The Effect of Methacrylate-POSS in Nanosilica Dispersion Addition on Selected Mechanical Properties of Photo-Cured Dental Resins and Nanocomposites †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials’ Composition

2.2. Sample Preparation

2.3. Flexural Strength

2.4. Diametral Tensile Strength

2.5. Hardness

2.6. Polymerization Shrinkage Stress

2.7. FTIR Analysis

2.8. Statistical Analysis

3. Results

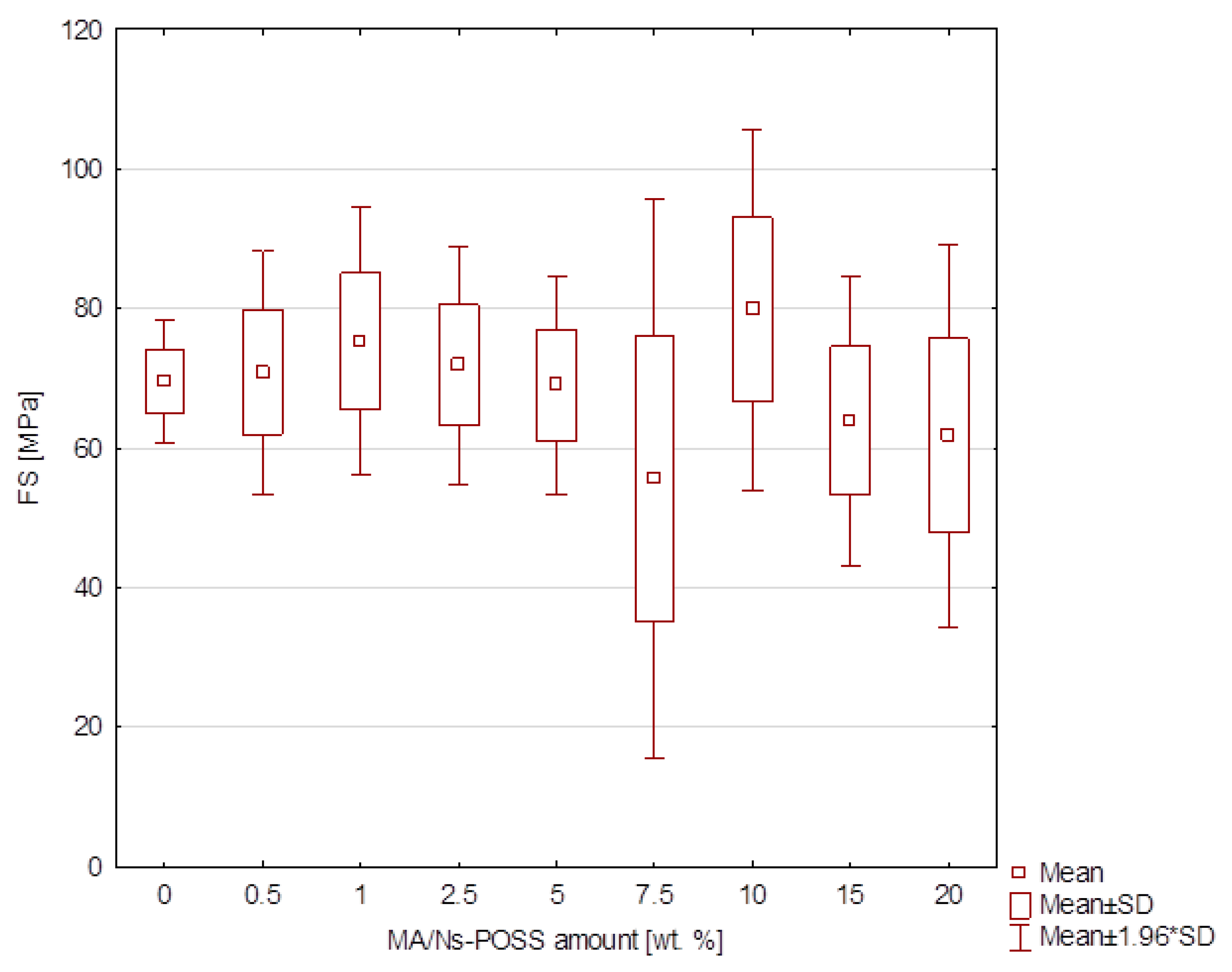

3.1. Flexural Strength

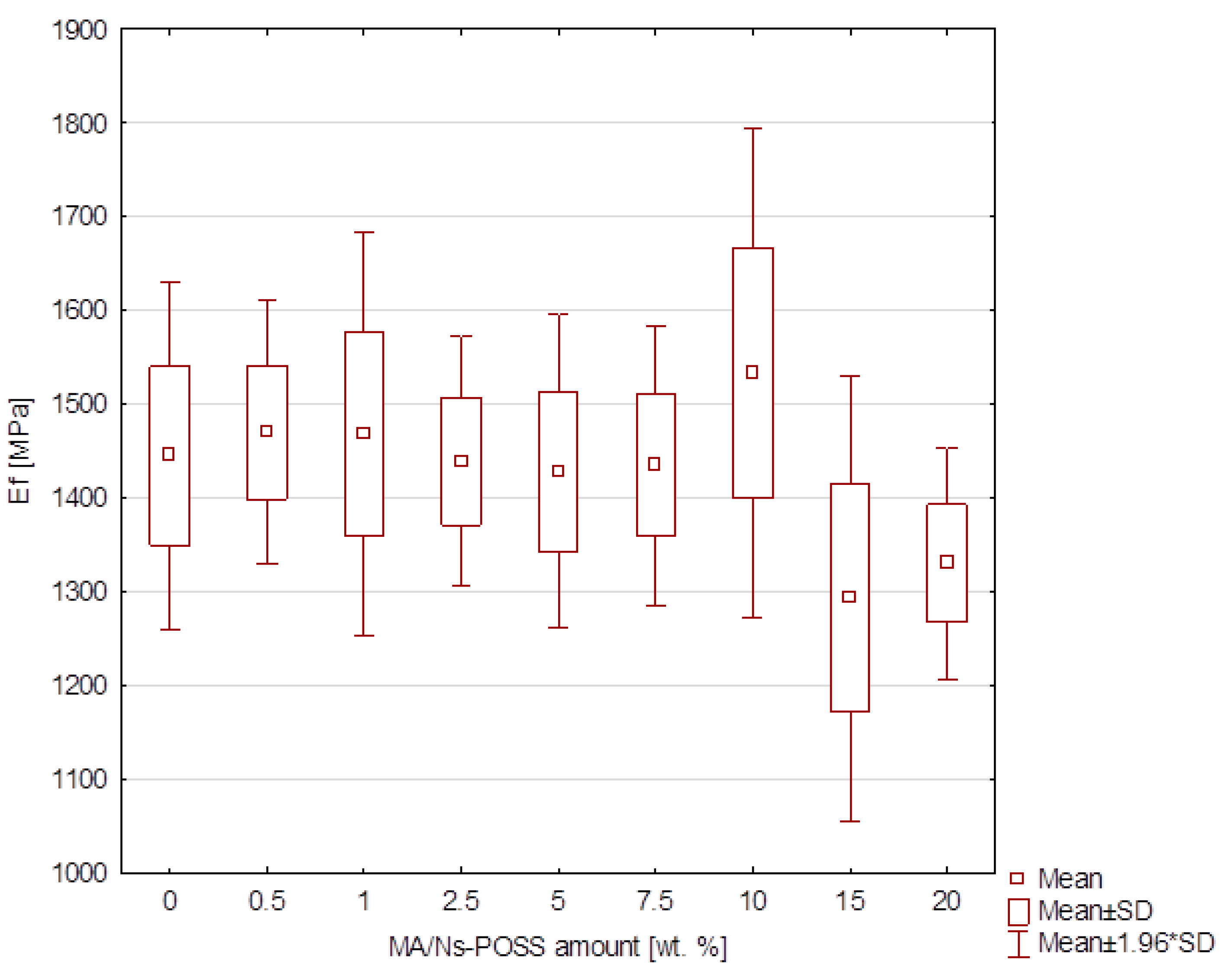

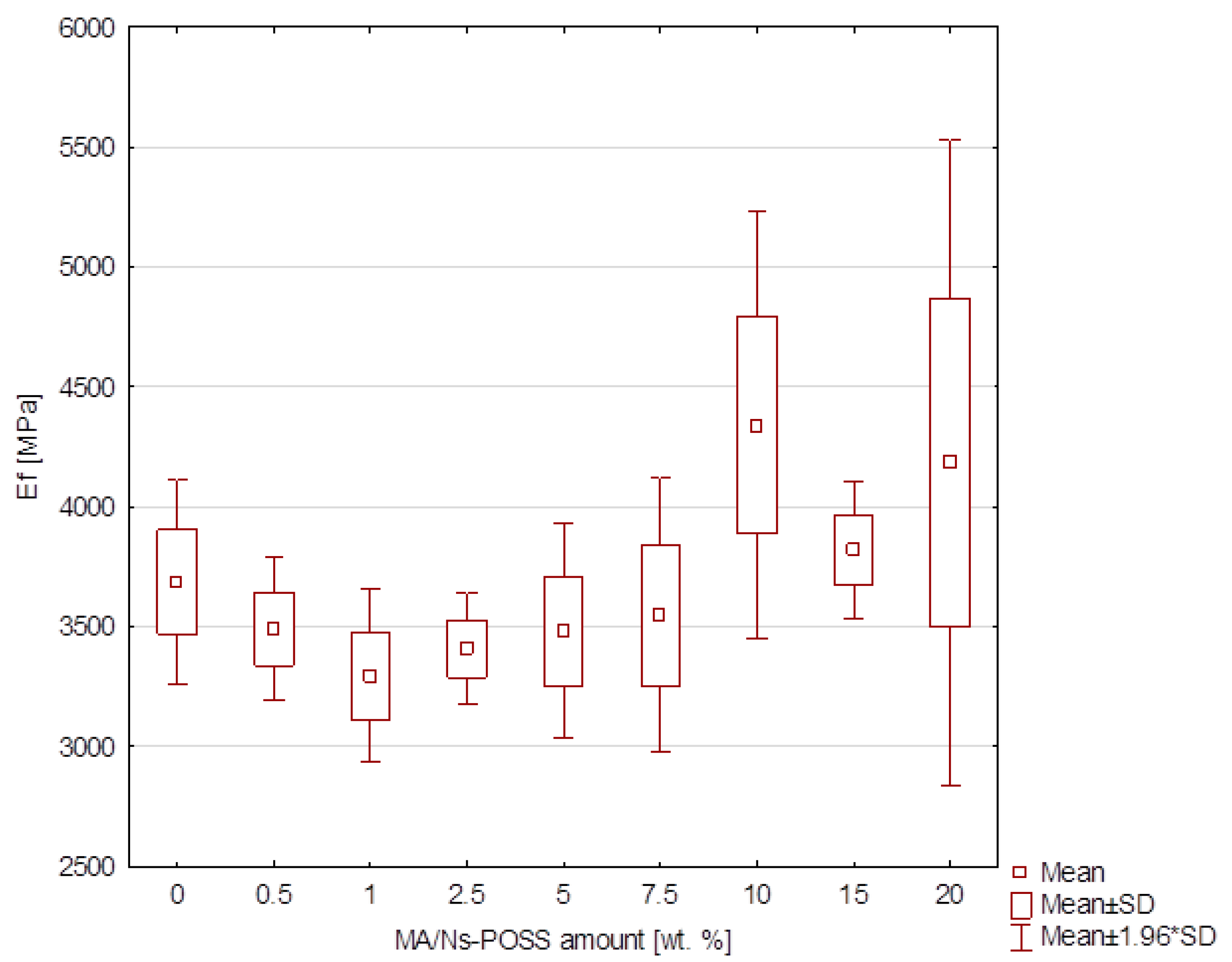

3.2. Elasticity Modulus in Bending

3.3. Diametral Tensile Strength

3.4. Hardness

3.5. Polymerization Shrinkage Stress

3.6. Degree of Conversion Analysis

4. Discussion

4.1. Flexural Strength and Elasticity Modulus in Bending

4.2. Diametral Tensile Strength

4.3. Hardness

4.4. Polymerization Shrinkage Stress

4.5. Degree of Conversion Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Amount of MA/Ns-POSS [wt.%] | Mean | SD | Median | Min | Max |

