1. Introduction

Lightweight concrete is a promising composite material and is used in many structural sectors, including hydrotechnical engineering for the construction of oil and gas platforms, floating docks, and other floating structures [

1,

2]. The most popular lightweight concrete option for the construction of hydrotechnical structures, including floating ones, is expanded clay concrete (ECC) [

3,

4]. In the construction of floating reinforced concrete structures, one of the most important objectives is to reduce the weight of the structure without losing strength properties, and the effectiveness of ECC composites is assessed by the ratio of the material’s strength to its weight. The effectiveness of ECC in hydrotechnical engineering has been confirmed by many studies. For example, colored ECCs developed for floating reinforced concrete structures containing iron oxide pigments have demonstrated excellent mechanical properties and frost resistance from F450 to F500 [

5]. The inclusion of complex plasticizing and antifreeze additives in the composition of ECC allows for significant improvement of their properties and the full use of these composites in construction in the conditions of the Far North and the Arctic [

6]. Self-compacting ultra-light foam concrete with 20% recycled expanded clay content demonstrates good strength properties and increased buoyancy [

7].

Despite all the potential advantages of using ECC composites in hydrotechnical engineering and for manufacturing floating structures, its actual application in this field is limited. Technological difficulties in the ECC manufacturing process are the main reason limiting its application. Lightweight expanded clay aggregate (LECA) has a cellular porous structure and high water absorption, which significantly affects the rheology of ECC mixtures [

8,

9]. In addition, a significant difference in the density of cement-sand mortar and LECA can lead to segregation and, as a result, to a decrease in the homogeneity of the composite structure [

10]. The use of formulation and technological techniques aimed at processing the surface of LECA grains allows us to solve the above-mentioned problems in the ECC manufacturing technology and improve their strength properties. Treatment of the LECA surface with cement mixtures with the addition of glass powder and ground granulated blast furnace slag allows us to reduce its water absorption and significantly increase the strength properties of the composite, while maintaining the same density [

11]. Pre-treatment of LECA with cement mortar improves its adhesion to the cement matrix and, therefore, increases compressive strength [

12]. The inclusion of LECA impregnated with polyethylene glycol reduces water absorption of concrete and increases its durability [

13]. Treatment of LECA with a geopolymer suspension and its inclusion in the composition of lightweight alkali-activated concrete ensures maximum compressive strength of up to 49.17 MPa [

14]. Other popular formulation and technological solutions aimed at improving the properties of concrete, including ECC, are modification with mineral additives and dispersed reinforcement with various types of fiber [

15,

16,

17,

18,

19,

20,

21]. The use of MS in the composition of cement-stable concrete improves its strength characteristics and increases corrosion resistance [

21]. Positive results from the use of MS additive in concrete have been demonstrated in several other studies [

22,

23,

24]. The addition of fibers to the concrete composition allows to improve its mechanical properties, reducing shrinkage, and increasing durability [

25,

26,

27]. The most popular and most accessible type of dispersed fiber used in concrete technology is basalt fiber. For example, the introduction of 0.3% basalt fiber (BF) into the composition of ECC reduces the drying shrinkage on the 90th day by 20.67% [

28]. BF in the composition of lightweight concrete in an amount of 0.3% increases its compressive and flexural strength by 24.7% and 33.9%, respectively [

29]. The combination of basalt and polypropylene fibers in dosages of 0.05% and 0.1% provides an increase in compressive strength by 13.7% and tensile splitting strength by 76.3% [

30]. Dispersed reinforcement of BF has a positive effect on the mechanism of concrete destruction, slowing down crack propagation through the mechanism of stress concentration transfer [

31]. Similarly, other studies have shown that including BF provides improved properties of composites [

32,

33,

34,

35,

36].

As seen from the review, the amount of scientific research aimed at developing strong and lightweight composite materials for the construction of floating reinforced concrete structures is currently limited. The use of lightweight porous aggregates in cement composite technology will allow for a significant reduction in density; however, the mechanical properties of the composites will also decrease [

37]. In addition, technological difficulties during the preparation of fresh concrete using lightweight aggregates, caused by their high water absorption capacity and uneven distribution of aggregate grains in the cement-sand mortar, limit the use of ECC. This study is aimed at exploring and selecting formulations and technological methods aimed at obtaining ECC with improved performance properties. It is possible to increase the strength of composites, in particular ECC, intended for the construction of floating structures through the use of various formulation and technological methods and their combinations in the process of selecting compositions and manufacturing ECC [

38,

39,

40]. The scientific novelty of this work lies in the development of new compositions of effective ECC with reinforced lightweight aggregate and dispersed fiber for the construction of floating hydrotechnical structures and the derivation of new relationships between the properties and structure of ECC and formulation and process parameters.

The aim of this study is to produce composite reinforced expanded clay concrete and basalt fiber concrete for hydrotechnical engineering for floating structures.

The objectives of the study included:

