Transient Thermo-Mechanical Analysis of Steel Ladle Refractory Linings Using Mechanical Homogenization Approach

Abstract

1. Introduction

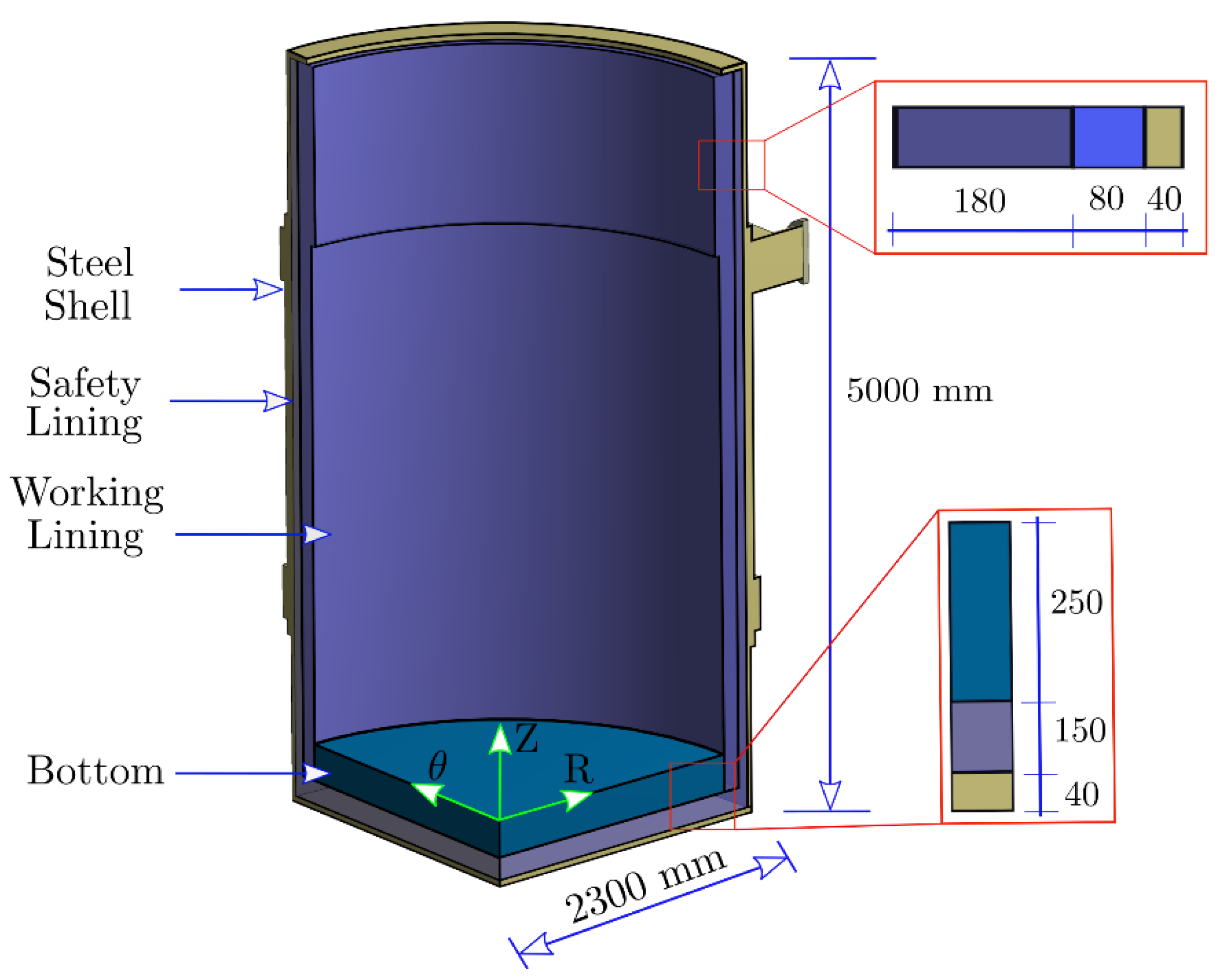

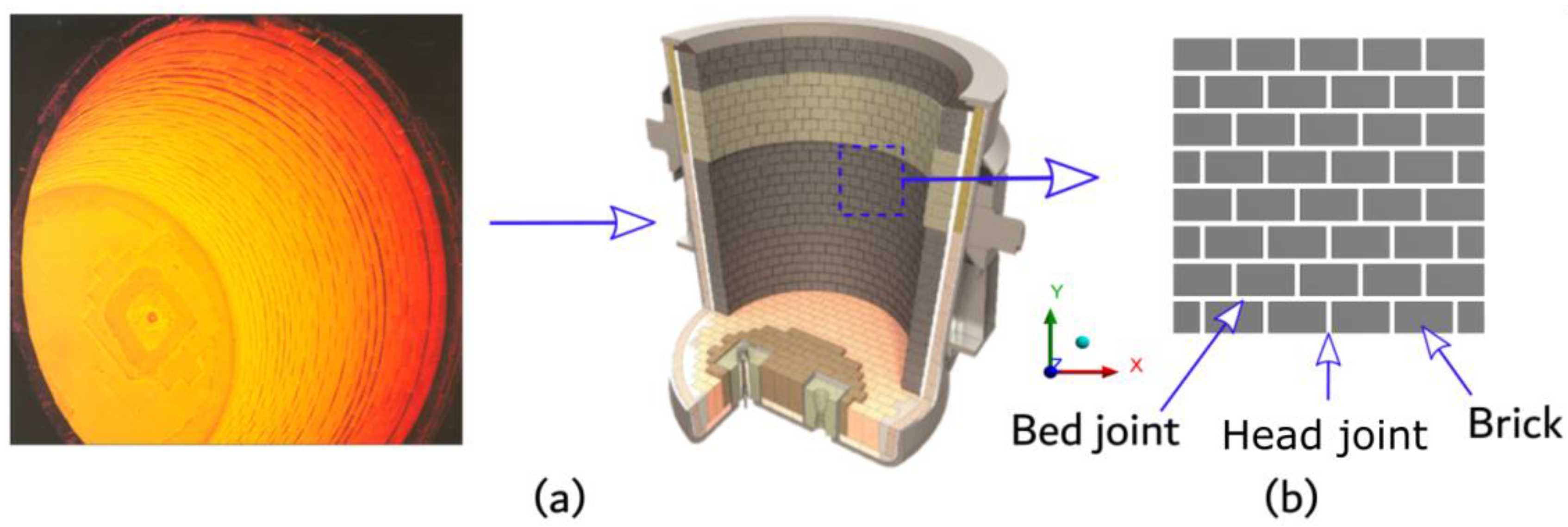

