Pretreatment of Hybrid Ceramics Using Ho: YAG, Low-Level Laser Therapy Activated Malachite Green, and Non-Thermal Plasma on Surface Roughness, Bond Strength, and Color Change, SEM and EDX Analysis

Abstract

1. Introduction

2. Materials and Methods

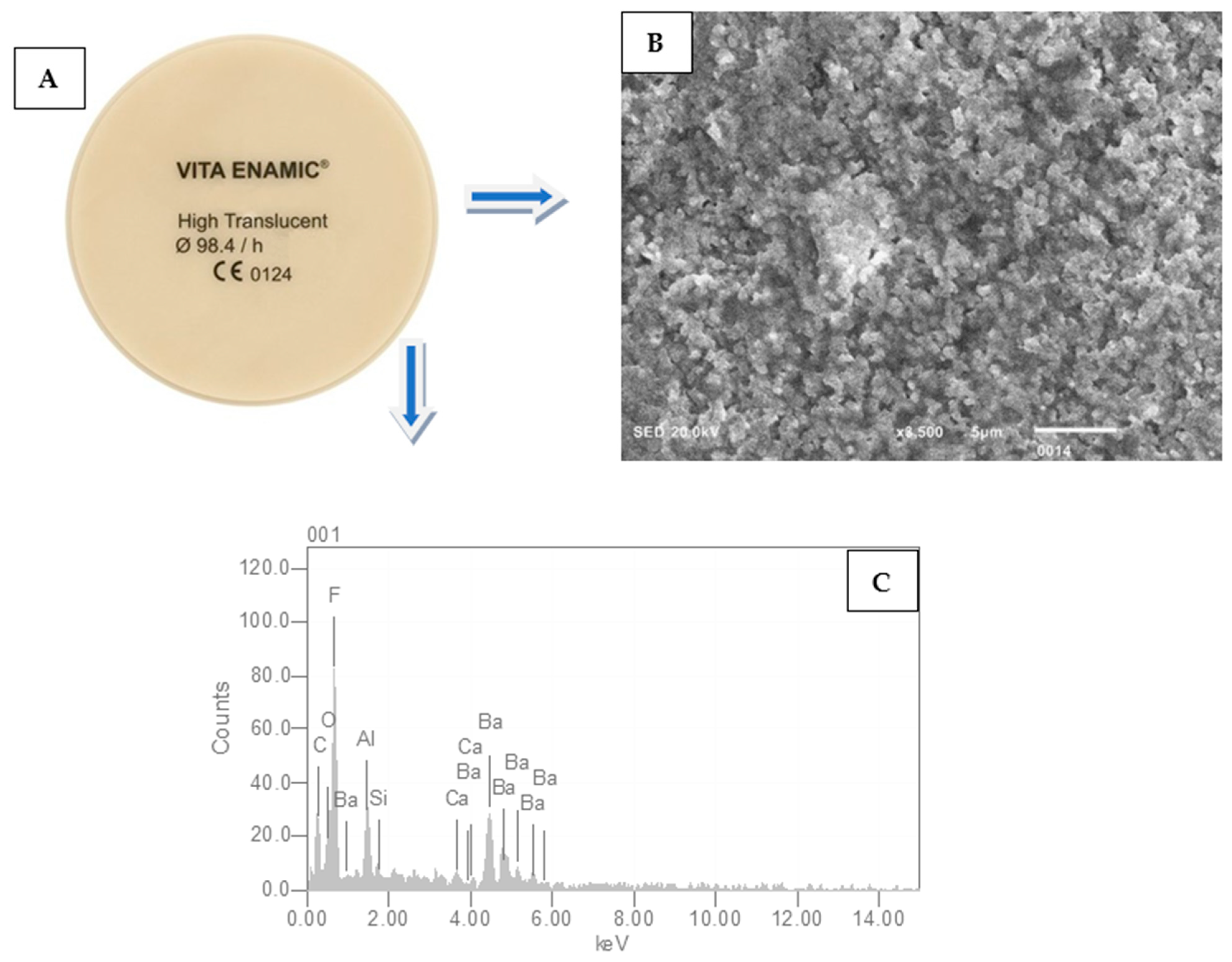

2.1. CAD-CAM Disc Preparation

2.2. Measurement of Ra

2.3. Assessment of Color Stability