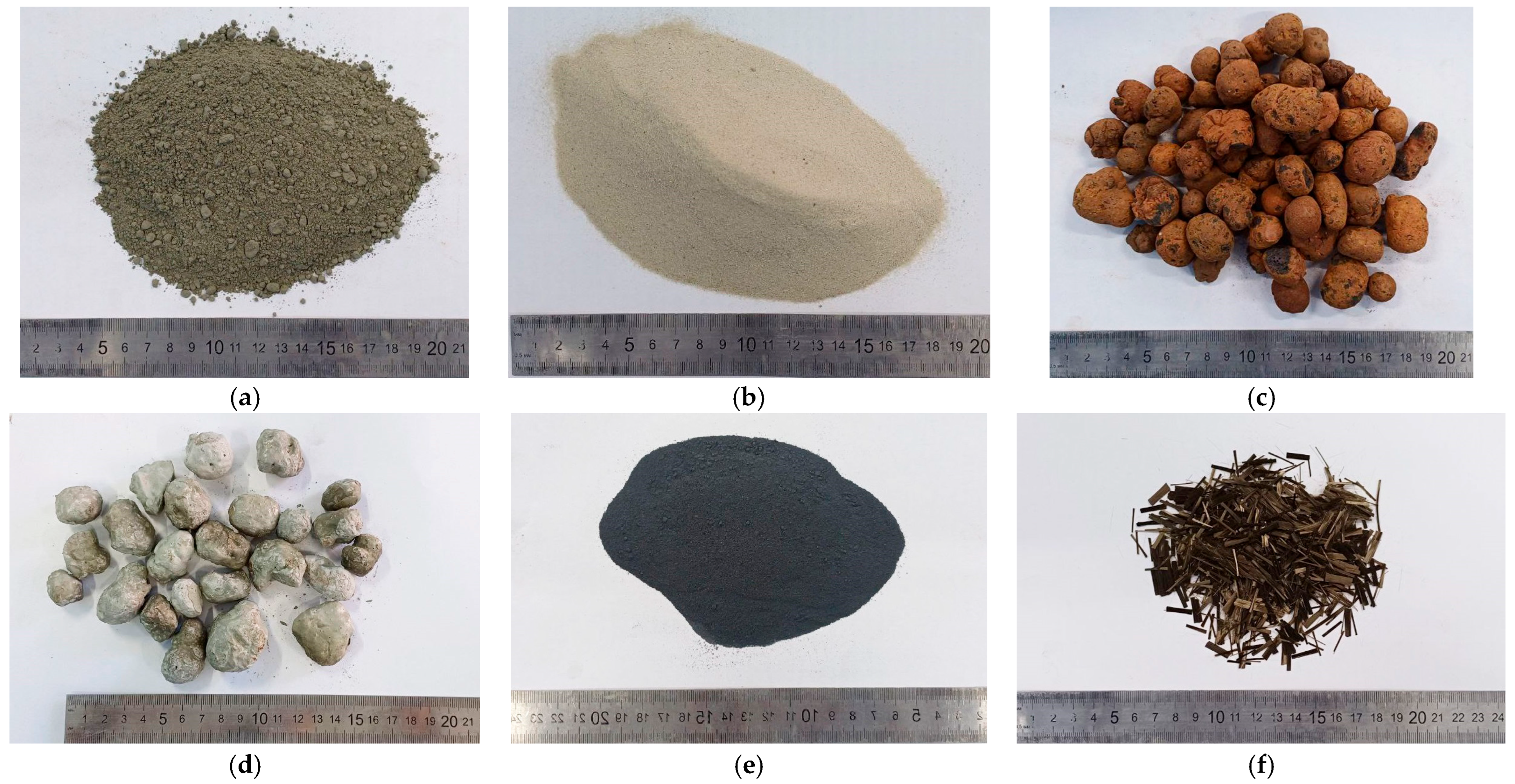

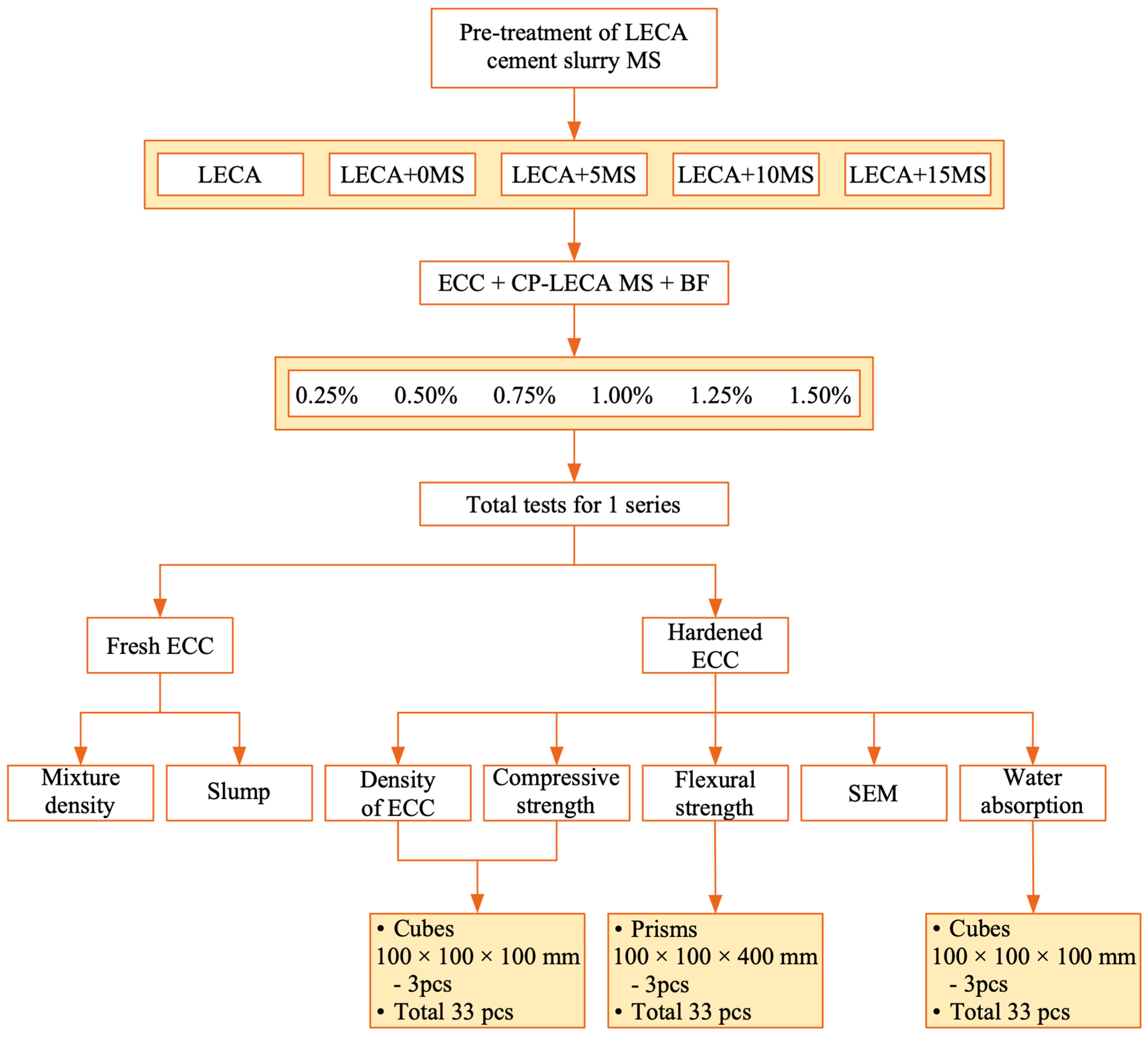

Developing compositions of cement pastes with varying MS dosages and their preparation;

Treating LECA with cement pastes and obtaining experimental samples of pre-treated LECA (CP-LECA);

Developing compositions of fresh ECC using experimental samples of CP-LECA and dispersed fiber BF, as well as the production of 11 series of experimental ECC samples;

Conducting a series of laboratory studies to evaluate the density and slump of fresh ECC, as well as the density, compressive strength, flexural strength, and water absorption of experimental ECC samples; determining the structural quality factor of the developed ECC;

Studying the structure of the developed ECC, processing experimental data, and determining optimal formulation parameters;

Describing the scope of application of the developed ECC.

3. Results and Discussion

The main properties, such as density and strength, of untreated LECA and pre-treated LECA are presented in

Table 4.

The data presented in

Table 4 demonstrate that treating LECA with cement pastes modified with varying amounts of MS increases its bulk density and strength. The highest bulk density and strength values were recorded for aggregate treated with a cement paste containing 10% MS. Therefore, this paste appears to be the most preferable for pre-treating LECA grains.

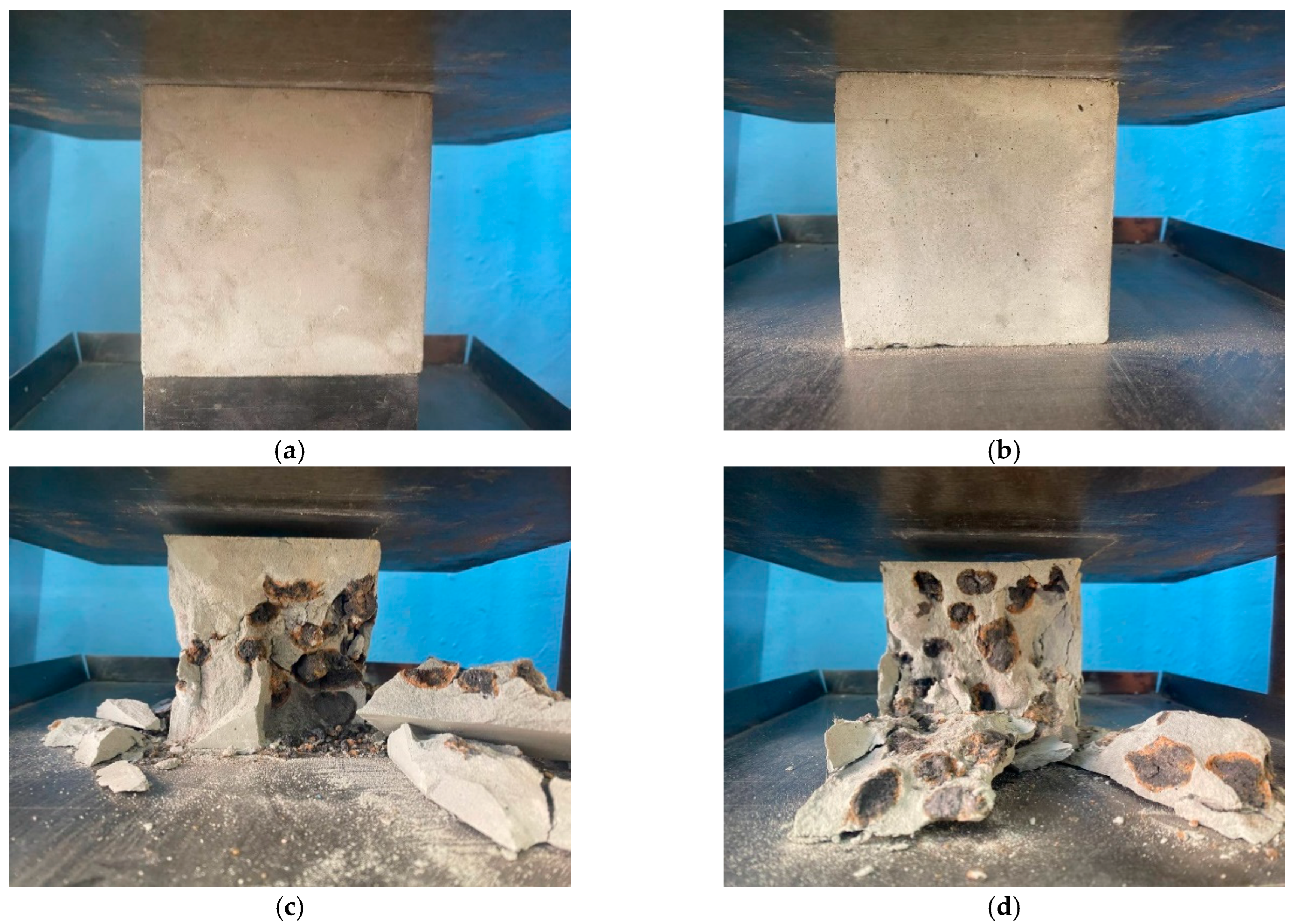

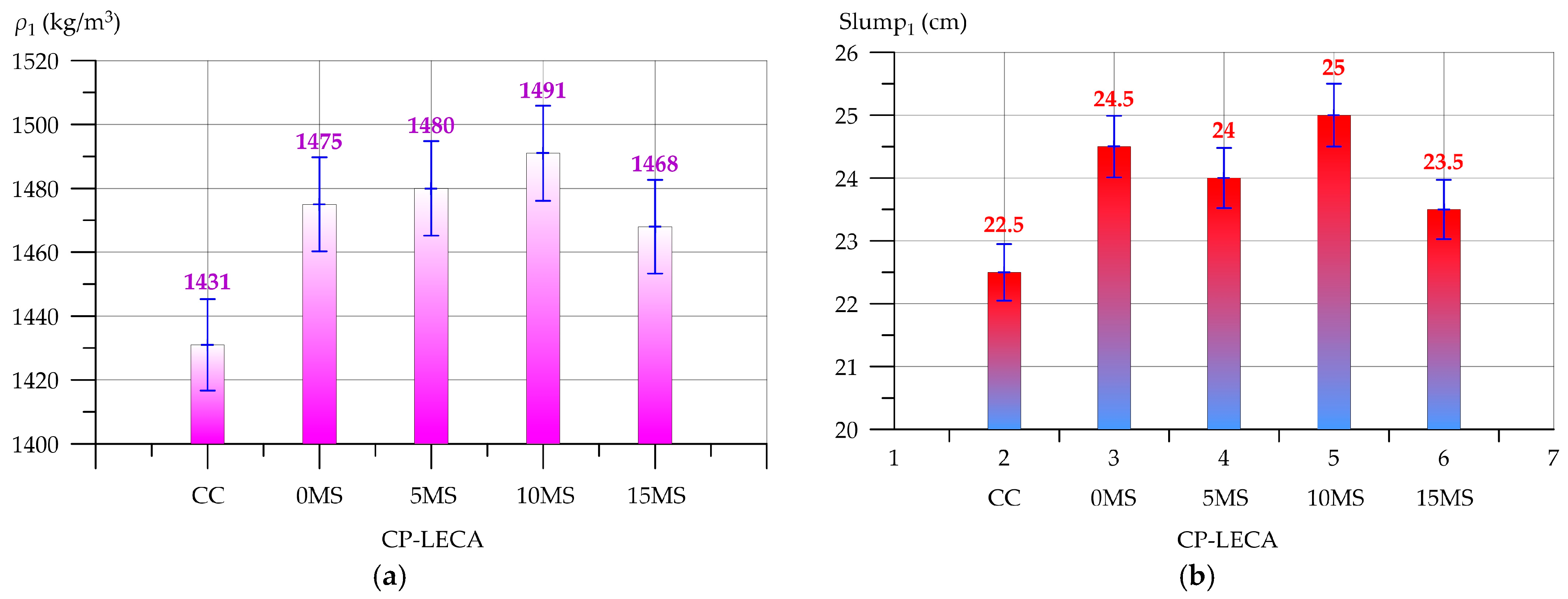

The results of determining the density and slump of fresh ECC produced using LECA pre-treated with cement pastes containing varying amounts of the modifying MS additive are presented in

