Multi-Criteria Comparison of Energy and Environmental Assessment Approaches for the Example of Cooling Towers

Abstract

:1. Introduction

1.1. Background of Evaluating Cooling Towers

1.2. Previous Research on Criteria-Based Method Comparison

1.3. Objectives of this Work

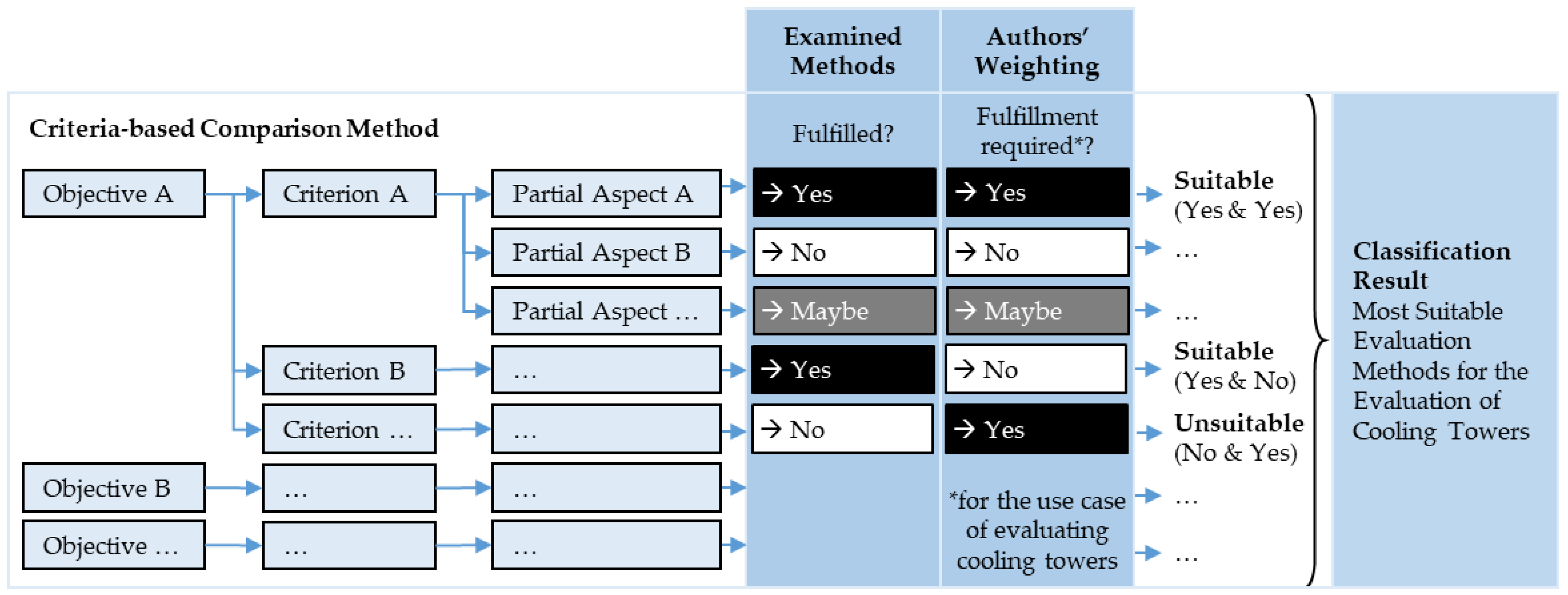

2. Methodology

2.1. Comparison Criteria

2.2. Methods for Energy and Environmental Assessment

2.2.1. First-Law Analysis Methods

2.2.2. Energy and Environmental Assessment Methods

3. Results

3.1. Application Area

3.2. Life Cycle Thinking

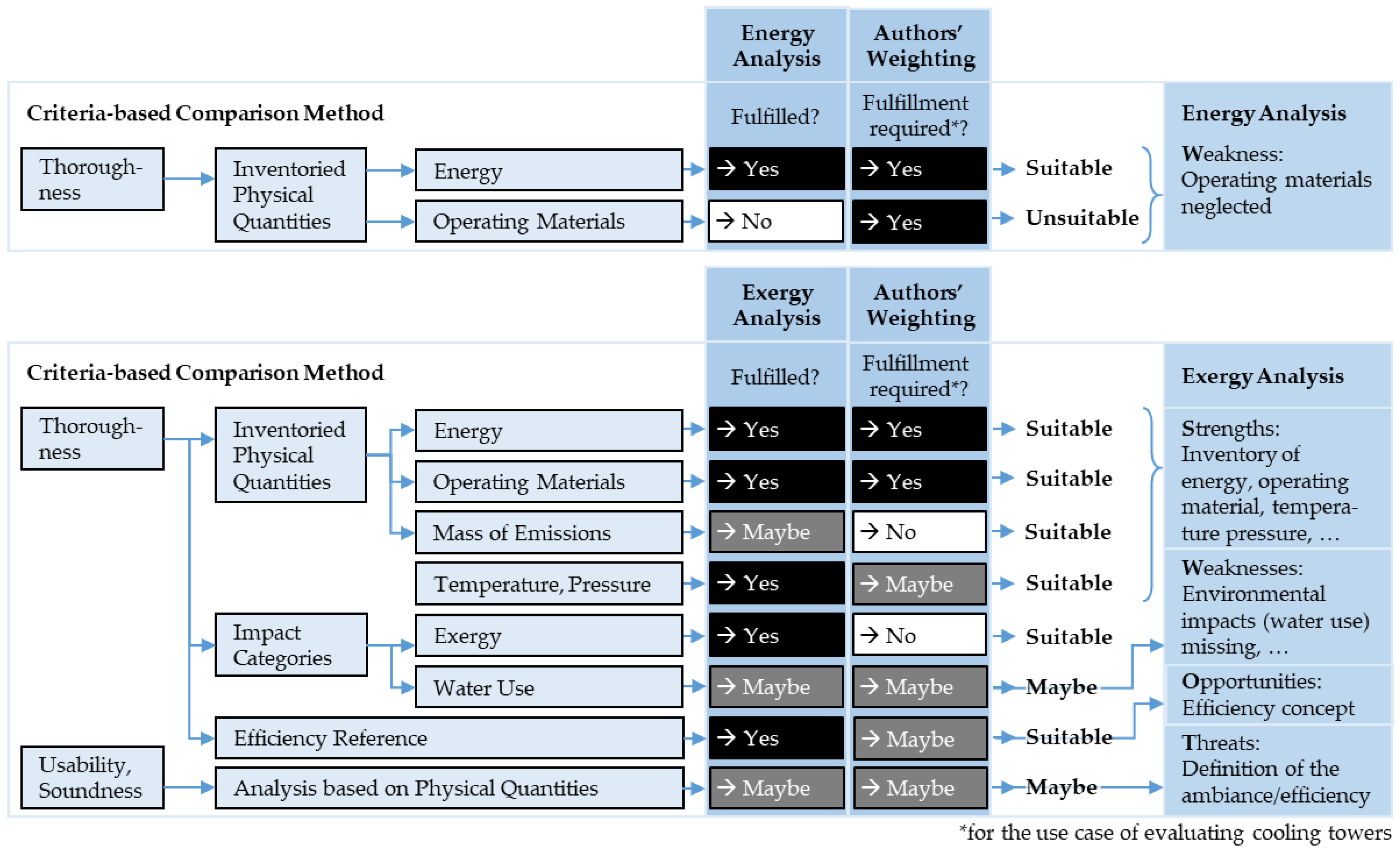

3.3. Inventoried Physical Quantities

3.4. Impact Categories

3.5. Efficiency Analysis

3.6. Temporal and Spatial Resolution

3.7. Scientific Soundness

3.8. Formalization

3.9. Data Availability

3.10. Existing Studies on Cooling Systems

3.11. Summary and Exemplary Weighting

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LCA | Life cycle assessment |

| PIOT | Physical input–output table |

| SFA | Substance flow analysis |

| MFA | Material flow analysis |

| ENA | Ecological network analysis |

| LCI | Life cycle inventory |

| LCA | Life cycle assessment |

| MIPS | Material-input per service unit |

| DPSIR | Drivers, pressures, state, impact, and response |

| NTU | Number of transfer units |

| MEFA | Material and energy flow analysis |

| PhO | Physical optimum |

Appendix A

| Criteria | |

|---|---|

| Abbaszadeh et al. [27] | Considered aspects and considered environmental media |

| Aktsoglou and Gaidajis [16] | Cross-sector (‘Do methods assess more than one sector?’), environmental issues (‘Do methods assess an adequate number of environmental issues?’), efficiency concept (‘Do methods promote energy and resource efficiency?’), possibility to communicate (‘Can methods communicate their results to public?’, ‘Can methods answer to the potential