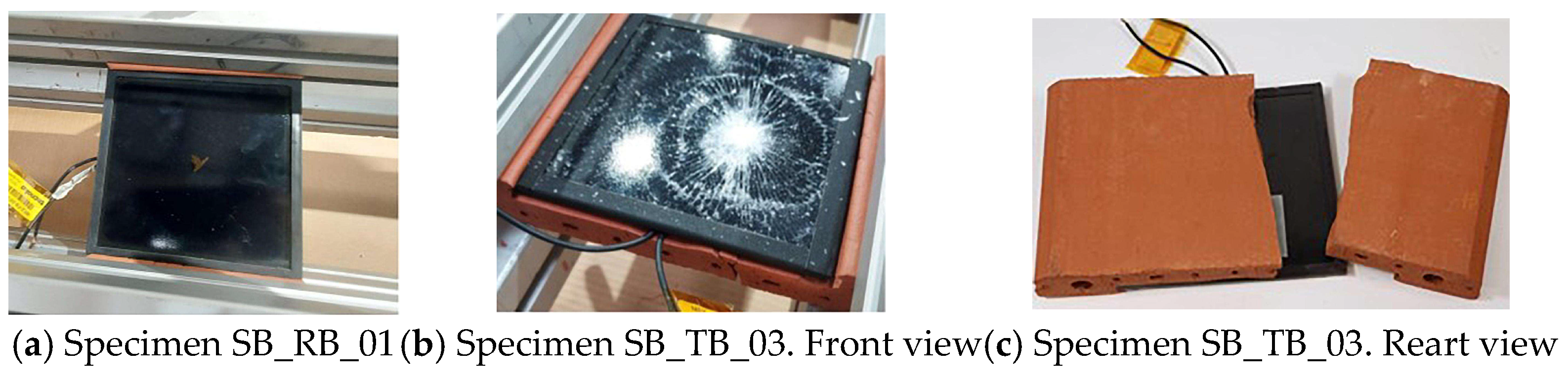

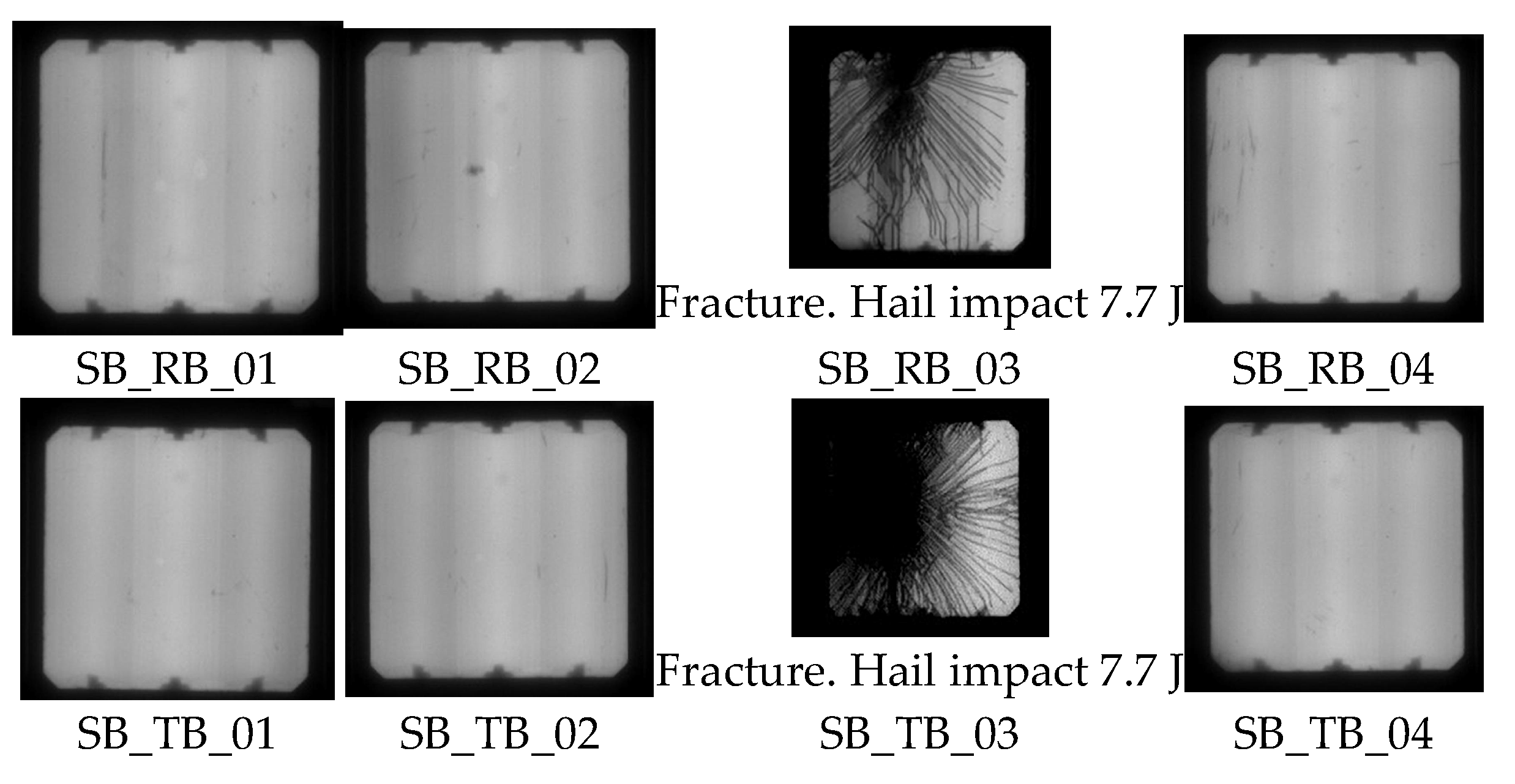

3.2.3. Hail Impact Test

3.2.4. Thermal Cycling Test

3.2.5. Humidity Freeze Test

3.3. Prototype 2: Results and Conclusions

3.3.1. Electroluminescence Inspection

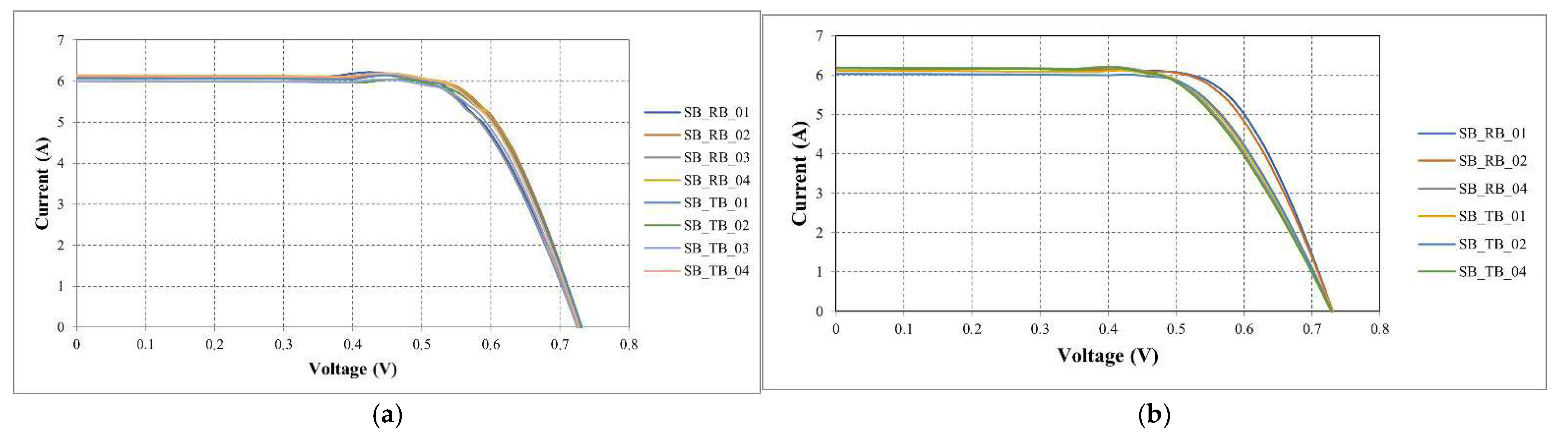

3.3.2. Electrical Parameters Before and After Testing

- Short-circuit current (Isc) remains exceptionally stable across all tests. Almost all ΔIsc values are below ±1%, and none exceed the ±5% tolerance established by IEC 61215-2. The maximum observed deviation is just −0.2%, indicating that the photoactive layers and encapsulant maintain electrical continuity even under thermal and mechanical cycling.

