Composite Materials Based on Spent Coffee Grounds and Paper Pulp

Abstract

1. Introduction

2. Materials and Methods

2.1. Method for Producing Composite Materials

2.2. Techniques for Characterizing Composite Materials

3. Results

3.1. Obtaining Composite Materials

3.2. Characterization of the Obtained Composite Materials

3.2.1. Thermal Analysis (TG, DTG, and DTA)

3.2.2. Morphological Characterization (SEM and EDX)

3.2.3. Characterization by ATR-FTIR Spectrometry

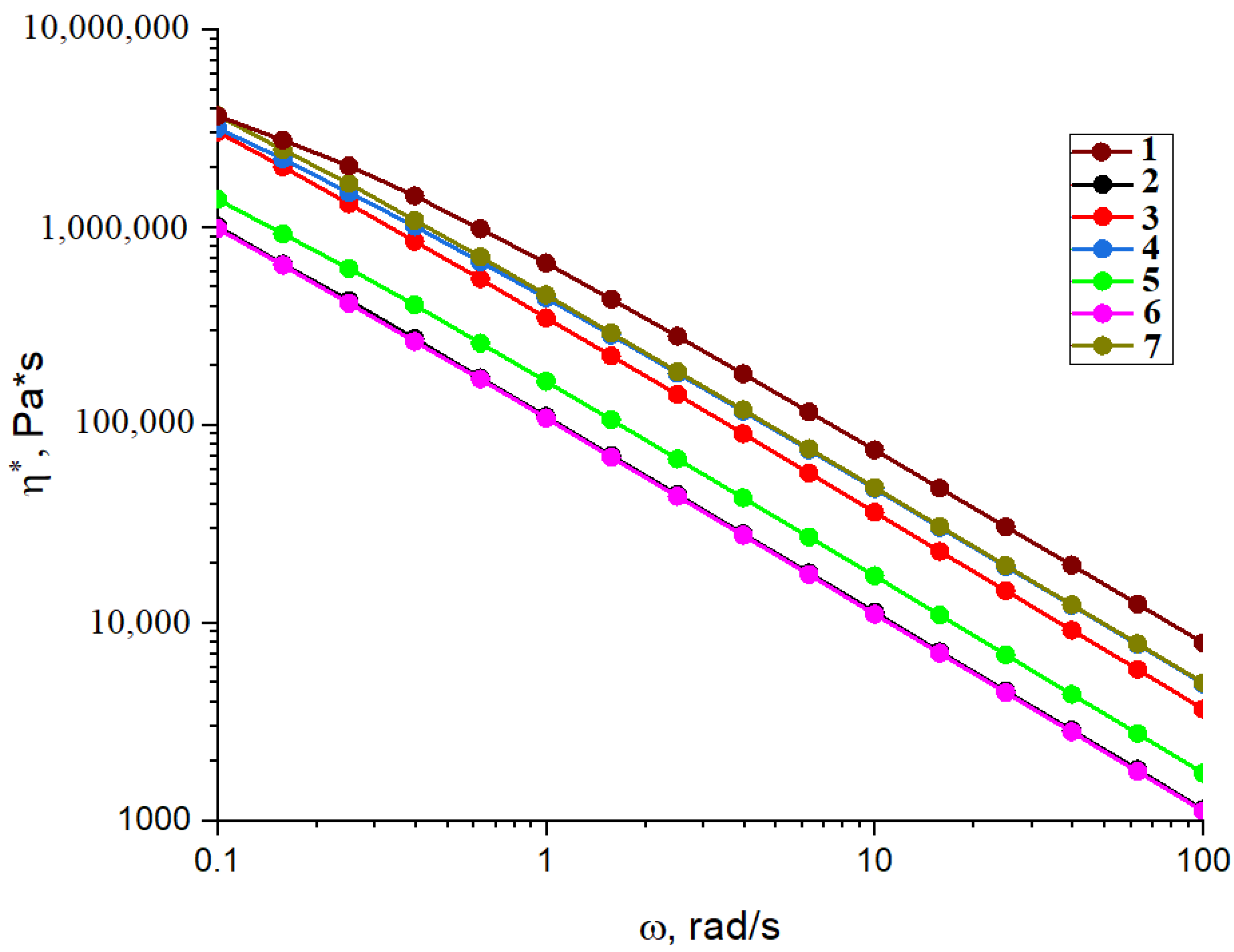

3.2.4. Rheological Characterization

3.3. Challenges and Opportunities

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Coffee Report and Outlook; International Coffee Organization (ICO): London, UK, 2023; pp. 1–39.

