Effect of Processing Routes on Physical and Mechanical Properties of Advanced Cermet System

Abstract

1. Introduction

2. Materials and Methods

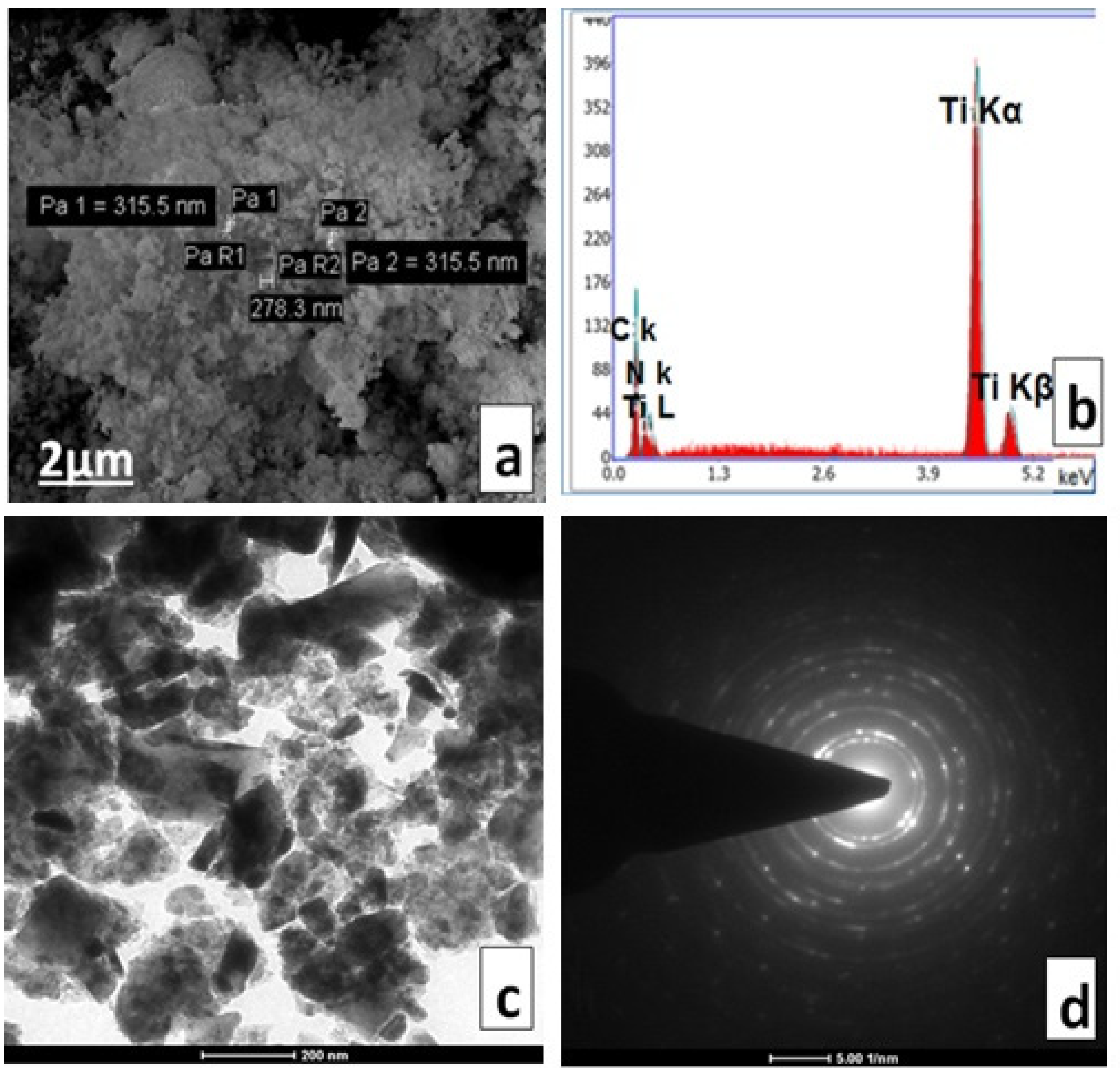

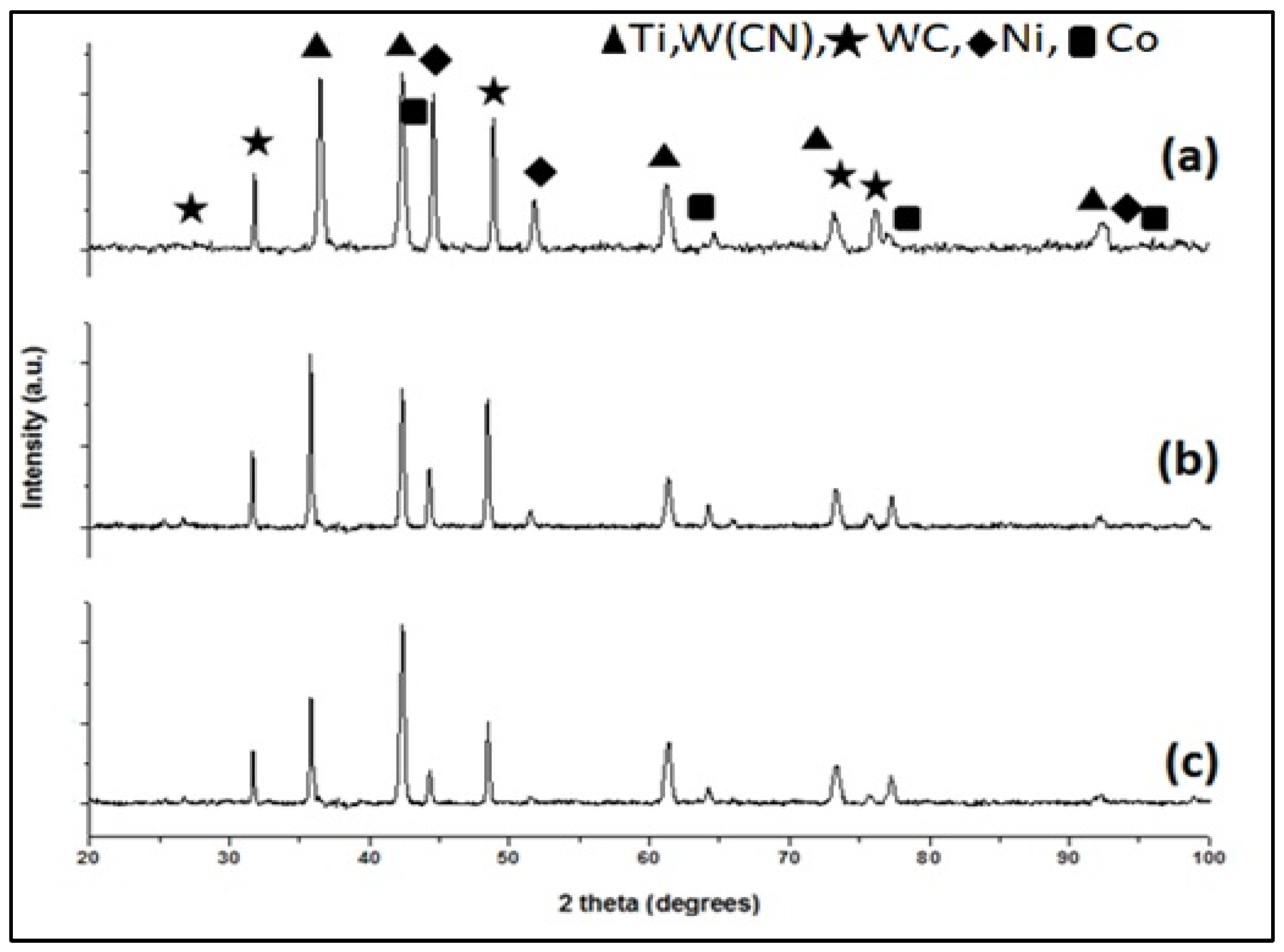

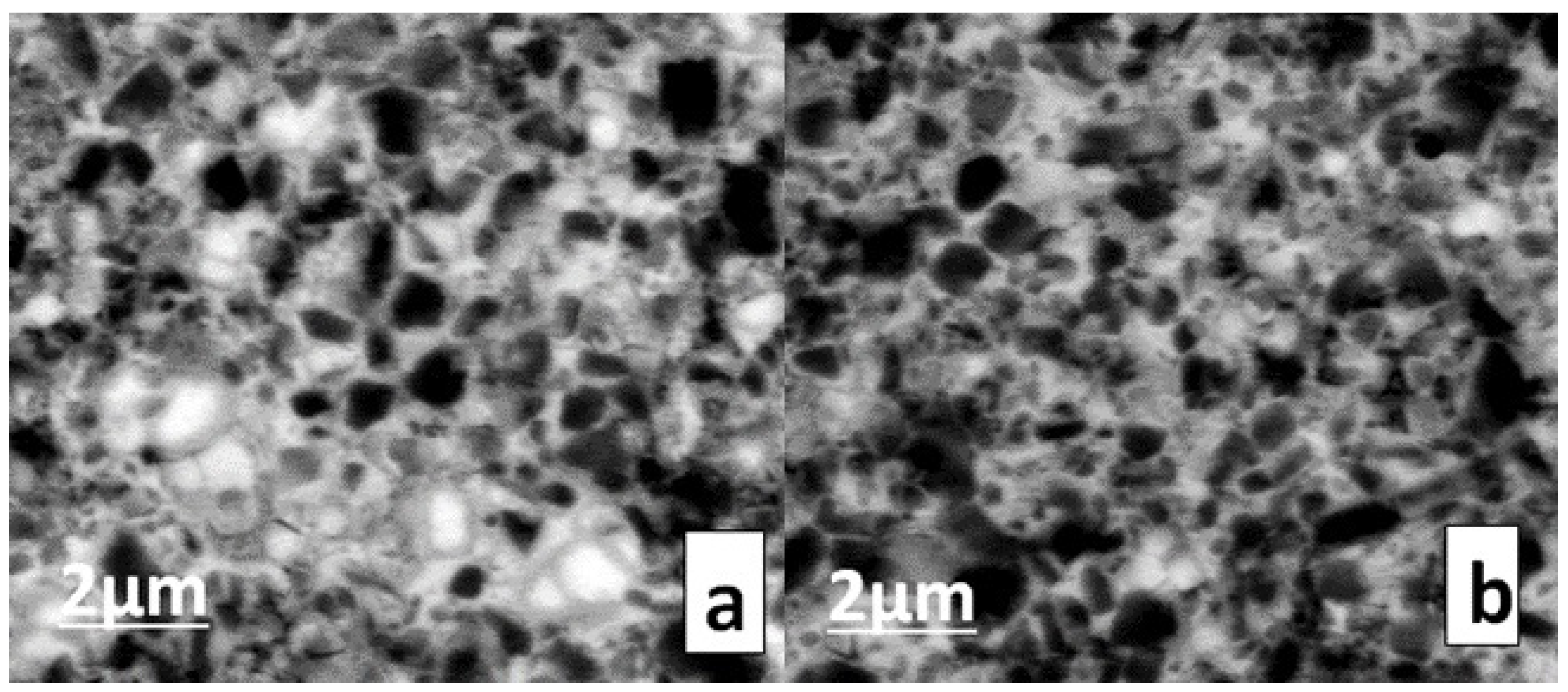

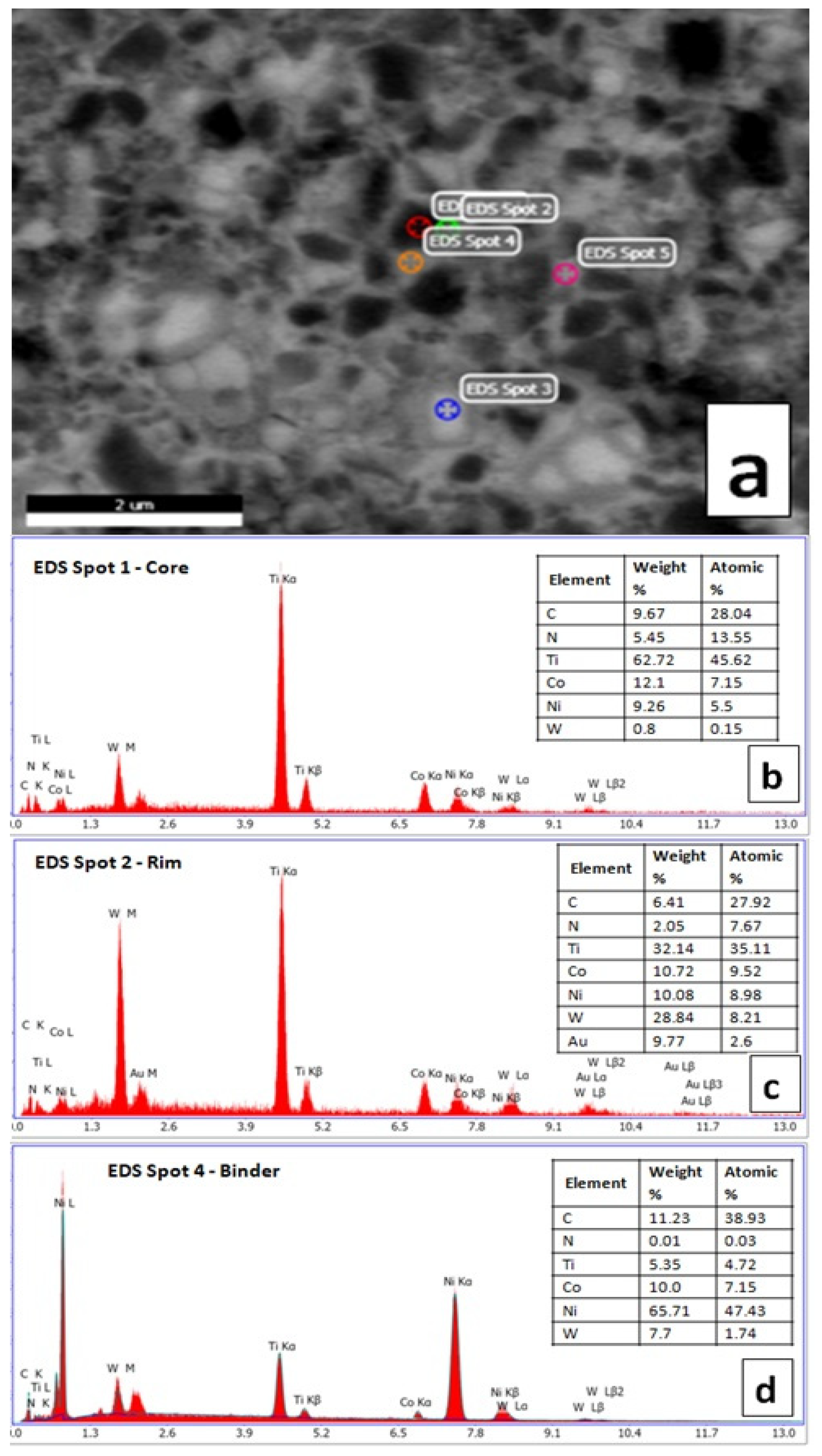

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peng, Y.; Miao, H.; Peng, Z. Development of Ti(CN)-based cermets: Mechanical properties and wear mechanism. Int. J. Refract. Met. Hard Mater. 2013, 39, 78–89. [Google Scholar] [CrossRef]

