Experimental Investigation on Heat Generation of Tread Rubber Materials Under Tensile-Compression Cyclic Conditions

Abstract

1. Introduction

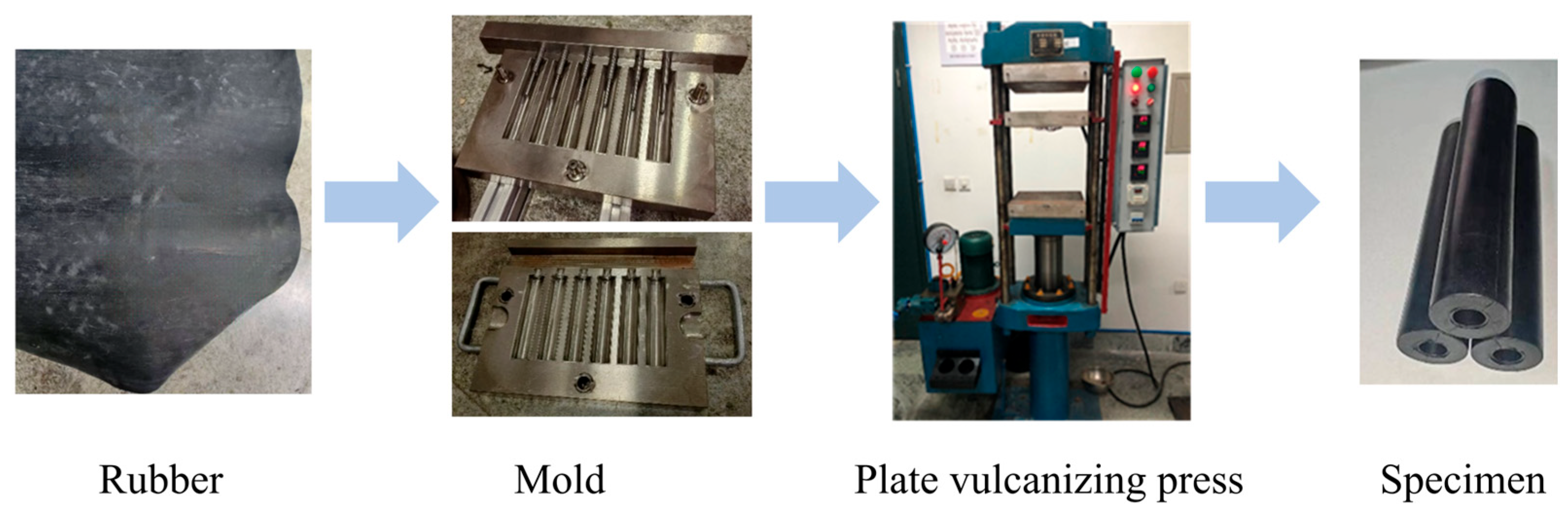

2. Materials and Methods

2.1. Materials

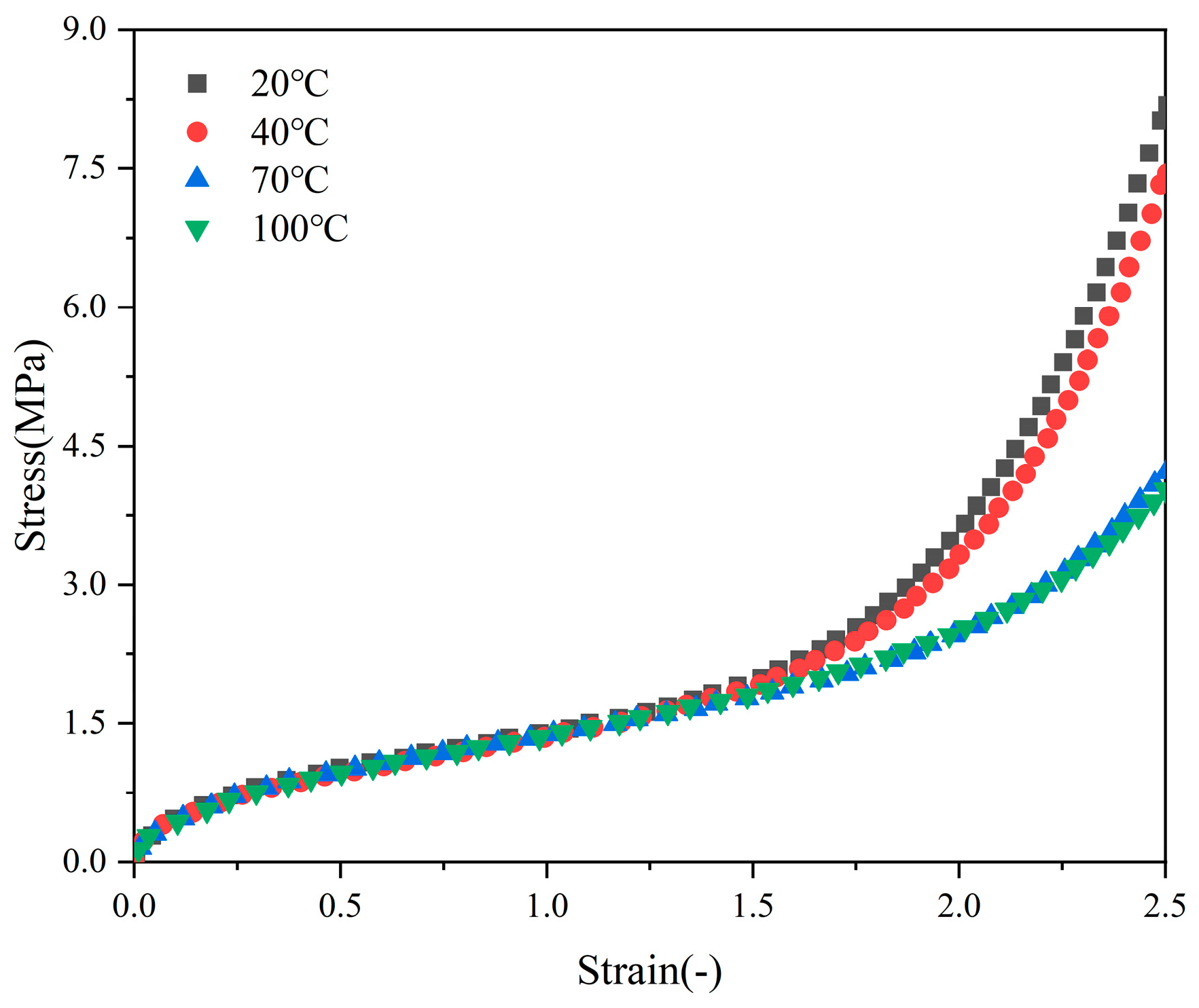

2.2. Tensile Test

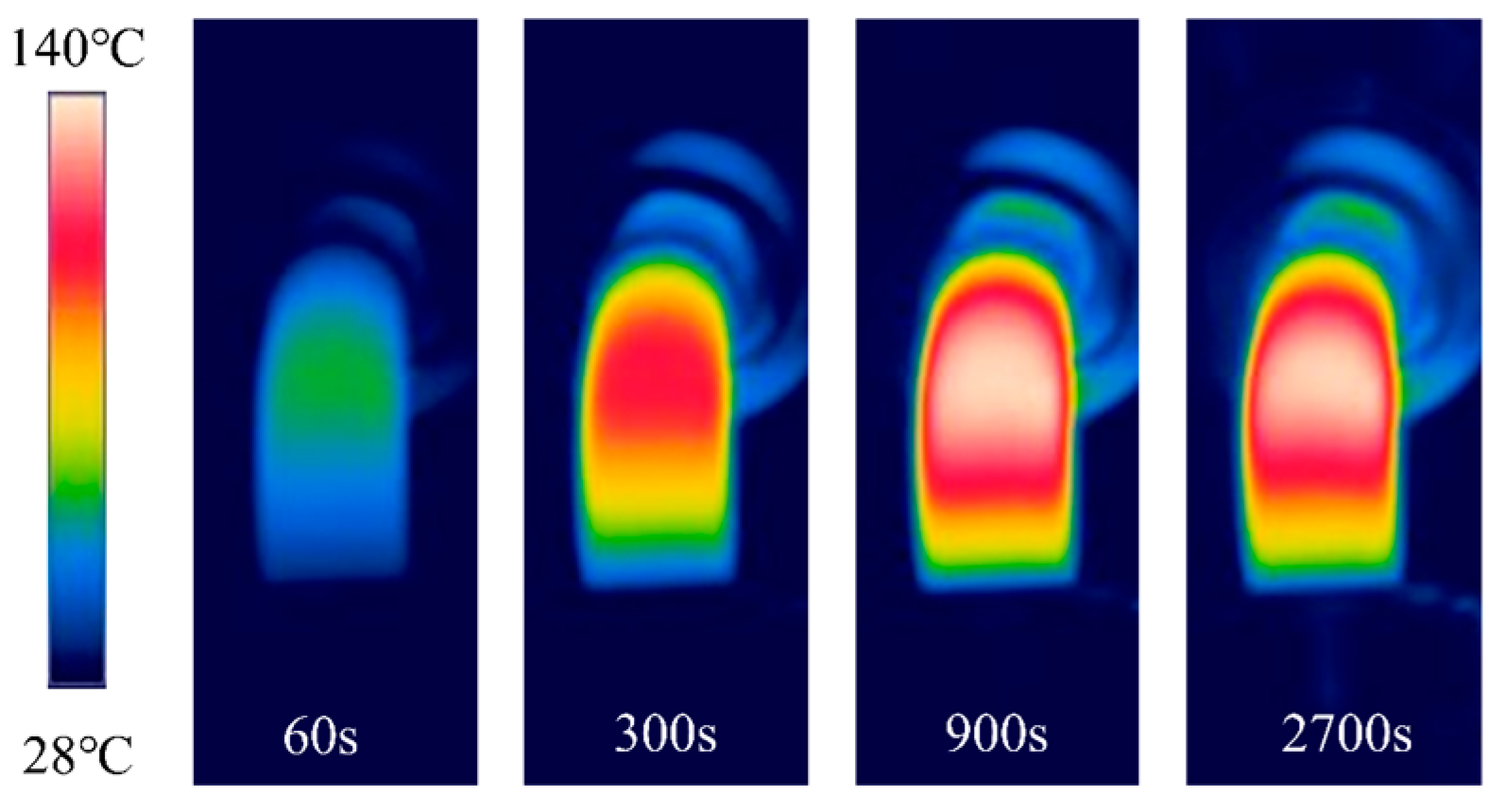

2.3. Heat Build-Up Test