- BEYOND COFFEE. Towards a Circular Coffee Economy; International Coffee Organization (ICO): London, UK, 2023.

- Yang, W.; Chang, W.; Zhang, J.; Yeoh, G.H.; Boyer, C.; Wang, C.H. Effects of waste coffee grounds on the mechanical properties, flame retardancy and toxic gas production of epoxy composites. Mater. Des. 2022, 224, 111347. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Loarca-Piña, G.; Vergara-Castañeda, H.A.; Oomah, B.D. Spent coffee grounds: A review on current research and future prospects. Trends Food Sci. Technol. 2015, 45, 24–36. [Google Scholar] [CrossRef]

- Jin Cho, E.; Gyo Lee, Y.; Song, Y.; Nguyen, D.-T.; Bae, H.-J. An integrated process for conversion of spent coffee grounds into value-added materials. Bioresour. Technol. 2022, 346, 126618. [Google Scholar] [CrossRef] [PubMed]

- Pacioni, T.R.; Soares, D.; Di Domenico, M.; Rosa, M.F.; Moreira, R.D.F.P.M.; José, H.J. Bio-syngas production from agro-industrial biomass residues by steam gasification. Waste Manag. 2016, 58, 221–229. [Google Scholar] [CrossRef]

- Kourmentza, C.; Economou, C.N.; Tsafrakidou, P.; Kornaros, M. Spent coffee grounds make much more than waste: Exploring recent advances and future exploitation strategies for the valorization of an emerging food waste stream. J. Clean. Prod. 2018, 172, 980–992. [Google Scholar] [CrossRef]

- Jang, H.; Ocon, J.D.; Lee, S.; Lee, J.K.; Lee, J. Direct power generation from waste coffee grounds in a biomass fuel cell. J. Power Sources 2015, 296, 433–439. [Google Scholar] [CrossRef]

- Al-Hamamre, Z.; Foerster, S.; Hartmann, F.; Kröger, M.; Kaltschmitt, M. Oil extracted from spent coffee grounds as a renewable source for fatty acid methyl ester manufacturing. Fuel 2012, 96, 70–76. [Google Scholar] [CrossRef]

- Caetano, N.S.; Caldeira, D.; Martins, A.A.; Mata, T.M. Valorisation of Spent Coffee Grounds: Production of Biodiesel via Enzymatic Catalysis with Ethanol and a Co-solvent. Waste Biomass Valorization 2017, 8, 1981–1994. [Google Scholar] [CrossRef]

- Kondamudi, N.; Mohapatra, S.K.; Misra, M. Spent Coffee Grounds as a Versatile Source of Green Energy. J. Agric. Food Chem. 2008, 56, 11757–11760. [Google Scholar] [CrossRef]

- Park, J.; Kim, B.; Lee, J.W. In-situ transesterification of wet spent coffee grounds for sustainable biodiesel production. Bioresour. Technol. 2016, 221, 55–60. [Google Scholar] [CrossRef]

- Vardon, D.R.; Moser, B.R.; Zheng, W.; Witkin, K.; Evangelista, R.L.; Strathmann, T.J.; Rajagopalan, K.; Sharma, B.K. Complete Utilization of Spent Coffee Grounds To Produce Biodiesel, Bio-Oil, and Biochar. ACS Sustain. Chem. Eng. 2013, 1, 1286–1294. [Google Scholar] [CrossRef]

- Wei, F.; Furihata, K.; Koda, M.; Hu, F.; Miyakawa, T.; Tanokura, M. Roasting Process of Coffee Beans as Studied by Nuclear Magnetic Resonance: Time Course of Changes in Composition. J. Agric. Food Chem. 2012, 60, 1005–1012. [Google Scholar] [CrossRef] [PubMed]

- Castro, C.S.; Abreu, A.L.; Silva, C.L.T.; Guerreiro, M.C. Phenol adsorption by activated carbon produced from spent coffee grounds. Water Sci. Technol. 2011, 64, 2059–2065. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.-S.; Min, H.-G.; Koo, N.; Park, J.; Lee, S.-H.; Bak, G.-I.; Kim, J.-G. The effectiveness of spent coffee grounds and its biochar on the amelioration of heavy metals-contaminated water and soil using chemical and biological assessments. J. Environ. Manag. 2014, 146, 124–130. [Google Scholar] [CrossRef]

