Recycling of Pultruded Vinyl Ester Thermoset Scraps into Polyethylene Composites: Toward Circular Composite Manufacturing

Abstract

1. Introduction

2. Materials and Methods

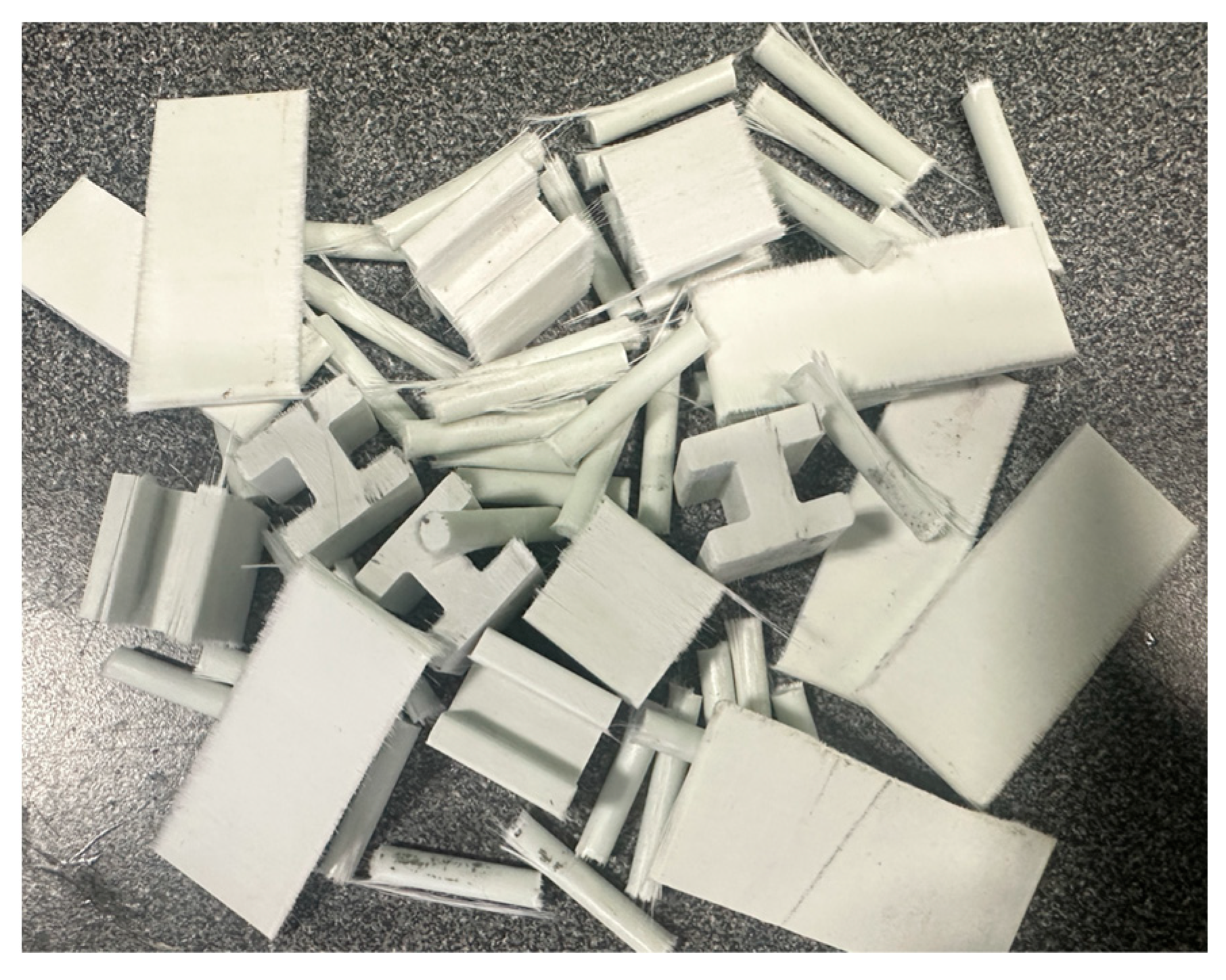

2.1. Materials

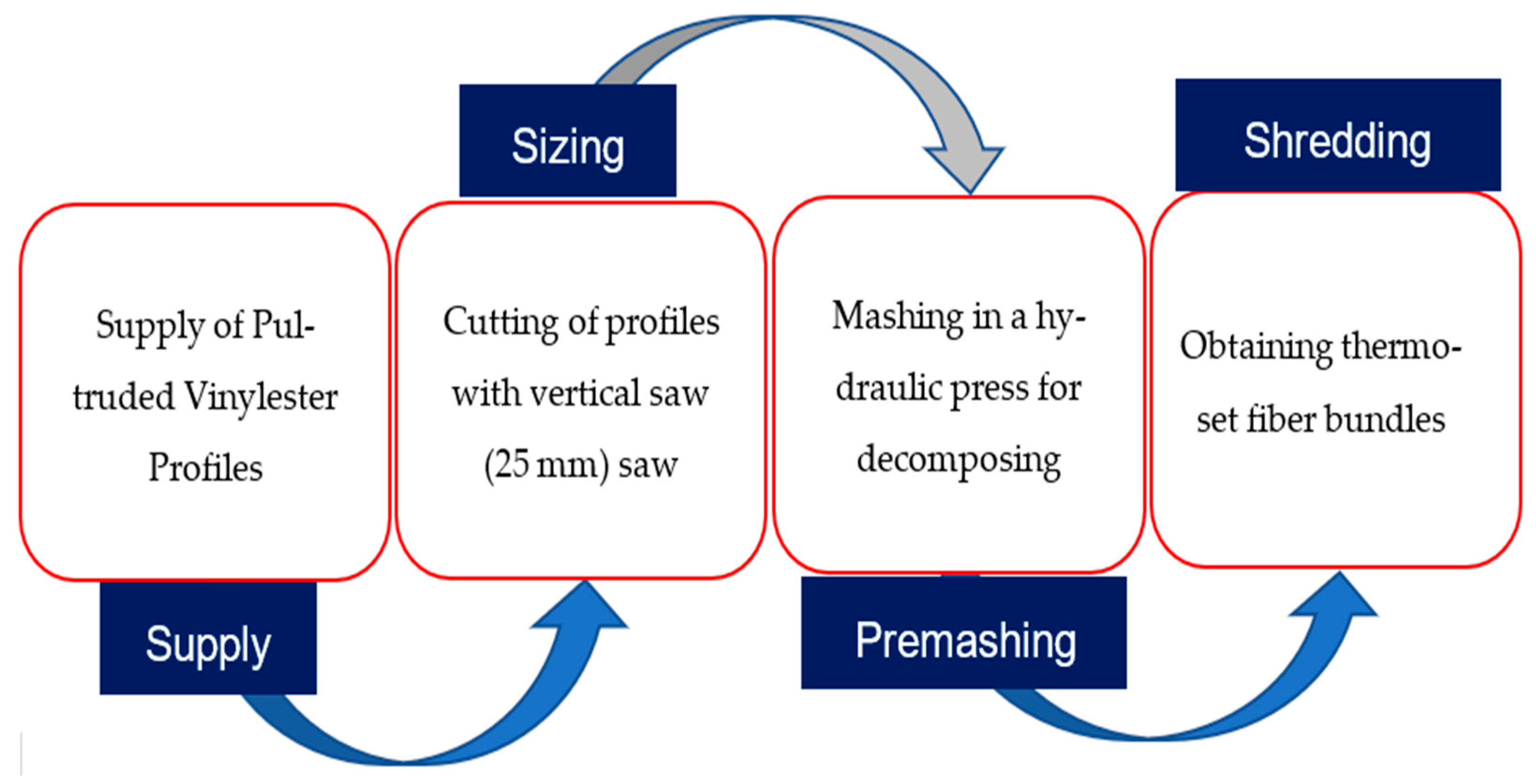

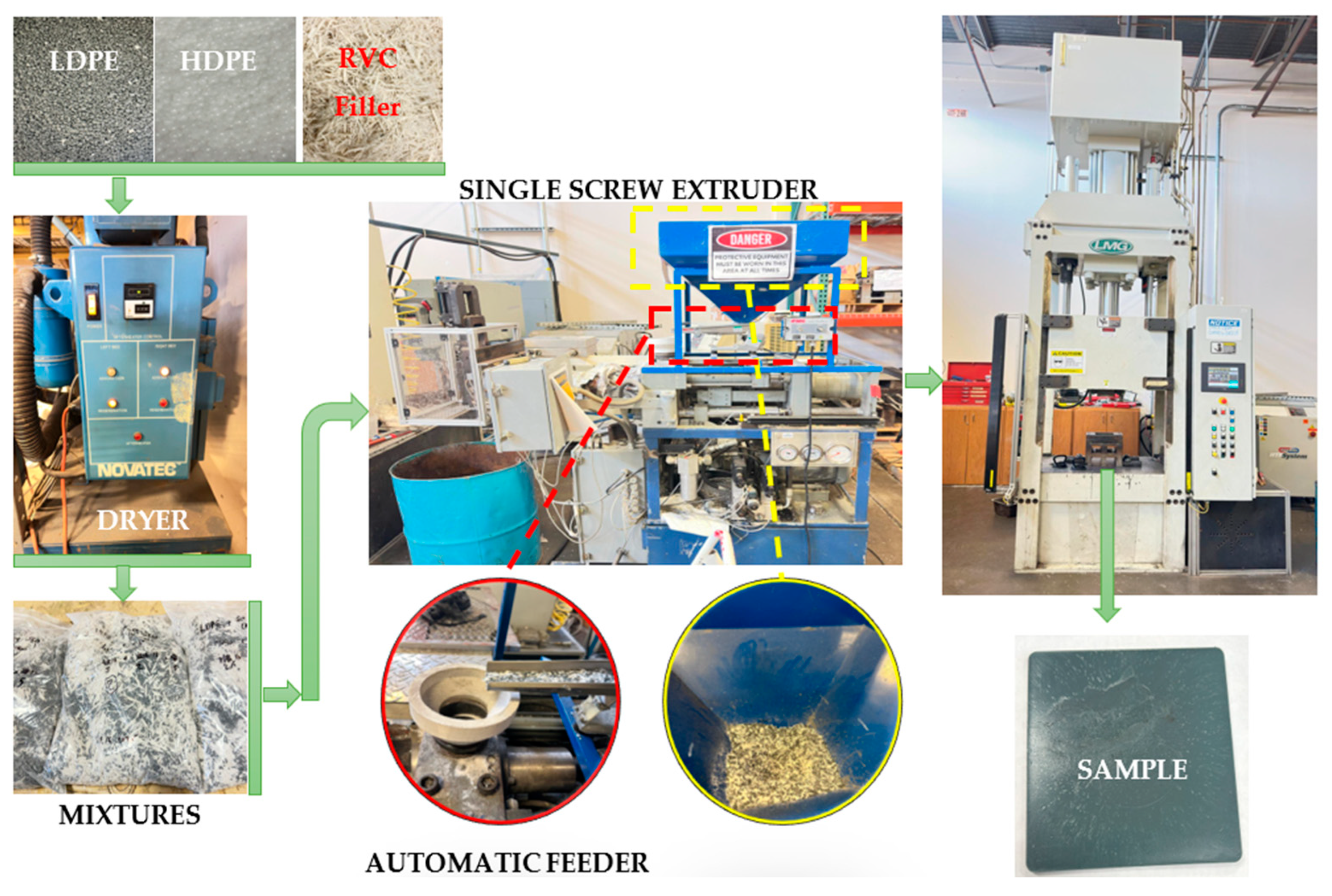

2.2. Preparation and Processing of Thermoset-Filled PE Composites (VPCs)

2.3. Physical Characterization of Recycled Vinyl Ester Composite (RVC) Filler

2.4. Analysis of Thermoset-Filled PE Composites (VPC)

2.4.1. Optical and Scanning Electron Microscopy (SEM) Analysis

2.4.2. Density and Moisture Absorption of the VPCs

2.5. Mechanical Properties of the VPCs

3. Results and Discussion

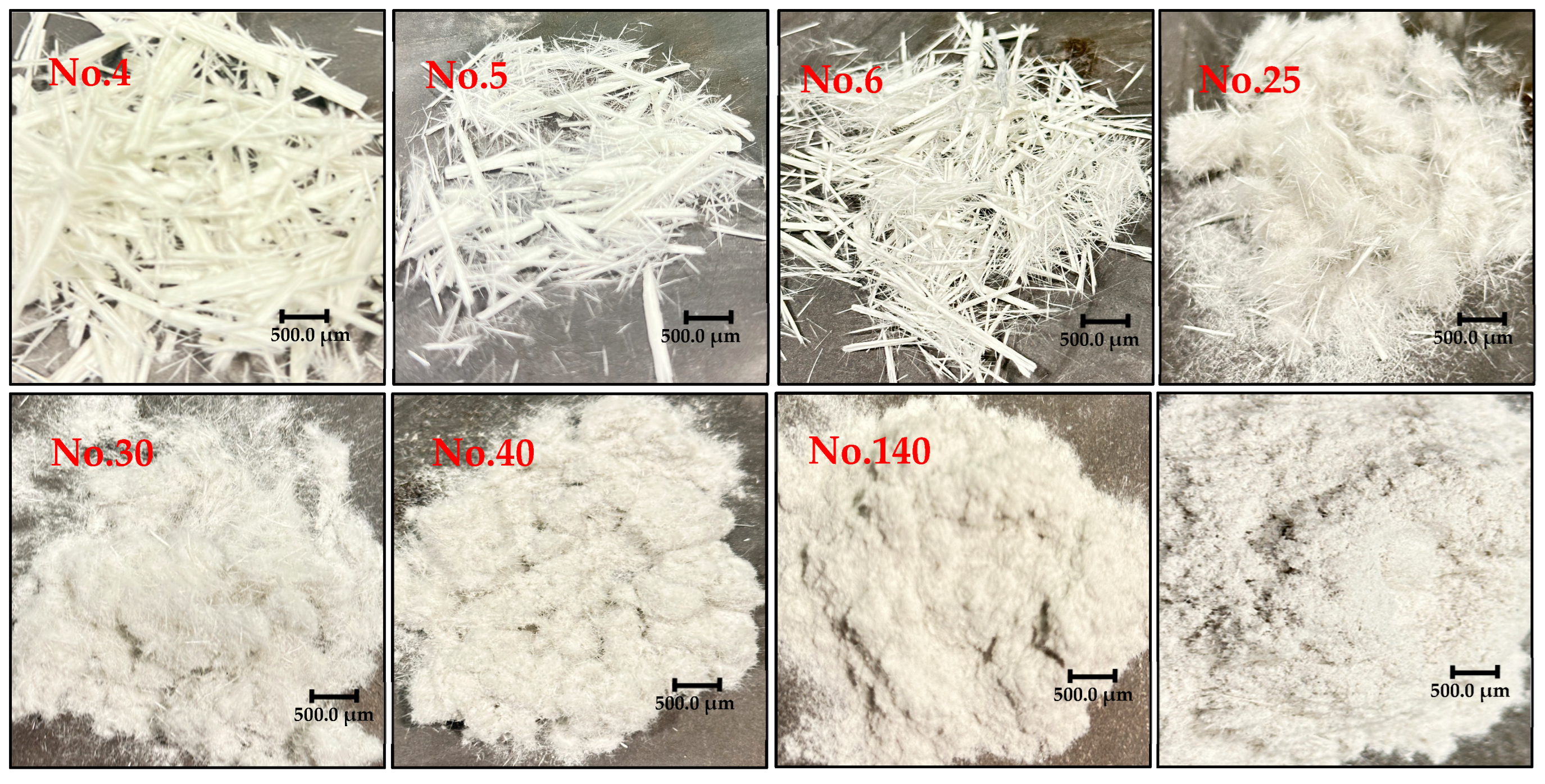

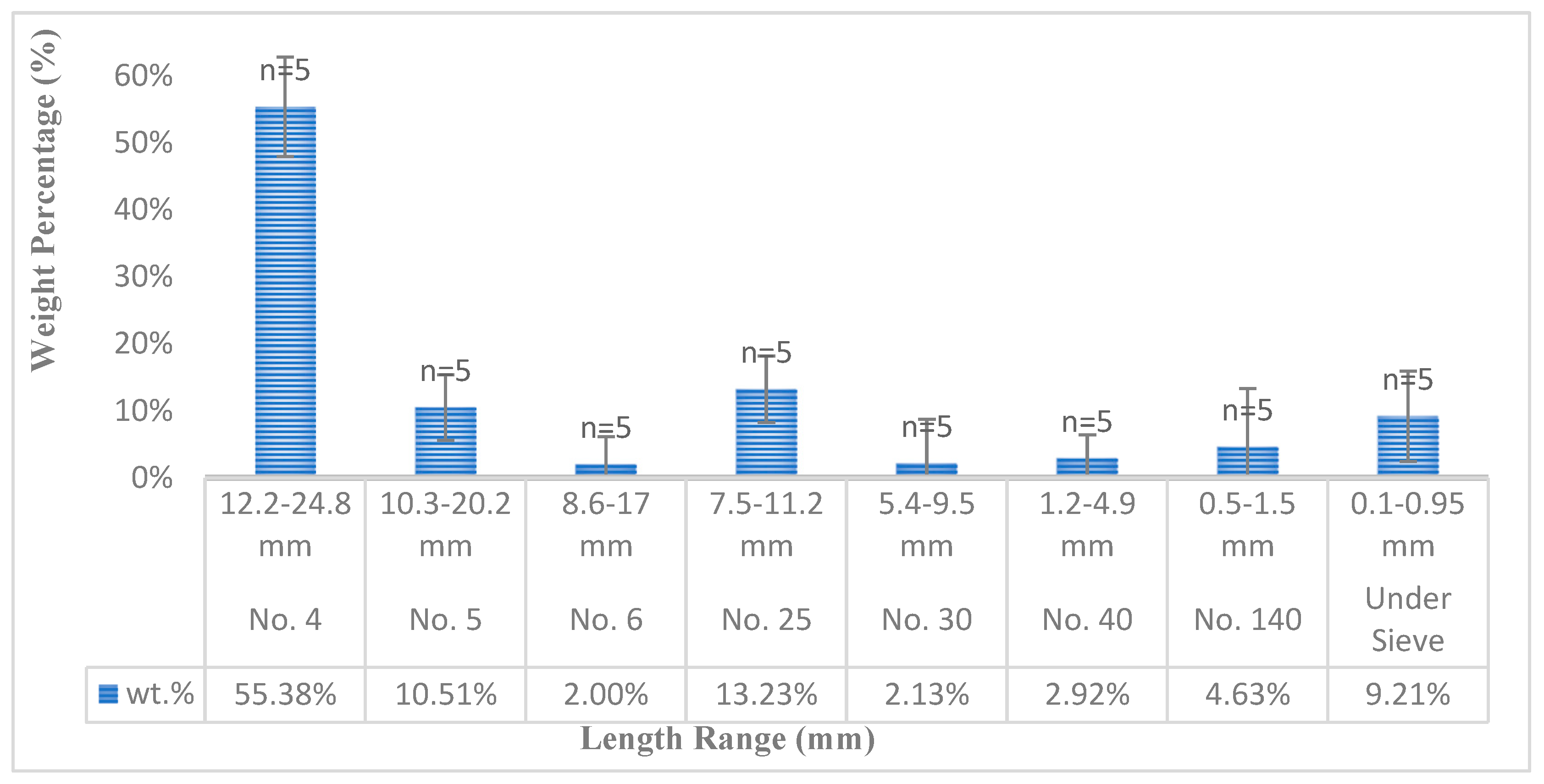

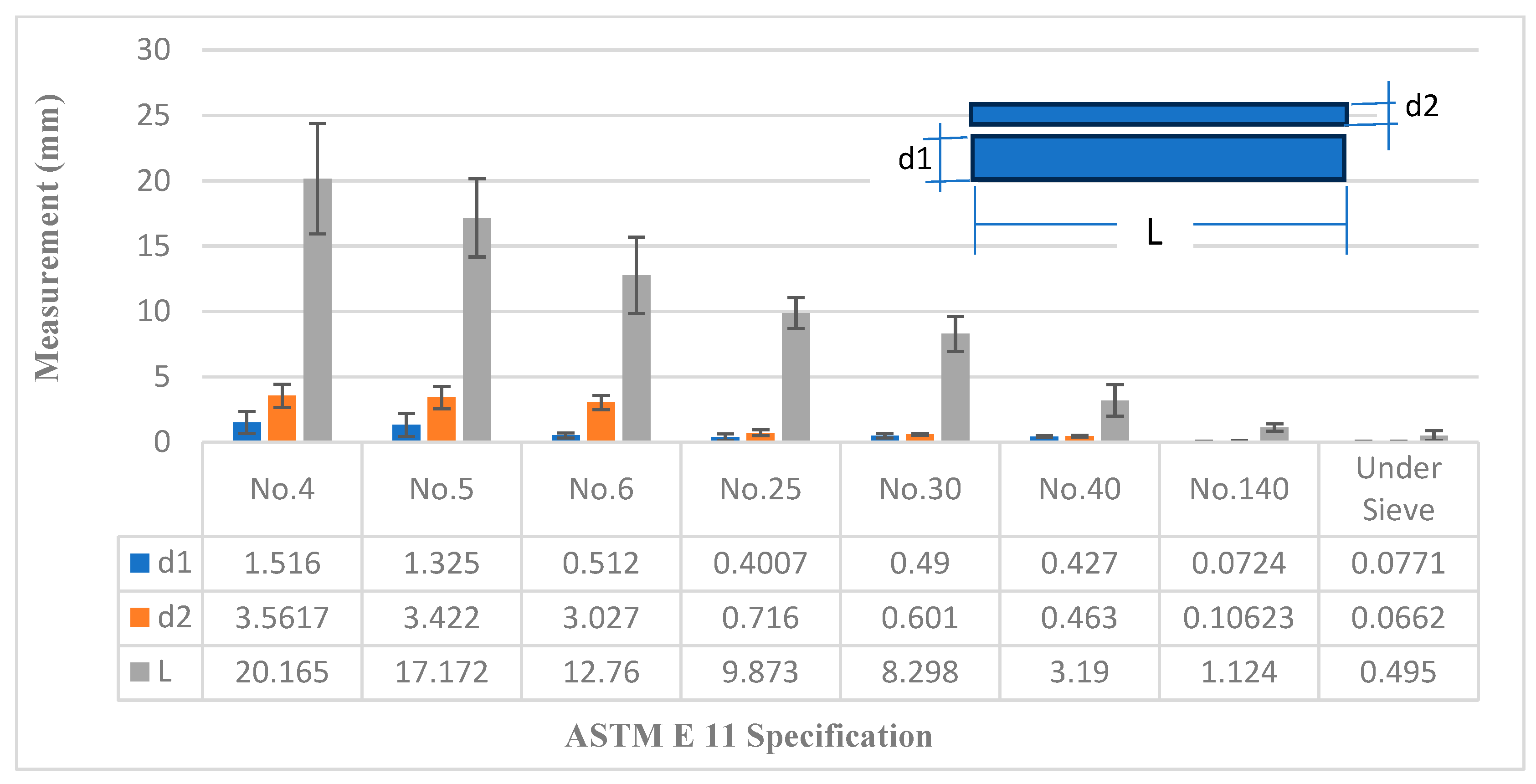

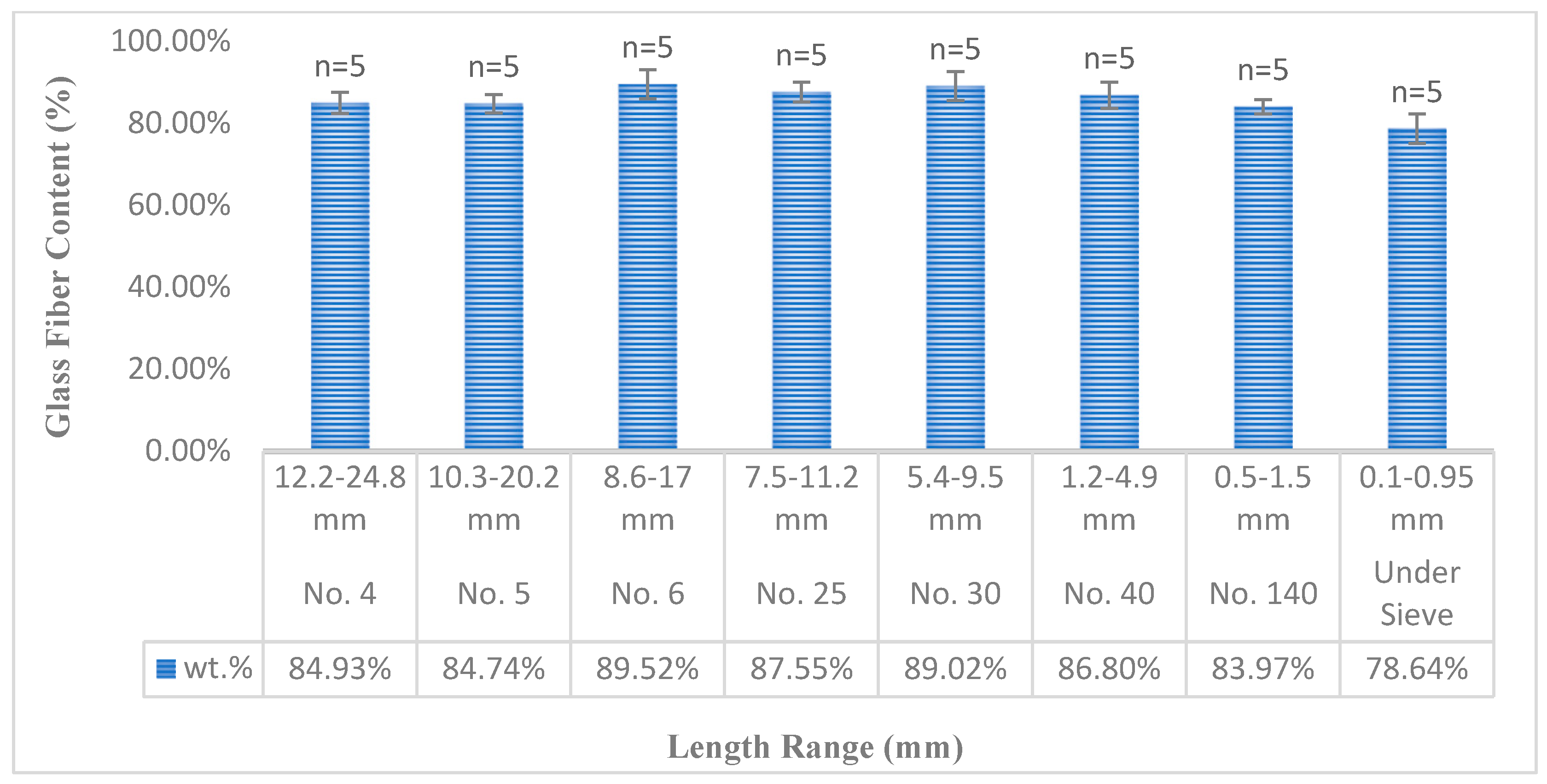

3.1. Assessment of Recycled Vinyl Ester Based Composite (RVC) Fillers

3.2. Assessment of Thermoset-Filled PE Composites (VPCs)

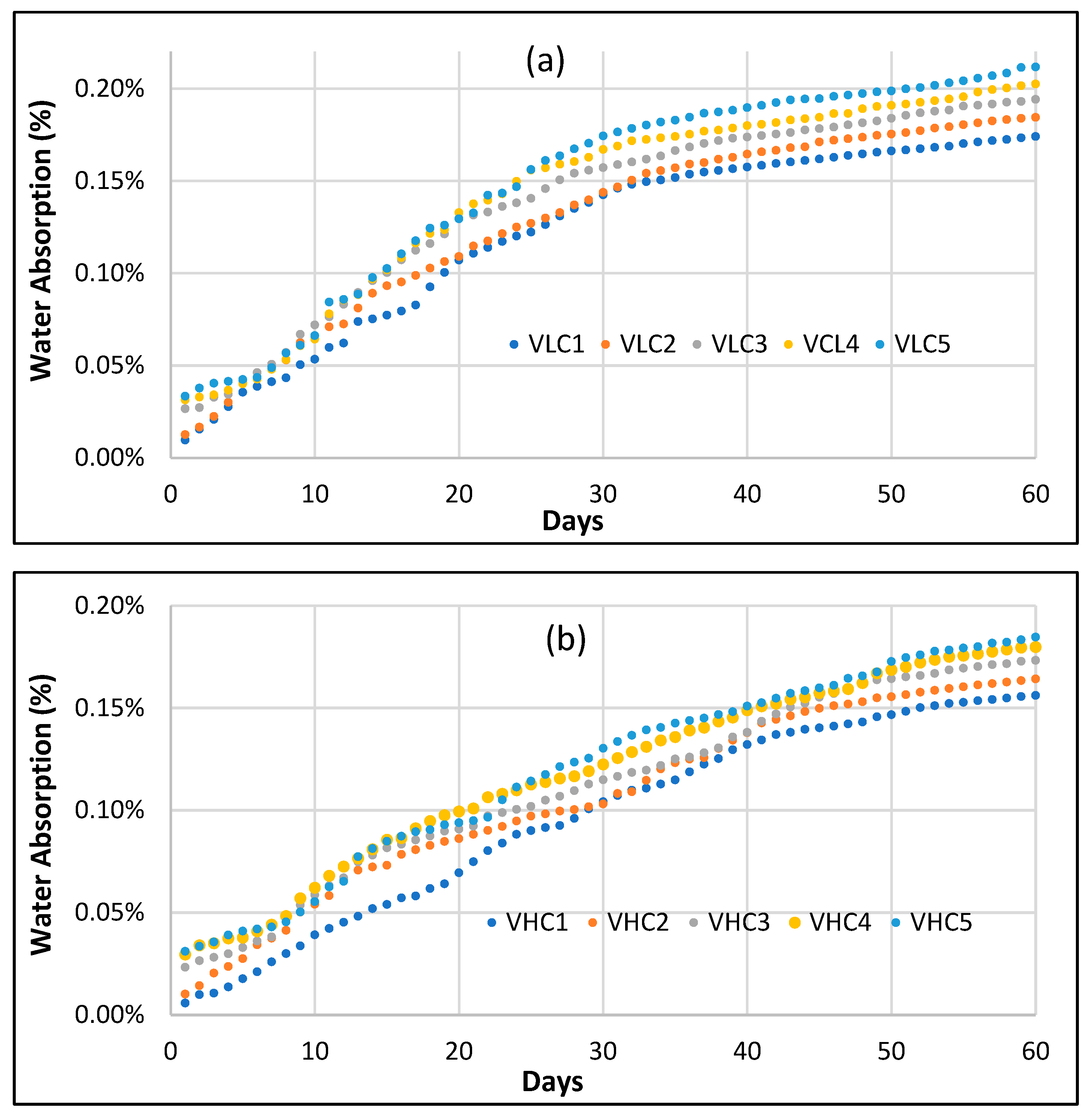

3.3. Evaluation of Density and Hygroscopic Behavior in VPCs

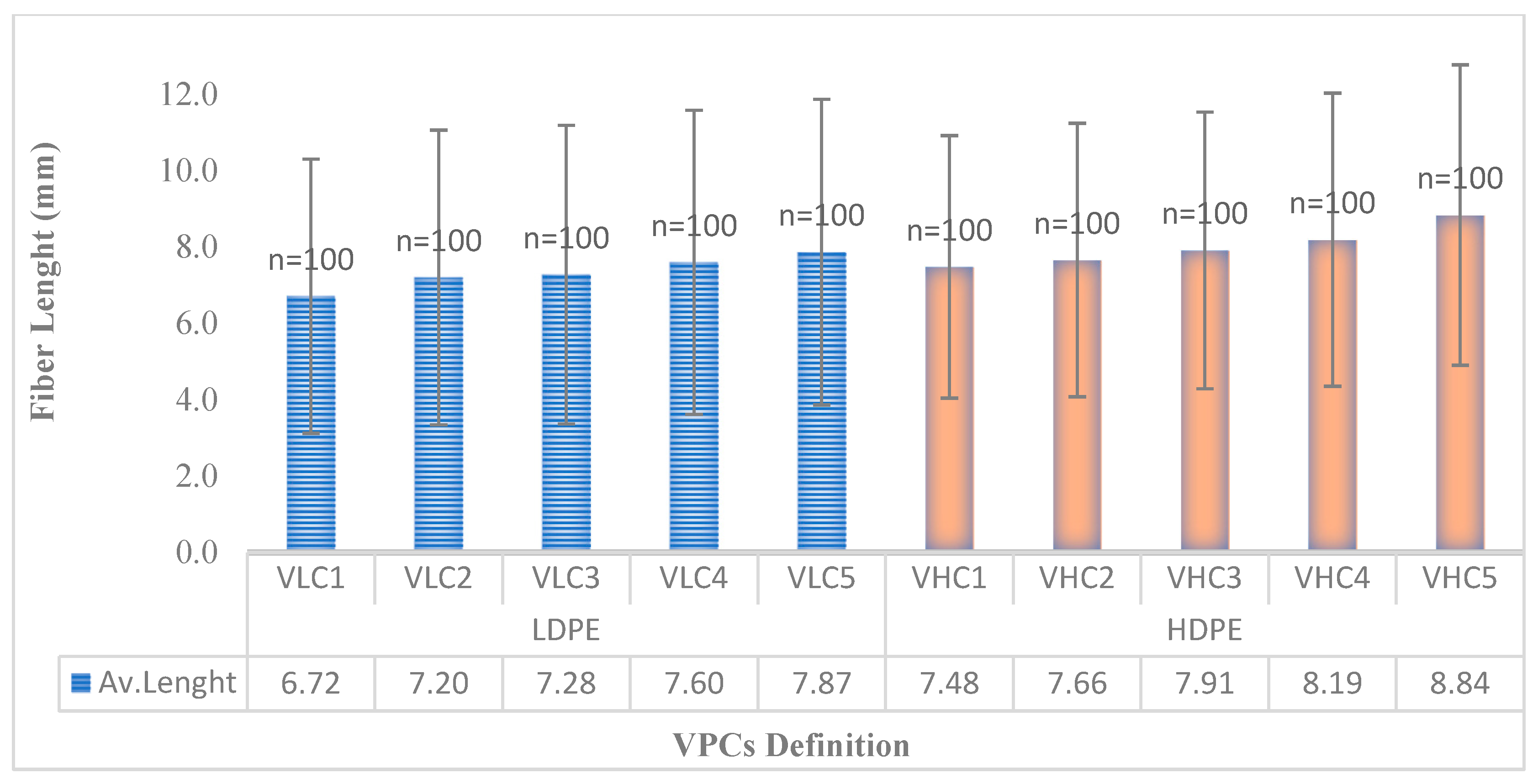

3.4. Analysis of Fiber Morphology and Distribution in VPCs

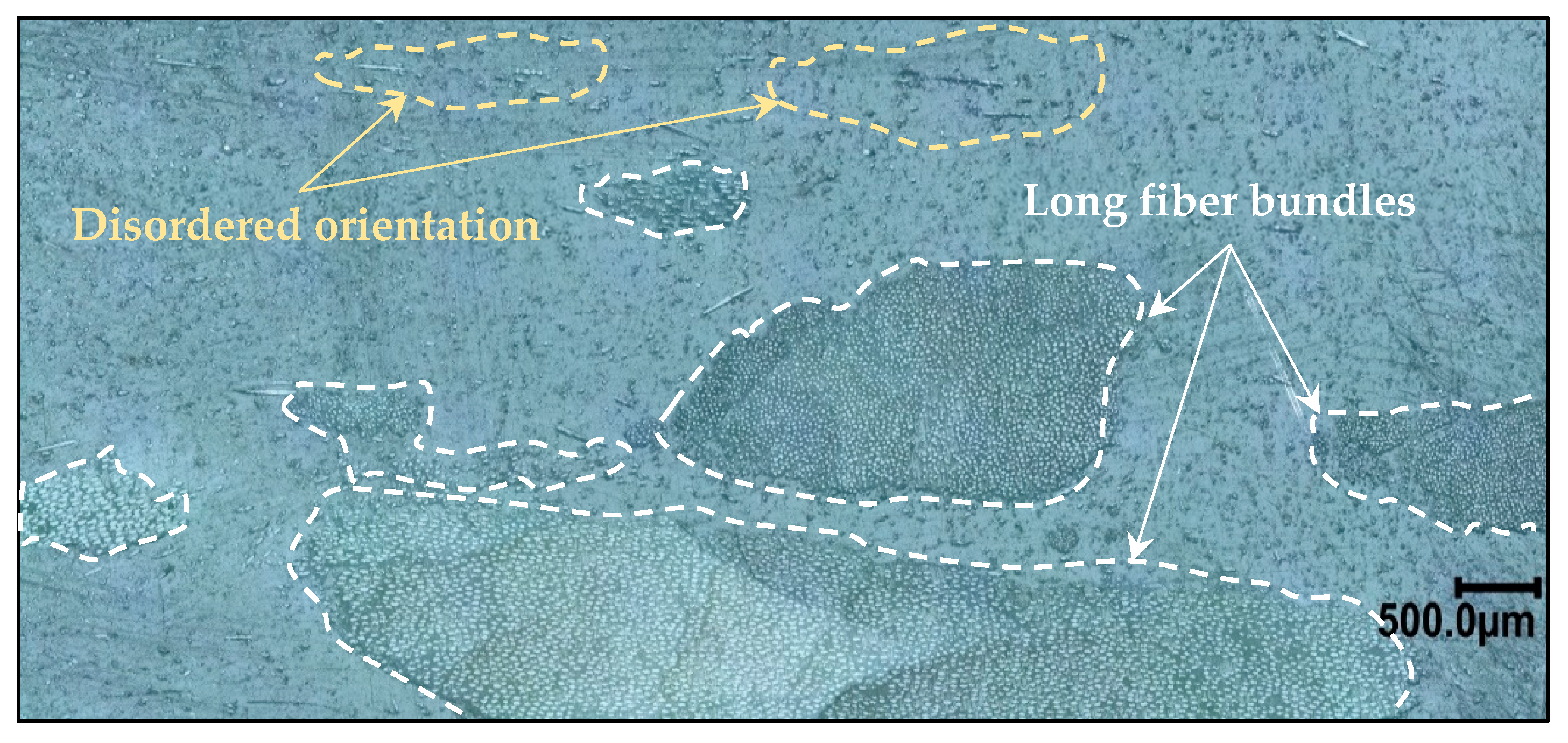

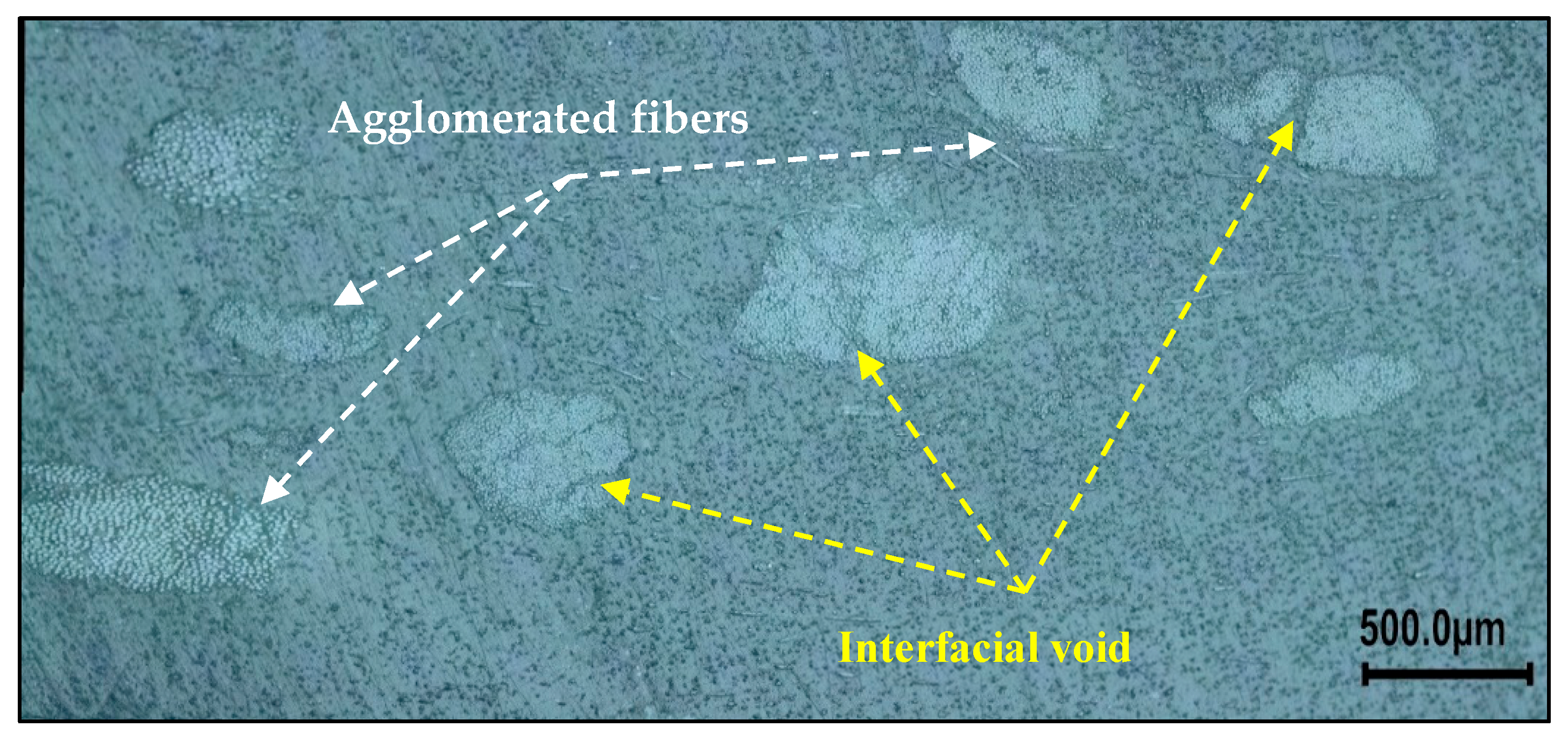

3.4.1. Optical Microscopy Analysis

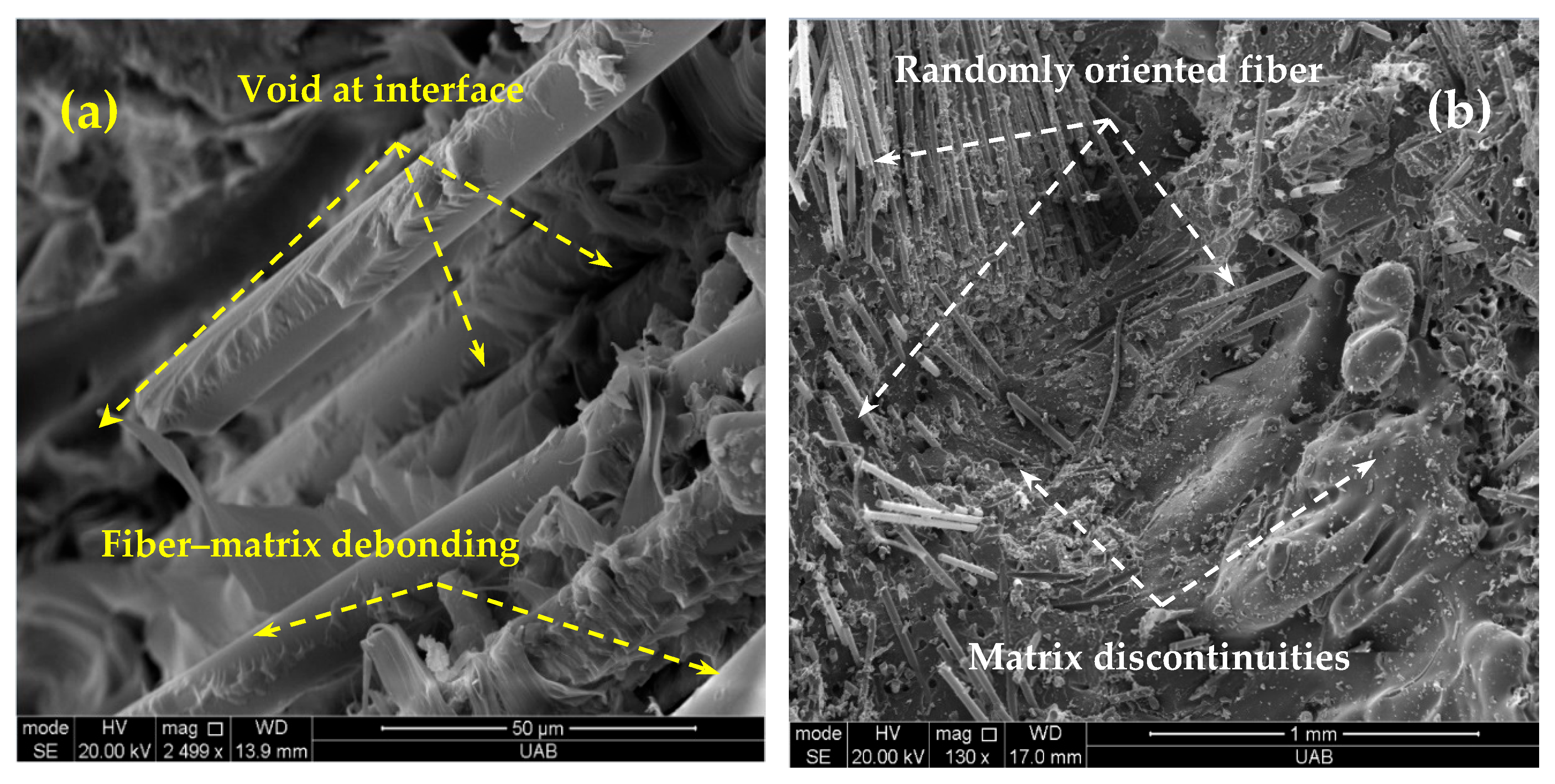

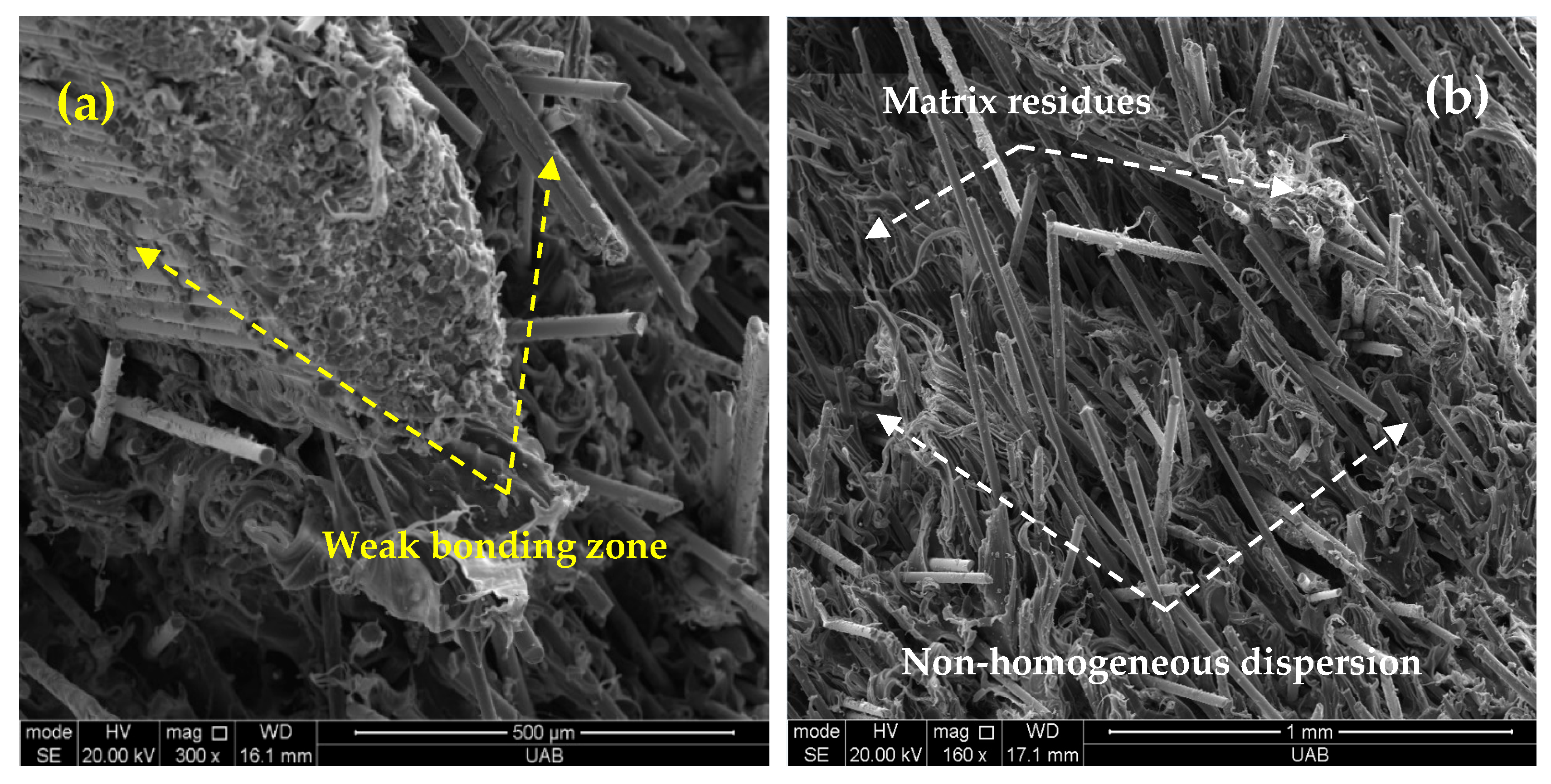

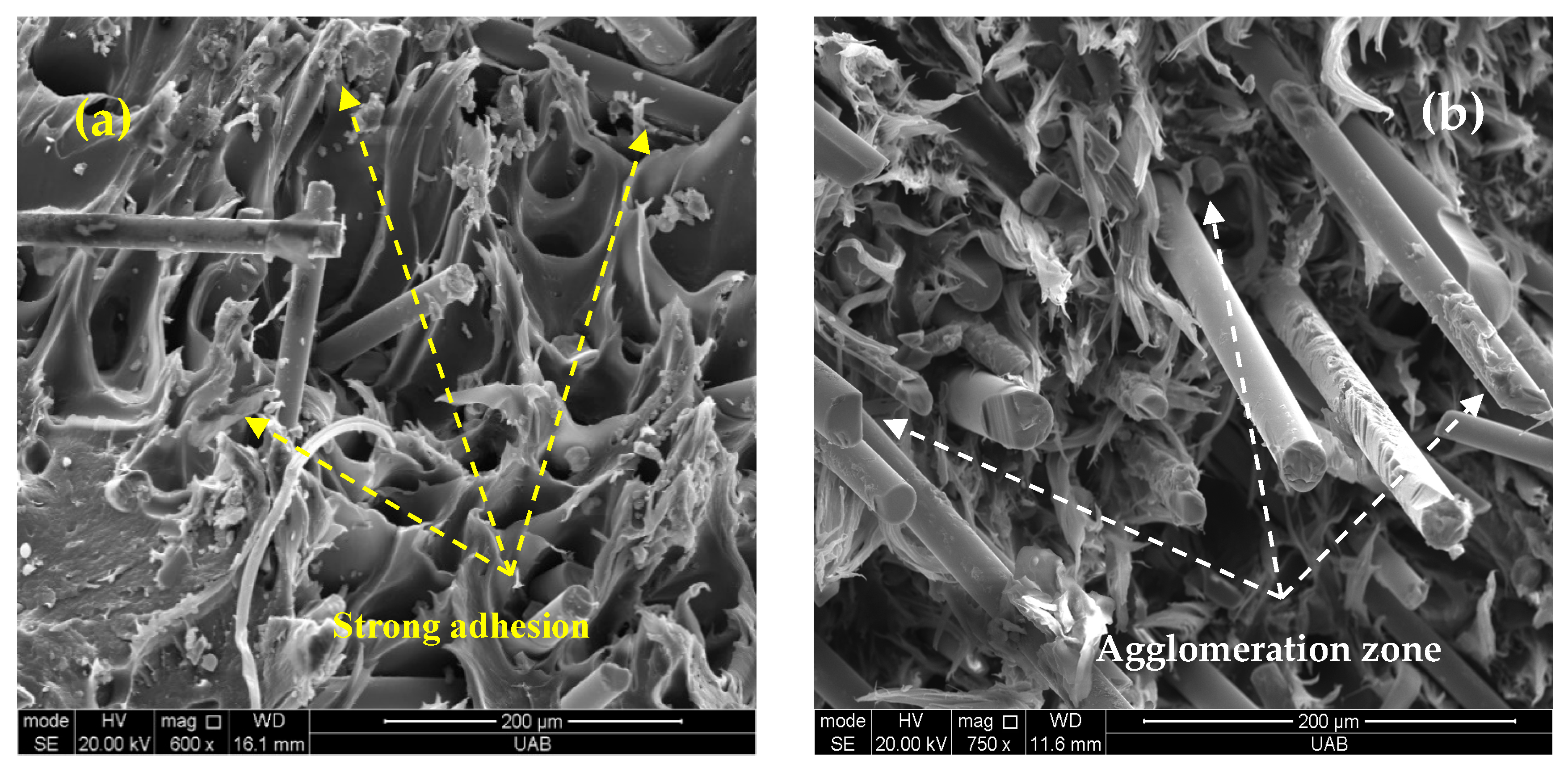

3.4.2. Scanning Electron Microscopy Analysis

3.5. Comprehensive Analysis of Mechanical Behavior of VPCs

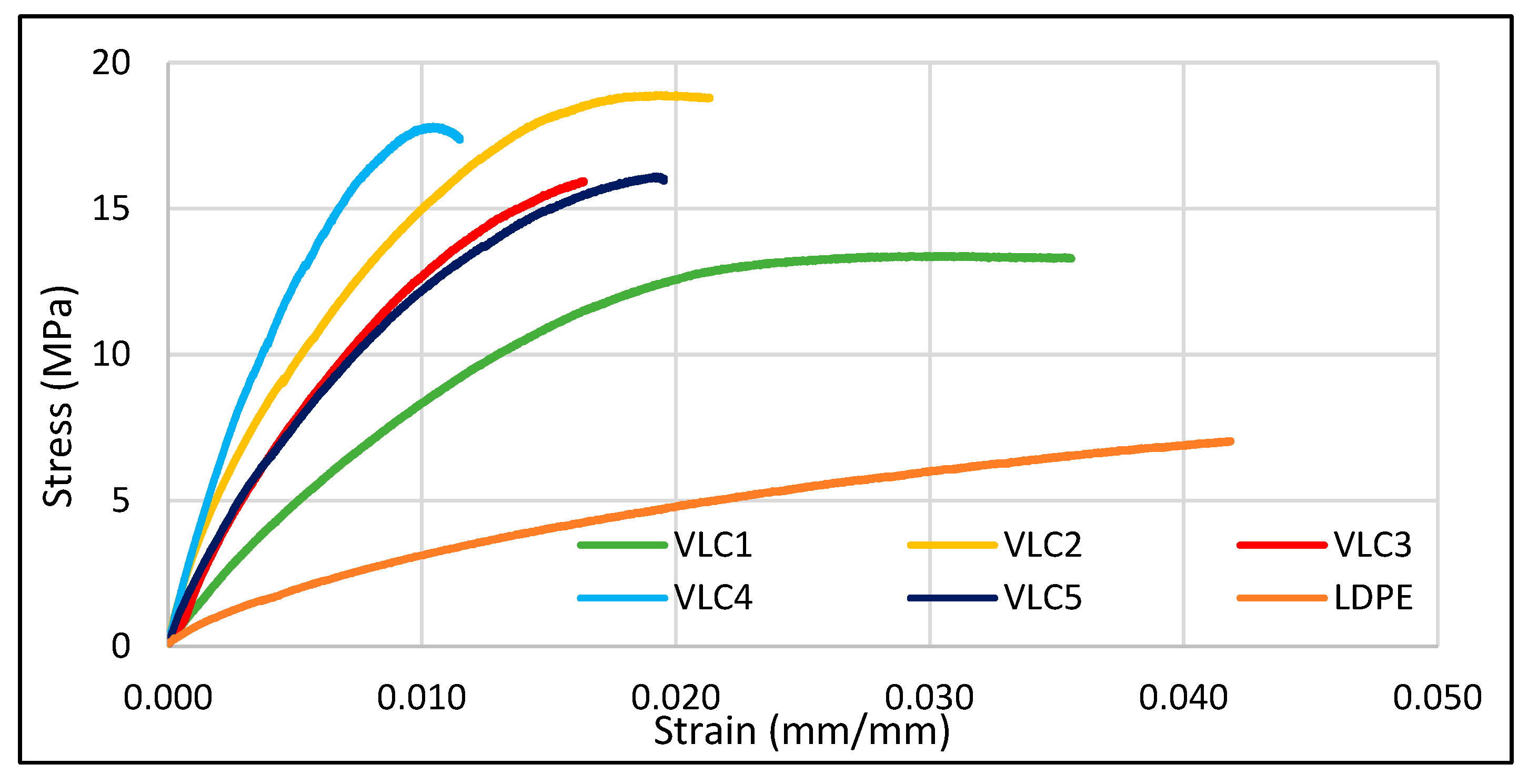

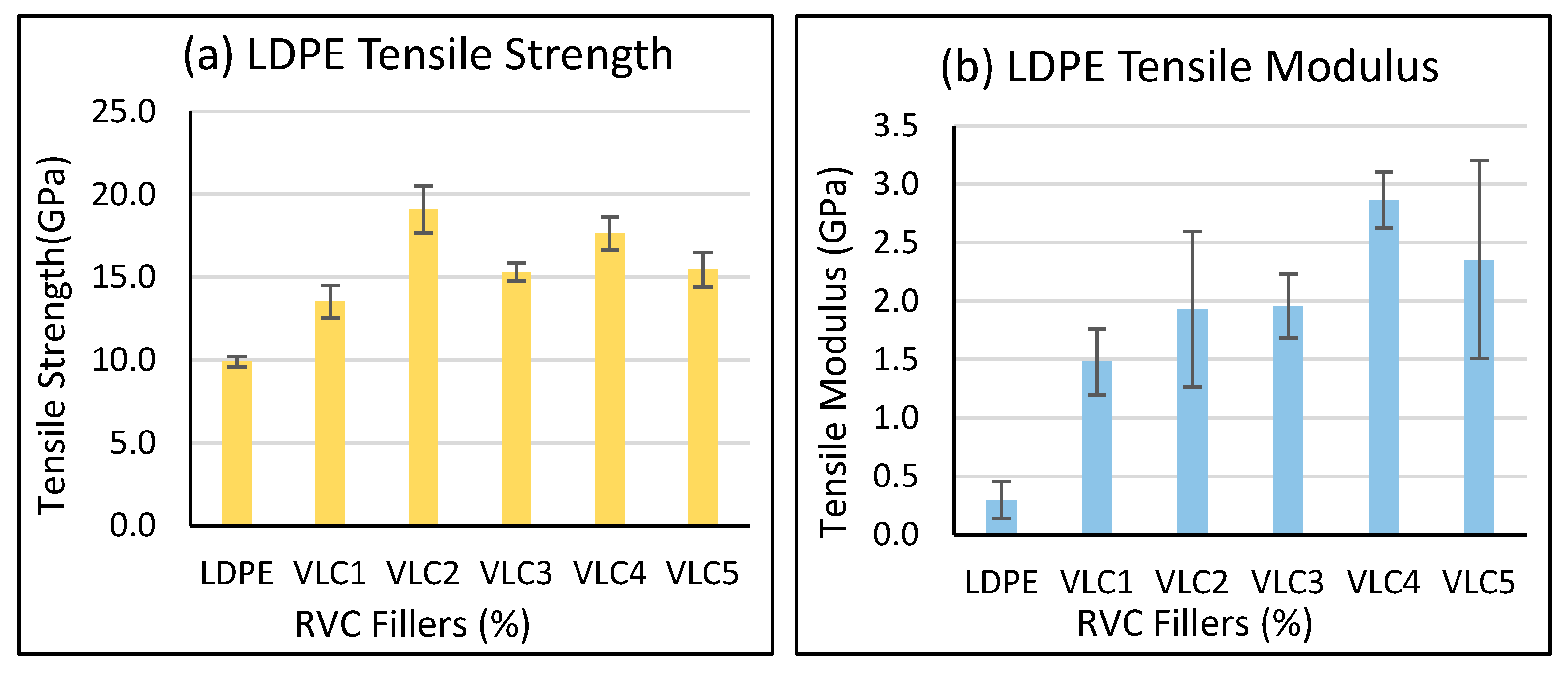