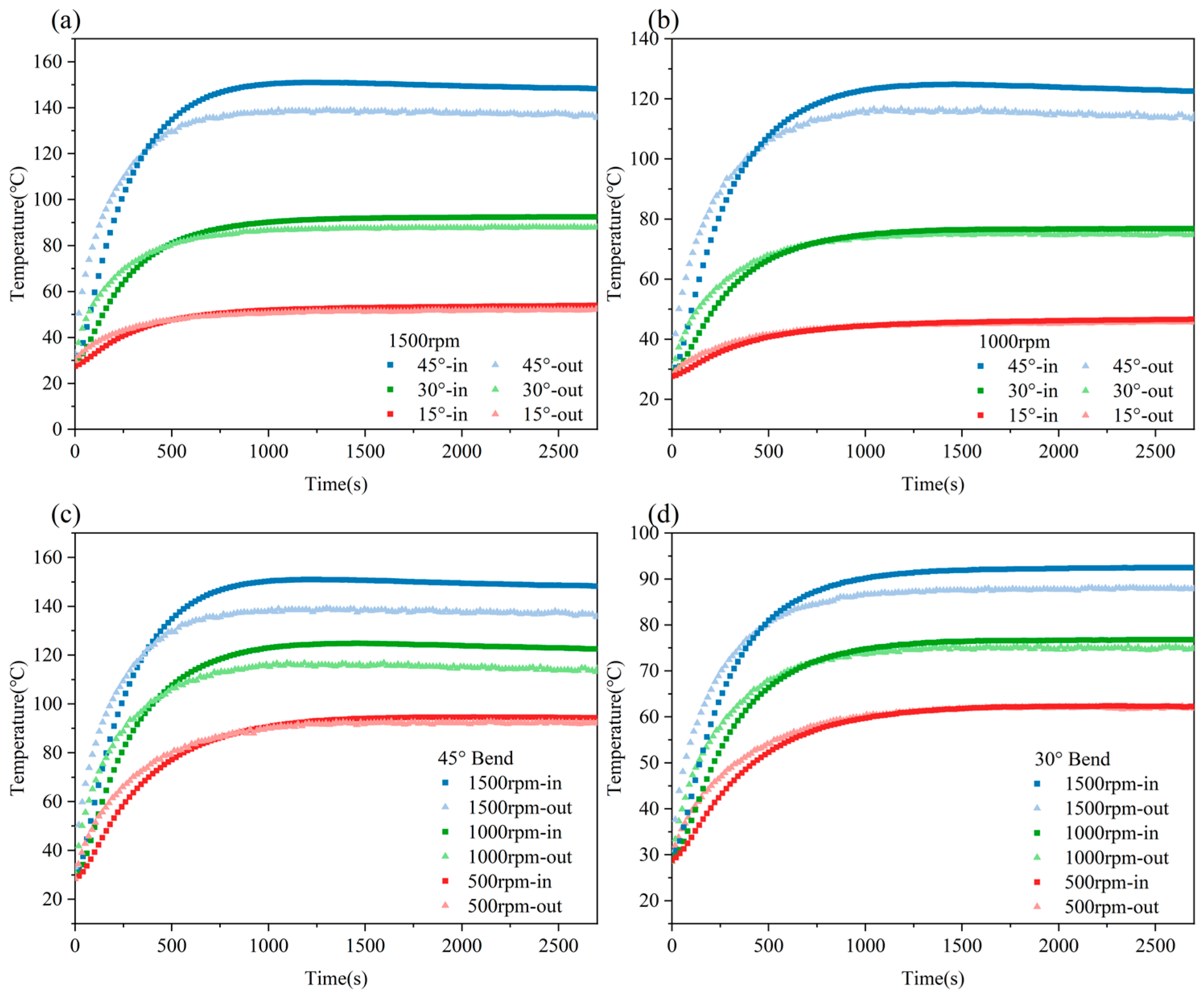

3. Results and Discussion

3.1. Process of Temperature Rise

3.2. Effect of Different Operating Conditions on Temperature Rise

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, B.; Zhao, Y.; You, J.; Zhang, Z. Experimental and numerical analysis of rubber isolator dynamic stiffness under hydrostatic pressure. Ocean Eng. 2024, 314, 119650. [Google Scholar] [CrossRef]

- Johnson, A.R.; Chen, T. Approximating thermo-viscoelastic heating of largely strained solid rubber components. Comput. Methods Appl. Mech. Eng. 2005, 194, 313–325. [Google Scholar] [CrossRef]

- Clark, S.K.; Dodge, R.N. Heat generation in aircraft tires. Comput. Struct. 1985, 20, 535–544. [Google Scholar] [CrossRef]

- He, H.; Liu, J.; Zhang, Y.; Han, X.; Mars, W.V.; Zhang, L.; Li, F. Heat Build-Up and Rolling Resistance Analysis of a Solid Tire: Experimental Observation and Numerical Simulation with Thermo-Mechanical Coupling Method. Polymers 2022, 14, 2210. [Google Scholar] [CrossRef] [PubMed]

