The Effects of Extraction on Mechanical and Morphological Properties of Sisal Polyester Composite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

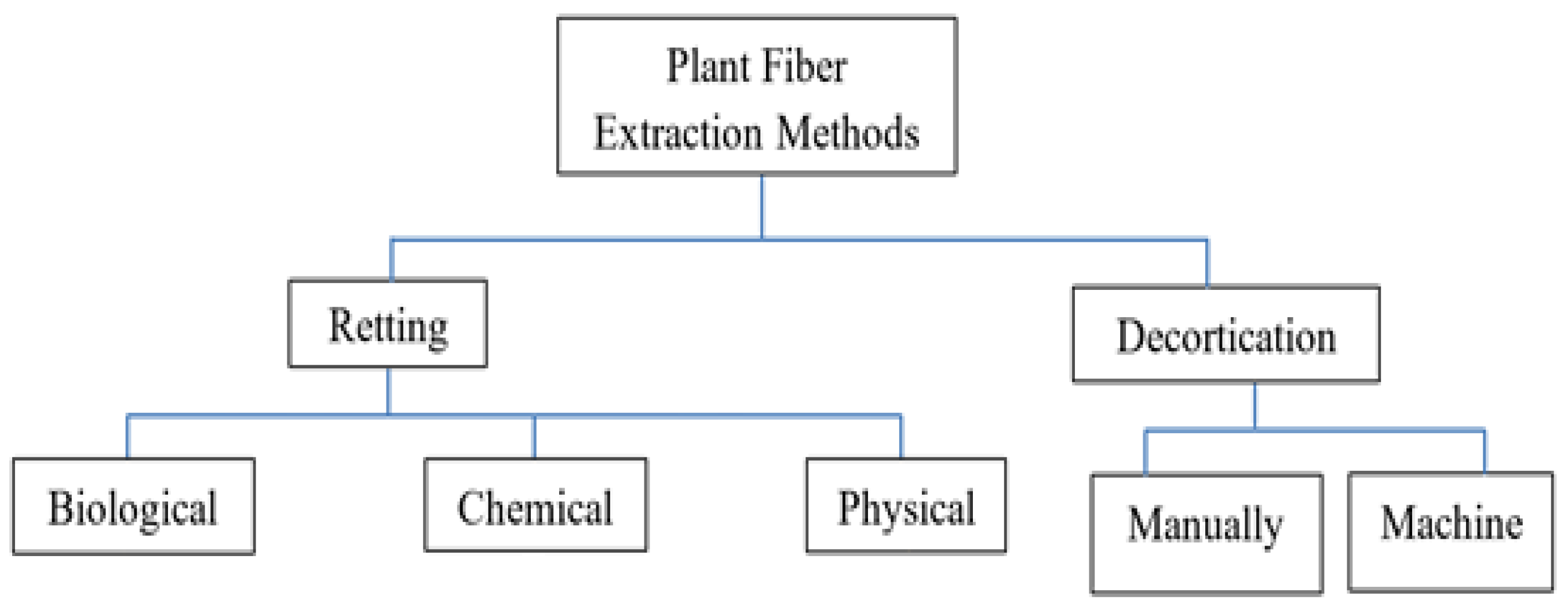

2.2. Fiber Extraction and Treatment Methods

2.3. Composite’s Fabrication Methods

2.4. Mechanical Testing Methods

2.4.1. Tensile Strength

2.4.2. Flexural Strength

2.4.3. Impact Strength

2.4.4. Water Absorption

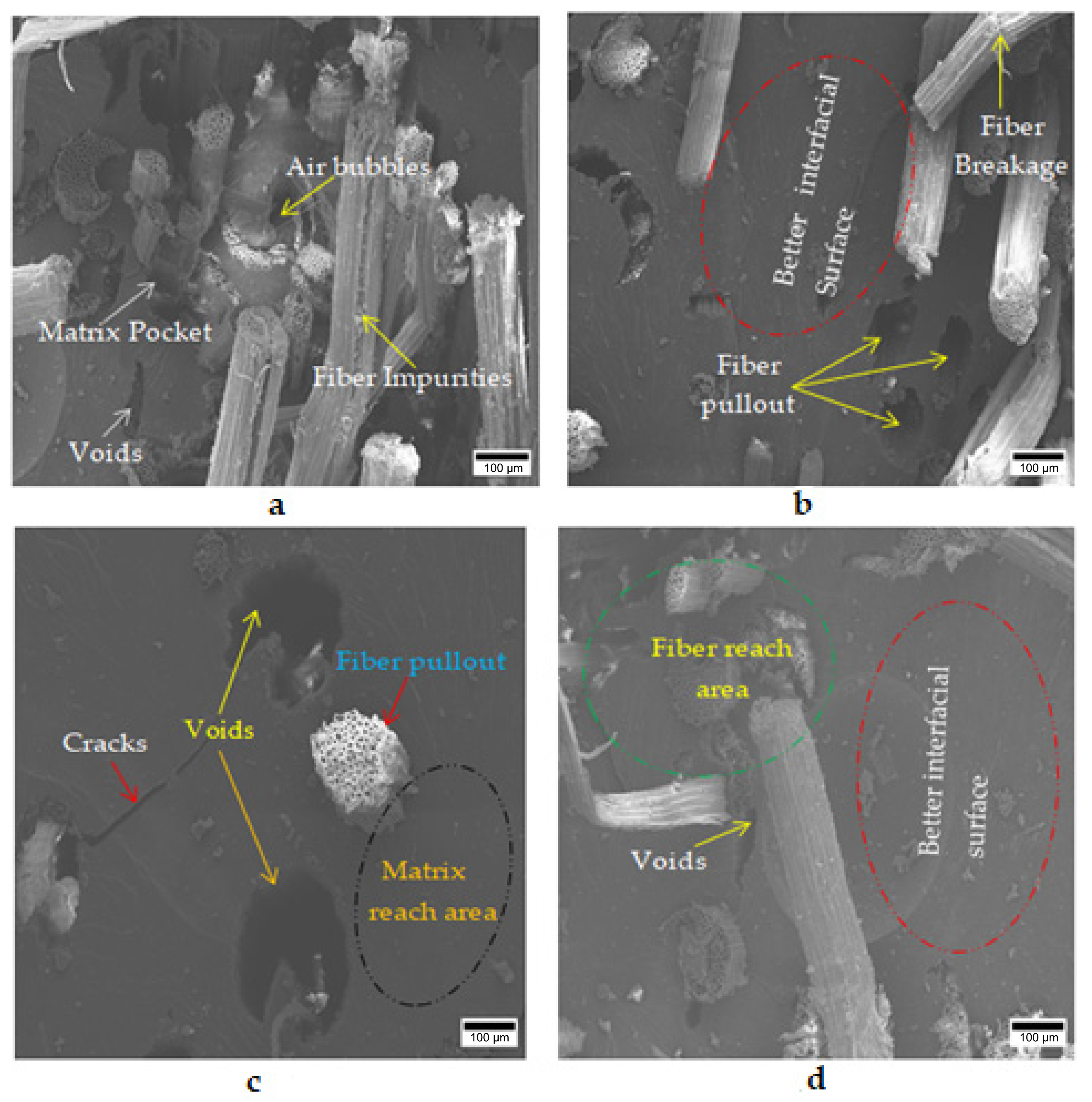

2.4.5. Composite’s Morphology

3. Results and Discussion

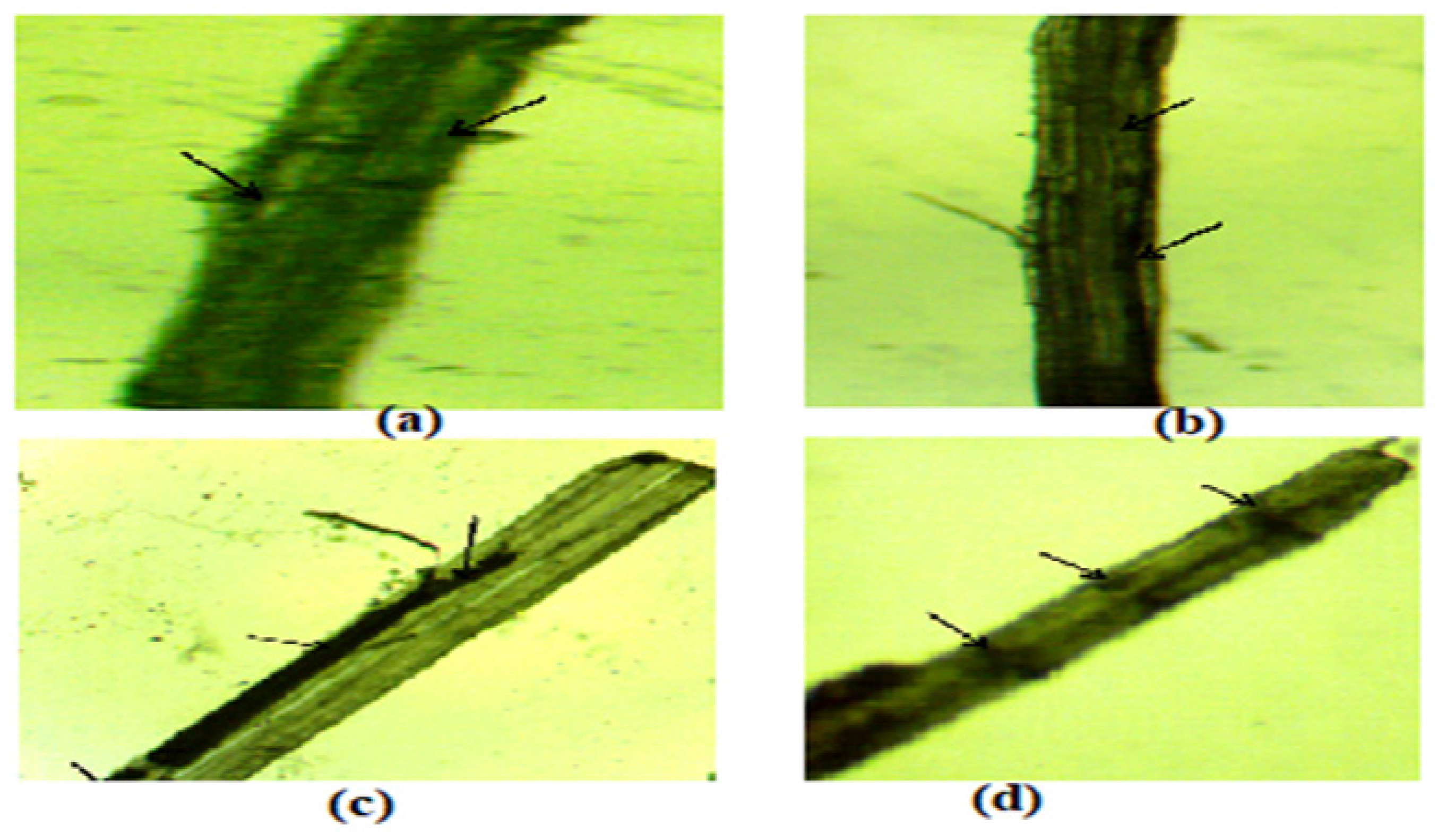

Fiber Structure Microscopy

4. Conclusions

- The microscopy images of the treated, machine-extracted fibers showed clearer surfaces and smaller diameters compared to those of the untreated, manually extracted fibers;

- The treated sisal fiber composites exhibited lower moisture absorption than the untreated fiber composites for both extraction methods;

