Recycling and Reuse of Grit Blasting Waste for Composite Materials: Directions, Properties and Physical Chemistry Approaches

Abstract

1. Introduction

2. Physicochemical Insights into Grit Blasting Waste

2.1. Physical Characteristics

2.2. Chemical Composition

2.3. Health and Environmental Concerns

2.4. Waste Management and Recycling

2.5. Environmental Approaches and Considerations

3. The Utilization of Grit Blasting Waste in Building Materials

4. The Utilization of Grit Blasting Waste in Asphalt Mixes/Road Construction

5. The Utilization of Grit Blasting Waste in Ceramics and Composite Materials

6. The Utilization of Grit Blasting Waste in Land Recovery

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABM | Abrasive Blasting Material |

| AW | Alumina waste |

| BET | Brunauer–Emmett–Teller |

| FA | Fly ash |

| FT-IR | Fourier Transform Infrared Spectroscopy |

| GC/MS | Gas Chromatography/mass spectroscopy |

| HDPE | High-density polyethylene |

| ICP-MS | Inductively coupled plasma mass spectrometry |

| LCA | Life-cycle assessment |

| LDPE | Low-density polyethylene |

| PP | Polypropylene |

| SEM | Scanning Electron Microscopy |

| TGA | Thermogravimetric analysis |

| XPS | X-ray Photoelectron Spectroscopy |

| XRD | X-Ray Diffraction |

| XRF | X-Ray Fluorescence |

References

- Firoozi, A.; Firoozi, A.; Oyejobi, D.O.; Avudaiappan, S.; Flores, E. Enhanced durability and environmental sustainability in marine infrastructure: Innovations in anti-corrosive coating technologies. Results Eng. 2025, 26, 105144. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Lye, C.Q.; Dhir, R.K. The role of glass waste in the production of ceramic-based products and other applications: A review. J. Clean. Prod. 2017, 167, 346–364. [Google Scholar] [CrossRef]

- Rosenberg, B.; Yuan, L.; Fulmer, S. Ergonomics of abrasive blasting: A comparison of high pressure water and steel shot. Appl. Ergon. 2006, 37, 659–667. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wang, B.; Lu, P.; Xiang, Q.; Jin, Q. Improving the wettability of oxide layers to enhance the bonding strength of shot-blasting steel substrates by using simple resin pre-coating method. Int. J. Adhes. Adhes. 2024, 131, 103661. [Google Scholar] [CrossRef]

- Zulkarnain, I.; Mohamad Kassim, N.A.; Syakir, M.I.; Abdul Rahman, A.; Md Yusuff, M.S.; Mohd Yusop, R.; Keat, N.O. Sus-tainability-based characteristics of abrasives in blasting industry. Sustainability 2021, 13, 8130. [Google Scholar] [CrossRef]

- Ardila-Rodríguez, L.A.; Boshuizen, B.; Rans, C.; Poulis, J.A. The influence of grit blasting and UV/Ozone treatments on Ti-Ti adhesive bonds and their durability after sol-gel and primer application. Int. J. Adhes. Adhes. 2021, 104, 102750. [Google Scholar] [CrossRef]

- Anwar, M.K.; Zhu, X.; Gilabert, F.A.; Siddiq, M.U. Recycling and optimum utilization of CRT glass as building materials: An application of low CO2 based circular economy for sustainable construction. Constr. Build. Mater. 2024, 453, 138798. [Google Scholar] [CrossRef]

- Aurich, J.C.; Linke, B.; Hauschild, M.; Carrella, M.; Kirsch, B. Sustainability of abrasive processes. CIRP Ann. 2013, 62, 653–672. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, W.; Zhang, H.; Zhang, H. On-line recycling of abrasives in abrasive water jet cleaning. Procedia Cirp 2014, 15, 278–282. [Google Scholar] [CrossRef]

- Hariyani, D.; Hariyani, P.; Mishra, S.; Sharma, M.K. A Literature Review on Waste Management Treatment and Control Techniques. Sustain. Futures 2025, 9, 100728. [Google Scholar] [CrossRef]

