Influence of Grinding Tool Mesh Size and Rotational Speed on Post-Machining Quality of CFRP Laminates by Acceleration Signal and Surface Roughness Analyses

Abstract

1. Introduction

2. Materials and Methods

2.1. CFRP Laminates’ Manufacturing

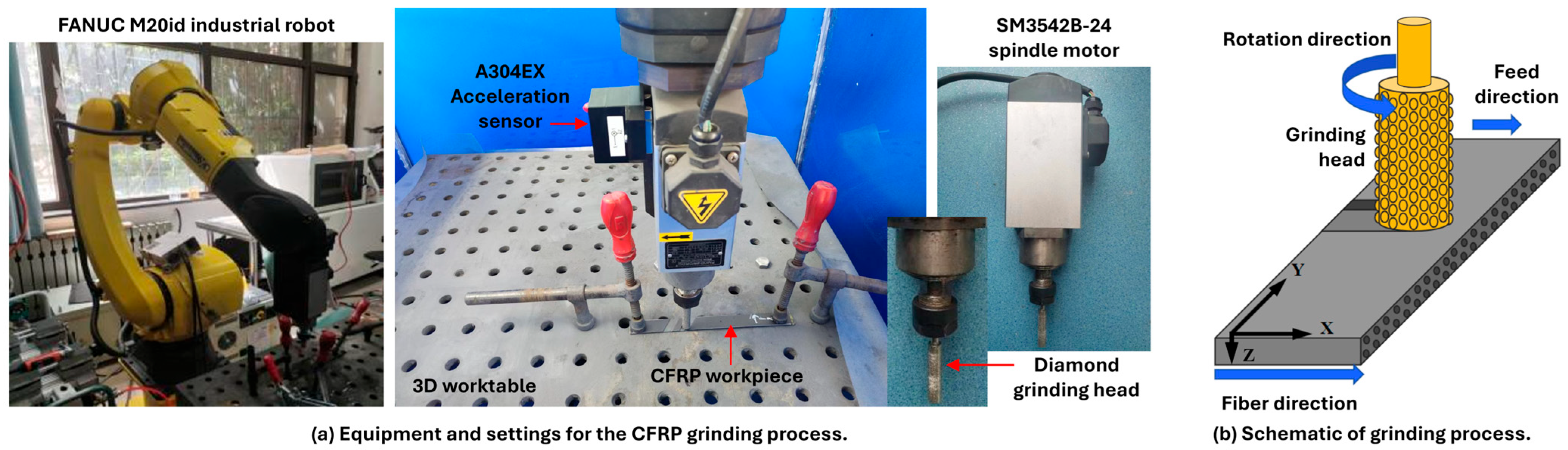

2.2. CFRP Grinding Process

3. Results and Discussion