- The machine-extracted fibers exhibited a rougher surface and fewer impurities compared to the manually extracted fibers, indicating a potential advantage in composite reinforcement applications;

- The machine-extracted fibers show a greater mechanical (tensile and flexural) strength than the manually extracted fiber composite;

- The manually extracted, untreated composites exhibited greater water absorption compared to the machine-extracted, treated composites, demonstrating the effectiveness of the treatment and extraction method in reducing moisture uptake;

- The SEM analysis demonstrated a superior fiber–matrix interface in the machine-extracted, treated fiber composites compared to the other types, in line with the mechanical and water absorption test results. This enhancement is attributed to the removal of surface impurities and the development of a rougher fiber surface through the machine extraction and treatment, which together facilitate stronger interfacial bonding and mitigate moisture-induced degradation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saba, N.; Paridah, M.T.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Athijayamani, A.; Thiruchitrambalam, M.; Natarajan, U.; Pazhanivel, B. Effect of moisture absorption on the mechanical properties of randomly oriented natural fibers/polyester hybrid composite. Mater. Sci. Eng. A 2009, 517, 344–353. [Google Scholar] [CrossRef]

- Amel, B.A.; Paridah, M.T.; Sudin, R.; Anwar, U.M.K.; Hussein, A.S. Effect of fiber extraction methods on some properties of kenaf bast fiber. Ind. Crops Prod. 2013, 46, 117–123. [Google Scholar] [CrossRef]

