Enhancement of Microwave Dielectric Properties in Mixed-Phase Ceramics Through CuB2O4 Doping: Achieving Ultra-Low Loss and High Dielectric Constant

Abstract

1. Introduction

2. Experimental Procedure

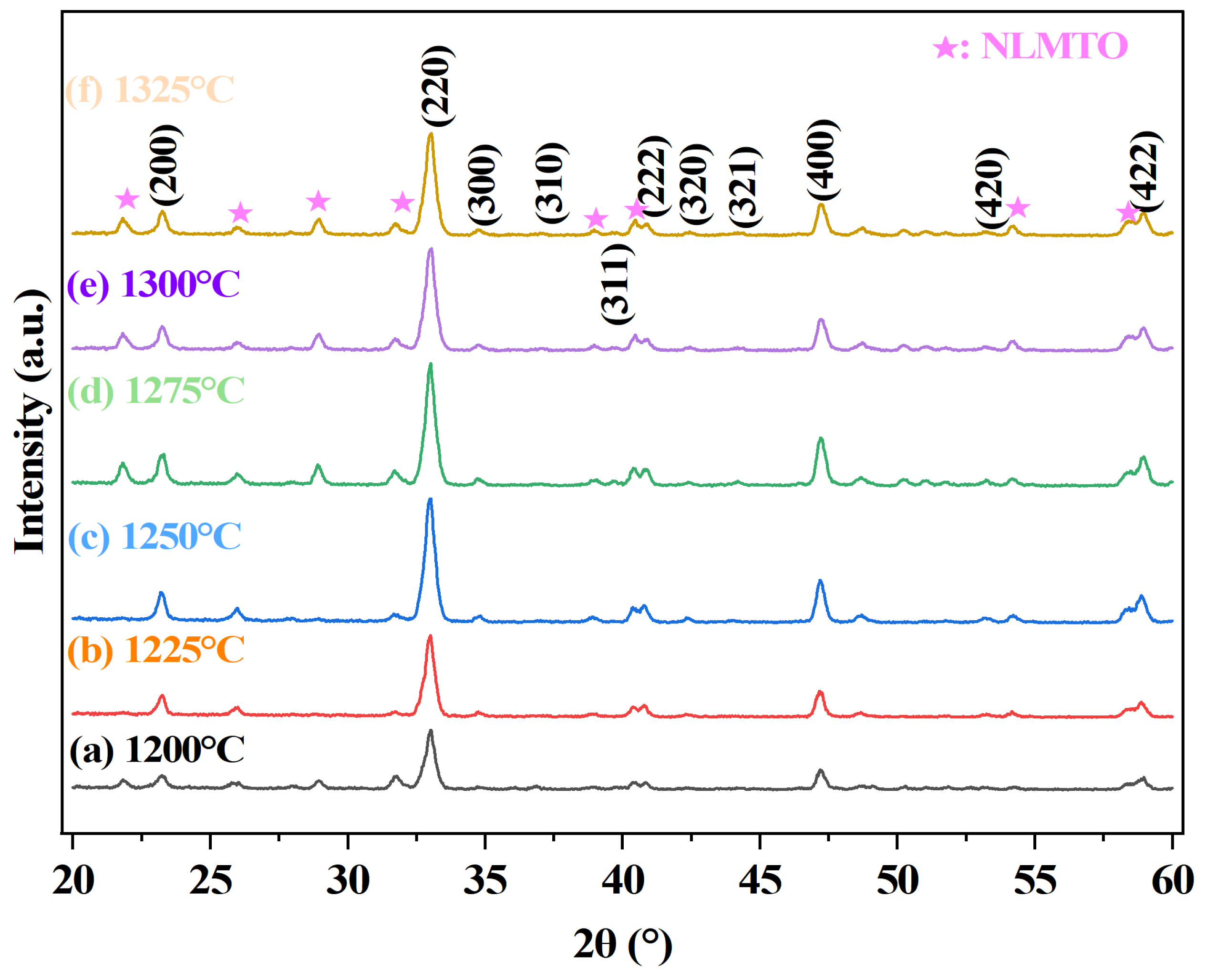

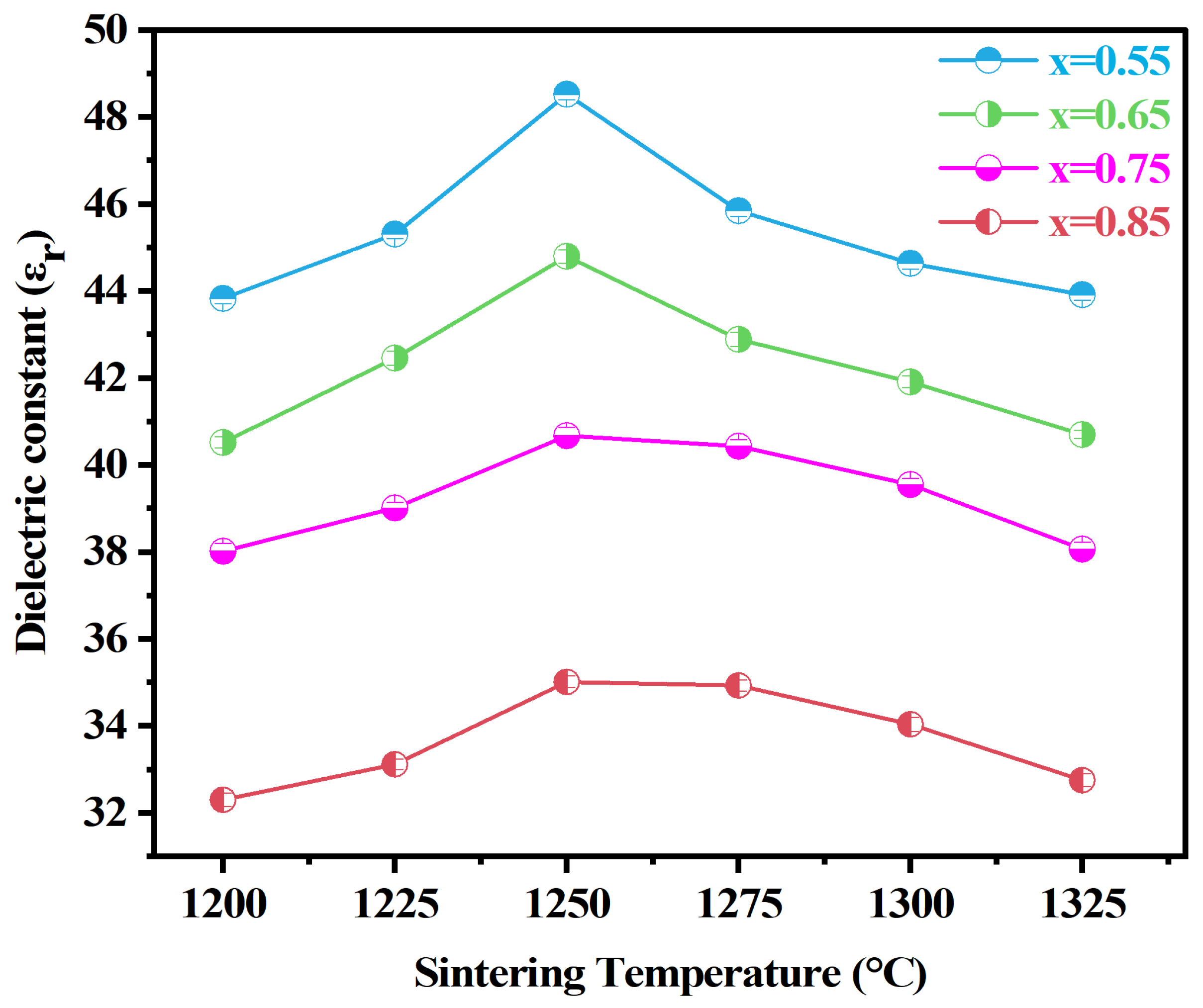

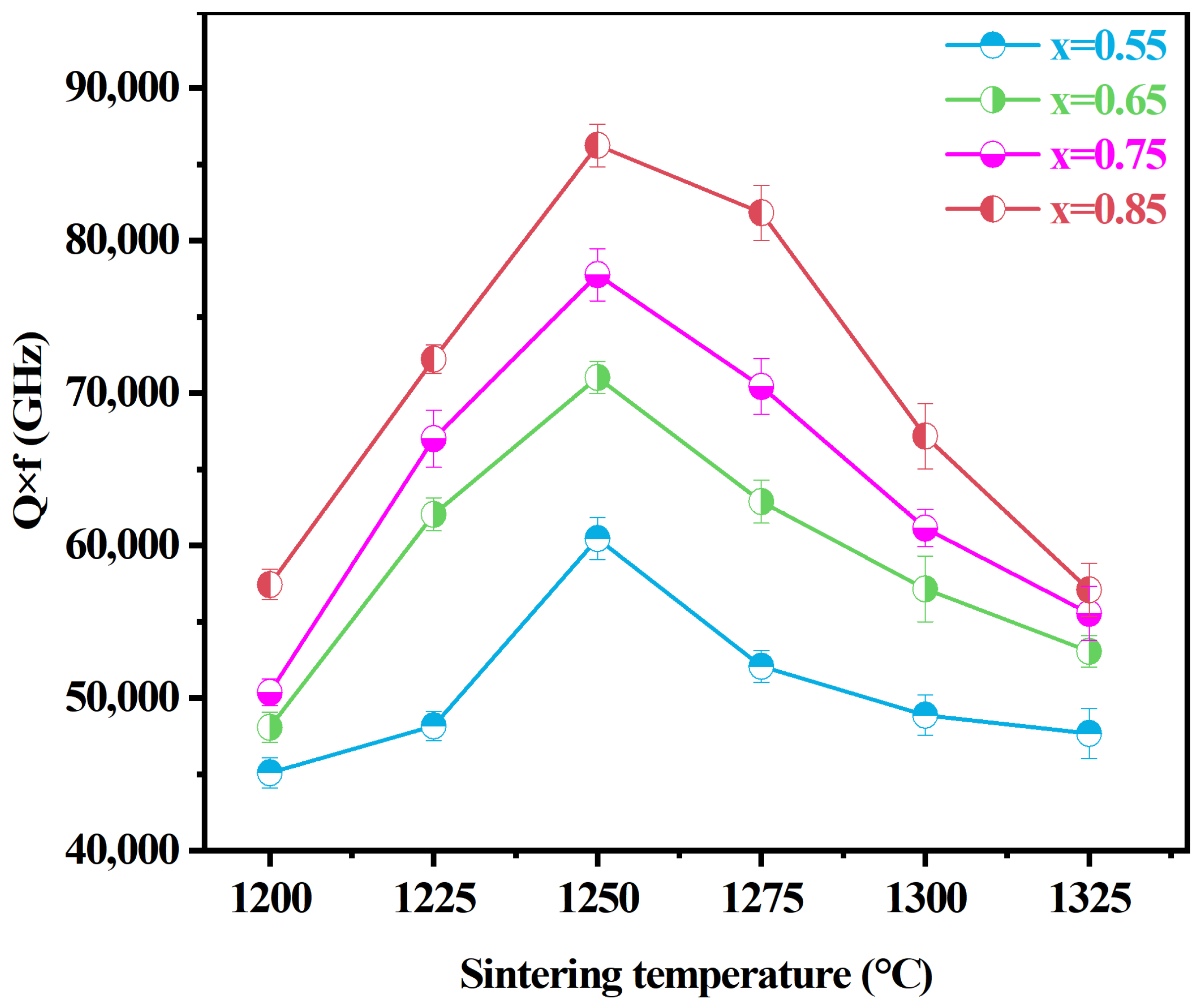