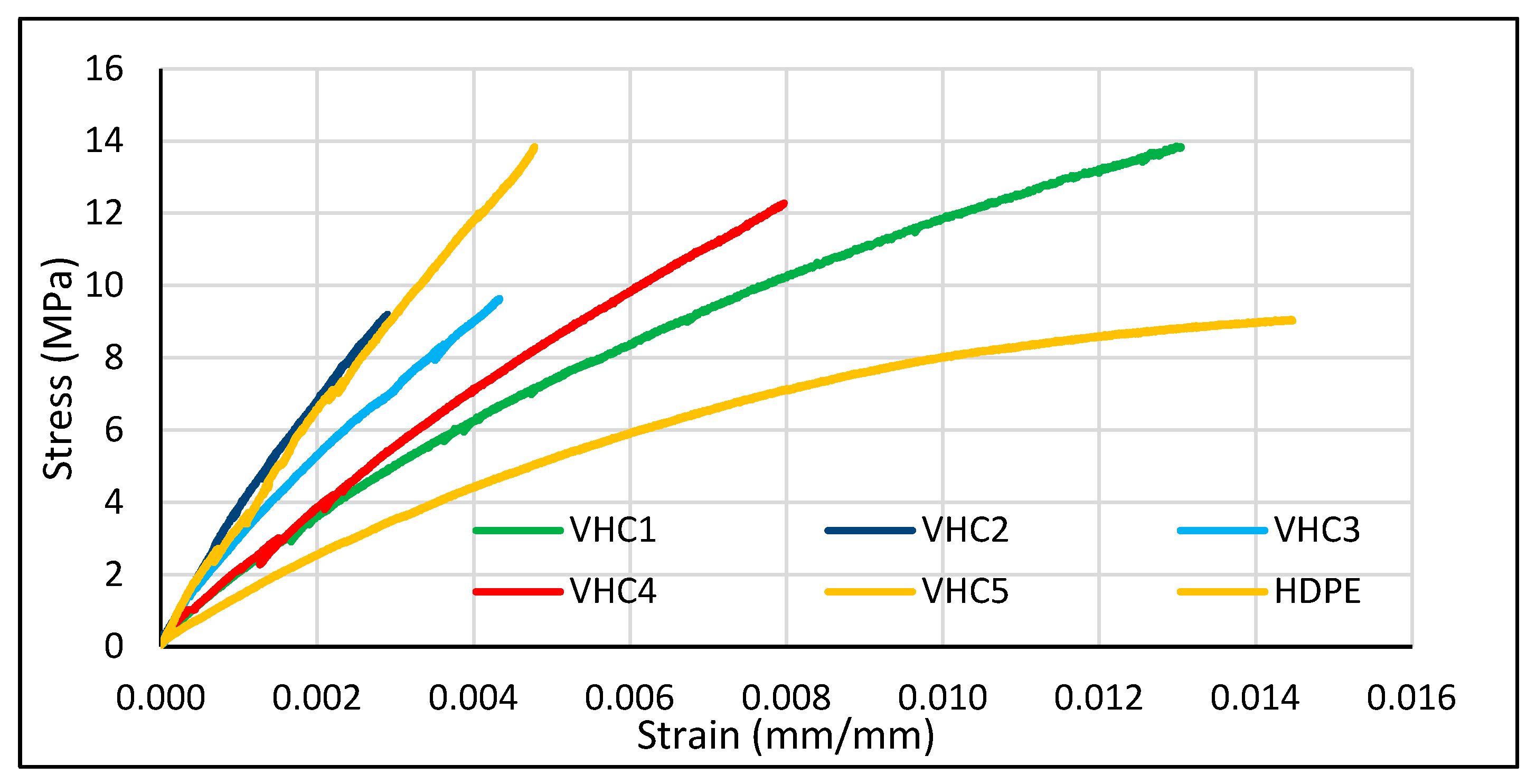

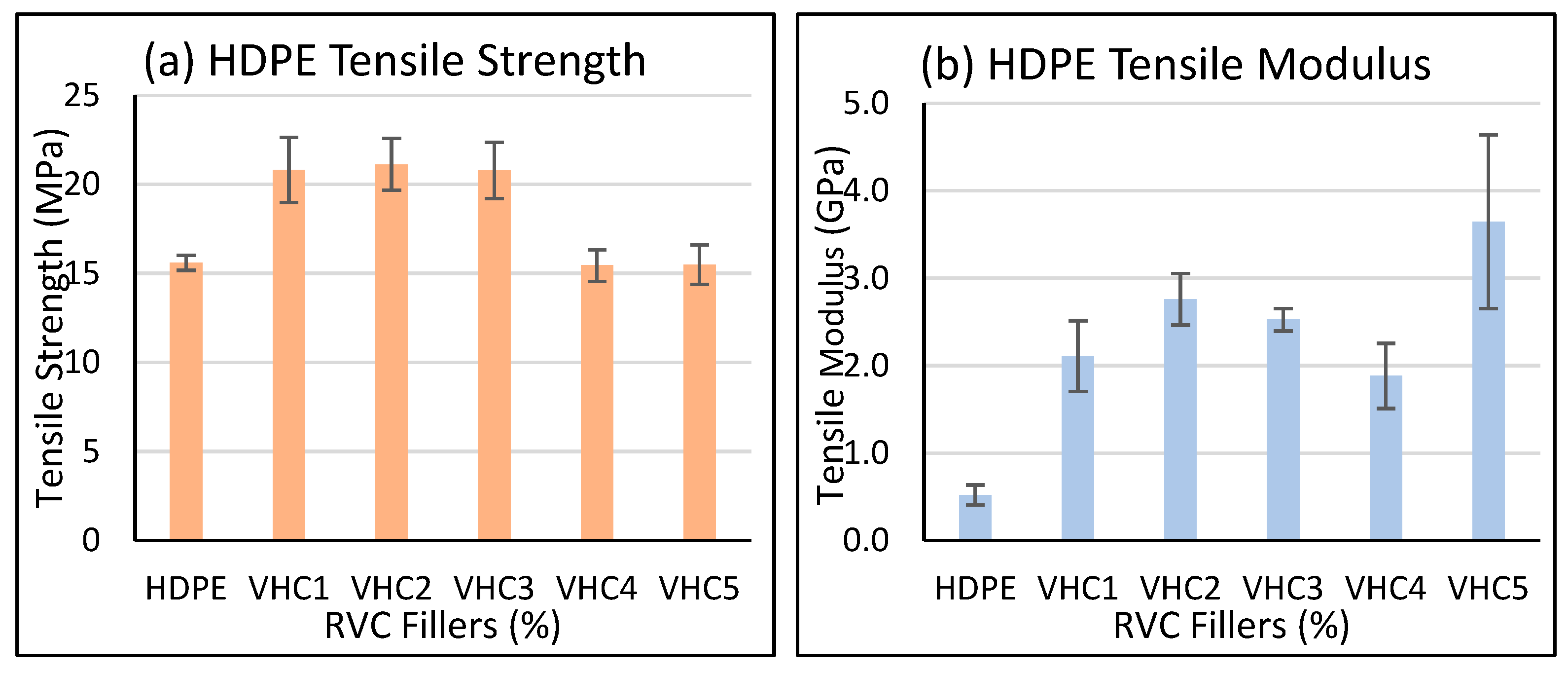

3.5.1. Mechanical Response Under Tensile Loading in VPCs

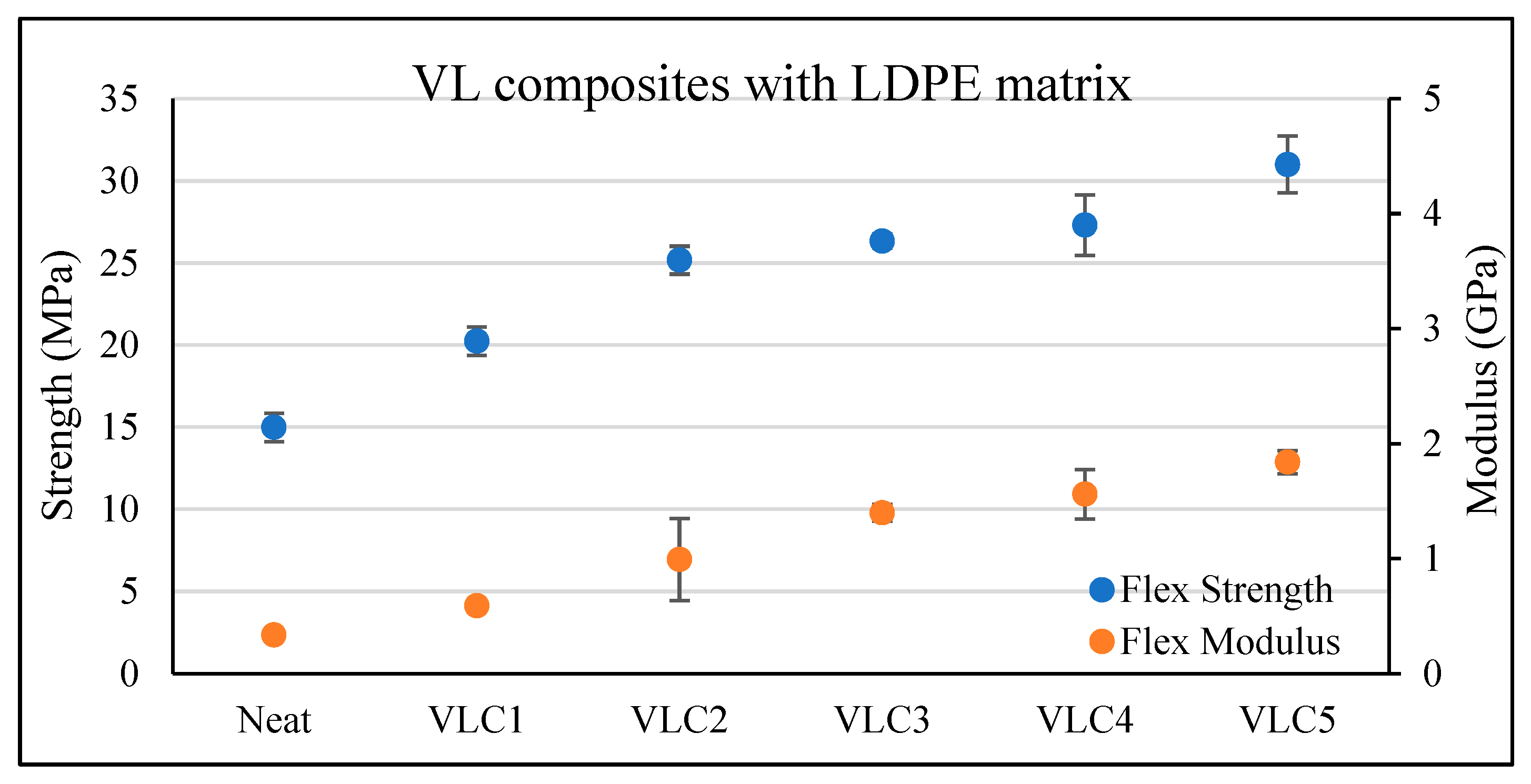

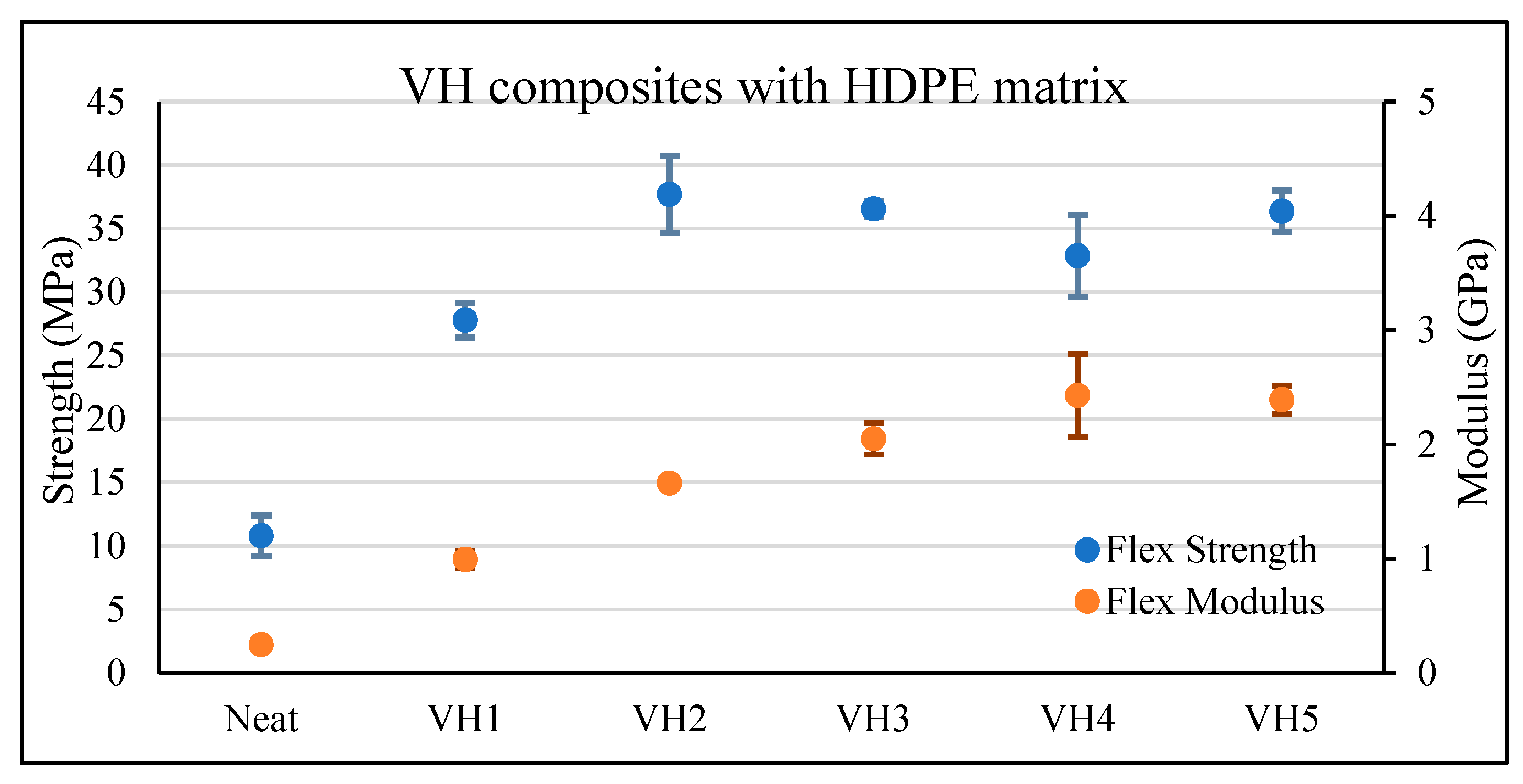

3.5.2. Flexural Properties of VPCs

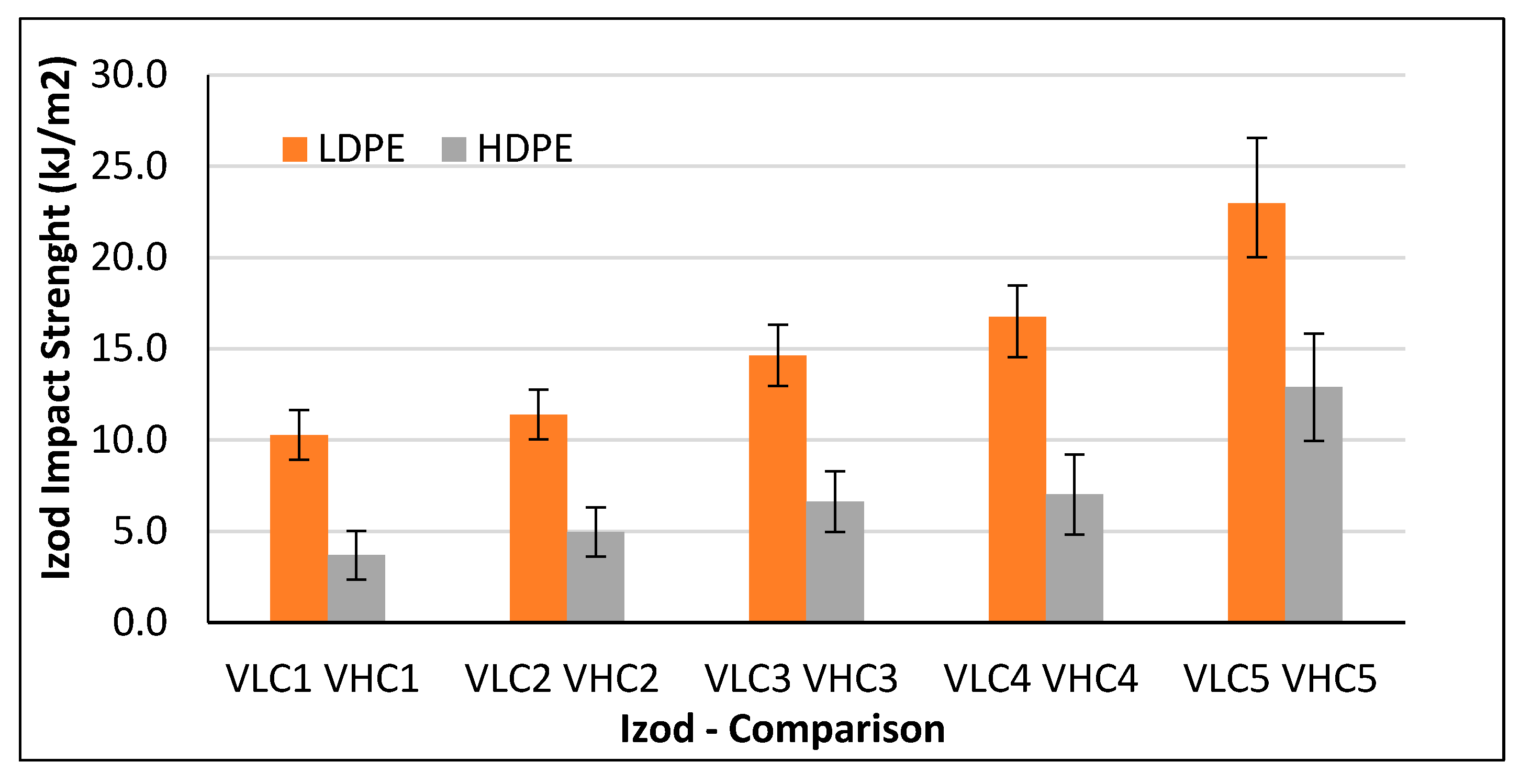

3.5.3. Izod Impact Properties of the VPCs

4. Conclusions

- -

- Vinyl ester-based pultruded profiles were mechanically processed into heterogeneous filler fractions comprising fiber bundles, microfibers, and resin residues. The sieving and burn-off analyses revealed that coarse fiber clusters retained high shape factors and glass fiber content (>85%), making them suitable for structural reinforcement, while finer fractions exhibited diminished fiber integrity and were more appropriate for volumetric or rheological modification.

- -

- LDPE and HDPE matrices were compounded with varying filler loadings (10–50 wt.%) using a single-screw extrusion process. Optical and SEM analyses confirmed that filler dispersion was more uniform in LDPE-based composites due to its amorphous nature and higher chain mobility, while HDPE’s crystalline structure led to localized agglomeration and reduced wetting at high loadings.

- -

- Density increased proportionally with filler content, while water absorption remained below 0.25% after 60 days, confirming satisfactory hygrothermal stability.

- -

- Tensile and flexural tests showed that the 20–30 wt.% filler range provided the most balanced performance: tensile modulus improved up to ≈300%, flexural strength doubled, and impact energy absorption increased by 124% in LDPE and ≈250% in HDPE systems.