- In contrast, maximum power output (Pmax) exhibits greater variability. While several samples show slight performance gains, others experience drops beyond 5%—particularly during thermal cycling:

- SB_RB_04: −7.3%

- SB_TB_01: −5.6%

- SB_TB_04: −6.7%

- 3

- Damp Heat (DH1000): All specimens passed this test, showing very limited electrical degradation. Isc typically increased slightly (0.2–0.9%), and Pmax fluctuations remained within acceptable limits, suggesting good moisture resistance.

- 4

- Thermal Cycling (TC50): This test revealed the greatest Pmax variation. Even though Isc remained stable, the loss in Pmax for some samples exceeded 5%, hinting at internal mechanical stress effects not always visible externally.

- 5

- Humidity Freeze (HF10): All modules tested passed with minor or even positive Pmax variations (e.g., +6.1% in SB_RB_01), reinforcing the structural integrity and thermal compatibility of materials under freeze–thaw conditions.

- 6

- Wind Test: Although performed at 100 km/h, all samples tested resisted without signs of mechanical or electrical degradation, validating their basic aerodynamic and structural robustness. However, more extreme wind scenarios would be necessary for complete validation in high-exposure regions.

- 7

- Hail Test (7.7 J): Two samples fractured and could not complete further tests (SB_RB_03, SB_TB_03), evidencing a clear limitation in impact resistance. Nevertheless, other modules (e.g., SB_RB_01 and SB_TB_01) showed negligible variation in Isc and moderate changes in Pmax (−6.6% to +6.6%), indicating that while fracture may occur, it does not necessarily compromise functionality unless it reaches critical internal components.

4. Conclusions

5. Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarrablo-Moreno, V. Flexible Sheet of Bricks for Construction of Architectural Elements, and Method for Manufacture of Said Sheet. Spain Patent ES 2011/0047914A1, 4 September 2012. [Google Scholar]

- Bernat-Maso, E.; Gil, L.; Roca, P.; Sarrablo, V.; Escrig, C. Structural characterisation of textile ceramic technology used. Eng. Struct. 2013, 57, 277–288. [Google Scholar] [CrossRef]

- Bernat-Maso, E.; Gil, L.; Roca, P.; Sarrablo, V.; Puigvert, F. Mechanical characterisation of Textile Ceramic plates. Testing on elastic foundations. Eng. Struct. 2014, 74, 193–204. [Google Scholar] [CrossRef]

- PMMT. Available online: https://www.pmmtarquitectura.es/proyectos/vivienda-unifamiliar-en-barcelona (accessed on 5 June 2025).

- Pich-Architects. Picharchitectes. Available online: https://www.picharchitects.com/portfolio-items/sant-pau-research-institute/?lang=en (accessed on 1 June 2025).

- Sarrablo, V. Casa Mingo. ConArquitectura 2011, 40, 45–52. [Google Scholar]

- Sarrablo, V.; Colom, J. Los tejidos cerámicos y la casa Mingo. Detail 2011, 6, 640–645. [Google Scholar]

- Trias de Bes, J.; Casariego, P. De la técnica a la tecnología: Construcción de forjados de cerámica abovedada mediante sistemas industrializados. Inf. Constr. 2016, 68, e169. [Google Scholar] [CrossRef]

- Roca, P.; López-Almansa, F.; Miquel, J.; Hanganu, A. Limit analysis of reinforced masonry vaults. Eng. Struct. 2007, 29, 431–439. [Google Scholar] [CrossRef]

- López-Almansa, F.; Sarrablo, V.; Lourenço, P.; Barros, J.; Roca, P.; da Porto, F.; Modena, C. Reinforced brick masonry light vaults: Semi-prefabrication, construction, testing and numerical modeling. Constr. Build. Mater. 2010, 24, 1799–1814. [Google Scholar] [CrossRef]

- Ghosh, A. Potential of building integrated and attached/applied photovoltaic (BIPV/BAPV) for adaptive less energy-hungry building’s skin: A comprehensive review. J. Clean. Prod. 2020, 276, 123343. [Google Scholar] [CrossRef]