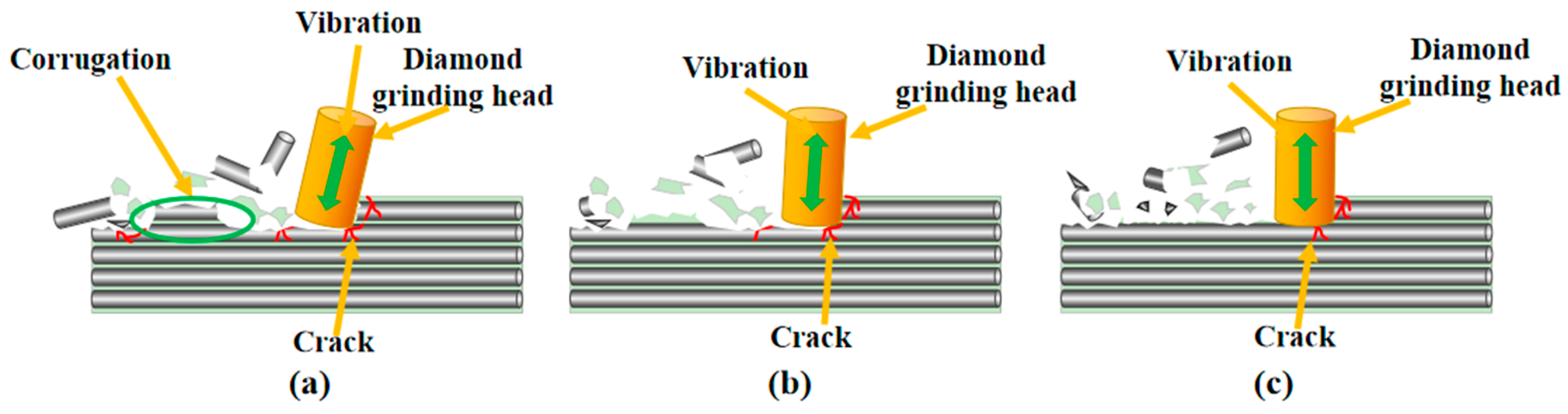

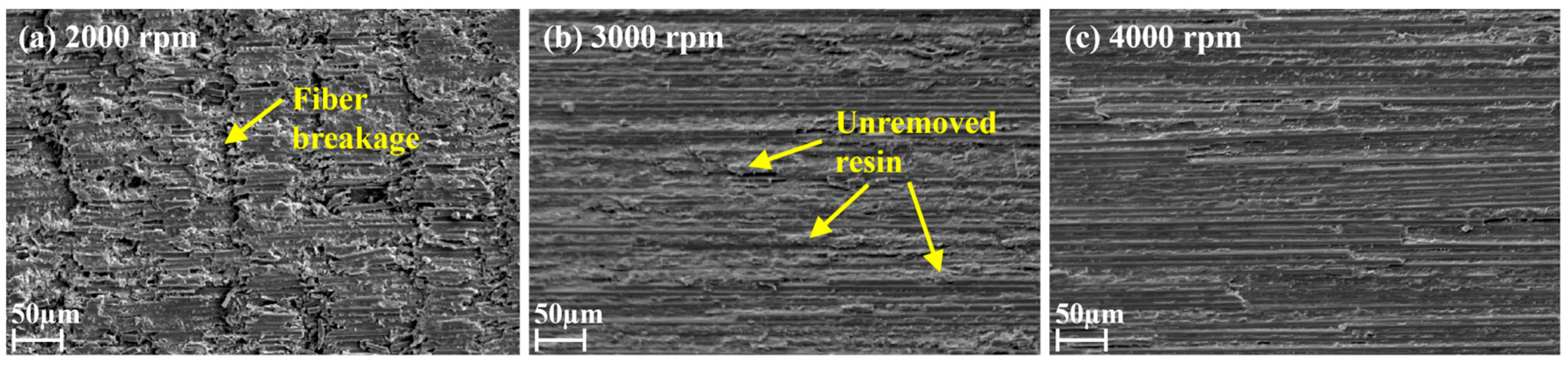

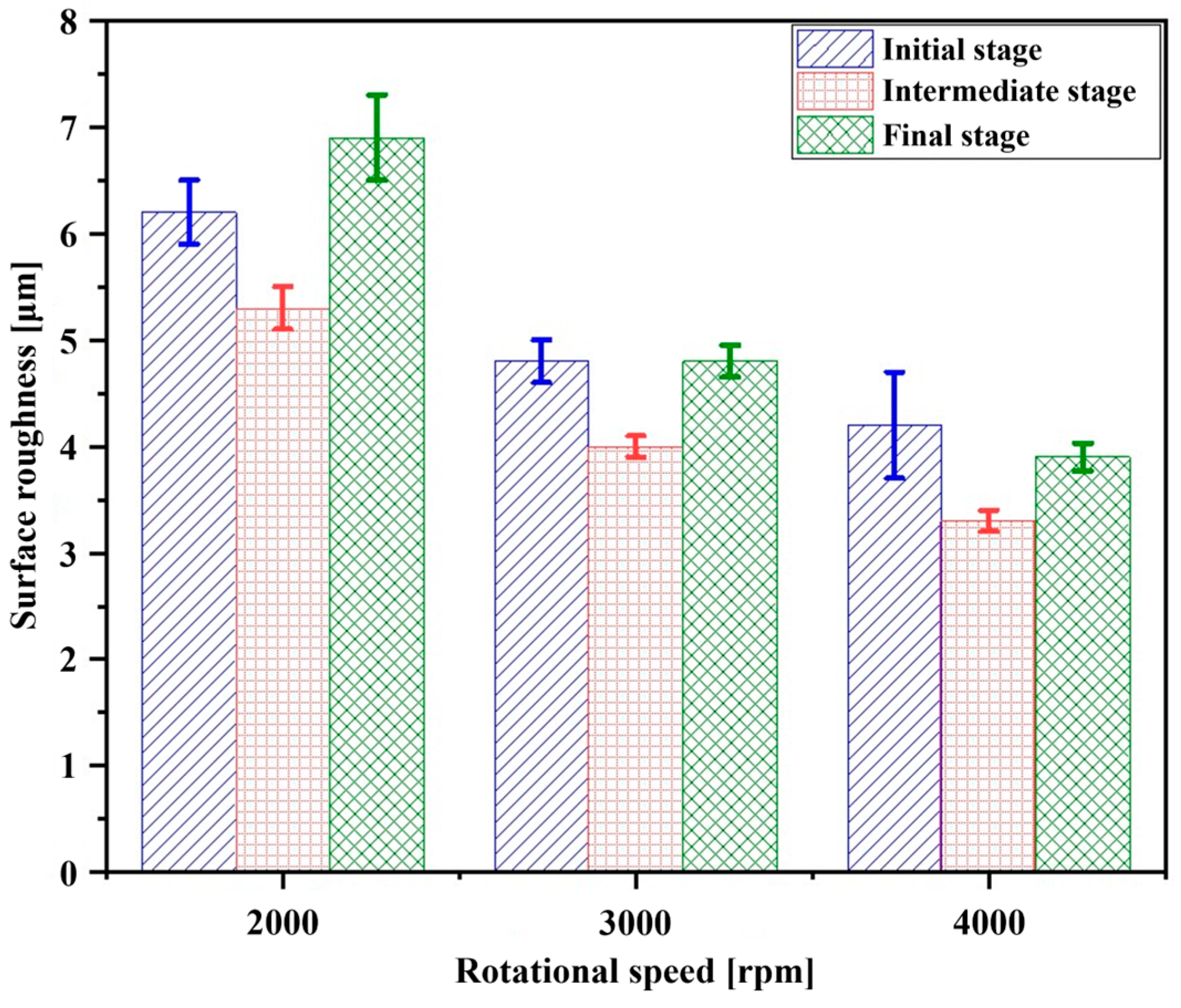

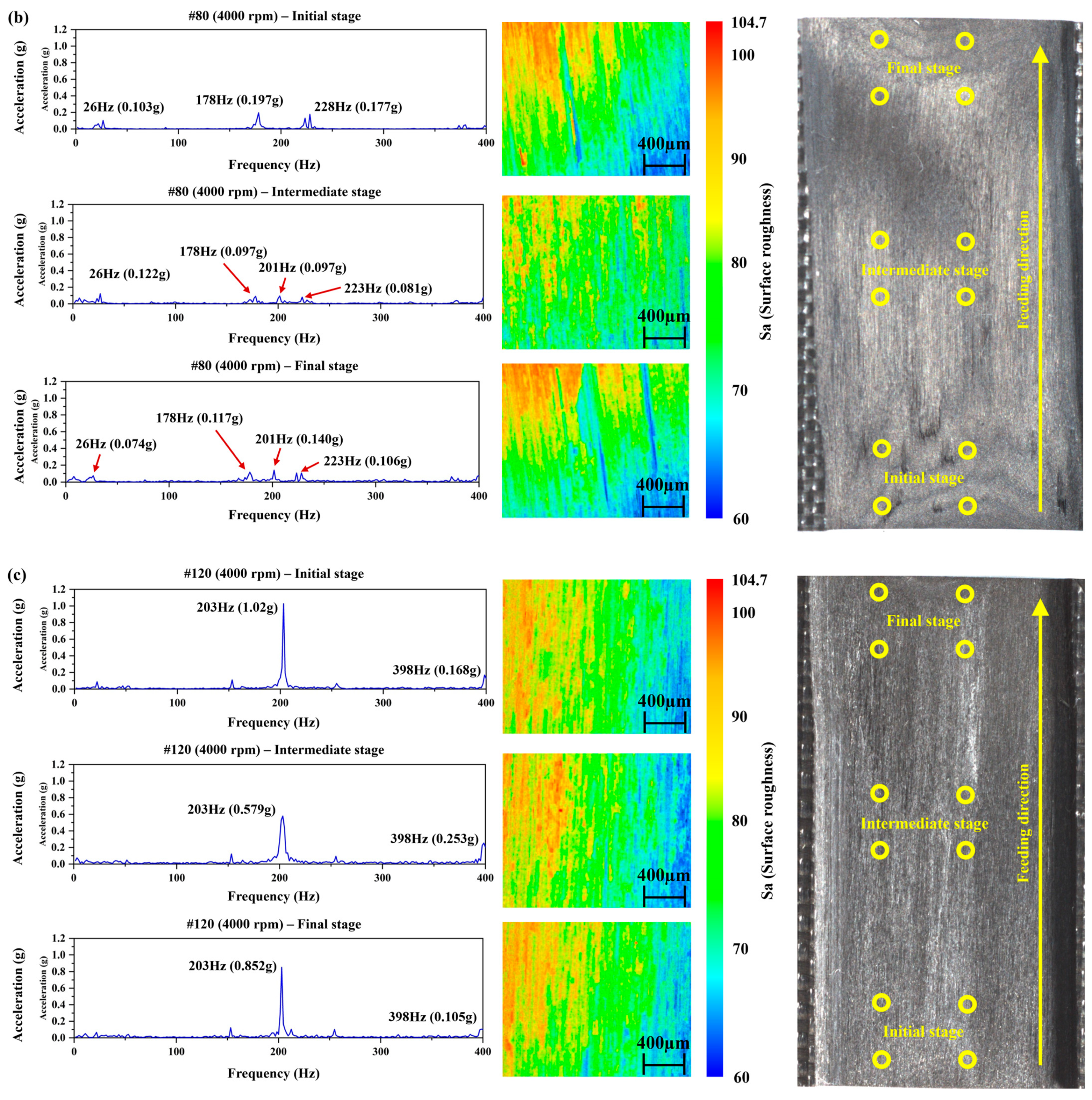

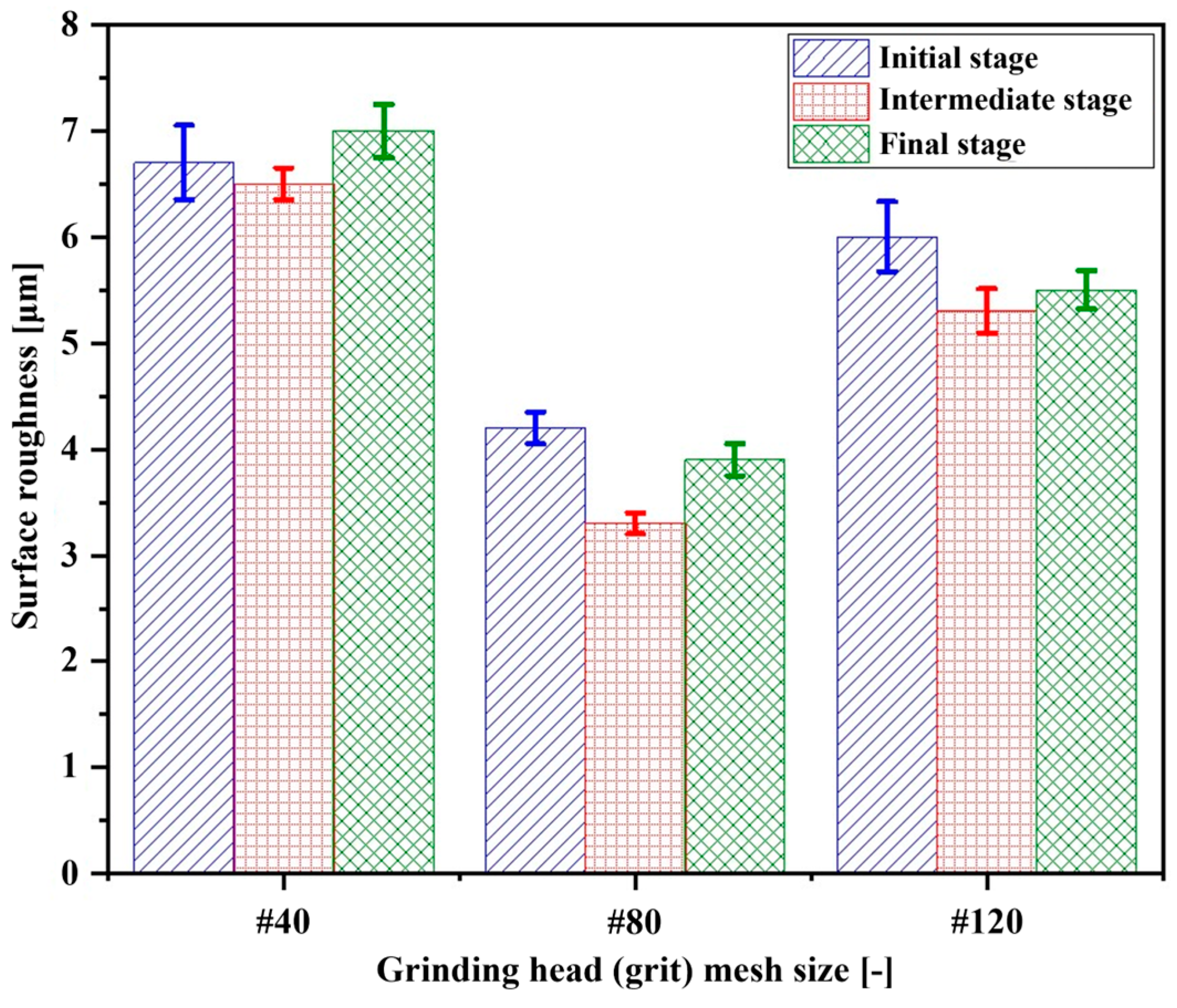

3.1. Relationship Between Speed and Acceleration Vibration Signals

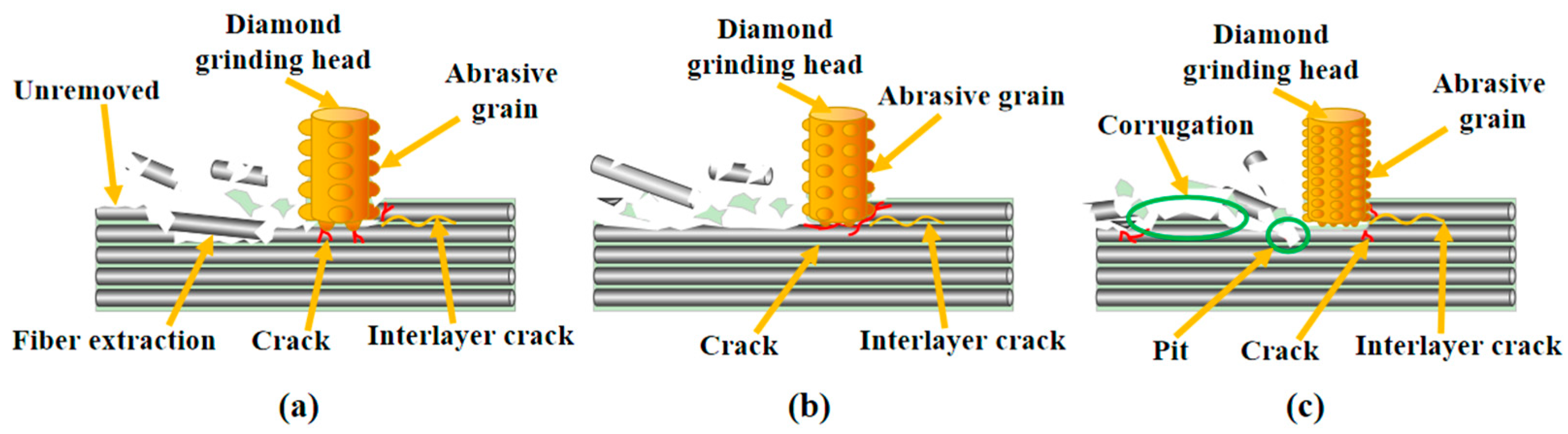