- Joardar, J.; Kim, S.W. Tribological Evaluation of Ultrafine Ti(CN) cermets. Mater. Manuf. Process. 2002, 17, 567–576. [Google Scholar] [CrossRef]

- Soboyejo, W. Special Issue—Materials and Manufacturing Processes on Multifunctional Micro- and Nano-Structures. Mater. Manuf. Process. 2007, 22, 139. [Google Scholar] [CrossRef]

- Kwona, W.T.; Park, J.S.; Kim, S.W.; Kang, S. Effect of WC and group IV carbides on the cutting performance of Ti(C,N) cermet tools. Int. J. Mach. Tools Manuf. 2004, 44, 341–346. [Google Scholar] [CrossRef]

- Ettmayer, P.; Kolaska, H.; Lengauer, W.; Dreyer, K. Ti(C,N) Cermets—Metallurgy and Properties. Int. J. Refract. Met. Hard Mater. 1995, 13, 343–351. [Google Scholar] [CrossRef]

- Shamanian, M.; Salehi, M.; Saatchi, A.; North, T.H. Influence of Ni Interlayers on the Mechanical Properties of Ti6Al4V/(WC-Co) Friction Welds. Mater. Manuf. Process. 2006, 18, 581–598. [Google Scholar] [CrossRef]