addition of a new activity?’), spatial focus (‘Can methods identify specific environmental ‘hot spots’ of the spatial entity?’), result aggregation (‘Can methods aggregate the results into single scores?’), and sustainability concepts (‘Do methods include specific thresholds/targets of sustainable performance?’, ‘Can methods be applied/Updated to compare overall sustainability?’) (p. 7) |

| Baumann et al. [17] | Approach character, approach type, comparison basis, data subject, data type, framework, interpretation, investigated dimensions, object analyzed, overall purpose, perspective, spatial modelling, system boundaries, and time modelling |

| Blanc et al. [15] | Acceptance, adaptability to global challenges, analytical potential, auditability, causality, comparability, compatibility, completeness, consistency, data availability, ease of use, environmental issues, inherent quantities, integration, intelligible, life cycle thinking, maturity, reliability, soundness, structure, transparency, univocity, and usability |

| Finnveden et al. [19] | Adaptive, cost-effective, credible, efficient, focused, integrated, interdisciplinary, participative, practicability, relevance, rigorous, systematic, and transparent |

| Finnveden et al. [28] | Impacts, object analyzed, scale, spatial characteristics, temporal characteristics, and timing of impacts |

| IAIA [24] | Adaptive, credible, efficient, focused, integrated, interdisciplinary, participative, practicability, purposive, relevance, rigorous, systematic, and transparent |

| Loiseau et al. [13] | Aggregation, data availability, exhaustiveness, feasibility, formalization, general public’s understanding, indicator type, indicators, inventoried flows, life cycle thinking, framework, multi-criteria assessment, site-dependent level, spatial differentiation, system modelling, top-down/bottom-up, and usability |

