Tailoring Basalt Fibers and E-Glass Fibers as Reinforcements for Increased Impact Resistance

Abstract

1. Introduction

2. Materials and Methods

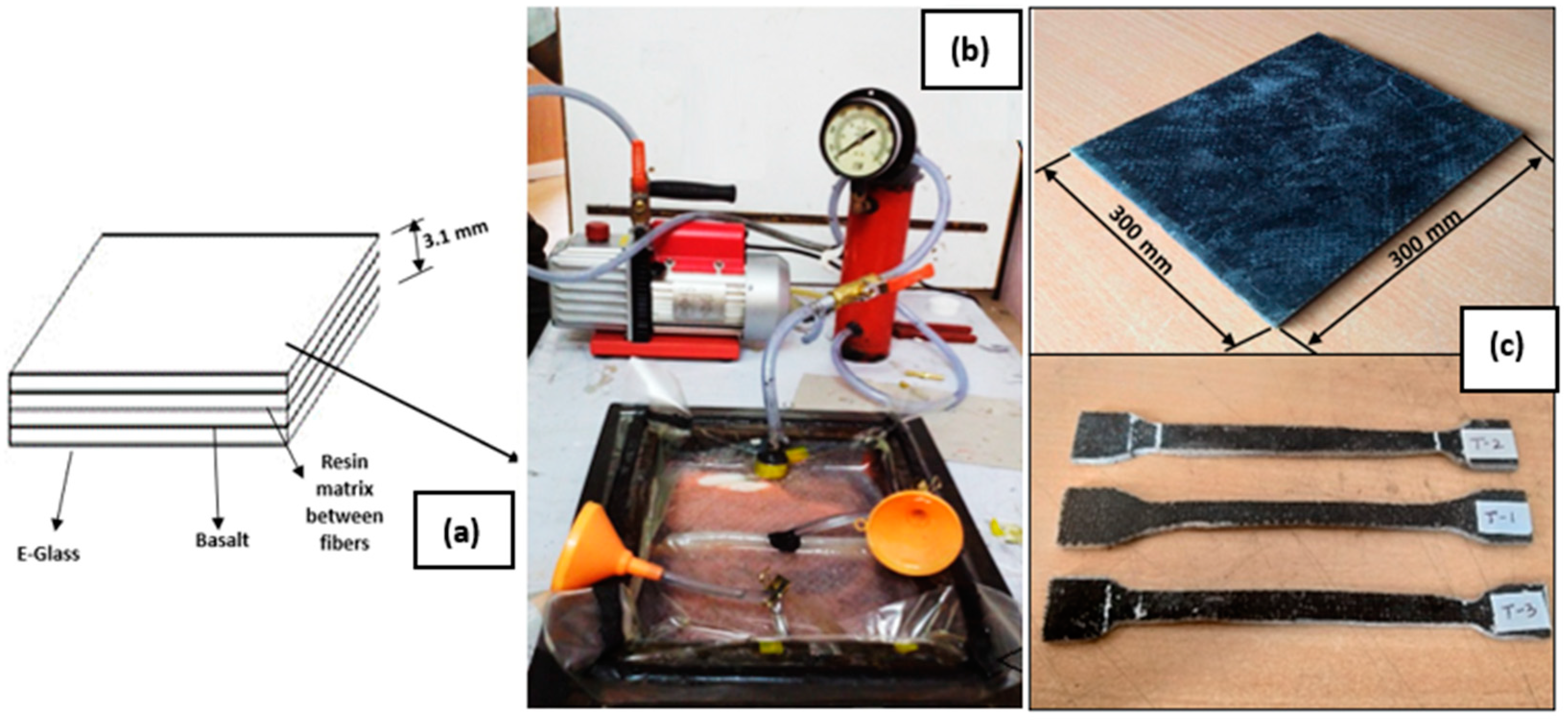

2.1. Sample Preparation

2.2. Method of Research

3. Results