- Ahn, S.Y.; Kang, S. Formation of core/rim structures in Ti(C,N)-WC-Ni cermets via a dissolution and precipitation process. J. Am. Ceram. Soc. 2003, 83, 1489–1494. [Google Scholar] [CrossRef]

- Ahn, S.Y.; Kang, S. Effect of various carbides on the dissolution behavior of Ti(C0.7N0.3) in a Ti(C0.7N0.3)-30 Ni system. Int. J. Refract. Met. Hard Mater. 2001, 19, 539–545. [Google Scholar] [CrossRef]

- Zhang, S. Titanium carbonitride-based cermets: Processes and properties. Mater. Sci. Eng. A 1993, 163, 141–148. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, G.Q. Sintering of Ti(C,N)Based Cermets: The Role of Compaction. Mater. Manuf. Process. 1995, 10, 773–783. [Google Scholar] [CrossRef]

- Yoo, S.H.; Sethuram, K.M.; Sudarshan, T.S. Apparatus for Bonding a Particle Materials to Near Theoretical Density. U.S. Patent 5,989,487, 23 November 1999. [Google Scholar]

- Yoo, S.H.; Sethuram, K.M.; Sudarshan, T.S. Method of Bonding a Particle Materials to Near Theoretical Density. U.S. Patent 6,001,304, 14 December 1999. [Google Scholar]

- Alvarez, M.; Sánchez, J.M. Spark plasma sintering of Ti(C,N) cermets with intermetallic binder phases. Int. J. Refract. Met. Hard Mater. 2007, 25, 107–118. [Google Scholar] [CrossRef]

- Ping, F.; Wei-hao, X.; Yong, Z.; Li-Xin, Y.; Yang-hua, X. Spark Plasma Sintering Properties of Ultrafine Ti (C, N)-based Cermet. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2004, 19, 69–72. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, S.; You, M.; Tana, H.; Xiong, W. Fabrication of nanocomposite Ti(C,N)-based cermet by spark plasma sintering. Mater. Chem. Phys. 2005, 92, 64–70. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Manigandan, K.; Petraroli, M.; Trejo, R.M.; Sudarshan, T.S. Influence of size of nanoparticles and plasma pressure compaction on microstructural development and hardness of bulk tungsten samples. Adv. Powder Technol. 2013, 24, 190–199. [Google Scholar] [CrossRef]

- Yoo, S.; Kalyanaraman, R.; Subhash, G.; Sudarshan, T.S.; Dowding, R.J. High Strain Rate Response of PAS (Plasma Activated Sintering) Consolidated Tungsten Powders, Materials Modification, Inc. Available online: https://www.matmod.com/Publications/p2c_1.pdf (accessed on 1 October 2002).

- Shetty, D.K.; Wright, I.G.; Mincer, P.N.; Clauer, A.H. Indentation fracture of WC-Co cermets. J. Mater. Sci. 1985, 20, 1873–1882. [Google Scholar] [CrossRef]

- Park, S.; Kang, S. Toughened ultra-fine (Ti,W)(CN)–Ni cermets. Scr. Mater. 2005, 52, 129–133. [Google Scholar] [CrossRef]

- Jun, W.; Ying, L.; Yan, F.; Jinwen, Y.; Mingjing, T. Effect of NbC on the microstructure and sinterability of Ti(C0.7, N0.3)-based cermets. Int. J. Refract. Met. Hard Mater. 2009, 27, 549–551. [Google Scholar]

- Zhang, X.; Liu, N.; Rong, C. Effect of molybdenum content on the microstructure and mechanical properties of ultra-fine Ti(C, N) based cermets. Mater. Charact. 2008, 59, 1690–1696. [Google Scholar] [CrossRef]

- Zhang, H.; Dikeb, Y.; Tang, S. Preparation and properties of ultra-fine TiCN matrix cermets by vacuum microwave sintering. Rare Met. 2010, 29, 528–532. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Kwon, W.T.; Seo, M.; Kang, S. Tool Performance of New Wear-resistant Cermets. Int. J. Precis. Eng. Manuf. 2012, 13, 941–946. [Google Scholar] [CrossRef]

- Jeon, E.T.; Joardar, J.; Kang, S. Microstructure and tribo-mechanical properties of ultrafine Ti(CN) cermets. Int. J. Refract. Met. Hard Mater. 2002, 20, 207–211. [Google Scholar] [CrossRef]

- Xiong, J.; Guo, Z.; Yang, M.; Shen, B. Preparation of ultra-fine TiC0.7N0.3-based cermet. Int. J. Refract. Met. Hard Mater. 2008, 26, 212–219. [Google Scholar] [CrossRef]

- Liu, Y.; Jin, Y.; Yu, H.; Ye, J. Ultrafine (Ti, M)(C, N)-based cermets with optimal mechanical properties. Int. J. Refract. Met. Hard Mater. 2011, 29, 104–107. [Google Scholar] [CrossRef]

- Jung, J.; Kang, S. Effect of ultra-fine powders on the microstructure of Ti(CN)–xWC–Ni cermets. Acta Mater. 2004, 52, 1379–1386. [Google Scholar] [CrossRef]

- Xiong, J.; Guo, Z.; Shen, B.; Cao, D. The effect of WC, Mo2C, TaC content on the microstructure and properties of ultra-fine TiC0.7N0.3 cermet. Mater. Des. 2007, 28, 1689–1694. [Google Scholar] [CrossRef]