| Moberg [18] | Considered effects, considered environmental burdens, efficiency concept, frequency being used, integration, object analyzed, overall purpose, reference object, standardization, system boundaries, unit, and usability |

| Ness et al. [14] | Product-related assessment, integration, spatial focus, and temporal characteristics |

| Payraudeau et al. [12] | Indicators, scale of impacts, spatial scale, spatial variability, sustainability dimensions, temporal scale, and temporal variation |

| Rodríguez et al. [12] | Aggregation, data availability, efficiency concept, feasibility, formalization, indicators, intelligible, inventoried flows, multi-criteria indicators, spatial scale, system modelling, top-down/bottom-up, and usability |

| Sala et al. [20] | Comprehensive, integration, scalable, strategic, system boundaries, and transparency |

References

- European Commission. Reference Document on the Application of Best Available Techniques to Industrial Cooling Systems: Integrated Pollution Prevention and Control (IPPC). 2001. Available online: https://eippcb.jrc.ec.europa.eu/sites/default/files/2019-11/cvs_bref_1201.pdf (accessed on 14 July 2022).

- DIN EN ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. Beuth Verlag GmbH: Berlin, Germany, 2021.

- Asdrubali, F.; Baldinelli, G.; Scrucca, F. Comparative life cycle assessment of an innovative CSP air-cooled system and conventional condensers. Int. J. Life Cycle Assess. 2015, 20, 1076–1088. [Google Scholar] [CrossRef]

- Schlei-Peters, I.; Wichmann, M.G.; Matthes, I.-G.; Gundlach, F.-W.; Spengler, T.S. Integrated material flow analysis and process modeling to increase energy and water efficiency of industrial cooling water systems. J. Ind. Ecol. 2017, 22, 41–54. [Google Scholar] [CrossRef]

- Schulze, C.; Thiede, S.; Herrmann, C. Life cycle assessment of industrial cooling towers. In Progress in Life Cycle Assessment; Schebek, L., Herrmann, C., Cerdas, F., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 135–146. ISBN 978-3-319-92237-9. [Google Scholar]

- DIN EN 13741; Thermal Performance Acceptance Testing of Mechanical Draught Series Wet Cooling Towers. Beuth Verlag GmbH: Berlin, Germany, 2004.

- Jaber, H.; Webb, R.L. Design of Cooling Towers by the Effectiveness-NTU Method. J. Heat Transf. 1989, 111, 837–843. [Google Scholar] [CrossRef]

- Merkel, F. Verdunstungskühlung. Ph.D. Thesis, VDI-Verl., Berlin, Germany, 1925. [Google Scholar]

- Poppe, M. Wärme- und Stoffübertragung bei der Verdunstungskühlung im Gegen- und Kreuzstrom: Mitteilung aus dem Institut für Thermodynamik der Technischen Universität Hannover; VDI-Verl.: Düsseldorf, Germany, 1973; ISBN 3-18-85-0560-1. [Google Scholar]

- Khan, J.-R.; Zubair, S.M. An Improved Design and Rating Analyses of Counter Flow Wet Cooling Towers. J. Heat Transf. 2001, 123, 770–778. [Google Scholar] [CrossRef]

- DIN EN 14705; Heat Exchangers—Method of Measurement and Evaluation of Thermal Performances of Wet Cooling Towers. Beuth Verlag GmbH: Berlin, Germany, 2005.

- Rodríguez, C.M.; Rengifo Rodas, C.F.; Corrales Muñoz, J.C.; Casas, A.F. A multi-criteria approach for comparison of environmental assessment methods in the analysis of the energy efficiency in agricultural production systems. J. Clean. Prod. 2019, 228, 1464–1471. [Google Scholar] [CrossRef]

- Loiseau, E.; Junqua, G.; Roux, P.; Bellon-Maurel, V. Environmental assessment of a territory: An overview of existing tools and methods. J. Environ. Manag. 2012, 112, 213–225. [Google Scholar] [CrossRef]

- Ness, B.; Urbel-Piirsalu, E.; Anderberg, S.; Olsson, L. Categorising tools for sustainability assessment. Ecol. Econ. 2007, 60, 498–508. [Google Scholar] [CrossRef]

- Blanc, I.; Friot, D. Evaluation of Environmental Accounting Methodologies for the Assessment of Global Environmental Impacts of Traded Goods and Services. Research report hal-00740712. Ph.D. Thesis, Mines ParisTech, Paris, France, 2010. [Google Scholar]

- Aktsoglou, D.; Gaidajis, G. Environmental Sustainability Assessment of Spatial Entities with Anthropogenic Activities-Evaluation of Existing Methods. Sustainability 2020, 12, 2680. [Google Scholar] [CrossRef]

- Baumann, H.; Cowell, S.J. An evaluative framework for conceptual and analytical approaches used in environmental management. Greener Manag. Int. 1999, 26, 109–122. [Google Scholar]

- Moberg, Å. Environmental Systems Analysis Tools: Differences and Similarities including a Brief Case Study on Heat Production using Ecological Footprint, MIPS, LCA and Exergy Analysis. Master’s Thesis, Stockholm University, Stockholm, Sweden, 1999. [Google Scholar]