- Jayaprabha, J.S.; Brahmakumar, M.; Manilal, V.B. Banana pseudostem characterization and its fiber property evaluation on physical and bioextraction. J. Nat. Fibers 2011, 8, 149–160. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid Amuthakkannan, M.P.; Chandrasekar, M. Mechanical and Physical Properties of Sisal and Hybrid Sisal Fiber-reinforced Polymer Composites; Elsevier Ltd.: London, UK, 2019. [Google Scholar]

- Sathish, S.; Karthi, N.; Prabhu, L.; Gokulkumar, S.; Balaji, D.; Vigneshkumar, N.; Farhan, T.A.; AkilKumar, A.; Dinesh, V. A review of natural fiber composites: Extraction methods, chemical treatments and applications. Mater. Today Proc. 2021, 45, 8017–8023. [Google Scholar] [CrossRef]

- Negawo, T.; Polat, A.Y.; Buyuknalcaci, F.; Kilic, N.A.; Saba, N.; Jawaid, M. Mechanical, morphological, structural and dynamic mechanical properties of alkali-treated Ensete stem fibers reinforced unsaturated polyester composites. Compos. Struct. 2019, 207, 589–597. [Google Scholar] [CrossRef]

- Schaefer, J. High-Resolution Pulsed Carbon-13 Nuclear Magnetic Resonance Analysis of Polyacrylonitrile. Macromolecules 1971, 4, 105–107. [Google Scholar] [CrossRef]

- Phong, N.; Fujii, T.; Chuong, T.B.; Viet, D.C.; Okubo, K. Study on How to Effectively Extract Bamboo Fibers from Raw Bamboo and Wastewater Treatment. J. Mater. Sci. Res. 2012, 1, 144–155. [Google Scholar] [CrossRef]

- Etefa, F.; Mekasha, A.; Firew, T. Design and Fabrication of Multi-Fiber Extraction Machine. Int. J. Mod. Trends Sci. Technol. 2019, 5, 28–31. [Google Scholar]

- Sreenivasan, V.S.; Somasundaram, S.; Ravindran, D.; Manikandan, V.; Narayanasamy, R. Microstructural, physico-chemical and mechanical characterisation of Sansevieria cylindrica fibres. Mater. Des. 2011, 32, 453–461. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekara, R. Characterization of new cellulose Sansevieria ehrenbergii fibers for polymer composites. Compos. Interfaces 2013, 20, 575–593. [Google Scholar] [CrossRef]

- Tarabi, N.; Mousazadeh, H.; Jafari, A.; Taghizadeh-Tameh, J. Evaluation of properties of bast fiber extracted from Calotropis (Milkweed) by a new decorticator machine and manual methods. Ind. Crops Prod. 2016, 83, 545–550. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Experimental study of physical, chemical, and mechanical properties of enset and sisal fibers. Polym. Test. 2022, 106, 107453. [Google Scholar] [CrossRef]

- Pouriman, M.; Caparanga, A.R.; Ebrahimi, M.; Dahresobh, A. Characterization of Untreated and Alkaline-Treated Salago Fibers. J. Nat. Fibers 2018, 15, 296–307. [Google Scholar] [CrossRef]

- Inder, J.; Singh, P.; Dhawan, V.; Singh, S.; Jangid, K. ScienceDirect Study of Effect of Surface Treatment on Mechanical Properties of Natural Fiber Reinforced Composites. Mater. Today Proc. 2017, 4, 2793–2799. [Google Scholar]

- Haghdan, S.; Smith, G.D. Natural fiber reinforced polyester composites: A literature review. J. Reinf. Plast. Compos. 2015, 14, 1179–1190. [Google Scholar] [CrossRef]

- Alshammari, B.A.; Saba, N.; Alotaibi, M.D.; Alotibi, M.; Jawaid, F.M.; Alothman, O.Y. Evaluation of mechanical, physical, and morphological properties of epoxy composites reinforced with different date palm fillers. Materials 2019, 12, 2145. [Google Scholar] [CrossRef] [PubMed]

- Mechanics, A.; Palaniyappan, S.; Kumar, R.; Gnanavelbabu, A. Mechanical Properties of Almond Shell-Sugarcane Leaves Hybrid Epoxy Mechanical Properties of Almond Shell-Sugarcane Leaves Hybrid Epoxy Polymer Composite. J. Appl. Mech. 2016, 852, 43–48. [Google Scholar]