- Zhu, G.; Liu, Y.; Ye, J. Influence of Ce–Co pre-alloyed powder addition on the microstructure and mechanical properties of Ti(C, N)-based cermets. Int. J. Refract. Met. Hard Mater. 2013, 37, 134–141. [Google Scholar] [CrossRef]

- Borrell, A.; Salvador, M.D.; Rocha, V.G.; Fernández, A.; Aviles, M.A.; Gotor, F.J. Bulk TiCxN1-x–15%Co cermets obtained by direct spark plasma sintering of mechanochemical synthesized powders. Mater. Res. Bull. 2012, 47, 4487–4490. [Google Scholar] [CrossRef]

- Gong, J.; Pan, X.; Miao, H.; Zhao, Z. Effect of metallic binder content on the microhardness of TiCN-based cermets. Mater. Sci. Eng. A 2003, 359, 391–395. [Google Scholar] [CrossRef]

- Liu, N.; Yin, W.; Zhu, L. Effect of TiC/TiN powder size on microstructure and properties of Ti(C, N)-based cermets. Mater. Sci. Eng. A 2007, 445–446, 707–716. [Google Scholar] [CrossRef]

- Zheng, Y.; Xiong, W.; Liu, W.; Lei, W.; Yuan, Q. Effect of nano addition on the microstructures and mechanical properties of Ti(C, N)-based cermets. Ceram. Int. 2005, 31, 165–170. [Google Scholar] [CrossRef]

- Liu, N.; Han, C.; Xu, Y.; Chao, S.; Shi, M.; Feng, J. Microstructures and mechanical properties of nano TiN modified TiC-based cermets for the milling tools. Mater. Sci. Eng. A 2004, 382, 122–131. [Google Scholar] [CrossRef]

- Xiong, J.; Guo, Z.; Wen, B.; Li, C.; Shen, B. Microstructure and properties of ultra-fine TiC0.7N0.3 cermet. Mater. Sci. Eng. A 2006, 416, 51–58. [Google Scholar] [CrossRef]

- Cardinal, S.; Malchère, A.; Garnier, V.; Fantozzi, G. Review Microstructure and mechanical properties of TiC–TiN based cermets for tools application. Int. J. Refract. Met. Hard Mater. 2009, 27, 521–527. [Google Scholar] [CrossRef]

- Yun, H.; Zou, B.; Wang, J. Effects of sintering temperature and nano Ti(C,N) on the microstructure and mechanical properties of Ti(C,N) cermets cutting tool materials with low Ni-Co. Mater. Sci. Eng. A Struct. 2017, 705, 98–104. [Google Scholar] [CrossRef]

- Zhang, G.; Huang, M.; Zhao, H.; Zhang, H.; Wang, Y.; Zhang, X.; Zheng, H.; Lu, P.; Zhao, Z. Investigation and properties of Ti(C,N)-based cermets with graphene nanosheet addition by spark plasma sintering. J. Mater. Res. Technol. 2023, 24, 185–199. [Google Scholar] [CrossRef]

- Yan, H.; Deng, Y.; Su, Y.Y.; Jiang, S.; Chen, Q.W.; Cao, S.X.; Liu, B. Ti(C, N)-Based Cermets with Two Kinds of Core-Rim Structures Constructed by β-Co Microspheres. Adv. Mater. Sci. Eng. 2020, 1–11, 4684529. [Google Scholar] [CrossRef]

- Shankar, E.; Prabu, S.B.; Padmanabhan, K.A. Mechanical properties and microstructures of TiCN/nano-TiB 2/TiN cermets prepared by spark plasma sintering. Ceram. Int. 2018, 44, 9384–9394. [Google Scholar] [CrossRef]

- Zhang, M.M.; Jiang, Y.; Lin, N.; Kang, X.Y.; Yan, Y.; Huang, J.H.; Liu, Y.; Qiu, S.; He, Y.H. Investigation of the oxidation behavior and high oxidation-resistant mechanism of Ti(C,N)-based cermets. Corros. Sci. 2020, 177, 108959. [Google Scholar] [CrossRef]

- De la Obra, A.G.; Sayagués, M.J.; Chicardi, E.; Gotor, F.J. Development of Ti(C,N)-based cermets with (Co,Fe,Ni)-based high entropy alloys as binder phase. J. Alloys Compd. 2019, 814, 152218. [Google Scholar] [CrossRef]

- Subin, A.J.; Merbin, J.; Menezes, P.L. Cermet Systems: Synthesis, Properties, and Applications. Ceramics 2022, 5, 210–236. [Google Scholar] [CrossRef]

- Comstock, G.J. Hard Cemented Carbide Material. U.S. Patent 2,033,513, 10 March 1936. [Google Scholar]

- Santrade, Ltd. Wear Resistant Alloy. U.S. Patent 4,145,213, 20 March 1979. [Google Scholar]

- Kennametal, Inc. Cermet Cutting Tool. U.S. Patent 4,942,097, 17 July 1990. [Google Scholar]

- Watanabe, T.; Doutsu, T.; Yagishita, O.; Yamamoto, H.; Kai, Y.; Agency of Industrial Science. Titanium Carbo-Nitride and Chromium Carbide-Based Ceramics Containing Metals. U.S. Patent 4,948,425, 14 August 1990. [Google Scholar]

- Isobe, K.; Nomura, T. Cermet Alloy Containing Nitrogen. U.S. Patent 5,186,739, 16 February 1993. [Google Scholar]

- Teruuchi, K.; Ueda, F.; Odani, N. Wear Resistant Titanium Carbonitride-Based Cermet Cutting Insert. U.S. Patent 5,370,719, 6 December 1994. [Google Scholar]