- Finnveden, G.; Nilsson, M.; Johansson, J.; Persson, Å.; Moberg, Å.; Carlsson, T. Strategic environmental assessment methodologies—Applications within the energy sector. Environ. Impact Assess. Rev. 2003, 23, 91–123. [Google Scholar] [CrossRef]

- Sala, S.; Ciuffo, B.; Nijkamp, P. A systemic framework for sustainability assessment. Ecol. Econ. 2015, 119, 314–325. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2009, 9, 189–212. [Google Scholar] [CrossRef]

- Angelakoglou, K.; Gaidajis, G. A review of methods contributing to the assessment of the environmental sustainability of industrial systems. J. Clean. Prod. 2015, 108, 725–747. [Google Scholar] [CrossRef]

- Smeets, E.; Weterings, R. Environmental Indicators: Typology and Overview: European Environment. Technical Report No 25. 1999. Available online: http://www.geogr.uni-jena.de/fileadmin/Geoinformatik/projekte/brahmatwinn/Workshops/FEEM/Indicators/EEA_tech_rep_25_Env_Ind.pdf (accessed on 14 July 2022).

- IAIA. Principles of Environmental Impact Assessment—Best Practice: Fargo, ND: International Association for Impact Assessment. 1999. Available online: https://www.iaia.org/uploads/pdf/principlesEA_1.pdf (accessed on 14 July 2022).

- Payraudeau, S.; van der Werf, H.M. Environmental impact assessment for a farming region: A review of methods. Agric. Ecosyst. Environ. 2005, 107, 1–19. [Google Scholar] [CrossRef]

- Klemm, C.; Wiese, F. Indicators for the optimization of sustainable urban energy systems based on energy system modeling. Energy Sustain. Soc. 2022, 12, 3. [Google Scholar] [CrossRef]

- Abbaszadeh, S.; Hassim, M.H. Comparison of methods assessing environmental friendliness of petrochemical process design. J. Clean. Prod. 2014, 71, 110–117. [Google Scholar] [CrossRef]

- Finnveden, G.; Moberg, Å. Environmental systems analysis tools—An overview. J. Clean. Prod. 2005, 13, 1165–1173. [Google Scholar] [CrossRef]

- Bilitewski, B.; Bringezu, S.; Bro-Rasmussen, F.; Clift, R.; Frischknecht, R.; Speck, S.; Sørup, P.; Ude de Haes, H.A. CHAINET Definition Document: Final version. 1998. Available online: http://www.leidenuniv.nl/cml/ssp/publications/defin_doc.pdf (accessed on 14 July 2022).

- European Commission. PEFCR Guidance Document: Guidance for the 13 Development of Product Environmental Footprint Category Rules (PEFCRs); Version 6.3; European Commission: Brüssel, Belgium, 2018.

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Nordmann, A. Analyse und Bewertung. In Umweltbewertung für Ingenieure; Kaltschmitt, M., Schebek, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 47–56. [Google Scholar]

- Radermacher, W.; Stahmer, C. Material and energy flow analysis in Germany—Accounting framework, information system, applications. In Environmental Accounting in Theory and Practice; Uno, K., Bartelmus, P., Eds.; Springer: Dordrecht, The Netherlands, 1998; pp. 187–211. ISBN 9789401714334. [Google Scholar]

- European Commission. Economy- Wide Material Flow Accounts and Derived Indicators: A Methodological Guide; Office for Official Publ. of the Europ. Communities: Luxembourg, 2001; ISBN 9289404590.

- Brunner, P.H.; Rechberger, H. Practical Handbook of Material Flow Analysis, 1st ed.; Lewis: Boca Raton, FL, USA, 2004; ISBN 1566706041. [Google Scholar]

- IFIAS. IFIAS Workshop Report, energy analysis and economics. International Federation of Institutes for Advanced. Resour. Energy 1978, 1, 151–204. [Google Scholar] [CrossRef]

- Fath, B.D.; Patten, B.C. Review of the Foundations of Network Environ Analysis. Ecosystems 1999, 2, 167–179. [Google Scholar] [CrossRef]

- DIN EN ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Beuth Verlag GmbH: Berlin, Germany, 2021.

- DIN EN ISO 14067; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. Beuth Verlag GmbH: Berlin, Germany, 2019.

- DIN EN ISO 14046; Environmental Management—Water Footprint—Principles, Requirements and Guidelines. Beuth Verlag GmbH: Berlin, Germany, 2016.

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard, 1st ed.; Earthscan: London, UK, 2011; ISBN 978-1-84971-279-8. [Google Scholar]

- Wackernagel, M.; Rees, W.E. Our Ecological Footprint: Reducing Human Impact on the Earth, [Nachdr.]; New Society Publishing: Gabriola Island, BC, Canada, 2007; ISBN 9781550922516. [Google Scholar]

- VDI 4600; Cumulative Energy Demand (KEA): Terms, Definitions, METHODS of Calculation. Association of German Engineers. Beuth Verlag GmbH: Berlin, Germany, 2012.

- VDI 4600-1; Cumulative Energy Demand: Examples. Association of German Engineers. Beuth Verlag GmbH: Berlin, Germany, 2015.