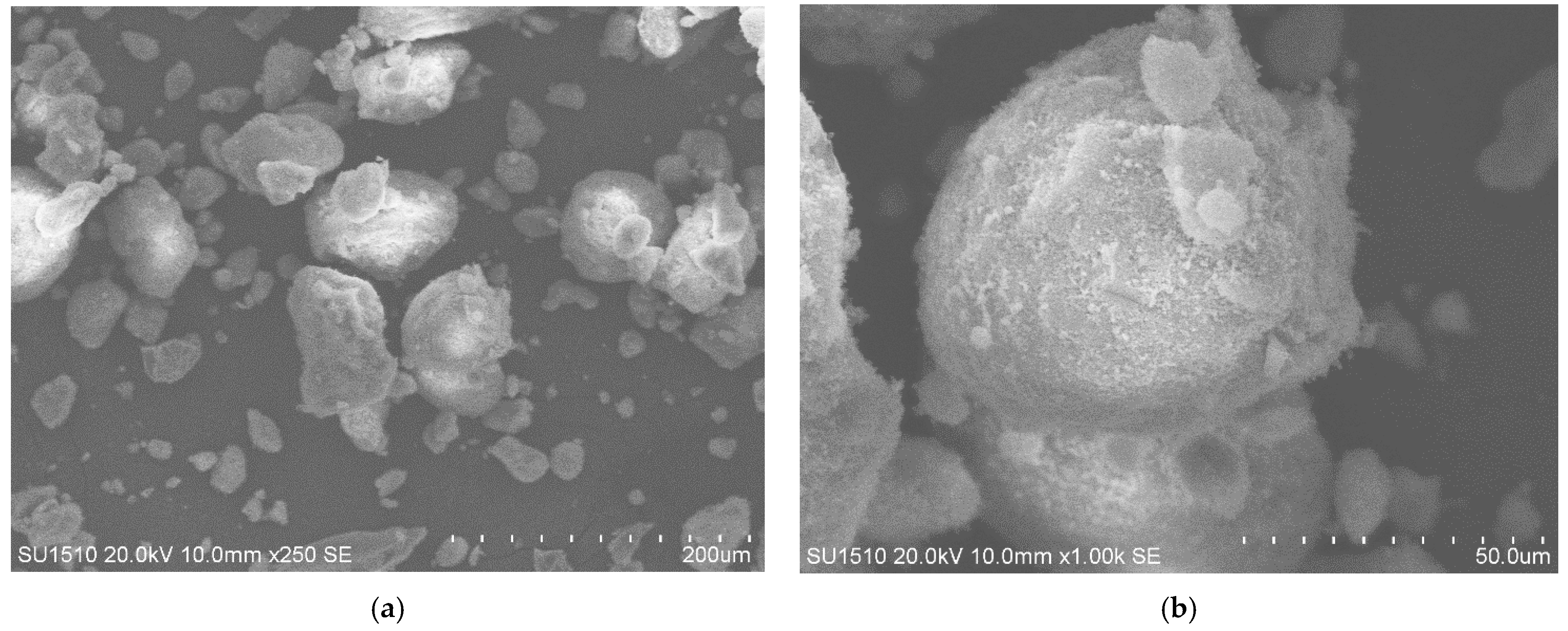

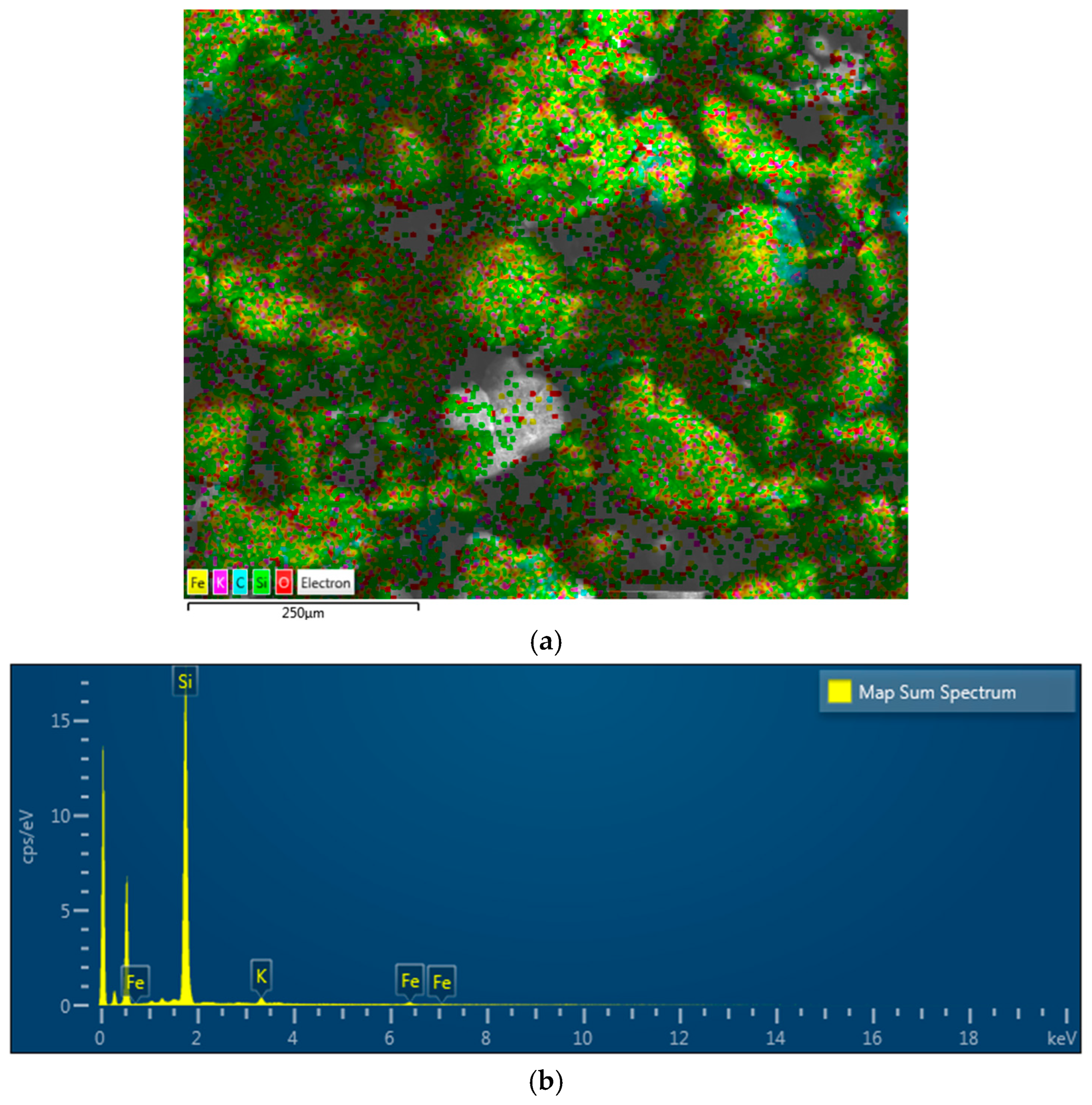

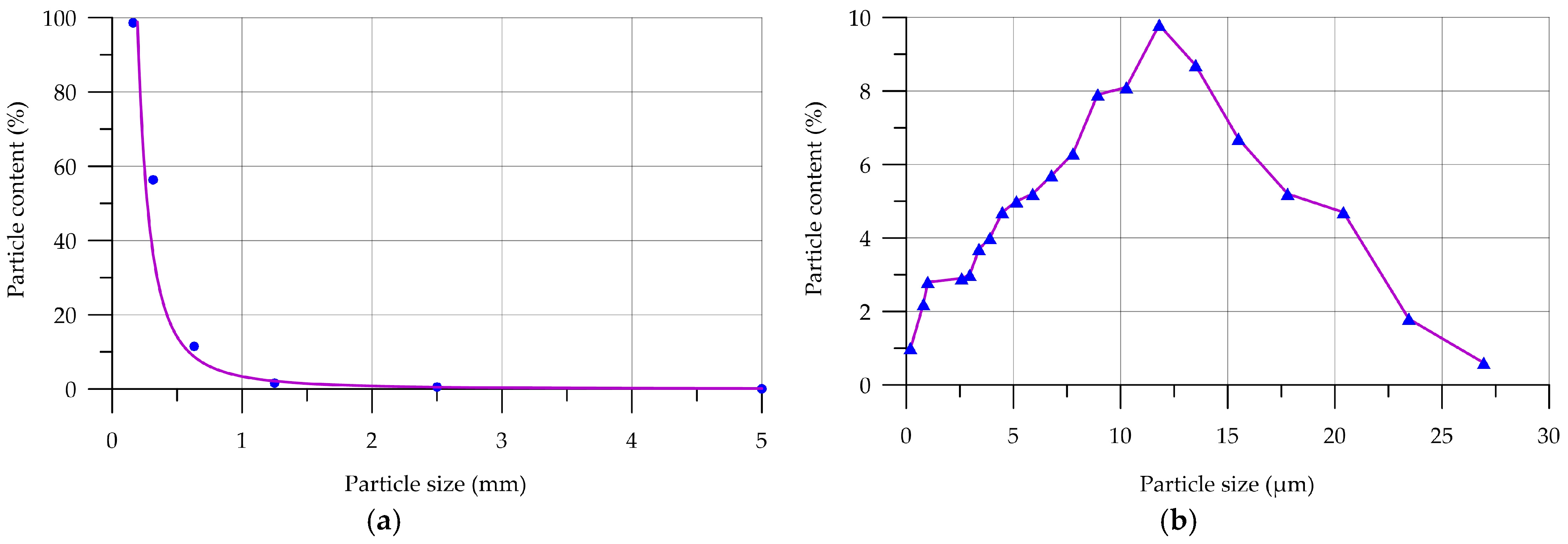

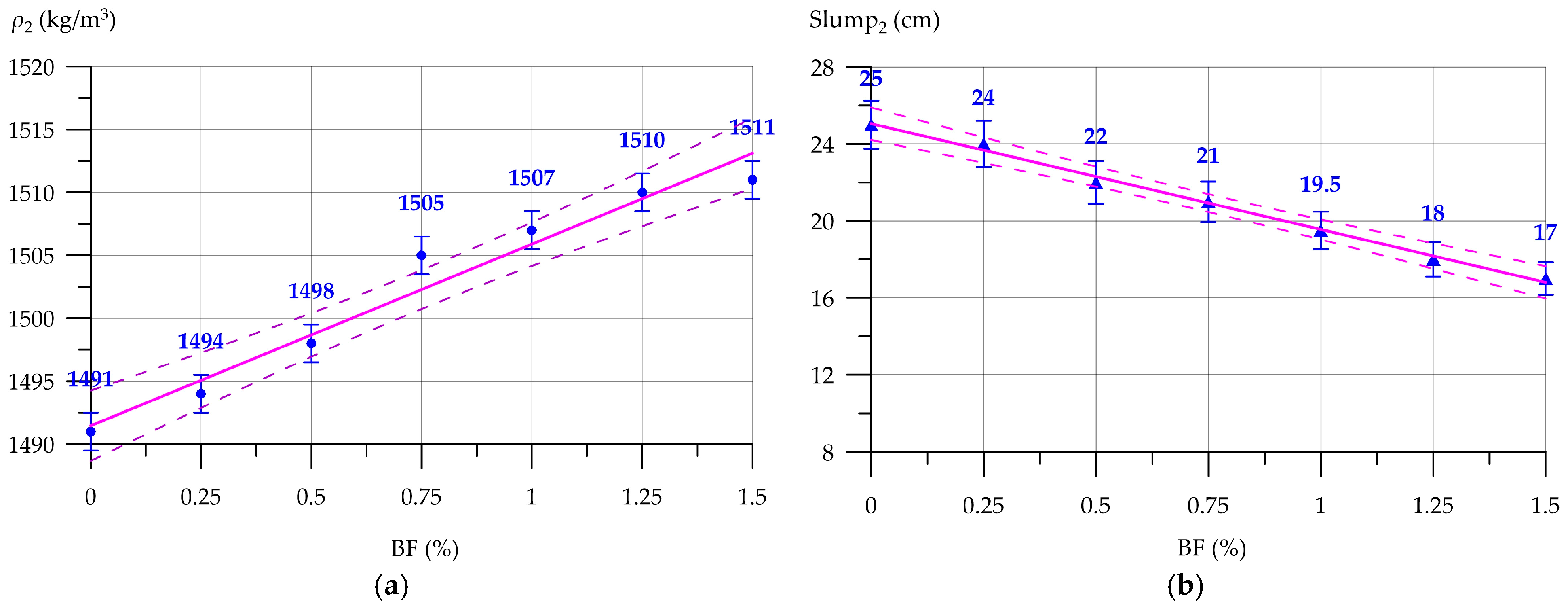

Figure 8.

As can be seen in

Figure 8a, the inclusion of pre-treated LECA with MS-added cement pastes increases the density of fresh ECC. The minimum density of 1431 kg/m

3 is observed for the fresh ECC of the control composition. The maximum density of 1491 kg/m

3 is observed for the CP-LECA10MS composition, which is 4.2% higher than that of the control composition. The slight increase in the density of fresh ECC can be explained by the inclusion of CP-LECA. Because of the porous structure of expanded clay grains, they are saturated with cement paste during processing. The paste partially penetrates the upper porous layers of the expanded clay grains and sets there, thereby slightly increasing their mass. An increase in the density of fresh ECC is observed with the inclusion of aggregates treated with cement pastes with varying MS contents from 0% to 10%. The inverse relationship between the decrease in the density of fresh ECC and the inclusion of aggregates treated with cement paste with 15% MS is explained by the supersaturation of the paste with the modifying additive and a decrease in its processing ability. The slump values of fresh ECC show a tendency to increase with the inclusion of CP-LECA. The CP-LECA10MS compound exhibits the highest slump of 25 cm, which is 11.1% higher than the control compound. The surface character of LECA also changes during treatment with cement pastes. Pore sealing occurs, and the water absorption capacity of LECA decreases, resulting in improved workability.

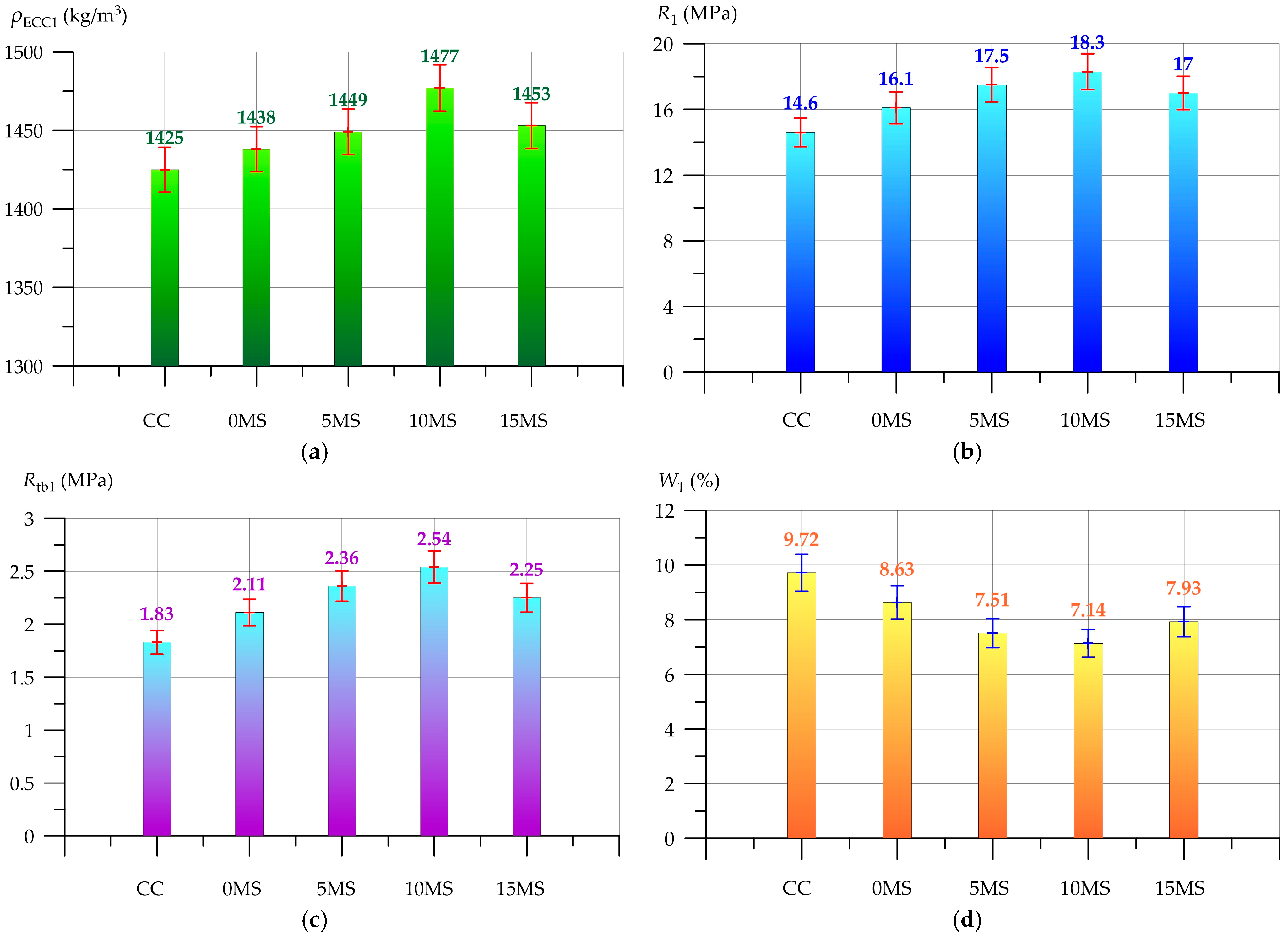

The results of determining the properties of ECC produced using CP-LECA are presented in

Figure 9.

Cured ECC with CP-LECA exhibits a slight increase in density. The highest density of 1477 kg/m

3 was recorded for the CP-LECA10MS composition, which is 3.6% higher than the density of the control composition. As noted above, the increase in ECC density is explained by the inclusion of CP-LECA. The compressive and flexural strengths of ECC increase because of the addition of CP-LECA. As seen from

