Thermomechanical Characterisation of Mullite Zirconia Composites Sintered from Andalusite for High Temperature Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Elaboration of Composites

2.2. Microstructural Analysis

2.3. Mechanical Characterisation and Acoustic Emission (AE) Recording

- Ultrasonic contact pulse echography in transmission and reflection mode for elastic constants,

- Four points bending test for mechanical behaviour,

- Acoustic Emission (AE) technique for damage monitoring at room temperature (coupled with bending tests) and at high temperature during thermal cycles.

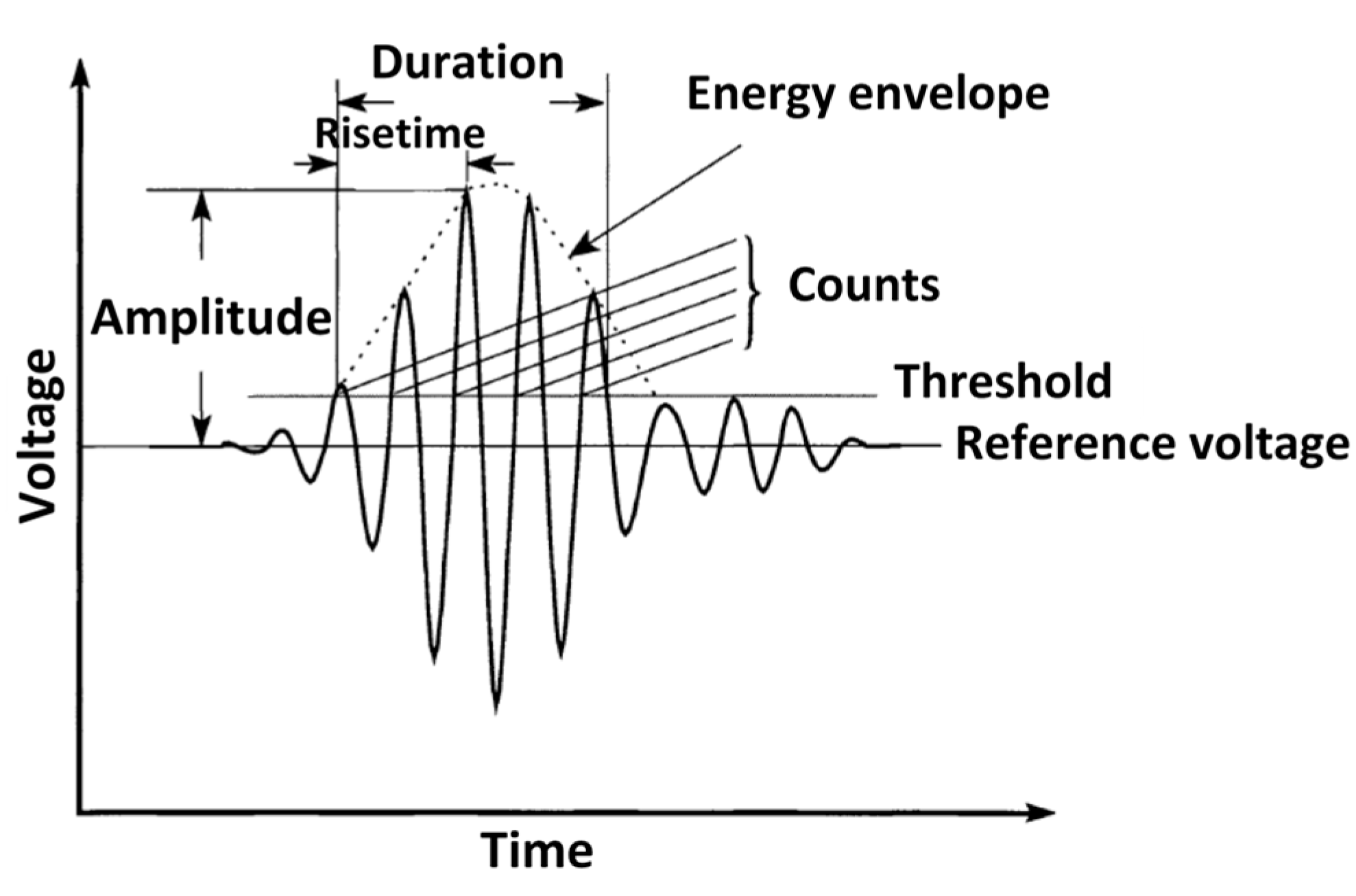

2.4. AE Recording

2.4.1. Background on Acoustic Emission Technique

- A high sensitivity to all damages mentioned above and the possibility of an early-stage detection;

- The possibility to detect defects in hard-to-reach areas;

- A real-time monitoring of phenomena in order to provide continuous information (also on the nature of AE source);

- AE monitoring is possible without interfering the normal functioning of material;

- The possibility of determining by triangulation of signal the location of the AE source and consequently of investigating changes occurring locally but also globally with respect to the complete structure.

