Assessment of Fruit and Vegetable Residues Suitable for Renewable Energy Production: GIS-Based Model for Developing New Frontiers within the Context of Circular Economy

Abstract

1. Introduction

2. Materials and Methods

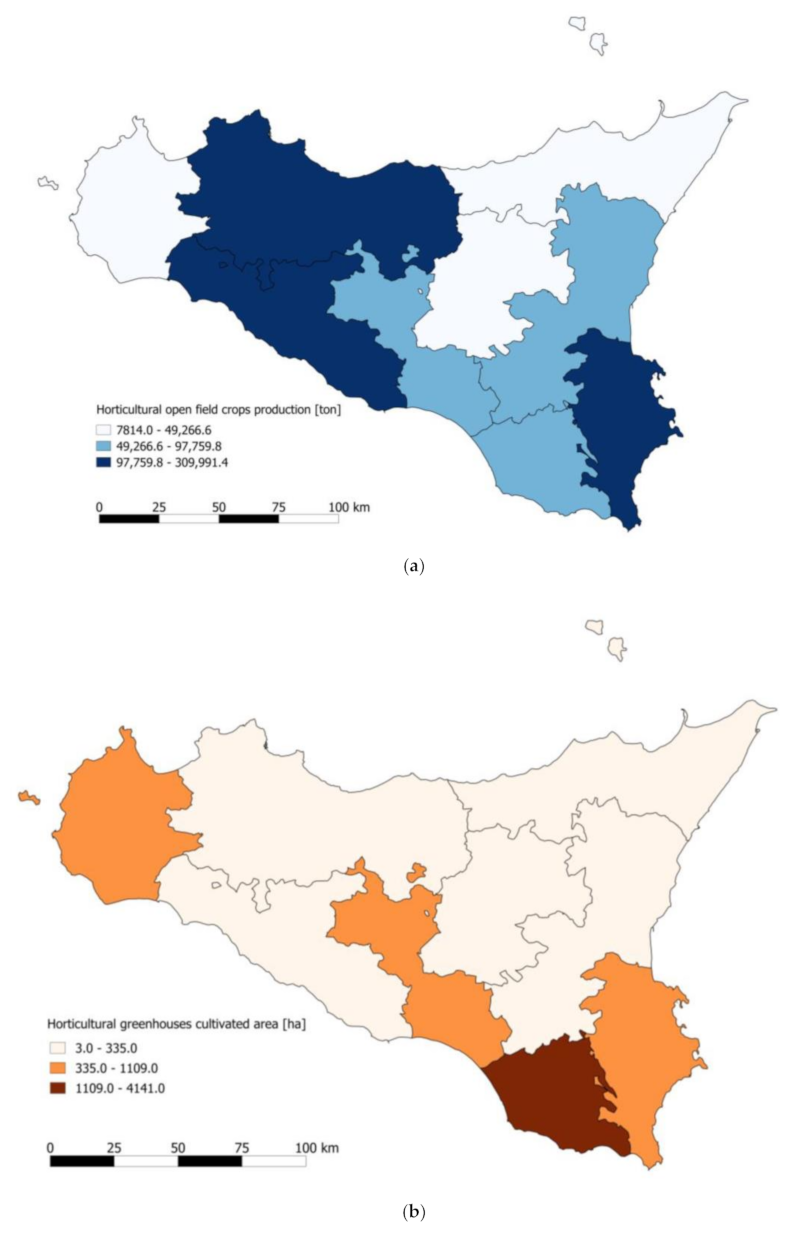

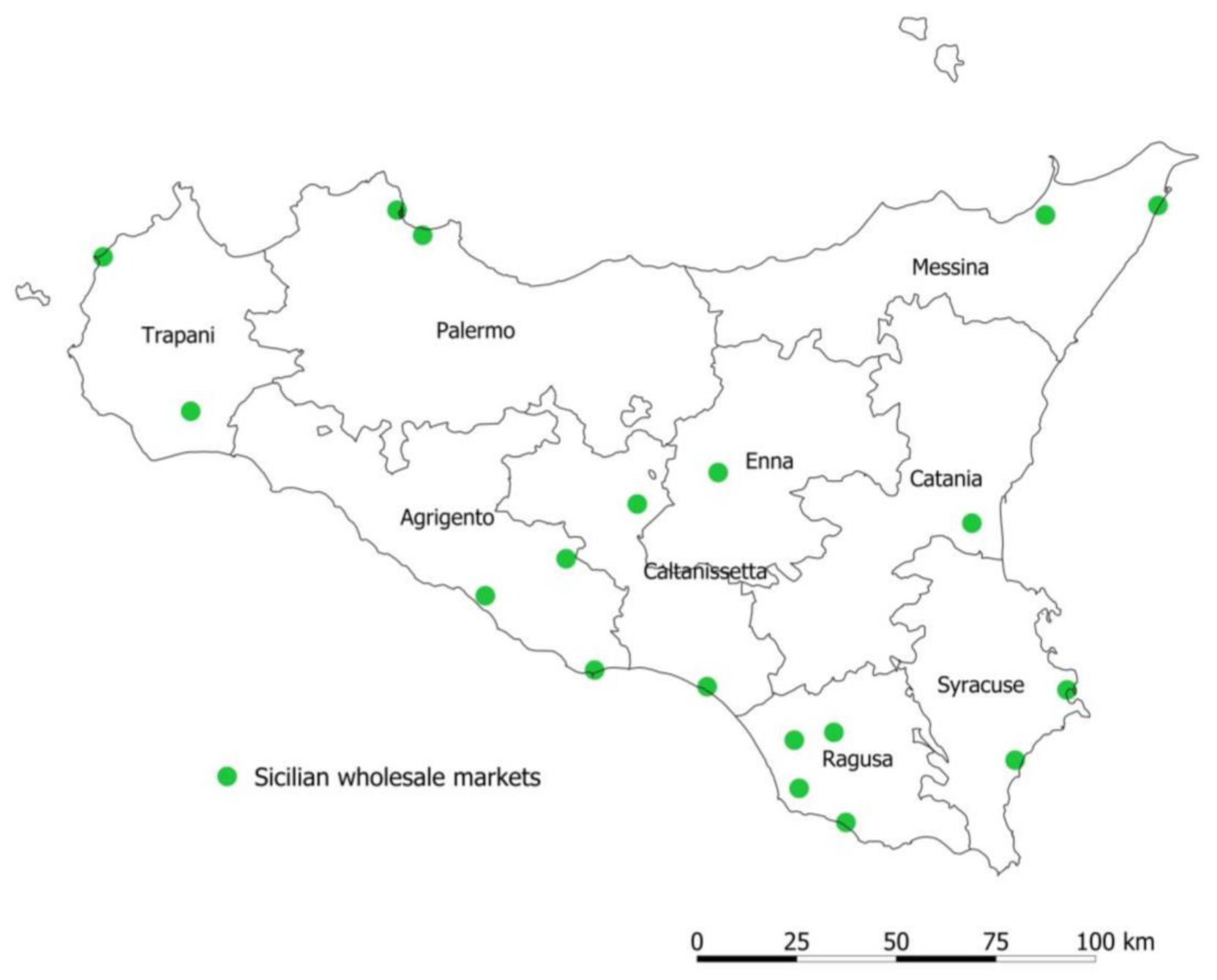

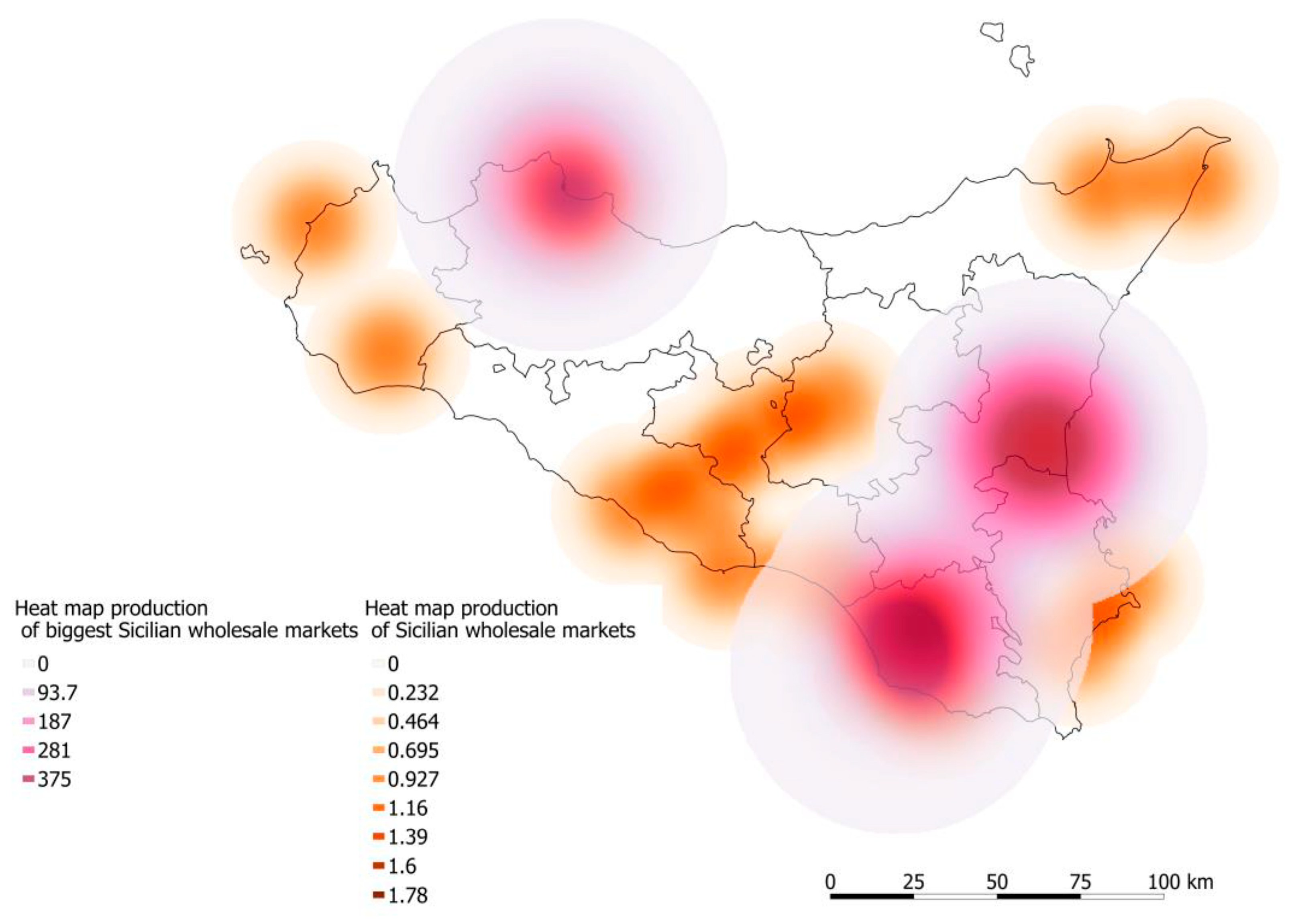

2.1. Case Study

2.2. Data Analysis

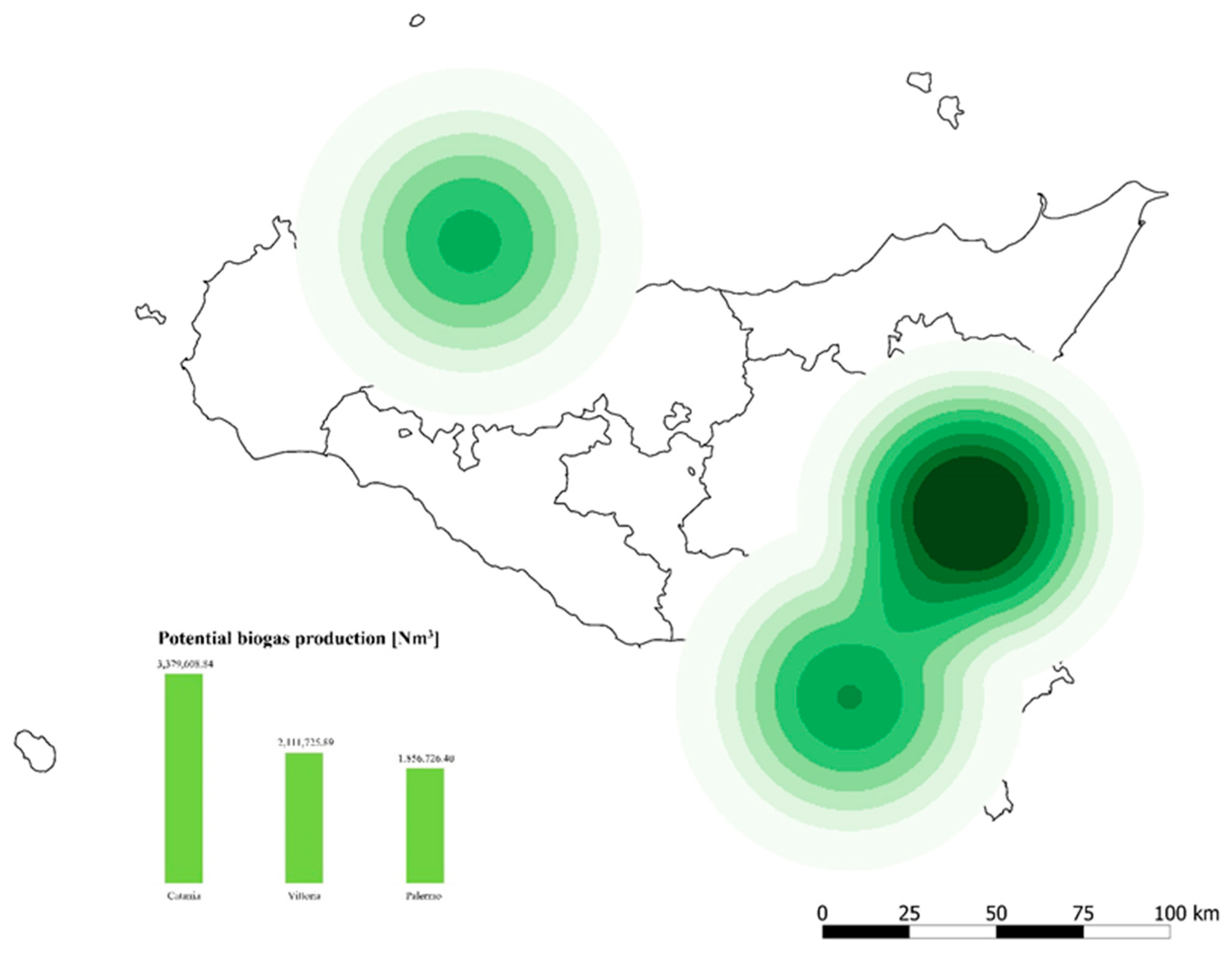

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Di Maria, F.; Sordi, A.; Cirulli, G.; Micale, C. Amount of energy recoverable from an existing sludge digester with the co-digestion with fruit and vegetable waste at reduced retention time. Appl. Energy 2015, 150, 9–14. [Google Scholar] [CrossRef]