Figure 9b,c the CP-LECA10MS composition has the highest compressive strength of 18.3 MPa and flexural strength of 2.54 MPa. The strength gains compared to the control composition were 25.3% and 38.8%, respectively. The inclusion of CP-LECA reduces the water absorption of ECC. The CP-LECA10MS composition has the lowest water absorption of 7.14%, which is 26.5% less than the control value. The pre-treatment process improves the strength properties of the composite by increasing the total amount of cementitious material in the matrix [

12]. Also, hydration processes are more active on the CP-LECA surface, and stronger bonds are formed at the interfaces of the CP-LECA-cement-sand mortar phases. The inclusion of up to 10% MS in the cement paste composition enhances the above-described effects. MS particles act as additional crystallization centers and, because of their high pozzolanic activity, bind free Ca (OH)

2, facilitating the formation of additional calcium silicate hydroxides (CSH). The formation of CSH accumulation zones at the phase boundaries increases the bond strength and the strength of the entire composite [

50]. Changes in ECC properties depending on the CP-LECA type are shown in

Table 5.

Figure 10 presents the results of property determination of fresh ECC with LECA pre-treated cement paste modified with 10% MS and different BF dosages.

The density of ECC mixtures containing CP-LECA10MS and varying amounts of BF varied from 1491 kg/m3 to 1511 kg/m3. As the BF content increased, the workability of the mixtures decreased. At a maximum BF content of 1.5%, the slump was 17 cm, which is 32% less than the slump of CP-LECA10MS.

The impact of the adopted formulation and process solutions, including the combined use of CP-LECA10MS and BF, on the density, compressive strength, flexural strength, and water absorption of ECC was assessed by comparison with a control type CC mixture. The test results are presented in

Figure 11,

Figure 12,

Figure 13 and

Figure 14.