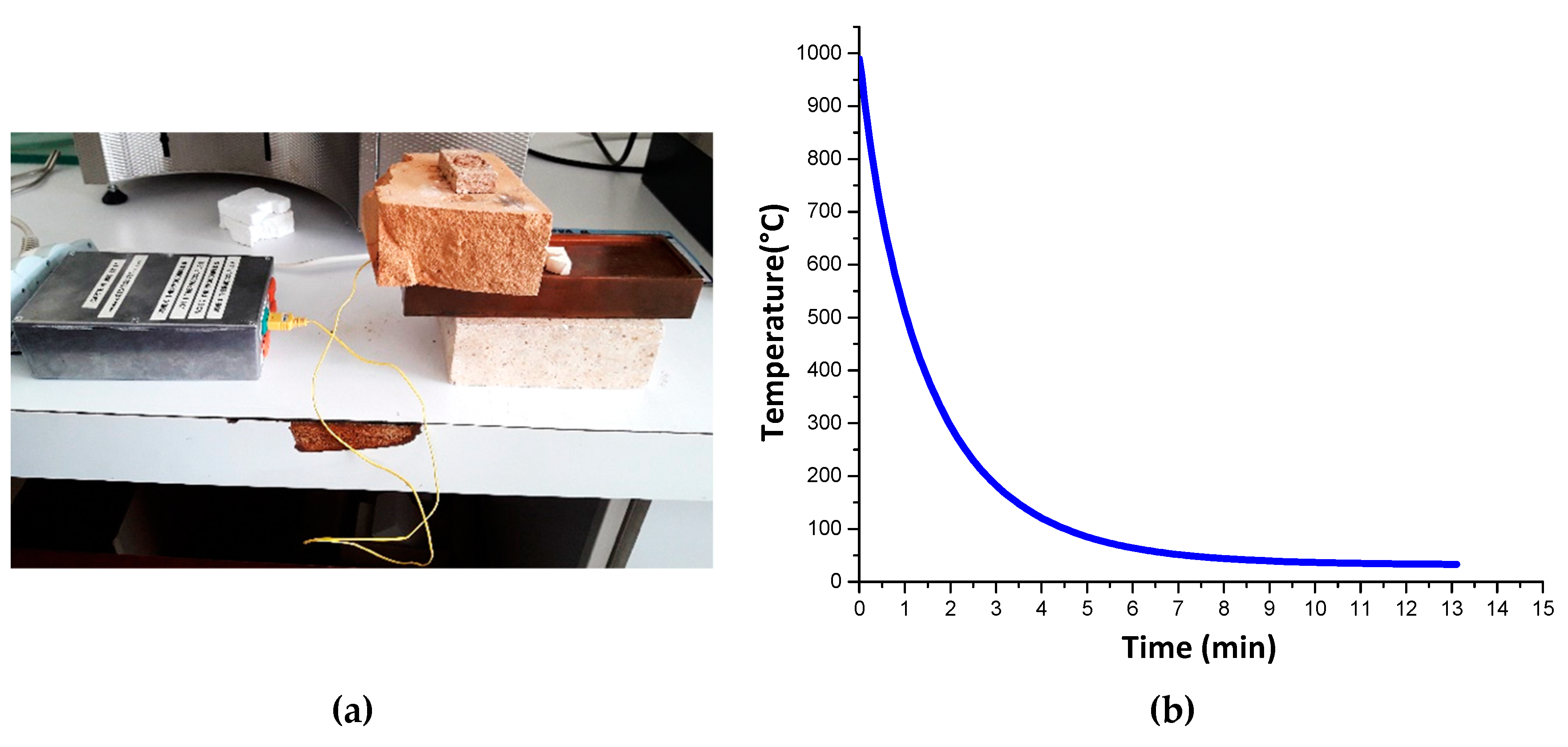

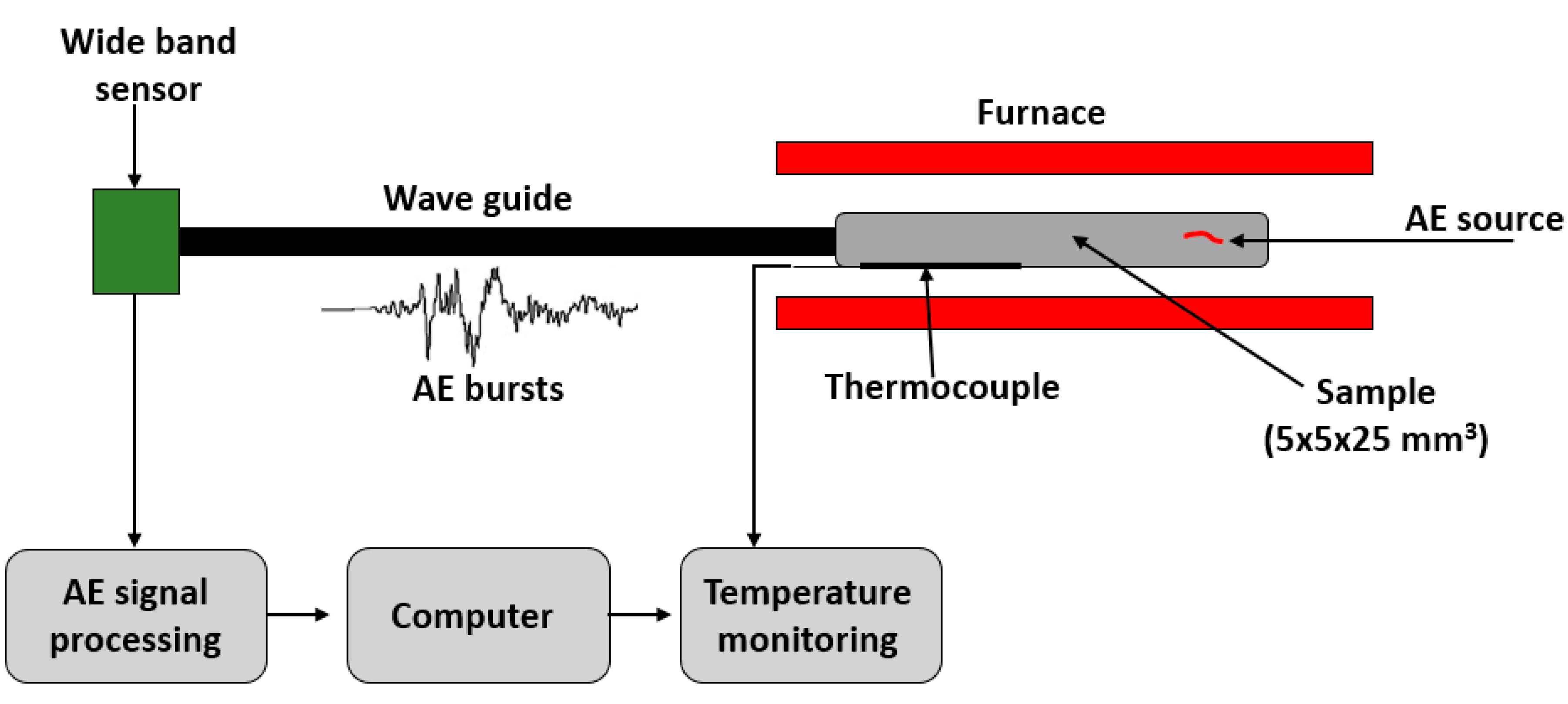

2.4.2. High-Temperature AE

3. Results and Discussion