- Zhi, J.; Wang, S.; Zhang, M.; Wang, H.; Lu, H.; Lin, W.; Qiao, C.; Hu, C.; Jia, Y. Numerical analysis of the dependence of rubber hysteresis loss and heat generation on temperature and frequency. Mech. Time-Depend. Mater. 2019, 23, 427–442. [Google Scholar] [CrossRef]

- Behnke, R.; Kaliske, M. Thermo-mechanically coupled investigation of steady state rolling tires by numerical simulation and experiment. Int. J. Non-Linear Mech. 2015, 68, 101–131. [Google Scholar] [CrossRef]

- Luo, W.; Li, M.; Huang, Y.; Yin, B.; Hu, X. Effect of Temperature on the Tear Fracture and Fatigue Life of Carbon-Black-Filled Rubber. Polymers 2019, 11, 768. [Google Scholar] [CrossRef]

- Luo, W.; Huang, Y.; Yin, B.; Jiang, X.; Hu, X. Fatigue Life Assessment of Filled Rubber by Hysteresis Induced Self-Heating Temperature. Polymers 2020, 12, 846. [Google Scholar] [CrossRef]

- Höfer, P.; Lion, A. Modelling of frequency- and amplitude-dependent material properties of filler-reinforced rubber. J. Mech. Phys. Solids 2009, 57, 500–520. [Google Scholar] [CrossRef]

- Luo, W.; Hu, X.; Wang, C.; Li, Q. Frequency- and strain-amplitude-dependent dynamical mechanical properties and hysteresis loss of CB-filled vulcanized natural rubber. Int. J. Mech. Sci. 2010, 52, 168–174. [Google Scholar] [CrossRef]

- Cruanes, C.; Deffarges, M.P.; Lacroix, F.; Méo, S. Modeling of the thermomechanical behavior of rubbers during fatigue tests from infrared measurements. Int. J. Fatigue 2019, 126, 231–240. [Google Scholar] [CrossRef]

- Mahdi, E.M.; Tan, J. Dynamic molecular interactions between polyurethane and ZIF-8 in a polymer-MOF nanocomposite: Microstructural, thermo-mechanical and viscoelastic effects. Polymer 2016, 97, 31–43. [Google Scholar] [CrossRef]

- Liu, J.; Lu, Y.L.; Tian, M.; Li, F.; Shen, J.; Gao, Y.; Zhang, L. The interesting influence of nanosprings on the viscoelasticity of elastomeric polymer materials: Simulation and experiment. Adv. Funct. Mater. 2013, 23, 1156–1163. [Google Scholar] [CrossRef]

- Katueangngan, K.; Tulyapitak, T.; Saetung, A.; Soontaranon, S.; Nithi Uthai, N. Interfacial interactions of silica and natural rubber enhanced by hydroxyl telechelic natural rubber as interfacial modifier. J. Vinyl Addit. Technol. 2020, 26, 291–303. [Google Scholar] [CrossRef]

- Song, J.; Tian, K.; Ma, L.; Li, W.; Yao, S. The effect of carbon black morphology to the thermal conductivity of natural rubber composites. Int. J. Heat Mass Tran. 2019, 137, 184–191. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Jiang, D. Review on heat generation of rubber composites. Polymers 2023, 15, 2. [Google Scholar] [CrossRef]

- Weng, G.; Huang, G.; Qu, L.; Zhang, P.; Nie, Y.; Wu, J. Natural rubber with low heat generation achieved by the inclusion of boron carbide. J. Appl. Polym. Sci. 2010, 118, 2050–2055. [Google Scholar] [CrossRef]

- Zhan, Y.; Wei, Y.; Zhang, H.; Luo, M.; Zheng, T.; Liao, S. Analysis of the thermogenesis mechanism of natural rubber under high speed strain. Polym. Advan. Technol. 2020, 31, 1994–2006. [Google Scholar] [CrossRef]