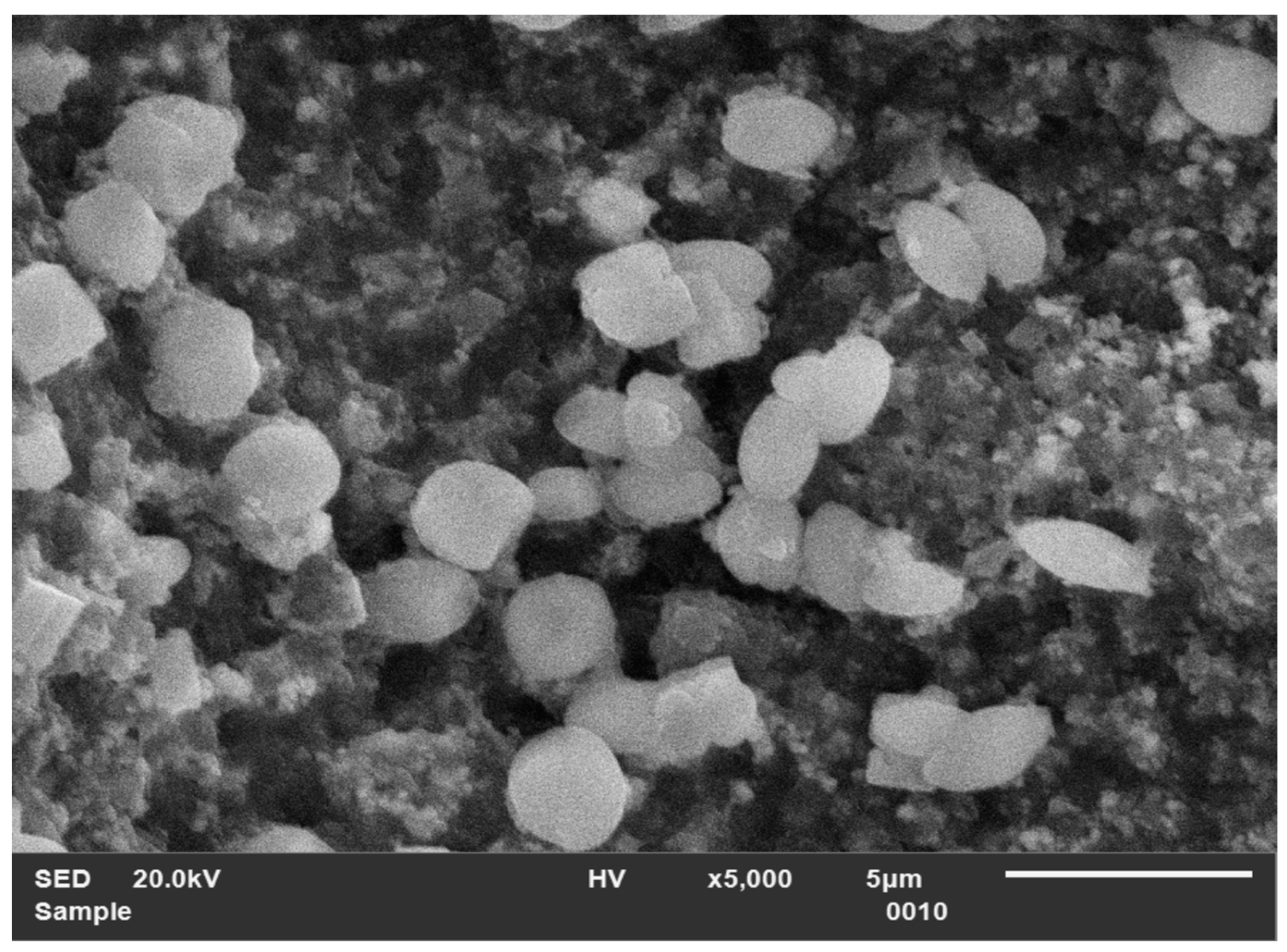

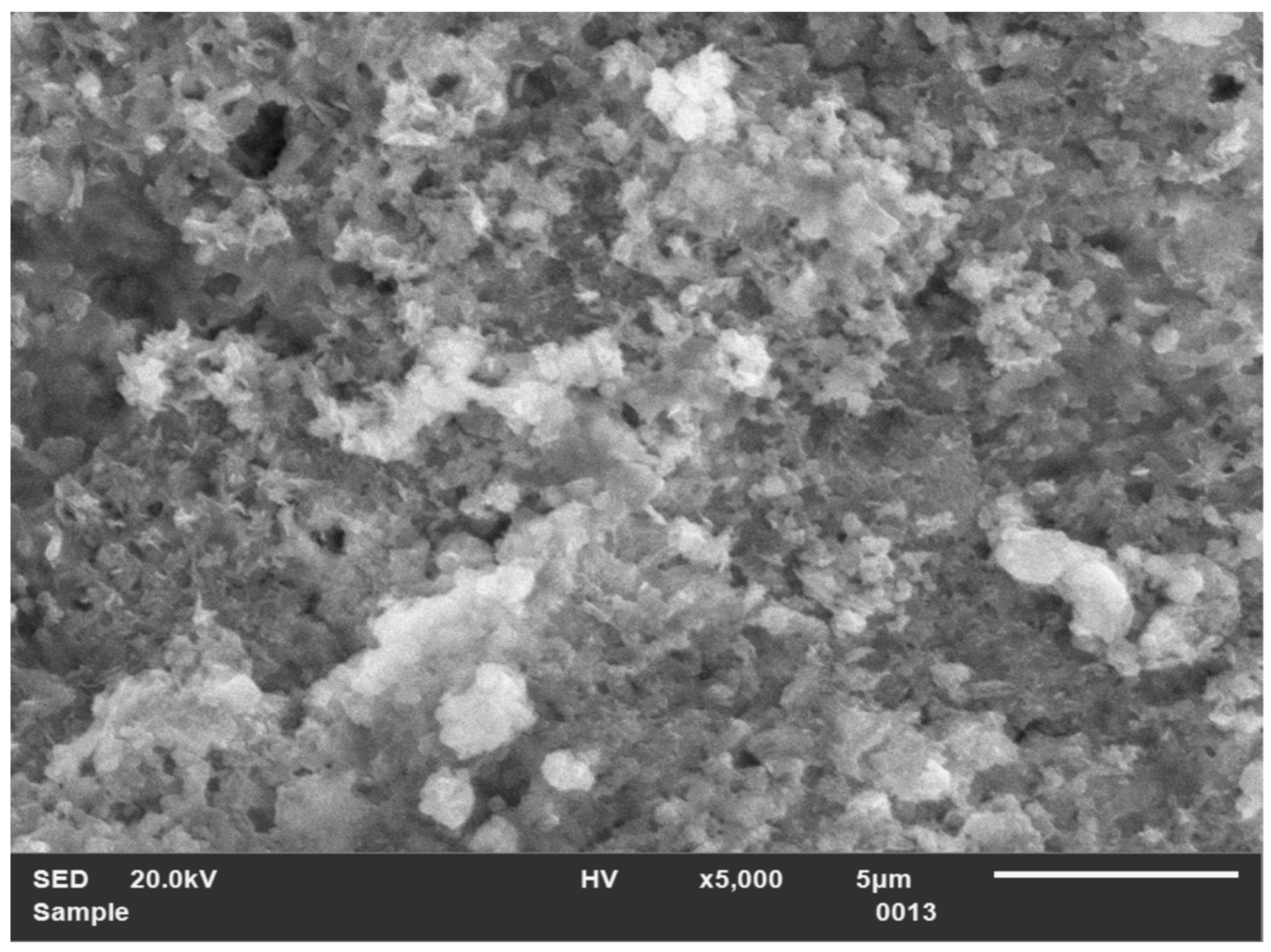

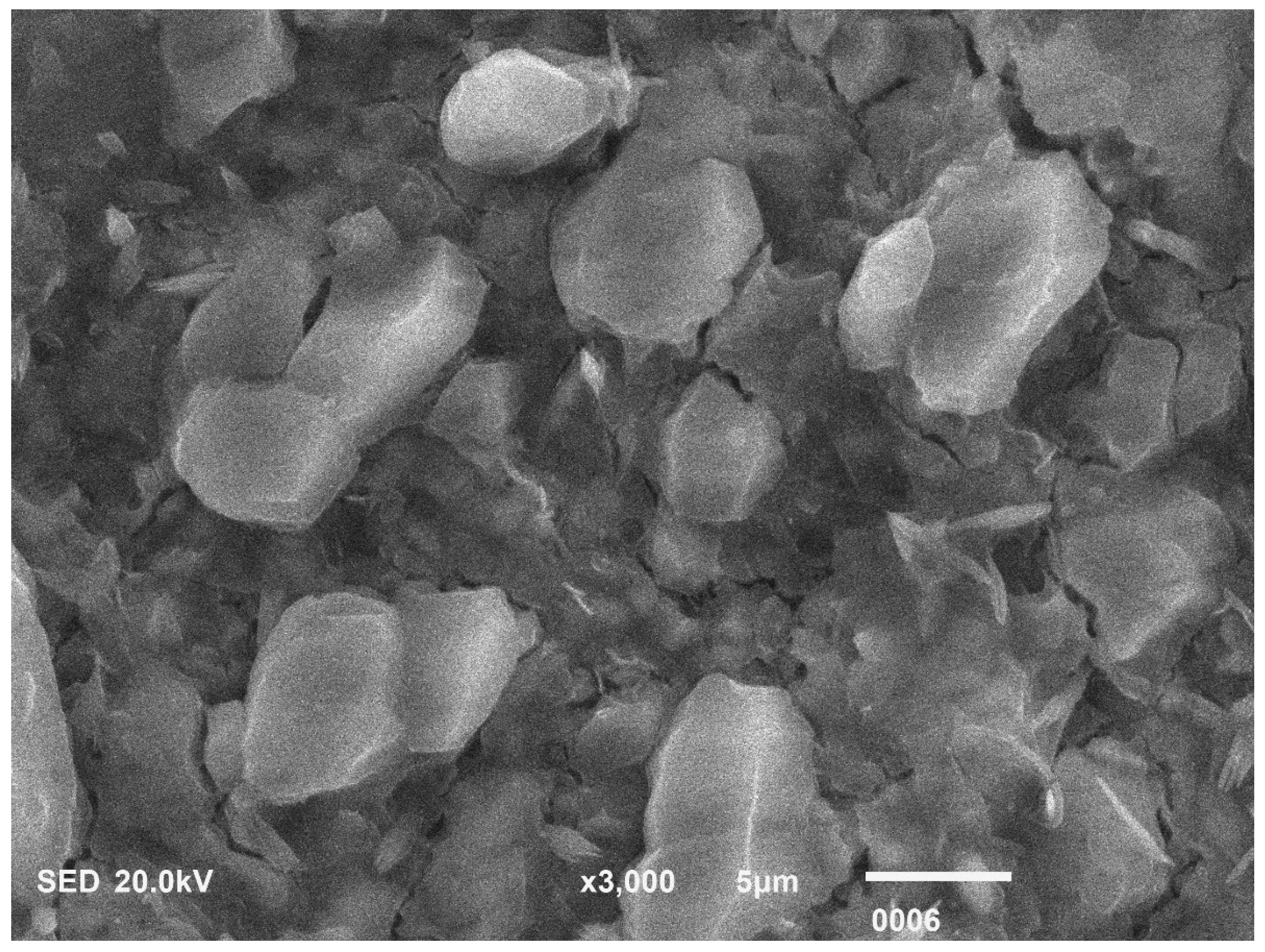

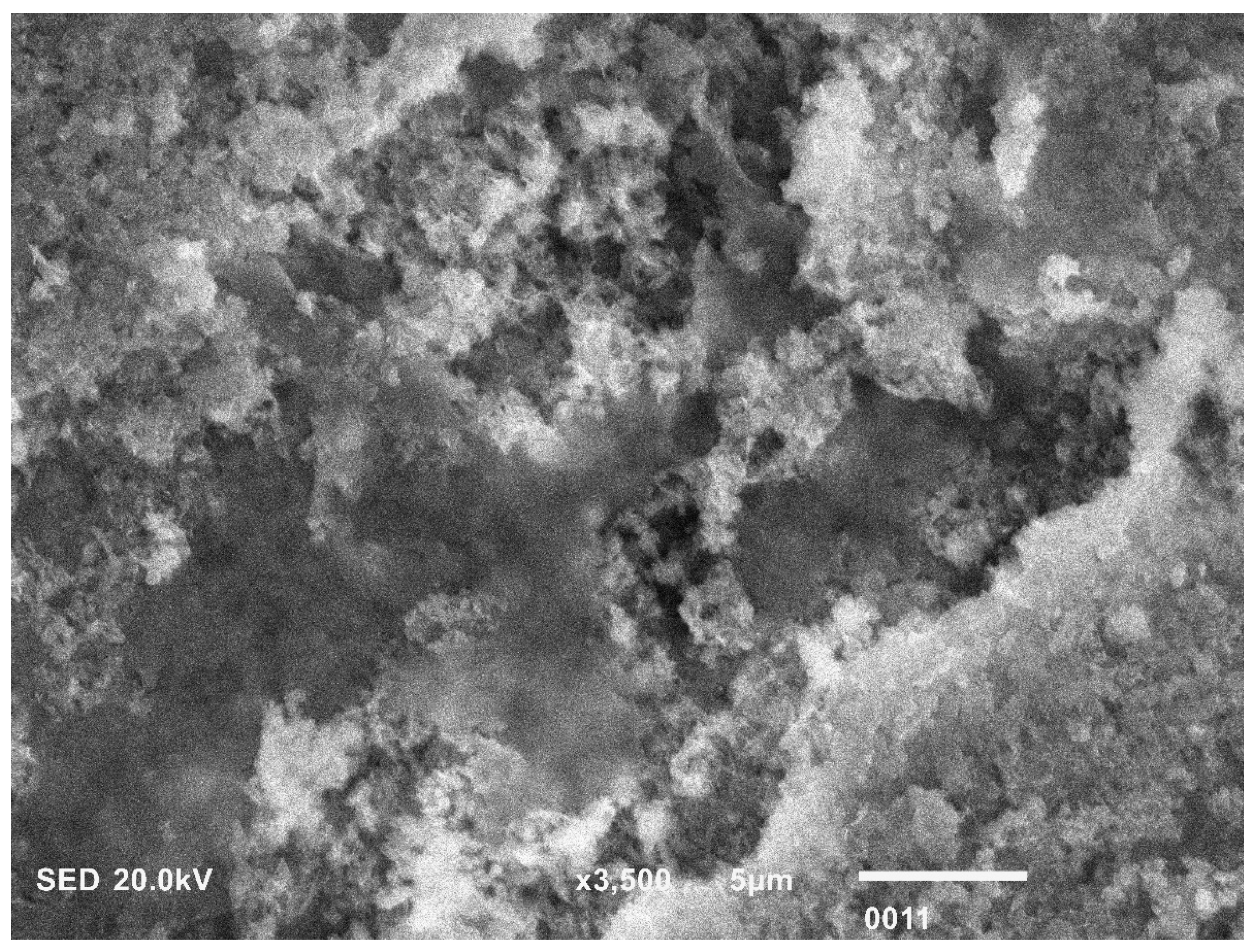

2.4. Scanning Electron Microscope (SEM)

2.5. Artificial Aging

2.6. Shear Adhesion Test between HBC Discs to Resin Cement

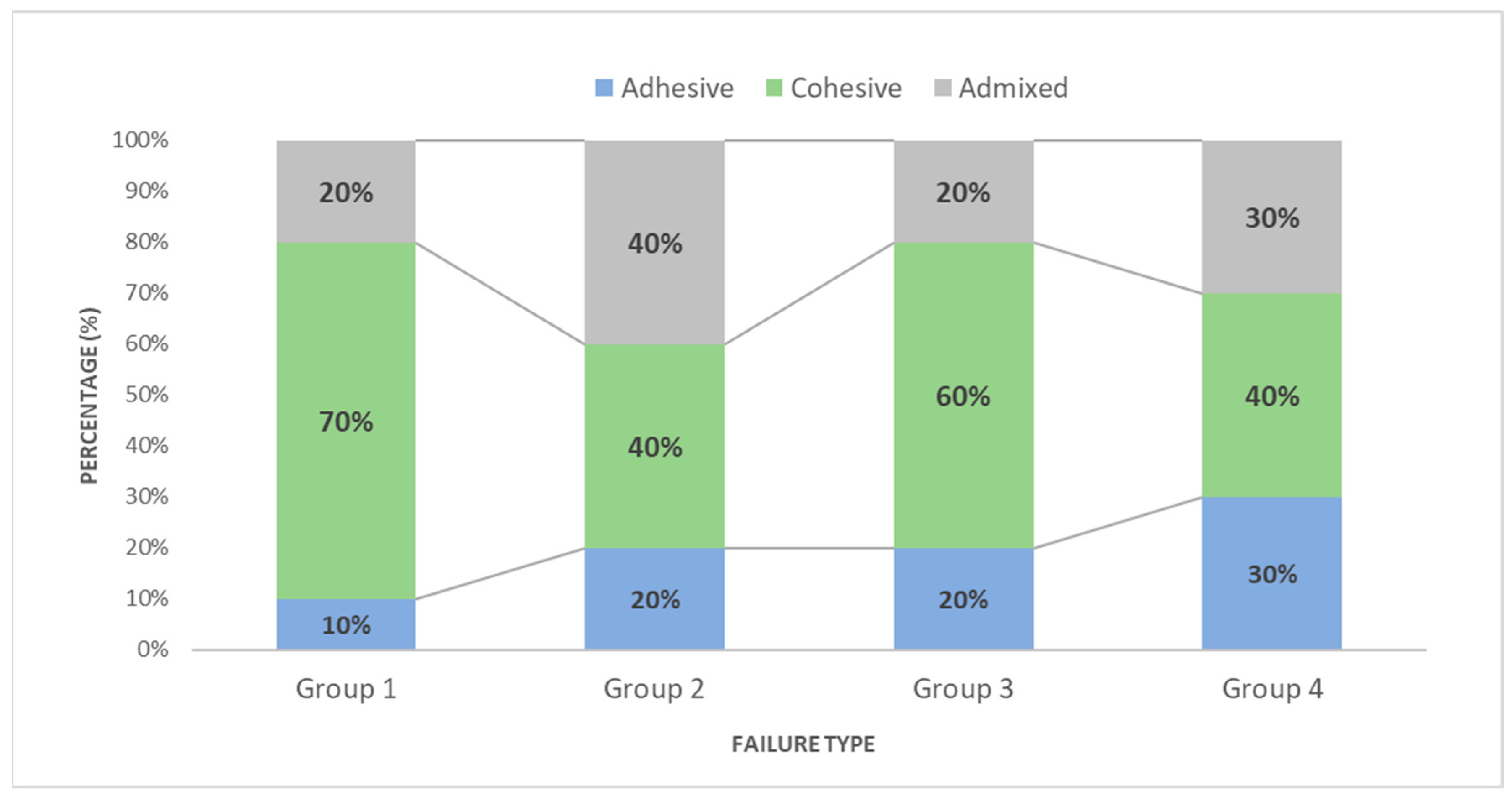

2.7. Evaluation of the Nature of Bond Failure under a Stereomicroscope

2.8. Statistical Analysis

