Optimization of Water Tank Shape in Terms of Firefighting Vehicle Stability

Abstract

1. Introduction

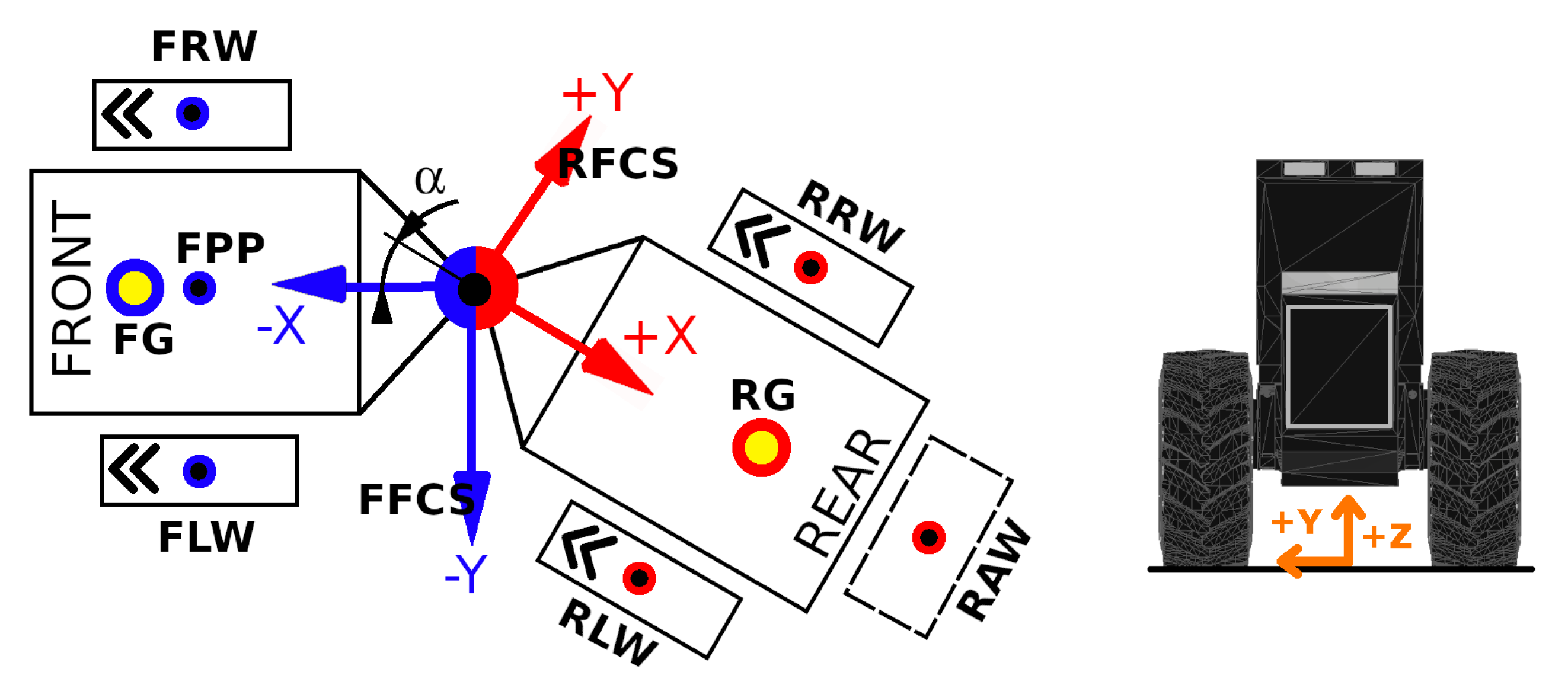

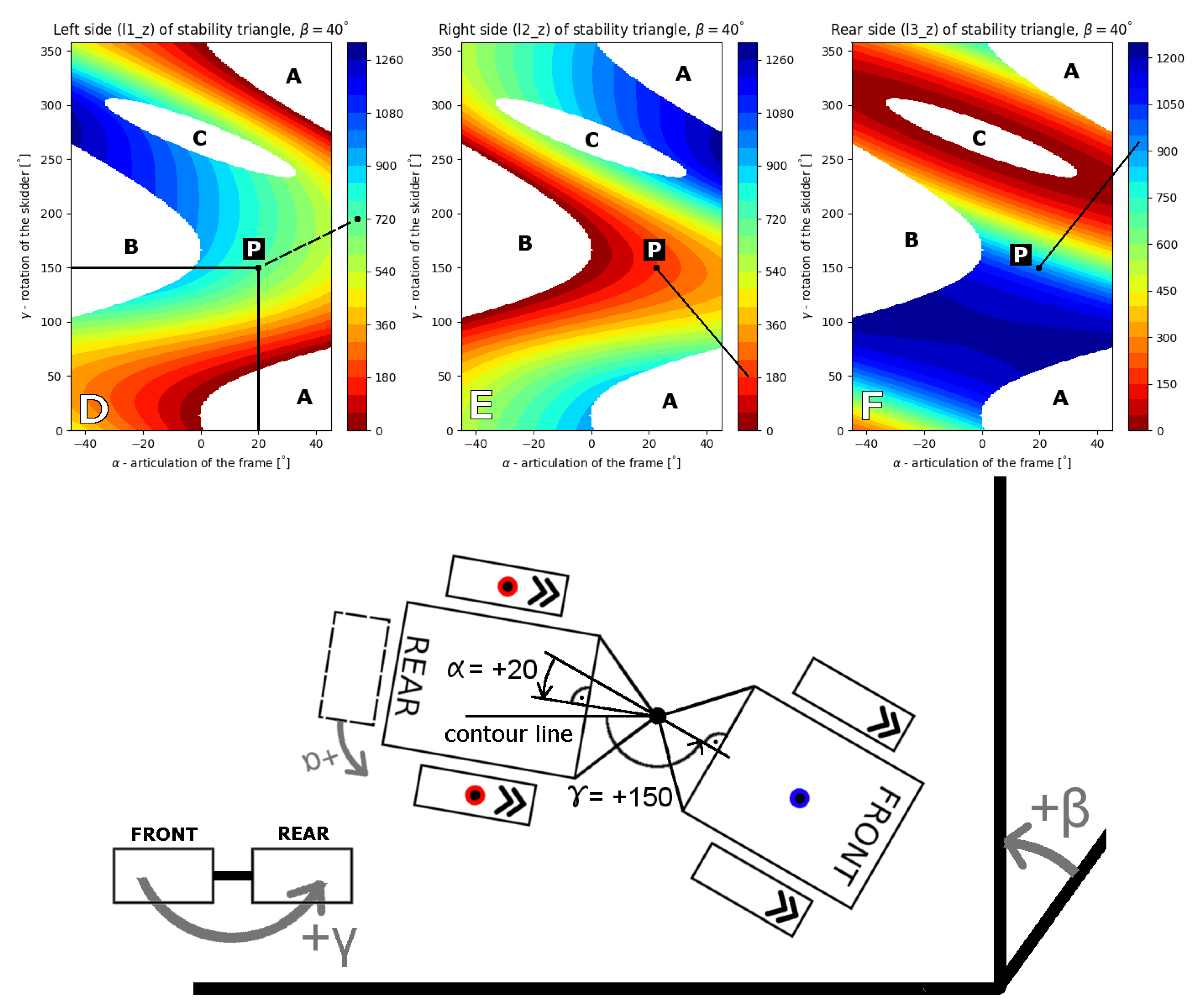

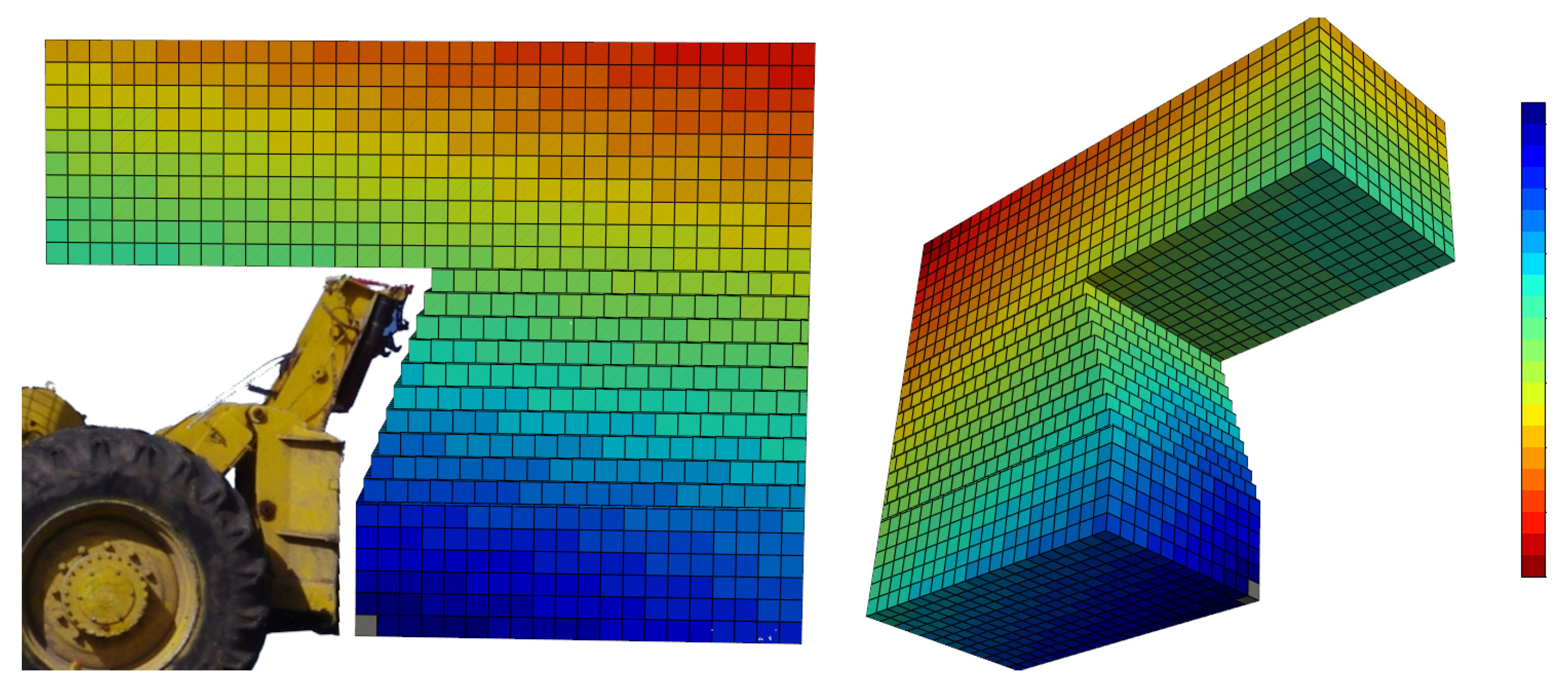