- Luo, W.; Yin, B.; Hu, X.; Zhou, Z.; Deng, Y.; Song, K. Modeling of the heat build-up of carbon black filled rubber. Polym. Test. 2018, 69, 116–124. [Google Scholar] [CrossRef]

- Li, F.; Liu, J.; Yang, H.; Lu, Y.; Zhang, L. Numerical simulation and experimental verification of heat build-up for rubber compounds. Polymer 2016, 101, 199–207. [Google Scholar] [CrossRef]

- Akutagawa, K.; Hamatani, S.; Nashi, T. The new interpretation for the heat build-up phenomena of rubbery materials during deformation. Polymer 2015, 66, 201–209. [Google Scholar] [CrossRef]

- Liu, C.; Gu, B.; Wang, F.; Lu, B.; Liu, F.; Liu, J.; Lu, Y.; Zhang, L.; Li, F. Waveform impact on thermo-mechanical fatigue crack growth of a non-crystallizing rubber: Experimental observation and numerical simulation. Compos. Part B Eng. 2023, 255, 110604. [Google Scholar] [CrossRef]

- Wu, J.; An, S.; Teng, F.; Su, B.L.; Wang, Y.S. Thermo-mechanical behavior of solid rubber tire under high-speed free rolling conditions. Polym. Bull. 2024, 81, 3743–3757. [Google Scholar] [CrossRef]

- Hottin, A.; Naït-Abdelaziz, M.; Talha, A.; Charrier, P. An attempt to predict the heat build-up of filled elastomers under multiaxial fatigue. Polym. Test. 2023, 128, 108239. [Google Scholar] [CrossRef]

- Peter, O.; Stoček, R.; Kratina, O. Experimental and Numerical Description of the Heat Build-Up in Rubber Under Cyclic Loading; Springer International Publishing: Cham, Switzerland, 2023; pp. 121–141. [Google Scholar]

- Kratina, O.; Pöschl, M.; Stoček, R. The effect of apparent density of sulfidic crosslink and their chemical nature on self-heat build-up in carbon black filled Natural Rubber under cyclic mechanical loading. Polym. Degrad. Stabil. 2024, 227, 110871. [Google Scholar] [CrossRef]

- ISO 37:2005; Rubber, Vulcanized or Thermoplastic-Determination of Tensile Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2005.

- ISO 23529:2004; Rubber-General Procedures for Preparing and Conditioning Test Pieces for Physical Test Methods. International Organization for Standardization: Geneva, Switzerland, 2004.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, P.; Wu, J.; She, T.; Su, J.; Weng, N.; Su, B.; Wang, Y. Experimental Investigation on Heat Generation of Tread Rubber Materials Under Tensile-Compression Cyclic Conditions. J. Compos. Sci. 2025, 9, 346. https://doi.org/10.3390/jcs9070346

Cao P, Wu J, She T, Su J, Weng N, Su B, Wang Y. Experimental Investigation on Heat Generation of Tread Rubber Materials Under Tensile-Compression Cyclic Conditions. Journal of Composites Science. 2025; 9(7):346. https://doi.org/10.3390/jcs9070346

Chicago/Turabian StyleCao, Pengtao, Jian Wu, Tenglong She, Juqiao Su, Naichi Weng, Benlong Su, and Youshan Wang. 2025. "Experimental Investigation on Heat Generation of Tread Rubber Materials Under Tensile-Compression Cyclic Conditions" Journal of Composites Science 9, no. 7: 346. https://doi.org/10.3390/jcs9070346

APA StyleCao, P., Wu, J., She, T., Su, J., Weng, N., Su, B., & Wang, Y. (2025). Experimental Investigation on Heat Generation of Tread Rubber Materials Under Tensile-Compression Cyclic Conditions. Journal of Composites Science, 9(7), 346. https://doi.org/10.3390/jcs9070346