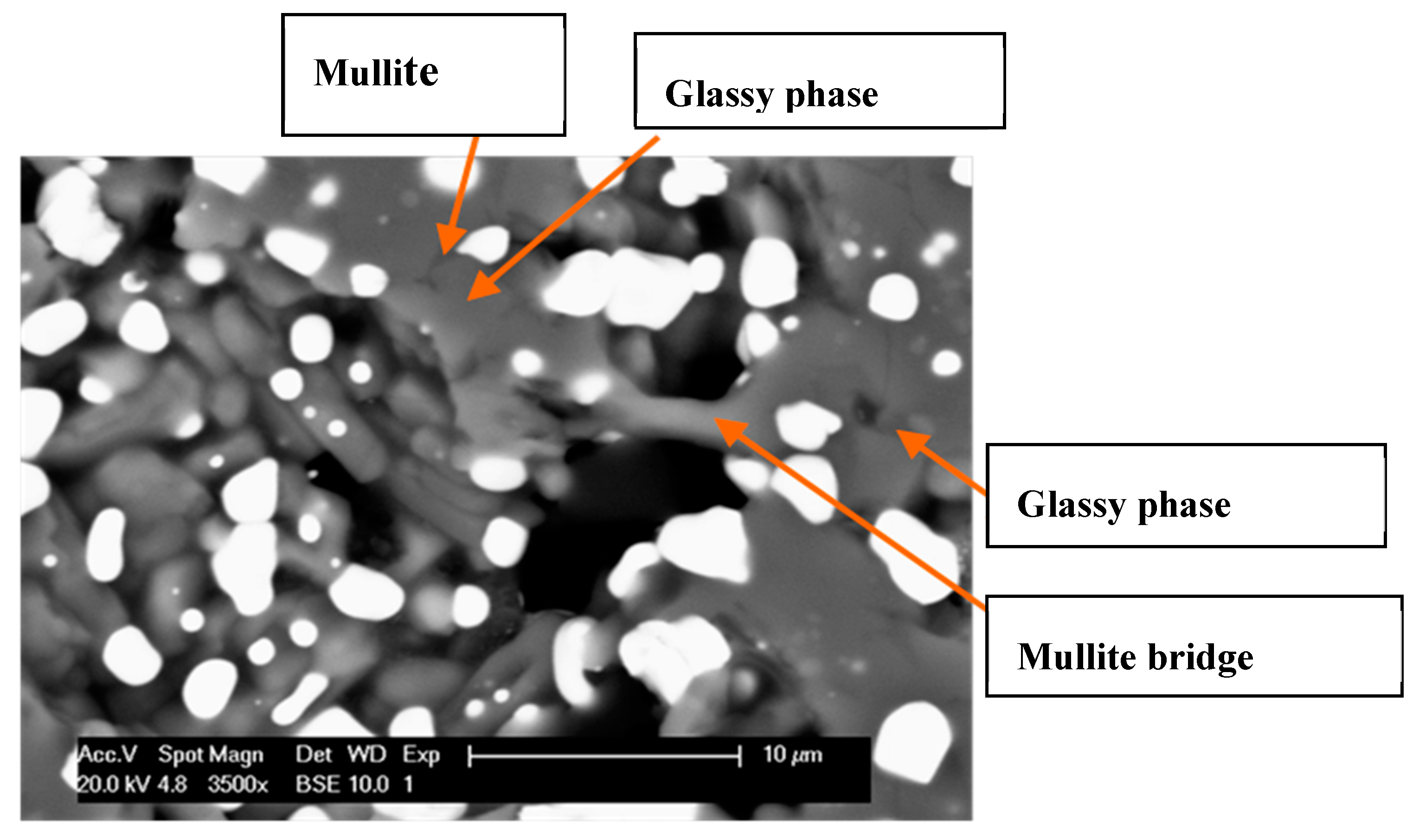

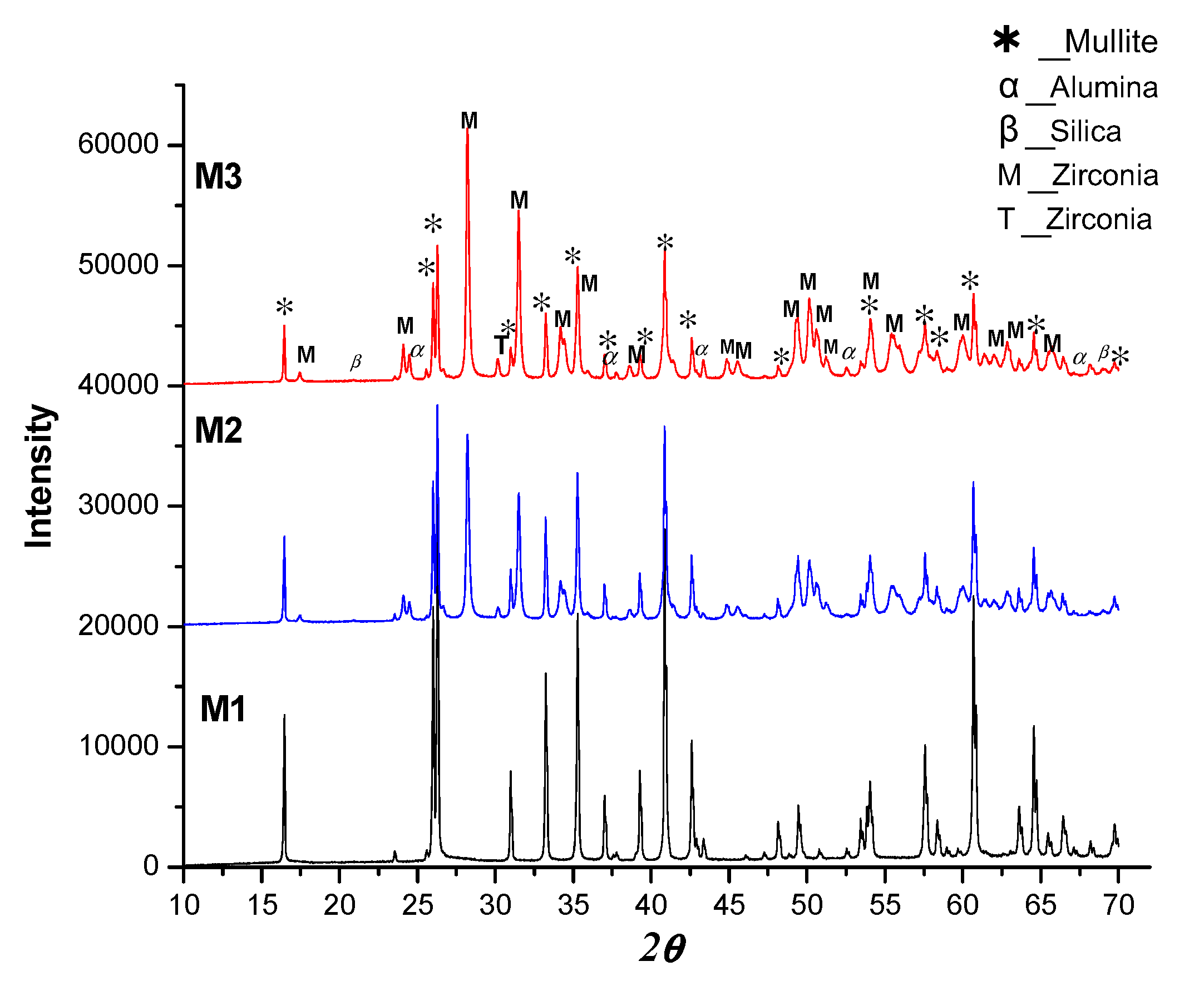

3.1. Microstructural Study

3.2. Mechanical and Thermomechanical Behaviour