- Singh, D.; Chaudhary, R.; Karthick, A. Review on the progress of building-applied/integrated photovoltaic system. Environ. Sci. Pollut. Res. 2021, 28, 47689–47724. [Google Scholar] [CrossRef]

- Joseph, B.; Pogrebnaya, T.; Kichonge, B. Semitransparent Building-Integrated Photovoltaic: Review on Energy Performance, Challenges, and Future Potential. Int. J. Photoenergy 2019, 17, 5214150. [Google Scholar] [CrossRef]

- European Commission. Update on BIPV Market and Stakeholder Analysis, BIPVBoost, Grant Agreement No: 817991; European Commission: Bruxelles/Brussel, Belgium, 2019. [Google Scholar]

- Almeida, E.; Alexandre, M.; Santos, I.M.; Martins, R.; Águas, H.; Mendes, M.J. Photonic-enhanced perovskite solar cells: Tailoring color and light capture. ACS Omega 2024, 9, 42839–42849. [Google Scholar] [CrossRef]

- Liu, Z.; Sofia, S.E.; Laine, H.S.; Woodhouse, M.; Wieghold, S.; Peters, I.M.; Buonassisi, T. Revisiting thin silicon for photovoltaics: A technoeconomic perspective. Energy Environ. Sci. 2020, 13, 12–23. [Google Scholar] [CrossRef]

- Águas, H.; Ram, S.K.; Araújo, A.; Gaspar, D.; Vicente, A.; Filonovich, S.A.; Fortunato, E.; Martins, R.; Ferreira, I. Silicon thin film solar cells on commercial tiles. Energy Environ. Sci. 2011, 4, 4476–4480. [Google Scholar] [CrossRef]

- Wang, X. Can Photovoltaic Power Generation Provides Hydrothermal Difunctional Green Building Material Tile. China Patent CN205857541U, 9 August 2016. [Google Scholar]

- Shu, X.; Zhu, J.J.; Jiang, H.; Chen, S.Y. Scientometric analysis of building integrated photovoltaics research: Development, themes, and main trends. J. Asian Archit. Build. Eng. 2024, 1–33. [Google Scholar] [CrossRef]

- Li, X.; Xu, J.; Su, Y. Research status and emerging trends in green building materials based on bibliometric network analysis. Buildings 2025, 15, 884. [Google Scholar] [CrossRef]

- Liang, J. Lap Joint Type Solar Photovoltaic Tile. China Patent CN218323539U, 23 August 2022. [Google Scholar]

- Melchior, B. Roofing Tile Assembly. U.S. Patent US5112408A, 12 May 1992. [Google Scholar]

- Metten, E.C.; Roddick, T.J.; Scultety, J.L. Photovoltaic Solar Roof Tile Assembly System. International Patent WO 2007/079584 A2, 19 July 2007. [Google Scholar]

- Pilliod, M.; Gougoussis, C.; Lefevre, O.; Laurin, M.; Liu, J. Tesla Solar Roof. U.S. Patent US2018/0122973A1, 3 May 2018. [Google Scholar]

- Dai, Y. Photovoltaic Panel Bearing Tile, Photovoltaic Tile and Roof System. China Patent CN217759664U, 8 November 2022. [Google Scholar]

- Melchior, B. Roofing Tile. Germany Patent DE4411458A1, 30 March 1995. [Google Scholar]

- Liang, W. Solar Photovoltaic Tile. China Patent CN113872502A, 31 December 2021. [Google Scholar]

- Keller, A.F. Solar Power Unit and System. U.S. Patent US2014007528A1, 9 January 2014. [Google Scholar]

- Wang, Z.; Ma, J.; Yang, H.; Lei, G.; Chu, H.; Shu, B.; Lu, J. Solar Cell Circuit High-Voltage Protection Design Structure and Preparation Method Thereof. China Patent CN111416010A, 26 November 2021. [Google Scholar]

- Jelle, B.P.; Breivik, C. State-of-the-art Building Integrated Photovoltaics. Energy Procedia 2012, 20, 68–77. [Google Scholar] [CrossRef]