- Weinl, G.; Oskarsson, R.; Hultman, L. Titanium-Based Carbonitride Alloy with Controlled Structure. U.S. Patent 5,395,421, 7 March 1995. [Google Scholar]

- Nakamura, S.; Fujisawa, T.; Teruuti, K.; Tsujisaki, H.; Nonaka, M. Cutting Blade Made of Titanium Carbonitride-Base Cermet, and Cutting Blade Made of Coated Cermet. U.S. Patent 5,766,742, 16 June 1998. [Google Scholar]

- Rolander, U.; Weinl, G.; Lindahl, P.; Andren, H.O. Titanium-Based Carbonitride Alloy with Controllable Wear Resistance and Toughness. U.S. Patent 6,004,371, 21 December 1999. [Google Scholar]

- Iyori, Y.; Nakahara, Y.; Kimura, Y. TICN-Based Cermet. U.S. Patent 6,387,552 B1, 14 May 2002. [Google Scholar]

- Mitsubishi Materials Corp. Cermet Cutting Insert. European Patent Application EP 1,043,414 A1, 5 April 2000. [Google Scholar]

- Weinl, G.; Rolander, U.; Zwinkels, M. Ti(C,N)-(Ti,Nb,W)(C,N)-Co Alloy for Milling Cutting Tool Applications. U.S. Patent 7,332,122 B2, 19 February 2008. [Google Scholar]

- Lee, H.H.; Kim, K.H.; Shin, S.J.; Kim, S.M. Method for Producing Titanium Carbonitride Powder. European Patent EP3,181,274B1, 18 December 2019. [Google Scholar]

- Rolander, U.; Zwinkels, M.; Weinl, G. Ti(C,N)-(Ti,Nb,W)(C,N)-Co Alloy for Finishing and Semi finishing Turning Cutting Tool Applications. U.S. Patent 7,645,316 B2, 12 January 2010. [Google Scholar]

- Mitsubishi Materials Corp. Cermet Insert and Cutting Tool. U.S. Patent 8,007,561 B2, 30 August 2011. [Google Scholar]

- Banerjee, D. Cemented Carbide with Ultra-Low Thermal Conductivity. U.S. Patent 8,202,344 B2, 19 June 2012. [Google Scholar]

| Powder Info | Composition Info | Milling Parameters | Sintering | Paper Info (Year) | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TiCxN1-x, µm | X | WC, µm | Velo (RPM) | Time (h) | Tech Used | Pressure (MPa) | Sintering Temp | Holding Time (min) | |||

| >0.1 | 0.7 | 0.85 | TiCN-43,WC-6.9,Ni-32, Mo-16,VC-0.6,C-1.5 | 200 | 24 h | SPS | 20 | 1350 | 3 | 2004 | [15] |

| 3–4 | 0.5 | 1–4 | TiCN-65,WC-15,Ni-20 | 250 | 20 | VS | 150 | 1510 | 60 | 2004 | [19] |

| 1 | 0.7 | 0.8 | TiCN–WC–Mo2C–(Co,Ni) | - | 80 | VS | 100 | 1360 | 60 | 2008 | [20] |

| 0.1 | 0.5 | 1.14 | TiCN-(47.5–57.5),WC-20,Co-15,Mo-(5–15),C-2.5 | - | 24 h | VS | 170 | 1430 | 60 | 2006 | [21] |

| <1 | 0.7 | <1 | TiCN-59,WC-15,Co + Ni-17,Mo2C-9 | 304 | 50 h | VMS | 300 | 1400 | 5 | 2009 | [22] |

| 0.8–3 | 0.5 | 5.9 | TiCN-50,WC-21.22,Ni-20,{Mo + Ta(Nb)}-8.47 | - | 24 h | VS | 125 | 1510 | 60 | 2012 | [23] |

| 0.7–0.95 | 0.5 | 0.4 | TiCN-55,WC-25,Ni-20 | - | 24 h | VS | 100 | 1510 | 60 | 2001 | [24] |

| 0.13 | 0.7 | 0.45 | TiCN-53.5,WC-15,Co + Ni-14.5,TaC-7,Mo2C-10 | - | 45 h | VS | - | 1450 | 60 | 2008 | [25] |

| 0.5–0.8 | 0.5 | 200 nm | TiCN-51.87,WC-16,Ni-11,Co-9,Mo2C-12,VC-0.13 | 30 | 72 h | VS | 120 | 1450 | 90 | 2010 | [26] |

| 0.3 | 0.7 | 0.2 | TiCN-55,WC-25,Ni-20 | - | 24 h | VS | 100 | 1510 | 60 | 2003 | [27] |

| 0.13 | 0.7 | 0.45 | TiCN-X, Ni + Co-14.5,Mo2C-10, (WC-15/TaC-10) | 68 | 48 h | VS | - | - | 2006 | [28] | |

| 1 | 0.7 | 0.2 | TiCN-51.4,WC-15,Co + Ni-15,Mo2C-10,TaC-8,Ce/Co-0.6 | - | 72 h | VS | 100 | 1465 | 60 | 2012 | [29] |

| - | 0.5 | - | TiCN-85,Co-15 | 400 | 30 min | SPS | 80 | 1300 | 1 | 2012 | [30] |

| - | 0.5 | - | TiCN-80.75,Al2O3-14.25,Mo-2.5,Ni-2.5 | - | - | SPS | 50 | 1450 | 2 | 2003 | [31] |

| 0.7 | 0.8 | 3.52 | TiCN-65,WC-15,Ni-7.5,Co-7.5,Mo-4,C-1 | 150 | 24 h | VS | 180 | 1430 | 60 | 2006 | [32] |

