Process Development for Additive Manufacturing of Alumina Toughened Zirconia for 3D Structures by Means of Two-Photon Absorption Technique

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

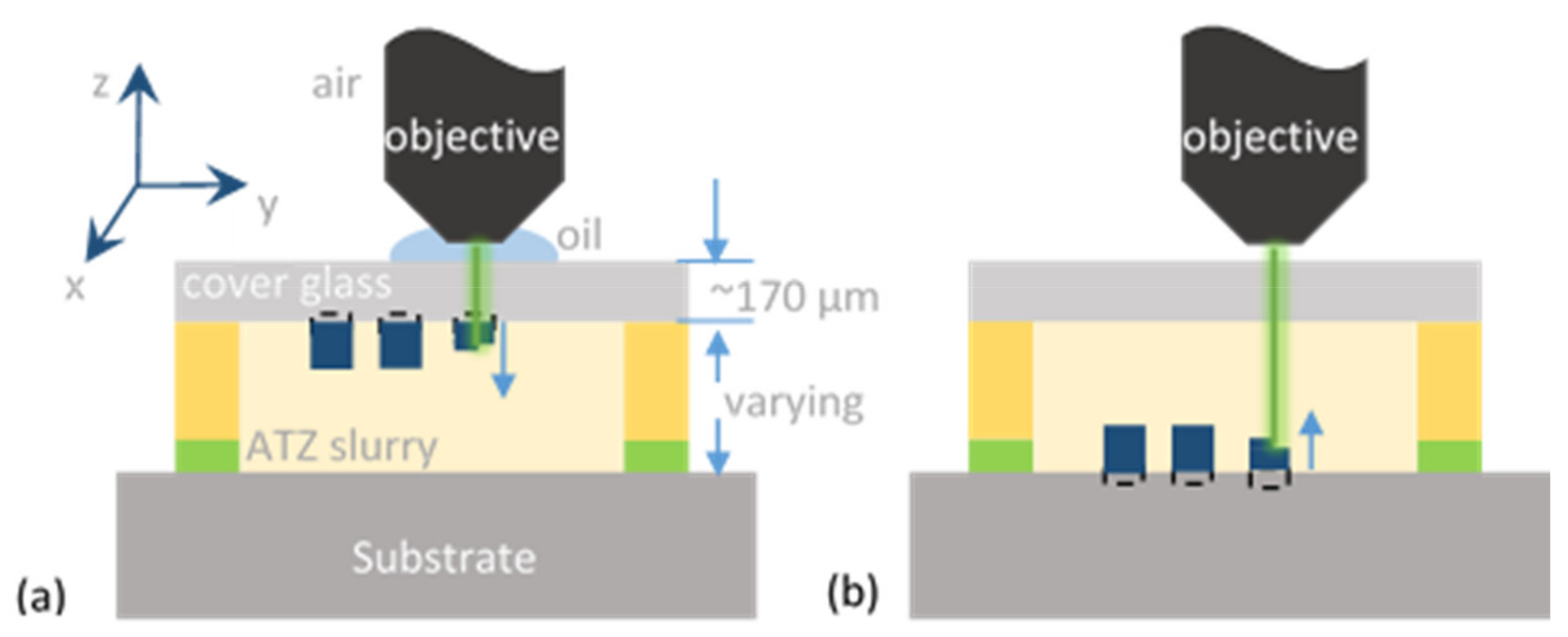

2.2.1. TPA Machine

2.2.2. Characterization of Test Structures and Biocompatibility Testing

3. Results and Discussion

3.1. Manufacturing of Ceramic Parts Using Heterogeneous Slurries and Conventional Technologies

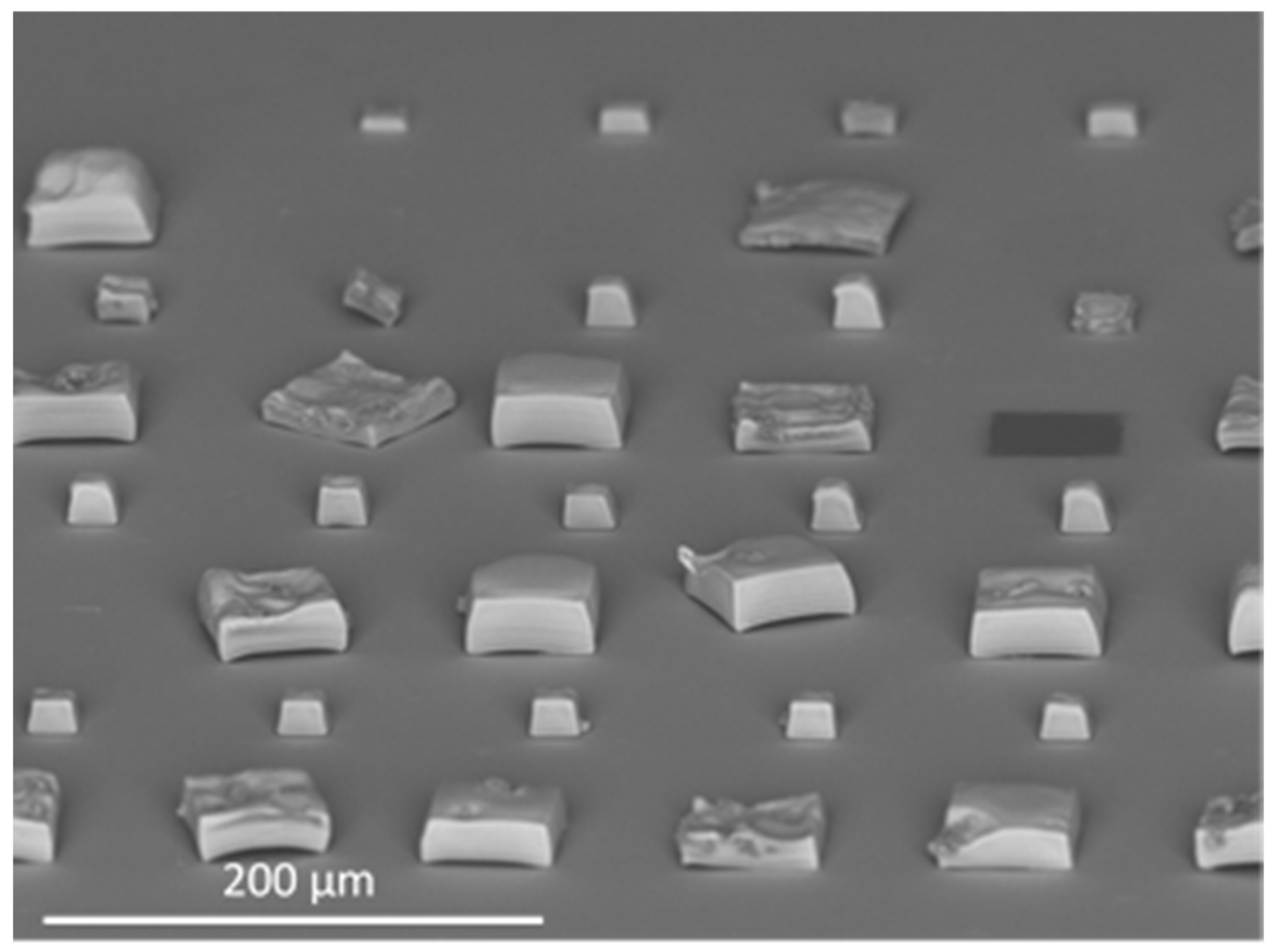

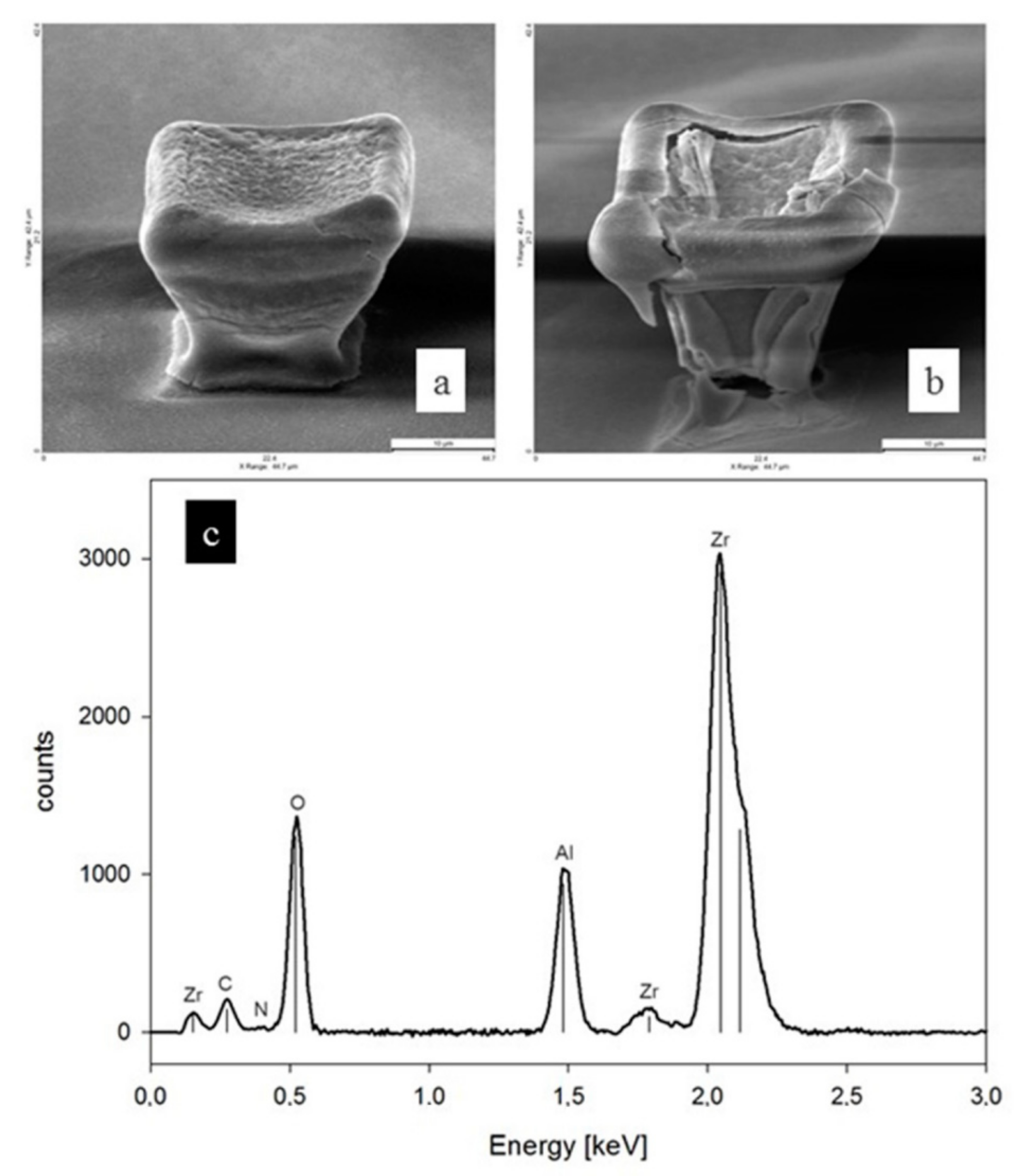

3.2. Structuring of an ATZ like Slurry with TPA

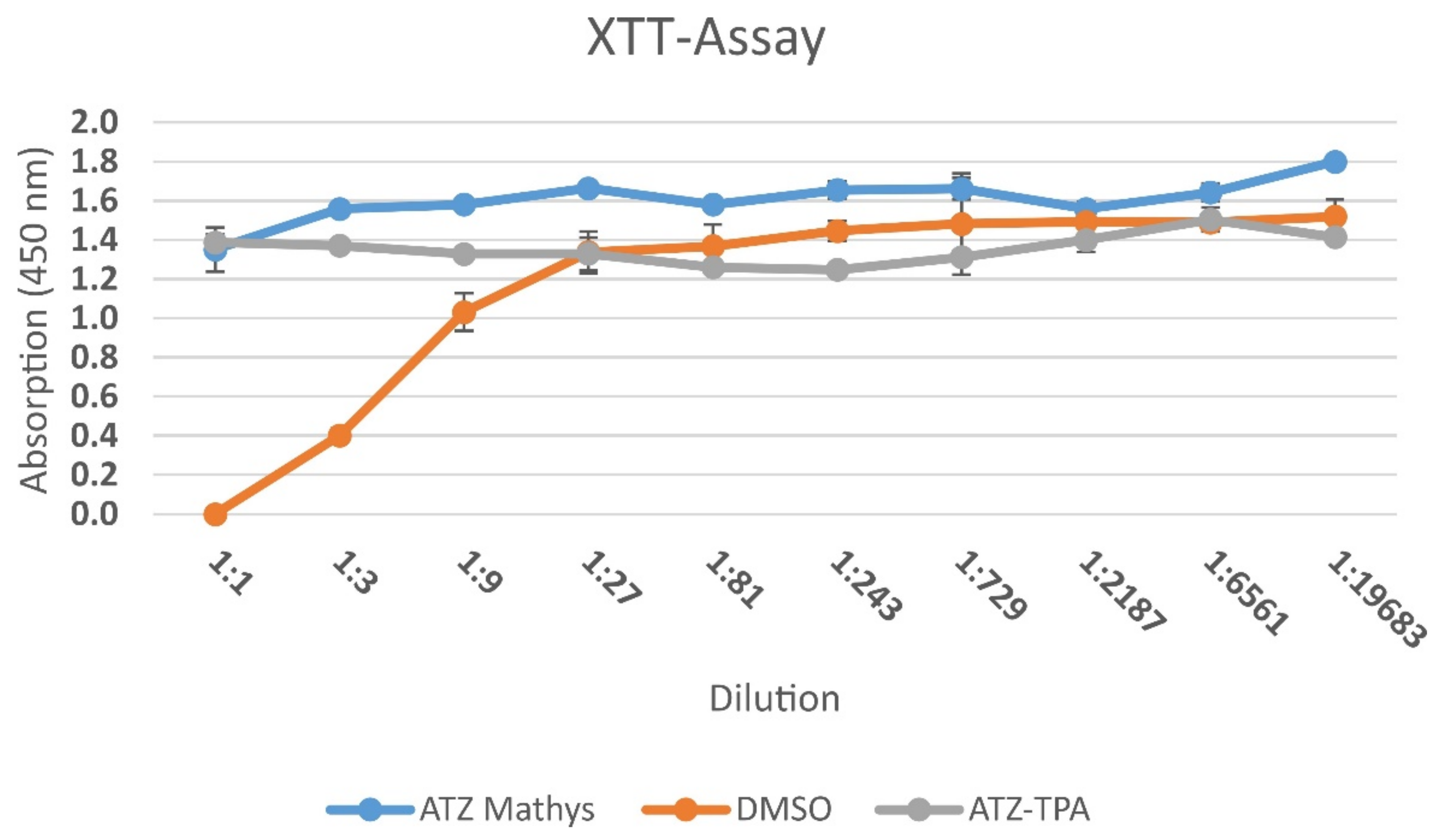

3.3. Biocompatibility Tests

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Doreau, F.; Chaput, C.; Chartier, T. Stereolithography for Manufacturing Ceramic Parts. Adv. Eng. Mater. 2000, 2, 493–496. [Google Scholar] [CrossRef]