2. Thermo-Mechanical Modeling of a Steel Ladle

2.1. Physical Model and Materials

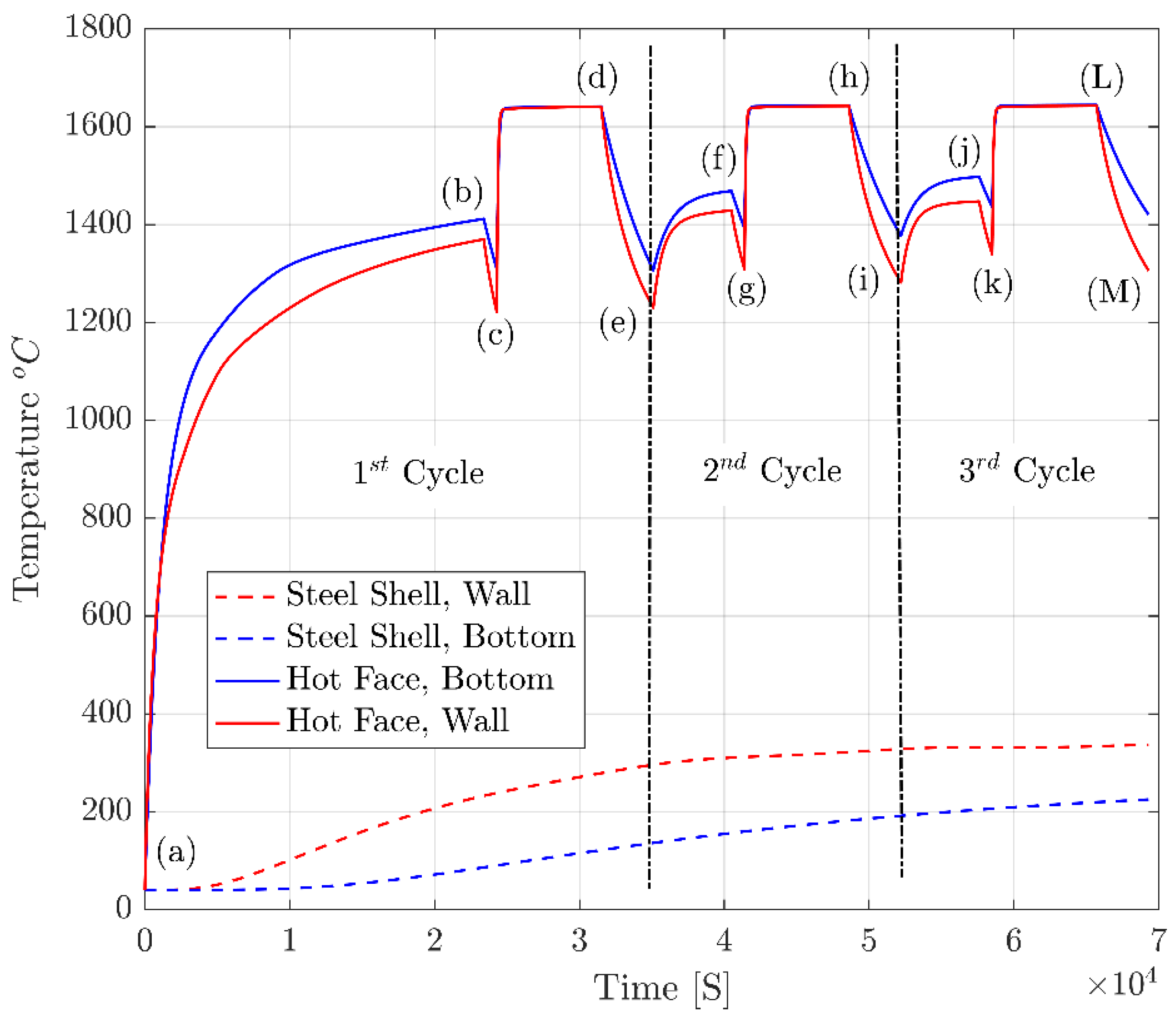

2.2. Process Description

2.3. Thermal and Mechanical Modelling