- -

- Izod impact tests revealed a steady and reproducible improvement in fracture energy absorption in the LDPE-based VLC series, with an overall increase of ~124% from VLC1 to VLC5. The HDPE-based VH series showed a more pronounced (~250%) but less consistent enhancement, with irregularities in intermediate compositions (VHC2–VHC4) attributed to inadequate filler dispersion and weak interfacial bonding.

- -

- These improvements originate from combined toughening mechanisms—matrix shear yielding, crack deflection, and partial fiber pull-out—activated by the rigid thermoset fragments within the polyolefin matrices.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFRP | Carbon Fiber-Reinforced Polymer Composites |

| FL | Fiber Length |

| HDPE | High-Density Polyethylene |

| LDPE | Low-Density Polyethylene |

| MPAD | Materials Processing and Applications Development |

| PE | Polyethylene |

| RVC | Recycled Vinyl Ester Based Composite |

| VE | Vinyl Ester |

| VHC | Thermoset-filled HDPE Composites |

| VLC | Thermoset-filled LDPE Composites |

| VPC | Thermoset-filled PE Composites |

| SEM | Scanning Electron Microscopy |

References

- Mallick, P.K. Thermoplastics and thermoplastic–matrix composites for lightweight automotive structures. In Materials, Design and Manufacturing for Lightweight Vehicles, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 187–228. [Google Scholar] [CrossRef]

- Thomason, J.; Xypolias, G. Hydrothermal Ageing of Glass Fibre Reinforced Vinyl Ester Composites: A Review. Polymers 2023, 15, 835. [Google Scholar] [CrossRef]