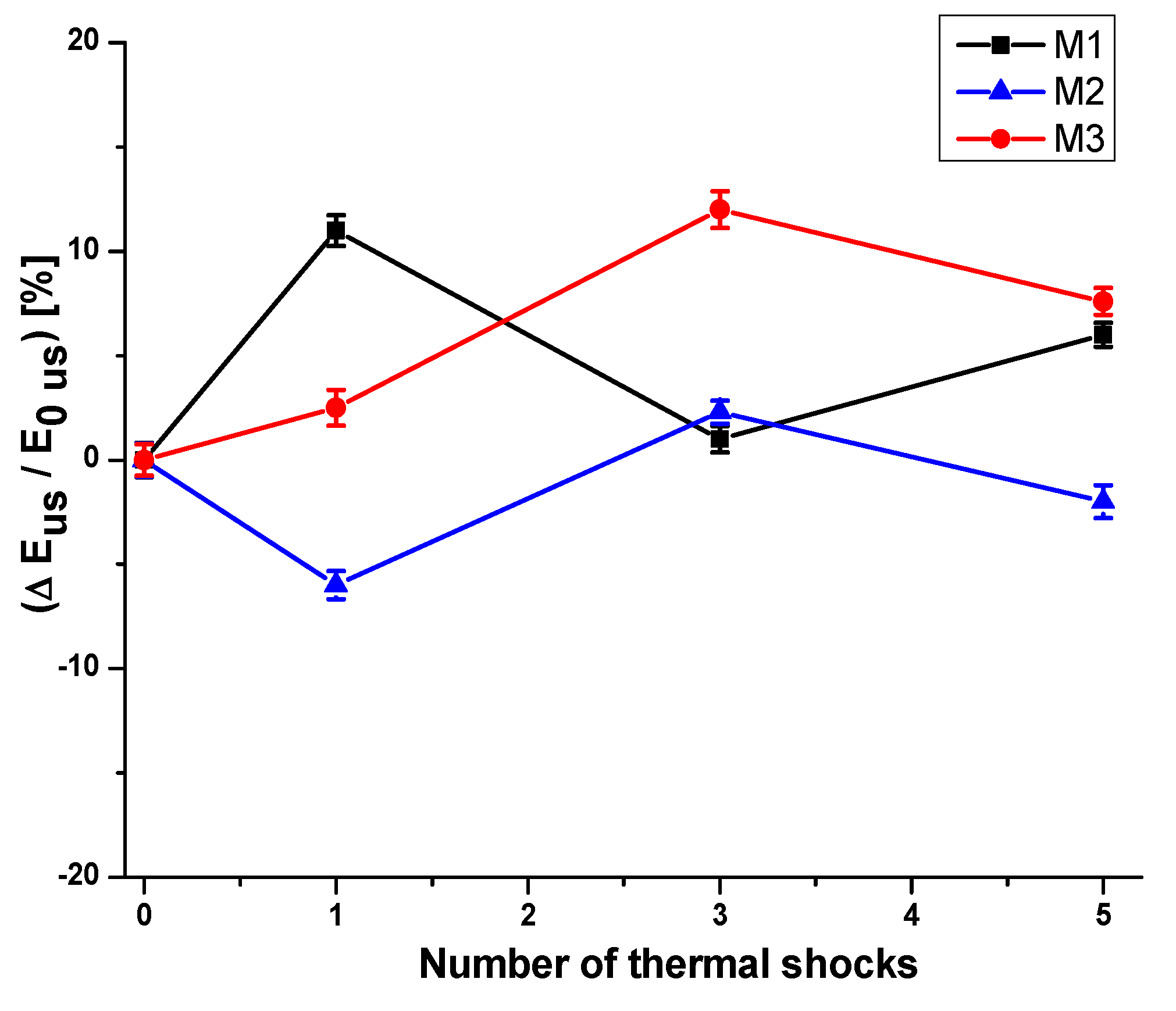

3.2.1. Elastic properties

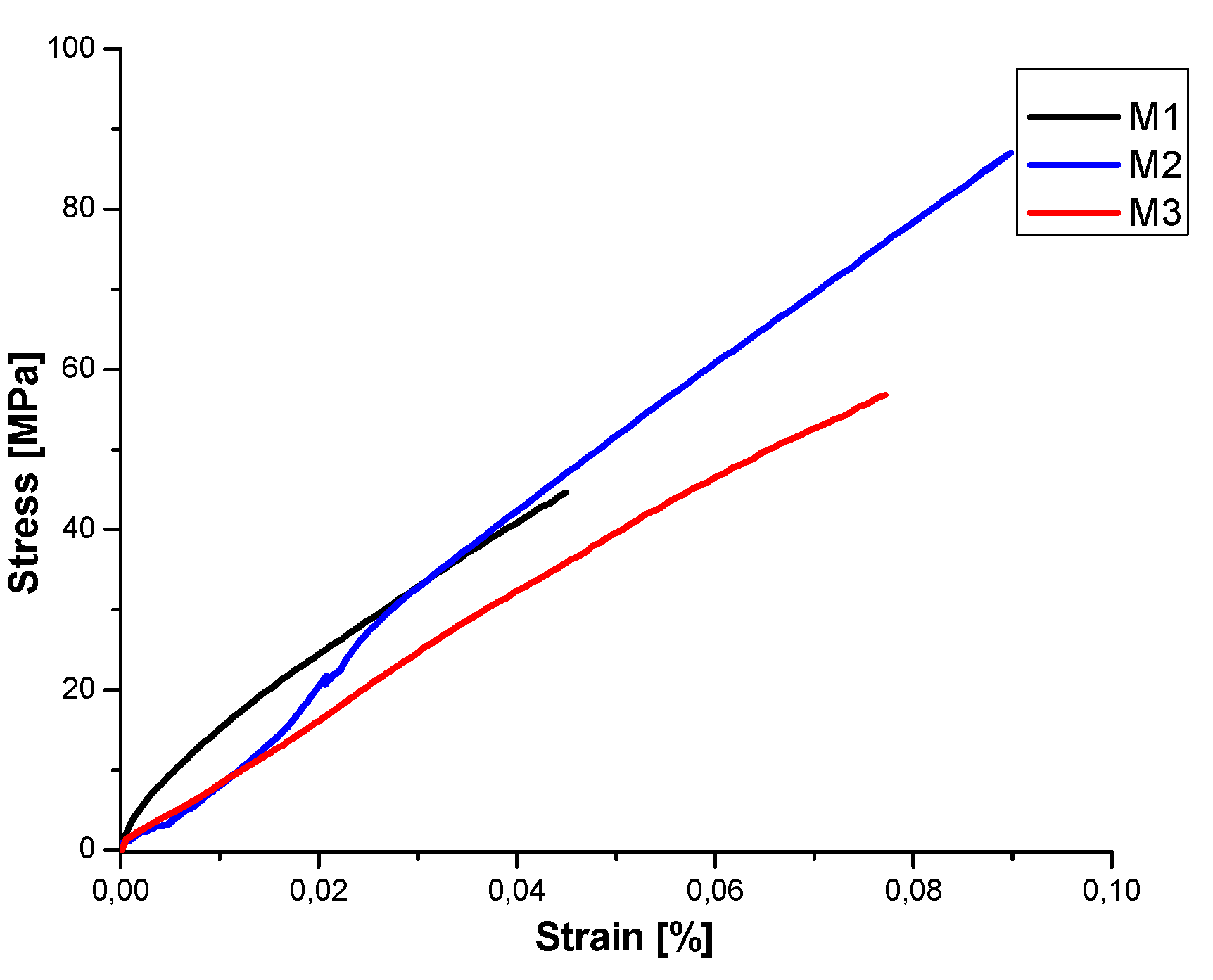