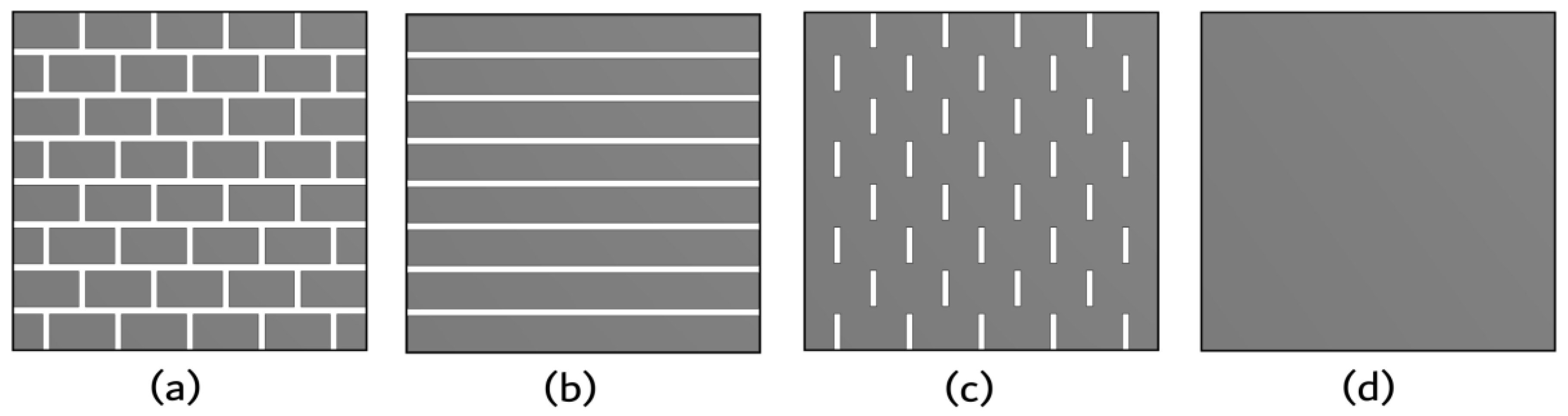

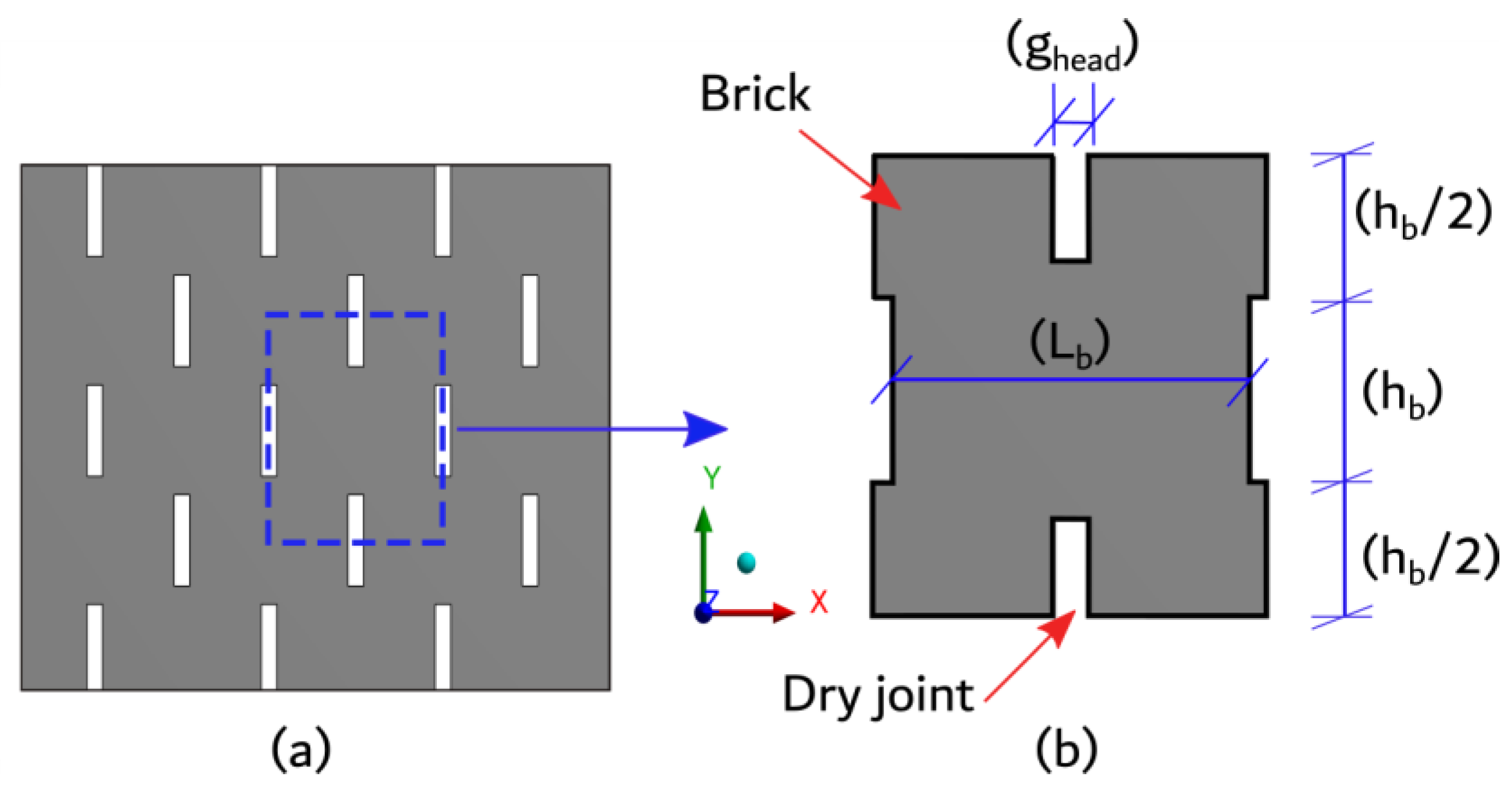

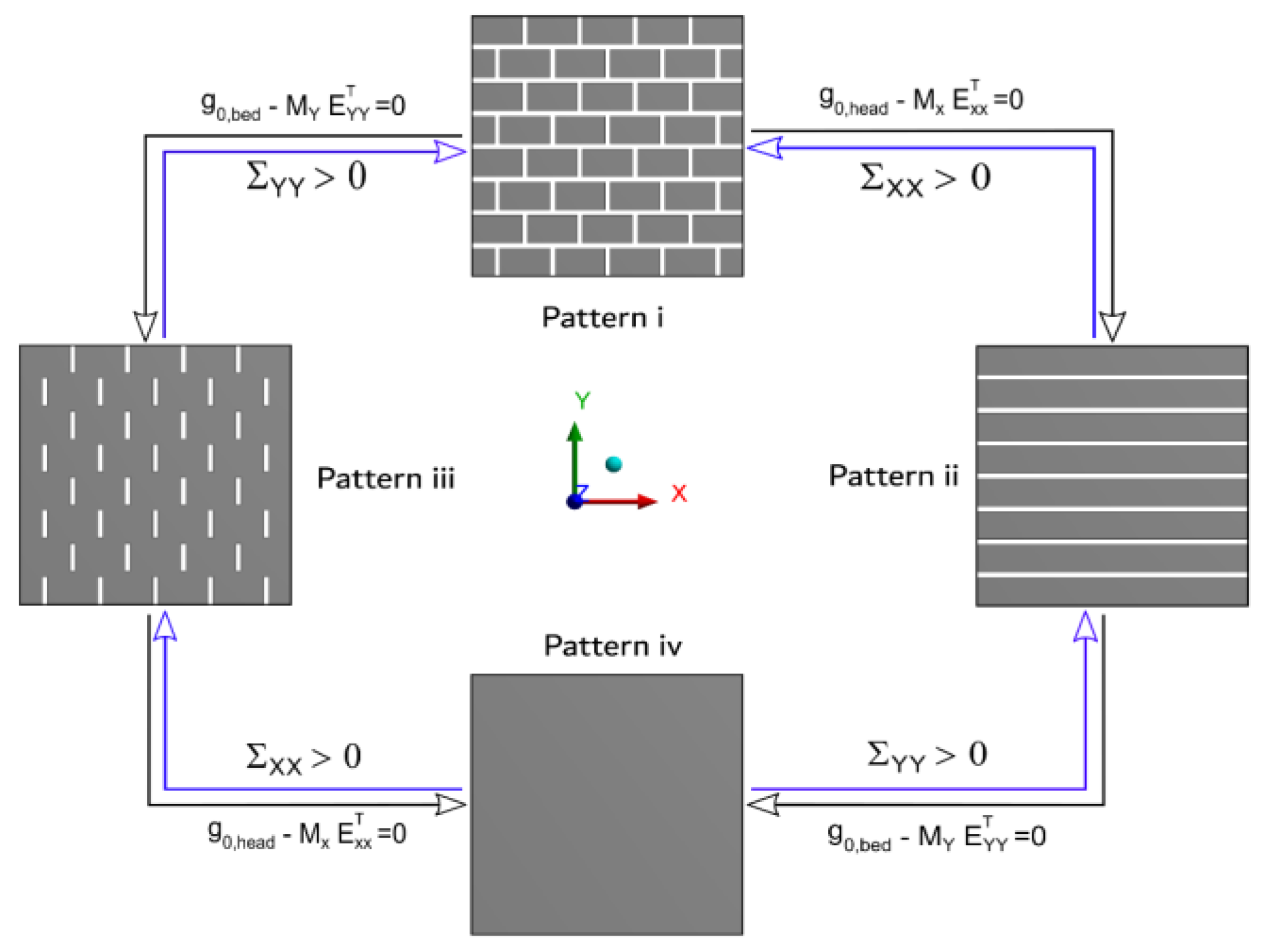

3. Mechanical Homogenization of Mortarless Masonry Structure

- Pattern i: Bed and head joints are open.