- Ingrao, C.; Selvaggi, R.; Valenti, F.; Matarazzo, A.; Pecorino, B.; Arcidiacono, C. Life cycle assessment of expanded clay granulate production using different fuels. Resour. Conserv. Recycl. 2019, 141, 398–409. [Google Scholar] [CrossRef]

- Appels, L.; Lauwers, J.; Degrève, J.; Helsen, L.; Lievens, B.; Willems, K.; Van Impe, J.; Dewil, R. Anaerobic digestion in global bio-energy production: Potential and research challenges. Renew. Sust. Energy Rev. 2011, 15, 4295–4301. [Google Scholar] [CrossRef]

- Beurskens, L.W.M.; Hekkenberg, M. European Environment Agency—Renewable Energy Projection as Published in the National Renewable Energy Action Plans of the European Members States. 2011. Available online: http://www.ecn.nl/docs/library/report/2010/e10069.pdf (accessed on 15 October 2020).

- Directive 2001/77/EC of the European Parliament and of the Council of 27 September 2001 on the promotion of electricity produced from renewable energy sources in the internal electricity market. Off. J. Eur. Communities 2001, L283, 33–44.

- Bolzonella, D.; Battistoni, P.; Susini, C.; Cecchi, F. Anaerobic codigestion of waste activated sludge and OFMSW: The experience of Viareggio and Treviso plants (Italy). Water Sci. Technol. 2006, 53, 203–211. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Zuo, J.; Gan, L.; Li, P.; Liu, F.; Wang, K.; Chen, L.; Gan, H. Effects of mixture ratio on anaerobic co-digestion with fruit and vegetable waste and food waste of China. J. Environ. Sci. 2011, 23, 1403–1408. [Google Scholar] [CrossRef]

- Selvaggi, R.; Pappalardo, G.; Chinnici, G.; Fabbri, C. Assessing land efficiency of biomethane industry: A case study of Sicily. Energy Policy 2018, 119, 689–695. [Google Scholar] [CrossRef]

- Mostafavi, M.; Tajrishi, M.; Babaeinejad, S.M. Technical and Economic Study of Wastes in Agricultural Industry; Research Project at Sharif University of Technology Environmental Office: Tehran, Iran, 2003. [Google Scholar]

- Li, J.; Zuo, J.; Cai, H.; Zillante, G. Construction waste reduction behavior of contractor employees: An extended theory of planned behavior model approach. J. Clean. Prod. 2018, 172, 1399–1408. [Google Scholar] [CrossRef]