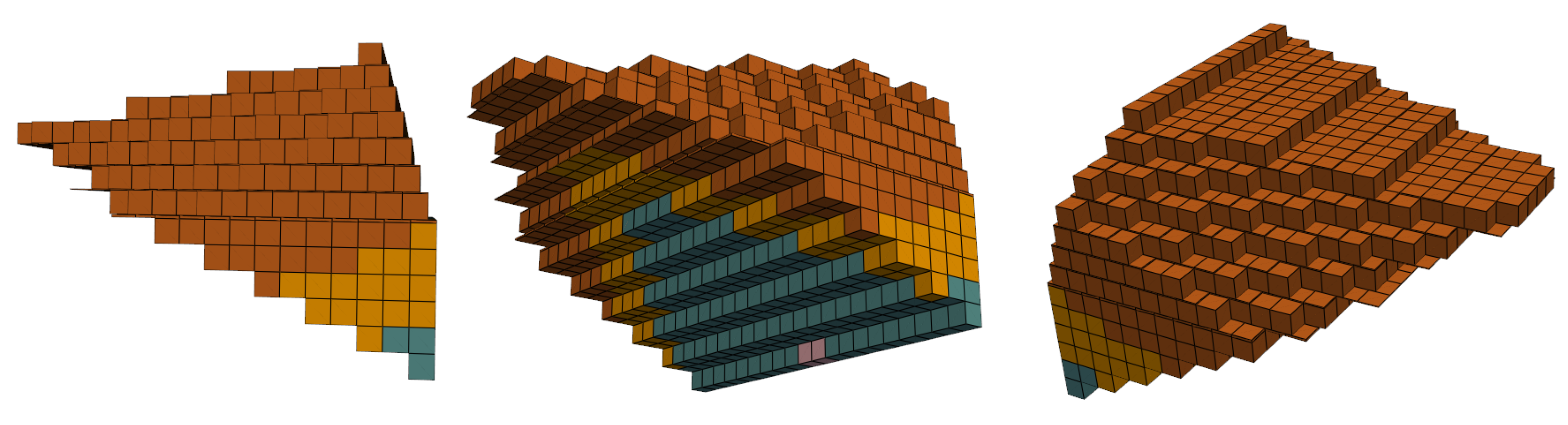

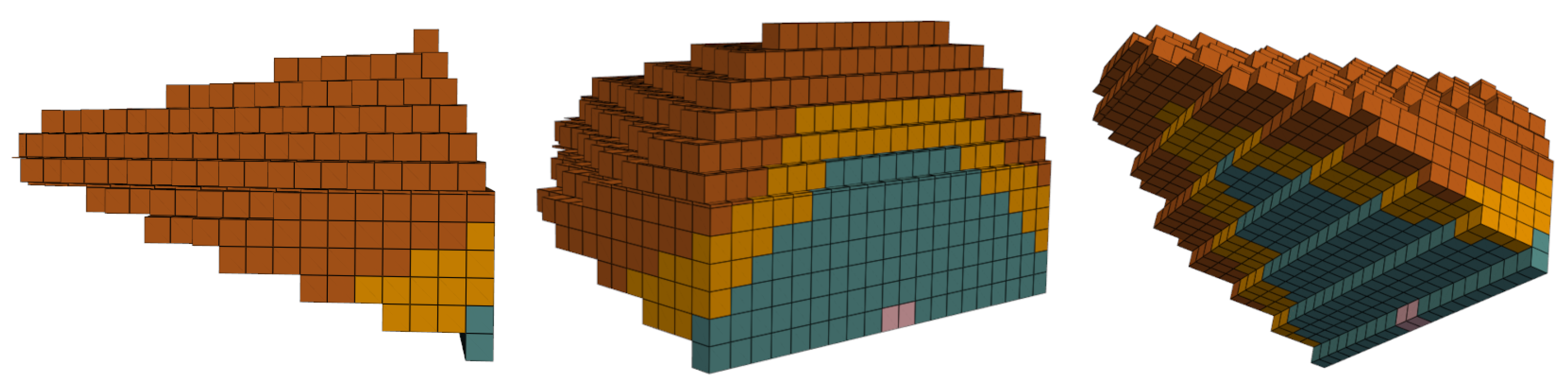

2. Materials and Methods

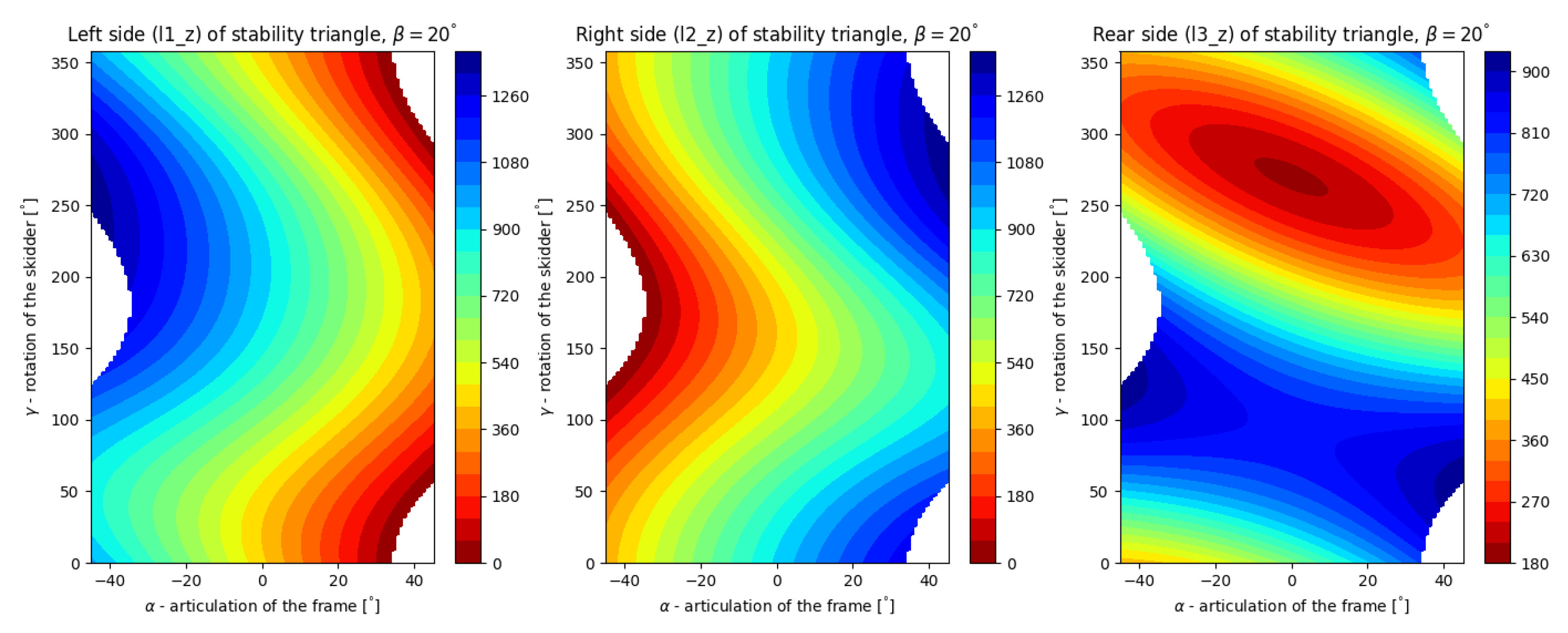

- Slope angle was a constant,

- Frame’s articulation was variable in interval of ,

- Skidder’s rotation on a slope was variable in interval of [9].

- Overall volume of the tank, using elements’ volumes in the first column,

- Position of the element, columns 2, 3 and 4.