- Pattern ii: Bed joints are open, and head joints are closed.

- Pattern iii: Bed joints are closed, and head joints are open.

- Pattern iv: Bed and head joints are closed.

3.1. Equivalent Mechanical Behavior of Each Joint Pattern

3.1.1. Joint Pattern iv

3.1.2. Joint Pattern iii

3.1.3. Joint Pattern i

3.1.4. Joint Pattern ii

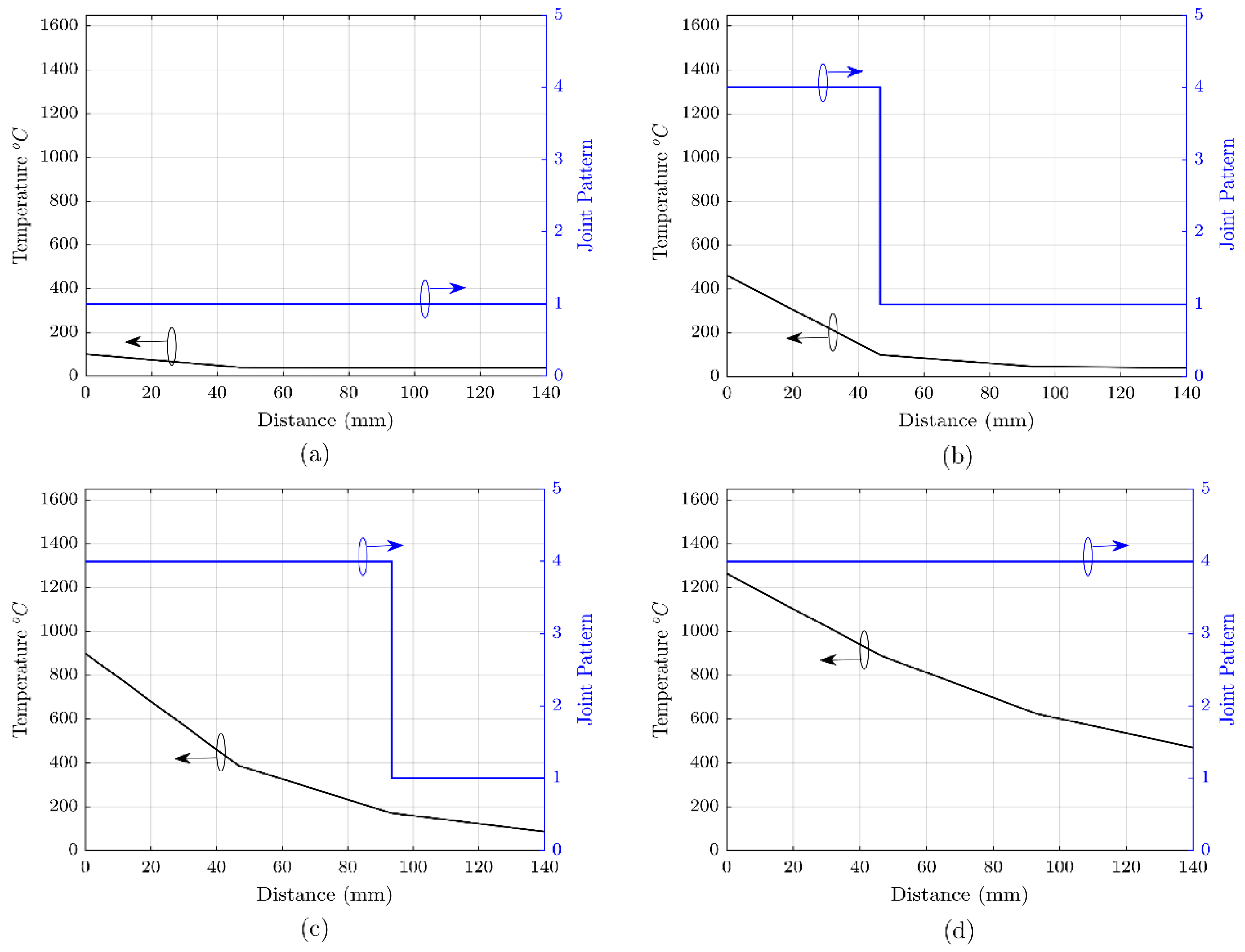

3.2. Joint Closure and Reopening Criteria

4. Results and Discussion

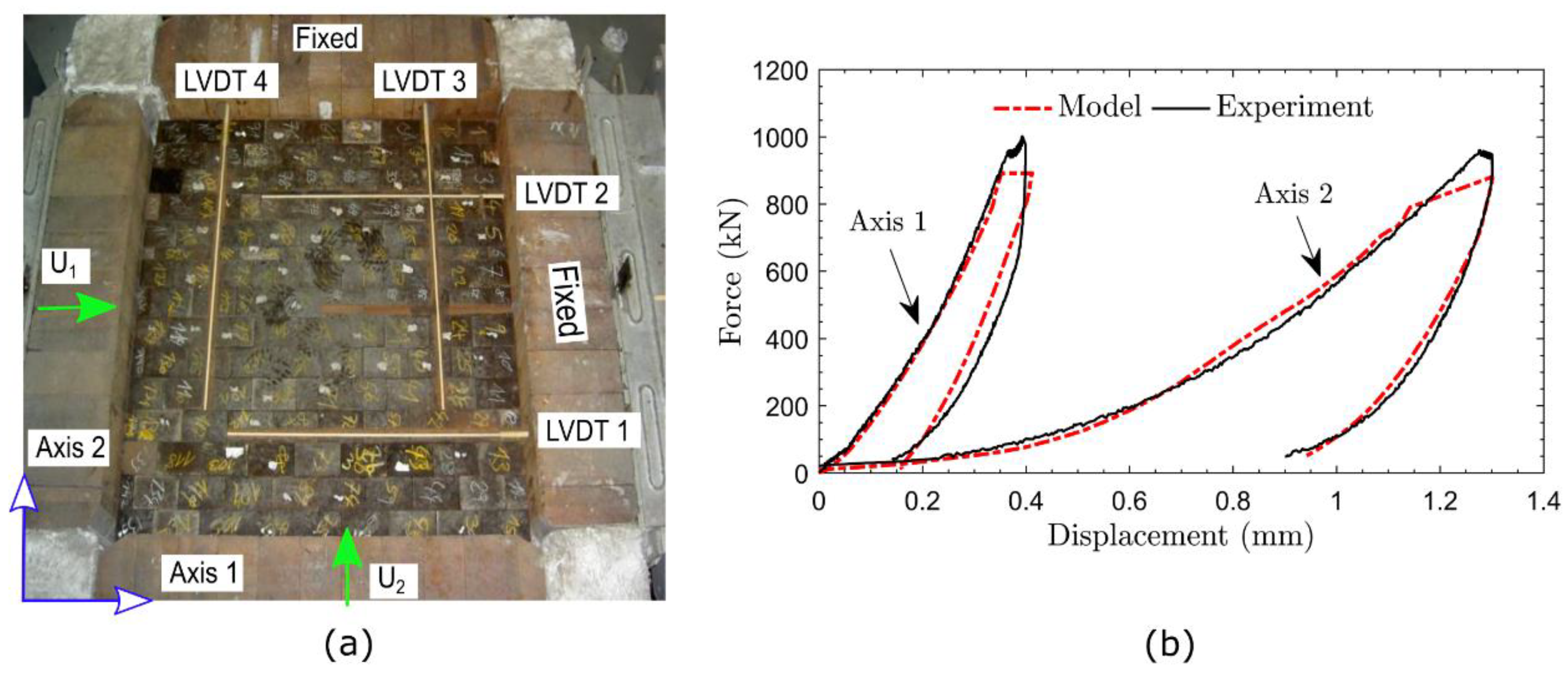

4.1. Validation of the Developed Homogenized Material Model

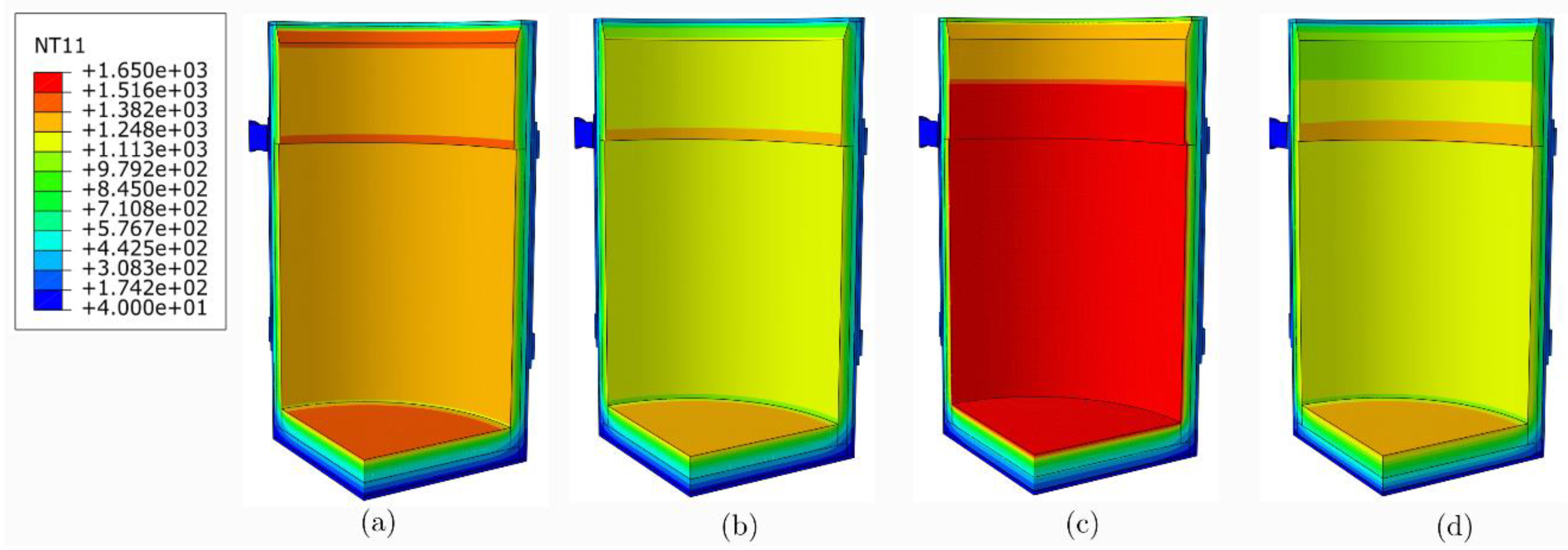

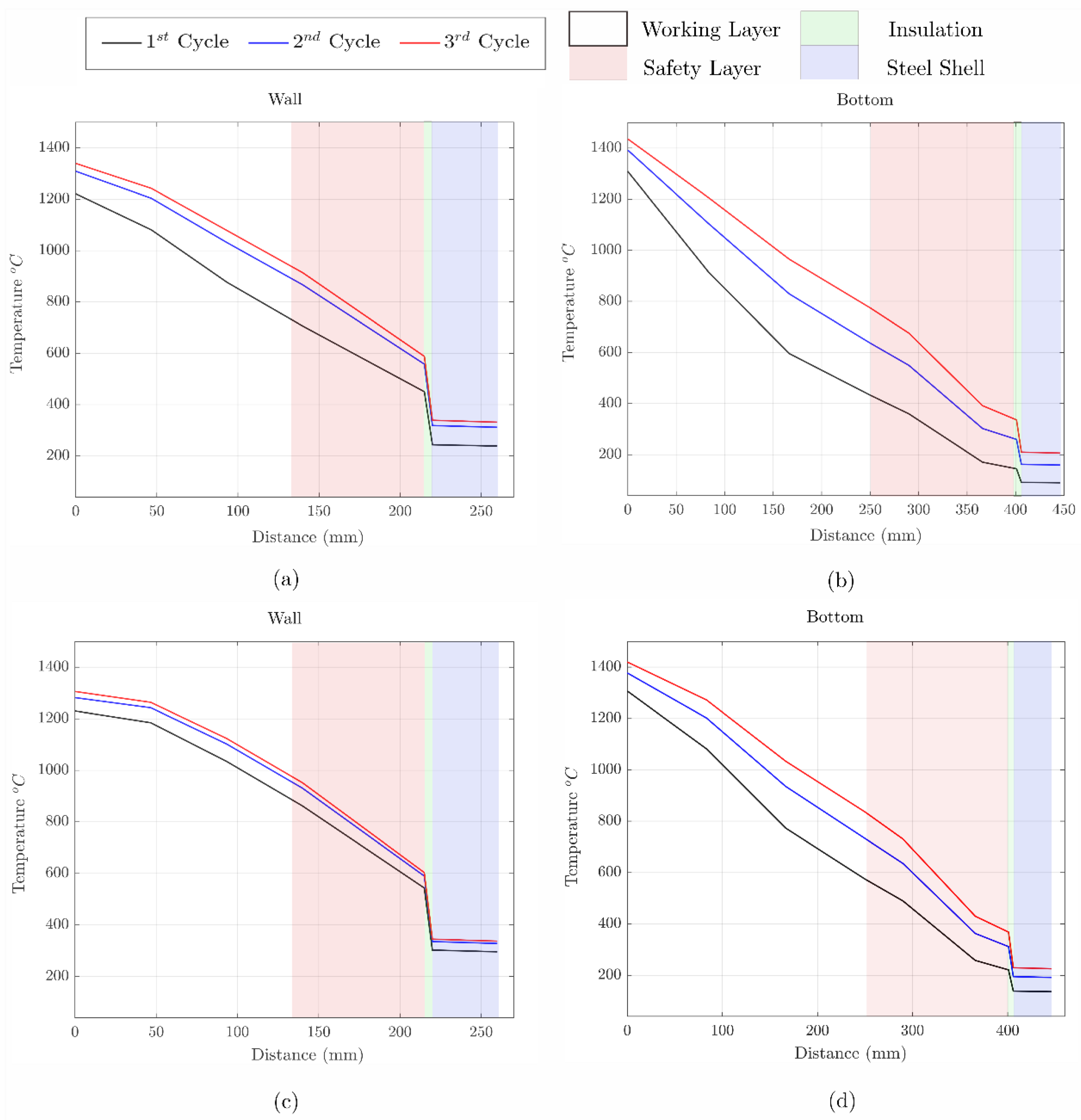

4.2. Temperature Distribution

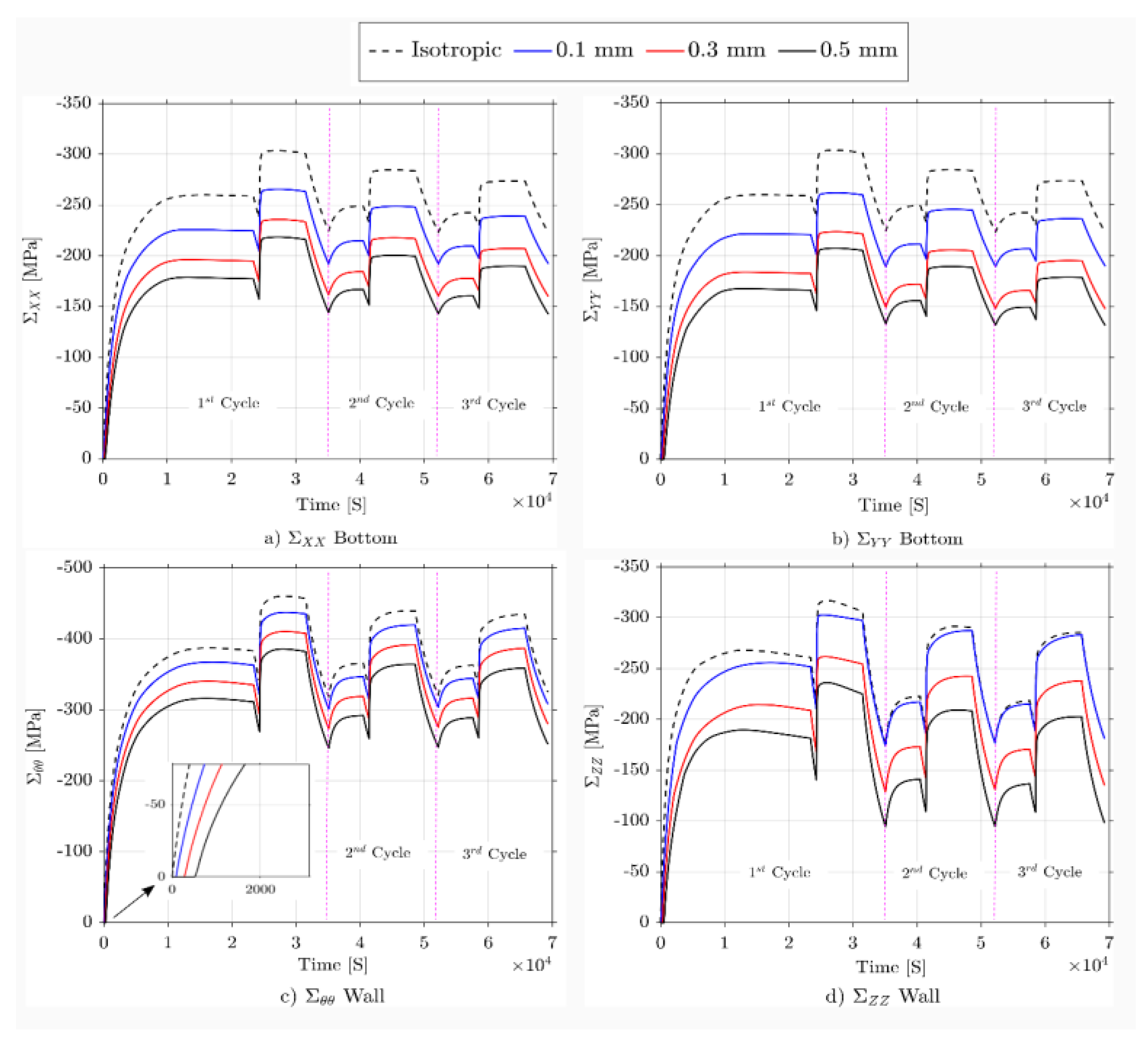

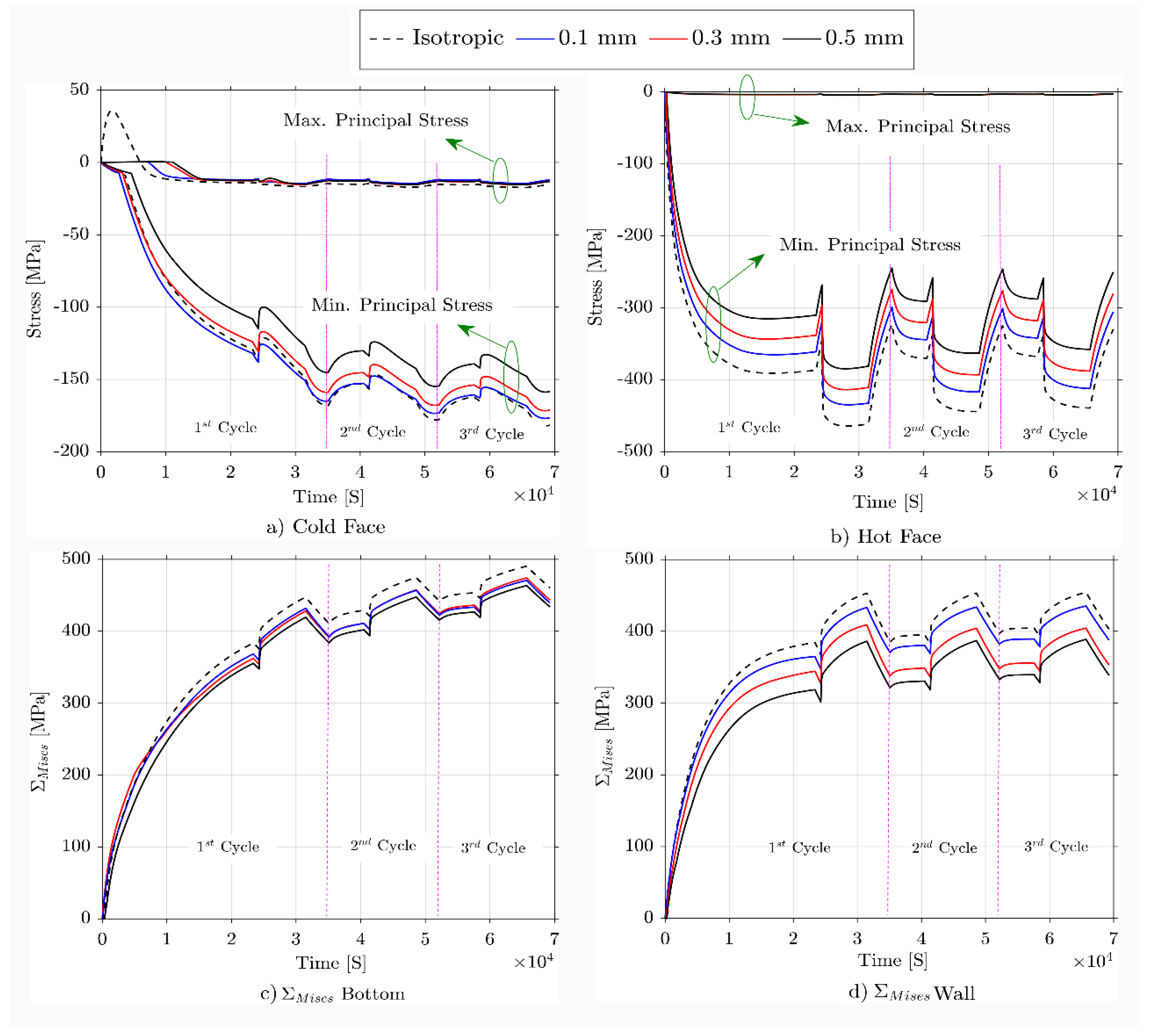

4.3. Stress Fields

5. Conclusions and Perspective

- With the increase in temperature, dry joints close gradually due to the thermal expansion of the bricks. Joints at the working lining hot surface close faster than joints at the cold surface.