- Elen, M.; Kumar, V.; Fifield, L.S. Feasibility of Recovering and Recycling Polymer Composites from End-of-Life Marine Renewable Energy Structures: A Review. Sustainability 2024, 16, 10515. [Google Scholar] [CrossRef]

- Chen, H.; Qin, R.; Chow, C.L.; Lau, D. Recycling Thermoset Plastic Waste for Manufacturing Green Cement Mortar. Cem. Concr. Compos. 2023, 137, 104922. [Google Scholar] [CrossRef]

- Barnett, P.R.; Brackenridge, J.A.; Advincula, A.A.; Taussig, L.A.; Nepal, D. Reformable and Sustainable Thermosetting Carbon Fiber Composites from Epoxy Vitrimer. Compos. Part B Eng. 2024, 274, 111270. [Google Scholar] [CrossRef]

- Yildirir, E.; Miskolczi, N.; Onwudili, J.A.; Németh, K.E.; Williams, P.T.; Sója, J. Evaluating the Mechanical Properties of Reinforced LDPE Composites Made with Carbon Fibres Recovered via Solvothermal Processing. Compos. Part B Eng. 2015, 78, 393–400. [Google Scholar] [CrossRef]

- Bream, C.E.; Hornsby, P.R. Comminuted Thermoset Recyclate as a Reinforcing Filler for Thermoplastics: Part I Characterization of Recyclate Feedstocks. J. Mater. Sci. 2001, 36, 2965–2975. [Google Scholar] [CrossRef]

- Tapper, R.J.; Longana, M.L.; Yu, H.; Hamerton, I.; Potter, K.D. Development of a Closed-Loop Recycling Process for Discontinuous Carbon Fibre Polypropylene Composites. Compos. Part B Eng. 2018, 146, 222–231. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Banatao, D.R.; Pastine, S.J.; Latteri, A.; Cicala, G. Recycling Treatment of Carbon Fibre/Epoxy Composites: Materials Recovery and Characterization and Environmental Impacts through Life Cycle Assessment. Compos. Part B Eng. 2016, 104, 17–25. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.; Ouederni, M.; Noorunnisa Khanam, P. Effect of Chain Structure on the Properties of Glass Fibre/Polyethylene Composites. Mater. Des. 2013, 47, 725–730. [Google Scholar] [CrossRef]

- Ares-Elejoste, P.; Seoane-Rivero, R.; Gandarias, I.; Iturmendi, A.; Gondra, K. Sustainable Alternatives for the Development of Thermoset Composites with Low Environmental Impact. Polymers 2023, 15, 2939. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.Y.; Lauke, B. Effects of Fiber Length and Fiber Orientation Distributions on the Tensile Strength of Short-Fiber-Reinforced Polymers. Compos. Sci. Technol. 1996, 56, 1179–1190. [Google Scholar] [CrossRef]

- Akil, H.M.; Cheng, L.W.; Affzan, M.H.; Bakar, A.A.; Ishak, Z.A.M. Water Absorption Study on Pultruded E-Glass Fibre Reinforced Unsaturated Polyester Composites. Adv. Compos. Lett. 2010, 19, 67–73. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Z.; Wang, B.; Li, P.; Zhu, J.; Ma, S. Closed-Loop Chemical Recycling of Thermosetting Polymers and Their Applications: A Review. Green Chem. 2022, 24, 5691–5708. [Google Scholar] [CrossRef]

- Podara, C.; Termine, S.; Modestou, M.; Semitekolos, D.; Tsirogiannis, C.; Karamitrou, M.; Trompeta, A.-F.; Milickovic, T.K.; Charitidis, C. Recent Trends of Recycling and Upcycling of Polymers and Composites: A Comprehensive Review. Recycling 2024, 9, 37. [Google Scholar] [CrossRef]

- Eselem Bungu, P.S.; Pasch, H. Comprehensive Analysis of Branched Polyethylene: The Multiple Preparative Fractionation Concept. Polym. Chem. 2017, 8, 4565–4575. [Google Scholar] [CrossRef]