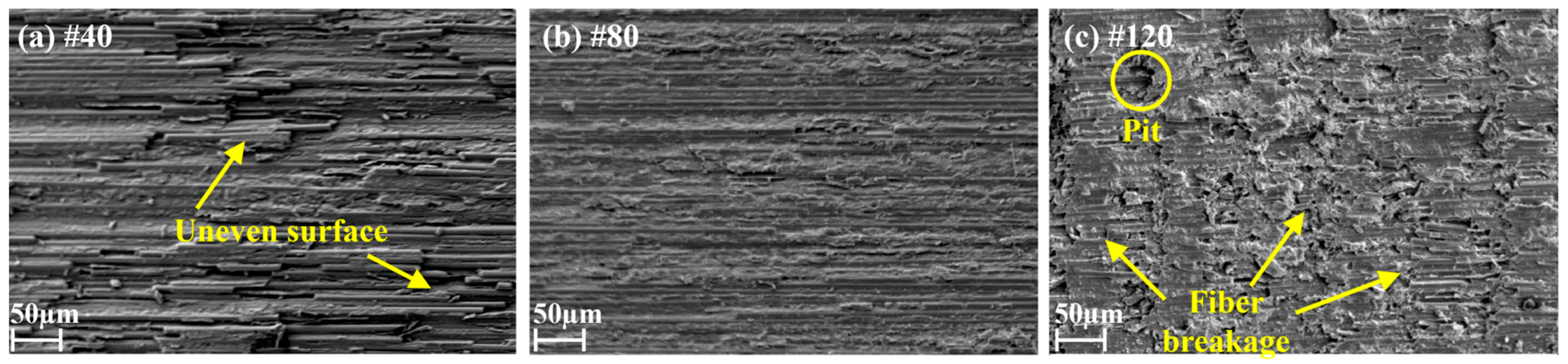

3.2. Relationship Between the Grinding Heads Mesh Size and the Acceleration Vibration Signal

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Lin, T.; Li, L.; Ji, M.; Davim, J.P.; Geier, N.; Chen, M. Numerical Study of Interface Damage Formation Mechanisms in Machining CFRP/Ti6Al4V Stacks under