- The temperature drop during the waiting time results in the opening of some joints at the outer top surface of the slag zone. Moreover, waiting time is an important issue to consider when defining the time period of each step of the ladle thermal cycle. Long waiting time leads to high energy losses and may result in the opening of joints at the wall and the bottom of the steel ladle just before tapping liquid steel in the ladle.

- Resulting thermal stresses in the hot face increase with the increase in temperature, and their trends are similar to those of the temperature during the four steps of the thermal ladle heating cycle. However, during the second and third thermal cycle, values of resulting thermal stresses are low compared to those of the first thermal cycle, as the maximum stress is proportional to the difference between the local maximum temperature and the average temperature in the thickness. Thus, after the second and third cycles, the average temperature is higher and the stress then decreases.

- The working lining hot face is under high compressive stresses; on the other hand, the cold face is under tensile stresses when joints are open during the first 10,000 s of step 1 of the first thermal cycle (1st preheating) and heat loss steps (steps 2 and 4 of the thermal cycle).

- Increasing joint thickness leads to a decrease in the resulting thermal stresses in the bottom and the wall of the working lining, as well as in the steel shell.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Blond, E.; Schmitt, N.; Hild, F.; Blumenfeld, P.; Poirier, J. Effect of Slag Impregnation on Thermal Degradations in Refractories. J. Am. Ceram. Soc. 2007, 90, 154–162. [Google Scholar] [CrossRef]

- Andreev, K.; Sinnema, S.; Rekik, A.; Allaoui, S.; Blond, E.; Gasser, A. Compressive behaviour of dry joints in refractory ceramic masonry. Constr. Build. Mater. 2012, 34, 402–408. [Google Scholar] [CrossRef]

- Allaoui, S.; Rekik, A.; Gasser, A.; Blond, E.; Andreev, K. Digital Image Correlation measurements of mortarless joint closure in refractory masonries. Constr. Build. Mater. 2018, 162, 334–344. [Google Scholar] [CrossRef]

- Nguyen, T.M.H.; Blond, E.; Gasser, A.; Prietl, T. Mechanical homogenisation of masonry wall without mortar. Eur. J. Mech. A Solids 2009, 28, 535–544. [Google Scholar] [CrossRef]