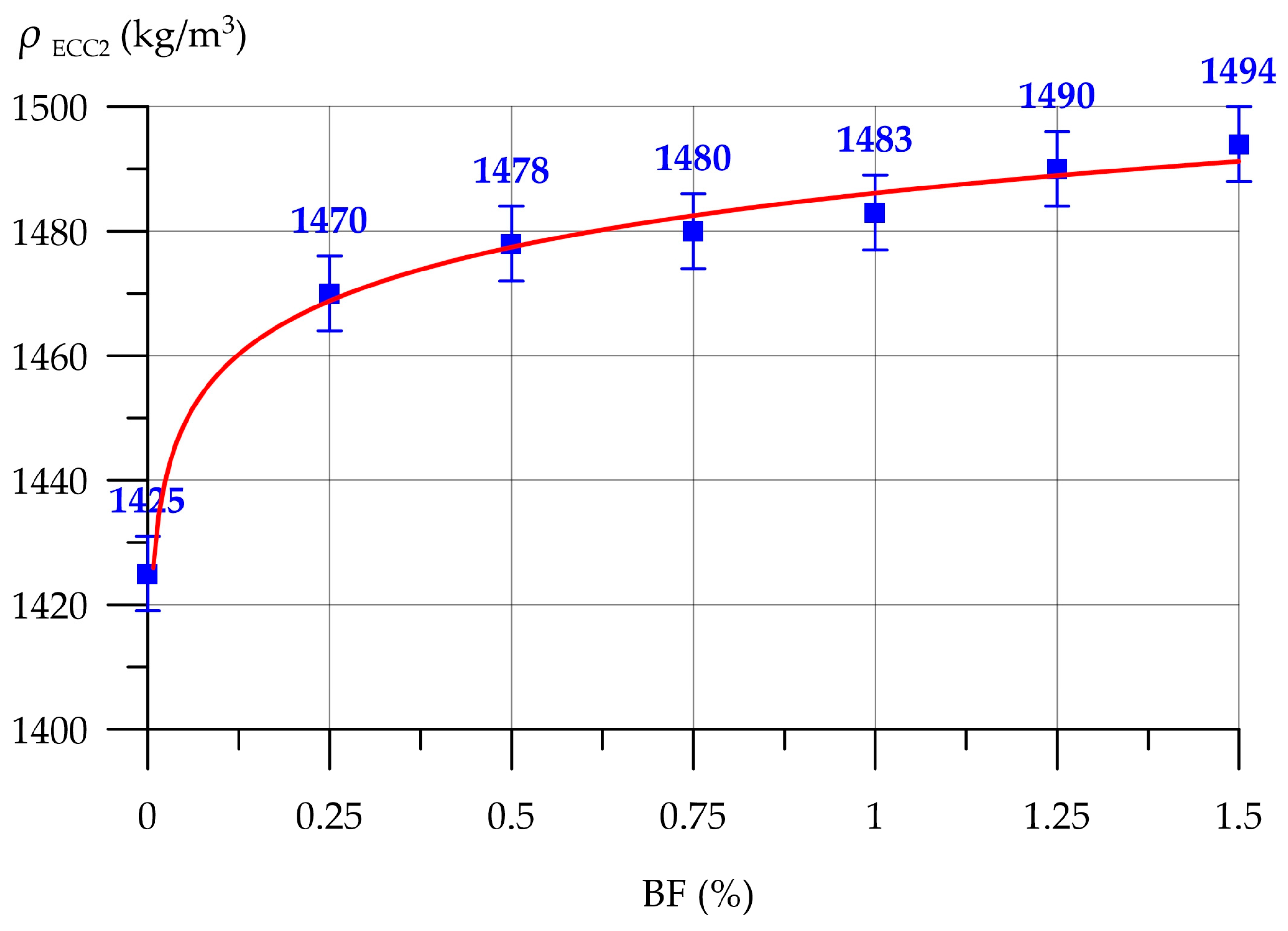

Figure 11 shows the dependence of the ECC density with CP-LECA10MS (

) on the amount of BF.

Figure 11 shows that the inclusion of up to 1.5% BF in ECC with CP-LECA10MS does not significantly affect the density of cured ECC. The maximum density of 1494 kg/m

3 was recorded for the CP-LECA10MS-1.50BF composition, which is 4.8% higher than the control composition.

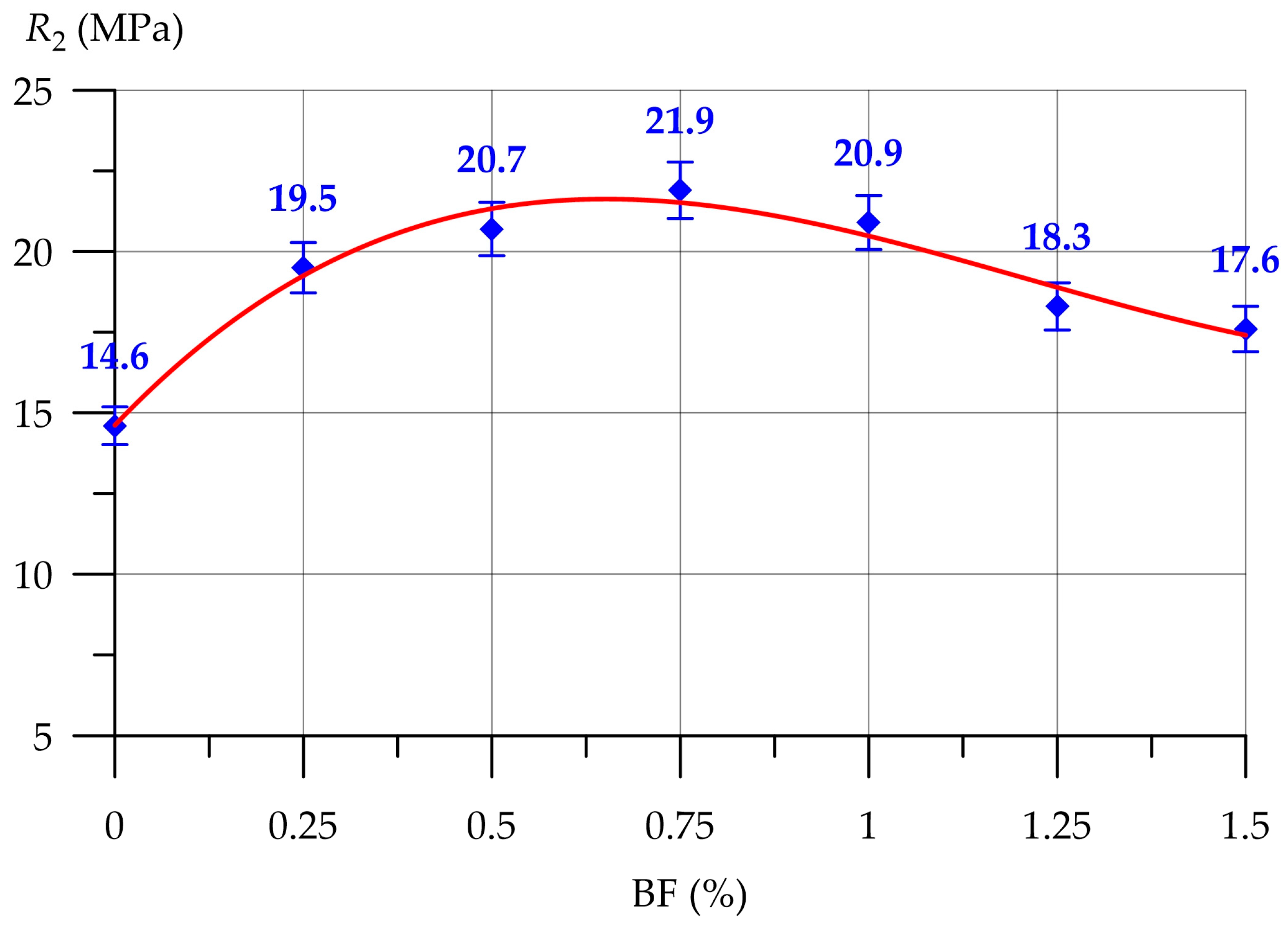

Figure 12 shows the compressive strength of ECC with CP-LECA10MS (

R2) versus BF content.

The dependence of the change in compressive strength of ECC with CP-LECA10MS on the BF content, shown in

Figure 12, is as follows. At BF content levels from 0.25% to 0.75%, an increase in compressive strength is observed, reaching a peak value of 21.9 MPa at 0.75% BF. As the BF content further increases above 0.75%, the effectiveness of dispersed reinforcement decreases. Thus, at the optimal BF dosage of 0.75%, the maximum increase in compressive strength was 50%. For the composition with 1.5% BF, the increase in compressive strength was 20.5%.

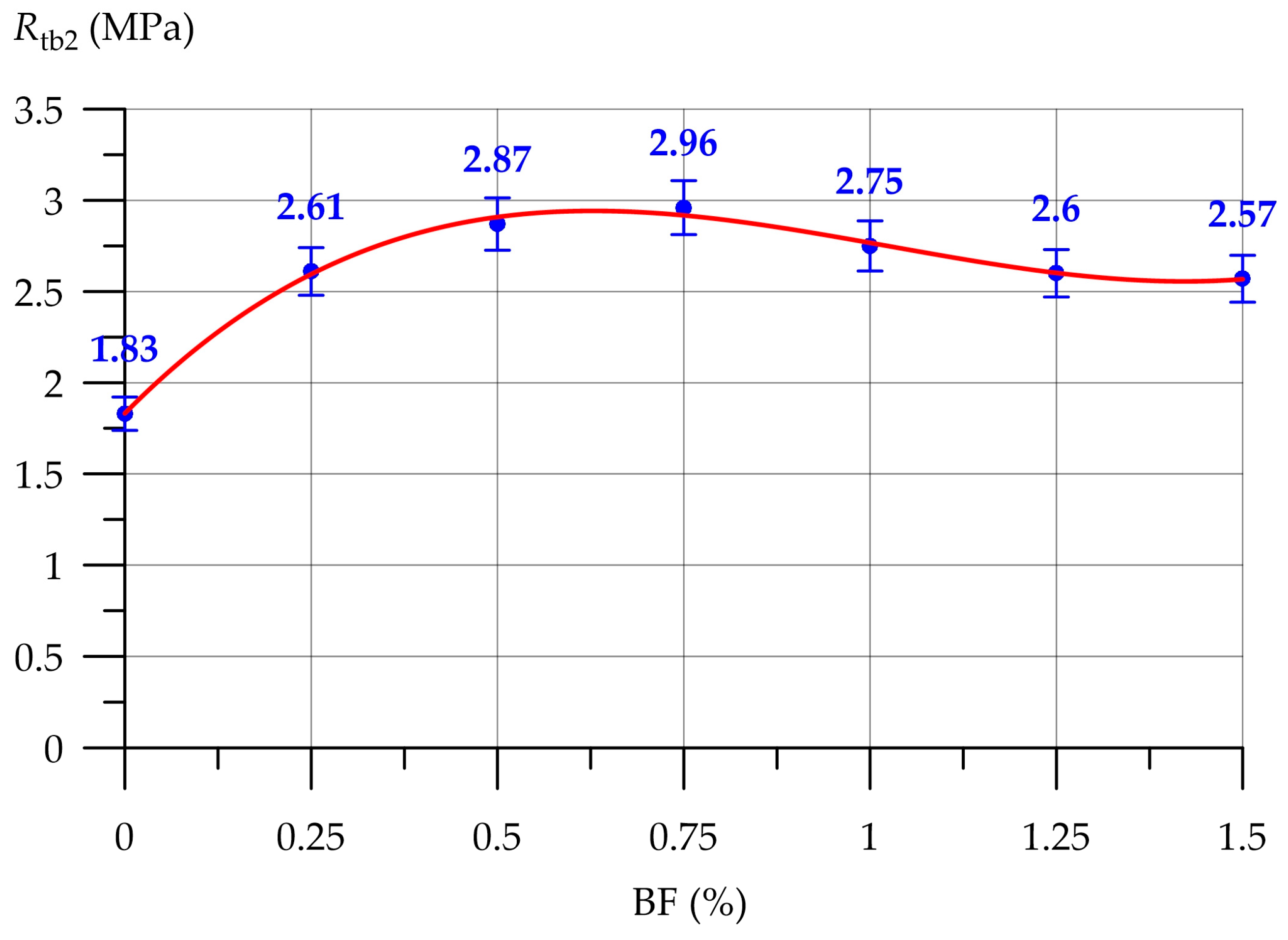

Figure 13 shows the dependence of the flexural strength of ECC with CP-LECA10MS (

Rtb2) on the BF content.