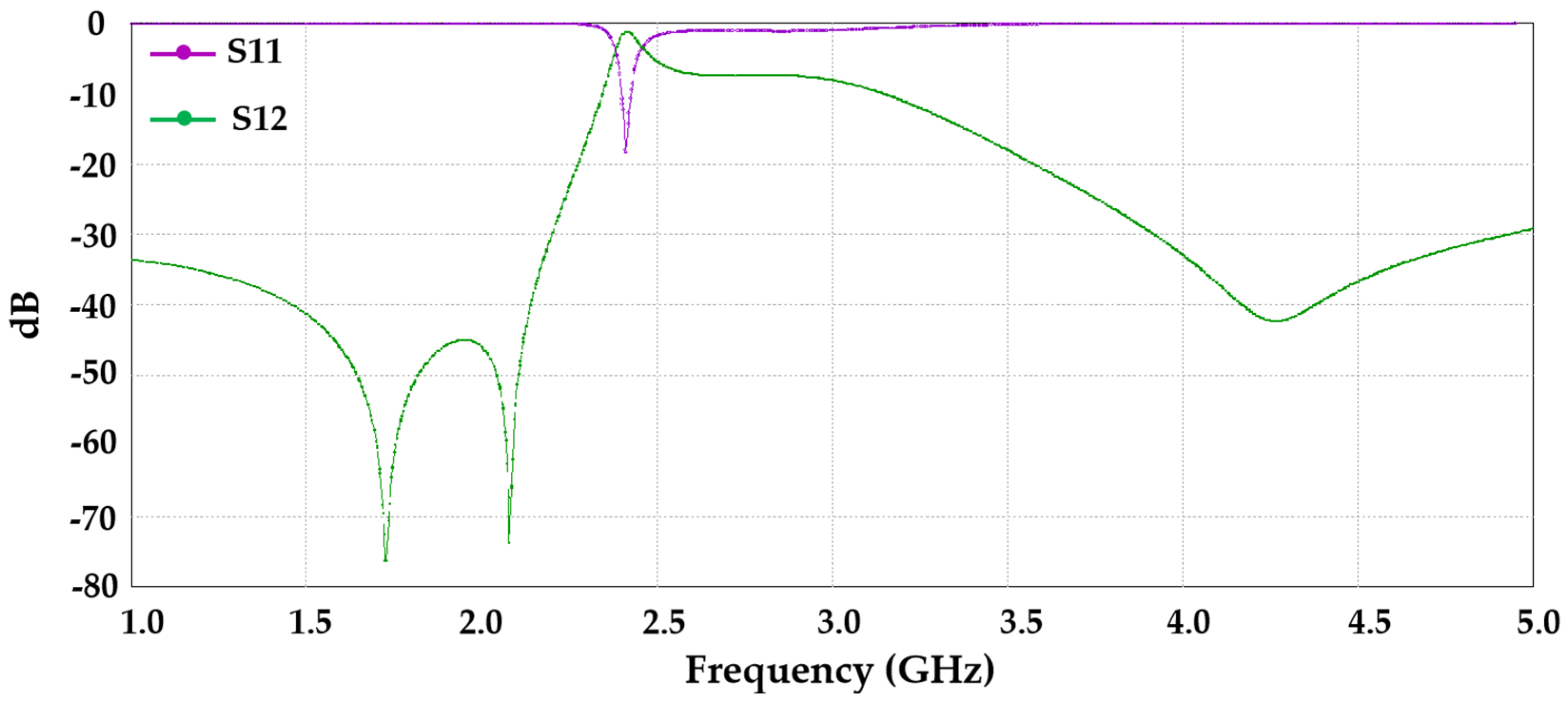

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, P.; Hao, M.; Xiao, M. Microwave dielectric properties of Li3Mg2NbO6-based ceramics with (MxW1−x)5+ (M = Li+, Mg2+, Al3+, Ti4+) substitutions at Nb5+ sites. J. Alloys Compd. 2021, 853, 157386. [Google Scholar] [CrossRef]