3. Results

3.1. Ra Evaluation

3.2. SBS Analysis

3.3. Nature of Bond Failure

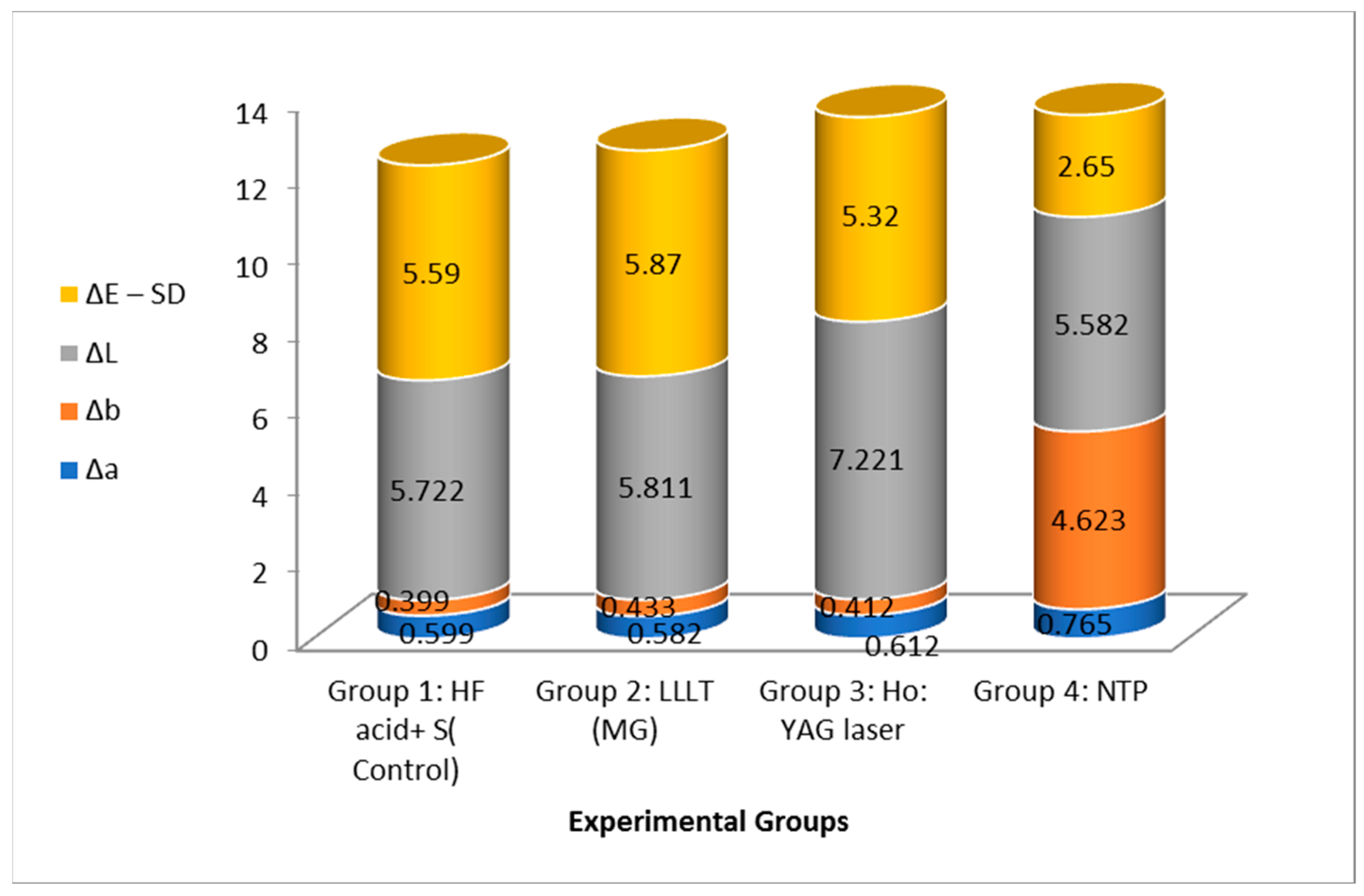

3.4. Evaluation of ΔE

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Coldea, A.; Swain, M.V.; Thiel, N. Mechanical Properties of Polymer-Infiltrated-Ceramic-Network Materials. Dent. Mater. 2013, 29, 419–426. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.N.; Rüttermann, S. Influence of Mechanical and Chemical Pre-Treatments on the Repair of a Hybrid Ceramic. Dent. Mater. 2022, 38, 1140–1148. [Google Scholar] [CrossRef]

- Bayraktar, Y.; Arslan, M.; Demirtag, Z. Repair Bond Strength and Surface Topography of Resin-Ceramic and Ceramic Restorative Blocks Treated by Laser and Conventional Surface Treatments. Microsc. Res. Tech. 2021, 84, 1145–1154. [Google Scholar] [CrossRef] [PubMed]

- Maawadh, A.M.; Almohareb, T.; Al-Hamdan, R.S.; Al Deeb, M.; Naseem, M.; Alhenaki, A.M.; Vohra, F.; Abduljabbar, T. Repair Strength and Surface Topography of Lithium Disilicate and Hybrid Resin Ceramics with LLLT and Photodynamic Therapy in Comparison to Hydrofluoric Acid. J. Appl. Biomater. Funct. Mater. 2020, 18, 2280800020966938. [Google Scholar] [CrossRef] [PubMed]