The dependence of the change in flexural strength of ECC with CP-LECA10MS on the BF content is similar to that of

R2. In the range from 0.25% to 0.75% BF, flexural strength increases with a peak value at 0.75%. The flexural strength of the CP-LECA10MS-0.75BF composition was 2.96 MPa, which is 61.7% higher than that of the control composition. Compositions with a higher BF content demonstrated smaller increases. At the maximum dosage of 1.5% BF, the increase in flexural strength was 40.4%. Dispersed BF reinforcement in an optimal amount forms additional bonds and macrostructural cells in the composite structure, which strengthens the composite structure [

51,

52].

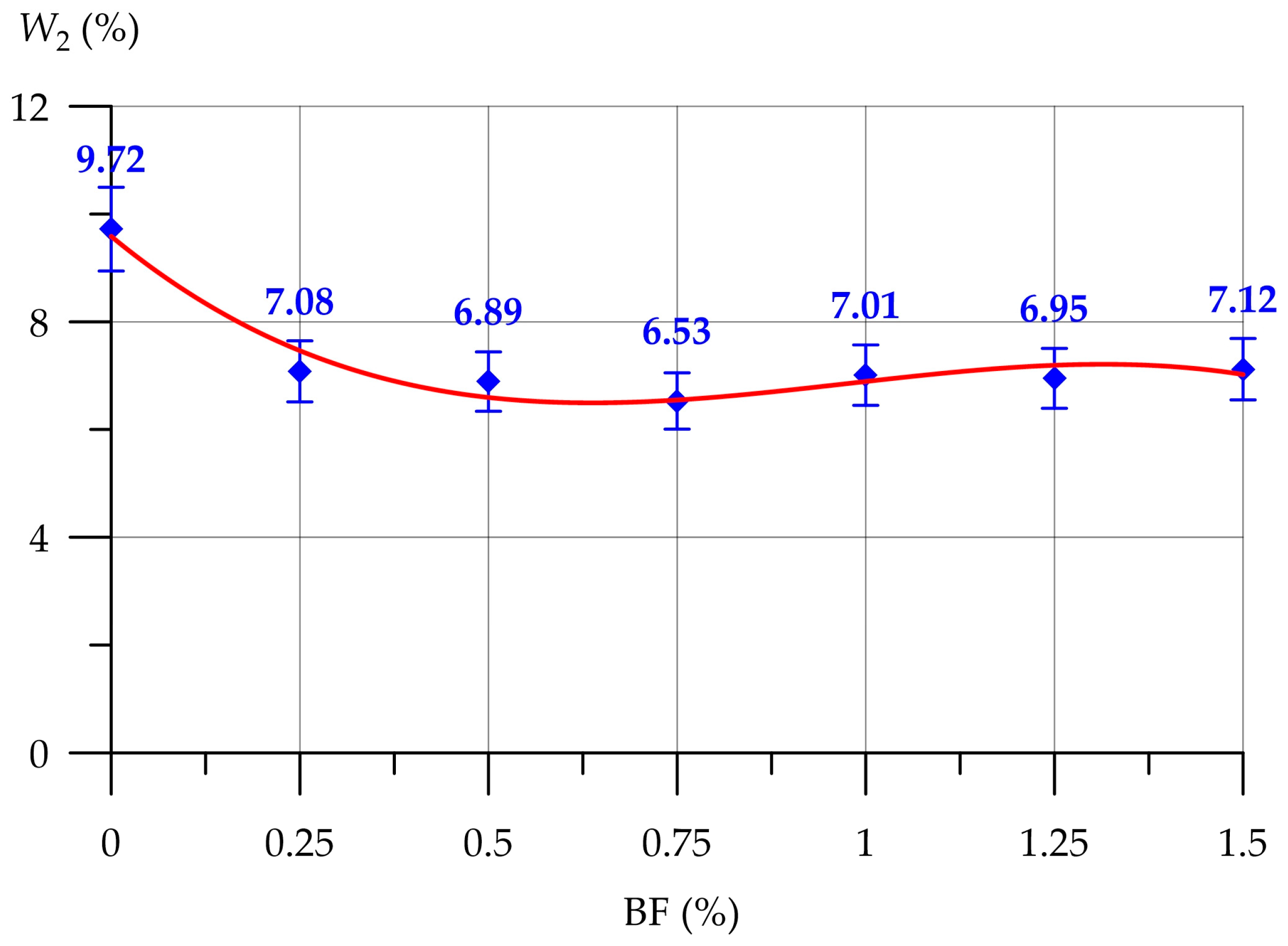

Figure 14 shows the dependence of water absorption of ECC with CP-LECA10MS (W2) on the amount of BF.

Dispersed BF reinforcement at optimal dosages also further reduces the water absorption of ECC with CP-LECA10MS. The minimum water absorption value was recorded at 0.75% and amounted to 6.53%, which is 32.8% lower than the control composition. The opposite effect was observed with increasing BF content. Dispersed reinforcement of ECC with basalt fibers in optimal quantities reduces water absorption by forming denser macro- and microstructural bonds. However, when the BF content exceeds the optimal amount, the opposite effect is observed. BF fibers are unevenly distributed throughout the composite, tangle into clumps, and form weak spots and voids. It should be noted that the reduction in water absorption of ECC due to dispersed BF reinforcement is very important for composites intended for use in floating structures. The water absorption properties of materials are important for floating structures and directly impact their durability. The water absorption of the CP-LECA10MS-1.5BF composition was 7.12%, which is 26.7% lower than the control value (

Table 6). The water absorption of the CP-LECA10MS-1.5BF type composition at 7.12% is somewhat higher in comparison with heavy concretes on dense aggregates, however, it is within the permissible standard values [

52].

The adopted formulation and technological solutions, such as pre-treatment of the LECA surface with MS-containing cement pastes and dispersed BF reinforcement, significantly improve the properties of ECC. ECC has compressive strength classes B10 (C12/15) and B15 (C16/20), which meet the requirements of regulatory and technical documentation classifying concrete composites [

52]. Concrete classes B10 (C12/15) and B15 (C16/20) can be fully applied in real construction practice, including in hydraulic engineering [

6,

53,

54]. The following key relationships were identified based on the experimental studies.

1. Density and slump of fresh ECC. Pre-treatment of LECA with MS-containing cement pastes increased the density of fresh ECC by 4.2% and the slump of the mixture by 11.1%. The inclusion of BF in fresh ECC with CP-LECA did not significantly affect the density; however, as the BF content increased, a decrease in the slump was observed.

2. Density, compressive strength, and flexural strength of ECC. The inclusion of CP-LECA in ECC provided a slight increase in density of 3.6%. ECC compositions with CP-LECA demonstrated increases in compressive and flexural strength. The maximum strength increases were 25.3% and 38.8%, respectively. The inclusion of 10% MS in the cement paste formulation was optimal and enhanced the effect of the LECA pretreatment. Additional dispersed reinforcement with 0.75% BF in CP-LECA10MS-containing formulations enhanced the effectiveness of the first formulation and technology step, providing increases in compressive and flexural strength of up to 50% and 61.7%, respectively, compared to the control formulation.

3. Water absorption of ECC. The inclusion of CP-LECA10MS and 0.75% BF had a complex positive effect and reduced water absorption by 32.8%.