| 1 | 0.7 | 0.72 | TiCN-43,WC-6.9,Ni-32,Mo-16,Cr3C2-0.6,C-1.5 | 150 | 12 h | VS | 300 | 1450 | 60 | 2004 | [33] |

| TiC-3.87, TiN-0.04 | 0.5 | 3.25 | TiCN-X,WC-15,Co + Ni-24, Mo-8/15, | - | 24 h | VS | 170 | 1450 | 60 | 2004 | [34] |

| 0.5 | 0.7 | 0.45 | TiCN-53.5,WC + TaC-22,Ni + Co-14.5,Mo2C-10 | 68 | 48 h | VS | - | - | 2005 | [35] | |

| TiC-1.5, TiN-2.9 | 0.5 | - | TiCN-70,Ni-20,Mo2C-10 | - | 24 h | VS | 100 | 1550 | 120 | 2008 | [36] |

| 0.21 | 0.7 | - | TiCN-76,Ni-12,Mo2C-12 | - | 36 h | SPS | 30 | 1250 | 3 | 2003 | [37] |

| Composition | Properties of Sintered Cermets | Ref. | |||||

|---|---|---|---|---|---|---|---|

| % Density | Relative Density (gm/cm3) | Grain Size (µm) | Hardness (GPa) | Fracture Toughness (MPa·m1/2) | Trans R.S. MPa | ||

| TiCN-76,Ni-12,Mo2C-12 | - | - | 0.42 | 16.78 | - | 295 | [14] |

| TiCN-43,WC-6.9,Ni-32,Mo-16,VC-0.6,C-1.5 | - | 6.48 | >100 nm | 14.2 | - | 879.5 | [15] |

| TiCN-65,WC-15,Ni-20 | 98.8 | 6.16 | 30–100 nm | 12.2 | 12 | - | [19] |

| TiCN–WC–Mo2C–(Co,Ni) | - | - | - | - | - | - | [20] |

| TiCN-57.5,WC-20,Co-15,Mo-5, C-2.5 | - | - | 1.17 | 15.98 | 13.2 | 870 | [21] |

| TiCN-52.5,WC-20,Co-15,Mo-10,C-2.5 | - | - | 1.15 | 17.39 | 11.9 | 990 | [21] |

| TiCN-47.5,WC-20,Co-15,Mo-15,C-2.5 | - | - | 0.79 | 17.87 | 11 | 1030 | [21] |

| TiCN-59,WC-15,Co + Ni-17,Mo2C-9 | 99.5 | - | >1 | 17.36 | - | - | [22] |

| TiCN-50,WC-21.22,Ni-20,{Mo + Ta(Nb)}-8.47 | - | - | 1–4 | ~11 | ~10 | - | [23] |

| TiCN-55,WC-25,Ni-20 | - | 6.5 | 0.7–0.9 | 14.2 | 8.8 | - | [24] |

| TiCN-53.5,WC-15,Co + Ni-14.5,TaC-7,Mo2C-10 | - | 6.39 | >1 | 17.54 | - | 965 | [25] |

| TiCN-51.87,WC-16,Ni-11,Co-9,Mo2C-12,VC-0.13 | 99.5 | 6.74 | 0.5–1 | 14.7 | 10.1 | 2210 | [26] |

| TiCN-55,WC-25,Ni-20 | - | - | 1.2 | 14 | 7.3 | - | [27] |

| TiCN-60.5,WC-15,Ni + Co-14.5,Mo2C-10 | - | - | 0.5 | 18.63 | - | 1500 | [28] |

| TiCN-75.5,Ni + Co-14.5,Mo2C-10 | - | - | 0.5 | 18.7 | - | 1320 | [28] |

| TiCN-50.5,WC-15,Ni + Co-14.5,Mo2C-10, TaC-10 | - | - | 0.5 | 18.65 | - | 1600 | [28] |

| TiCN-51.4,WC-15,Co + Ni-15,Mo2C-10, TaC-8, Ce/Co-0.6 | - | - | 1–2 | 17.06 | 9.21 | 1639 | [29] |

| TiCN-85,Co-15 | 99 | - | >1 | 17.1 | 5.51 | 904 | [30] |

| TiCN-80.75,Al2O3-14.25,Mo-2.5,Ni-2.5 | - | 5.115 | 0.5> | 14.45 | - | - | [31] |

| TiCN-65,WC-15,Ni-7.5,Co-7.5,Mo-4,C-1 | - | 6.258 | >1 | 18.63 | 14.5 | 1623.5 | [32] |

| TiCN-43,WC-6.9,Ni-32,Mo-16,Cr3C2-0.6,C-1.5 | 98> | - | >1 | 12.3 | - | 2884 | [33] |

| TiCN-53,WC-15,Mo-8,Co + Ni-24 | - | - | 1 | 12.5 | 17 | 1425 | [34] |

| TiCN-46,WC-15,Mo-15,Co + Ni-24 | - | - | 1 | 12.74 | 18.2 | 1600 | [34] |

| TiCN-53.5,WC + TaC-22,Ni + Co-14.5,Mo2C-10 | - | 6.7 | 0.3 | 19.5 | 10.6 | 1740 | [35] |

| TiCN-70,Ni-20,Mo2C-10 | >98 | 5.56 | 3.2 | - | 14.2 | - | [36] |

| S. No. | Patent Ref. | Filing Date | Publication Date | Applicant | Title | Ref. No. |

|---|---|---|---|---|---|---|

| 1 | US2033513 | 12 June 1935 | 10 March 1936 | Firth Sterling Steel Co. | Hard cemented carbide material | [44] |

| 2 | US4145213 | 17 May 1976 | 20 March 1979 | Sandvik Aktiebolag | Wear-resistant alloy | [45] |