- Ghara, T.; Paul, S.; Bandyopadhyay, P.P. Effect of grit blasting parameters on surface and near-surface properties of different metal alloys. J. Therm. Spray Technol. 2021, 30, 251–269. [Google Scholar] [CrossRef]

- Anaç, N.; Doğan, Z. Effect of Organic Powders on Surface Quality in Abrasive Blasting Process. Processes 2023, 11, 1925. [Google Scholar] [CrossRef]

- Qi, C.; Weinell, C.E.; Dam-Johansen, K.; Wu, H. A review of blasting waste generation and management in the ship repair industry. J. Environ. Manag. 2021, 300, 113714. [Google Scholar] [CrossRef]

- Zanetti, M.C.; Genon, G. Physical properties of industrial wastes: Laboratory tests. Resour. Conserv. Recycl. 1999, 25, 195–213. [Google Scholar] [CrossRef]

- Madl, A.K.; Donovan, E.P.; Gaffney, S.H.; McKinley, M.A.; Moody, E.C.; Henshaw, J.L.; Paustenbach, D.J. State-of-the-science review of the occupational health hazards of crystalline silica in abrasive blasting operations and related requirements for respiratory protection. J. Toxicol. Environ. Health Part B 2008, 11, 548–608. [Google Scholar] [CrossRef]

- Singh, N.; Turner, A. Trace metals in antifouling paint particles and their heterogeneous contamination of coastal sediments. Mar. Pollut. Bull. 2009, 58, 559–564. [Google Scholar] [CrossRef]

- Li, L.; Hong, H.; Cao, J.; Yang, Y. Progress in Marine Antifouling Coatings: Current Status and Prospects. Coatings 2023, 13, 1893. [Google Scholar] [CrossRef]

- Ehrlich, C.; Noll, G.; Wusterhausen, E.; Kalkoff, W.D.; Remus, R.; Lehmann, C. Respirable Crystalline Silica (RCS) emissions from industrial plants–Results from measurement programmes in Germany. Atmos. Environ. 2013, 68, 278–285. [Google Scholar] [CrossRef]

- Haghighizadeh, A.; Rajabi, O.; Nezarat, A.; Hajyani, Z.; Haghmohammadi, M.; Hedayatikhah, S.; Asl, S.D.; Beni, A.A. Comprehensive analysis of heavy metal soil contamination in mining Environments: Impacts, monitoring Techniques, and remediation strategies. Arab. J. Chem. 2024, 17, 105777. [Google Scholar] [CrossRef]

- Medici, S.; Peana, M.; Pelucelli, A.; Zoroddu, M.A. An updated overview on metal nanoparticles toxicity. Semin. Cancer Biol. 2021, 76, 17–26. [Google Scholar] [PubMed]

- Rees, A.B.; Turner, A.; Comber, S. Metal contamination of sediment by paint peeling from abandoned boats, with particular reference to lead. Sci. Total Environ. 2014, 494, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Turner, A.; Comber, S.; Rees, A.B.; Gkiokas, D.; Solman, K. Metals in boat paint fragments from slipways, repair facilities and abandoned vessels: An evaluation using field portable XRF. Talanta 2015, 131, 372–378. [Google Scholar] [CrossRef] [PubMed]

- Xing, P.; Ma, B.; Wang, C.; Wang, L.; Chen, Y. A simple and effective process for recycling zinc-rich paint residue. Waste Manag. 2018, 76, 234–241. [Google Scholar] [CrossRef]

- Rachmat, A.; Emil, B.; Herdis, H.; Mahawan, K.; Putri, A.S. Minimize the impact of waste pollution in ship repair processes to Improving Shipyard Industrial Infrastructure Sustainability. E3S Web Conf. 2018, 73, 08006. [Google Scholar] [CrossRef]

- Guth, K.; Bourgeois, M.; Harbison, R. Assessment of Lead exposures during abrasive blasting and vacuuming in ventilated field containments: A case study. Occup. Dis. Environ. Med. 2022, 10, 116–131. [Google Scholar] [CrossRef]