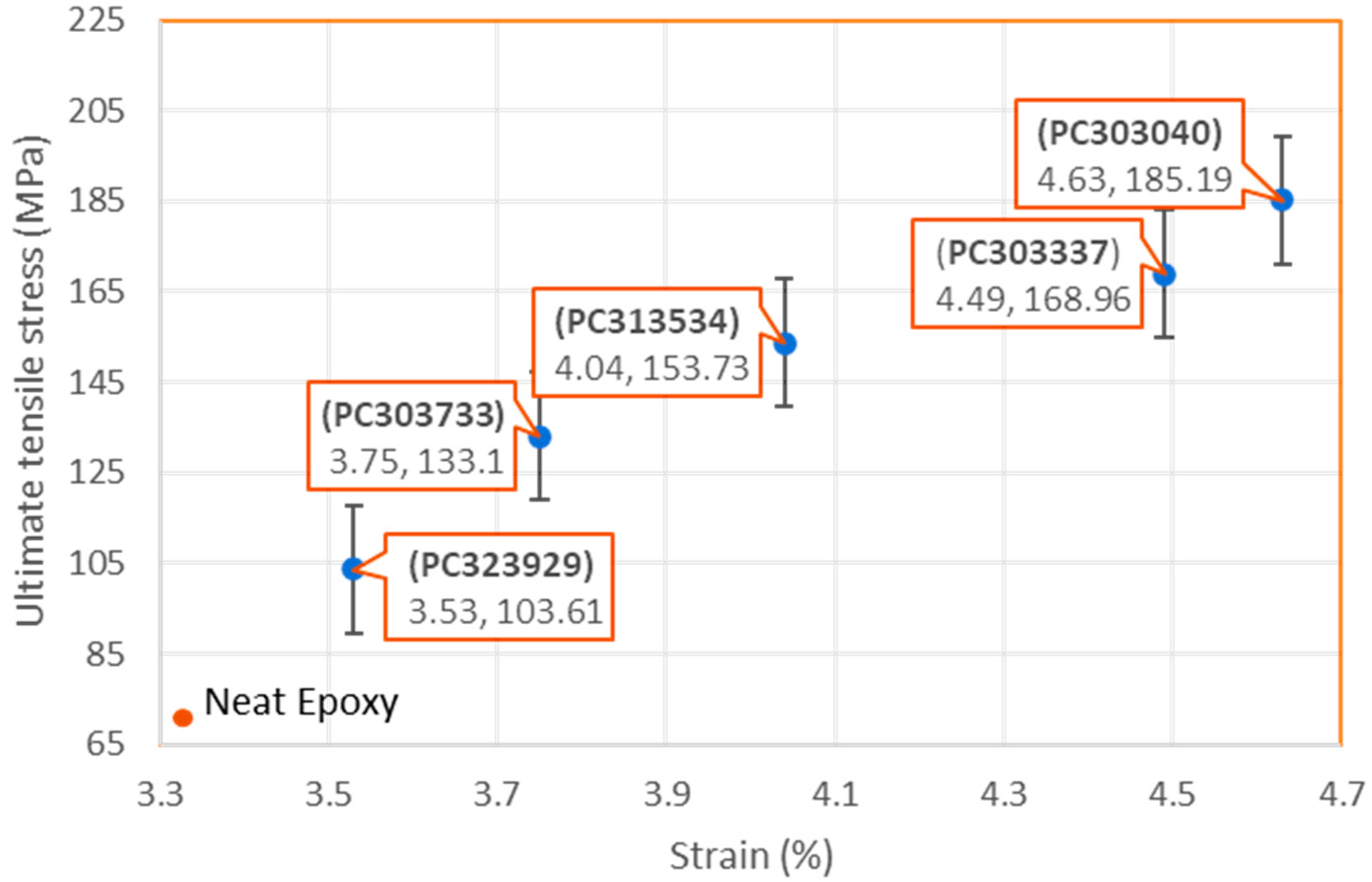

3.1. Tensile Test

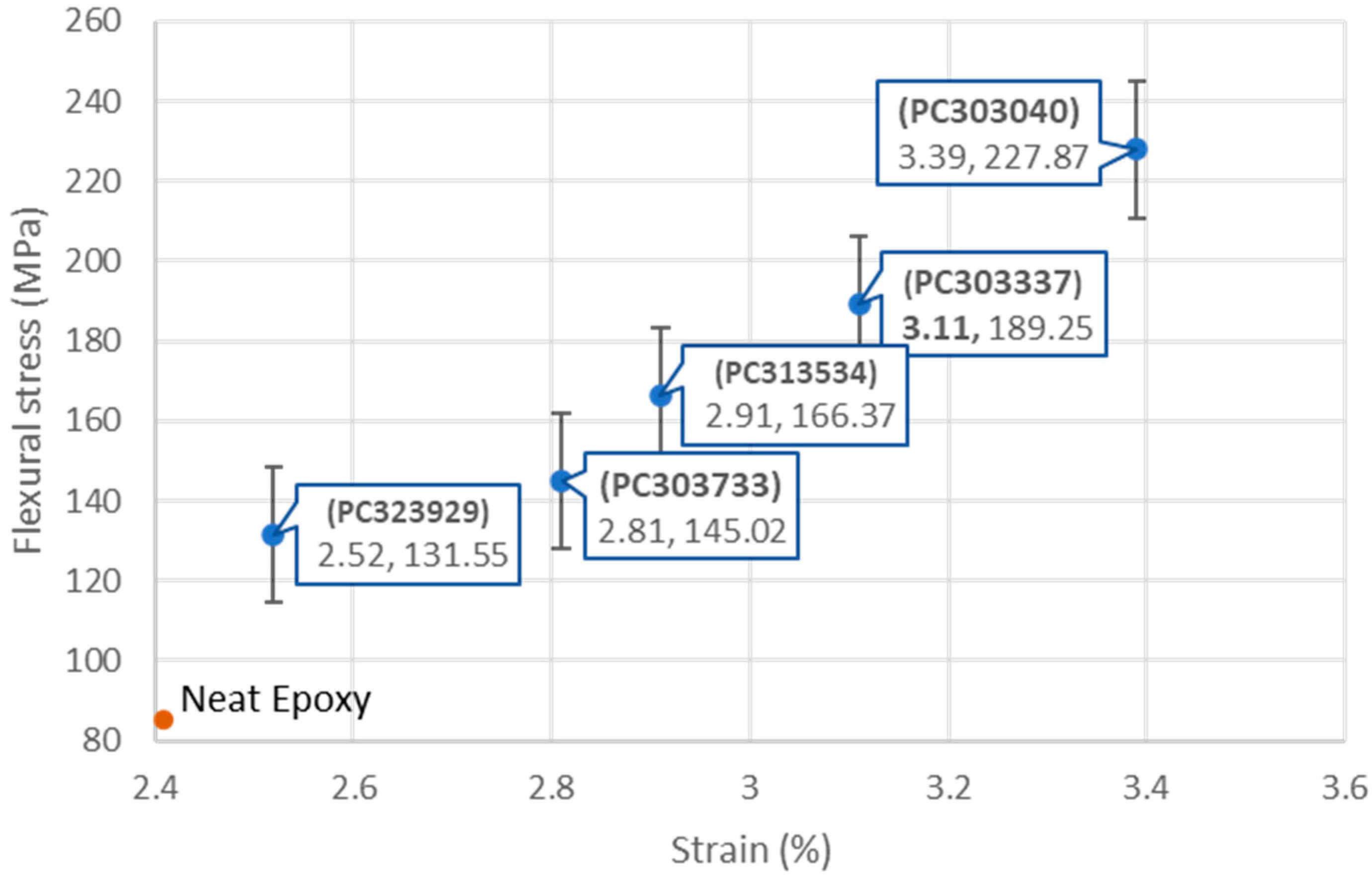

3.2. Flexural Test

3.3. Low-Velocity Impact Test

3.4. Thermogravimetric Analysis

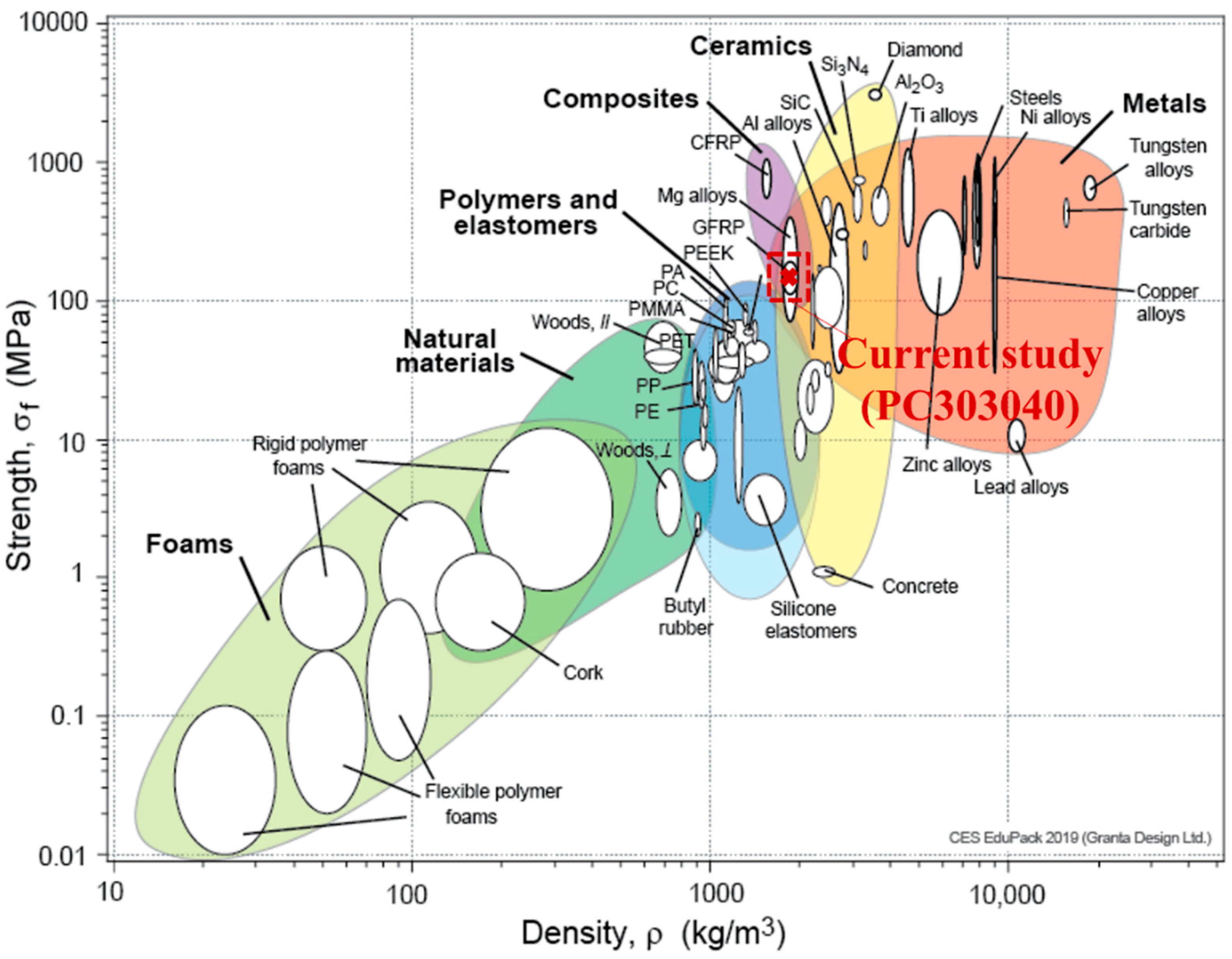

4. Discussion

Fracture Surface Analysis

5. Conclusions

- The experimental results showed that a 10% higher volume fraction of basalt fiber provides excellent impact energy absorption, i.e., 40–70%.

- The tensile test results revealed that 40 vol. % E-glass fiber as reinforcement shows better tensile strength than 40 vol. % basalt-fiber-reinforced composites.

- Similarly, the three-point bending flexural test results depicted that a higher volume fraction of E-glass fiber provides reasonable flexural strength, i.e., 80% higher than other fabricated laminates.