- Nakagoshi, Y.; Sato, J.; Morimoto, M.; Suzuki, Y. Near-zero volume-shrinkage in reactive sintering of porous MgTi2O5 with pseudobrookite-type structure. Ceram. Int. 2016, 42, 9139–9144. [Google Scholar] [CrossRef][Green Version]

- Lin, S.H.; Chen, Y.B. Structure and characterization of B2O3 modiffed yNd(Mg1/2Ti1/2)O3-(1-y)Ca0.8Sr0.2TiO3 ceramics with a near-zero temperature coefffcient at microwave frequency. Ceram. Int. 2017, 43, 2368–2371. [Google Scholar] [CrossRef]

- Zaman, A.; Uddin, S.; Mehboob, N.; Ali, A. Structural investigation and improvement of microwave dielectric properties in Ca(HfxTi1-x)O3 ceramics. Phys. Scr. 2021, 96, 025701. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, H.; Luan, X.; Hu, S.; Zhou, X.; He, S.; Wang, X.; Zhou, S.; Chen, X. NaTaO3 microwave dielectric ceramic a with high relative permittivity and as an excellent compensator for the temperature coefffcient of resonant frequency. Ceram. Int. 2021, 47, 121–129. [Google Scholar] [CrossRef]

- Pei, C.; Tan, J.; Li, Y.; Yao, G.; Jia, Y.; Ren, Z.; Liu, P.; Zhang, H. Effect of Sb-site nonstoichiometry on the structure and microwave dielectric properties of Li3Mg2Sb1−xO6 ceramics. J. Adv. Ceram. 2020, 9, 588–594. [Google Scholar] [CrossRef]

- Chen, C.; Peng, Z.; Xie, L.; Bi, K.; Fu, X. Microwave dielectric properties of novel (1 − x)MgTiO3−xCa0.5Sr0.5TiO3 ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 13696–13703. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Liu, H.; Qiu, T.; Fan, C. Structure, morphology, and microwave dielectric properties of SmAlO3 synthesized by stearic acid route. J. Adv. Ceram. 2020, 9, 558–566. [Google Scholar] [CrossRef]

- Hameed, X.; Liu, Q.; Li, L.; Liu, M.Y.; Chen, X.M. Structure evolution and improved microwave dielectric characteristics in CaTi1−x(Al0.5Nb0.5)xO3 ceramics. J. Alloys Compd. 2020, 845, 155435. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, Y.; Xiang, M. Synthesis, characterization and dielectric properties of a novel temperature stable (1− x)CoTiNb2O8−xZnNb2O6 ceramic. J. Adv. Ceram. 2019, 8, 228–237. [Google Scholar] [CrossRef]

- Shi, F.; Fu, G.; Xiao, E.; Li, J. Lattice vibrational characteristics and dielectric properties of pure phase CaTiO3 ceramic. J. Mater. Sci. Mater. Electron. 2020, 31, 18070–18076. [Google Scholar] [CrossRef]

- Yang, S.; Liang, B.; Liu, C.; Liu, J.; Fang, C.; Ai, Y. Microwave sintering and microwave dielectric properties of (1–x)Ca0.61La0.26TiO3−xNd(Mg0.5Ti0.5)O3 ceramics. Materials 2021, 14, 438. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H.; Baba, Y.; Ezaki, K.; Okamoto, Y.; Shibaba, K.; Kuroki, K.; Nakano, S. Dielectric characteristics of (A1+ 0.5A3+ 0.5)TiO3 ceramics at microwave frequencies. Jpn. J. Appl. Phys. 1991, 30, 2339–2342. [Google Scholar] [CrossRef]

- Mercurio, J.P.; Manier, M.; Frit, B. Dielectric properties of ceramics within the BaOLn2O3-TiO2 system. Ferroelectrics 1992, 127, 35–40. [Google Scholar] [CrossRef]

- Ezaki, K.; Baba, Y.; Takahashi, H.; Shibata, K.; Nakano, S. Microwave dielectric properties of CaO-Li2O-Ln2O3-TiO2 ceramics. Jpn. J. Appl. Phys. 1993, 1, 4319–4322. [Google Scholar] [CrossRef]