- Gautam, S.P.; Bundela, P.S.; Murumkar, M. Paint sludge waste co-processing at the ACC Wadi Cement Works in Karnataka, India. WIT Trans. Ecol. Env. 2010, 140, 57–66. [Google Scholar]

- Katsikaris, K.; Voutsas, E.; Magoulas, K.; Andronikos, G.; Stamataki, S. Recycling ferrous-nickel slag in blast cleaning. Waste Manag. Res. 2002, 20, 269–278. [Google Scholar] [CrossRef]

- Singh, N.; Turner, A. Leaching of copper and zinc from spent antifouling paint particles. Environ. Pollut. 2009, 157, 371–376. [Google Scholar] [CrossRef]

- SP, S.P.; Swaminathan, G.; Joshi, V.V. Energy conservation–A novel approach of co-combustion of paint sludge and Australian lignite by principal component analysis, response surface methodology and artificial neural network modeling. Environ. Technol. Innov. 2020, 20, 101061. [Google Scholar]

- Song, Y.C.; Woo, J.H.; Park, S.H.; Kim, I.S. A study on the treatment of antifouling paint waste from shipyard. Mar. Pollut. Bull. 2005, 51, 1048–1053. [Google Scholar] [CrossRef]

- Cornelis, C.; Bierkens, J.; Joris, I.; Nielsen, P.; Pensaert, S. Quality Criteria for Re-Use of Organotin-Containing Sediments on Land (7 pp). J. Soils Sediments 2006, 6, 156–162. [Google Scholar] [CrossRef]

- Kotrikla, A. Environmental management aspects for TBT antifouling wastes from the shipyards. J. Environ. Manag. 2009, 90, S77–S85. [Google Scholar] [CrossRef]

- Hansel, D. Abrasive blasting systems. Met. Finish. 2000, 98, 23–37. [Google Scholar] [CrossRef]

- Rahman, S.M.; Handler, R.M.; Mayer, A.L. Life cycle assessment of steel in the ship recycling industry in Bangladesh. J. Clean. Prod. 2016, 135, 963–971. [Google Scholar] [CrossRef]

- Alankaya, V.; Celebi, U.B. Investigation of alternative blasting process in terms of impact behaviour of blasting materials for green shipyards. Int. J. Glob. Warm. 2015, 7, 499–517. [Google Scholar] [CrossRef]

- Jayakishan, B.; Nagarajan, G.; Arun, J. Co-thermal liquefaction of Prosopis juliflora biomass with paint sludge for liquid hydrocarbons production. Bioresour. Technol. 2019, 283, 303–307. [Google Scholar] [CrossRef] [PubMed]

- Madany, I.M.; Raveendran, E. Leachability of Heavy Metals Blasting Waste. Waste Manag. Res. 1992, 10, 87–91. [Google Scholar] [CrossRef]

- Arevalo, E.; Calmano, W. Studies on electrochemical treatment of wastewater contaminated with organotin compounds. J. Hazard. Mater. 2007, 146, 540–545. [Google Scholar] [CrossRef]

- Adeleye, A.S.; Oranu, E.A.; Tao, M.; Keller, A.A. Release and detection of nanosized copper from a commercial antifouling paint. Water Res. 2016, 102, 374–382. [Google Scholar] [CrossRef]

- Amara, I.; Miled, W.; Slama, R.B.; Ladhari, N. Antifouling processes and toxicity effects of antifouling paints on marine environment. A review. Environ. Toxicol. Pharmacol. 2018, 57, 115–130. [Google Scholar] [CrossRef]