- The analysis of the results allowed to conclude that 40 vol. % E-glass-fiber-reinforced composites are better for tensile and flexural conditions, while 40 vol. % basalt-reinforced composites are better for applications involving impact energy.

- During the thermogravimetric analysis, it was noticed that PC313534 (35 vol. % basalt and 34 vol. % E-glass) possesses the lowest decomposition temperature of 381.1 °C. Similarly, samples with basalt and E-glass fiber in almost equal quantities (PC313534—35 vol. % basalt and 34 vol. % E-glass) provide better thermal stability than other compositions.

- The outcome from the present study can be used in designing composite materials that exhibit high strength-to-weight ratio, which can be useful in defense armors and aerospace applications such as flaps, slats, and fuselages.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Birkner, M.; Spange, S.; Koschek, K. Basalt fiber reinforced polymers with improved thermal and mechanical properties by combination of twin polymerization with epoxide chemistry. Polym. Compos. 2019, 40, 3115–3121. [Google Scholar] [CrossRef]

- Bauer, F.; Kempf, M.; Weiland, F.; Middendorf, P. Structure-property relationships of basalt fibers for high performance applications. Compos. B Eng. 2018, 145, 121–128. [Google Scholar] [CrossRef]

- Wolter, N.; Beber, V.C.; Sandinge, A.; Blomqvist, P.; Goethals, F.; Van Hove, M. Carbon, Glass and Basalt Fiber Reinforced Polybenzoxazine: The Effects of Fiber Reinforcement on Mechanical, Fire, Smoke and Toxicity Properties. Polymers 2020, 12, 2379. [Google Scholar] [CrossRef]

- Fragassa, C.; Pavlovic, A.; Santulli, C. Mechanical and impact characterisation of flax and basalt fibre vinylester composites and their hybrids. Compos. B Eng. 2018, 137, 247–259. [Google Scholar] [CrossRef]

- Khazaie, M.; Eslami-Farsani, R.; Saeedi, A. Evaluation of repeated high velocity impact on polymer-based composites reinforced with basalt and Kevlar fibers. Mater. Today. Commun. 2018, 17, 76–81. [Google Scholar] [CrossRef]

- Malik, A.; Chakraborty, T.; Rao, K.S. Strain rate effect on the mechanical behavior of basalt: Observations from static and dynamic tests. Thin-Walled Struct. 2018, 126, 127–137. [Google Scholar] [CrossRef]

- Boria, S.; Pavlovic, A.; Fragassa, C.; Santulli, C. Modeling of Falling Weight Impact Behavior of Hybrid Basalt/Flax Vinylester Composites. Procedia Eng. 2016, 167, 223–230. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Ferrante, L.; Valente, M.; Valente, T.; Lampani, L. Drop-weight impact behaviour of woven hybrid basalt–carbon/epoxy composites. Compos. B Eng. 2014, 59, 204–220. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Valente, M.; Valente, T.; Cioffi, S.; Iannace, S. Effect of basalt fiber hybridization on the impact behavior under low impact velocity of glass/basalt woven fabric/epoxy resin composites. Compos. A Appl. Sci. Manuf. 2013, 47, 109–123. [Google Scholar] [CrossRef]

- Živković, I.; Fragassa, C.; Pavlović, A.; Brugo, T. Influence of moisture absorption on the impact properties of flax, basalt and hybrid flax/basalt fiber reinforced green composites. Compos. B Eng. 2017, 111, 148–164. [Google Scholar] [CrossRef]

- Soares, B.; Preto, R.; Sousa, L.; Reis, L. Mechanical behavior of basalt fibers in a basalt-UP composite. Procedia Struct. Integr. 2016, 1, 82–89. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.; Pham, T.M.; Hao, H. Bond behavior between basalt fibres reinforced polymer sheets and steel fibres reinforced concrete. Eng. Struct. 2018, 176, 812–824. [Google Scholar] [CrossRef]

- Ferrante, L.; Sarasini, F.; Tirillò, J.; Lampani, L.; Valente, T.; Gaudenzi, P. Low velocity impact response of basalt-aluminium fibre metal laminates. Mater. Des. 2016, 98, 98–107. [Google Scholar] [CrossRef]