|---|---|---|---|---|---|

| Hardness HV [-] | |||||

| 0 | 21.00 | 1.71 | 21.0 | 18.0 | 25.0 |

| 0.5 | 20.58 | 2.07 | 20.5 | 18.0 | 24.0 |

| 1 | 20.58 | 2.27 | 21.0 | 17.0 | 25.0 |

| 2.5 | 21.33 | 1.15 | 22.0 | 19.0 | 23.0 |

| 5 | 20.83 | 1.64 | 21.0 | 18.0 | 23.0 |

| 7.5 | 21.00 | 1.71 | 21.0 | 18.0 | 25.0 |

| 10 * | 23.50 | 2.39 | 23.0 | 20.0 | 28.0 |

| 15 | 21.08 | 1.51 | 21.0 | 19.0 | 23.0 |

| 20 * | 20.08 | 1.16 | 20.0 | 19.0 | 22.0 |

| Flexural modulus [MPa] | |||||

| 0 | 1445.00 | 95.03 | 1480.0 | 1290.0 | 1530.0 |

| 0.5 | 1470.00 | 71.55 | 1465.0 | 1380.0 | 1580.0 |

| 1 | 1468.33 | 109.44 | 1485.0 | 1310.0 | 1600.0 |

| 2.5 | 1439.17 | 68.29 | 1435.0 | 1330.0 | 1540.0 |

| 5 | 1428.33 | 85.65 | 1435.0 | 1320.0 | 1540.0 |

| 7.5 | 1435.00 | 76.09 | 1445.0 | 1300.0 | 1510.0 |

| 10 * | 1533.33 | 133.67 | 1530.0 | 1370.0 | 1700.0 |

| 15 * | 1293.33 | 121.27 | 1315.0 | 1060.0 | 1410.0 |

| 20 | 1330.00 | 62.93 | 1325.0 | 1240.0 | 1410.0 |

| Flexural strength [MPa] | |||||

| 0 | 67.55 | 4.35 | 67.85 | 61.00 | 74.10 |

| 0.5 | 69.17 | 3.03 | 69.15 | 65.80 | 72.90 |

| 1 | 67.92 | 2.48 | 67.80 | 65.00 | 70.60 |

| 2.5 | 69.97 | 1.44 | 70.15 | 67.70 | 71.90 |

| 5 | 67.10 | 1.91 | 66.25 | 65.20 | 70.30 |

| 7.5 | 66.90 | 5.30 | 67.90 | 58.50 | 72.50 |

| 10 * | 71.62 | 3.58 | 71.65 | 67.50 | 75.60 |

| 15 * | 63.58 | 4.42 | 63.70 | 55.70 | 69.10 |

| 20 | 65.18 | 2.97 | 66.05 | 59.20 | 67.20 |

| Amount of MA/Ns-POSS [wt.%] | Mean | SD | Median | Min | Max |

|---|---|---|---|---|---|

| Hardness [-] | |||||

| 0 * | 34.22 | 1.56 | 34.0 | 32.0 | 37.0 |

| 0.5 | 38.78 | 1.72 | 39.0 | 37.0 | 42.0 |

| 1 | 37.33 | 1.73 | 37.0 | 35.0 | 40.0 |

| 2.5 | 37.67 | 1.94 | 38.0 | 33.0 | 40.0 |

| 5 * | 36.56 | 1.33 | 36.0 | 35.0 | 39.0 |

| 7.5 * | 36.11 | 1.83 | 36.0 | 34.0 | 40.0 |

| 10 * | 35.89 | 2.03 | 36.0 | 33.0 | 38.0 |

| 15 | 37.56 | 1.51 | 38.0 | 35.0 | 40.0 |

| 20 * | 42.22 | 1.86 | 42.0 | 40.0 | 46.0 |

| Flexural modulus [MPa] | |||||

| 0 | 3686.0 | 217.78 | 3720.0 | 3470.0 | 3990.0 |

| 0.5 | 3490.0 | 151.66 | 3530.0 | 3270.0 | 3650.0 |

| 1 * | 3294.0 | 183.52 | 3200.0 | 3140.0 | 3560.0 |

| 2.5 * | 3408.0 | 119.04 | 3370.0 | 3310.0 | 3600.0 |