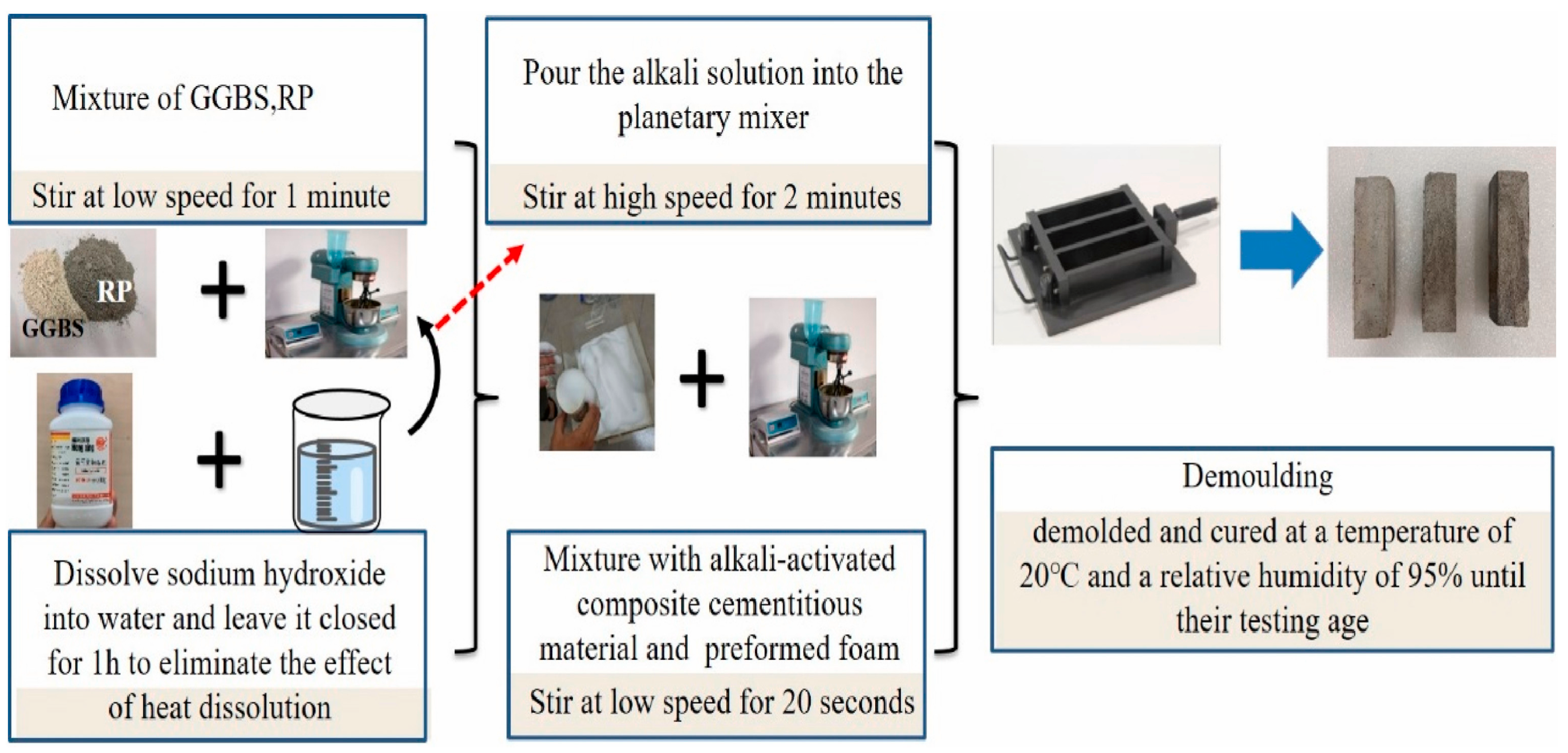

- Yao, T.; Tian, Q.; Zhang, M.; Qi, S.; Wang, C.; Ruan, M. Laboratory investigation of foamed concrete prepared by recycled waste concrete powder and ground granulated blast furnace slag. J. Clean. Prod. 2023, 426, 139095. [Google Scholar] [CrossRef]

- Qomariah, Q.; Rochman, T. On the Review of Utilization of Sandblasting Waste in Concrete: Cracks Propagation and Sem Results. Civ. Eng. Arch. 2023, 11, 101–113. [Google Scholar] [CrossRef]

- Sabarinathan, P.; Annamalai, V.E.; Sangeetha, P. Mechanical and abrasion resistance properties of concrete containing recycled abrasive waste as partial replacement of fine aggregate. Arab. J. Sci. Eng. 2021, 46, 10943–10952. [Google Scholar] [CrossRef]