3.2.2. Damage Behaviour (before Thermal Shock)

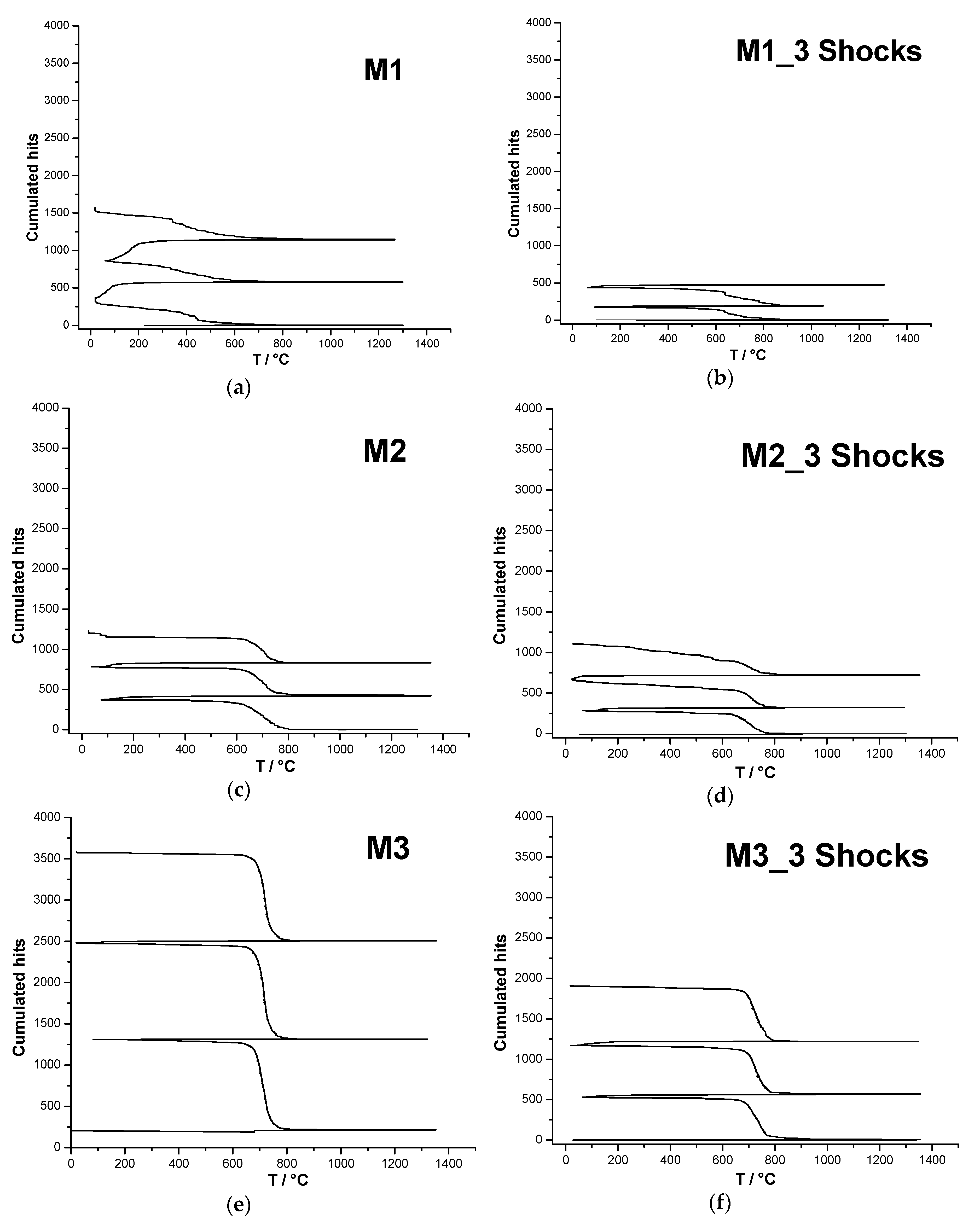

- Firstly, the AE activity (number of hits) increases with the amount of zirconia grains,

- The chronology of AE events occurrence is different between mullite sample (M1) and zirconia composites (M2 and M3).