| 5 | 3482.0 | 228.19 | 3470.0 | 3200.0 | 3760.0 |

| 7.5 | 3548.0 | 292.52 | 3540.0 | 3110.0 | 3900.0 |

| 10 * | 4340.0 | 453.82 | 4330.0 | 3700.0 | 4780.0 |

| 15 | 3818.0 | 147.21 | 3760.0 | 3680.0 | 4050.0 |

| 20 * | 4184.0 | 687.81 | 3900.0 | 3510.0 | 4990.0 |

| Flexural strength [MPa] | |||||

| 0 | 69.56 | 4.46 | 68.8 | 64.6 | 76.8 |

| 0.5 | 70.84 | 8.89 | 69.2 | 59.0 | 80.9 |

| 1 | 75.28 | 9.8 | 71.2 | 66.9 | 88.3 |

| 2.5 | 71.84 | 8.65 | 70.5 | 60.7 | 80.7 |

| 5 | 69.06 | 7.99 | 69.6 | 60.6 | 77.2 |

| 7.5 | 55.72 | 20.45 | 59.5 | 31.3 | 84.3 |

| 10 | 79.84 | 13.23 | 83.8 | 64.9 | 97.6 |

| 15 | 63.94 | 10.61 | 68.8 | 46.4 | 71.9 |

| 20 | 61.76 | 13.94 | 58.3 | 47.1 | 78.2 |

| Diametral tensile strength [MPa] | |||||

| 0 | 27.61 | 5.24 | 27.86 | 17.34 | 33.51 |

| 0.5 * | 35.37 | 1.24 | 35.33 | 33.57 | 37.84 |

| 1 * | 33.31 | 4.76 | 34.70 | 22.26 | 36.95 |

| 2.5 | 31.45 | 6.41 | 32.30 | 21.96 | 42.38 |

| 5 * | 23.42 | 5.15 | 22.08 | 17.20 | 32.36 |

| 7.5 * | 25.46 | 5.10 | 25.33 | 18.54 | 34.28 |

| 10 * | 25.43 | 5.64 | 26.63 | 14.51 | 33.26 |

| 15 * | 25.94 | 4.54 | 26.79 | 19.49 | 31.80 |

| 20* | 24.45 | 1.78 | 24.19 | 22.37 | 27.81 |

References

- Yadav, R.; Kumar, M. Dental Restorative Composite Materials: A Review. J. Oral. Biosci. 2019, 61, 78–83. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhu, M.; Zhu, X.X. Functional Fillers for Dental Resin Composites. Acta Biomater. 2021, 122, 50–65. [Google Scholar] [CrossRef]

- Xue, J.; Wang, J.; Feng, D.; Huang, H.; Wang, M. Application of Antimicrobial Polymers in the Development of Dental Resin Composite. Molecules 2020, 25, 4738. [Google Scholar] [CrossRef]

- Wang, W.; Sun, X.; Huang, L.; Gao, Y.; Ban, J.; Shen, L.; Chen, J. Structure–Property Relationships in Hybrid Nanocomposite Resins Containing and Multifunctional Oligomeric Silsesquioxanes. Int. J. Nanomed. 2014, 9, 841–852. [Google Scholar] [CrossRef] [PubMed]

- Shah, Y.; Shiraguppi, V.; Deosarkar, B.; Shelke, U. Long-Term Survival and Reasons for Failure in Direct Anterior Composite Restorations: A Systematic Review. J. Conserv. Dent. 2021, 24, 415. [Google Scholar] [CrossRef]