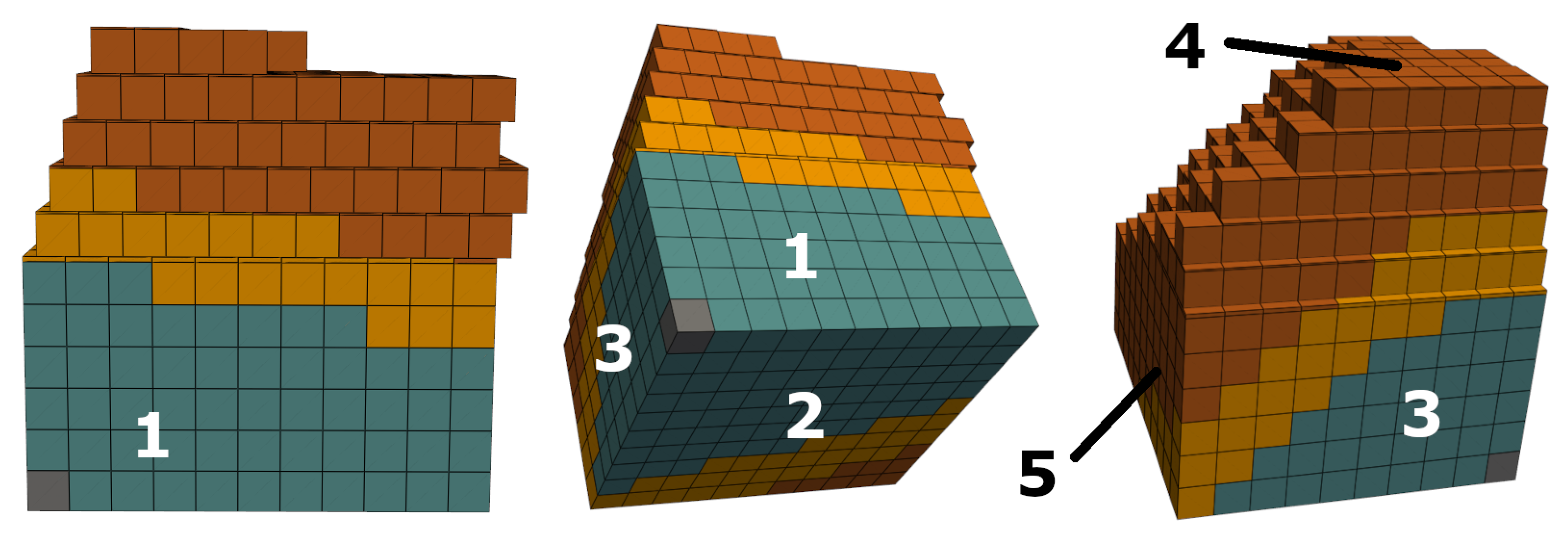

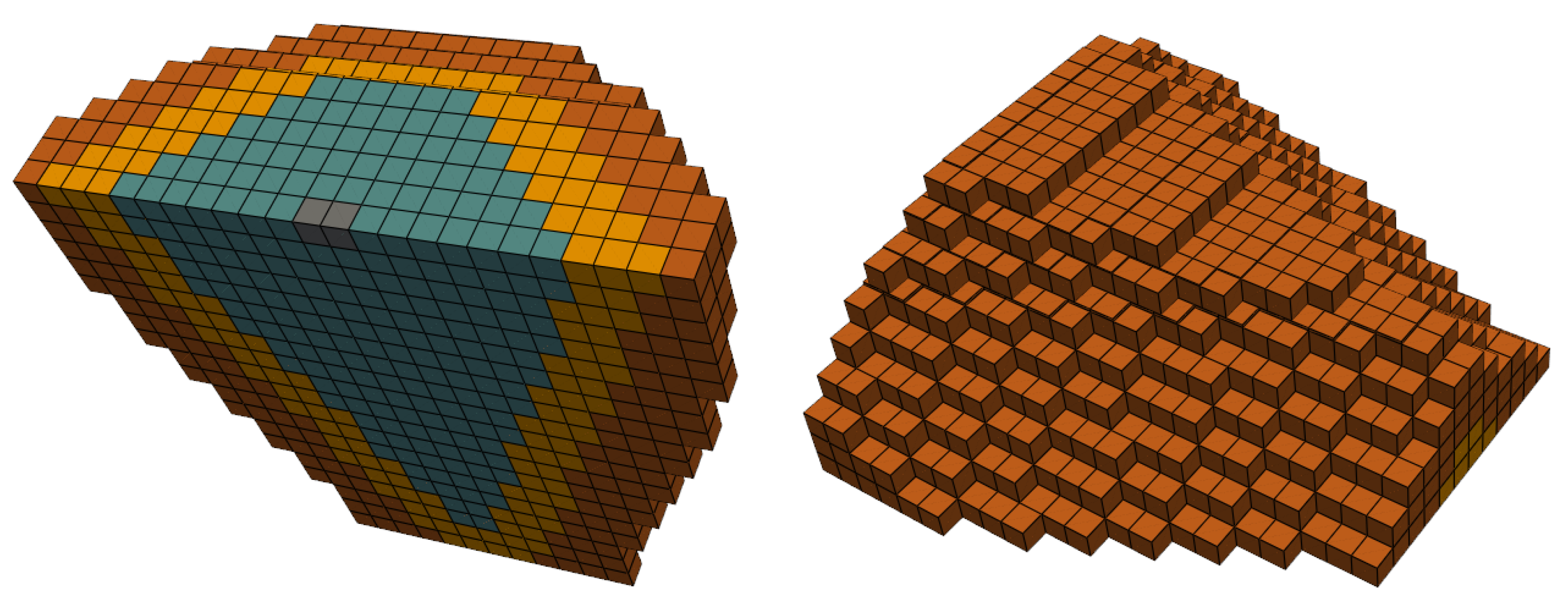

3. Results

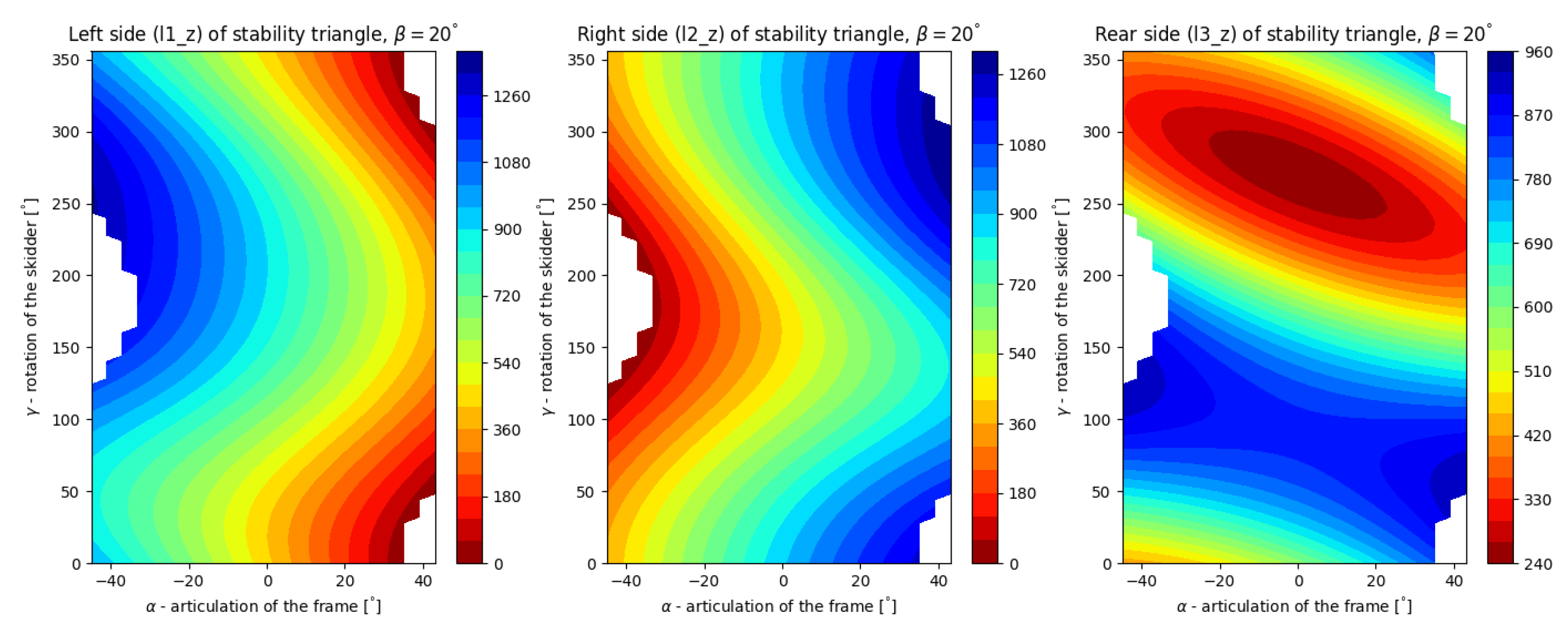

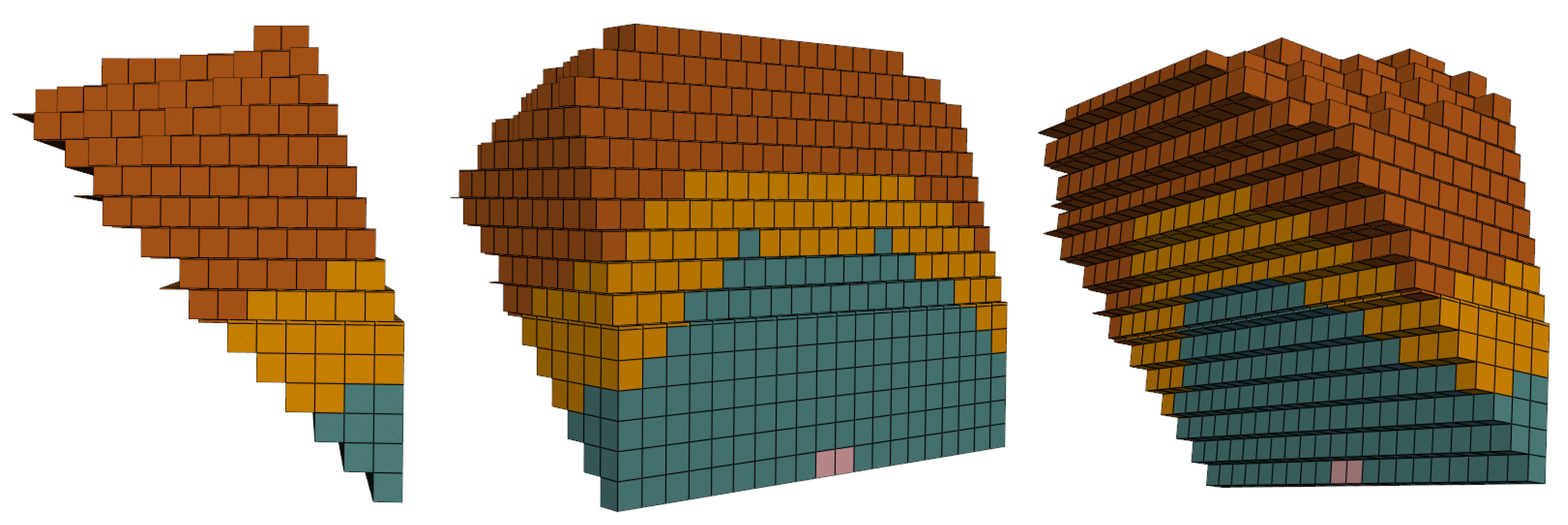

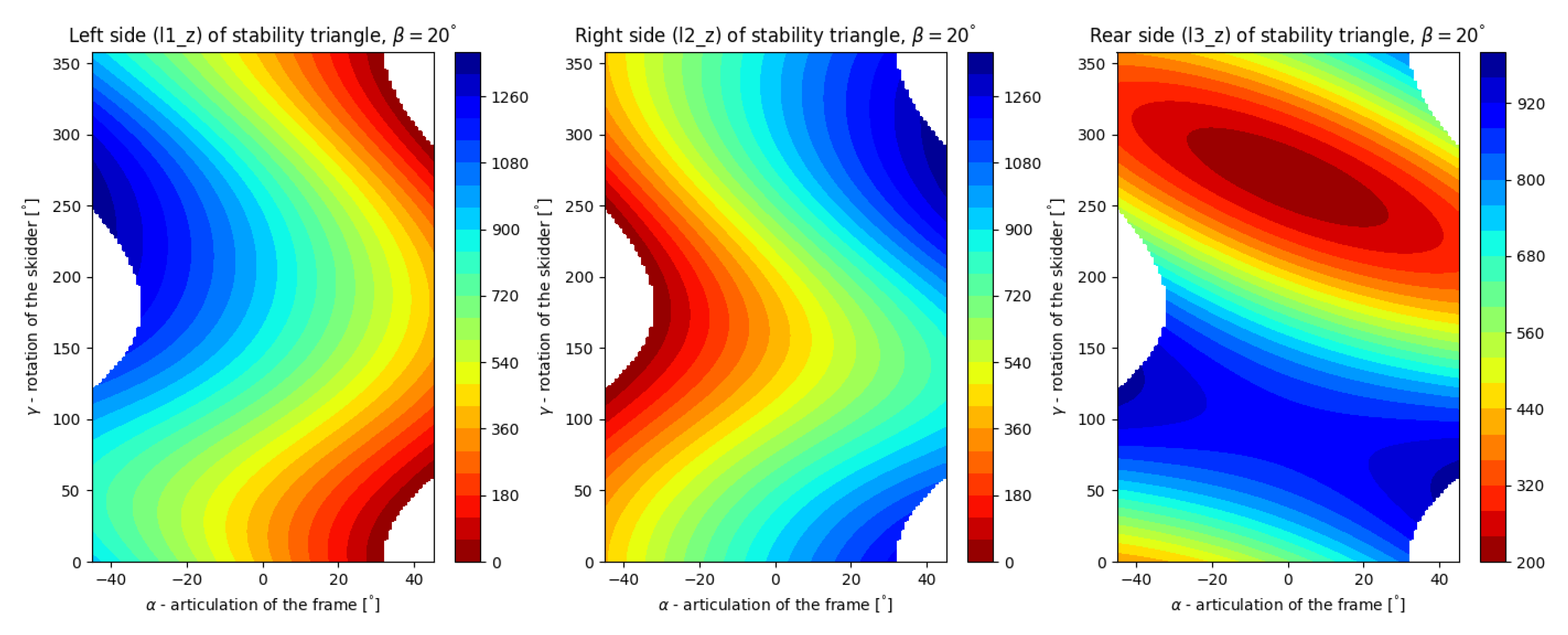

3.1. Shape No. 1

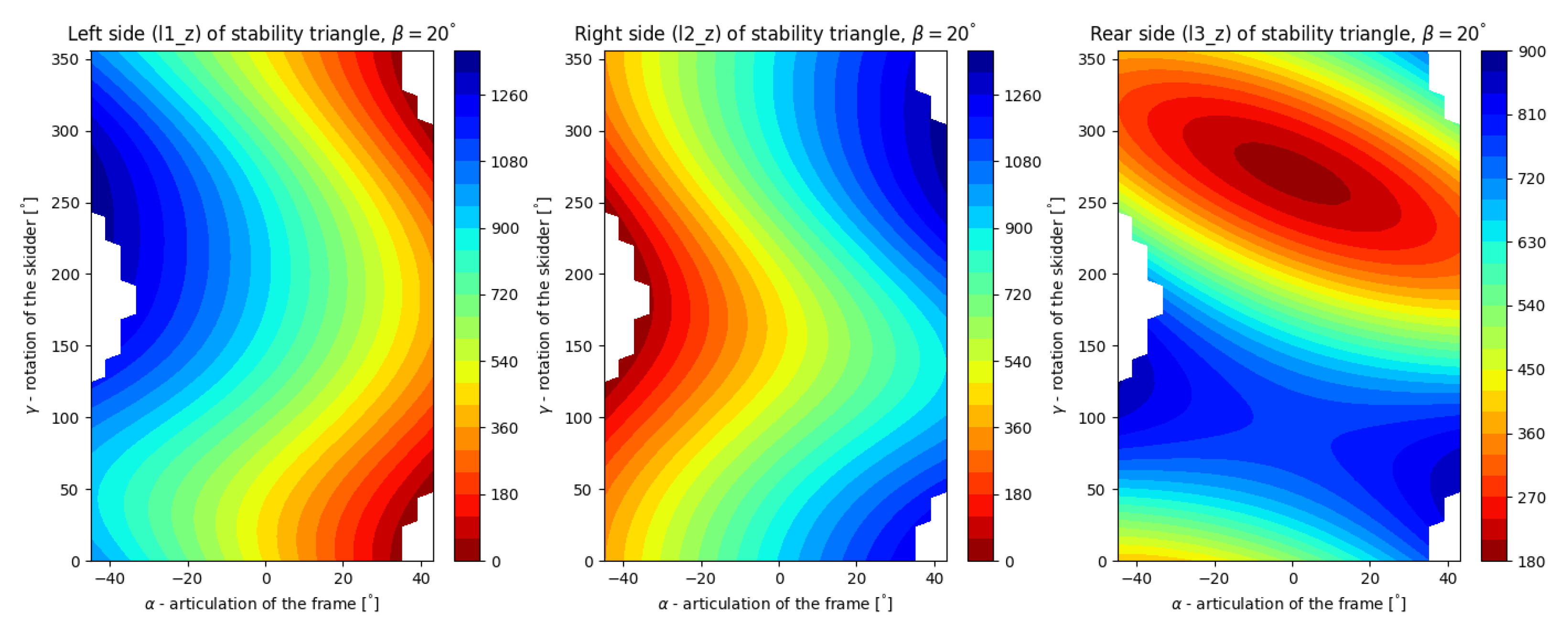

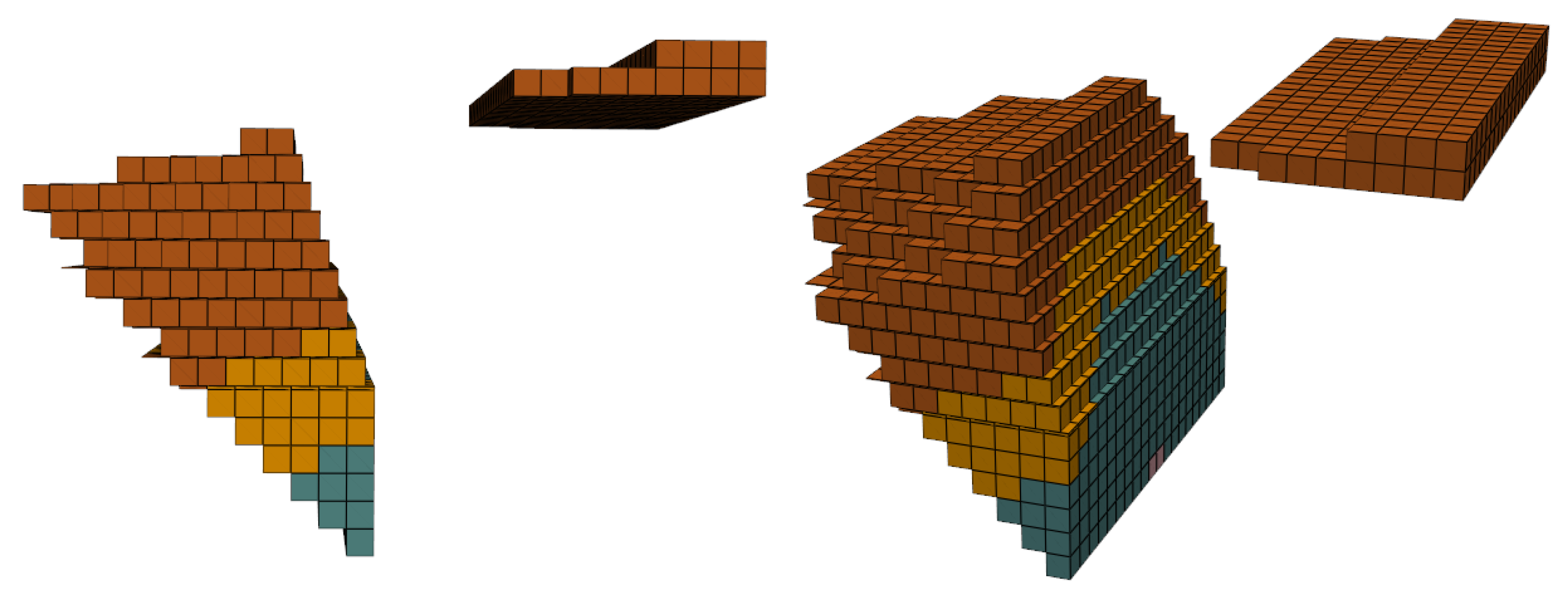