| 3 | US4942097 | 14 October 1987 | 17 July 1990 | Kennametal Inc. | Cermet cutting tool (TiCN,WC,TiC,Mo2C,Co,Ni) | [46] |

| 4 | US4948425 | 6 April 1989 | 14 August 1990 | Agency of Industrial Science and Technology | Titanium carbo-nitride and chromium carbide-based ceramics containing metals (TiC.5N.5,Cr3C2,Mo2C,B4C,Co,Ni,Si) | [47] |

| 5 | US5186739 | 21 February 1990 | 16 February 1993 | Sumitomo Electric Industries, Ltd. | Cermet alloy containing nitrogen | [48] |

| 6 | US5370719 | 16 November 1993 | 6 December 1994 | Mitsubishi Materials Corporation | Wear-resistant titanium carbonitride-based cermet cutting insert (TiCN,WC,Cr3C2, Mo2C,ZrC,TaC,NbCN,VC,Ni,Co) | [49] |

| 7 | US5395421 | 30 September 1993 | 7 March 1995 | Sandvik Ab | Titanium-based carbonitride alloy with controlled structure (TiC,TiN,WC,Mo2C,TaC,VC,Co,Ni) | [50] |

| 8 | US5766742 | 31 October 1996 | 16 June 1998 | Mitsubishi Materials Corporation | Cutting blade made of titanium carbonitride-base cermet, and cutting blade made of coated cermet (TiCN,TiN,TaC,NbC,WC,VC,ZrC, Cr3C2,Mo2C,Co,Ni, graphite powder C) | [51] |

| 9 | US6004371 | 19 January 1996 | 21 December 1999 | Sandvik Ab | Titanium-based carbonitride alloy with controllable wear resistance and toughness (TiC,TiN,WC,Mo2C,TaC,VC,Co,Ni) | [52] |

| 10 | US 6,387,552 B1 | 21 September 2000 | 14 May 2002 | Hitachi Tool Engineering, Ltd., Tokyo (JP) | TiCN-Based Cermet (TiN,TiC,TiCN,WC,MoC,TaC,Ni,Co) | [53] |

| 11 | EP1043414A1 | 5 April 2000 | 11 October 2000 | Mitsubishi Materials Corporation | Cermet cutting insert | [54] |

| 12 | US7332122 | 7 October 2003 | 19 February 2008 | Sandvik Intellectual Property Ab | Ti(C,N)-(Ti,Nb,W)(C,N)-Co alloy for milling cutting tool applications | [55] |

| 13 | EP3 181 274B1 | 2 April 2015 | 18 December 2019 | Nano Tech Co., Ltd. | Method For Producing Titanium Carbonitride Powder (TiO2,Ca,C,N2) | [56] |

| 14 | US7645316 | 30 October 2006 | 12 January 2010 | Sandvik Intellectual Property Aktiebolag | Ti(C,N)-(Ti,Nb,W)(C,N)-Co alloy for finishing and semifinishing turning cutting tool applications | [57] |

| 15 | US8007561 | 13 June 2006 | 30 August 2011 | Ngk Spark Plug Co., Ltd. | Cermet insert and cutting tool | [58] |

| 16 | US 8202344 B2 | 21 May 2007 | 19 June 2012 | Kennametal Inc. | Cemented carbide with ultra-low thermal conductivity (TiC,WC,Cr3C2,TaNbC,Mo2C,Ni,Co) | [59] |

| Cermet (wt%): 75TiCN-10WC-15(Ni-Co) | ||||||

|---|---|---|---|---|---|---|

| Sintering Technique | Sintering Temp. (°C) | Holding Time (min) | Pressure (MPa) | Relative Density (%) | HV10 (GPa) | KIc (MPa m1/2) |

| Conventional | 1400 | 60 | 150-uniaxial 300-isostatic | ~98 | 15.0 ± 0.15 | 7.7 ± 0.45 |

| SPS | 1200 | 3 | 60 | >98 | 15.8 ± 0.23 | 8.0 ± 0.30 |

| 1250 | 3 | 60 | >98.5 | 16.3 ± 0.34 | 8.5 ± 0.21 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verma, V.; García-Hernández, M.; Luna-Domínguez, J.H.; Suárez-Domínguez, E.J.; Monteiro Júnior, S.; Câmara Cozza, R. Effect of Processing Routes on Physical and Mechanical Properties of Advanced Cermet System. Ceramics 2024, 7, 625-638. https://doi.org/10.3390/ceramics7020041

Verma V, García-Hernández M, Luna-Domínguez JH, Suárez-Domínguez EJ, Monteiro Júnior S, Câmara Cozza R. Effect of Processing Routes on Physical and Mechanical Properties of Advanced Cermet System. Ceramics. 2024; 7(2):625-638. https://doi.org/10.3390/ceramics7020041

Chicago/Turabian StyleVerma, Vikas, Margarita García-Hernández, Jorge Humberto Luna-Domínguez, Edgardo Jonathan Suárez-Domínguez, Samuel Monteiro Júnior, and Ronaldo Câmara Cozza. 2024. "Effect of Processing Routes on Physical and Mechanical Properties of Advanced Cermet System" Ceramics 7, no. 2: 625-638. https://doi.org/10.3390/ceramics7020041

APA StyleVerma, V., García-Hernández, M., Luna-Domínguez, J. H., Suárez-Domínguez, E. J., Monteiro Júnior, S., & Câmara Cozza, R. (2024). Effect of Processing Routes on Physical and Mechanical Properties of Advanced Cermet System. Ceramics, 7(2), 625-638. https://doi.org/10.3390/ceramics7020041