- Williams, H.; Wikstrom, F.; Otterbring, T.; Lofgren, M.; Gustafsson, A. Reasons for household food waste with special attention to packaging. J. Clean. Prod. 2012, 24, 141–148. [Google Scholar] [CrossRef]

- Pattnaik, S.; Reddy, M.V. Assessment of municipal solid waste management in Puducherry (Pondicherry), India. Resour. Conserv. Recycl. 2010, 54, 512–520. [Google Scholar] [CrossRef]

- Augustin, M.A.; Sanguansria, L.; Foxa, E.M.; Cobiac, L.; Cole, M.B. Recovery of wasted fruit and vegetables for improving sustainable diets. Trends Food Sci. Technol. 2020, 95, 75–85. [Google Scholar] [CrossRef]

- Viturtia, M.A.; Mata-Alvarez, J.; Cecchi, F. Two-phase continuous anaerobic digestion of fruit and vegetable wastes. Resour. Conserv. Recycl. 1995, 13, 257–267. [Google Scholar] [CrossRef]

- Abadi, B.; Mahdavian, S.; Fattahi, F. The waste management of fruit and vegetable in wholesale markets: Intention and behavior analysis using path analysis. J. Clean. Prod. 2021, 279, 123802. [Google Scholar] [CrossRef]

- Borowski, S. Co-digestion of the hydromechanically separated organic fraction of municipal solid waste with sewage sludge. J. Environ. Manag. 2015, 147, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Masebinu, S.O.; Akinlabi, E.T.; Muzenda, E.; Aboyade, A.O.; Mbohwa, C. Experimental and feasibility assessment of biogas production by anaerobic digestion of fruit and vegetable waste from Joburg Market. Waste Manag. 2018, 75, 236–250. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- FAO—Food and Agriculture Organization. Developing sustainable Food Value Chains—Guiding Principles; FAO: Rome, Italy, 2014. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste: Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2011. [Google Scholar]

- Segrè, A.; Falasconi, L. Il Libro Nero Dello Spreco in Italia: Il Cibo; Ambiente Edizioni: Milan, Italy, 2011. [Google Scholar]

- Scano, E.A.; Asquer, C.; Pistis, A.; Ortu, L.; Demontis, V.; Cocco, D. Biogas from anaerobic digestion of fruit and vegetable wastes: Experimental results on pilot-scale and preliminary performance evaluation of a full-scale power plant. Energy Convers. Manag. 2014, 77, 22–30. [Google Scholar] [CrossRef]

- Esparza, I.; Jimenez-Moreno, N.; Bimbela, F.; Ancín-Azpilicueta, C.; Gandía, L.M. Fruit and vegetable waste management: Conventional and emerging approaches. J. Environ. Manag. 2020, 265, 110510. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union 2008, L312/3, 1–32.

- Pavi, S.; Kramer, L.E.; Gomes, L.P.; Miranda, L.A.S. Biogas production from co-digestion of organic fraction of municipal solid waste and fruit and vegetable waste. Bioresour. Technol. 2017, 228, 362–367. [Google Scholar] [CrossRef]

- Directive 2006/12/EC of the European Parliament and of the Council of 5 April 2006 on Waste. Off. J. Eur. Union 2006, L114/9, 1–14.

- Pappalardo, G.; Selvaggi, R.; Lusk, J. Procedural invariance as a result of commitment costs: Evidence from an economic experiment on farmers’ willingness to pay for digestate. Appl. Econ. Lett. 2019, 26, 1243–1246. [Google Scholar] [CrossRef]

- Cristobal, J.; Caldeira, C.; Corrado, S.; Sala, S. Techno-economic and profitability analysis of food waste biorefineries at European level. Bioresour. Technol. 2018, 259, 244–252. [Google Scholar] [CrossRef] [PubMed]

- Heck, S.; Rogers, M. Century Resource Revolution: How to Capture the Biggest Business Opportunity in a Century; McKinsey Company: Seattle, WA, USA, 2014. [Google Scholar]

- Valenti, F.; Liao, W.; Porto, S.M.C. Life cycle assessment of agro-industrial by-product reuse: A comparison between anaerobic digestion and conventional disposal treatments. Green Chem. 2020, 22, 7119–7139. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.C.; Selvaggi, R.; Pecorino, B. Co-digestion of by-products and agricultural residues: A bioeconomy perspective for a Mediterranean feedstock mixture. Sci. Total Environ. 2020, 700, 134440. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.C.; Chinnici, G.; Cascone, G.; Arcidiacono, C. A GIS-based model to estimate citrus pulp availability for biogas production: An application to a region of the Mediterranean Basin. Biofuels Bioprod. Biorefining 2016, 10, 710–727. [Google Scholar] [CrossRef]