Different Cutting Sequence Strategies. Compos. Struct. 2022, 285, 115236. [Google Scholar] [CrossRef]

- Wang, F.; Qian, B.; Jia, Z.; Fu, R.; Cheng, D. Secondary Cutting Edge Wear of One-Shot Drill Bit in Drilling CFRP and Its Impact on Hole Quality. Compos. Struct. 2017, 178, 341–352. [Google Scholar] [CrossRef]

- Zhang, F.; Lin, Y.; Huang, Y.; Zhang, Z.; Wu, J.; Du, L. Forming Characteristics of Channel-Section CFRP-Aluminum Hybrid Profiles Manufactured by Inflatable Mandrel Assisted Hot-Pressing Process. Compos. Struct. 2022, 296, 115895. [Google Scholar] [CrossRef]

- Mei, J.; Tan, P.J.; Bosi, F.; Zhang, T.; Liu, J.Y.; Wang, B.; Huang, W. Fabrication and Mechanical Characterization of CFRP X-Core Sandwich Panels. Thin-Walled Struct. 2021, 158, 107144. [Google Scholar] [CrossRef]

- Tatsuno, D.; Yoneyama, T.; Kinari, T.; Sakanishi, E.; Ochiai, T.; Taniichi, Y. Braid-Press Forming for Manufacturing Thermoplastic CFRP Tube. Int. J. Mater. Form. 2021, 14, 753–762. [Google Scholar] [CrossRef]

