Durable and High-Efficiency Air Filtration by Superamphiphobic Silica Composite Aerogel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization

2.3. Test Method

3. Results

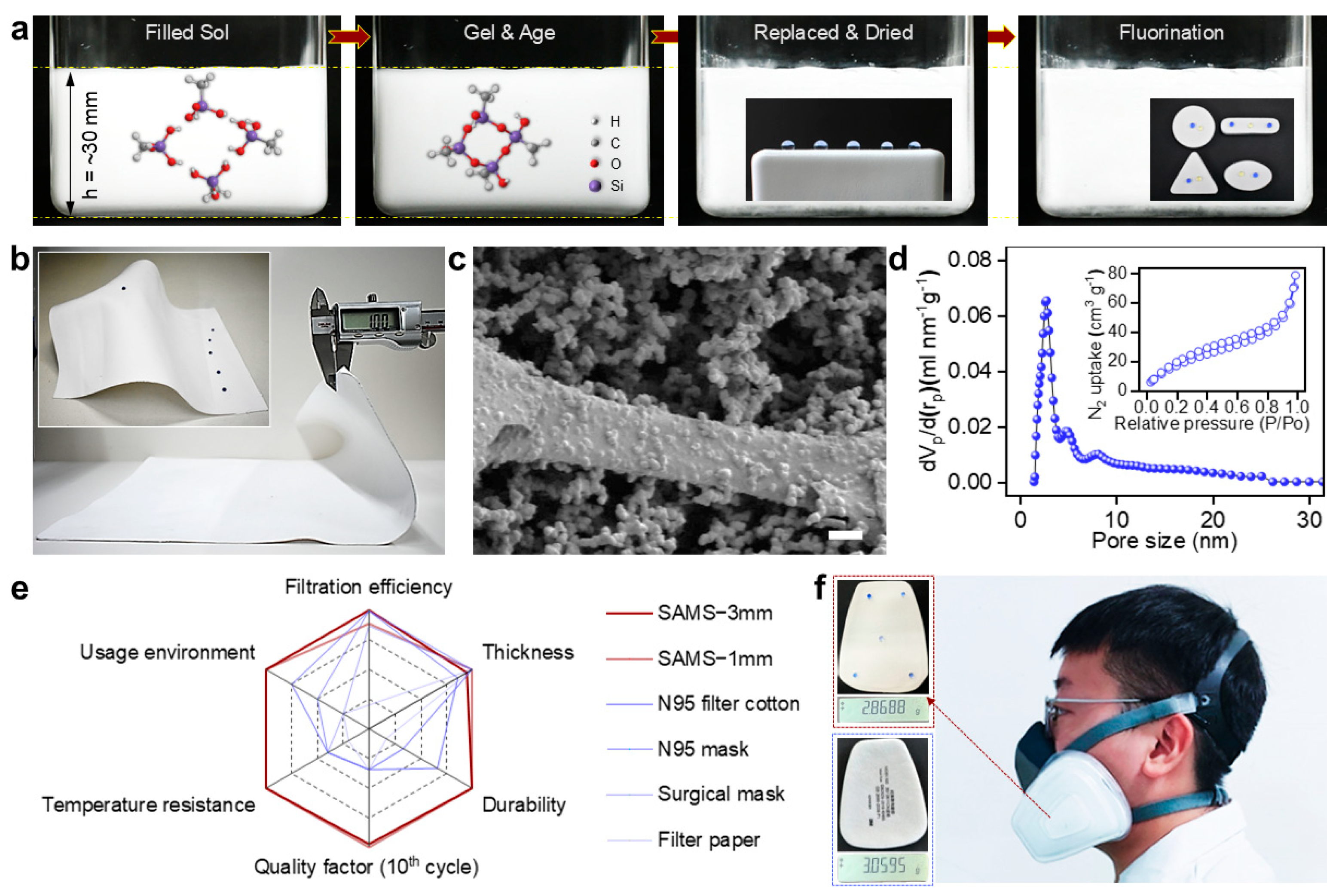

3.1. Fabrication and Key Characteristics of SAMS

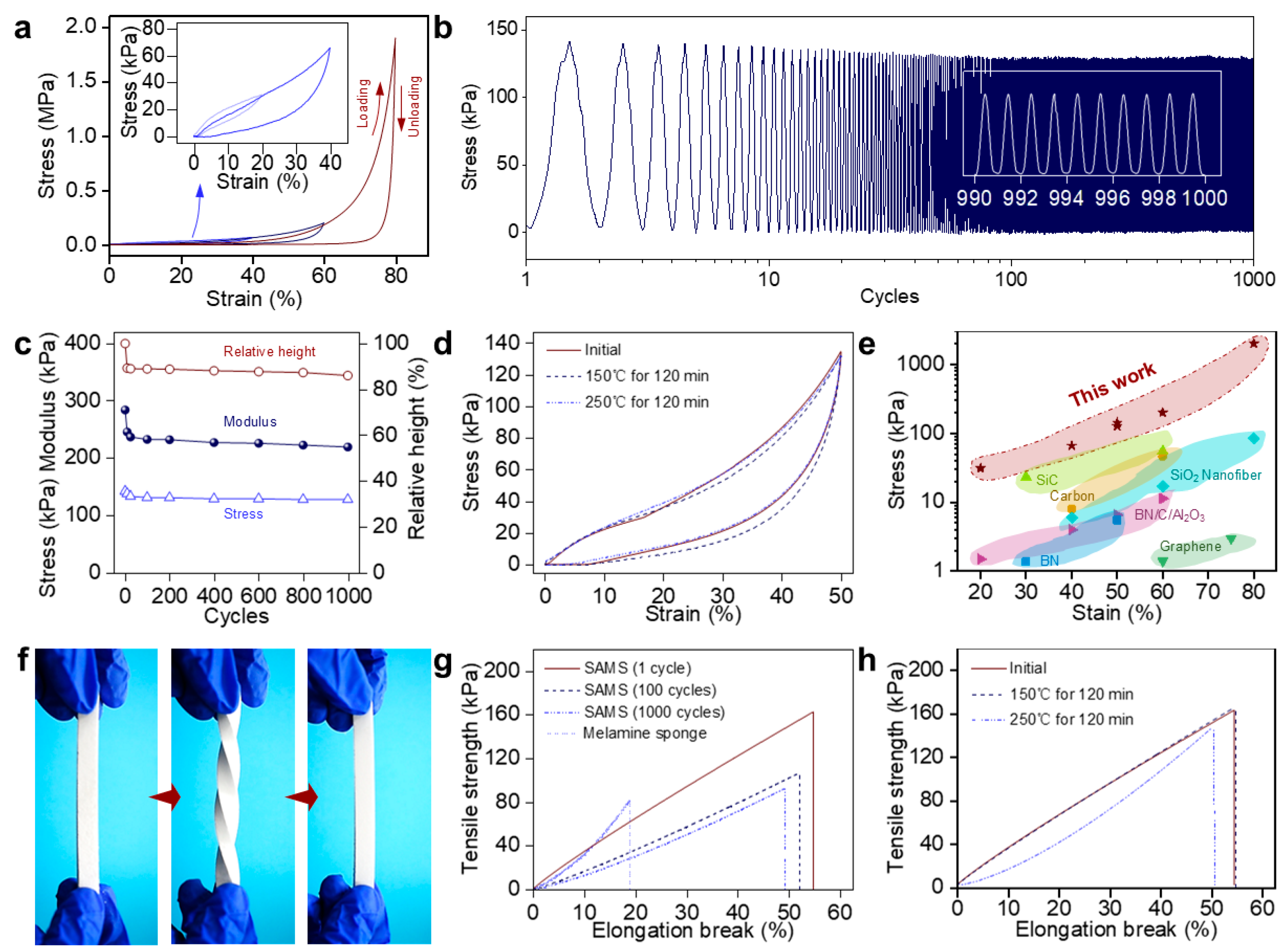

3.2. Mechanical Properties and Thermomechanical Stability of SAMS

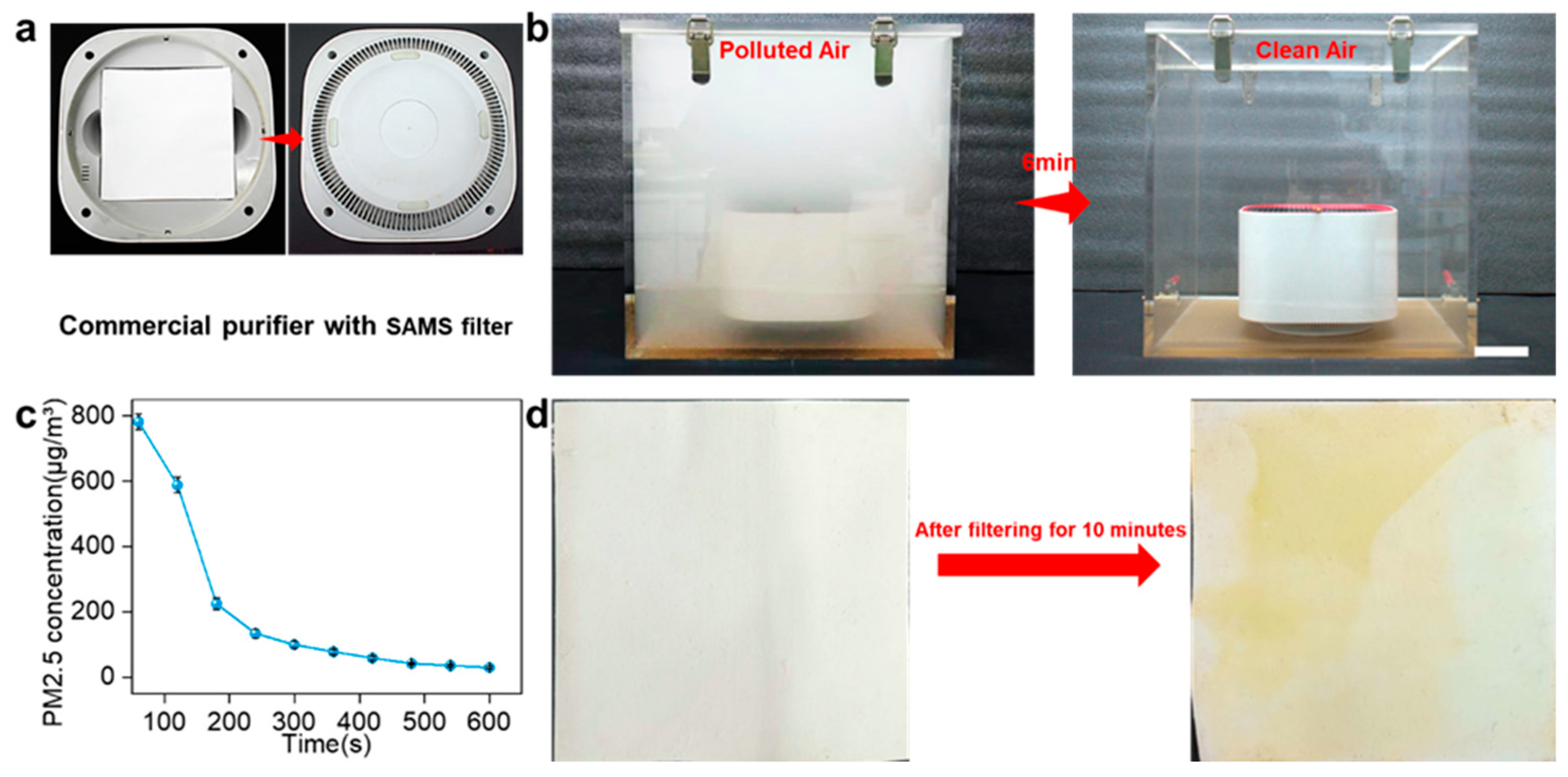

3.3. Filtration Performance of SAMS in Traditional Artificial Simulation Environments

3.4. Filtration Performance of SAMS in Extreme Environments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rentschler, J.; Leonova, N. Global air pollution exposure and poverty. Nat. Commun. 2023, 14, 4432. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Gao, Y.; Nie, G.; Yan, X.; Wang, S.; Zhang, T.; Ramakrishna, S.; Long, Y.Z.; Han, W. Biodegradable Poly (L-Lactic acid) Fibrous Membrane with Ribbon-Structured Fibers and Ultrafine Nanofibers Enhances Air Filtration Performance. Small 2024, 20, 2402317. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hu, S.; Chen, Y.; Qi, H. High-efficiency air filter aerogel resembling blood cell with heterogeneous epitaxial growth of zeolitic imidazolate framework-8 anchored on tunicate cellulose nanofibers for integrated air cleaning. Chem. Eng. J. 2023, 475, 146415. [Google Scholar] [CrossRef]