- Shukla, A.; Sudhakar, K.; Baredar, P. A comprehensive review on design of building integrated photovoltaic system. Energy Build. 2016, 128, 99–110. [Google Scholar] [CrossRef]

- Norton, B.; Eames, P.; Mallick, T.; Huang, M.; McCormack, S.; Mondol, J.; Yohanis, Y. Enhancing the performance of building integrated photovoltaics. Sol. Energy 2011, 85, 1629–1664. [Google Scholar] [CrossRef]

- Chen, T.; Tai, K.F.; Raharjo, G.P.; Heng, C.K.; Leow, S.W. A novel design approach to prefabricated BIPV walls for multi-storey buildings. J. Build. Eng. 2023, 63 Pt A, 105469. [Google Scholar] [CrossRef]

- UNE-EN IEC 61215-2:2021; Módulos Fotovoltaicos (FV) Para Uso Terrestre. Cualificación del Diseño y Homologación. Parte 2: Procedimientos de Ensayo. UNE: Madrid, Spain, 2021.

- UNE-EN 12179; Fachadas Ligeras. Resistencia a la Carga de Viento. Método de Ensayo. UNE: Madrid, Spain, 2000.

- ASTM E330/E330M-14 (2021); Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference. ASTM International: West Conshohocken, PA, USA, 2021.

- EAD 090062-00-0404; Kits for External Wall Claddings Mechanically Fixed. European Organisation for Technical Assessment: Bruxelles, Belgium, 2018.

- AAMA 501.1-17; Standard Test Method for Water Penetration of Windows, Curtain Walls and Doors Using Dynamic Pressure. AAMA: Chicago, IL, USA, 2017.

- Friesen, T. Hail testing of PV modules: Results of a round robin for hail grain quality determination and testing results of different module designs. In Proceedings of the 28th European Photovoltaic Solar Energy Conference, Paris, France, 30 September 2013. [Google Scholar]

- Jenkins, D.R.; Mathey, R.G. Hail Impact Test Procedure for Solar Collector Covers; U.S. Department of Commerce, National Bureau of Standards: Washington, DC, USA, 1982. [Google Scholar]

- QAIST-Quality Assurance in Solar Thermal Heating and Cooling Technology; European project supported by IEE—Intelligent Energy Europe. Impact resistance testing. Deliverable D2.2–R2.16; ESTIF: Brussels, Belgium, 2012.

- Moore, D.; Wilson, A. Photovoltaic Solar Panel Resistance to Simulated Hail; Department of Energy: Washington, DC, USA, 1978. [Google Scholar]

- UNE-EN 13583:2013; Flexible Sheets for Waterproofing–Bitumen, Plastic and Rubber Sheets for Roof Waterproofing–Determination of Hail Resistance. UNE: Madrid, Spain, 2013.

- UNE-EN ISO 9806:2020; Solar Energy–Solar Thermal Collectors–Test Methods (ISO 9806:2017). UNE: Madrid, Spain, 2020.

- Alassaf, Y. Comprehensive Review of the Advancements, Benefits, Challenges, and Design Integration of Energy-Efficient Materials for Sustainable Buildings. Buildings 2024, 14, 2994. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, M.; Yang, H. A Review of the Energy Performance and Life-Cycle Assessment of Building-Integrated Photovoltaic (BIPV) Systems. Energies 2018, 11, 3175. [Google Scholar] [CrossRef]

- Celadyn, W.; Filipek, P. Investigation of the Effective Use of Photovoltaic Modules in Architecture. Buildings 2020, 10, 145. [Google Scholar] [CrossRef]

- Constantinou, S.; Al-naemi, F.; Alrashidi, H.; Mallick, T.; Issa, W. A review on technological and urban sustainability perspectives of advanced building-integrated photovoltaics. Energy Sci. Eng. 2024, 12, 1265–1293. [Google Scholar] [CrossRef]