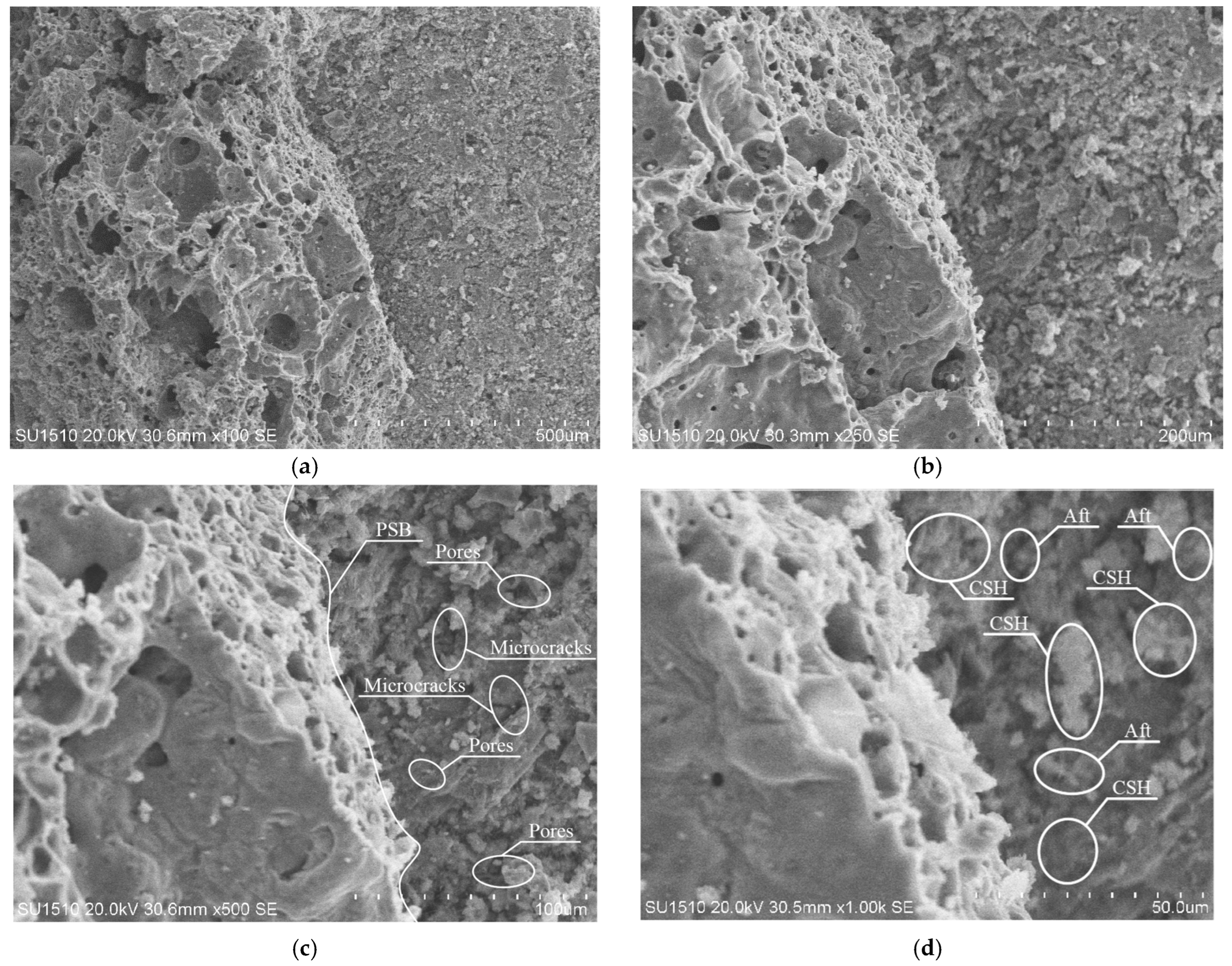

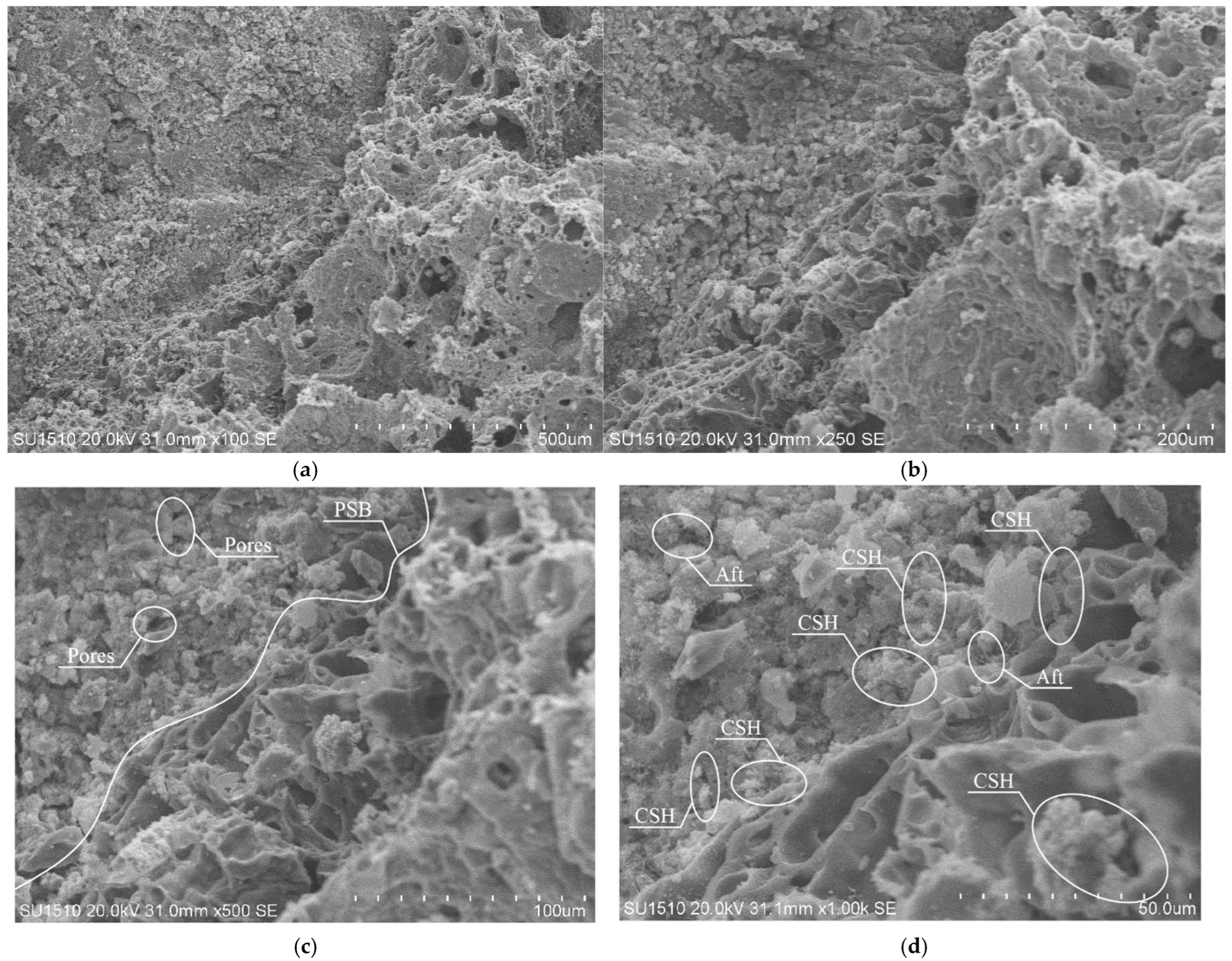

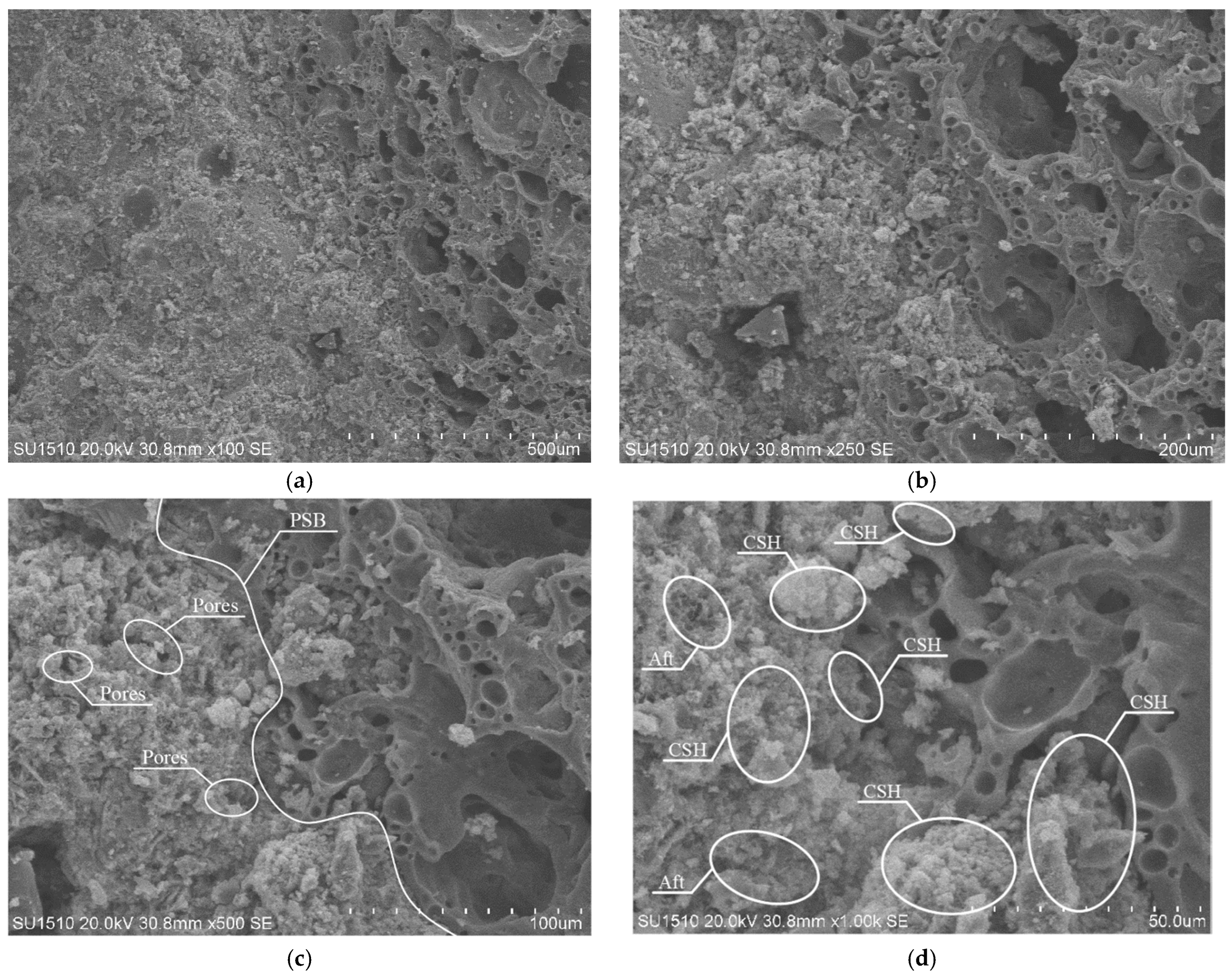

The results of SEM analysis of the ECC of the control, CP-LECA10MS, and CP-LECA10MS-0.75BF formulations are presented in

Figure 15,

Figure 16 and

Figure 17, respectively. The microstructural analysis of these compositions was based on the analysis of the phase boundaries between the coarse aggregate and the cement-sand mortar, as well as on the overall assessment of the structural features of the aggregate and mortar.