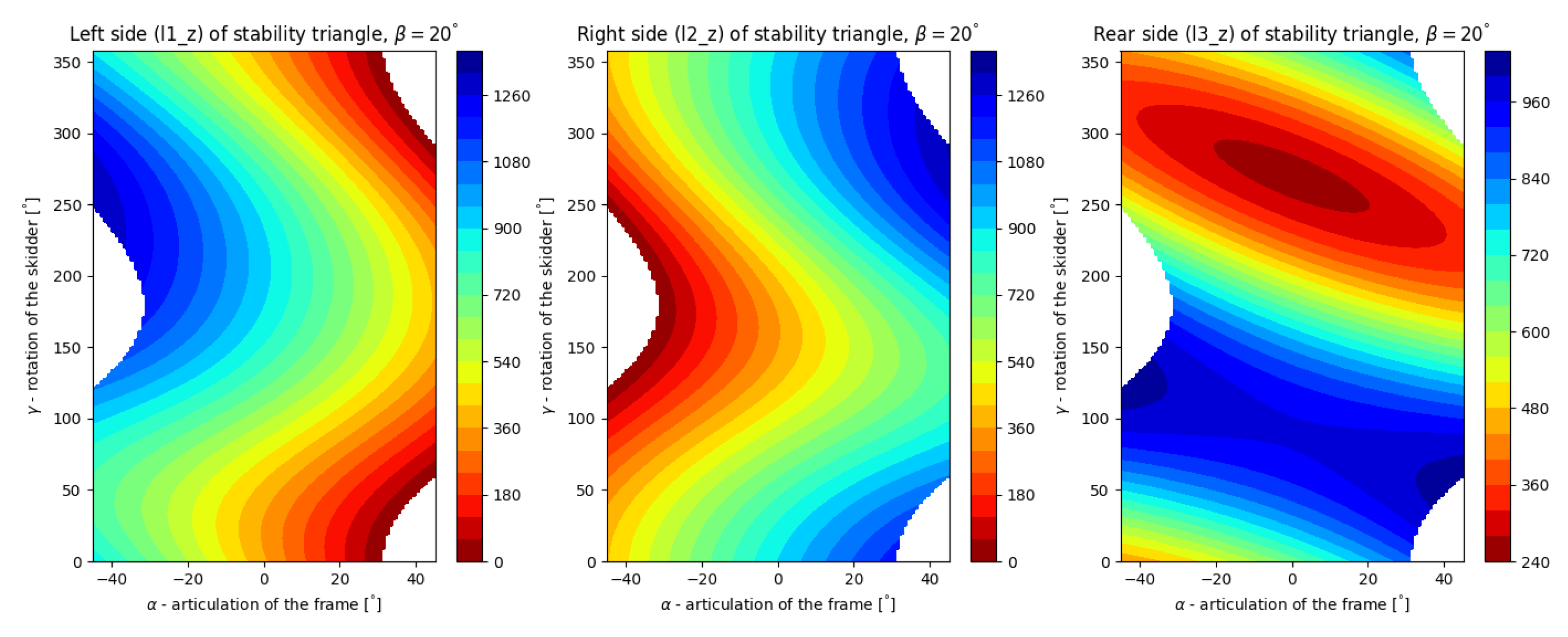

3.2. Shape No. 2

3.3. Shape No. 3

3.4. Shape No. 4

3.5. Shape No. 5

3.6. Shape No. 6

3.7. Shape No. 7

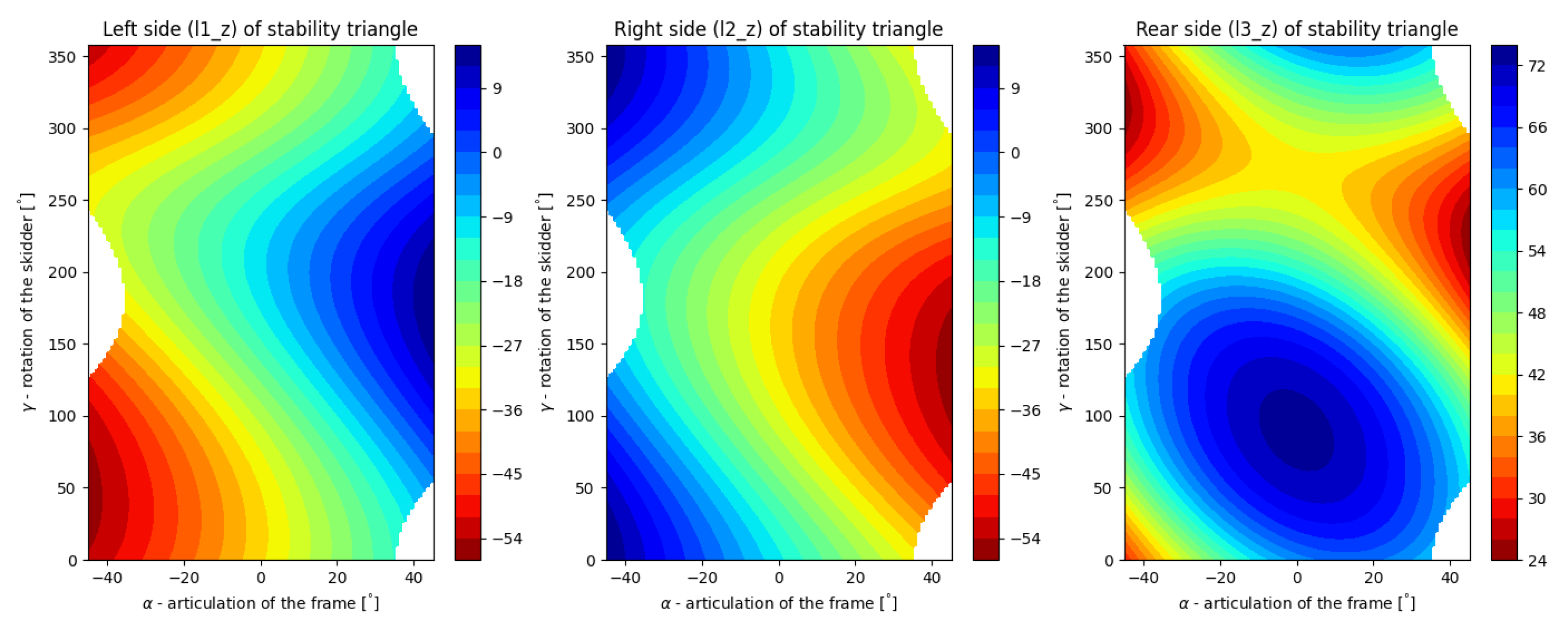

3.8. Evaluation of Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Forest Research. Forest Fires and Climate Change. Available online: https://www.forestresearch.gov.uk/research/climate-change-impacts/forest-fires-and-climate-change/ (accessed on 24 June 2022).

- Wiesik, J.; Aniszewska, M. Urzadzenia Techniczne w Produkcji Lesnej; SGGW: Warszawa, Poland, 2011; pp. 237–240. [Google Scholar]

- Fire Apparatus Magazine. Wildland Firefighting 4 × 4 Brush Truck. Available online: https://www.fireapparatusmagazine.com/fire-apparatus/wildland-firefighting-4x4-brush-truck/ (accessed on 11 July 2022).

- Howe and Howe. Termite. Available online: https://www.howeandhowe.com/civil/thermite (accessed on 11 July 2022).

- BAI. Fire Fighting and Rescue Vehicles. Available online: https://www.bai.it/en/ (accessed on 11 July 2022).