- Valenti, F.; Arcidiacono, C.; Chinnici, G.; Cascone, G.; Porto, S.M.C. Quantification of olive pomace availability for biogas production by using a GIS-based model. Biofuels Bioprod. Biorefining 2017, 11, 784–797. [Google Scholar] [CrossRef]

- Valenti, F.; Liao, W.; Porto, S.M.C. A GIS-based spatial index of feedstock-mixture availability for anaerobic co-digestion of Mediterranean by-products and agricultural residues. Biofuels Bioprod. Biorefining 2018, 12, 362–378. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.C. Net electricity and heat generated by reusing Mediterranean agro-industrial by-products. Energies 2019, 12, 470. [Google Scholar] [CrossRef]

- Panda, S.K.; Mishra, S.S.; Kayitesi, E.; Ray, R.C. Microbial-processing of fruit and vegetable wastes for production of vital enzymes and organic acids: Biotechnology and scopes. Environ. Res. 2016, 146, 161–172. [Google Scholar] [CrossRef]

- Diaz, A.I.; Laca, A.; Laca, A.; Diaz, M. Treatment of supermarket vegetable wastes to be used as alternative substrates in bioprocesses. Waste Manag. 2017, 67, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Liakou, V.; Paterakia, C.; Palaiogeorgoua, A.M.; Kopsahelisa, N.; De Castroc, M.M.; Freired, D.M.G.; Nychasa, G.J.E.; Papanikolaoua, S.; Koutinasa, A. Valorisation of fruit and vegetable waste from open markets for the production of 2,3-butanediol. Food Bioprod. Process. 2018, 108, 27–36. [Google Scholar] [CrossRef]

- Manetto, G.; Pecorino, B.; Selvaggi, R. Sustainability of a consortial anaerobic fermentation plant in Sicily. Qual. Access Success 2016, 17 (Suppl. 1), 106–112. [Google Scholar]

- Plazzotta, S.; Cottes, M.; Simeoni, P.; Manzocco, L. Evaluating the environmental and economic impact of fruit and vegetable waste valorisation: The lettuce waste study-case. J. Clean. Prod. 2020, 262, 121435. [Google Scholar] [CrossRef]

- ISTAT—Several Years. Available online: www.dati.istat.it (accessed on 7 November 2020).

- Valenti, F.; Porto, S.M.C.; Dale, B.E.; Liao, W. Spatial analysis of feedstock supply and logistics to establish regional biogas power generation: A case study in the region of Sicily. Renew. Sustain. Energy Rev. 2018, 97, 50–63. [Google Scholar] [CrossRef]

- Adani, F.; Schievano, A.; D’Imporzano, G. I Fattori Che Rendono Ottimale la Razione Per il Digestore. L’Informatore Agrario 2008, 40/2008:19. Available online: https://www.ilbiogas.it/biogas-ricerche-e-studi/fattori-razione-digestore.pdf (accessed on 24 November 2020).

- Schievano, A.; Pognani, M.; D’Imporzano, G.; Adani, F. Predicting anaerobic biogasification potential of ingestates and digestates of a full-scale biogas plant using chemical and biological parameters. Bioresour. Technol. 2008, 99, 8112–8117. [Google Scholar] [CrossRef]

- Pappalardo, G.; Selvaggi, R.; Bracco, S.; Chinnici, G.; Pecorino, B. Factors affecting purchasing process of digestate: Evidence from an economic experiment on Sicilian farmers’ willingness to pay. Agric. Food Econ. 2018, 6, 1–12. [Google Scholar] [CrossRef]

- Giuseppe, M.; Emanuele, C.; Rita, P.; Roberta, S.; Biagio, P. Performance evaluation of digestate spreading machines in vineyards and citrus orchards: Preliminary trials. Helyon 2020, 6, e04257. [Google Scholar] [CrossRef]

- Viswanath, P.; Devi, S.S.; Nand, S.K. Anaerobic digestion of fruit and vegetable processing wastes for biogas production. Biores. Technol. 1992, 40, 43–48. [Google Scholar] [CrossRef]

- Chinnici, G.; Selvaggi, R.; D’Amico, M.; Pecorino, B. Assessment of the potential energy supply and biomethane from the anaerobic digestion of agro-food feedstocks in Sicily. Renew. Sustain. Energy Rev. 2018, 82, 6–13. [Google Scholar] [CrossRef]