- Kilinc, E.; Antonson, S.A.; Hardigan, P.C.; Kesercioglu, A. Resin Cement Color Stability and Its Influence on the Final Shade of All-Ceramics. J. Dent. 2011, 39, e30–e36. [Google Scholar] [CrossRef] [PubMed]

- Vohra, F.; Labban, N.; Al-Hussaini, A.; Al-Jarboua, M.; Zawawi, R.; Alrahlah, A.; Naseem, M. Influence of Er;Cr:YSGG Laser on Shear Bond Strength and Color Stability of Lithium Disilicate Ceramics: An in Vitro Study. Photobiomodulation Photomed. Laser Surg. 2019, 37, 483–488. [Google Scholar] [CrossRef]

- Turgut, S.; Bagis, B.; Ayaz, E.A.; Korkmaz, F.M.; Ulusoy, K.U.; Bagis, Y.H. Erratum to How Will Surface Treatments Affect the Translucency of Porcelain Laminate Veneers? J. Adv. Prosthodont. 2014, 6, 150. [Google Scholar] [CrossRef]

- Panah, F.G.; Rezai, S.M.M.; Ahmadian, L. The Influence of Ceramic Surface Treatments on the Micro-Shear Bond Strength of Composite Resin to IPS Empress 2. J. Prosthodont. 2008, 17, 409–414. [Google Scholar] [CrossRef]

- Alsunbul, H.; Almutairi, B.; Aljanakh, M.; Abduljabbar, T. Hybrid Ceramic Repair Strength, Surface Roughness, and Bond Failure, Using Methylene Blue-Activated Low-Level Laser Therapy, Carbon Dioxide, and Ti: Al2O3 Laser. Photodiagnosis Photodyn. Ther. 2023, 43, 103693. [Google Scholar] [CrossRef]

- Campos, F.; Almeida, C.S.; Rippe, M.P.; De Melo, R.M.; Valandro, L.F.; Bottino, M.A. Resin Bonding to a Hybrid Ceramic: Effects of Surface Treatments and Aging. Oper. Dent. 2016, 41, 171–178. [Google Scholar] [CrossRef]

- Al Deeb, L.; Bin-Shuwaish, M.S.; Abrar, E.; Naseem, M.; Al-Hamdan, R.S.; Maawadh, A.M.; Al Deeb, M.; Almohareb, T.; Al Ahdal, K.; Vohra, F.; et al. Efficacy of Chlorhexidine, Er Cr YSGG Laser and Photodynamic Therapy on the Adhesive Bond Integrity of Caries Affected Dentin. An in-Vitro Study. Photodiagnosis Photodyn. Ther. 2020, 31, 101875. [Google Scholar] [CrossRef] [PubMed]

- Akram, Z. How Effective Is Adjunctive Antimicrobial Photodynamic Therapy in Treating Deep Periodontal Pockets in Periodontal Disease? A Systematic Review. J. Investig. Clin. Dent. 2018, 9, e12345. [Google Scholar] [CrossRef] [PubMed]

- Al Ahdal, K.; Maawadh, A.M.; Al Deeb, L.; Alshamrani, A.S.; Almohareb, T.; Alrahlah, A. Effect of Malachite Green, Ocimum Sanctum, and Er, Cr: YSGG Laser on Antimicrobial Activity against S.Mutans and CAD Disinfection Bonded to Resin Restoration. Photodiagnosis Photodyn. Ther. 2023, 42, 103571. [Google Scholar] [CrossRef] [PubMed]

- Alqahtani, W.M.S.; Qamar, Z.; Yousief, S.A.; Abdul, N.S.; Reddy, R.N.; Alghufaili, S.; Khuthija Khanam, H.M.; Barakat, A.; Niazi, F.H. Use of Final Irrigants MTAD, Salvedora Perscia, Malachite Green, and Ti-Sapphire Laser on Push-out Bond Strength of Zirconia Post. Photodiagnosis Photodyn. Ther. 2023, 43, 103605. [Google Scholar] [CrossRef] [PubMed]

- Alrahlah, A.; Naseem, M.; Tanveer, S.A.; Abrar, E.; Charania, A.; AlRifaiy, M.Q.; Vohra, F. Influence of Disinfection of Caries Effected Dentin with Different Concentration of Silver Diamine Fluoride, Curcumin and Er, Cr:YSGG on Adhesive Bond Strength to Resin Composite. Photodiagnosis Photodyn. Ther. 2020, 32, 102065. [Google Scholar] [CrossRef] [PubMed]

- Bartlett, J.A.; Indig, G.L. Spectroscopic and Photochemical Properties of Malachite Green Noncovalently Bound to Bovine Serum Albumin. Dye. Pigment. 1999, 43, 219–226. [Google Scholar] [CrossRef]

- Gorler, O.; Dogan, D.O.; Ulgey, M.; Goze, A.; Hubbezoğlu, I.; Zan, R.; Ozdemir, A.K. The Effects of Er:YAG, Nd:YAG, and Ho:YAG Laser Surface Treatments to Acrylic Resin Denture Bases on the Tensile Bond Strength of Silicone-Based Resilient Liners. Photomed. Laser Surg. 2015, 33, 409–414. [Google Scholar] [CrossRef] [PubMed]

- Gorler, O.; Ozdemir Dogan, D.; Ulgey, M.; Goze, A.; Zan, R.; Hubbezoğlu, I.; Kemal Ozdemir, A. Dual Effect of Ho: YAG Laser on Tensile Bond Strength of Acrylate and Soft Liner Materials. Int. J. Acad. Res. 2016, 8, 10–15. [Google Scholar] [CrossRef]

- Vechiato Filho, A.J.; Dos Santos, D.M.; Goiato, M.C.; De Medeiros, R.A.; Moreno, A.; Bonatto, L.D.R.; Rangel, E.C. Surface Characterization of Lithium Disilicate Ceramic after Nonthermal Plasma Treatment. J. Prosthet. Dent. 2014, 112, 1156–1163. [Google Scholar] [CrossRef] [PubMed]