- Jarvis, R. An autonomous heavy duty outdoor robotic tracked vehicle. In Proceedings of the 1997 IEEE/RSJ International Conference on Intelligent Robot and Systems. Innovative Robotics for Real-World Applications. IROS ’97, Grenoble, France, 11 September 1997; Volume 1, pp. 352–359. [Google Scholar] [CrossRef]

- Cao, S.; Chen, S.; Yu, W.; Chen, S.; Xu, X. Research on Ride Comfort of Diminutive Forest Fire-fighting Vehicles. Open Autom. Control Syst. J. 2014, 6, 706–710. [Google Scholar] [CrossRef]

- Hnilica, R.; Ťavodová, M.; Hnilicová, M.; Matej, J.; Messingerová, V. The Innovative Design of the Fire-Fighting Adapter for Forest Machinery. Forests 2020, 11, 843. [Google Scholar] [CrossRef]

- Matej, J.; Hnilica, R.; Hnilicová, M. Research on Static Stability of Firefighting Adapter. Forests 2022, 13, 1180. [Google Scholar] [CrossRef]

- Gibson, H.G.; Elliott, K.C.; Persson, S.P.E. Side Slope Stability of Articulated-Frame Logging Tractors. J. Terramech. 1971, 8, 65–79. [Google Scholar] [CrossRef]

- Franceschetti, B.; Rondelli, V.; Capacci, E. Lateral Stability Performance of Articulated Narrow-Track Tractors. Agronomy 2021, 11, 2512. [Google Scholar] [CrossRef]

- Sierzputowski, G.; Dudziński, P. A mathematical model for determining and improving rollover stability of four-wheel earthmoving vehicles with arbitrary undercarriage system design. Arch. Civ. Mech. Eng. 2020, 20, 52. [Google Scholar] [CrossRef]

- Bołoz, Ł.; Kozłowski, A. Methodology for Assessing the Stability of Drilling Rigs Based on Analytical Tests. Energies 2021, 14, 8588. [Google Scholar] [CrossRef]

- Tomašić, Ž.; Šušnjar, M.; Horvat, D.; Pandur, Z. Forces Affecting Timber Skidding. Croat. J. For. Eng. 2009, 30, 2. [Google Scholar]

- Bietresato, M.; Mazzetto, F. Increasing The Safety of Agricultural Machinery Operating on Sloping Grounds by Performing Static and Dynamic Tests of Stability on a New-Concept Facility. Int. J. Saf. Secur. Eng. 2018, 8, 77–89. [Google Scholar] [CrossRef]

- Bietresato, M.; Mazzetto, F. Definition of the Layout for a New Facility to Test the Static and Dynamic Stability of Agricultural Vehicles Operating on Sloping Grounds. Appl. Sci. 2019, 9, 4135. [Google Scholar] [CrossRef]

- Bietresato, M.; Mazzetto, F. Stability Tests of Agricultural and Operating Machines by Means of an Installation Composed by a Rotating Platform (the “Turntable”) with Four Weighting Quadrants. Appl. Sci. 2020, 10, 3786. [Google Scholar] [CrossRef]

- Majdan, R.; Abrahám, R.; Tkáč, Z.; Drlička, R.; Matejková, E.; Kollárová, K.; Mareček, J. Static Lateral Stability of Tractor with Rear Wheel Ballast Weights: Comparison of ISO 16231-2 (2015) with Experimental Data Regarding Tyre Deformation. Appl. Sci. 2021, 11, 381. [Google Scholar] [CrossRef]

- ISO 16231-2:2015; Self-Propelled Agricultural Machinery-Assessment of Stability Part 2: Determination of Static Stability and Test Procedures. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/61583.html (accessed on 11 July 2025).

- Mazzetto, F.; Bietresato, M.; Gasparetto, A.; Vidoni, R. Simulated stability tests of a small articulated tractor designed for extreme-sloped vineyards. J. Agric. Eng. 2013, XLIV (Suppl. S1), e133. [Google Scholar] [CrossRef][Green Version]

- Demšar, I.; Bernik, R.; Duhovnik, J. A Mathematical Model and Numerical Simulation of the Static Stability of a Tractor. Agric. Conspec. Sci. 2012, 77, 143–150. [Google Scholar][Green Version]

- Bołoz, Ł.; Kozłowski, A.; Horak, W. Assessment of the stability of BEV LHD loader. Manag. Syst. Prod. Eng. 2022, 30, 377–387. [Google Scholar] [CrossRef]

- Tianlong, L.; Jixin, W.; Zongwei, Y. Modelling and Stability Analysis of Articulated Vehicles. Appl. Sci. 2021, 11, 3663. [Google Scholar] [CrossRef]

- Tota, A.; Galvagno, E.; Velardocchia, M. Analytical Study on the Cornering Behavior of an Articulated Tracked Vehicle. Machines 2021, 9, 38. [Google Scholar] [CrossRef]

- Reński, A. Investigation of the Influence of the Centre of Gravity Position on the Course of Vehicle Rollover. In Proceedings of the 24th Enhanced Safety of Vehicles Conference, Gothenburg, Sweden, 8–11 June 2015; Available online: https://www.researchgate.net/publication/279449206_Investigation_of_the_Influence_of_the_Centre_of_Gravity_Position_on_the_Course_of_Vehicle_Rollover (accessed on 24 June 2022).

- Keisan Online Calculator: Shortest Distance Between Two Lines Calculator. Available online: https://web.archive.org/web/20220802094641/https://keisan.casio.com/exec/system/1223531414 (accessed on 16 November 2021).

- Duka, A.; Poršinsky, T.; Pentek, T.; Pandur, Z.; Vusić, D.; Papa, I. Mobility Range of a Cable Skidder for Timber Extraction on Sloped Terrain. Forests 2018, 9, 526. [Google Scholar] [CrossRef]

| Coordinates of important points (x, y, z) [mm] | FPP (−1200, 0, 500), RRW (1200, 1010, 0), RLW (1200, −1010, 0), FRW (−1200, 1010, 0), FLW (−1200, −1010, 0), FG (−1100, 0, 1000), RG (1100, 0, 800) |

| Gravities [N] | FG (gravity) = 0.615 × 7145 kg × 9.81 m/s2 = 43,106 N, RG (gravity) = 0.385 × 7145 kg × 9.81 m/s2 = 26,985 N (skidder’s weight of 7145 kg, where 61.5% is on front axle) |

| Volume | Corner.x | Corner.y | Corner.z | Size.x | Size.y | Size.z | Suitability |

|---|---|---|---|---|---|---|---|

| 1.0 | 2385 | 0 | 300 | 100 | 100 | 100 | 57.371803 |

| 1.0 | 2385 | 100 | 300 | 100 | 100 | 100 | 57.335552 |

| 1.0 | 2385 | 0 | 400 | 100 | 100 | 100 | 57.34385 |

| 1.0 | 2485 | 0 | 400 | 100 | 100 | 100 | 57.33817 |

| ⋮ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matej, J.; Hnilicová, M. Optimization of Water Tank Shape in Terms of Firefighting Vehicle Stability. Appl. Syst. Innov. 2025, 8, 112. https://doi.org/10.3390/asi8040112

Matej J, Hnilicová M. Optimization of Water Tank Shape in Terms of Firefighting Vehicle Stability. Applied System Innovation. 2025; 8(4):112. https://doi.org/10.3390/asi8040112

Chicago/Turabian StyleMatej, Jaroslav, and Michaela Hnilicová. 2025. "Optimization of Water Tank Shape in Terms of Firefighting Vehicle Stability" Applied System Innovation 8, no. 4: 112. https://doi.org/10.3390/asi8040112

APA StyleMatej, J., & Hnilicová, M. (2025). Optimization of Water Tank Shape in Terms of Firefighting Vehicle Stability. Applied System Innovation, 8(4), 112. https://doi.org/10.3390/asi8040112