- Le, T.T.; Curry, E.J.; Vinikoor, T.; Das, R.; Liu, Y.; Sheets, D.; Tran, K.T.M.; Hawxhurst, C.J.; Stevens, J.F.; Hancock, J.N.; et al. Piezoelectric Nanofiber Membrane for Reusable, Stable, and Highly Functional Face Mask Filter with Long-Term Biodegradability. Adv. Funct. Mater. 2022, 32, 2113040. [Google Scholar] [CrossRef]

- Jerrett, M.J.N. Atmospheric science: The death toll from air-pollution sources. Nature 2015, 525, 330–331. [Google Scholar] [CrossRef]

- Yue, H.; He, C.; Huang, Q.; Zhang, D.; Shi, P.; Moallemi, E.A.; Xu, F.; Yang, Y.; Qi, X.; Ma, Q.; et al. Substantially reducing global PM2.5-related deaths under SDG3.9 requires better air pollution control and healthcare. Nat. Commun. 2024, 15, 2729. [Google Scholar] [CrossRef]

- Li, C.; van Donkelaar, A.; Hammer, M.S.; McDuffie, E.E.; Burnett, R.T.; Spadaro, J.V.; Chatterjee, D.; Cohen, A.J.; Apte, J.S.; Southerland, V.A.; et al. Reversal of trends in global fine particulate matter air pollution. Nat. Commun. 2023, 14, 5349. [Google Scholar] [CrossRef]

- Shi, Z.; Song, C.; Liu, B.; Lu, G.; Xu, J.; Van Vu, T.; Elliott, R.J.R.; Li, W.; Bloss, W.J.; Harrison, R.M. Abrupt but smaller than expected changes in surface air quality attributable to COVID-19 lockdowns. Sci. Adv. 2021, 7, eabd6696. [Google Scholar] [CrossRef]

- Apte, J.S.; Brauer, M.; Cohen, A.J.; Ezzati, M.; Pope, C.A. Ambient PM2.5 Reduces Global and Regional Life Expectancy. Environ. Sci. Technol. Lett. 2018, 5, 546–551. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Zhou, Z.; Qiu, Q.; Chen, W.; Huang, J.; Cai, W.; Qin, X.; Lai, Y. Ultrathin, ultralight dual-scale fibrous networks with high-infrared transmittance for high-performance, comfortable and sustainable PM0.3 filter. Nat. Commun. 2024, 15, 1586. [Google Scholar] [CrossRef]

- Tcharkhtchi, A.; Abbasnezhad, N.; Zarbini Seydani, M.; Zirak, N.; Farzaneh, S.; Shirinbayan, M. An overview of filtration efficiency through the masks: Mechanisms of the aerosols penetration. Bioact. Mater. 2021, 6, 106–122. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Iacoviello, F.; Fernandez, T.; Loureiro, R.; Brett, D.J.L.; Shearing, P.R. Microstructure analysis and image-based modelling of face masks for COVID-19 virus protection. Commun. Mater. 2021, 2, 69. [Google Scholar] [CrossRef]

- Zhao, M.; Liao, L.; Xiao, W.; Yu, X.; Wang, H.; Wang, Q.; Lin, Y.L.; Kilinc-Balci, F.S.; Price, A.; Chu, L.; et al. Household Materials Selection for Homemade Cloth Face Coverings and Their Filtration Efficiency Enhancement with Triboelectric Charging. Nano Lett. 2020, 20, 5544–5552. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Li, A.; Liu, Y.; Wang, L.; Qin, X.; Yu, J. Multi-Scale Nanoarchitectured Fibrous Networks for High-Performance, Self-Sterilization, and Recyclable Face Masks. Small 2021, 18, 2105570. [Google Scholar] [CrossRef]

- Deng, C.; Seidi, F.; Yong, Q.; Jin, X.; Li, C.; Zheng, L.; Yuan, Z.; Xiao, H. Virucidal and biodegradable specialty cellulose nonwovens as personal protective equipment against COVID-19 pandemic. J. Adv. Res. 2022, 39, 147–156. [Google Scholar] [CrossRef]