- Moritz, T.; Partsch, U.; Ziesche, S.; Scheithauer, U.; Ahlhelm, M.; Schwarzer, E.; Richter, H.-J. Additive Fertigung von Keramik; Jahresbericht 2014/2015; Fraunhofer IKTS: Hermsdorf, Germany, 2015; pp. 28–31. [Google Scholar]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Deckers, J.; Vleugels, J.; Kruth, J.-P. Additive manufacturing of ceramics: A review. J. Ceram. Sci. Technol. 2014, 5, 245–260. [Google Scholar]

- Halloran, J.W. Ceramic Stereolithography: Additive Manufacturing for Ceramics by Photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; Yi, H. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Schwarzer, E.; Holtzhausen, S.; Scheithauer, U.; Ortmann, C.; Oberbach, T.; Moritz, T.; Michaelis, A. Process development for additive manufacturing of functionally graded alumina toughened zirconia components intended for medical implant application. J. Eur. Ceram. Soc. 2018. [Google Scholar] [CrossRef]

- Mudge, R.P.; Wald, N.R. Laser engineered net shaping advances additive manufacturing and repair. Weld. J. 2007, 86, 44. [Google Scholar]

- Balla, V.K.; Bose, S.; Bandyopadhyay, A. Processing of Bulk Alumina Ceramics Using Laser Engineered Net Shaping. Int. J. Appl. Ceram. Technol. 2008, 5, 234–242. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Thao, L.; Tian, T.; Yang, S. Direct selective laser sintering and melting of ceramics. a review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.; Du, S.; Zhang, J. Al2O3 Ceramics Preparation by LOM (Laminated Object Manufacturing). Int. J. Adv. Manuf. Technol. 2001, 17, 531–534. [Google Scholar] [CrossRef]

- Schwentenwein, M.; Homa, J. Additive Manufacturing of Dense Alumina Ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 1–7. [Google Scholar] [CrossRef]

- Cima, M.J.; Sachs, E.M. Three dimensional printing: Forms, materials and performance. In 1991 International Solid Freeform Fabrication Symposium; Massachusetts Institute of Technology, Department of Materials Science and Mechanical Engineering: Cambridge, MA, USA, 1991; pp. 187–194. [Google Scholar]

- Kalita, S.J.; Bose, S.; Hosick, H.L.; Bandyopadhyay, A. Development of controlled porosity polymer-ceramic composite scaffolds via fused deposition modeling. Mater. Sci. Eng. C 2003, 23, 611–620. [Google Scholar] [CrossRef]

- Sirringhaus, H.; Shimoda, T. Inkjet printing of functional materials. MRS Bull. 2003, 28, 802–806. [Google Scholar] [CrossRef]

- Bruinink, A.; Bitar, M.; Pleskova, M.; Wick, P.; Krug, H.F.; Maniura-Weber, K. Addition of nanoscaled bioinspired surface features: A revolution for bone related implants and scaffolds? J. Biomed. Mater. Res. A 2014, 102, 275–294. [Google Scholar] [CrossRef]

- Al-Hajjar, M. Wear of novel ceramic-on-ceramicbearings under adverse ans clinically relevant hip simulator conditions. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 1456–1462. [Google Scholar] [CrossRef]