- Selvaggi, R.; Valenti, F.; Pappalardo, G.; Rossi, L.; Bozzetto, S.; Pecorino, B.; Dale, B.E. Sequential crops for food, energy, and economic development in rural areas: The case of Sicily. Biofuels Bioprod. Biorefining 2018, 12, 22–28. [Google Scholar] [CrossRef]

- Legislative Decree 205/2010 about Provisions Implementing Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; (10G0235) (OJ General Series n.288 of 10-12-2010—Ordinary Supplement n. 269); Off. J. Italian: Italy, 2010.

| Cultivated Area (ha) | Mean (ha) | |||||

|---|---|---|---|---|---|---|

| 2015 | 2016 | 2017 | 2018 | 2019 | ||

| Agrigento | ||||||

| 17,519 | 17,449 | 17,358 | 17,898 | 18,557 | 17,756 |

| 100.0 | 99.6 | 99.1 | 102.2 | 105.9 | ||

| 346 | 342 | 329 | 329 | 329 | 335 |

| 100.0 | 98.9 | 95.1 | 95.0 | 95.1 | ||

| Caltanissetta | ||||||

| 10,102 | 10,331 | 9978 | 9107 | 9019 | 9707 |

| 100.0 | 102.3 | 98.8 | 90.2 | 89.3 | ||

| 830 | 830 | 829 | 829 | 829 | 829 |

| 100.0 | 100.0 | 99.9 | 99.9 | 99.9 | ||

| Catania | ||||||

| 3846 | 3847 | 3232 | 3847 | 3849 | 3724 |

| 100.0 | 100.0 | 84.0 | 100.0 | 100.1 | ||

| 15 | 0.2 | 0.2 | 0.2 | 0.2 | 3 |

| 100.0 | 1.0 | 1.0 | 1.0 | 1.0 | ||

| Enna | ||||||

| 560 | 560 | 560 | 560 | 560 | 560 |

| 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | ||

| 11 | 9.0 | 9.0 | 9.0 | 9.0 | 9 |

| 100.0 | 85.7 | 85.7 | 85.7 | 85.7 | ||

| Messina | ||||||

| 1243 | 1703 | 1706 | 1717 | 1781 | 1630 |

| 100.0 | 137.0 | 137.2 | 138.1 | 143.3 | ||

| 55 | 0.9 | 0.9 | 0.9 | 0.9 | 12 |

| 100.0 | 1.6 | 1.6 | 1.6 | 1.6 | ||

| Palermo | ||||||

| 7185 | 7143 | 7663 | 7794 | 8015 | 7560 |

| 100.0 | 99.4 | 106.7 | 108.5 | 111.6 | ||

| 61 | 58.3 | 58.3 | 57.8 | 58.9 | 59 |

| 100.0 | 96.3 | 96.3 | 95.5 | 97.4 | ||

| Ragusa | ||||||

| 1835 | 1985 | 2095 | 2225 | 2170 | 2062 |

| 100.0 | 108.2 | 114.2 | 121.3 | 118.3 | ||

| 4470 | 4380.0 | 3970.0 | 3960.0 | 3925.0 | 4141 |

| 100.0 | 98.0 | 88.8 | 88.6 | 87.8 | ||

| Syracuse | ||||||

| 4943 | 5425 | 5453 | 5662 | 5802 | 5457 |

| 100.0 | 109.8 | 110.3 | 114.5 | 117.4 | ||

| 1135 | 1124.0 | 1108.5 | 1093.0 | 1083.1 | 1109 |

| 100.0 | 99.0 | 97.7 | 96.3 | 95.4 | ||

| Trapani | ||||||

| 2690 | 2315 | 2305 | 2195 | 1965 | 2294 |

| 100.0 | 86.1 | 85.7 | 81.6 | 73.0 | ||

| 1104 | 1094.0 | 1094.0 | 1134.0 | 1114.0 | 1108 |

| 100.0 | 99.1 | 99.1 | 102.7 | 100.9 | ||

| Production (t) | Mean (t) | |||||

|---|---|---|---|---|---|---|

| 2015 | 2016 | 2017 | 2018 | 2019 | ||

| Agrigento | ||||||

| 322,937 | 302,870 | 300,227 | 307,831 | 316,093 | 309,991 |

| 100.0 | 93.8 | 93.0 | 95.3 | 97.9 | ||

| 21,932 | 14,449 | 12,826 | 13,017 | 13,093 | 15,064 |

| 100.0 | 65.9 | 58.5 | 59.4 | 59.7 | ||

| Caltanissetta | ||||||

| 99,284 | 114,852 | 115,566 | 85,641 | 71,303 | 97,329 |

| 100.0 | 115.7 | 116.4 | 86.3 | 71.8 | ||

| 41,725 | 41,725 | 41,698 | 41,696 | 41,696 | 41,708 |

| 100.0 | 100.0 | 99.9 | 99.9 | 99.9 | ||