- Demarco, F.F.; Cenci, M.S.; Montagner, A.F.; de Lima, V.P.; Correa, M.B.; Moraes, R.R.; Opdam, N.J.M. Longevity of Composite Restorations Is Definitely Not Only About Materials. Dent. Mater. 2023, 39, 1–12. [Google Scholar] [CrossRef]

- Zheng, Y.; Gao, Z.; Han, J. Current Chemistry of Cyclic Oligomeric Silsesquioxanes. Curr. Org. Chem. 2018, 21, 2814–2828. [Google Scholar] [CrossRef]

- Abbasi, M.R.; Karimi, M.; Atai, M. Modified POSS Nano-Structures as Novel Co-Initiator-Crosslinker: Synthesis and Characterization. Dent. Mater. 2021, 37, 1283–1294. [Google Scholar] [CrossRef]

- Yu, X.; Yang, S.; Han, D.; Wang, T.; Xie, Q.; Xie, W. A Novel Dental Resin Composite Based on POSS and MDP-Modified Zirconia: Preparation and Evaluation. J. Dent. 2025, 155, 105638. [Google Scholar] [CrossRef]

- Liu, S.; Guo, R.; Li, C.; Lu, C.; Yang, G.; Wang, F.; Nie, J.; Ma, C.; Gao, M. POSS Hybrid Hydrogels: A Brief Review of Synthesis, Properties and Applications. Eur. Polym. J. 2021, 143, 110180. [Google Scholar] [CrossRef]

- Yudovin-Farber, I.; Beyth, N.; Nyska, A.; Weiss, E.I.; Golenser, J.; Domb, A.J. Surface Characterization and Biocompatibility of Restorative Resin Containing Nanoparticles. Biomacromolecules 2008, 9, 3044–3050. [Google Scholar] [CrossRef] [PubMed]

- Szwarc-Rzepka, K.; Ciesielczyk, F.; Jesionowski, T. Preparation and Physicochemical Properties of Functionalized Silica/Octamethacryl-Silsesquioxane Hybrid Systems. J. Nanomater. 2013, 2013, 674237. [Google Scholar] [CrossRef]

- Blanco, I.; Abate, L.; Bottino, F.A.; Bottino, P. Synthesis, Characterization and Thermal Stability of New Dumbbell-Shaped Isobutyl-Substituted POSSs Linked by Aromatic Bridges. J. Therm. Anal. Calorim. 2014, 117, 243–250. [Google Scholar] [CrossRef]

- Fong, H.; Dickens, S.; Flaim, G. Evaluation of Dental Restorative Composites Containing Polyhedral Oligomeric Silsesquioxane Methacrylate. Dent. Mater. 2005, 21, 520–529. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, Y.; Yu, J.; Sun, Y.; Xie, W. Study of POSS on the Properties of Novel Inorganic Dental Composite Resin. Polymers 2020, 12, 478. [Google Scholar] [CrossRef]

- Kreutz, M.; Wiegand, A.; Stawarczyk, B.; Lümkemann, N.; Rizk, M. Characterization of Methacrylate-Based Resins Containing Methacryl-Polyhedral Oligomeric Silsesquioxanes (MA-POSS-8). Materials 2021, 14, 1680. [Google Scholar] [CrossRef]

- Canellas, T.A.T.; de Almeida Neves, A.; dos Santos, I.K.B.; de Rezende, A.R.P.; Fellows, C.E.; da Silva, E.M. Characterization of Low-Shrinkage Dental Composites Containing Methacrylethyl-Polyhedral Oligomeric Silsesquioxane (ME-POSS). J. Mech. Behav. Biomed. Mater. 2019, 90, 566–574. [Google Scholar] [CrossRef]

- Ozimek, J.; Łukaszewska, I.; Pielichowski, K. POSS and SSQ Materials in Dental Applications: Recent Advances and Future Outlooks. Int. J. Mol. Sci. 2023, 24, 4493. [Google Scholar] [CrossRef]