- Schmidt-Bleek, F. Das MIPS-Konzept: Weniger Naturverbrauch—Mehr Lebensqualität durch Faktor 10; Droemer Knaur: München, Germany, 1998; ISBN 3426269821. [Google Scholar]

- Szargut, J. Minimization of the consumption of natural resources. Bull. Polish Acad. Sci. Tech. Sci. 1978, 26, 41–46. [Google Scholar]

- Hau, J.L.; Bakshi, B.R. Expanding Exergy Analysis to Account for Ecosystem Products and Services. Environ. Sci. Technol. 2004, 38, 3768–3777. [Google Scholar] [CrossRef] [PubMed]

- Odum, H.T. Environmental Accounting: Emergy and Environmental Decision Making; Wiley: New York, NY, USA, 1996; ISBN 0471114421. [Google Scholar]

- Cornelissen, R.L. Thermodynamics and Sustainable Development: The Use of Exergy Analysis and the Reduction of Irreversibility. Ph.D. Thesis, Universiteit Twente, Enschede, The Netherlands, 1997. [Google Scholar]

- Gong, M.; Wall, G. On exergetics, economics and optimization of technical prozesses to meet environmental conditions: Exergy Studies. In Thermodynamic Analysis and Improvement of Energy Systems, Proceedings of the International Conference, Obninsk, Russia, 10–13 June 1997; Cai, R., Moran, M.J., Eds.; World Publishing Corporation: Beijing, China, 1997; pp. 453–460. ISBN 7-5062-3264-Z. [Google Scholar]

- VDI 4663-1; Evaluation of Energy and Material Efficiency—Methodical Application of the Physical Optimum. Association of German Engineers: Draft. Beuth Verlag GmbH: Berlin, Germany, 2019.

- Torres, T.M.; Barros, C.M.; Bello, P.M.; Casares, J.J.; Rodriguez-Blas, J.M. Energy and material flow analysis: Application to the storage stage of clay in the roof-tile manufacture. Energy 2008, 33, 963–973. [Google Scholar] [CrossRef]

- United Nations; European Commission; International Monetary Fund; Organisation for Economic Co-operation and Development; World Bank. Handbook of National Accounting: Integrated Environmental and Economic Accounting; Final draft circulated for information prior to official editing Series F, No.61, Rev.1 (ST/ESA/STAT/SER.F/61/Rev.1); 2003. Available online: https://unstats.un.org/unsd/environment/seea2003.pdf (accessed on 14 July 2022).

- Bao, Z.; Zhang, S.; Chen, Y.; Liu, S.; Zhang, Y.; Wang, H. A Review of Material Flow Analysis. In Proceedings of the 2010 International Conference on Management and Service Science, Wuhan, China, 24–26 August 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Guinée, J.B.; van der Voet, E. Risks of metal flows and accumulation. In A Handbook of Industrial Ecology; Ayres, L., Ayres, R.U., Eds.; Edward Elgar Pub: Cheltenham, UK; Northampton, MA, USA, 2002; pp. 382–390. ISBN 1-84064-506-7. [Google Scholar]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical and Metallurgical Processes; Hemisphere Publ. Corp: New York, NY, USA, 1988; ISBN 9780891165743. [Google Scholar]

- Riedl, K. Exergetische und Exergoökonomische Bewertung von Verfahren der Energie- und Stoffwandlung. Ph.D. Thesis, Martin Luther University Halle-Wittenberg, Merseburg, Germany, 2007. [Google Scholar]

- Volta, D.; Weber, S.A. The Physical Optimum as an Ideal Reference Value for Balancing Thermodynamic Processes Integrating the Exergetic Evaluation by the Example of Heat Supply. Energies 2021, 14, 4426. [Google Scholar] [CrossRef]

- Guinee, J.B. (Ed.) Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Springer: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Heijungs, R. Towards eco-efficiency with LCA’s prevention principle: An epistemological foundation of LCA using axioms. In Product Innovation and Eco-Efficiency: Twenty-Three Industry Efforts to Reach the Factor 4; Klostermann, J.E.M., Tukker, A., Eds.; Springer: Dordrecht, The Netherlands, 1998; pp. 175–185. ISBN 9789401589451. [Google Scholar]

- Hoekstra, A.Y. Human appropriation of natural capital: A comparison of ecological footprint and water footprint analysis. Ecol. Econ. 2009, 68, 1963–1974. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Hauschild, M.Z.; Boulay, A.-M.; Fantke, P.; Laurent, A.; Nunez, M.; Vieira, M. Life Cycle Impact Assessment. In Life Cycle Assessment; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Swierland, 2018; pp. 167–270. [Google Scholar]

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. A Review of Footprint analysis tools for monitoring impacts on sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Cornelissen, R.L.; Hirs, G.G. The value of the exergetic life cycle assessment besides the LCA. Energy Convers. Manag. 2002, 43, 1417–1424. [Google Scholar] [CrossRef]

- Brown, M.T.; Ulgiati, S. Energy quality, emergy, and transformity: H.T. Odum’s contributions to quantifying and understanding systems. Ecol. Modell. 2004, 178, 201–213. [Google Scholar] [CrossRef]