- Burande, B.C. Utilisation of paint sludge from automotive industries into valuable products. Int. J. Recent Trends Eng. Res. 2017, 3, 513–519. [Google Scholar]

- Lermen, R.T.; Prauchner, M.B.; Silva, R.D.A.; Bonsembiante, F.T. Using wastes from the process of blasting with steel shot to make a radiation shield in mortar. Sustainability 2020, 12, 6674. [Google Scholar] [CrossRef]

- Borucka-Lipska, J.; Techman, M.; Skibicki, S. Use of contaminated sand blasting grit for production of cement mortars. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 032055. [Google Scholar] [CrossRef]

- Tajunnisa, Y.; Bayuaji, R.; Husin, N.A.; Wibowo, Y.N.; Shigeishi, M. Characterization alkali-activated mortar made from fly ash and sandblasting. GEOMATE J. 2019, 17, 183–189. [Google Scholar] [CrossRef]

- Qomariah, Q.; Sugiharti, S.; Riyanto, S. The utilization of sandblasting sand waste for mortar and normal concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 732, 012036. [Google Scholar] [CrossRef]

- Gholampour, A.; Zheng, J.; Ozbakkaloglu, T. Development of waste-based concretes containing foundry sand, recycled fine aggregate, ground granulated blast furnace slag and fly ash. Constr. Build. Mater. 2021, 267, 121004. [Google Scholar] [CrossRef]

- Sukmana, N.C.; Melati, M.S.; Setyawan, M.I.; Prayoggi, E.; Anggarini, U. Optimization of cellular lightweight concrete using silica sand of sandblasting waste based on factorial experimental design. IOP Conf. Ser. Mater. Sci. Eng. 2019, 509, 012096. [Google Scholar] [CrossRef]

- Suaiam, G.; Makul, N. Incorporation of high-volume fly ash waste and high-volume recycled alumina waste in the production of self-consolidating concrete. J. Clean. Prod. 2017, 159, 194–206. [Google Scholar] [CrossRef]

- Avci, H.; Ghorbanpoor, H.; Topcu, I.B.; Nurbas, M. Investigation and recycling of paint sludge with cement and lime for producing lightweight construction mortar. J. Environ. Chem. Eng. 2017, 5, 861–869. [Google Scholar] [CrossRef]

- Mokhtar, S.; Kulian, E.; Daud, N.H. Effect of Blasting Waste as An Additive in Bitumen Mixtures. J. Kejuruter. 2023, 35, 671–674. [Google Scholar] [CrossRef]

- Buruiana, D.; Bordei, M.; Sandu, A.V.; Hirculescu, A. Studies on Grit Use in Asphalt Mixtures (II). Mater. Plast. 2013, 50, 36–39. [Google Scholar]

- Taha, R.; Al-Alawi, D.; Al-Nabhani, M.; Pillay, A.E.; Al-Hamdi, A. Recycling of paint-contaminated grit. J. Environ. Monit. 2001, 3, 421–424. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Zanetti, M.C.; Ruffino, B.; Vercelli, A.; Dalmazzo, D.; Santagata, E. Reuse of paint sludge in road pavements: Technological and environmental issues. Waste Manag. Res. 2018, 36, 1023–1028. [Google Scholar] [CrossRef]

- Al-Sayed, M.H.; Madany, I.M. Use of copper blasting grit waste in asphalt mixes in Bahrain. Constr. Build. Mater. 1992, 6, 113–116. [Google Scholar] [CrossRef]

- Vishnu, T.B.; Singh, K.L. A study on the suitability of solid waste materials in pavement construction: A review. Int. J. Pavement Res. Technol. 2021, 14, 625–637. [Google Scholar] [CrossRef]

- Means, J.; Heath, J.; Barth, E.; Monlux, K.; Solare, J. The feasibility of recycling spent hazardous sandblasting grit into asphalt concrete. Stud. Environ. Sci. 1991, 48, 553–560. [Google Scholar]

- López-Alonso, M.; Martinez-Echevarria, M.J.; Garach, L.; Galán, A.; Ordoñez, J.; Agrela, F. Feasible use of recycled alumina combined with recycled aggregates in road construction. Constr. Build. Mater. 2019, 195, 249–257. [Google Scholar] [CrossRef]