- Kyzas, G.Z. Commercial Coffee Wastes as Materials for Adsorption of Heavy Metals from Aqueous Solutions. Materials 2012, 5, 1826–1840. [Google Scholar] [CrossRef]

- Dávila-Guzmán, N.E.; de Jesús Cerino-Córdova, F.; Soto-Regalado, E.; Rangel-Mendez, J.R.; Díaz-Flores, P.E.; Garza-Gonzalez, M.T.; Loredo-Medrano, J.A. Copper Biosorption by Spent Coffee Ground: Equilibrium, Kinetics, and Mechanism. CLEAN Soil Air Water 2013, 41, 557–564. [Google Scholar] [CrossRef]

- Davila-Guzman, N.E.; Cerino-Córdova, F.J.; Loredo-Cancino, M.; Rangel-Mendez, J.R.; Gómez-González, R.; Soto-Regalado, E. Studies of Adsorption of Heavy Metals onto Spent Coffee Ground: Equilibrium, Regeneration, and Dynamic Performance in a Fixed-Bed Column. Int. J. Chem. Eng. 2016, 2016, 9413879. [Google Scholar] [CrossRef]

- Mantonanaki, A.; Pellera, F.M.; Gidarakos, E. Use of biochar generated from spent coffee grounds for the removal of Zn (II) from aqueous solutions. In Proceedings of the International Conference on Environmental Science and Technology, Rhodes, Greece, 3–5 September 2015; pp. 3–5. [Google Scholar]

- Aouay, F.; Attia, A.; Dammak, L.; Ben Amar, R.; Deratani, A. Activated Carbon Prepared from Waste Coffee Grounds: Characterization and Adsorption Properties of Dyes. Materials 2024, 17, 3078. [Google Scholar] [CrossRef]

- Oliveira, G.A.; Gevaerd, A.; Mangrich, A.S.; Marcolino-Junior, L.H.; Bergamini, M.F. Biochar obtained from spent coffee grounds: Evaluation of adsorption properties and its application in a voltammetric sensor for lead (II) ions. Microchem. J. 2021, 165, 106114. [Google Scholar] [CrossRef]

- Jeníček, L.; Tunklová, B.; Malaťák, J.; Neškudla, M.; Velebil, J. Use of Spent Coffee Ground as an Alternative Fuel and Possible Soil Amendment. Materials 2022, 15, 6722. [Google Scholar] [CrossRef]

- Zungu, V.; Hadebe, L.; Mpungose, P.; Hamza, I.; Amaku, J.; Gumbi, B. Fabrication of Biochar Materials from Biowaste Coffee Grounds and Assessment of Its Adsorbent Efficiency for Remediation of Water-Soluble Pharmaceuticals. Sustainability 2022, 14, 2931. [Google Scholar] [CrossRef]

- de Souza, L.Z.M.; Pinto, B.C.; Alves, A.B.; de Oliveira Ribeiro, A.V.; Teodoro Feliciano, D.C.; da Silva, L.H.; Moraes Dias, T.T.; Yılmaz, M.; de Oliveira, M.A.; da Silva Bezerra, A.C.; et al. Ecotoxicological Effects of Biochar Obtained from Spent Coffee Grounds. Mater. Res. 2022, 25, e20220013. [Google Scholar] [CrossRef]

- Andrade, T.S.; Vakros, J.; Mantzavinos, D.; Lianos, P. Biochar obtained by carbonization of spent coffee grounds and its application in the construction of an energy storage device. Chem. Eng. J. Adv. 2020, 4, 100061. [Google Scholar] [CrossRef]

- Liu, S.-H.; Huang, Y.-Y. Valorization of coffee grounds to biochar-derived adsorbents for CO2 adsorption. J. Clean. Prod. 2018, 175, 354–360. [Google Scholar] [CrossRef]

- Stylianou, M.; Christou, A.; Dalias, P.; Polycarpou, P.; Michael, C.; Agapiou, A.; Papanastasiou, P.; Fatta-Kassinos, D. Physicochemical and structural characterization of biochar derived from the pyrolysis of biosolids, cattle manure and spent coffee grounds. J. Energy Inst. 2020, 93, 2063–2073. [Google Scholar] [CrossRef]