- Peng, Z.; Shi, J.; Xiao, X.; Hong, Y.; Li, X.; Zhang, W.; Cheng, Y.; Wang, Z.; Li, W.J.; Chen, J.; et al. Self-charging electrostatic face masks leveraging triboelectrification for prolonged air filtration. Nat. Commun. 2022, 13, 7835. [Google Scholar] [CrossRef]

- Lyu, P.; Ju, Z.; Hu, J.; Pan, H.; Li, X.; Liu, Y.; Ren, J.; Shang, B.; Liu, X.; Xu, W. Heat-Resistant Air Filters Based on Self-Sustained Electrostatic and Antibacterial Polyimide/Silver Fiber Mats. Adv. Funct. Mater. 2024, 34, 2400685. [Google Scholar] [CrossRef]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Wu, X.; Wang, L.; Zheng, H. A network effect on the decoupling of industrial waste gas emissions and industrial added value: A case study of China. J. Clean. Prod. 2019, 234, 1338–1350. [Google Scholar] [CrossRef]

- McDuffie, E.E.; Martin, R.V.; Spadaro, J.V.; Burnett, R.; Smith, S.J.; O’Rourke, P.; Hammer, M.S.; van Donkelaar, A.; Bindle, L.; Shah, V.; et al. Source sector and fuel contributions to ambient PM2.5 and attributable mortality across multiple spatial scales. Nat. Commun. 2021, 12, 3594. [Google Scholar] [CrossRef]

- Sales, E.; Mulatier, N.; Wittmann, L.; Fernandes, A.; Vacher, B.; Penuelas, J. Effect of dry heat treatment between room temperature and 160 °C on surgical masks. Mater. Lett. 2022, 308, 131270. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Wang, G.; Xiang, C.; Cong, X.; Gai, X.; Zhang, S.; Zhang, M.; Zhang, H.; Luan, J. Preparation of a novel poly (ether ether ketone) nonwoven filter and its application in harsh conditions for dust removal. Sep. Purif. Technol. 2020, 253, 117555. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, Y.; Wang, S.; Wang, X.; Yu, J.; Zhang, S.; Ding, B. Ultrathin aerogel-structured micro/nanofiber metafabric via dual air-gelation synthesis for self-sustainable heating. Nat. Commun. 2024, 15, 6416. [Google Scholar] [CrossRef]

- Li, Y.; Cao, L.; Yin, X.; Si, Y.; Yu, J.; Ding, B. Semi-Interpenetrating Polymer Network Biomimetic Structure Enables Superelastic and Thermostable Nanofibrous Aerogels for Cascade Filtration of PM2.5. Adv. Funct. Mater. 2020, 30, 1910426. [Google Scholar] [CrossRef]

- Hu, Z.; Yan, S.; Li, X.; You, R.; Zhang, Q.; Kaplan, D.L. Natural Silk Nanofibril Aerogels with Distinctive Filtration Capacity and Heat-Retention Performance. ACS Nano 2021, 15, 8171–8183. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Yang, F.; Xue, T.; Wali, Q.; Fan, W.; Liu, T. Metal-organic framework decorated polyimide nanofiber aerogels for efficient high-temperature particulate matter removal. Sep. Purif. Technol. 2022, 300, 121881. [Google Scholar] [CrossRef]

- Wang, F.; Si, Y.; Yu, J.; Ding, B. Tailoring Nanonets-Engineered Superflexible Nanofibrous Aerogels with Hierarchical Cage-Like Architecture Enables Renewable Antimicrobial Air Filtration. Adv. Funct. Mater. 2021, 31, 2107223. [Google Scholar] [CrossRef]

- Vareda, J.P.; Matias, T.; Durães, L. Facile preparation of ambient pressure dried aerogel-like monoliths with reduced shrinkage based on vinyl-modified silica networks. Ceram. Int. 2018, 44, 17453–17458. [Google Scholar] [CrossRef]