- Tripathy, M.; Sadhu, P.K.; Panda, S.K. A critical review on building integrated photovoltaic products and their applications. Renew. Sustain. Energy Rev. 2016, 61, 451–465. [Google Scholar] [CrossRef]

| Sample | Voc (V) | Isc (mA/cm2) | Pmax (W) | FF (%) | η (%) | Rs (Ω·cm2) | Rsh (kΩ·cm2) |

|---|---|---|---|---|---|---|---|

| SPM-1 | 7.7 | 3.2 | 1.1 | 72.8 | 22.4 | 35.5 | 119.3 |

| SPM-Mesh | 7.3 | 2.9 | 5.1 | 67.9 | 17.5 | 297.2 | 89.4 |

| Condition | PIN (W/m2) | Voc (V) | Isc (mA/cm2) | Pmax (W) | FF (%) | η (%) | Rs (Ω·cm2) | Rsh (kΩ·cm2) |

|---|---|---|---|---|---|---|---|---|

| SPM-1 (RA) | 740 | 7.4 | 2.0 | 7.1 | 72.1 | 16.3 | 38.5 | 298.2 |

| SPM-Mesh (RA) | 740 | 8.0 | 2.0 | 3.9 | 67.7 | 14.7 | 335.6 | 119.3 |

| SPM-Mesh (RB) | 140 | 7.0 | 0.2 | 3.9 | 63.3 | 7.4 | 318.9 | 577.1 |

| Condition | PIN (W/m2) | Voc (V) | Isc (mA/cm2) | Pmax (W) | FF (%) | η (%) | Rs (Ω·cm2) | Rsh (kΩ·cm2) |

|---|---|---|---|---|---|---|---|---|

| Prototype Tracker (RA) | 700 | 8.0 | 2.0 | 3.9 | 67.7 | 14.7 | 335.6 | 119.3 |

| Prototype Vertical (RA) | 700 | 7.9 | 2.1 | 4.0 | 67.5 | 15.3 | 234.1 | 357.8 |

| Sample | Pmax (W) | Vmp (V) | Imp (A) | Voc (V) | Isc (A) |

|---|---|---|---|---|---|

| SBSB | 3.46 | 0.5 | 6.92 | 0.6 | 7.26 |

| Specimen Code | DH1000 | WIND | HAIL | TC50 | HF10 |

|---|---|---|---|---|---|

| SB_RB_01 | ✔ | ✔ | ✔ | ✔ | ✔ |

| SB_RB_02 | ✔ | ✔ | ✔ | ✔ | |

| SB_RB_03 | ✔ | ✔ | ✔ | ✔ | |

| SB_RB_04 | ✔ | ✔ | ✔ | ||

| SB_TB_01 | ✔ | ✔ | ✔ | ✔ | ✔ |

| SB_TB_02 | ✔ | ✔ | ✔ | ✔ | |

| SB_TB_03 | ✔ | ✔ | ✔ | ✔ | |

| SB_TB_04 | ✔ | ✔ | ✔ |

| Level | Wind Speed [km/h] | Fan Speed [RPM] |

|---|---|---|

| 1 | 16.67 | 129 |

| 2 | 33.33 | 252 |

| 3 | 50.00 | 374 |

| 4 | 66.67 | 496 |

| 5 | 83.33 | 618 |

| 6 | 100.00 | 740 |

| Standard ICE 61215. Hail Ball | Energy (J) | Adapted. Stell Ball | ||||

|---|---|---|---|---|---|---|

| Speed (m/s) | Mass (g) | Diameter (mm) | Mass (g) | Diameter (mm) | Height (m) | |

| 23 | 7.53 | 25 | 2.0 | 95.9 | 28.575 | 2.117 |

| 27.2 | 20.7 | 35 | 7.7 | 200.1 | 36.512 | 3.902 |

| 30.7 | 43.9 | 45 | 20.7 | 767.2 | 57.15 | 2.749 |

| 33.9 | 80.2 | 55 | 46.1 | 1600.6 | 73.025 | 2.935 |

| Sample Reference | Energy (J) | Observations | Result |

|---|---|---|---|

| SB_RB_01 | 2.0 | – | PASSED |

| SB_RB_03 | 7.7 | Ceramic piece and PV module broken | NOT PASSED |

| SB_TB_01 | 2.0 | – | PASSED |

| SB_TB_03 | 7.7 | Ceramic piece and PV module broken | NOT PASSED |

| Sample | Test | Isc Before | Pmax Before | Isc After | Pmax After | ΔIsc (%) | ΔPmax (%) | Result |