- Lapena, M.H.; Marinucci, G. Mechanical Characterization of Basalt and Glass Fiber Epoxy Composite Tube. Mater. Res. 2017, 21, e20170324. [Google Scholar] [CrossRef]

- Atmakuri, A.; Kolli, L.; Palevicius, A.; Urbaite, S.; Janusas, G. Influence of Filler Materials on Wettability and Mechanical Properties of Basalt/E-Glass Woven Fabric–Reinforced Composites for Microfluidics. Micromachines 2022, 13, 1875. [Google Scholar] [CrossRef]

- Plappert, D.; Ganzenmüller, G.C.; May, M.; Beisel, S. Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Composite. J. Compos. Sci. 2020, 4, 101. [Google Scholar] [CrossRef]

- Patel, N. Investigations on Mechanical Strength of Hybrid Basalt/Glass Polyester Composites. Int. J. Appl. Eng. 2018, 13, 4083–4088. [Google Scholar]

- Vijayan, R.; Natarajan, E.; Palanikumar, K.; Krishnamoorthy, A.; Markandan, K.; Ramesh, S. Effect of hybridization and stacking sequences on mechanical properties and thermal stability of aloe vera-roselle-glass fiber reinforced polymer composites. Polym. Compos. 2023, 44, 6593–6603. [Google Scholar] [CrossRef]

- Natarajan, E.; Freitas, L.I.; Santhosh, M.S.; Markandan, K.; Majeed Al-Talib, A.A.; Hassan, C.S. Experimental and numerical analysis on suitability of S-Glass-Carbon fiber reinforced polymer composites for submarine hull. Def. Technol. 2023, 19, 1–11. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Recovery of Particle Reinforced Composite 3D Printing Filament from Recycled Industrial Polypropylene and Glass Fibre Waste. In Proceedings of the 8th World Congress on Mechanical, Chemical, and Material Engineering (MCM’22), Prague, Czech Republic, 31 July–2 August 2022. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, X.; Wang, C.; Li, S.; Cao, D. Post-Heat Flexural Properties of Siloxane-Modified Epoxy/Phenolic Composites Reinforced by Glass Fiber. Polymers 2024, 16, 708. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D.; Zhang, H.; Huang, L.; Yao, Y.; Li, G.; Mobasher, B. Mechanical Characterization of the Tensile Properties of Glass Fiber and Its Reinforced Polymer (GFRP) Composite under Varying Strain Rates and Temperatures. Polymers 2016, 8, 196. [Google Scholar] [CrossRef] [PubMed]

- Uthaman, A.; Xian, G.; Thomas, S.; Wang, Y.; Zheng, Q.; Liu, X. Durability of an Epoxy Resin and Its Carbon Fiber- Reinforced Polymer Composite upon Immersion in Water, Acidic, and Alkaline Solutions. Polymers 2020, 12, 614. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Sandoval-Valderrama, B.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M.; Opazo-Vega, A. Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Laminated Veneer Lumber. Appl. Sci. 2023, 13, 10032. [Google Scholar] [CrossRef]

- Santhosh, M.S.; Sasikumar, R.; Khadar, S.D.A.; Natrayan, L. Ammonium Polyphosphate Reinforced E-Glass/Phenolic Hybrid Composites for Primary E-Vehicle Battery Casings –A Study on Fire Performance. J. New Mater. Electrochem. Syst. 2021, 24, 247–253. [Google Scholar] [CrossRef]

- Santhosh, M.S.; Sasikumar, R.; Natarajan, E. E-Glass/phenolic matrix/APP laminate as a potential candidate for battery casing of e-vehicle—Experimental investigations. Mater. Res. Express. 2021, 8, 045310. [Google Scholar] [CrossRef]

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D6110; Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- Gong, L.-X.; Zhao, L.; Tang, L.-C.; Liu, H.-Y.; Mai, Y.-W. Balanced electrical, thermal and mechanical properties of epoxy composites filled with chemically reduced graphene oxide and rubber nanoparticles. Compos. Sci. Technol. 2015, 121, 104–114. [Google Scholar] [CrossRef]