- Attia, M.A.; Shokry, T.E.; Abdel-Aziz, M. Effect of Different Surface Treatments on the Bond Strength of Milled Polyetheretherketone Posts. J. Prosthet. Dent. 2022, 127, 866–874. [Google Scholar] [CrossRef]

- AlShahrani, I.; Kamran, M.A.; Almoammar, S.; Alhaizaey, A. Photosensitization of Lithium Di-Silicate Ceramic by Er, Cr: YSGG and Fractional Carbon Dioxide Laser Bonded to Orthodontic Bracket. Photodiagnosis Photodyn. Ther. 2019, 28, 273–276. [Google Scholar] [CrossRef] [PubMed]

- Lanza, M.D.S.; Rodrigues Lanza, F.J.S.; Manso, A.P.; Matinlinna, J.P.; Carvalho, R.M. Innovative Surface Treatments for Improved Ceramic Bonding: Lithium Disilicate Glass Ceramic. Int. J. Adhes. Adhes. 2018, 82, 60–66. [Google Scholar] [CrossRef]

- Dilber, E.; Yavuz, T.; Kara, H.B.; Ozturk, A.N. Comparison of the Effects of Surface Treatments on Roughness of Two Ceramic Systems. Photomed. Laser Surg. 2012, 30, 308–314. [Google Scholar] [CrossRef] [PubMed]

- Pham, C.M.; Chen, C.Y.; Kim, D.M. The Effects of Using Erbium, Chromium-Doped:Yttrium-Scandium-Gallium-Garnet Laser on the Surface Modification, Bacterial Decontamination, and Cell Adhesion on Zirconia Discs: An in Vitro Study. Lasers Med. Sci. 2021, 36, 1701–1708. [Google Scholar] [CrossRef] [PubMed]

- Alkhudhairy, F.; Naseem, M.; Ahmad, Z.H.; Alnooh, A.N.; Vohra, F. Efficacy of Phototherapy with Different Conventional Surface Treatments on Adhesive Quality of Lithium Disilicate Ceramics. Photodiagnosis Photodyn. Ther. 2019, 25, 292–295. [Google Scholar] [CrossRef]

- Alkhudhairy, F.; Vohra, F.; Naseem, M.; Owais, M.M.; Amer, A.H.B.; Almutairi, K.B. Color Stability and Degree of Conversion of a Novel Dibenzoyl Germanium Derivative Containing Photo-Polymerized Resin Luting Cement. J. Appl. Biomater. Funct. Mater. 2020, 18, 2280800020917326. [Google Scholar] [CrossRef] [PubMed]

- Alkhudhairy, F.; AlRefeai, M.H. Self-Etch Adhesive-Loaded ZrO2/Ag3PO4 Nanoparticles on Caries-Affected Dentin: A Tensile Bond Strength, Scanning Electron Microscopy, Energy Dispersive X-Ray Spectroscopy, Survival Rate Assessment of S. Mutans, and Degree of Conversion Analysis. Appl. Sci. 2024, 14, 563. [Google Scholar] [CrossRef]

- Aljamhan, A.S.; Alrefeai, M.H.; Alhabdan, A.; Alhusseini, S.A.; Farooq, I.; Vohra, F.; Naseem, M.; Alkhudhairy, F. Influence of ER-CR-YSGG Laser and Photodynamic Therapy on the Dentin Bond Integrity of Nano-Hydroxyapatite Containing Resin Dentin Adhesive: SEM-EDX. Polymers 2021, 13, 1903. [Google Scholar] [CrossRef] [PubMed]

- Almuammar, M.F.; Schulman, A.; Salama, F.S. Shear Bond Strength of Six Restorative Materials. J. Clin. Pediatr. Dent. 2001, 25, 221–225. [Google Scholar] [CrossRef]

- De Melo, R.M.; Travassos, A.C.; Neisser, M.P. Shear Bond Strengths of a Ceramic System to Alternative Metal Alloys. J. Prosthet. Dent. 2005, 93, 64–69. [Google Scholar] [CrossRef]

- Albakri, A.S. Pretreatment of Hybrid Ceramics Using Alumina (Al2O3) Nanoparticles, Hydrofluoric Acid, and Holmium: YAG Laser for Optimizing Surface Roughness, Shear Bond Strength, and Topography. J. Biomater. Tissue Eng. 2024, 13, 1133–1138. [Google Scholar] [CrossRef]

- Yildirim, A.Z.; Unver, S.; Mese, A.; Bayram, C.; Denkbas, E.B.; Cevik, P. Effect of Argon Plasma and Er:YAG Laser on Tensile Bond Strength between Denture Liner and Acrylic Resin. J. Prosthet. Dent. 2020, 124, 799.e1–799.e5. [Google Scholar] [CrossRef] [PubMed]

- Bahar, A. The Use of Holmium-Yttrium Aluminum Garnet Laser as Pit and Fissure Cleaner. Dent. J. (Majalah Kedokt. Gigi) 2009, 42, 147. [Google Scholar] [CrossRef][Green Version]

- Alkhudhairy, F.; Aljamhan, A.S. Surface conditioning of PEEK post using Nd: YVO4 laser, photodynamic therapy, and sulfuric acid on the pushout bond strength to canal dentin. Photodiagnosis Photo Dyn. Ther. 2023, 42, 103601. [Google Scholar] [CrossRef] [PubMed]

- Çelik, E.; Sahin, S.C.; Dede, D.Ö. Shear Bond Strength of Nanohybrid Composite to the Resin Matrix Ceramics after Different Surface Treatments. Photomed. Laser Surg. 2018, 36, 424–430. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulos, K.; Pahinis, K.; Saltidou, K.; Dionysopoulos, D.; Tsitrou, E. Evaluation of the Surface Characteristics of Dental CAD/CAM Materials after Different Surface Treatments. Materials 2020, 13, 981. [Google Scholar] [CrossRef] [PubMed]