- Ruffino, B.; Farina, A.; Dalmazzo, D.; Blengini, G.; Zanetti, M.; Santagata, E. Cost analysis and environmental assessment of recycling paint sludge in asphalt pavements. Environ. Sci. Pollut. Res. 2021, 28, 24628–24638. [Google Scholar] [CrossRef]

- Buruiana, D.L.; Georgescu, P.L.; Carp, G.B.; Ghisman, V. Recycling micro polypropylene in modified hot asphalt mixture. Sci. Rep. 2023, 13, 3639. [Google Scholar] [CrossRef]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef]

- Mattei, N.J.; Khanfar, A. Reduction of landfill waste by recycling spent blast abrasives in hot mix asphalt in New Orleans. In GeoCongress 2008: Geosustainability and Geohazard Mitigation; ASCE: Reston, VA, USA, 2008; pp. 417–424. [Google Scholar]

- Karlsson, M.C.; Corr, D.; Forsgren, C.; Steenari, B.M. Recovery of titanium dioxide and other pigments from waste paint by pyrolysis. J. Coat. Technol. Res. 2015, 12, 1111–1122. [Google Scholar] [CrossRef]

- Karlsson, M.C.; Abbas, Z.; Bordes, R.; Cao, Y.; Larsson, A.; Taylor, P.; Steenari, B.M. Characterisation of silicon, zirconium and aluminium coated titanium dioxide pigments recovered from paint waste. Dye Pigment. 2019, 162, 145–152. [Google Scholar] [CrossRef]

- Suchanek, W.; Yoshimura, M. Processing and properties of hydroxyapatite-based biomaterials for use as hard tissue replacement implants. J. Mater. Res. 1998, 13, 94–117. [Google Scholar] [CrossRef]

- Brabrand, D.J.; Loehr, R.C. Solidification/stabilization of spent abrasives and use as nonstructural concrete. Waste Manag. 1993, 13, 333–339. [Google Scholar] [CrossRef]

- Mymrin, V.; Ribeiro, R.A.; Alekseev, K.; Zelinskaya, E.; Tolmacheva, N.; Catai, R. Environment friendly ceramics from hazardous industrial wastes. Ceram. Int. 2014, 40, 9427–9437. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.G.; Yue, Q.R.; Zheng, M.Z. Shear resistance of a novel wet connection for prefabricated composite beams under shear-bending coupling loading. J. Build. Eng. 2022, 45, 103636. [Google Scholar] [CrossRef]

- Palaniyappan, S.; Annamalai, V.E.; Ashwinkumaran, S.; Thenmuhil, D.; Veeman, D. Utilization of abrasive industry waste as a substitute material for the production of fireclay brick. J. Build. Eng. 2022, 45, 103606. [Google Scholar] [CrossRef]

- Bautista-Marín, J.D.; Esguerra-Arce, A.; Esguerra-Arce, J. Use of an industrial solid waste as a pigment in clay bricks and its effects on the mechanical properties. Constr. Build. Mater. 2021, 306, 124848. [Google Scholar] [CrossRef]

- Rodriguez, A.L.; Queiroz, É.V.; López, D.A.R.; Wermuth, T.B.; Basegio, T.M.; Bergmann, C.P. Utilization of foundry waste to produce ceramic matrix composites. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2016; Volume 869, pp. 149–154. [Google Scholar]

- Pintér, Á.S.; Sarka, F. Research into the uses of sandblasting waste. Des. Mach. Struct. 2020, 10, 97–105. [Google Scholar] [CrossRef]

- Ramaswamy, K.; O’Higgins, R.M.; Kadiyala, A.K.; McCarthy, M.A.; McCarthy, C.T. Evaluation of grit-blasting as a pre-treatment for carbon-fibre thermoplastic composite to aluminium bonded joints tested at static and dynamic loading rates. Compos. Part B Eng. 2020, 185, 107765. [Google Scholar] [CrossRef]