- Li, S.; Huang, S.; Li, H.; Liu, W.; Wu, W.; Liu, J. Multi-Condition Tool Wear Prediction for Milling CFRP Base on a Novel Hybrid Monitoring Method. Meas. Sci. Technol. 2024, 35, 035017. [Google Scholar] [CrossRef]

- Guo, N.; Chen, Y.; Yan, C.; Meng, X.; Li, Y. Machinability of CFRP/Ti6Al4V Stacks with Low-Frequency-Vibration Assisted Drilling under Different Cooling Strategies. J. Manuf. Process. 2023, 108, 852–862. [Google Scholar] [CrossRef]

- Wang, F.; Xuan, S.; Chang, Z.; Jin, K.; Gao, Y.; Wang, H.; Song, Q. Effect of Grinding Parameters on Industrial Robot Grinding of CFRP and Defect Formation Mechanism. Int. J. Precis. Eng. Manuf. Green Technol. 2024, 11, 427–438. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, K.; Li, H.; Cao, Z.; Zhao, S. Multi-Objective Optimization of Process Parameters in Longitudinal-Torsional Ultrasonic Vibration Face Grinding CFRP. Machines 2023, 11, 935. [Google Scholar] [CrossRef]

- Wen, Z.; Zhao, H.; Yan, X.; Peng, Z.; Ding, H. Grinding Performance Study of CF/Epoxy and CF/PEEK Composites. Polym. Compos. 2023, 44, 4565–4578. [Google Scholar] [CrossRef]

- Hu, N.S.; Zhang, L.C. Some Observations in Grinding Unidirectional Carbon Fibre-Reinforced Plastics. J. Mater. Process. Technol. 2004, 152, 333–338. [Google Scholar] [CrossRef]

- Wang, Y.G.; Yan, X.P.; Chen, X.G.; Sun, C.Y.; Liu, G. Cutting Performance of Carbon Fiber Reinforced Plastics Using PCD Tool. Adv. Mater. Res. 2011, 215, 14–18. [Google Scholar] [CrossRef]

- Nomura, M.; Kurashige, S.; Ito, Y.; Fukuhara, Y.; Sasahara, H. Development of Electrodeposited Wire Mesh Grinding Wheel for Cutoff and Grooving Carbon Fiber Reinforced Plastic. Materials 2023, 16, 5247. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Lin, T.; Davim, J.P. On the Machining Temperature and Hole Quality of CFRP Laminates When Using Diamond-Coated Special Drills. J. Compos. Sci. 2022, 6, 45. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, Y.; Chen, B.; Fan, B.; Yan, C.; Fu, Y. Feasibility of Ultrasonic Vibration Assisted Grinding for Carbon Fiber Reinforced Polymer with Monolayer Brazed Grinding Tools. Int. J. Precis. Eng. Manuf. 2019, 20, 1083–1094. [Google Scholar] [CrossRef]

- Soo, S.L.; Shyha, I.S.; Barnett, T.; Aspinwall, D.K.; Sim, W.M. Grinding Performance and Workpiece Integrity When Superabrasive Edge Routing Carbon Fibre Reinforced Plastic (CFRP) Composites. CIRP Ann. Manuf. Technol. 2012, 61, 295–298. [Google Scholar] [CrossRef]

- Wang, H.; Ning, F.; Hu, Y.; Fernando, P.K.S.C.; Pei, Z.J.; Cong, W. Surface Grinding of Carbon Fiber-Reinforced Plastic Composites Using Rotary Ultrasonic Machining: Effects of Tool Variables. Adv. Mech. Eng. 2016, 8, 1–14. [Google Scholar] [CrossRef]

- Yu, T.; Cheng, J.; Gao, C.; Wu, J.; Guo, Z. Modeling and Experimental Study of Different Discontinuous Micro-Grinding Tools. Int. J. Adv. Manuf. Technol. 2020, 107, 4009–4032. [Google Scholar] [CrossRef]