- Salem, A.; Mohsen, C. Atomic Force Microscope Surface Roughness Analysis of Surface Treated Ceramics. Open Access Maced. J. Med. Sci. 2020, 8, 134–138. [Google Scholar] [CrossRef]

- Henningsen, A.; Smeets, R.; Heuberger, R.; Jung, O.T.; Hanken, H.; Heiland, M.; Cacaci, C.; Precht, C. Changes in Surface Characteristics of Titanium and Zirconia after Surface Treatment with Ultraviolet Light or Non-Thermal Plasma. Eur. J. Oral Sci. 2018, 126, 126–134. [Google Scholar] [CrossRef]

- Liebermann, A.; Keul, C.; Bähr, N.; Edelhoff, D.; Eichberger, M.; Roos, M.; Stawarczyk, B. Impact of plasma treatment of PMMA-based CAD/CAM blanks on surface properties as well as on adhesion to self-adhesive resin composite cements. Dent. Mater. 2013, 29, 935–944. [Google Scholar] [CrossRef]

- Adımcı, P.; İbiş, F.; Ercan, U.K.; Bagis, B. Evaluation of effects of non-thermal plasma treatment on surface properties of CAD/CAM materials. J. Adhes. Sci. Technol. 2019, 33, 35–49. [Google Scholar] [CrossRef]

- Huang, P.Y.; Masri, R.; Romberg, E.; Driscoll, C.F. The Effect of Various Disinfectants on Dental Shade Guides. J. Prosthet. Dent. 2014, 112, 613–617. [Google Scholar] [CrossRef]

- Hejazy, M.; Shebl, A.; Desoky, M.; El Gabrouny, M. Effect of Laser Debonding on Color Change of Three Different Ceramic Materials. Dent. Sci. Updates 2023, 4, 301–312. [Google Scholar] [CrossRef]

- Sasany, R.; Saraç, D.; Özcan, M. Effect of Different Liner Techniques and Argon Plasma Treatment of Zirconia Base on the Adhesion and Color Change of Veneering Ceramic. J. Adhes. Sci. Technol. 2021, 35, 1981–1994. [Google Scholar] [CrossRef]

- Abdelhamid Hafez, P.; Elgabarouny, M.; Abdelgawad, L.; Shebl, A. Effect of Surface Treatments on the Color Change and Shear Bond Strength of Porcelain Laminate Veneer. Dent. Sci. Updates 2020, 1, 15–22. [Google Scholar] [CrossRef][Green Version]

- Gré, C.P.; de Ré Silveira, R.C.; Shibata, S.; Lago, C.T.R.; Vieira, L.C.C. Effect of Silanization on Microtensile Bond Strength of Different Resin Cements to a Lithium Disilicate Glass Ceramic. J. Contemp. Dent. Pract. 2016, 17, 149–153. [Google Scholar] [CrossRef] [PubMed]

- Maruo, Y.; Nishigawa, G.; Irie, M.; Yoshihara, K.; Matsumoto, T.; Minagi, S. Does Acid Etching Morphologically and Chemically Affect Lithium Disilicate Glass Ceramic Surfaces? J. Appl. Biomater. Funct. Mater. 2017, 15, 93–100. [Google Scholar] [CrossRef]

- Matani, J.D.; Kheur, M.; Jambhekar, S.S.; Bhargava, P.; Londhe, A. Evaluation of Experimental Coating to Improve the Zirconia-Veneering Ceramic Bond Strength. J. Prosthodont. 2014, 23, 626–633. [Google Scholar] [CrossRef]

| Investigated Groups | Mean ± SD (µm) | p-Value! |

|---|---|---|

| Group 1: HFA+S (Control) | 1115.44 ± 0.023 a | <0.05 |

| Group 2: LLLT (MG) | 890.17 ± 0.015 b | |

| Group 3: Ho: YAG laser | 1282.88 ± 0.031 a | |

| Group 4: NTP | 880.32 ± 0.012 b |

| Investigated Groups | Mean ± SD (MPa) | p-Value! |

|---|---|---|

| Group 1: HF acid+ S (Control) | 10.87 ± 5.5 a | <0.05 |

| Group 2: LLLT (MG) | 8.41 ± 3.2 b | |

| Group 3: Ho: YAG laser | 11.22 ± 6.2 a | |

| Group 4: NTP | 8.22 ± 2.9 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkhudhairy, F.; AlFawaz, Y.F. Pretreatment of Hybrid Ceramics Using Ho: YAG, Low-Level Laser Therapy Activated Malachite Green, and Non-Thermal Plasma on Surface Roughness, Bond Strength, and Color Change, SEM and EDX Analysis. Ceramics 2024, 7, 944-957. https://doi.org/10.3390/ceramics7030061

Alkhudhairy F, AlFawaz YF. Pretreatment of Hybrid Ceramics Using Ho: YAG, Low-Level Laser Therapy Activated Malachite Green, and Non-Thermal Plasma on Surface Roughness, Bond Strength, and Color Change, SEM and EDX Analysis. Ceramics. 2024; 7(3):944-957. https://doi.org/10.3390/ceramics7030061

Chicago/Turabian StyleAlkhudhairy, Fahad, and Yasser F. AlFawaz. 2024. "Pretreatment of Hybrid Ceramics Using Ho: YAG, Low-Level Laser Therapy Activated Malachite Green, and Non-Thermal Plasma on Surface Roughness, Bond Strength, and Color Change, SEM and EDX Analysis" Ceramics 7, no. 3: 944-957. https://doi.org/10.3390/ceramics7030061

APA StyleAlkhudhairy, F., & AlFawaz, Y. F. (2024). Pretreatment of Hybrid Ceramics Using Ho: YAG, Low-Level Laser Therapy Activated Malachite Green, and Non-Thermal Plasma on Surface Roughness, Bond Strength, and Color Change, SEM and EDX Analysis. Ceramics, 7(3), 944-957. https://doi.org/10.3390/ceramics7030061