- Durães, L.; Ochoa, M.; Rocha, N.; Patrício, R.; Duarte, N.; Redondo, V.; Portugal, A. Effect of the Drying Conditions on the Microstructure of Silica Based Xerogels and Aerogels. J. Nanosci. Nanotechnol. 2012, 12, 6828–6834. [Google Scholar] [CrossRef]

- Omranpour, H.; Motahari, S. Effects of processing conditions on silica aerogel during aging: Role of solvent, time and temperature. J. Non-Cryst. Solids 2013, 379, 7–11. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Provisional). Pure Appl. Chem. 1982, 54, 2201–2218. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Liao, Y.; Yu, J.; Liu, Y.T.; Ding, B. Building-Envelope-Inspired, Thermomechanically Robust All-Fiber Ceramic Meta-Aerogel for Temperature-Controlled Dominant Infrared Camouflage. Adv. Mater. 2024, 36, 2313720. [Google Scholar] [CrossRef]

- Wang, J.; Liu, D.; Li, Q.; Chen, C.; Chen, Z.; Song, P.; Hao, J.; Li, Y.; Fakhrhoseini, S.; Naebe, M.; et al. Lightweight, Superelastic Yet Thermoconductive Boron Nitride Nanocomposite Aerogel for Thermal Energy Regulation. ACS Nano 2019, 13, 7860–7870. [Google Scholar] [CrossRef]

- Chang, X.; Yang, Y.; Cheng, X.; Yin, X.; Yu, J.; Liu, Y.T.; Ding, B. Multiphase Symbiotic Engineered Elastic Ceramic-Carbon Aerogels with Advanced Thermal Protection in Extreme Oxidative Environments. Adv. Mater. 2024, 36, 2406055. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Tian, H.; Li, L.; Liu, W.; Liu, J.; Zeng, Z.; Wu, N. Graphene-Assisted Assembly of Electrically and Magnetically Conductive Ceramic Nanofibrous Aerogels Enable Multifunctionality. Adv. Funct. Mater. 2024, 34, 2314653. [Google Scholar] [CrossRef]

- Yan, M.; Zhang, H.; Fu, Y.; Pan, Y.; Lun, Z.; Zhang, Z.; He, P.; Cheng, X. Implementing an Air Suction Effect Induction Strategy to Create Super Thermally Insulating and Superelastic SiC Aerogels. Small 2022, 18, 2201039. [Google Scholar] [CrossRef]

- Wang, N.; Feng, Y.; Zheng, Y.; Zhang, L.; Feng, M.; Li, X.; Zhou, F.; Wang, D. New Hydrogen Bonding Enhanced Polyvinyl Alcohol Based Self-Charged Medical Mask with Superior Charge Retention and Moisture Resistance Performances. Adv. Funct. Mater. 2021, 31, 2009172. [Google Scholar] [CrossRef]

- Sun, B.; Zhao, J.; Wang, T.; Li, Y.; Yang, X.; Tan, F.; Li, Y.; Chen, C.; Sun, D. Highly efficient construction of sustainable bacterial cellulose aerogels with boosting PM filter efficiency by tuning functional group. Carbohydr. Polym. 2023, 309, 120664. [Google Scholar] [CrossRef]

- Tian, Z.; Lei, Y.; Ye, X.; Fan, Y.; Zhou, P.; Zhu, Z.; Sun, H.; Liang, W.; Li, A. Efficient capture of airborne PM by nanotubular conjugated microporous polymers based filters under harsh conditions. J. Hazard. Mater. 2022, 423, 127047. [Google Scholar] [CrossRef]

- Ma, X.Y.D.; Zeng, Z.; Wang, Z.; Xu, L.; Zhang, Y.; Ang, J.M.; Wan, M.P.; Ng, B.F.; Lu, X. Robust microhoneycomb-like nanofibrous aerogels derived from cellulose and lignin as highly efficient, low-resistant and anti-clogging air filters. J. Membr. Sci. 2022, 642, 119977. [Google Scholar] [CrossRef]

- Qiao, S.; Yan, J.; Wang, Z.; Wang, Y.; Yu, J.; Hu, Z. Tough and lightweight polyimide/cellulose nanofiber aerogels with hierarchical porous structures as an efficient air purifier. Sep. Purif. Technol. 2023, 325, 124668. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, J.; Mei, T.; He, X.; Zhong, W.; Liu, K.; Wang, W.; Wang, Y.; Li, M.; Wang, D. A facile route to the production of polymeric nanofibrous aerogels for environmentally sustainable applications. J. Mater. Chem. A 2018, 6, 3692–3704. [Google Scholar] [CrossRef]