- Oberbach, T. Current state and future trends in bioceramics for orthopaedic applications. In Proceedings of the Global Roadmap for Ceramics—ICC, International Congress on Ceramics, Verona, Italy, 1 September 2008. [Google Scholar]

- Begand, S.; Oberbach, T.; Glien, W. ATZ—A new material with high Potential in Joint Replacement. Key Eng. Mater. 2005, 284–286, 983–986. [Google Scholar] [CrossRef]

- Razzante, M.C.; Ehredt, D.J.; Clougherty, C.O.; Kriger, S.J.; Menninger, B.A.; Behan Dionisopoulos, S.; Bhakta, P.J.; Bruning, N.G. Type IV Cell-Mediated Hypersensitivity Reaction Caused by Titanium Implant Following Double Calcaneal Osteotomy and First Metatarsal-Cuneiform Arthrodesis: A Case Report and Review of the Literature. J. Foot Ankle Surg. 2019, 58, 974–979. [Google Scholar] [CrossRef]

- Hofmann, S.C.; Plett, M.; Jansen, S.; Thomas, P.; Tholken, K.F.M. Titanium hypersensitivity causing painful intra-abdominal oedema after staple-fixed inguinal hernia repair. Contact Dermat. 2018, 79, 48–49. [Google Scholar] [CrossRef]

- Thomas, P.; Bandl, W.D.; Maier, S.; Summer, B.; Przybilla, B. Hypersensitivity to titanium osteosynthesis with impaired fracture healing, eczema, and T-cell hyperresponsiveness in vitro: Case report and review of the literature. Contact Dermat. 2006, 55, 199–202. [Google Scholar] [CrossRef]

- Oberbach, T.; Ortmann, C.; Müller, J.C.; Hildebrand, G.; Liefeith, K. Herstellung von Keramikstrukturen Mittels Mehr-Photonenpolymerisation. German Patent No.: DE102017205432, 1 April 2018. [Google Scholar]

- Houbertz, R.; Steenhusen, S.; Stichel, T.; Sextl, G. Two-Photon Polymerization of Inorganic-Organic Hybrid Polymers as Scalable Technology Using Ultra-Short Laser Pulses. In Coherence and Ultrashort Pulse Laser Emission Source; InTech: London, UK, 2010. [Google Scholar] [CrossRef]

- Doraiswamy, A.; Patz, T.; Narayan, R.J.; Chichkov, B.; Ovsianikov, A.; Houbertz, R.; Chrisey, D.B. Biocompatibility of CAD/CAM ORMOCER polymer scaffold structures. MRS Proc. 2004, 845. [Google Scholar] [CrossRef]

- Stichel, T.; Hecht, B.; Houbertz, R.; Sextl, G. Two-photon Polymerization as Method for the Fabrication of Large Scale Biomedical Scaffold Applications. JLMN J. Laser Micro Nanoeng. 2010, 5. [Google Scholar] [CrossRef]

- Burmeister, F.; Steenhusen, S.; Houbertz, R.; Asche, T.S.; Nickel, J.; Nolte, S.; Tucher, N.; Tünnermann, A.; Walles, H. Two-photon polymerization of inorganic-organic polymers for biomedical and microoptical applications. In Optically Induced Nanostructures; Ostendorf, A., König, K., Eds.; De Gruyter: Berlin, Germany, 2015; pp. 239–265. [Google Scholar]

- Chapute, C.; Chartier, T. Fabrication of ceramics by stereolithography. Rapid Prototyp. 4 Ausgabe 2007. Available online: www.rtejournal.de (accessed on 7 March 2021).

- Platte, D. Grenzflächenselektive Verkapselung von anorganischen Latentwärmespeicher-Materialien mit Hybridpoylmeren. Ph.D. Thesis, Julius Maximilian University Würzburg, Würzburg, Germany, 2012. [Google Scholar]

- Sänger, J.C.; Pauw, B.R.; Sturm, H.; Günster, J. First time additively manufactured advanced ceramics by using two-photon polymerization for powder processing. Open Ceram. 2020, 4, 100040. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Ultraviolet curing of highly loaded ceramic suspensions for stereolithography of ceramics. In Proceedings Solid Freeform Fabrication Symposium; 1994; pp. 396–403. Available online: http://hdl.handle.net/2152/68676 (accessed on 7 March 2021).