- Kato, J.; Kagata, H.; Nishimoto, K. Dielectric properties of lead alkaline-earth zirconate at microwave frequencies. Jpn. J. Appl. Phys. 1991, 30, 2343–2346. [Google Scholar] [CrossRef]

- Yan, Y.; Li, Z.; Zhang, M.; Sun, P.; Xu, Y. Preparation and microwave dielectric properties of Ca0.6La0.8/3(SnxTi1−x)O3 ceramics. Ceram. Int. 2017, 43, 8534–8537. [Google Scholar] [CrossRef]

- Wise, P.L.; Reaney, I.M.; Lee, W.E.; Price, T.J.; Iddles, D.M.; Cannell, D.S. Structure–microwave property relations in (SrxCa(1−x))n+1TinO3n+1. J. Eur. Ceram. Soc. 2001, 21, 1723–1726. [Google Scholar] [CrossRef]

- Takada, T.; Wang, S.F.; Yoshikawa, S.; Jang, S.-J.; Newnham, R.E. Effect of Glass Additions on BaO-TiO2-WO3 Microwave Ceramics. J. Am. Ceram. Soc. 1994, 77, 1909–1916. [Google Scholar] [CrossRef]

- Takada, T.; Wang, S.F.; Yoshikawa, S.; Jang, S.-J.; Newnham, R.E. Effects of glass additions on (Zr, Sn) TiO4 for microwave applications. J. Am. Ceram. Soc. 1994, 77, 2485–2488. [Google Scholar] [CrossRef]

- Hirno, S.; Hayashi, T.; Hattori, A. Chemical Processing and Microwave Characteristics of (Zr,Sn)TiO4 Microwave Dielectrics. J. Am. Ceram. Soc. 1991, 74, 1320–1324. [Google Scholar] [CrossRef]

- Tolmer, V.; Desgardin, G. Low-temperature sintering and influence of the process on the dielectric properties of Ba (Zn1/3Ta2/3) O3. J. Am. Ceram. Soc. 1997, 80, 1981. [Google Scholar] [CrossRef]

- Choy, J.H.; Han, Y.S. Microwave characteristics of BaO–TiO2 ceramics prepared via a citrate route. J. Am. Ceram. Soc. 1995, 78, 1167–1172. [Google Scholar] [CrossRef]

- Weng, M.H.; Liang, T.J.; Huang, C.L. Lowering of sintering temperature and microwave dielectric properties of BaTi4O9 ceramics prepared by the polymeric precursor method. J. Eur. Ceram. Soc. 2002, 22, 1693–1698. [Google Scholar] [CrossRef]

- Yang, C.F. The microwave characteristics of glass-BaTi4O9 ceramics. Jpn. J. Appl. Phys. 1999, 38, 3576–3579. [Google Scholar] [CrossRef]

- Yang, J.; Huang, M.; Wang, F.; Zhu, K.; Yan, K. Low temperature sintering, structure and electrical properties of BiFeO3-BaTiO3 based piezoelectric ceramics using CuO-B2O3 composite sintering aids. Mater. Sci. Eng. B 2023, 298, 116872. [Google Scholar] [CrossRef]

- Kim, D.W.; Lee, D.G.; Hong, K.S. Low-temperature firing and microwave dielectric properties of BaTi4O9 with Zn–B–O glass system. Mater. Res. Bull. 2001, 36, 585–595. [Google Scholar] [CrossRef]

- Lu, S.G.; Kwok, K.W.; Chan, H.L.; Choy, C.L. Structural and electrical properties of BaTi4O9 microwave ceramics incorporated with glass phase. Mater. Sci. Eng. 2003, B99, 491–494. [Google Scholar] [CrossRef]

- Cheng, C.M.; Yang, C.F.; Lo, S.H.; Tseng, T.Y. Sintering BaTi4O9/Ba2Ti9O20-based ceramics by glass addition. J. Eur. Ceram. Soc. 2000, 20, 1061–1067. [Google Scholar] [CrossRef]