|---|---|---|---|---|---|---|---|---|

| SB_RB_01 | Damp Heat | 6.15 | 3.13 | 6.18 | 3.15 | +0.6 | +0.7 | PASSED |

| Wind | – | – | – | – | – | – | N.P * | |

| Hail | 6.18 | 3.15 | 6.17 | 2.94 | −0.16 | −6.6 | PASSED | |

| Thermal Cyc | 6.17 | 2.94 | 6.16 | 3.02 | −0.2 | +2.8 | PASSED | |

| Humidity Frz | 6.16 | 3.02 | 6.18 | 3.21 | +0.3 | +6.1 | PASSED | |

| SB_RB_02 | Damp Heat | 6.13 | 3.24 | 6.18 | 3.10 | +0.5 | −1.0 | PASSED |

| Wind | – | – | – | – | – | – | N.P * | |

| Thermal Cyc | 6.17 | 3.21 | 6.15 | 3.01 | −0.2 | −5.3 | PASSED | |

| Humidity Frz | 6.15 | 3.01 | 6.18 | 3.15 | +0.4 | +4.9 | PASSED | |

| SB_RB_03 | Damp Heat | 6.12 | 3.08 | 6.17 | 3.08 | +0.8 | −0.1 | PASSED |

| SB_RB_04 | Damp Heat | 6.14 | 3.22 | 6.20 | 3.05 | +0.9 | −5.4 | PASSED |

| Thermal Cyc | 6.19 | 3.16 | 6.18 | 2.93 | −0.1 | −7.3 | PASSED | |

| Humidity Frz | 6.18 | 2.93 | 6.19 | 2.94 | +0.1 | −0.1 | PASSED | |

| SB_TB_01 | Damp Heat | 6.08 | 3.20 | 6.10 | 3.05 | +0.4 | −4.7 | PASSED |

| Wind | – | – | – | – | – | – | N.P * | |

| Hail | 6.10 | 3.05 | 6.11 | 3.25 | +0.16 | +6.6 | PASSED | |

| Thermal Cyc | 6.11 | 3.25 | 6.11 | 3.04 | 0.0 | −5.6 | PASSED | |

| Humidity Frz | 6.11 | 3.04 | 6.12 | 2.96 | +0.1 | −2.5 | PASSED | |

| SB_TB_02 | Damp Heat | 6.00 | 3.16 | 6.04 | 3.08 | +0.6 | −2.4 | PASSED |

| Wind | – | – | – | – | – | – | N.P * | |

| Thermal Cyc | 6.03 | 3.14 | 6.02 | 2.99 | 0.0 | −4.7 | PASSED | |

| Humidity Frz | 6.02 | 2.99 | 6.03 | 2.96 | +0.1 | −0.9 | PASSED | |

| SB_TB_03 | Damp Heat | 6.00 | 3.10 | 6.01 | 2.98 | +0.2 | −3.9 | PASSED |

| SB_TB_04 | Damp Heat | 6.14 | 3.20 | 6.16 | 2.90 | +0.5 | −9.2 | PASSED |

| Thermal Cyc | 6.19 | 2.98 | 6.17 | 2.77 | −0.2 | −6.7 | PASSED | |

| Humidity Frz | 6.17 | 2.77 | 6.18 | 2.91 | +0.2 | +4.5 | PASSED |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casariego, P.; Sarrablo, V.; Barrientos, R.; Santamaria-Fernandez, S. Silicon-Based Solar Brick for Textile Ceramic Technology. Ceramics 2025, 8, 106. https://doi.org/10.3390/ceramics8030106

Casariego P, Sarrablo V, Barrientos R, Santamaria-Fernandez S. Silicon-Based Solar Brick for Textile Ceramic Technology. Ceramics. 2025; 8(3):106. https://doi.org/10.3390/ceramics8030106

Chicago/Turabian StyleCasariego, P., V. Sarrablo, R. Barrientos, and S. Santamaria-Fernandez. 2025. "Silicon-Based Solar Brick for Textile Ceramic Technology" Ceramics 8, no. 3: 106. https://doi.org/10.3390/ceramics8030106

APA StyleCasariego, P., Sarrablo, V., Barrientos, R., & Santamaria-Fernandez, S. (2025). Silicon-Based Solar Brick for Textile Ceramic Technology. Ceramics, 8(3), 106. https://doi.org/10.3390/ceramics8030106