- Keichel, C. Methode der Grenzwertorientierten Bewertung. Ph.D. Thesis, Technische Universität Clausthal, Clausthal, Germany, 2017. [Google Scholar]

- Fang, K.; Heijungs, R.; de Snoo, G.R. Theoretical exploration for the combination of the ecological, energy, carbon, and water footprints: Overview of a footprint family. Ecol. Indic. 2014, 36, 508–518. [Google Scholar] [CrossRef]

- Stahl, B. Methodenvergleich und Methodenentwicklung zur Lösung der Bewertungsproblematik in Produktbezogenen Ökobilanzen. Ph.D. Thesis, Universität Bremen, Bremen, Germany, 1998. [Google Scholar]

- Meyer, R.; Benetto, E.; Mauny, F.; Lavandier, C. Characterization of damages from road traffic noise in life cycle impact assessment: A method based on emission and propagation models. J. Clean. Prod. 2019, 231, 121–131. [Google Scholar] [CrossRef]

- Myllyviita, T.; Sironen, S.; Saikku, L.; Holma, A.; Leskinen, P.; Palme, U. Assessing biodiversity impacts in life cycle assessment framework—Comparing approaches based on species richness and ecosystem indicators in the case of Finnish boreal forests. J. Clean. Prod. 2019, 236, 117641. [Google Scholar] [CrossRef]

- Mattila, T.J. Use of Input–Output Analysis in LCA. In Life Cycle Assessment; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 349–374. [Google Scholar]

- Bonnin, M.; Azzaro-Pantel, C.; Pibouleau, L.; Domenech, S.; Villeneuve, J. Development and validation of a dynamic material flow analysis model for French copper cycle. Chem. Eng. Res. Des. 2013, 91, 1390–1402. [Google Scholar] [CrossRef]

- Pivnenko, K.; Laner, D.; Astrup, T.F. Material Cycles and Chemicals: Dynamic Material Flow Analysis of Contaminants in Paper Recycling. Environ. Sci. Technol. 2016, 50, 12302–12311. [Google Scholar] [CrossRef]

- Kleijn, R.; Huele, R.; van der Voet, E. Dynamic substance flow analysis: The delaying mechanism of stocks, with the case of PVC in Sweden. Ecol. Econ. 2000, 32, 241–254. [Google Scholar] [CrossRef]

- Su, S.; Li, X.; Zhu, Y.; Lin, B. Dynamic LCA framework for environmental impact assessment of buildings. Energy Build. 2017, 149, 310–320. [Google Scholar] [CrossRef]

- Bjorn, A.; Moltesen, A.; Laurent, A.; Owsianiak, M.; Corona, A.; Birkved, M.; Hauschild, M.Z. Life Cycle Inventory Analysis. In Life Cycle Assessment; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 117–165. [Google Scholar]

- Alizadeh kheneslu, R.; Jahangiri, A.; Ameri, M. Interaction effects of natural draft dry cooling tower (NDDCT) performance and 4E (energy, exergy, economic and environmental) analysis of steam power plant under different climatic conditions. Sustain. Energy Technol. Assess. 2020, 37, 100599. [Google Scholar] [CrossRef]

- Eggers, N.; Böttger, J.N.J.; Kerpen, L.; Sankol, B.U.; Birth, T. Refining VDI guideline 4663 to evaluate the efficiency of a power-to-gas process by employing limit-oriented indicators. Energy Effic. 2021, 14, 73. [Google Scholar] [CrossRef]

- Schebek, L.; Herrmann, C.; Cerdas, F. (Eds.) Progress in Life Cycle Assessment; Springer International Publishing: Cham, Switerland, 2019; ISBN 978-3-319-92237-9. [Google Scholar]

- VDMA 24659; Economic Analysis and Partial Carbon Footprint of Evaporative Cooling Equipment: Guideline for Ealculation. Beuth Verlag GmbH: Berlin, Germany, 2016.

- Mertens, J.; Prieur-Vernat, A.; Corbisier, D.; Favrot, E.; Boon, G. Water footprinting of electricity generated by combined cycle gas turbines using different cooling technologies: A practitioner’s experience. J. Clean. Prod. 2015, 86, 201–208. [Google Scholar] [CrossRef]

- Guerras, L.S.; Martín, M. On the water footprint in power production: Sustainable design of wet cooling towers. Appl. Energy 2020, 263, 114620. [Google Scholar] [CrossRef]

- Muangnoi, T.; Asvapoositkul, W.; Wongwises, S. An exergy analysis on the performance of a counterflow wet cooling tower. Appl. Therm. Eng. 2007, 27, 910–917. [Google Scholar] [CrossRef]

- Ünver, Ü.; Mert, M.S.; Direk, M.; Yüksel, F.; Kılıç, M. Design of an Inlet Air-Cooling System for a Gas Turbine Power Plant. In Exergy for A Better Environment and Improved Sustainability; Aloui, F., Dincer, I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1089–1100. ISBN 978-3-319-62571-3. [Google Scholar]

- Jakrawatana, N.; Ngammuangtueng, P.; Gheewala, S.H. Linking substance flow analysis and soil and water assessment tool for nutrient management. J. Clean. Prod. 2017, 142, 1158–1168. [Google Scholar] [CrossRef]