- Seabra, M.P.; Salak, A.N.; Avdeev, M.; Ferreira, V.M. Structure and dielectric characterization of the La(Mg1/2Ti1/2)O3-Nd(Mg1/2Ti1/2)O3 system. J. Phys. Condens. Matter 2003, 15, 4229. [Google Scholar] [CrossRef]

- Lin, S.-H.; Lin, Z.-Q.; Chen, C.-W. Microwave dielectric characterization of Ca0.6(La1−xYx)0.2667TiO3 perovskite ceramics with high positive temperature coefficient. Ceram. Int. 2021, 47, 16828–16832. [Google Scholar] [CrossRef]

- Jhou, M.Z.; Jean, J.H. Low-fire processing of microwave BaTi4O9 with BaO–ZnO–B2O3 glass. J. Am. Ceram. Soc. 2006, 89, 786–791. [Google Scholar] [CrossRef]

- Lim, J.B.; Kim, M.H.; Kim, J.C.; Nahm, S.; Paik, J.H.; Kim, J.H. Effect of BaCuB2O5 additive on the sintering temperature and microwave dielectric properties of BaTi4O9 ceramics. Jpn. J. Appl. Phys. 2006, 45, 242–244. [Google Scholar] [CrossRef]

- Choi, Y.J.; Park, J.H.; Ko, W.J.; Park, J.H.; Nahm, S.; Park, J.G. Low temperature sintering of BaTi4O9-based middle-k dielectric composition for LTCC applications. J. Electroceramics 2005, 14, 157–162. [Google Scholar] [CrossRef]

- Hakki, B.W.; Coleman, P.D. A dielectric resonator method of measuring inductive capacities in the millimeter range. IEEE Trans. Microw. Theory Tech. 1960, 8, 402–410. [Google Scholar] [CrossRef]

| Spot | Element Atomic (%) | ||||||

|---|---|---|---|---|---|---|---|

| Ca | La | Y | Ti | O | Nd | Mg | |

| A | 10.2 | 5.5 | 0.45 | 18.5 | 60 | 1.5 | 3.85 |

| B | 9.8 | 4.9 | 0.61 | 17.1 | 61.74 | 1.91 | 3.94 |

| C | 9.9 | 5.2 | 0.49 | 16.2 | 62.93 | 1.45 | 3.83 |

| D | 10.1 | 6 | 0.48 | 15.3 | 62.63 | 1.39 | 4.1 |

| Substrate | tanδ | εr | Size (mm2) | Insertion Loss (dB) | Return Loss (dB) | fo (GHz) |