| Catania | ||||||

| 59,667 | 59,685 | 47,401 | 59,846 | 60,039 | 57,328 |

| 100.0 | 100.0 | 79.4 | 100.3 | 100.6 | ||

| 750 | 750 | 750 | 750 | 750 | 750 |

| 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | ||

| Enna | ||||||

| 7265 | 7970 | 8550 | 7750 | 7535 | 7814 |

| 100.0 | 109.7 | 117.7 | 106.7 | 103.7 | ||

| 695 | 1265 | 1265 | 1265 | 1265 | 1151 |

| 100.0 | 182.1 | 182.1 | 182.1 | 182.1 | ||

| Messina | ||||||

| 18,290 | 36,379 | 36,555 | 37,055 | 37,445 | 33,145 |

| 100.0 | 198.9 | 199.9 | 202.6 | 204.7 | ||

| 3181 | 1705 | 1818 | 1818 | 1818 | 7794 |

| 100.0 | 5.4 | 5.7 | 5.7 | 5.7 | ||

| Palermo | ||||||

| 85,253 | 84,611 | 106,318 | 106,939 | 109,989 | 98,622 |

| 100.0 | 99.2 | 124.7 | 125.4 | 129.0 | ||

| 20,173 | 19,664 | 19,666 | 19,736 | 20,051 | 19,858 |

| 100.0 | 97.5 | 97.5 | 97.8 | 99.4 | ||

| Ragusa | ||||||

| 52,057 | 52,640 | 71,350 | 82,100 | 83,300 | 68,289 |

| 100.0 | 101.1 | 137.1 | 157.7 | 160.0 | ||

| 239,300 | 232,300 | 209,250 | 220,300 | 243,000 | 228,830 |

| 100.0 | 97.1 | 87.4 | 92.1 | 101.5 | ||

| Syracuse | ||||||

| 111,035 | 122,614 | 123,920 | 124,616 | 125,591 | 121,555 |

| 100.0 | 110.4 | 111.6 | 112.2 | 113.1 | ||

| 45,240 | 44,224 | 45,320 | 44,815 | 45,412 | 45,002 |

| 100.0 | 97.8 | 100.2 | 99.1 | 100.4 | ||

| Trapani | ||||||

| 32,458 | 27,120 | 25,380 | 24,390 | 21,900 | 26,250 |

| 100.0 | 83.6 | 78.2 | 75.1 | 67.5 | ||

| 9704 | 9704 | 9754 | 10,474 | 10,434 | 10,014 |

| 100.0 | 100.0 | 100.5 | 107.9 | 107.5 | ||

| Site of the Wholesale Market | Incoming Products (Vegetables and Fruit) | Wastes | |

|---|---|---|---|

| (t) | (t) | (%) | |

| Catania | 308,579 | 21,376 | 6.9% |

| Vittoria | 261,901 | 13,357 | 5.1% |

| Palermo | 183,500 | 11,744 | 6.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selvaggi, R.; Valenti, F. Assessment of Fruit and Vegetable Residues Suitable for Renewable Energy Production: GIS-Based Model for Developing New Frontiers within the Context of Circular Economy. Appl. Syst. Innov. 2021, 4, 10. https://doi.org/10.3390/asi4010010

Selvaggi R, Valenti F. Assessment of Fruit and Vegetable Residues Suitable for Renewable Energy Production: GIS-Based Model for Developing New Frontiers within the Context of Circular Economy. Applied System Innovation. 2021; 4(1):10. https://doi.org/10.3390/asi4010010

Chicago/Turabian StyleSelvaggi, Roberta, and Francesca Valenti. 2021. "Assessment of Fruit and Vegetable Residues Suitable for Renewable Energy Production: GIS-Based Model for Developing New Frontiers within the Context of Circular Economy" Applied System Innovation 4, no. 1: 10. https://doi.org/10.3390/asi4010010

APA StyleSelvaggi, R., & Valenti, F. (2021). Assessment of Fruit and Vegetable Residues Suitable for Renewable Energy Production: GIS-Based Model for Developing New Frontiers within the Context of Circular Economy. Applied System Innovation, 4(1), 10. https://doi.org/10.3390/asi4010010