- Liu, J.; Chen, M.; Yang, J.; Wu, Z. Study on Mechanical Properties of Basalt Fibers Superior to E-glass Fibers. J. Nat. Fibers 2022, 19, 882–894. [Google Scholar] [CrossRef]

- Xiao, X.; Lu, S.; Qi, B.; Zeng, C.; Yuan, Z.; Yu, Y. Enhancing the thermal and mechanical properties of epoxy resins by addition of a hyperbranched aromatic polyamide grown on microcrystalline cellulose fibers. RSC Adv. 2014, 4, 14928. [Google Scholar] [CrossRef]

- Elmahdy, A.; Verleysen, P. Mechanical behavior of basalt and glass textile composites at high strain rates: A comparison. Polym. Test. 2020, 81, 106224. [Google Scholar] [CrossRef]

- McNiffe, E.; Ritter, T.; Higgins, T.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Ghabezi, P.; Finnegan, W.; Mitchell, S.; Harrison, N.M. Advancements in Functionally Graded Polyether Ether Ketone Components: Design, Manufacturing, and Characterisation Using a Modified 3D Printer. Polymers 2023, 15, 2992. [Google Scholar] [CrossRef]

| Epoxy LY 556 | Hardener W152 LR | |

|---|---|---|

| Color | Pale yellow | Clear White |

| Specific gravity at RT | 1.10–1.20 | 1.90–2.10 |

| Viscosity [cps] | 8000–12,000 | 16,000–18,000 |

| Volatile content [wt. %] | 0.75 | 1.0 |

| Basalt | E-Glass | |

|---|---|---|

| Density [g/cm3] | 2.40 | 1.95 |

| Tensile strength [MPa] | 3600–4850 | 3050–3600 |

| Elastic modulus [GPa] | 75–105 | 72–77 |

| Elongation at break [%] | 2.8 | 4.7 |

| Maximum service temperature [°C] | 345 | 380 |

| Designation | Thickness [mm] | Epoxy Matrix [vol. %] | Basalt [vol. %] | E-Glass [vol. %] |

|---|---|---|---|---|

| PC303040 | 3.2 | 30 | 30 | 40 |

| PC303337 | 3.1 | 30 | 33 | 37 |

| PC303733 | 3.2 | 30 | 37 | 33 |

| PC313534 | 3.4 | 31 | 35 | 34 |

| PC323929 | 3.3 | 32 | 39 | 29 |

| Sample Code | Energy Absorption along Horizontal Fiber Orientation [J] | Energy Absorption along Vertical Fiber Orientation [J] |

|---|---|---|

| PC303040 | 3.1 | 4.6 |

| PC303337 | 3.3 | 4.8 |

| PC303733 | 3 | 5.5 |

| PC313534 | 3.9 | 6.1 |

| PC323929 | 4.5 | 7.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Natarajan, E.; Mozhuguan Sekar, S.; Markandan, K.; Ang, C.K.; Franz, G. Tailoring Basalt Fibers and E-Glass Fibers as Reinforcements for Increased Impact Resistance. J. Compos. Sci. 2024, 8, 137. https://doi.org/10.3390/jcs8040137

Natarajan E, Mozhuguan Sekar S, Markandan K, Ang CK, Franz G. Tailoring Basalt Fibers and E-Glass Fibers as Reinforcements for Increased Impact Resistance. Journal of Composites Science. 2024; 8(4):137. https://doi.org/10.3390/jcs8040137

Chicago/Turabian StyleNatarajan, Elango, Santhosh Mozhuguan Sekar, Kalaimani Markandan, Chun Kit Ang, and Gérald Franz. 2024. "Tailoring Basalt Fibers and E-Glass Fibers as Reinforcements for Increased Impact Resistance" Journal of Composites Science 8, no. 4: 137. https://doi.org/10.3390/jcs8040137

APA StyleNatarajan, E., Mozhuguan Sekar, S., Markandan, K., Ang, C. K., & Franz, G. (2024). Tailoring Basalt Fibers and E-Glass Fibers as Reinforcements for Increased Impact Resistance. Journal of Composites Science, 8(4), 137. https://doi.org/10.3390/jcs8040137