- Griffith, M.L.; Halloran, J.W. Freeform Fabrication of Ceramics via Stereolithography. J. Am. Ceram. Soc. 1996, 79, 2601–2608. [Google Scholar] [CrossRef]

- Zhou, W.; Li, D.; Wang, H. A novel aqueous ceramic suspension for ceramic stereolithography. Rapid Prototyp. J. 2010, 16, 29–35. [Google Scholar] [CrossRef]

- Chen, Z.; Li, D.; Zhou, W.; Wang, L. Curing characteristics of ceramic stereolithography for an aqueous-based silica suspension. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 641–651. [Google Scholar] [CrossRef]

- Tian, X.; Li, D.; Chen, Z.; Zhou, W. Study on the fabrication accuracy of ceramic parts by direct stereolithography. Virtual Phys. Prototyp. 2012, 7, 195–202. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, X.N.; Sun, C. Micro-stereolithography of polymeric and ceramic microstructures. Sens. Actuators A Phys. 1999, 77, 149–156. [Google Scholar] [CrossRef]

- Weiguo, B.; Dichen, L.; Qin, L.; Weijie, Z.; Linzhong, Z.; Xiang, L.; Zhongmin, J. Design and fabrication of a novel porous implant with pre-set channels based on ceramic stereolithography for vascular implantation. Biofabrication 2011, 3, 034103. [Google Scholar]

- Corcione, C.E.; Greco, A.; Montagna, F.; Licciulli, A.; Maffezzoli, A. Silica moulds built by stereolithography. J. Mater. Sci. 2005, 40, 4899–4904. [Google Scholar] [CrossRef]

- Corcione, C.E.; Montagna, F.; Greco, A.; Licciulli, A.; Maffezzoli, A. Free form fabrication of silica moulds for aluminium casting by stereolithography. Rapid Prototyp. J. 2006, 12, 184–188. [Google Scholar] [CrossRef]

- Bae, C.-J.; Halloran, J.W. Integrally Cored Ceramic Mold Fabricated by Ceramic Stereolithography. Int. J. Appl. Ceram. Technol. 2011, 8, 1255–1262. [Google Scholar] [CrossRef]

- Bae, C.J.; Halloran, J.W. Influence of Residual Monomer on Cracking in Ceramics Fabricated by Stereolithography. Int. J. Appl. Ceram. Technol. 2011, 8, 1289–1295. [Google Scholar] [CrossRef]

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-dimensional printing of transparent fused silica glass. Nature 2017, 544, 337–339. [Google Scholar] [CrossRef]

- Hinczewski, C.; Corbel, S.; Chartier, T. Ceramic suspensions suitable for stereolithography. J. Eur. Ceram. Soc. 1998, 18, 583–590. [Google Scholar] [CrossRef]

- Hinczewski, C.; Corbel, S.; Chartier, T. Stereolithography for the fabrication of ceramic three dimensional parts. Rapid Prototyp. J. 1998, 4, 104–111. [Google Scholar] [CrossRef]

- Chartier, T.; Chaput, C.; Doreau, F.; Loiseau, M. Stereolithography of structural complex ceramic parts. J. Mater. Sci. 2002, 37, 3141–3147. [Google Scholar] [CrossRef]

- Goswami, A.; Ankit, K.; Balashanmugam, N.; Umarji, A.M.; Madras, G. Optimization of rheological properties of photopolymerizable alumina suspensions for ceramic microstereolithography. Ceram. Int. 2014, 40, 3655–3665. [Google Scholar] [CrossRef]

- Adake, C.V.; Gandhi, P.; Bhargava, P. Fabrication of Ceramic Component Using Constrained Surface Microstereolithography. Procedia Mater. Sci. 2014, 5, 355–361. [Google Scholar] [CrossRef]

- Wang, J.-C. A novel fabrication method of high strength alumina ceramic parts based on solvent-based slurry stereolithography and sintering. Int. J. Precis. Eng. Manuf. 2013, 14, 485–491. [Google Scholar] [CrossRef]

- Bertsch, A.; Sébastien, J.; Philippe, R. Microfabrication of ceramic components by microstereolithography. J. Micromech. Microeng. 2004, 14, 197. [Google Scholar] [CrossRef]

- Buerkle, A.; Brakora, K.F.; Sarabandi, K. Fabrication of a DRA Array Using Ceramic Stereolithography. IEEE Antennas Wirel. Propag. Lett. 2006, 5, 479–482. [Google Scholar] [CrossRef]

- Shan, X.; Takagi, T.; Yanagisawa, K.; Nakajima, N. Development of a Manufacturing Process for Ceramic Microstructures by Using Micro Photoforming (1st Report)-Principle of the Process and Photoforming Experiment. J. Jpn. Soc. Precis. Eng. 1995, 61, 420. [Google Scholar] [CrossRef]

- Jang, J.H.; Wang, S.; Pilgrim, S.M.; Schulze, W.A. Preparation and Characterization of Barium Titanate Suspensions for Stereolithography. J. Am. Ceram. Soc. 2000, 83, 1804–1806. [Google Scholar] [CrossRef]