- Wu, X.; Sun, Y.; Xie, W.; Liu, Y.; Song, X. Development of Novel Dental Nanocomposites Reinforced with Polyhedral Oligomeric Silsesquioxane (POSS). Dent. Mater. 2010, 26, 456–462. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Sun, Y.; Zeng, F.; Xie, W.; Liu, Y.; Geng, L. Effect of Nano SiO2 Particles on the Morphology and Mechanical Properties of POSS Nanocomposite Dental Resins. J. Nanopart. Res. 2014, 16, 2736. [Google Scholar] [CrossRef]

- Bociong, K.; Szczesio, A.; Krasowski, M.; Sokolowski, J. The Influence of Filler Amount on Selected Properties of New Experimental Resin Dental Composite. Open Chem. 2018, 16, 905–911. [Google Scholar] [CrossRef]

- Sabbagh, J.; Ryelandt, L.; Bachérius, L.; Biebuyck, J.-J.; Vreven, J.; Lambrechts, P.; Leloup, G. Characterization of the Inorganic Fraction of Resin Composites. J. Oral. Rehabil. 2004, 31, 1090–1101. [Google Scholar] [CrossRef] [PubMed]

- ISO 4049; Dentistry—Polymer-Based Restorative Materials. ISO: Geneva, Switzerland, 2019.

- Timoshenko, S.; Timoshenko, S.; Goodier, J.N. Theory of Elasticity, 2nd ed.; Timoshenko, S., Goodier, J.N., Eds.; McGraw-Hill Book Company: New York, NY, USA, 1951. [Google Scholar]

- Bociong, K.; Szczesio, A.; Sokolowski, K.; Domarecka, M.; Sokolowski, J.; Krasowski, M.; Lukomska-Szymanska, M. The Influence of Water Sorption of Dental Light-Cured Composites on Shrinkage Stress. Materials 2017, 10, 1142. [Google Scholar] [CrossRef]

- Domarecka, M.; Szczesio-Wlodarczyk, A.; Krasowski, M.; Fronczek, M.; Gozdek, T.; Sokolowski, J.; Bociong, K. A Comparative Study of the Mechanical Properties of Selected Dental Composites with a Dual-Curing System with Light-Curing Composites. Coatings 2021, 11, 1255. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, X.; Sun, Y.; Xie, W. POSS Dental Nanocomposite Resin: Synthesis, Shrinkage, Double Bond Conversion, Hardness, and Resistance Properties. Polymers 2018, 10, 369. [Google Scholar] [CrossRef]

- Gundogdu, M. The Evaluation of Flexural Strength of Composite Resin Materials with and without Fiber. Dentistry 2014, 4, 1. [Google Scholar] [CrossRef]

- Baldi, F.; Bignotti, F.; Fina, A.; Tabuani, D.; Riccò, T. Mechanical Characterization of Polyhedral Oligomeric Silsesquioxane/Polypropylene Blends. J. Appl. Polym. Sci. 2007, 105, 935–943. [Google Scholar] [CrossRef]

- Sokolowski, G.; Szczesio, A.; Bociong, K.; Kaluzinska, K.; Lapinska, B.; Sokolowski, J.; Domarecka, M.; Lukomska-Szymanska, M. Dental Resin Cements-The Influence of Water Sorption on Contraction Stress Changes and Hydroscopic Expansion. Materials 2018, 10, 11973. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, H.; Xiong, G.; Zhang, J.; Guo, R.; Li, L.; Zhou, H.; Chen, G.; Zhou, Z.; Li, Q. A Low-Shrinkage Dental Composite with Epoxy-Polyhedral Oligomeric Silsesquioxane. J. Mech. Behav. Biomed. Mater. 2020, 103, 103515. [Google Scholar] [CrossRef] [PubMed]

- Correa Netto, L.R.; Borges, A.L.S.; Guimarães, H.B.; de Almeida, E.R.N.; Poskus, L.T.; da Silva, E.M. Marginal Integrity of Restorations Produced with a Model Composite Based on Polyhedral Oligomeric Silsesquioxane (POSS). J. Appl. Oral Sci. 2015, 23, 450–458. [Google Scholar] [CrossRef] [PubMed]