3.2.3. Damage Behaviour (after Thermal Shock)

- The temperature range in the mullite-zirconia composites, where a sudden increase in acoustic activity is observed, could correspond to the temperature range of the martensitic transformation of zirconia during cooling. A previous study on high zirconia content refractories [22] showed that this activity could be related to the possible movement of the crystallographic variants present in zirconia grain at the time of transformation. The author also showed that this expansive transformation generates significant microcracking episodes, especially in the vitreous phase present at the ZrO2 dendrite interface. However, since this transformation is reversible, an acoustic activity during heating should have been recorded. The absence of signals during heating is explained by the low viscosity of the glassy phase at high temperature that acts as a low pass filter of the emitted signals, in this case high frequency signals.

- The higher value of accumulated hits (both before and after three thermal shocks) for M3 is most probably related to the higher amount of glassy phase present in the material. Unfortunately, we could not quantify the amount of secondary mullite after thermal shocks for the M3 samples, which would have most probably reinforced the above argumentation. However, a higher amount of zirconia particles is also noticed.

- The explanation for the difference in accumulated hit level (especially for M3; Figure 12e,f) before and after thermal shocks, could be associated with the following. The consecutive aspect of thermal shock in a composite containing the highest silica glassy phase amount leads to the possibility of the multiplication of secondary mullite bridges, consequently opposing the propagation of the microcracking induced by the thermal expansion and, in fact, generating less acoustic emission.

4. Conclusions

- Microcracking onset and propagation in mullite material for low stress-low strain level,

- Microcracking onset and propagation in zirconia-mullite composites for a higher level of stress and strain (increase of mechanical properties).

- Detection at an early stress-strain level of microcracking in glass rich composite sample (M3), where a greater amount of amorphous phase generated an increase in AE.

- The movement of crystallographic variants due to the martensitic transformation (M-T) to the cooling of zirconia particles.

- Cracks induced by expansion in the amorphous phase surrounding the zirconia particles.

Author Contributions

Funding

Conflicts of Interest

References

- Salmang, H.; Scholze, H.; Telle, R. Keramik, 7th ed.; Telle, R., Ed.; Springer: Berlin/Heideberg, Germany, 2007. [Google Scholar]

- Boch, P.; Giry, J.P. Preparation and properties of reaction-sintered mullite-ZrO2 ceramics. Mat. Sci. Eng. 1985, 71, 39–48. [Google Scholar] [CrossRef]

- Cambier, F.; Baudin, C.; La Lastra, D.; Pilate, P.; Leriche, A. Formation of microstructural defects in mullite-zirconia and mullite-alumina-zirconia composites obtained by reaction-sintering of mixed powders. Br. Ceram. Trans. J. 1984, 83, 196–200. [Google Scholar]

- Di Rupo, E.; Anseau, M.R. Solid state reactions in the ZrO2–SiO2–αAl2O3 system. J. Mater. Sci. 1980, 15, 114–118. [Google Scholar] [CrossRef]

- Rendtorff, N.; Garrido, L.; Aglietti, E. Mullite–zirconia–zircon composites: Properties and thermal shock resistance. Ceram. Int. 2009, 35, 779–786. [Google Scholar] [CrossRef]

- Rendtorff, N.; Garrido, L.; Aglietti, E. Thermal shock behaviour of dense mullite-zirconia composites obtained by two processing routes. Ceram. Int. 2008, 34, 2017–2024. [Google Scholar] [CrossRef]

- Hamidouche, M.; Bouaouadja, N.; Osmani, H.; Torrecillias, R.; Fantozzi, G. Thermomechanical behaviour of mullite-zirconia composite. J. Eur. Ceram. Soc. 1996, 16, 441–445. [Google Scholar] [CrossRef]

- Rendtorff, N.; Garrido, L.; Aglietti, E. Effect of the addition of mullite-zirconia to the thermal shock behavior of zircon materials. Mater. Sci. Eng. A 2008, 498, 208–215. [Google Scholar] [CrossRef]

- Chan, C.F.; Ko, Y.C. Effect of Cr2O3 on slag resistance of Al2O3-SiO2 refractories. J. Am. Ceram. Soc. 1992, 75, 2857–2861. [Google Scholar] [CrossRef]

- Bouchetou, M.L.; Poirier, J.; Joubert, O.; Weissenbacher, M. A new raw material: A sintered zirconia-mullite refractory composite. In Proceedings of the 60th International colloquium on refractories, Aachen, Germany, 18 October 2017; 2017; pp. 162–165. [Google Scholar]

- Walaan, T.; Psiuka, B.; Kubackib, J.; Steca, K.; Podwórnya, J. Mullitisation process of andalusite concentrates—role of natural inclusions. Ceram. Int. 2014, 40, 5129–5136. [Google Scholar]

- Xu, X.; Li, J.; Wu, J.; Tang, Z.; Chen, L.; Li, Y.; Lu, C. Preparation and thermal shock resistance of corundum-mullite composite ceramics from andalusite. Ceram. Int. 2017, 43, 1762–1767. [Google Scholar] [CrossRef]

- Bouchetou, M.L.; Poirier, J.; Morales, L.A.; Chotard, T.; Joubert, O.; Weissenbacher, M. Synthesis of an innovative zirconia-mullite raw material sintered from andalusite and zircon precursors and an evaluation of its corrosion and thermal shock performance. Ceram. Int. 2019, 45, 12832–12844. [Google Scholar] [CrossRef]

- Shull, P.J. Nondestructive Evaluation: Theory, Techniques, and Applications; CRC press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Integrity Diagnostics. Introduction to Acoustic Emission. Available online: http://www.idinspections.com/acoustic-emission-phenomenon/ (accessed on 31 March 2019).