- Woodward, D.I.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A.; Leigh, S.J. Additively-manufactured piezoelectric devices. Phys. Status Solidi 2015, 212, 2107–2113. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, X. Experimental and numerical investigations on microstereolithography of ceramics. J. Appl. Phys. 2002, 92, 4796–4802. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, X. The influences of the material properties on ceramic micro-stereolithography. Sens. Actuators A Phys. 2002, 101, 364–370. [Google Scholar] [CrossRef]

- Kwok, K.W.; Chan, H.L.W.; Choy, C.L. Evaluation of the material parameters of piezoelectric materials by various methods. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 733–742. [Google Scholar] [CrossRef]

- Satoh, N.; Ueda, Y.; Yorimoto, T.; Aita, H.; Matsuo, S.; Ohata, N.; Watari, F. Firing Shrinkage of Porcelain-resin Composites Prepared by Laser Lithography. Dent. Mater. J. 1999, 18, 444–452. [Google Scholar] [CrossRef]

- Mori, H.; Kirihara, S.; Miyamoto, Y. Fabrication of three-dimensional ceramic photonic crystals and their electromagnetic properties. J. Eur. Ceram. Soc. 2006, 26, 2195–2198. [Google Scholar] [CrossRef]

- Delhote, N.; Baillargeat, D.; Verdeyme, S.; Delage, C.; Chaput, C. Ceramic Layer-By-Layer Stereolithography for the Manufacturing of 3-D Millimeter-Wave Filters. IEEE Trans. Microw. Theory Tech. 2007, 55, 548–554. [Google Scholar] [CrossRef]

- Jankowski, N.R.; Everhart, L.; Geil, B.R.; Tipton, C.W.; Chaney, J.; Heil, T.; Zimbeck, W. Stereolithographically fabricated aluminum nitride microchannel substrates for integrated power electronics cooling. In Proceedings of the 2008 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 28–31 May 2008; pp. 180–188. [Google Scholar]

- Popov, V.K.; Evseev, A.V.; Ivanov, A.L.; Roginski, V.V.; Volozhin, A.I.; Howdle, S.M. Laser stereolithography and supercritical fluid processing for custom-designed implant fabrication. J. Mater. Sci. Mater. Med. 2004, 15, 123–128. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Chen, X.; Zhao, N.; Dong, H.; Li, Y.; Lin, C. Stiff macro-porous bioactive glass–ceramic scaffold: Fabrication by rapid prototyping template, characterization and in vitro bioactivity. Mater. Chem. Phys. 2013, 141, 76–80. [Google Scholar] [CrossRef]

- Talib, M.; Covington, J.A.; Bolarinwa, A. Characterization of Fabricated Three Dimensional Scaffolds of Bioceramic-Polymer Composite via Microstereolithography Technique. AIP Conf. Proc. 2014, 1584, 129–135. [Google Scholar] [CrossRef]

- Hanemann, T.; Boehm, J.; Henzi, P.; Honnef, K.; Litfin, K.; Ritzhaupt-Kleissl, E.; Hausselt, J. From micro to nano: Properties and potential applications of micro- and nano-filled polymer ceramic composites in microsystem technology. IEE Proc. Nanobiotechnol. 2004, 151, 167–172. [Google Scholar] [CrossRef]

- Chartier, T.; Duterte, C.; Delhote, N.; Baillargeat, D.; Verdeyme, S.; Delage, C.; Chaput, C. Fabrication of Millimeter Wave Components Via Ceramic Stereo- and Microstereolithography Processes. J. Am. Ceram. Soc. 2008, 91, 2469–2474. [Google Scholar] [CrossRef]

- Kirihara, S.; Niki, T. Three-Dimensional Stereolithography of Alumina Photonic Crystals for Terahertz Wave Localization. Int. J. Appl. Ceram. Technol. 2015, 12, 32–37. [Google Scholar] [CrossRef]

- Chen, S.; Li, D.; Tian, X.; Wang, M.; Dai, W. Effective fabrication method of 3D ceramic photonic crystals with diamond structure. Rapid Prototyp. J. 2012, 18, 49–55. [Google Scholar] [CrossRef]

- Brakora, K.F.; Halloran, J.; Sarabandi, K. Design of 3-D Monolithic MMW Antennas Using Ceramic Stereolithography. IEEE Trans. Antennas Propag. 2007, 55, 790–797. [Google Scholar] [CrossRef]

- Stender, B.; Hilbert, F.; Dupuis, Y.; Krupp, A.; Mantei, W.; Houbertz, R. Manufacturing strategies for scalable high-precision 3D printing of structures from the micro to macro range. Adv. Opt. Technol. 2019, 8, 225–231. [Google Scholar] [CrossRef]

- Serbin, J.; Egbert, A.; Ostendorf, A.; Chichkov, B.N.; Houbertz, R.; Domann, G.; Schulz, J.; Cronauer, C.; Fröhlich, L.; Popall, M. Femtosecond laser-induced two-photon polymerization of inorganic–organic hybrid materials for applications in photonics. Opt. Lett. 2003, 28, 301–303. [Google Scholar] [CrossRef]