- Hossain, M.K.; Karim, M.R.; Chowdhury, M.R.; Imam, M.A.; Hosur, M.; Jeelani, S.; Farag, R. Comparative mechanical and thermal study of chemically treated and untreated single sugarcane fiber bundle. Ind. Crops Prod. 2014, 58, 78–90. [Google Scholar] [CrossRef]

- Shehu, U.; Isa, M.T.; Aderemi, B.O.; Bello, T.K. Effects of NaOH modification on the mechanical properties of baobab pod fiber reinforced LDPE composites. Niger. J. Technol. 2017, 36, 87–95. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J. Thermoplast. Compos. Mater. 2019, 34, 238–284. [Google Scholar] [CrossRef]

- Chaudhary, V. Studies on Mechanical and Morphological Characterization of Developed Jute/Hemp/Flax Reinforced Hybrid Composite. J. Nat. Fibers 2017, 15, 1–18. [Google Scholar]

- Balachandar, M.; Jagadeeshwar, V.R.B.P.; Yokesh, R. ScienceDirect Mechanical behaviour of Natural and Glass fiber reinforced with polymer matrix composite. Mater. Today Proc. 2019, 16, 1297–1303. [Google Scholar]

- Mukhopadhyay, S.; Fangueiro, R. Physical modification of natural fibers and thermoplastic films for composites review. J. Thermoplast. Compos. Mater. 2009, 22, 135–162. [Google Scholar]

- Kengkhetkit, N.; Amornsakchai, T. A new approach to ‘Greening’ plastic composites using pineapple leaf waste for performance and cost effectiveness. J. Mater. 2014, 55, 292–299. [Google Scholar]

- Kannojiya, R.; Gaurav, K.; Ranjan, R.; Tiyer, N.K.; Pandey, K.M. Extraction of pineapple fibres for making commercial products. J. Environ. Res. Dev. 2013, 7, 1385–1390. [Google Scholar]

- Mukhopadhyay, S.; Fangueiro, R.; Yusuf, A.; Ülkü, Ş. Banana Fibers—Variability and Fracture Behaviour. J. Eng. Fibers Fabr. 2008, 3, 39–45. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Deme, T.H. Studies on lignocellulosic fibers of Brazil: Part III—Morphology’ fibers and properties of Brazilian curaua. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2227–2236. [Google Scholar] [CrossRef]

- Zhi, M.; Qiu, M.; Liu, Y.; Cheng, G.; Min, H. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Chand, N.; Sood, S.; Singh, D.K.; Rohatgi, P.K. Structural and thermal studies on sisal fibre. J. Therm. Anal. 1987, 32, 595–599. [Google Scholar] [CrossRef]

- Thomas, S.; Paul, S.A.; Pothan, L.A.; Deepa, B. Natural fibres: Structure, properties and applications. In Cellulose Fibers: Bio-And Nano-Polymer Composites: Green Chemistry and Technology; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–42. [Google Scholar]

- Meijer, W.J.M.; Vertregt, N.; Rutgers, B.; Van De Waart, M. The pectin content as a measure of the retting and rettability of flax. Ind. Crops Prod. 1995, 4, 273–284. [Google Scholar] [CrossRef]

- Münder, F.; Fürll, C.; Hempel, H. Advanced Decortication Technology for Unretted Bast Fibres. J. Nat. Fibers 2004, 1, 49–65. [Google Scholar] [CrossRef]

- Gupta, N.P.; Ghosh, S.K. Performance of Ramie-Polypropylene Blends. Indian J. Text. Res. 1984, 9, 74–76. [Google Scholar]

- Ashimori, M.; Katayama, T.; Aoyama, E.; Nagai, S. Study on Splitting of Bamboo Fibers Due to Freezing and Tensile Strength of FRTP Using Bamboo Fibers. JSME Int. J. Ser. A 2004, 47, 566–569. [Google Scholar] [CrossRef]

- Zakikhani, P.; Zahari, R.; Sultan, M.T.H.; Majid, D.L. Extraction and preparation of bamboo fibre-reinforced composites. Mater. Des. 2014, 63, 820–828. [Google Scholar] [CrossRef]

- Kengkhetkit, N.; Amornsakchai, T. Utilisation of pineapple leaf waste for plastic reinforcement: A novel extraction method for short pineapple leaf fiber. Ind. Crops Prod. 2012, 40, 55–61. [Google Scholar] [CrossRef]