- Kaphle, M.R. Analysis of Acoustic Emission Data for Accurate Damage Assessment for Structural Health Monitoring Applications. Ph.D. Thesis, Queensland University of Technology, Brisbane City, Australia, 2012. Available online: https://eprints.qut.edu.au/53201/ (accessed on 20 November 2018).

- Finlayson, R.D.; Friesel, M.; Carlos, M.; Cole, P.; Lenain, J.C. Health monitoring of aerospace structures with acoustic emission and acousto-ultrasonics. Insight-Wigston then Northampton 2001, 43, 155–158. [Google Scholar]

- Pannhorst, W.; Schneider, H. The high-temperature transformation of andalusite (A12SiO5) into 3/2-mullite (3A12O32SiO2) and vitreous silica (SiO2). Miner. Mag. 1978, 42, 195–198. [Google Scholar] [CrossRef]

- Aksel, C. Mechanical Properties of Alumina-Mullite-Zircon Refractories. In Key Engineering Materials; Trans Tech Publications: Stafa-Zurich, Switzerland, 2004; Volume 264–268, pp. 1791–1794. [Google Scholar] [CrossRef]

- Pooladvand, H.; Mirhadi, B.; Baghshahi, S.; Souri, A.R.; Arzani, K. Effects of alumina and zirconia addition on transformation of andalusite to mullite. Adv. Appl. Ceram. 2009, 108, 389–395. [Google Scholar] [CrossRef]

- Aksel, C.; Riley, F.L.; Konieczny, F. The Corrosion Resistance of Alumina-Mullite-Zircon Refractories in Molten Glass. In Key Engineering Materials; Trans Tech Publications: Stafa-Zurich, Switzerland, 2004; Volume 264–268, pp. 1803–1806. [Google Scholar] [CrossRef]

- Patapy, C. Comportement thermomécanique et transformations de phase de matériaux réfractaires électrofondus à très haute teneur en zircone. Ph.D. Thesis, Université de Limoges, Limoges, France, 2010. [Google Scholar]

| Component/Sample | D50 (µm) | M1 | M2 | M3 |

|---|---|---|---|---|

| Andalusite (% weight) | 5 | 69.49 | 28.46 | 5.05 |

| Alumina (% weight) | 0.8 | 30.51 | 39.35 | 44.40 |

| Zircon (% weight) | 1.3 | 0 | 32.19 | 50.55 |

| Solid fraction (Ø) | NA | NA | NA | NA |

| Phase Quantification (Rietveld) | M1 | M2 | M3 |

|---|---|---|---|

| Mullite (%) | 96.7 | 63.7 | 42.5 |

| Alumina (α) (%) | 3.3 | 1.9 | 5.5 |

| Monoclinic Zirconia (M) (%) | - | 16.7 | 23.4 |

| Tetragonal Zirconia (T) (%) | - | 0.5 | 1.1 |

| Quartz (%) | - | 0.9 | - |

| Amorphous phase (%) | - | 16.3 | 27.5 |

| Sample | M1 | M1_1S | M1_3S | M1_5S |

|---|---|---|---|---|

| E (GPa) | 91.5 | 103.0 | 92.4 | 97.9 |

| Sample | M2 | M2_1S | M2_3S | M2_5S |

| E (GPa) | 136.4 | 127.8 | 139.6 | 133.5 |

| Sample | M3 | M3_1S | M3_3S | M3_5S |

| E (GPa) | 116.9 | 120.0 | 132.5 | 126.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chotard, T.; Arbelaez Morales, L.; Bouchetou, M.-L.; Poirier, J. Thermomechanical Characterisation of Mullite Zirconia Composites Sintered from Andalusite for High Temperature Applications. Ceramics 2019, 2, 587-601. https://doi.org/10.3390/ceramics2040046

Chotard T, Arbelaez Morales L, Bouchetou M-L, Poirier J. Thermomechanical Characterisation of Mullite Zirconia Composites Sintered from Andalusite for High Temperature Applications. Ceramics. 2019; 2(4):587-601. https://doi.org/10.3390/ceramics2040046

Chicago/Turabian StyleChotard, Thierry, Lizeth Arbelaez Morales, Marie-Laure Bouchetou, and Jacques Poirier. 2019. "Thermomechanical Characterisation of Mullite Zirconia Composites Sintered from Andalusite for High Temperature Applications" Ceramics 2, no. 4: 587-601. https://doi.org/10.3390/ceramics2040046

APA StyleChotard, T., Arbelaez Morales, L., Bouchetou, M.-L., & Poirier, J. (2019). Thermomechanical Characterisation of Mullite Zirconia Composites Sintered from Andalusite for High Temperature Applications. Ceramics, 2(4), 587-601. https://doi.org/10.3390/ceramics2040046