- Meyer, L. Exergiebasierte Untersuchung der Entstehung von Umweltbelastungen in Energieumwandlungsprozessen auf Komponentenebene: Exergoökologische Analyse; Technische Universität Darmstadt: Darmstadt, Germany, 2006; ISBN 3932518748. [Google Scholar]

- Borrett, S.R.; Sheble, L.; Moody, J.; Anway, E.C. Bibliometric review of ecological network analysis: 2010–2016. Ecol. Modell. 2018, 382, 63–82. [Google Scholar] [CrossRef]

| Aktsoglou and Gaidajis [16] | Baumann and Cowell [17] | Moberg [18] | Finnveden et al. [19] | Ness et al. [14] | Blanc and Friot [15] | Loiseau et al. [13] | Rodríguez et al. [12] | |

|---|---|---|---|---|---|---|---|---|

| Examined Methods | ||||||||

| PIOT | X | X | ||||||

| SFA | X | X | X | X | X | |||

| MFA | X | X | X | X | X | |||

| Energy Analysis | X | X | ||||||

| ENA | X | X | ||||||

| LCA | X | X | X | X | X | X | X | X |

| Carbon Footprint | ||||||||

| Water Footprint | X | X | ||||||

| Ecological Footprint | X | X | X | X | X | X | ||

| MIPS | X | X | ||||||

| Emergy Analysis | X | X | X | X | X | |||

| Exergy Analysis | X | X | X | X | X | |||

| Criteria | ||||||||

| Life Cycle Thinking | X | X | ||||||

| Inventoried Flows | X | X | X | |||||

| Indicators Provided | X | X | X | X | X | X | ||

| Efficiency Concept | X | X | X | X | X | |||

| Temporal Resolution | X | X | X | |||||

| Spatial Resolution | X | X | X | X | X | |||

| Scientific Soundness | X | X | X | |||||

| Formalization | X | X | X | X | ||||

| Data Availability | X | X | X | X |

| Objective | Criteria | Partial Aspect (If Needed) | Underlying Question |

|---|---|---|---|

| Applicable for the Studied Objects | Process | Applicable to this type of studied object? | |

| Product | Applicable to this type of studied object? | ||

| Service | Applicable to this type of studied object? | ||

| Region/Sector | Applicable to this type of studied object? | ||

| Thoroughness: Completeness and Resolution | Life Cycle Thinking | Entire life cycle considered, cradle-to-grave? | |

| Inventoried Physical Quantities | Energy (J) | Is this physical quantity inventoried? | |

| Mass of Operating Materials (kg) | Is the mass of these materials inventoried? | ||

| Mass of Construction Materials (kg) | Is the mass of these materials inventoried? | ||

| Mass of Emissions (kg) | Is the mass of these materials inventoried? | ||

| Temperature (K), Pressure (Pa) | Are the pressure and temperature inventoried? | ||

| Impact Categories | Exergy (J) | Is this impact category addressed? | |

| Climate Change (kg CO2-eq) | Is this impact category addressed? | ||

| Water/Land Use/… (m3, ha, …) | Is this impact category addressed? | ||

| Noise | Is noise considered? | ||

| Efficiency Analysis | Is it referred to as a useful output? | ||

| Temporal Resolution (Dynamic Analysis) | Is a dynamic analysis intended or possible? | ||

| Spatial or Sectoral Resolution | Is a bottom-up analysis intended? | ||

| Usability, Soundness | Pure Analysis based on Physical Quantities | Is the method scientifically sound? | |

| Formalization (Methodological Framework, Rigor) | Are there mature and strict standards? | ||

| Data Availability | Are the required data available, e.g., as databases? | ||

| Existing studies on Cooling Systems | Are there studies assessing cooling systems? | ||

| Abbr. | Name | Description | References |

|---|---|---|---|

| First-Law Analysis Methods | |||

| PIOT | Physical Input–Output Table | Physical equivalent of the monetary input–output analysis (or table) regarding a sectoral perspective | Radermacher and Stahmer [33] |

| SFA | Substance Flow Analysis | Input–output analysis, mostly includes only one or a limited group of undesirable substances | EC [34] |

| MFA | Material Flow Analysis | Input–output analysis, may also include energy flows, mostly referring to a national economy | EC [34]; Brunner and Rechberger [35] |

| EA | Energy Analysis | Quantification of direct and indirect energy inputs of economic production | IFIAS [36]; first law of thermodynamics |

| ENA | Ecological Network Analysis | Objects studied as part of a connected system; the indirect effects can be identified and quantified | Fath and Patten [37] |

| LCI | Life Cycle Inventory | ‘Compilation and quantification of inputs and outputs for a product throughout its life cycle’, phase of LCA [2] (p. 7) | ISO 14040 [2] and 14044 [38] |

| Energy and Environmental Assessment Methods | |||

| LCA | Life Cycle Assessment | ‘Compilation and evaluation of the inputs, outputs and the potential environmental impacts of a product system throughout its life cycle’ [2] (p. 7) | ISO 14040 [2] and 14044 [38] |

| CF | Carbon Footprint | ‘Sum of GHG [greenhouse gas] emissions […] and GHG removals […] based on an life cycle assessment […] using the single impact category […] of climate change’ [39] (p. 16) (kg CO2eq/functional unit) | ISO 14067 [39] |