The microstructure images of the ECC control composition, shown in

Figure 15, clearly show the phase boundary (PSB) between the LECA and cement-sand mortar. No significant mortar accumulations were observed within the porous structure of the aggregate. The mortar structure is compact, with isolated pores and microcracks. Zones of calcium silicate hydroxides (CSH) and ettringite (AFt) accumulation are also observed (

Figure 15d). The CSH and AFt phases are products of cement clinker hydration and are identified as follows. CSH consists of short silicate chains held together by calcium oxide regions, with water trapped within the structure. CSH provides the bonding of numerous other crystal hydrates. CSH accumulation zones are randomly arranged within the composite structure. AFt crystallizes as acicular structures, which can also be randomly arranged within the composite structure.

Figure 16 shows the microstructure of the CP-LECA10MS composite. The contact zone between CP-LECA and cement–sand mortar exhibits distinctive features compared to the control composite, which used coarse aggregate without pre-treatment. Cement paste clusters are present within the porous structure of the aggregate, primarily in the boundary zone. The area where the mortar adheres to the aggregate grain is dense and contains CSH clusters, indicating a high level of adhesion between CP-LECA and the ECC mortar component. The presence of CSH clusters at the interface is explained by the presence of the MS modifying additive in the cement slurry, which was applied to the surface of the coarse aggregate. The structure of the solution is compact, and zones of accumulation of calcium hydrosilicates (CSH) and ettringite (AFt) are also observed (

Figure 16d).

The microstructure of the CP-LECA10MS-0.75BF composite, shown in

Figure 17, is similar to that of CP-LECA10MS. Cement paste accumulations are observed within the pores of the coarse aggregate, and CSH accumulation zones are also present at the phase boundary. CP-LECA adheres tightly to the mortar. The mortar structure is compact, and zones of calcium silicate hydrous (CSH) accumulation are observed (

Figure 17d). SEM analysis of the structure of the developed ECC control composition, compositions of the CP-LECA10MS and CP-LECA10MS-0.75BF types is comparable with the obtained values of strength properties. Significant accumulations of cement paste in the porous structure of the filler in the boundary zone of “CP-LECA—cement-sand mortar” contribute to the formation of stronger bonds in the PSB zones, which ensures higher values of compressive and flexural strength of ECC containing treated coarse aggregate [

11,

55]. The practical significance of the preliminary treatment of LECA with modified cement pastes, according to the results of the studies, is determined by the following criteria: an increase in the strength of LECA, a decrease in water absorption of LECA, the formation of denser bonds at the interfaces of the “CP-LECA—cement-sand mortar” phases.

The formulation and technological techniques used in this study to improve the properties of ECC demonstrate a positive effect. The use of processed filler and dispersion-reinforcing fiber allows for an increase in the composite class from B10 (C12/15) to B15 (C16/20). ECC with a compressive strength class of B15 (C16/20) can be used in hydraulic engineering in accordance with the requirements of regulatory and technical documentation [

52]. Thus, the obtained ECC possesses the required operational properties and can be used in hydraulic engineering during the construction of oil and gas platforms, floating docks, and other floating structures. Pretreatment of LECA mitigates the effects that occur during the ECC manufacturing process. Upon mixing, the LECA grains begin to absorb moisture from the cement-sand mortar. Hydration processes occur simultaneously, forming crystalline hydrates that fuse with the LECA grains, forming a contact zone and strengthening the composite. Subsequently, under the influence of shrinkage deformations of the hardened cement paste, LECA compression occurs, which is enhanced by the expansion of saturated aggregate grains [

11]. The strength properties of ECC largely depend on the compression effect and the strength of the contact zone. However, a large amount of moisture accumulated in LECA migrates back into the mortar, leading to decompression of the contact zone. Thus, reinforcing LECA grains with MS-containing cement pastes closes pores, reduces water absorption, and increases strength. CSH formation on the CP-LECA surface is more active due to unreacted cement and MS particles, resulting in a denser and stronger contact zone [

53,

54]. The inclusion of BF improves the properties of ECC by changing the mechanism of failure and redistribution of stresses that arise in the composite body under compressive and tensile loads. Typically, when an experimental ECC specimen with BF is subjected to a load, the fibers absorb part of the stress and dissipate it. BF delays the initiation and propagation of micro cracks in the composite matrix, thereby optimizing and increasing its strength properties [

56,

57,

58].

The key indicator for ECC used in the construction of floating structures is the coefficient of the structural quality (CCQ). The structural quality coefficient is calculated using Formula (6):

R is compressive strength (MPa);

—density (g/cm3).

This formula allows one to evaluate the effectiveness of developed ECCs based on their strength-to-density ratio. When designing and constructing reinforced concrete floating structures, the density and strength of the composites used are critical parameters and directly impact their technical and operational performance. Increasing the strength of composites without increasing their density will ensure higher CCQ values, which is desirable for floating reinforced concrete structures.

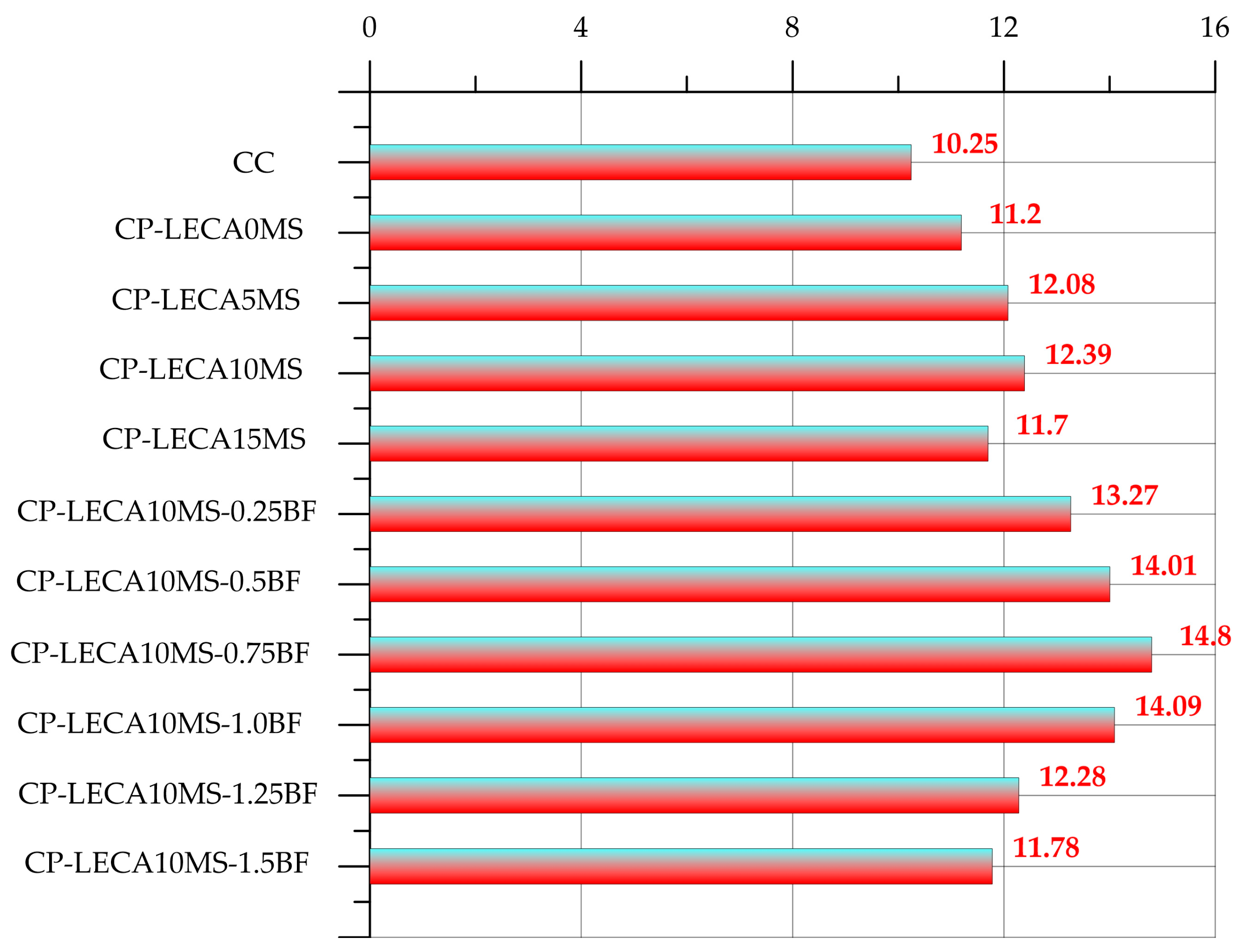

The results of determining the CCQ for the ECC developed in this study are presented in

Figure 18.

As seen in

Figure 18, LECA values vary depending on the formulation and process decisions adopted and tend to increase. After pre-treatment of LECA with cement pastes with dosages ranging from 0% to 15% MS, CCQ values range from a minimum CC of 10.2 to a maximum of 12.4 for a composition with 10% MS. The inclusion of BF at an optimal dosage of 0.75% increases CCQ to 14.8. For the best-performing composition, CP-LECA10MS-0.75BF, the CCQ increase was 44.4%. The increase in CCQ also proves the rationality of the proposed formulation and technological methods, which make it possible to obtain the most effective ECC for floating structures in terms of the strength-to-density ratio.

The results obtained in this study, the relationships, and the identified mechanisms of the influence of formulation and process techniques on the final properties of the composite are in good agreement with similar previous studies (

Table 7).

Based on the results of this study and similar work by other authors, it can be concluded that pre-treatment of LECA grains is a feasible formulation and technological solution that can mitigate a number of disadvantages, such as high water absorption, low strength, and insufficient adhesion of cement-sand mortar [

63,

64]. Dispersed reinforcement is one of the most popular formulation solutions aimed at improving the strength properties of cementitious composites. Depending on the type of fiber and composite, a series of experimental studies is required to select the optimal amount of dispersed fiber, which was carried out in this study. The inclusion of 0.75% BF further enhances the effect obtained through the use of CP-LECA in the manufacture of ECC [

65,

66,

67,

68,

69,

70,

71].

The developed ECC possesses sufficient performance properties and, if they meet design requirements, can be fully applied in industrial and civil construction, including hydraulic engineering for floating structures. Formulation and manufacturing techniques, such as LECA pretreatment and BF dispersed reinforcement, will serve as the basis for the development of high-strength ECCs intended for the construction of floating platforms in the Far North and Arctic regions.

To obtain a more complete picture and confirm the results obtained in this study, future work will examine the long-term properties of ECCs, such as frost resistance, chloride penetration resistance, and water resistance.