|---|---|---|---|---|---|---|

| FR4 | 0.015 | 4.5 | 24 × 64 | 2.5 | 23.9 | 2.4 |

| Al2O3 | 0.003 | 9.8 | 15 × 42 | 1.5 | 21 | 2.4 |

| 0.15CLYT-0.85LNMT | 0.0001 | 35 | 7.51 × 9.5 | 0.7 | 21.1 | 2.4 |

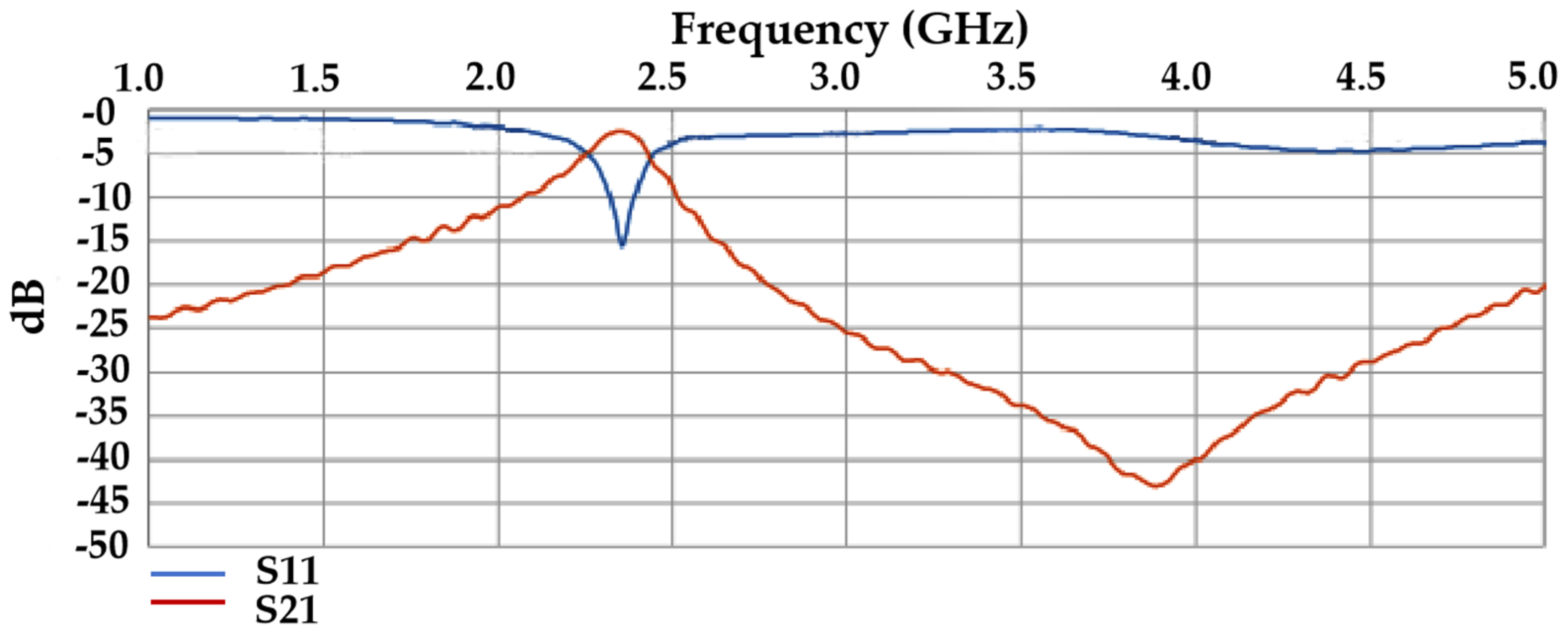

| f0 (GHz) | S11 (dB) | S21 (dB) | Bandwidth (%) | Size (mm2) | ||

|---|---|---|---|---|---|---|

| 0.15CLYT-0.85LNMT | simulation | 2.4 | −19.44 | −0.37 | 10.1% | 7.51 × 9.5 |

| measured | 2.4 | −15.24 | −1.69 | 10.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.-B.; Xiong, S.; Peng, J. Enhancement of Microwave Dielectric Properties in Mixed-Phase Ceramics Through CuB2O4 Doping: Achieving Ultra-Low Loss and High Dielectric Constant. Ceramics 2024, 7, 1895-1904. https://doi.org/10.3390/ceramics7040119

Chen Y-B, Xiong S, Peng J. Enhancement of Microwave Dielectric Properties in Mixed-Phase Ceramics Through CuB2O4 Doping: Achieving Ultra-Low Loss and High Dielectric Constant. Ceramics. 2024; 7(4):1895-1904. https://doi.org/10.3390/ceramics7040119

Chicago/Turabian StyleChen, Yuan-Bin, Siyi Xiong, and Jie Peng. 2024. "Enhancement of Microwave Dielectric Properties in Mixed-Phase Ceramics Through CuB2O4 Doping: Achieving Ultra-Low Loss and High Dielectric Constant" Ceramics 7, no. 4: 1895-1904. https://doi.org/10.3390/ceramics7040119

APA StyleChen, Y.-B., Xiong, S., & Peng, J. (2024). Enhancement of Microwave Dielectric Properties in Mixed-Phase Ceramics Through CuB2O4 Doping: Achieving Ultra-Low Loss and High Dielectric Constant. Ceramics, 7(4), 1895-1904. https://doi.org/10.3390/ceramics7040119