- Yusof, Y.; Asia, S.; Adam, A. Novel technology for sustainable pineapple leaf fiber production. Procedia CIRP 2015, 26, 756–760. [Google Scholar] [CrossRef]

- Brandt, S.; Spring, A.; Hiebsch, C.; McCabe, J.T.; Tabogie, E.; Diro, M.; Wolde-Michael, G.; Yntiso, G.; Shigeta, M.; Tesfaye, S. The tree against hunger. Enset-based Agricultural Systems in Ethiopia. Am. Ass. Adv. Sc. 1997, 56. [Google Scholar]

- Butkut, B.; Gruzdevien, E.; Fernando, A.L. Chemical composition and physical properties of dew- and water-retted hemp fibers. Ind. Crops Prod. 2015, 75, 206–211. [Google Scholar]

- ASTM D3039/D3039M-08; Standard Test Methods for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTMD790-10; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTMD256:06ae1; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTMD570-98; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- Yousif, B.F.; Shalwan, A.; Chin, C.W.; Ming, K.C. Flexural properties of treated and untreated kenaf/epoxy composites. Mater. Des. 2012, 40, 378–385. [Google Scholar] [CrossRef]

- Peijs, A.A.J.M.; Catsman, P.; Govaert, L.E.; Lemstra, P.J. Hybrid composites based on polyethylene and carbon fibres Part 2: Influence of composition and adhesion level of polyethylene fibres on mechanical properties. Composites 1990, 21, 513–521. [Google Scholar] [CrossRef]

- Lima Lopes Junior, J.; Rodrigues Brabo, D.; Leandro Santos Amaral, E.; Wilson da Cruz Reis, A.; Bastos do Amarante, C.; Gilda Barroso Tavares Dias, C. Characterization of the natural fibers extracted from the aninga’s stem and development of a unidirectional polymeric sheet. Sci. Rep. 2024, 14, 24780. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Surface modifications of natural fibers and performance of the resulting biocomposites: An overview. Interfaces 2001, 8, 313–343. [Google Scholar] [CrossRef]

| Types of Fibers | Extraction Techniques | Reference |

|---|---|---|

| Sisal | Retting, hand scraper, machine decortication | [32,33] |

| Flax | Water retting, dew retting, machine decortication, ultrasonic treatment | [34] |

| Abaca | Hand scraper, machine decortication | [9] |

| Banana | Hand scraper and machine decortication | [5] |

| Coir | Hand scraper, beating on stone, retting, decortication machine | [35] |

| Remie | Hand scraper, decortication husk | [36] |

| Bamboo | Mechanical extraction and steam explosion | [37,38] |

| Pineapple leaf | Mechanical milling, machine decortication, and hand scraping | [39,40] |