- Ho, C.H.; Lo, H.M.; Lin, K.L.; Lan, J.Y. Characteristics of porous ceramics prepared from sandblasting waste and waste diatomite by co-sintering process. Environ. Prog. Sustain. Energy 2019, 38, 321–328. [Google Scholar] [CrossRef]

- Ho, C.H.; Lo, H.M.; Lin, K.L.; Lan, J.Y. Characteristics of water-retaining porous ceramics with sandblasting waste. Constr. Build. Mater. 2017, 157, 75–82. [Google Scholar] [CrossRef]

- Meneghel, L.; Farias, M.C.M.; Catafesta, J. Recycling carbon-steel waste from blast cleaning by powder metallurgy employing the augmented simplex lattice design. Res. Soc. Dev. 2022, 11, e16211527980. [Google Scholar] [CrossRef]

- Oranli, E.; Gungoren, N.; Astaraee, A.H.; Maleki, E.; Bagherifard, S.; Guagliano, M. Numerical and experimental analysis of sand blasting on polymeric substrates. Forces Mech. 2023, 12, 100208. [Google Scholar] [CrossRef]

- Lin, Y.W.; Lee, W.H.; Lin, K.L. A novel approach for preparing ecological zeolite material from solar panel waste lass and sandblasting waste: Microscopic characteristics and humidity control performance. J. Mater. Res. Technol. 2022, 19, 4128–4140. [Google Scholar] [CrossRef]

- Rozhkovskaya, A.; Rajapakse, J.; Millar, G.J. Synthesis of LTA zeolite beads using alum sludge and silica rich wastes. Adv. Powder Technol. 2021, 32, 3248–3258. [Google Scholar] [CrossRef]

- Lim, T.T.; Chu, J. Assessment of the use of spent copper slag for land reclamation. Waste Manag. Res. 2006, 24, 67–73. [Google Scholar] [CrossRef] [PubMed]

- Nikolić, I.; Zejak, R.; Blečić, D.; Tadić, M.; Radmilović, V.R. Geopolymerization of fly ash as a possible solution for stabilization of used sandblasting grit. Zaštitamaterijala 2012, 53, 361–364. [Google Scholar]

- Prasad, P.S.; Ramana, G.V. Feasibility study of copper slag as a structural fill in reinforced soil structures. Geotext. Geomembr. 2016, 44, 623–640. [Google Scholar] [CrossRef]

| Agricultural Waste | Natural Minerals | Mineral Slag | Metallic Grits | Synthetic Grits |

|---|---|---|---|---|

| Walnut shells | Sand | Fe-Ni slag | Steel | Plastic beads |

| Corn cob | Alumina | Scrap metals | Zn | SiC |

| Plum stones | Silica | Ni | ||

| Apricot stones | Zeolites | Co | ||

| Peach stones | Garnets | Cu | ||

| Glass/Ceramics | Fe |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kavalarakis, K.; Vouvoudi, E.C.; Kartsonakis, I.A. Recycling and Reuse of Grit Blasting Waste for Composite Materials: Directions, Properties and Physical Chemistry Approaches. J. Compos. Sci. 2025, 9, 453. https://doi.org/10.3390/jcs9080453

Kavalarakis K, Vouvoudi EC, Kartsonakis IA. Recycling and Reuse of Grit Blasting Waste for Composite Materials: Directions, Properties and Physical Chemistry Approaches. Journal of Composites Science. 2025; 9(8):453. https://doi.org/10.3390/jcs9080453

Chicago/Turabian StyleKavalarakis, Konstantinos, Evangelia C. Vouvoudi, and Ioannis A. Kartsonakis. 2025. "Recycling and Reuse of Grit Blasting Waste for Composite Materials: Directions, Properties and Physical Chemistry Approaches" Journal of Composites Science 9, no. 8: 453. https://doi.org/10.3390/jcs9080453

APA StyleKavalarakis, K., Vouvoudi, E. C., & Kartsonakis, I. A. (2025). Recycling and Reuse of Grit Blasting Waste for Composite Materials: Directions, Properties and Physical Chemistry Approaches. Journal of Composites Science, 9(8), 453. https://doi.org/10.3390/jcs9080453