- Agrawal, P.; Silva, M.H.A.; Cavalcanti, S.N.; Freitas, D.M.G.; Araújo, J.P.; Oliveira, A.D.B.; Mélo, T.J.A. Rheological Properties of High-Density Polyethylene/Linear Low-Density Polyethylene and High-Density Polyethylene/Low-Density Polyethylene Blends. Polym. Bull. 2022, 79, 2321–2343. [Google Scholar] [CrossRef]

- Felgel-Farnholz, A.; Schweighuber, A.; Klampfl, C.W.; Fischer, J. Comparative Study on the Degradation of HDPE, LLDPE and LDPE during Multiple Extrusions. Polym. Degrad. Stab. 2023, 216, 110486. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, G.; Lin, N.; Lan, H.; Li, Q.; Yao, D.; Tang, J. A Review of Degradation and Life Prediction of Polyethylene. Appl. Sci. 2023, 13, 3045. [Google Scholar] [CrossRef]

- Alikhani, H.; Sharifzadeh, F.; Khoramishad, H. Mechanical and Physical Properties of Glass-Fiber Reinforced Polymer Rods Manufactured by Different Pultrusion Methods. Mech. Adv. Compos. Struct. 2021, 8, 99–107. [Google Scholar] [CrossRef]

- da Silva, L.V.; de Menezes, E.A.W.; Tarpani, J.R.; Amico, S.C. Accelerated Ageing Effects on Short-Beam Strength Behavior of Pultruded CFRP Rods. Appl. Compos. Mater. 2022, 29, 855–869. [Google Scholar] [CrossRef]

- Manca, F.; Giordano, S.; Palla, P.L.; Cleri, F. Stochastic Mechanical Degradation of Multi-Cracked Fiber Bundles with Elastic and Viscous Interactions. Eur. Phys. J. E 2015, 38, 44. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, H.; Zhang, M.; Fu, S.; Zhu, K. Fiber Orientation Reconstruction from SEM Images of Fiber-Reinforced Composites. Appl. Sci. 2023, 13, 3700. [Google Scholar] [CrossRef]