- Houbertz, R.; Schulz, J.; Serbin, J.; Chichkov, B. Schnelle Herstellung photonischer Kristalle: Echtzeit-3D-Lithographie mit Hybridpolymeren. Phys. Unserer Zeit 2005, 36, 278–285. [Google Scholar] [CrossRef]

- Farsari, M.; Filippidis, G.; Fotakis, C. Fabrication of three-dimensional structures by three-photon polymerization. Opt. Lett. 2005, 30, 3180–3182. [Google Scholar] [CrossRef]

- Collin, D. Untersuchungen zu photostrukturierbaren piezo- und ferroelektrischen Dünnschichten. Ph.D. Thesis, Julius Maximilian University Würzburg, Würzburg, Germany, 2014. [Google Scholar]

- Houbertz, R.; Declerck, P.; Passinger, S.; Ovsianikov, A.; Serbin, J.; Chichkov, B. Investigations on the generation of photonic crystals using two-photon polymerization (2PP) of inorganic-organic hybrid polymers with ultra-short laser pulses. Phys. Status Solidi 2007, 204, 3662–3675. [Google Scholar] [CrossRef]

- Stichel, T.; Hecht, B.; Houbertz, R.; Sextl, G. Compensation of spherical aberration influences for two-photon polymerization patterning of large 3D scaffolds. Appl. Phys. A Mater. 2015, 121, 187–191. [Google Scholar] [CrossRef]

- Williams, C.G.; Malik, A.N.; Kim, T.K.; Manson, P.N.; Elisseeff, J.H. Variable cytocompatibility of six cell lines with photoinitiators used for polymerizing hydrogels and cell encapsulation. Biomaterials 2005, 26, 1211–1218. [Google Scholar] [CrossRef] [PubMed]

- Obel, K.; Steenhusen, S.; Hümmer, J.; Jurado, G.; Wolter, H.; Houbertz, R.; Nique, S.; Sextl, G.; Walles, H. Novel partially degradable hybrid polymers for biomedical applications. In Proceedings of the 3rd European Symposium of Photopolymer Science, Wien, Austria, 9–12 September 2014. [Google Scholar]

- Hildebrand, G.; Müller, J.C.; Rost, J.; Liefeith, K. Zwei-Photonen-Polymerisation zur Additiven Fertigung von Keramiken. Abschlussbericht des iba Heiligenstadt zum Verbundvorhaben 2015 VF 0041 bzw. iba Teilprojekt (2015 FE 9117) im Rahmen der Richtlinie zur Förderung von Forschung, Technologie und Innovation (FTI) des Freistaats Thüringen; Thüringer Aufbaubank: Erfurt, Germany, 2019; pp. 1–54. [Google Scholar]

| Ceramic | Producer | Particle Size d50 [nm] | Particle Load [wt.%] | |

|---|---|---|---|---|

| Aerodisp W440 | Al2O3 | Evonik | 110 | 40 |

| Zirkonsol | ZrO2 | Nanostone | 35 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hildebrand, G.; Sänger, J.C.; Schirmer, U.; Mantei, W.; Dupuis, Y.; Houbertz, R.; Liefeith, K. Process Development for Additive Manufacturing of Alumina Toughened Zirconia for 3D Structures by Means of Two-Photon Absorption Technique. Ceramics 2021, 4, 224-239. https://doi.org/10.3390/ceramics4020017

Hildebrand G, Sänger JC, Schirmer U, Mantei W, Dupuis Y, Houbertz R, Liefeith K. Process Development for Additive Manufacturing of Alumina Toughened Zirconia for 3D Structures by Means of Two-Photon Absorption Technique. Ceramics. 2021; 4(2):224-239. https://doi.org/10.3390/ceramics4020017

Chicago/Turabian StyleHildebrand, Gerhard, Johanna C. Sänger, Uwe Schirmer, Willi Mantei, Yannick Dupuis, Ruth Houbertz, and Klaus Liefeith. 2021. "Process Development for Additive Manufacturing of Alumina Toughened Zirconia for 3D Structures by Means of Two-Photon Absorption Technique" Ceramics 4, no. 2: 224-239. https://doi.org/10.3390/ceramics4020017

APA StyleHildebrand, G., Sänger, J. C., Schirmer, U., Mantei, W., Dupuis, Y., Houbertz, R., & Liefeith, K. (2021). Process Development for Additive Manufacturing of Alumina Toughened Zirconia for 3D Structures by Means of Two-Photon Absorption Technique. Ceramics, 4(2), 224-239. https://doi.org/10.3390/ceramics4020017