- Madhuranthakam, C.M.R.; Pandiyan, S.; Elkamel, A. Molecular Simulations of Low-Shrinkage Dental Resins Containing Methacryl-Based Polyhedral Oligomeric Silsesquioxane (POSS). Polymers 2023, 15, 432. [Google Scholar] [CrossRef] [PubMed]

- Stansbury, J.W.; Dickens, S.H. Determination of Double Bond Conversion in Dental Resins by near Infrared Spectroscopy. Dent. Mater. 2001, 17, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Lin, J.; Li, Q. Study of High-Strength, Low-Shrinkage Dental Resin Composites with Bifunctional Polysilsesquioxane. Dent. Mater. 2025, 41, 755–767. [Google Scholar] [CrossRef] [PubMed]

| Amount of MA/Ns-POSS [wt.%] | σr [MPa] | σϴ [MPa] | σint [MPa] |

|---|---|---|---|

| 0 | 12.2 ± 0.7 | −13.6 ± 0.8 | 25.8 ± 1.5 |

| 0.5 | 12.3 ± 0.2 | −13.8 ± 0.2 | 26.0 ± 0.3 |

| 1.0 | 11.9 ± 1.4 | −13.8 ± 1.1 | 25.7 ± 2.5 |

| 2.5 | 11.8 ± 0.8 | −13.4 ± 0.7 | 25.2 ± 1.5 |

| 5.0 | 11.5 ± 0.8 | −13.1 ± 0.7 | 24.6 ± 1.4 |

| 7.5 | 12.1 ± 0.2 | −13.6 ± 0.2 | 25.7 ± 0.4 |

| 10.0 | 11.2 ± 0.4 | −12.8 ± 0.4 | 24.1 ± 0.8 |

| 15.0 | 9.4 ± 1.6 | −10.9 ± 1.4 | 20.3 ± 3.0 |

| 20.0 | 10.0 ± 0.8 | −11.4 ± 1.0 | 21.4 ± 1.8 |

| Amount of MA/Ns-POSS [wt.%] | DC [%] |

|---|---|

| 0 | 58.0 |

| 0.5 | 58.4 |

| 1.0 | 53.0 |

| 2.5 | 60.0 |

| 5.0 | 63.1 |

| 7.5 | 60.6 |

| 10.0 | 60.6 |

| 15.0 | 78.0 |

| 20.0 | 70.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobon, N.; Krasowski, M.; Kopacz, K.; Lapinska, B.; Barszczewska-Rybarek, I.; Kula, P.; Bociong, K. The Effect of Methacrylate-POSS in Nanosilica Dispersion Addition on Selected Mechanical Properties of Photo-Cured Dental Resins and Nanocomposites. J. Compos. Sci. 2025, 9, 403. https://doi.org/10.3390/jcs9080403

Sobon N, Krasowski M, Kopacz K, Lapinska B, Barszczewska-Rybarek I, Kula P, Bociong K. The Effect of Methacrylate-POSS in Nanosilica Dispersion Addition on Selected Mechanical Properties of Photo-Cured Dental Resins and Nanocomposites. Journal of Composites Science. 2025; 9(8):403. https://doi.org/10.3390/jcs9080403

Chicago/Turabian StyleSobon, Norbert, Michal Krasowski, Karolina Kopacz, Barbara Lapinska, Izabela Barszczewska-Rybarek, Patrycja Kula, and Kinga Bociong. 2025. "The Effect of Methacrylate-POSS in Nanosilica Dispersion Addition on Selected Mechanical Properties of Photo-Cured Dental Resins and Nanocomposites" Journal of Composites Science 9, no. 8: 403. https://doi.org/10.3390/jcs9080403

APA StyleSobon, N., Krasowski, M., Kopacz, K., Lapinska, B., Barszczewska-Rybarek, I., Kula, P., & Bociong, K. (2025). The Effect of Methacrylate-POSS in Nanosilica Dispersion Addition on Selected Mechanical Properties of Photo-Cured Dental Resins and Nanocomposites. Journal of Composites Science, 9(8), 403. https://doi.org/10.3390/jcs9080403