| Ventricosum | Manual decortication | [41] |

| Hemp | Dew and water retting | [42] |

| Types of Extraction | Fibers | Diameter (µm) |

|---|---|---|

| Machine extraction | Untreated | 411.4 ± 0.025 |

| 5% NaOH | 298.7 ± 0.121 | |

| Manual extraction | Untreated | 464.3 ± 0.045 |

| 5% NaOH | 309.8 ± 0.123 |

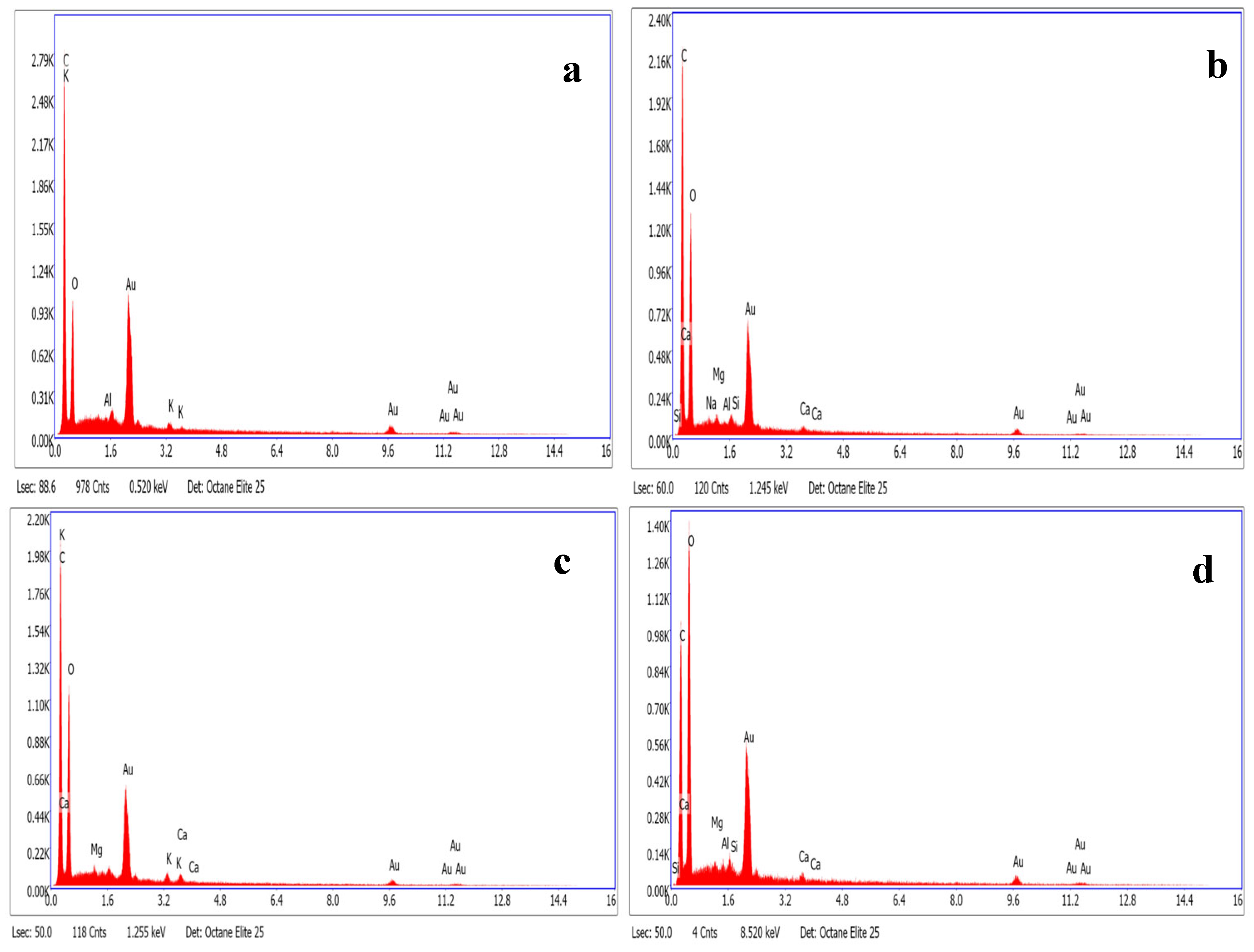

| Element | Weight Percentages (wt%) | |||

|---|---|---|---|---|

| Machine Treated | Machine Untreated | Manually Treated | Manual Untreated | |

| C | 39.91 | 52.19 | 55.22 | 65.27 |

| O | 55.97 | 42.67 | 41.74 | 34.07 |

| Al | 0.92 | - | 0.15 | 0.01 |

| Mg | 1.45 | - | 0.72 | - |

| Ca | 1.48 | 1.54 | 1.04 | - |

| Si | 0.52 | 1.9 | 0.27 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Endesha, A.; Tefera, G.; Adali, S.; Bright, G. The Effects of Extraction on Mechanical and Morphological Properties of Sisal Polyester Composite. J. Compos. Sci. 2025, 9, 613. https://doi.org/10.3390/jcs9110613

Endesha A, Tefera G, Adali S, Bright G. The Effects of Extraction on Mechanical and Morphological Properties of Sisal Polyester Composite. Journal of Composites Science. 2025; 9(11):613. https://doi.org/10.3390/jcs9110613

Chicago/Turabian StyleEndesha, Abera, Getahun Tefera, Sarp Adali, and Glen Bright. 2025. "The Effects of Extraction on Mechanical and Morphological Properties of Sisal Polyester Composite" Journal of Composites Science 9, no. 11: 613. https://doi.org/10.3390/jcs9110613

APA StyleEndesha, A., Tefera, G., Adali, S., & Bright, G. (2025). The Effects of Extraction on Mechanical and Morphological Properties of Sisal Polyester Composite. Journal of Composites Science, 9(11), 613. https://doi.org/10.3390/jcs9110613