- Qin, B.; Yu, Z.L.; Huang, J.; Meng, Y.F.; Chen, R.; Chen, Z.; Yu, S.H. A Petrochemical-Free Route to Superelastic Hierarchical Cellulose Aerogel. Angew. Chem. Int. Ed. 2022, 62, e202214809. [Google Scholar] [CrossRef] [PubMed]

- Shin, W.; Lee, K.S.; Kim, K.D.; Park, S.; Choa, Y.; Park, Y.O. Particulate removal characteristics of commercial-scale DeNOx catalyst cartridge coupled filter bags. Powder Technol. 2024, 445, 120071. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Z.; Yu, Q.; Li, P.; Zhou, F.; Xu, C.; Zhao, X.; Teng, Y. Superdurable Full-Life Superhydrophobic Composite Block. Adv. Mater. 2024, 36, 2403853. [Google Scholar] [CrossRef] [PubMed]

- Guan, H.; Lian, R.; Li, R.; Zhu, J.; Zhao, Z.; Liu, L.; Chen, X.; Jiao, C.; Kuang, S. A Low-Temperature Carbonization Strategy for Efficient Viscous Crude Oil Spill Disposal without Hydrophobic Coating: CoFe-PBA-Catalyzed Carbonization of Superhydrophobic Flame Retardant Melamine Sponge. Adv. Funct. Mater. 2023, 34, 2313224. [Google Scholar] [CrossRef]

- Venkateswara Rao, A.; Pajonk, G.M.; Parvathy, N.N. Influence of molar ratios of precursor, catalyst, solvent and water on monolithicity and physical properties of TMOS silica aerogels. J. Sol-Gel Sci. Technol. 1994, 3, 205–217. [Google Scholar] [CrossRef]

- Martins da Silva Filho, P.; Higor Rocha Mariano, P.; Lopes Andrade, A.; Barros Arrais Cruz Lopes, J.; de Azevedo Pinheiro, A.; Itala Geronimo de Azevedo, M.; Carneiro de Medeiros, S.; Alves de Vasconcelos, M.; Gonçalvez da Cruz Fonseca, S.; Barbosa Grangeiro, T.; et al. Antibacterial and antifungal action of CTAB-containing silica nanoparticles against human pathogens. Int. J. Pharm. 2023, 641, 123074. [Google Scholar] [CrossRef]

- Sharma, A.; Tiwari, S.; Deb, M.K.; Marty, J.L. Severe acute respiratory syndrome coronavirus-2 (SARS-CoV-2): A global pandemic and treatment strategies. Int. J. Antimicrob. Agents 2020, 56, 106054. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Q.; Mu, Y.; Li, P.; Zhou, W.; Zhang, J.; Li, J.; Wei, Y.; Wang, S. Durable and High-Efficiency Air Filtration by Superamphiphobic Silica Composite Aerogel. Colloids Interfaces 2025, 9, 38. https://doi.org/10.3390/colloids9030038

Yu Q, Mu Y, Li P, Zhou W, Zhang J, Li J, Wei Y, Wang S. Durable and High-Efficiency Air Filtration by Superamphiphobic Silica Composite Aerogel. Colloids and Interfaces. 2025; 9(3):38. https://doi.org/10.3390/colloids9030038

Chicago/Turabian StyleYu, Qiang, Yuxin Mu, Pengfei Li, Wenjun Zhou, Jianwen Zhang, Jinchao Li, Yong Wei, and Shanlin Wang. 2025. "Durable and High-Efficiency Air Filtration by Superamphiphobic Silica Composite Aerogel" Colloids and Interfaces 9, no. 3: 38. https://doi.org/10.3390/colloids9030038

APA StyleYu, Q., Mu, Y., Li, P., Zhou, W., Zhang, J., Li, J., Wei, Y., & Wang, S. (2025). Durable and High-Efficiency Air Filtration by Superamphiphobic Silica Composite Aerogel. Colloids and Interfaces, 9(3), 38. https://doi.org/10.3390/colloids9030038