- Guay, D.; Sutherland, N.R.; Rantanen, W.; Malandri, N.; Stephens, A.; Mattingly, K.; Schneider, M. Comparison of Fiber Length Analyzers. In Proceedings of the 2005 TAPPI Practical Papermaking Conference, Atlanta, GA, USA, 22–26 May 2005; pp. 413–442. [Google Scholar]

- Wang, S.; Yatagawa, T.; Suzuki, H.; Ohtake, Y. Image Based Measurement of Individual Fiber Lengths for Randomly Oriented Short Fiber Composites. J. Nondestruct. Eval. 2022, 41, 45. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling Technologies for Thermoset Composite Materials—Current Status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Slapnik, J.; Lucyshyn, T.; Pinter, G. Relationships between the Decomposition Behaviour of Renewable Fibres and Their Reinforcing Effect in Composites Processed at High Temperatures. Polymers 2021, 13, 4448. [Google Scholar] [CrossRef]

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Recycling of Reinforced Glass Fibers Waste: Current Status. Materials 2022, 15, 1596. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A Review on the Recycling of Waste Carbon Fibre/Glass Fibre-Reinforced Composites: Fibre Recovery, Properties and Life-Cycle Analysis. SN Appl. Sci. 2020, 2, 2195. [Google Scholar] [CrossRef]

- Szatkowski, P.; Twaróg, R. Thermal Recycling Process of Carbon Fibers from Composite Scrap—Characterization of Pyrolysis Conditions and Determination of the Quality of Recovered Fibers. Fibers 2024, 12, 68. [Google Scholar] [CrossRef]

- Han, Z.; Jeong, S.; Noh, J.; Oh, D. Comparative Study of Glass Fiber Content Measurement Methods for Inspecting Fabrication Quality of Composite Ship Structures. Appl. Sci. 2020, 10, 5130. [Google Scholar] [CrossRef]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Scott, J.H.J.; Joy, D.C. Scanning Electron Microscopy and X-Ray Microanalysis; Springer: New York, NY, USA, 2017; pp. 1–550. [Google Scholar] [CrossRef]

- Swain, S.S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Investigation of Fibre Orientation Using SEM Micrograph and Prediction of Mechanical Properties through Micromechanical Modelling. Bull. Mater. Sci. 2016, 39, 837–846. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Y.; Zhang, X.; Kang, Z.; Zhang, J. Effect Mechanism and Simulation of Voids on Hygrothermal Performances of Composites. Polymers 2022, 14, 901. [Google Scholar] [CrossRef] [PubMed]

- Hamdan, M.H.M.; Siregar, J.P.; Cionita, T.; Jaafar, J.; Efriyohadi, A.; Junid, R.; Kholil, A. Water Absorption Behaviour on the Mechanical Properties of Woven Hybrid Reinforced Polyester Composites. Int. J. Adv. Manuf. Technol. 2019, 104, 1075–1086. [Google Scholar] [CrossRef]

- Al-darkazali, A.; Çolak, P.; Kadıoğlu, K.; Günaydın, E.; Inanç, I.; Demircan, Ö. Mechanical Properties of Thermoplastic and Thermoset Composites Reinforced with 3D Biaxial Warp-Knitted Fabrics. Appl. Compos. Mater. 2018, 25, 939–951. [Google Scholar] [CrossRef]

- Sarkar, F.; Akonda, M.; Shah, D.U. Mechanical Properties of Flax Tape-Reinforced Thermoset Composites. Materials 2020, 13, 5485. [Google Scholar] [CrossRef] [PubMed]

- Ghaffari, S.; Seon, G.; Makeev, A. Effect of Fiber–Matrix Interface Friction on Compressive Strength of High-Modulus Carbon Composites. Molecules 2023, 28, 2049. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of Composite Materials. Chem. Eng. Process. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Cai, H.; Ye, J.; Wang, Y.; Shi, Y.; Saafi, M.; Ye, J. Microscopic Failure Characteristics and Critical Length of Short Glass Fiber Reinforced Composites. Compos. Part B Eng. 2023, 266, 110973. [Google Scholar] [CrossRef]

- Delli, E.; Giliopoulos, D.; Bikiaris, D.N.; Chrissafis, K. Fibre Length and Loading Impact on the Properties of Glass Fibre Reinforced Polypropylene Random Composites. Compos. Struct. 2021, 263, 113678. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.A.E. Carbon Fibre Reinforced Composite Waste: An Environmental Assessment of Recycling, Energy Recovery and Landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Zhang, S.; Gao, D.; Huang, L.; Ji, Y.; Yan, Y.; Zhu, H.; Tang, J. Investigation on the Utilization of Fiber Clusters Recycled from Waste HFRP Bars in Concrete. Constr. Build. Mater. 2024, 421, 135775. [Google Scholar] [CrossRef]

- Bernardeau, F.; Perrin, D.; Caro, A.S.; Benezet, J.C.; Ienny, P. Valorization of Waste Thermoset Material as a Filler in Thermoplastic: Mechanical Properties of Phenolic Molding Compound Waste-Filled PP Composites. J. Appl. Polym. Sci. 2018, 135, 45849. [Google Scholar] [CrossRef]

- Longana, M.L.; Tapper, R.J.; Blok, L.G.; Hamerton, I. Recycling of Fiber Reinforced Thermosetting Composites. In Fiber Reinforced Composites: Constituents, Compatibility, Perspectives, and Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 561–595. [Google Scholar] [CrossRef]

- Sharan Chandran, M.; Padmanabhan, K. Microbond Fibre Bundle Pullout Technique to Evaluate the Interfacial Adhesion of Polyethylene and Polypropylene Self Reinforced Composites. Appl. Adhes. Sci. 2019, 7, 5. [Google Scholar] [CrossRef]

- Morici, E.; Dintcheva, N.T. Recycling of Thermoset Materials and Thermoset-Based Composites: Challenge and Opportunity. Polymers 2022, 14, 4153. [Google Scholar] [CrossRef]

- Piggott, M.R. The Effect of Aspect Ratio on Toughness in Composites. J. Mater. Sci. 1974, 9, 494–502. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of Particle Size, Particle/Matrix Interface Adhesion and Particle Loading on Mechanical Properties of Particulate-Polymer Composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Rybak, A.; Gaska, K. Functional Composites with Core–Shell Fillers: I. Particle Synthesis and Thermal Conductivity Measurements. J. Mater. Sci. 2015, 50, 7779–7789. [Google Scholar] [CrossRef]

- Drzal, L.T.; Madhukar, M. Fibre-Matrix Adhesion and Its Relationship to Composite Mechanical Properties. J. Mater. Sci. 1993, 28, 569–610. [Google Scholar] [CrossRef]

- Zhang, S.; He, E.; Liang, H.; Yang, Z.; Wang, Y.; Yang, Z.; Gao, C.; Wang, G.; Wei, Y.; Ji, Y. Chemical Recycling of Epoxy Thermosets: From Sources to Wastes. Actuators 2024, 13, 449. [Google Scholar] [CrossRef]

- Haque, N.; Chang, H.C.; Chang, C.C.; Davis, C.S. Visualizing Fiber End Geometry Effects on Stress Distribution in Composites Using Mechanophores. Soft Matter 2025, 21, 573–584. [Google Scholar] [CrossRef]

- Guo, M.; Li, X.; Maia, J.M. Fiber Length Distribution in Twin-Screw Extrusion of Fiber-Reinforced Polymer Composites: A Comparison between Shear and Extensional Mixing. Int. Polym. Process. 2021, 36, 350–357. [Google Scholar] [CrossRef]

- Masubuchi, Y.; Terada, M.; Yamanaka, A.; Yamamoto, T.; Ishikawa, T. Distribution Function of Fiber Length in Thermoplastic Composites. Compos. Sci. Technol. 2016, 134, 43–48. [Google Scholar] [CrossRef]

- Teßmann, M.; Mohr, S.; Gayetskyy, S.; Haßler, U.; Hanke, R.; Greiner, G. Automatic Determination of Fiber-Length Distribution in Composite Material Using 3D CT Data. EURASIP J. Adv. Signal Process. 2010, 2010, 545030. [Google Scholar] [CrossRef]

- Benthien, J.T.; Bähnisch, C.; Heldner, S.; Ohlmeyer, M. Effect of Fiber Size Distribution on Medium-Density Fiberboard Properties Caused by Varied Steaming Time and Temperature of Defibration Process. Wood Fiber Sci. 2014, 46, 175–185. [Google Scholar]

- Pavlyuchkova, E.A.; Malkin, A.Y.; Kornev, Y.V.; Simonov-Emel’yanov, I.D. Distribution of Filler in Polymer Composites. Role of Particle Size and Concentration. Polym. Sci. Ser. A 2024, 66, 113–120. [Google Scholar] [CrossRef]

- Vincent, G.A.; de Bruijn, T.A.; Wijskamp, S.; Abdul Rasheed, M.I.; van Drongelen, M.; Akkerman, R. Shredding and Sieving Thermoplastic Composite Scrap: Method Development and Analyses of the Fibre Length Distributions. Compos. Part B Eng. 2019, 176, 107197. [Google Scholar] [CrossRef]

- Castro, J.; Ostoja-Starzewski, M. Particle Sieving in a Random Fiber Network. Appl. Math. Model. 2000, 24, 523–534. [Google Scholar] [CrossRef]

- Austermann, V.; Neuhaus, J.; Schneider, D.; Dahlmann, R.; Hopmann, C. Investigation of the Mechanical Properties of Vinylester-Based Sheet Moulding Compound (SMC) Subject to Particle Recycling. J. Compos. Sci. 2022, 6, 84. [Google Scholar] [CrossRef]

- Dai, Y.; Fang, H.; Lu, Z.; Yang, Z.; Wei, Y. Toughening of Vinylester Resins by Two-Dimensional MXene Nanosheets. Front. Chem. Sci. Eng. 2022, 16, 1651–1658. [Google Scholar] [CrossRef]

- Li, Y.Q.; Zhang, D.H. Correction to: Local Stress Distributions in Fiber-Reinforced Composites with Consideration of Thermal Stresses During the Curing Process. Mech. Compos. Mater. 2022, 58, 859. [Google Scholar] [CrossRef]

- Benkhelladi, A.; Laouici, H.; Bouchoucha, A. Tensile and Flexural Properties of Polymer Composites Reinforced by Flax, Jute and Sisal Fibres. Int. J. Adv. Manuf. Technol. 2020, 108, 895–916. [Google Scholar] [CrossRef]

- Gribniak, V.; Rimkus, A.; Plioplys, L.; Misiūnaitė, I.; Garnevičius, M.; Boris, R.; Šapalas, A. An Efficient Approach to Describe the Fiber Effect on Mechanical Performance of Pultruded GFRP Profiles. Front. Mater. 2021, 8, 746376. [Google Scholar] [CrossRef]

- He, W.; Li, X.; Li, P.; Fang, S.; Ding, A. Experimental Investigation on Hygroscopic Aging of Glass Fiber Reinforced Vinylester Resin Composites. Polymers 2022, 14, 3828. [Google Scholar] [CrossRef]

- Salakhov, I.I.; Shaidullin, N.M.; Chalykh, A.E.; Matsko, M.A.; Shapagin, A.V.; Batyrshin, A.Z.; Shandryuk, G.A.; Nifant’ev, I.E. Low-Temperature Mechanical Properties of High-Density and Low-Density Polyethylene and Their Blends. Polymers 2021, 13, 1821. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Nguyen, V.K.; Pham, T.T.H.; Pham, T.T.; Nguyen, T.D. Effects of Surface Modification with Stearic Acid on the Dispersion of Some Inorganic Fillers in PE Matrix. J. Compos. Sci. 2021, 5, 270. [Google Scholar] [CrossRef]

- Zhang, D.; He, M.; Qin, S.; Yu, J. Effect of Fiber Length and Dispersion on Properties of Long Glass Fiber Reinforced Thermoplastic Composites Based on Poly(Butylene Terephthalate). RSC Adv. 2017, 7, 15439–15454. [Google Scholar] [CrossRef]

- Qiao, J.; Zhang, Q.; Wu, C.; Wu, G.; Li, L. Effects of Fiber Volume Fraction and Length on the Mechanical Properties of Milled Glass Fiber/Polyurea Composites. Polymers 2022, 14, 3080. [Google Scholar] [CrossRef] [PubMed]

- Rohde, M.; Ebel, A.; Wolff-Fabris, F.; Altstädt, V. Influence of Processing Parameters on the Fiber Length and Impact Properties of Injection Molded Long Glass Fiber Reinforced Polypropylene. Int. Polym. Process. 2011, 26, 292–303. [Google Scholar] [CrossRef]

- Ville, J.; Inceoglu, F.; Ghamri, N.; Pradel, J.L.; Durin, A.; Valette, R.; Vergnes, B. Influence of Extrusion Conditions on Fiber Breakage along the Screw Profile During Twin Screw Compounding of Glass Fiber-Reinforced PA. Int. Polym. Process. 2013, 28, 49–57. [Google Scholar] [CrossRef]

- Chang, T.C.; Senior, A.B.; Celik, H.; Brands, D.; Yanev, A.; Osswald, T. Validation of Fiber Breakage in Simple Shear Flow with Direct Fiber Simulation. J. Compos. Sci. 2020, 4, 134. [Google Scholar] [CrossRef]

- Zhu, G.W.; Ma, F.D.; Jia, Y.X.; Qu, P.; Guo, Y.L.; Sun, X.C. Resin Matrix Shear Band and Its Special Effect on Stress Concentration of Fiber Composites. Chin. J. Polym. Sci. 2014, 32, 703–710. [Google Scholar] [CrossRef]

- Liang, J.Z. Melt Strength and Drawability of HDPE, LDPE and HDPE/LDPE Blends. Polym. Test. 2019, 73, 433–438. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in Fiber-Reinforced Polymer Composites: A Review on Their Formation, Characteristics, and Effects on Mechanical Performance. J. Compos. Mater. 2019, 53, 1579–1605. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, L.; Cai, X.; Zheng, X.; Liu, W.; Wang, G.; Dong, M. Heterogeneous Structures and Morphological Transitions of Composite Materials and Its Applications. Adv. Compos. Hybrid Mater. 2024, 7, 251. [Google Scholar] [CrossRef]

- Kayani, S.H.; Kim, B.-J. Microstructure and Mechanical Behavior of Structural Materials. Crystals 2024, 14, 1076. [Google Scholar] [CrossRef]

- Guo, G.; Finkenstadt, V.L.; Nimmagadda, Y. Mechanical Properties and Water Absorption Behavior of Injection-Molded Wood Fiber/Carbon Fiber High-Density Polyethylene Hybrid Composites. Adv. Compos. Hybrid Mater. 2019, 2, 690–700. [Google Scholar] [CrossRef]