- Ali, M.; Sayet, T.; Gasser, A.; Blond, E. Thermomechanical Modelling of Refractory Mortarless Masonry Wall Subjected to Biaxial Compression. In Proceedings of the Unified International Technical Conference of Refractories, Yokohama, Japan, 13–16 October 2019. [Google Scholar]

- Xia, J.L.; Ahokainen, T. Transient flow and heat transfer in a steelmaking ladle during the holding period. Metall. Mater. Trans. B 2001, 32, 733–741. [Google Scholar] [CrossRef]

- Glaser, B.; Görnerup, M.; Sichen, D. Fluid Flow and Heat Transfer in the Ladle during Teeming. Steel Res. Int. 2011, 82, 827–835. [Google Scholar] [CrossRef]

- Santos, M.F.; Moreira, M.H.; Campos, M.G.G.; Pelissari, P.I.B.G.B.; Angélico, R.A.; Sako, E.Y.; Sinnema, S.; Pandolfelli, V.C. Enhanced numerical tool to evaluate steel ladle thermal losses. Ceram. Int. 2018, 44, 12831–12840. [Google Scholar] [CrossRef]

- Yilmaz, S. Thermomechanical Modelling for Refractory Lining of a Steel Ladle Lifted by Crane. Steel Res. Int. 2003, 74, 485–490. [Google Scholar] [CrossRef]