| WF | Water Footprint | Volumetric accounting of water referred to a functional unit (m3/functional unit) or ‘metric(s) that quantifies the potential environmental impacts related to water’ [40] (p. 13) | ISO 14046 [40]; Hoekstra et al. [41] |

| EF | Ecological Footprint | Converts the environmental impact to theoretical area used to produce the bio resources and assimilate waste (ha/functional unit) | Wackernagel and Rees [42] |

| CED | Cumulative Energy Demand | ‘entire demand, valued as primary energy, which arises in connection with the production, use and disposal of an economic good (product or service) or which may be attributed respectively to it in a causal relation’ [43] (p. 6) (kJ/functional unit) | VDI 4600 [43]; VDI 4600-1 [44] |

| MIPS | Material Input per Service | Converts the environmental impact to material theoretically used per functional unit, life cycle (t/service) | Schmidt-Bleek [45] |

| CExC | Cumulative Exergy Consumption | Upstream resource consumption of a product is considered by its exergy (only materials, energy carriers, and products) | Szargut [46] |

| ECEC | Ecological Cumulative Exergy Consumption | Upstream resource consumption of a product is considered by its exergy (exergy of natural resources/ecosystem) | Hau and Bakshi [47] |

| EmA | Emergy Analysis | Upstream resource consumption considered by emergy, which is work completed by nature or man for the realization of a product or service | Odum [48] |

| ELCA | Exergetic Life Cycle Assessment | Life cycle irreversibility as the exergy loss during the life cycle is the impact category (LCA extension) (kJloss/functional unit) | Cornelissen [49] |

| LCEA | Life Cycle Exergy Analysis | Converts the environmental impact to natural resource consumption measured by exergy (kJ/functional unit) | Gong and Wall [50] |

| ExA | Exergy Analysis | Second-law analysis, definition of useful output | Second law of thermodynamics |

| PhO | Physical Optimum Method | PhO as ideal reference value, PhO factor = real/limit value (PhO) | VDI 4663-1 [51] |

| Objectives | Criteria | Partial Aspect | MFA | Energy Analysis | ENA | LCI | LCA | Footprints | Emergy Analysis | Exergy Analysis | PhO | Exemplary Weighting |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicable for the Studied Objects | Process | 1 | 2 | 3 | 4 | |||||||

| Product | 5 | 5 | 5 | 6 | 5 | 5 | 7 | |||||

| Service | 2 | 6 | 8 | |||||||||

| Region/Sector | 2 | 6 | 5 | 5 | ||||||||

| Thoroughness: Completeness and Resolution | Life Cycle Thinking | 9 | 9 | 2, 9 | 6 | 9 | 9 | |||||

| Inventoried Physical Quantities | Energy (J) | 2, 10 | 11, 12 | 4 | ||||||||

| Mass of Operating Materials (kg) | 2 | 12 | 4 | |||||||||

| Mass of Construction Materials (kg) | ||||||||||||

| Mass of Emissions (kg) | 7 | |||||||||||

| Temperature (K) and Pressure (Pa) | 4 | |||||||||||

| Impact Categories | Exergy (J) | 2, 8 | ||||||||||

| Climate change (kg CO2-eq) | ||||||||||||

| Water/Water Use/Others (m3, ha…) | ||||||||||||

| Noise | 13 | 2, 8 | ||||||||||

| Efficiency Reference | 14 | 7 | ||||||||||

| Temporal Resolution (Dynamic Analysis) | 15 | 16 | 7 | |||||||||

| Spatial or Sectoral Resolution | 9 | 9 | 9 | 9 | 14 | 9 | 9 | |||||

| Usability, Soundness | Pure Analysis based on Physical Quantities | 3 | 3 | 17 | 3 | |||||||

| Formalization (Methodological Framework and Rigor) | 14 | 18 | 14 | 14 | 14 | 14 | 14 | |||||

| Data Availability | 14 | 14 | 14 | 14 | 14 | 14 | 14 | |||||

| Existing Studies on Cooling Systems | 19 | 20 | 21 | 22 | 23 | 4, 24 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wenzel, P.M.; Radgen, P. Multi-Criteria Comparison of Energy and Environmental Assessment Approaches for the Example of Cooling Towers. Appl. Syst. Innov. 2022, 5, 89. https://doi.org/10.3390/asi5050089

Wenzel PM, Radgen P. Multi-Criteria Comparison of Energy and Environmental Assessment Approaches for the Example of Cooling Towers. Applied System Innovation. 2022; 5(5):89. https://doi.org/10.3390/asi5050089

Chicago/Turabian StyleWenzel, Paula M., and Peter Radgen. 2022. "Multi-Criteria Comparison of Energy and Environmental Assessment Approaches for the Example of Cooling Towers" Applied System Innovation 5, no. 5: 89. https://doi.org/10.3390/asi5050089

APA StyleWenzel, P. M., & Radgen, P. (2022). Multi-Criteria Comparison of Energy and Environmental Assessment Approaches for the Example of Cooling Towers. Applied System Innovation, 5(5), 89. https://doi.org/10.3390/asi5050089