- Cao, S.; Zhang, X.; Wu, C.; Yang, M.; Xia, K. Towards Understanding the Material Removal Mechanism on the Effect of Ultrasonic Vibration and Anisotropy for Unidirectional CFRP by Scratching. J. Mater. Process. Technol. 2024, 324, 118250. [Google Scholar] [CrossRef]

- Yao, L.; Liu, Z.; Song, Q.; Wang, B.; Cai, Y.; Zhao, J. Numerical Prediction of Surface Morphology and Roughness in Rotary Ultrasonic Face Grinding SiO2f/SiO2 Composite. J. Mater. Res. Technol. 2023, 25, 5917–5937. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, S.; Li, Q.; Gao, X.; Ouyang, X.; Luo, Y. Investigation on the Machined Surface Quality and Removal Mechanism of SiCf/SiC Composites in Ultrasonic-Assisted Grinding. Int. J. Adv. Manuf. Technol. 2022, 123, 4427–4445. [Google Scholar] [CrossRef]

- Ji, W.; Wang, L. Industrial Robotic Machining: A Review. Int. J. Adv. Manuf. Technol. 2019, 103, 1239–1255. [Google Scholar] [CrossRef]

- Makulavičius, M.; Petkevičius, S.; Rožėnė, J.; Dzedzickis, A.; Bučinskas, V. Industrial Robots in Mechanical Machining: Perspectives and Limitations. Robotics 2023, 12, 160. [Google Scholar] [CrossRef]

- Cen, L.; Melkote, S.N. Effect of Robot Dynamics on the Machining Forces in Robotic Milling. Procedia Manuf. 2017, 10, 486–496. [Google Scholar] [CrossRef]

| Characteristic | Value |

|---|---|

| Fiber content [vol. %] | 54% |

| Matrix polymer | Thermoset epoxy resin |

| Prepreg fiber angle | 0°/90° |

| Tensile moduli E11, E22 [GPa] | 128, 8.7 |

| Shear modulus G12 [GPa] | 4.74 |

| Tensile strengths σ11, σ22 [MPa] | 2000, 61 |

| Shear strength τ12 [MPa] | 70 |

| Parameter | Levels |

|---|---|

| Rotational speed [rpm] | 2000, 3000, 4000 |

| Peripheral speed [m/min] | 62.8, 94.2, 125.7 |

| Grinding head mesh size | #40, #80, #120 |

| Feed speed [mm/s] | 4 |

| Grinding depth [mm] | 1 |

| Grinding width [mm] | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Song, Z.; Zhang, X.; Wang, F.; Song, P.; Jin, K.; Lee, T.; Quagliato, L. Influence of Grinding Tool Mesh Size and Rotational Speed on Post-Machining Quality of CFRP Laminates by Acceleration Signal and Surface Roughness Analyses. J. Compos. Sci. 2024, 8, 543. https://doi.org/10.3390/jcs8120543

Li L, Song Z, Zhang X, Wang F, Song P, Jin K, Lee T, Quagliato L. Influence of Grinding Tool Mesh Size and Rotational Speed on Post-Machining Quality of CFRP Laminates by Acceleration Signal and Surface Roughness Analyses. Journal of Composites Science. 2024; 8(12):543. https://doi.org/10.3390/jcs8120543

Chicago/Turabian StyleLi, Lichen, Ziyuan Song, Xinxin Zhang, Fangyuan Wang, Pengda Song, Kai Jin, Taeyong Lee, and Luca Quagliato. 2024. "Influence of Grinding Tool Mesh Size and Rotational Speed on Post-Machining Quality of CFRP Laminates by Acceleration Signal and Surface Roughness Analyses" Journal of Composites Science 8, no. 12: 543. https://doi.org/10.3390/jcs8120543

APA StyleLi, L., Song, Z., Zhang, X., Wang, F., Song, P., Jin, K., Lee, T., & Quagliato, L. (2024). Influence of Grinding Tool Mesh Size and Rotational Speed on Post-Machining Quality of CFRP Laminates by Acceleration Signal and Surface Roughness Analyses. Journal of Composites Science, 8(12), 543. https://doi.org/10.3390/jcs8120543