- Hou, A.; Jin, S.; Harmuth, H.; Gruber, D. A Method for Steel Ladle Lining Optimization Applying Thermomechanical Modeling and Taguchi Approaches. JOM 2018, 70, 2449–2456. [Google Scholar] [CrossRef]

- Gasser, A.; Chen, L.; Genty, F.; Daniel, J.L.; Blond, E.; Andreev, K.; Sinnema, S. Influence of different masonry designs of bottom linings. In Proceedings of the Unified International Technical Conference of Refractories, Victoria, BC, Canada, 10–13 September 2013. [Google Scholar]

- Shakhtin, D.M.; Pechenezhskii, V.I.; Karaulov, A.G.; Kvasman, N.M.; Kravchenko, V.P.; Kabakova, I.I.; Ustichenko, V.A.; Kalita, G.E.; Shcherbenko, G.N.; Yakobchuk, L.M. Thermal conductivity of corundum, high-alumina, magnesia, zirconium, and chromate refractories in the 400–1800 °C range. Refractories 1982, 23, 223–227. [Google Scholar] [CrossRef]

- Nemets, I.I.; Nestertsov, A.I.; Zagoskin, V.T.; Vysotskii, D.A.; Stavrovskii, G.I.; Chekhovskoi, V.Y. The thermal conductivity of periclase and periclase—Spinel refractories. Refractories 1975, 16, 178–180. [Google Scholar] [CrossRef]

- Díaz, L.A.; Torrecillas, R.; Simonin, F.; Fantozzi, G. Room temperature mechanical properties of high alumina refractory castables with spinel, periclase and dolomite additions. J. Eur. Ceram. Soc. 2008, 28, 2853–2858. [Google Scholar] [CrossRef]

- Pletcher, R.H.; Tannehill, J.C.; Anderson, D. Computational Fluid Mechanics and Heat Transfer; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Rekik, A.; Nguyen, T.T.N.; Gasser, A. Multi-level modeling of viscoelastic microcracked masonry. Int. J. Solids Struct. 2016, 81, 63–83. [Google Scholar] [CrossRef]

- Xia, Z.; Zhang, Y.; Ellyin, F. A unified periodical boundary conditions for representative volume elements of composites and applications. Int. J. Solids Struct. 2003, 40, 1907–1921. [Google Scholar] [CrossRef]

- Iltchev, A.; Marcadon, V.; Kruch, S.; Forest, S. Computational homogenisation of periodic cellular materials: Application to structural modelling. Int. J. Mech. Sci. 2015, 93, 240–255. [Google Scholar] [CrossRef]

- Hill, R. The essential structure of constitutive laws for metal composites and polycrystals. J. Mech. Phys. Solids 1967, 15, 79–95. [Google Scholar] [CrossRef]

- Michel, J.C.; Moulinec, H.; Suquet, P. Effective properties of composite materials with periodic microstructure: a computational approach. Comput. Methods Appl. Mech. Eng. 1999, 172, 109–143. [Google Scholar] [CrossRef]

| Lining | Zone | Properties | References | |

|---|---|---|---|---|

| Steel shell | Steel shell | ρ (kg/m3) | 7840 | [8,10] |

| k (W/m.K) | 47.3 at 200 °C 42.3 at 350 °C 37.3 at 500 °C | |||

| Cp (J/kg.K) | 530 at 200 °C | |||

| Y (GPa) | 210 at 20 °C 170 at 400 °C | |||

| CTE ( | 12 | |||

| Safety Lining | Bottom and wall bricks (dense layer) | ρ (kg/m3) | 2660 | [12] |

| k (W/m.K) | 2.6 at 400 °C 2.1 at 800 °C 2 at 1200 °C | |||

| Cp (J/kg.K) | 1144 at 1200 °C | |||

| Y (GPa) | 45 | |||

| CTE ( | 6 | |||

| Bottom and wall insulation (porous layer) | ρ (kg/m3) | 510 | [8,10] | |

| k (W/m.K) | 0.15 at 250 °C 0.25 at 800 °C 0.34 at 1350 °C | |||

| Cp (J/kg.K) | 1047 | |||

| Y (GPa) | 0.3 | |||

| CTE ( | 9 | |||

| Working Lining | Bottom and wall | ρ (kg/m3) | 3210 | [10,13,14] |

| k (W/m.K) | 4.65 at 400 °C 3.49 at 700 °C 4.65 at 1000 °C 5.81 at 1300 °C | |||

| Cp (J/kg.K) | 1090 | |||

| Y (GPa) | 35 at 20 °C 37 at 1000 °C 38 at 1500 °C | |||

| CTE ( | 11 | |||

| Parameter | Pattern i | Pattern ii | Pattern iii | Pattern iv |

|---|---|---|---|---|

| 0 | 1 | 1 | ||

| 0 | 0 | |||

| 0 | 0 | |||

| 0 | ||||

| 0 | 0 | |||

| 0 | 0 | |||

| First Cycle | Second Cycle | Third Cycle | ||||

|---|---|---|---|---|---|---|

| Duration (h) | Corresponding Points | Duration (h) | Corresponding Points | Duration (h) | Corresponding Points | |

| Step 1 | 6.5 | a to b | 1.5 | e to f | 1.5 | i to j |

| Step 2 | 0.25 | b to c | 0.25 | f to g | 0.25 | j to k |

| Step 3 | 2 | c to d | 2 | g to h | 2 | k to L |

| Step 4 | 1 | d to e | 1 | h to i | 1 | L to M |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.; Sayet, T.; Gasser, A.; Blond, E. Transient Thermo-Mechanical Analysis of Steel Ladle Refractory Linings Using Mechanical Homogenization Approach. Ceramics 2020, 3, 171-189. https://doi.org/10.3390/ceramics3020016

Ali M, Sayet T, Gasser A, Blond E. Transient Thermo-Mechanical Analysis of Steel Ladle Refractory Linings Using Mechanical Homogenization Approach. Ceramics. 2020; 3(2):171-189. https://doi.org/10.3390/ceramics3020016

Chicago/Turabian StyleAli, Mahmoud, Thomas Sayet, Alain Gasser, and Eric Blond. 2020. "Transient Thermo-Mechanical Analysis of Steel Ladle Refractory Linings Using Mechanical Homogenization Approach" Ceramics 3, no. 2: 171-189. https://doi.org/10.3390/ceramics3020016

APA StyleAli, M., Sayet, T., Gasser, A., & Blond, E. (2020). Transient Thermo-Mechanical Analysis of Steel Ladle Refractory Linings Using Mechanical Homogenization Approach. Ceramics, 3(2), 171-189. https://doi.org/10.3390/ceramics3020016