- Hassanpour, B.; Karbhari, V.M. Characteristics and Models of Moisture Uptake in Fiber-Reinforced Composites: A Topical Review. Polymers 2024, 16, 2265. [Google Scholar] [CrossRef]

- Abdelmola, F.; Carlsson, L.A. Water Uptake in Epoxy Matrix with Voids: Experiments and Modeling. J. Compos. Mater. 2019, 53, 1049–1065. [Google Scholar] [CrossRef]

- Carlsson, L.A.; Du, E. Water Uptake in Polymer Composites with Voids. In Durability of Composites in a Marine Environment 2; Solid Mechanics and Its Applications; Springer: Berlin/Heidelberg, Germany, 2018; Volume 245, pp. 33–57. [Google Scholar] [CrossRef]

- Thomason, J.L. The interface region in glass fibre-reinforced epoxy resin composites: 2. Water absorption, voids and the interface. Composites 1995, 26, 477–485. [Google Scholar] [CrossRef]

- Awad, S.A. Mechanical and Thermal Characterisations of Low-Density Polyethylene/Nanoclay Composites. Polym. Polym. Compos. 2021, 29, 1325–1332. [Google Scholar] [CrossRef]

- Ramirez, F.A.; Carlsson, L.A.; Acha, B.A. Evaluation of Water Degradation of Vinylester and Epoxy Matrix Composites by Single Fiber and Composite Tests. J. Mater. Sci. 2008, 43, 5230–5242. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Y.; Miao, Y.; Xian, G. Water Absorption, Hydrothermal Expansion, and Thermomechanical Properties of a Vinylester Resin for Fiber-Reinforced Polymer Composites Subjected to Water or Alkaline Solution Immersion. Polymers 2019, 11, 505. [Google Scholar] [CrossRef]

- Van Chau, D. A Study on Water Absorption and Its Effects on Strength of Nano Organoclay-Epoxy Composites. J. Appl. Sci. 2012, 12, 1939–1945. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Dashatan, S.H. Influence of Fiber/Matrix Interface Properties on the Performance of Fiber Reinforced Polymer Composites. In Comprehensive Mechanics of Materials; Silberschmidt, V., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 1–4, pp. 22–32. [Google Scholar] [CrossRef]

- Sarmah, A.; Sarikaya, S.; Thiem, J.; Upama, S.T.; Khalfaoui, A.N.; Dasari, S.S.; Green, M.J. Recycle and Reuse of Continuous Carbon Fibers from Thermoset Composites Using Joule Heating. ChemSusChem 2022, 15, e202200989. [Google Scholar] [CrossRef] [PubMed]

- Alshammari, B.A.; Alenad, A.M.; Al-Mubaddel, F.S.; Alharbi, A.G.; Al-shehri, A.S.; Albalwi, H.A.; Mourad, A.H.I. Impact of Hybrid Fillers on the Properties of High Density Polyethylene Based Composites. Polymers 2022, 14, 3427. [Google Scholar] [CrossRef] [PubMed]

- Pearson, A.; Liao, W.; Kazemi, Y.; Duncan, M.; Slingerland, E.; Kakroodi, A.; Naguib, H.E. Fiber-Matrix Adhesion Between High-Density Polyethylene and Carbon Fiber. Polym. Test. 2022, 105, 107423. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.N.; Srinivasan, N.; Kumar, D.V.; Balaji, D. Influence of Filler Material on Properties of Fiber-Reinforced Polymer Composites: A Review. E-Polymers 2022, 22, 898–916. [Google Scholar] [CrossRef]

- Liu, L.; Du, M.; Liu, F. Recent Advances in Interface Microscopic Characterization of Carbon Fiber-Reinforced Polymer Composites. Front. Mater. 2023, 10, 1124338. [Google Scholar] [CrossRef]

- Kang, B.; Kim, D.; Sohn, J.S.; Park, N.; Kim, K.; Kim, H.J.; Choi, B.H. Observations of Short- and Long-Term Mechanical Properties of Glass Fiber Reinforced Polypropylenes with Post-Consumer Recycled Materials. Int. J. Precis. Eng. Manuf. Green Technol. 2024, 11, 523–535. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Mäder, E.; Yue, C.Y.; Hu, X. Tensile Properties of Short-Glass-Fiber- and Short-Carbon-Fiber-Reinforced Polypropylene Composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Thomason, J.L. The Influence of Fibre Length and Concentration on the Properties of Glass Fibre Reinforced Polypropylene: 5. Injection Moulded Long and Short Fibre PP. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S.; Abu Bakar, A. Mechanical Performance of Oil Palm Empty Fruit Bunches/Jute Fibres Reinforced Epoxy Hybrid Composites. Mater. Sci. Eng. A 2010, 527, 7944–7949. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A Review on Interface Modification and Characterization of Natural Fiber Reinforced Plastic Composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Huang, R.; Xu, X.; Lee, S.; Zhang, Y.; Kim, B.J.; Wu, Q. High Density Polyethylene Composites Reinforced with Hybrid Inorganic Fillers: Morphology, Mechanical and Thermal Expansion Performance. Materials 2013, 6, 4122–4138. [Google Scholar] [CrossRef]

- Ribeiro, M.; Dinis, M. On the Recyclability of Glass Fiber Reinforced Thermoset Polymeric Composites Towards the Sustainability of Polymers’ Industry. Int. J. Waste Resour. 2016, 6, 250. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Mavinkere Rangappa, S.; Siengchin, S.; Puttegowda, M.; Thiagamani, S.M.K.; Rajeshkumar, G.; Moure Cuadrado, M.M. Sustainable Recycling Technologies for Thermoplastic Polymers and Their Composites: A Review of the State of the Art. Polym. Compos. 2022, 43, 5095–5114. [Google Scholar] [CrossRef]

- Meira Castro, A.C.; Ribeiro, M.C.S.; Santos, J.; Meixedo, J.P.; Silva, F.J.G.; Fiúza, A.; Alvim, M.R. Sustainable Waste Recycling Solution for the Glass Fibre Reinforced Polymer Composite Materials Industry. Constr. Build. Mater. 2013, 45, 87–94. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Y.; Du, S.; Zhu, J.; Ma, S. Upcycling of Thermosetting Polymers into High-Value Materials. Mater. Horiz. 2022, 9, 2952–2960. [Google Scholar] [CrossRef] [PubMed]

- Goodarz, M.; Behzadnia, A.; Dastan, T. Assessing the Flexural Properties of Interlayer Hybrid Thermoset–Thermoplastic Composites and Their Repairability. Compos. Mech. Comput. Appl. 2022, 13, 77–94. [Google Scholar] [CrossRef]

- Demircan, O.; Ibrahim, M.H.I. Enhanced Tensile and Flexural Properties in Carbon Nanotubes and Modified Carbon Nanotubes Added Carbon Fiber-Reinforced Epoxy Resin Thermoset Composites. J. Mater. Eng. Perform. 2025, 34, 1–12. [Google Scholar] [CrossRef]

- Periasamy, D.; Karuppiah, P.; Manoharan, B.; Arockiasamy, F.; Kannan, S.; Mohanavel, V.; Velmurugan, P.; Arumugam, N.; Almansour, A.; Sivakumar, S. Assessing the Recycling Potential of Thermosetting Polymer Waste in High-Density Polyethylene Composites for Safety Helmet Applications. E-Polymers 2024, 24, 20230080. [Google Scholar] [CrossRef]

- Scott, C.; Ishlda, H.; Maurer, F.H.J. Infrared Analysis and Izod Impact Testing of Multicomponent Polymer Composites: Polyethylene/EPDM/Filler Systems. J. Mater. Sci. 1987, 22, 3963–3973. [Google Scholar] [CrossRef]

- Tarani, E.; Arvanitidis, I.; Christofilos, D.; Bikiaris, D.N.; Chrissafis, K.; Vourlias, G. Calculation of the Degree of Crystallinity of HDPE/GNPs Nanocomposites by Using Various Experimental Techniques: A Comparative Study. J. Mater. Sci. 2023, 58, 1621–1639. [Google Scholar] [CrossRef]

- Ran, X.; Qin, J.; Wang, M.; Jiang, Q.; Zeng, Y.; Liu, W. Synergistic Toughening of Carbon Fiber/Vinyl Ester Resin Composites with Core–Shell Rubber Particles and Polyphenylene Sulfide Veils. Polym. Compos. 2024, 44, e29447. [Google Scholar] [CrossRef]

- Wang, Z.; Lai, Y.; Xu, P.; Ma, J.; Xu, Y.; Yang, X. Synergistic Effects of Liquid Rubber and Thermoplastic Particles for Toughening Epoxy Resin. Polymers 2024, 16, 2775. [Google Scholar] [CrossRef]

- Sun, J.; Li, Q.; Jiang, Y.; Jiang, J.; Yang, L.; Jia, C.; Chen, F.; Wang, X. Lightweight and High Impact Toughness PP/PET/POE Composite Foams Fabricated by In Situ Nanofibrillation and Microcellular Injection Molding. Polymers 2023, 15, 227. [Google Scholar] [CrossRef]

| Matrix Type | Definition of VPCs | Thermoplastic Matrix (wt.%) | RVC Fillers (wt.%) |

|---|---|---|---|

| LDPE | VLC1 | 90 | 10 |

| VLC2 | 80 | 20 | |

| VLC3 | 70 | 30 | |

| VLC4 | 60 | 40 | |

| VLC5 | 50 | 50 | |

| HDPE | VHC1 | 90 | 10 |

| VHC2 | 80 | 20 | |

| VHC3 | 70 | 30 | |

| VHC4 | 60 | 40 | |

| VHC5 | 50 | 50 |

| Mesh Range (ASTM E 11) | Opening Sizes (µm) | Morphological Characteristics | Fiber Structure |

|---|---|---|---|

| No. 4 | >4.75 mm | Elongated, coarse fiber bundles with a high shape factor | Preserved orientation, entangled/separated fibers |

| No. 5 | >4 mm | ||

| No. 6 | >3.35 mm | Medium-sized, partially separated fiber segments | Partially separated, lower density bundles |

| No. 25 | >710 µm | Short fiber fragments, partially matrix-coated microfibers | Fragmented structure, weak fiber-matrix separation |

| No. 30 | >600 µm | ||

| No. 40 | >425 µm | Amorphous powdery particles, resin residues, microfiber fragments | Lost fiber structure |

| No. 140 | >106 µm | ||

| Under Sieve | <106 µm |

| Definition of VPCs | Loading Fraction | Post-Test Content | |||

|---|---|---|---|---|---|

| Matrix (wt.%) | RVC Fillers (wt.%) | Matrix (wt.%) | Glass Fiber (wt.%) | ±SD | |

| VLC1 | 90 | 10 | 91.37 | 8.63 | 0.26 |

| VLC 2 | 80 | 20 | 84.24 | 15.76 | 0.39 |

| VLC 3 | 70 | 30 | 74.77 | 25.23 | 0.66 |

| VLC 4 | 60 | 40 | 66.60 | 33.40 | 0.81 |

| VLC 5 | 50 | 50 | 58.52 | 41.48 | 1.15 |

| VHC 1 | 90 | 10 | 91.23 | 8.77 | 0.47 |

| VHC 2 | 80 | 20 | 84.26 | 15.74 | 0.53 |

| VHC 3 | 70 | 30 | 75.24 | 24.77 | 0.92 |

| VHC 4 | 60 | 40 | 66.45 | 33.55 | 1.08 |

| VHC 5 | 50 | 50 | 57.26 | 42.74 | 1.43 |

| Definition of VPCs | Loading Fraction | Post-Test Content | ||

|---|---|---|---|---|

| Matrix (wt.%) | RVC Fillers (wt.%) | Density (g/cm3) | ±SD | |

| VLC1 | 90 | 10 | 0.98 | 0.014 |

| VLC 2 | 80 | 20 | 1.05 | 0.016 |

| VLC 3 | 70 | 30 | 1.11 | 0.018 |

| VLC 4 | 60 | 40 | 1.18 | 0.029 |

| VLC 5 | 50 | 50 | 1.20 | 0.031 |

| VHC 1 | 90 | 10 | 0.99 | 0.012 |

| VHC 2 | 80 | 20 | 1.04 | 0.023 |

| VHC 3 | 70 | 30 | 1.11 | 0.025 |

| VHC 4 | 60 | 40 | 1.20 | 0.033 |

| VHC 5 | 50 | 50 | 1.21 | 0.041 |

| Definition of VPCs | Test Results | |||

|---|---|---|---|---|

| Break Energy (J) | ±SD (*) | Izod Impact Strength (kJ/m2) | ±SD (*) | |

| VLC1 | 0.49 | 0.06 | 10.27 | 1.38 |

| VLC 2 | 0.64 | 0.08 | 11.38 | 1.39 |

| VLC 3 | 0.62 | 0.08 | 14.63 | 1.69 |

| VLC 4 | 0.78 | 0.08 | 16.74 | 1.73 |

| VLC 5 | 1.03 | 0.16 | 22.97 | 3.59 |

| VHC1 | 0.19 | 0.02 | 3.69 | 1.33 |

| VHC 2 | 0.27 | 0.07 | 4.97 | 1.34 |

| VHC 3 | 0.35 | 0.09 | 6.62 | 1.66 |

| VHC 4 | 0.47 | 0.15 | 7.02 | 2.20 |

| VHC 5 | 0.48 | 0.11 | 12.9 | 2.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasim, H.; Mohamed, M.; Ning, H.; Pillay, S. Recycling of Pultruded Vinyl Ester Thermoset Scraps into Polyethylene Composites: Toward Circular Composite Manufacturing. J. Compos. Sci. 2025, 9, 641. https://doi.org/10.3390/jcs9120641

Kasim H, Mohamed M, Ning H, Pillay S. Recycling of Pultruded Vinyl Ester Thermoset Scraps into Polyethylene Composites: Toward Circular Composite Manufacturing. Journal of Composites Science. 2025; 9(12):641. https://doi.org/10.3390/jcs9120641

Chicago/Turabian StyleKasim, Hasan, Mahmoud Mohamed, Haibin Ning, and Selvum Pillay. 2025. "Recycling of Pultruded Vinyl Ester Thermoset Scraps into Polyethylene Composites: Toward Circular Composite Manufacturing" Journal of Composites Science 9, no. 12: 641. https://doi.org/10.3390/jcs9120641

APA StyleKasim, H., Mohamed, M., Ning, H., & Pillay, S. (2025). Recycling of Pultruded Vinyl Ester Thermoset Scraps into Polyethylene Composites: Toward Circular Composite Manufacturing. Journal of Composites Science, 9(12), 641. https://doi.org/10.3390/jcs9120641