- Shin, J.; Lee, S.-H.; Kim, S.; Ochir, D.; Park, Y.; Kim, J.; Lee, Y.-G.; Chon, K. Effects of physicochemical properties of biochar derived from spent coffee grounds and commercial activated carbon on adsorption behavior and mechanisms of strontium ions (Sr2+). Environ. Sci. Pollut. Res. 2021, 28, 40623–40632. [Google Scholar] [CrossRef]

- Venkatesan, S.; Baloch, H.A.; Jamro, I.A.; Rafique, N. Evaluation of the production of hydrochar from spent coffee grounds under different operating conditions. J. Water Process Eng. 2022, 49, 103037. [Google Scholar] [CrossRef]

- Cervera-Mata, A.; Lara, L.; Fernández-Arteaga, A.; Ángel Rufián-Henares, J.; Delgado, G. Washed hydrochar from spent coffee grounds: A second generation of coffee residues. Evaluation as organic amendment. Waste Manag. 2021, 120, 322–329. [Google Scholar] [CrossRef]

- Hu, Y.; Gallant, R.; Salaudeen, S.; Farooque, A.A.; He, S. Hydrothermal Carbonization of Spent Coffee Grounds for Producing Solid Fuel. Sustainability 2022, 14, 8818. [Google Scholar] [CrossRef]

- Tang, J.; Chen, Y.; He, L.; Li, Y.; Li, H.; Sun, F.; Liu, Y. Effect of hydrochar from sludge mixed with coffee grounds on the immobilization of Cu, Cr and Ni in soil. Environ. Technol. 2024, 1–13. [Google Scholar] [CrossRef]

- Dang, C.H.; Farru, G.; Glaser, C.; Fischer, M.G.; Libra, J.A. Enhancing the Fuel Properties of Spent Coffee Grounds through Hydrothermal Carbonization: Output Prediction and Post-Treatment Approaches. Sustainability 2024, 16, 338. [Google Scholar] [CrossRef]

- Mukherjee, A.; Saha, B.; Niu, C.; Dalai, A.K. Preparation of activated carbon from spent coffee grounds and functionalization by deep eutectic solvent: Effect of textural properties and surface chemistry on CO2 capture performance. J. Environ. Chem. Eng. 2022, 10, 108815. [Google Scholar] [CrossRef]

- Figueroa Campos, G.A.; Perez, J.P.H.; Block, I.; Sagu, S.T.; Saravia Celis, P.; Taubert, A.; Rawel, H.M. Preparation of Activated Carbons from Spent Coffee Grounds and Coffee Parchment and Assessment of Their Adsorbent Efficiency. Processes 2021, 9, 1396. [Google Scholar] [CrossRef]

- Biegun, M.; Dymerska, A.; Chen, X.; Mijowska, E. Study of the Active Carbon from Used Coffee Grounds as the Active Material for a High-Temperature Stable Supercapacitor with Ionic-Liquid Electrolyte. Materials 2020, 13, 3919. [Google Scholar] [CrossRef]

- Kusuma, J.; Indartono, Y.S.; Mujahidin, D. Biodiesel and activated carbon from arabica spent coffee grounds. MethodsX 2023, 10, 102185. [Google Scholar] [CrossRef]

- Ren, J.; Chen, N.; Wan, L.; Li, G.; Chen, T.; Yang, F.; Sun, S. Preparation of High-Performance Activated Carbon from Coffee Grounds after Extraction of Bio-Oil. Molecules 2021, 26, 257. [Google Scholar] [CrossRef]

- Bartczak, P.; Stachowiak, J.; Szmitko, M.; Grząbka-Zasadzińska, A.; Borysiak, S. Multifunctional Polyurethane Composites with Coffee Grounds and Wood Sawdust. Materials 2023, 16, 278. [Google Scholar] [CrossRef]

- Yoo, J.; Chang, S.J.; Wi, S.; Kim, S. Spent coffee grounds as supporting materials to produce bio-composite PCM with natural waxes. Chemosphere 2019, 235, 626–635. [Google Scholar] [CrossRef]

- Leow, Y.; Yew, P.Y.M.; Chee, P.L.; Loh, X.J.; Kai, D. Recycling of spent coffee grounds for useful extracts and green composites. RSC Adv. 2021, 11, 2682–2692. [Google Scholar] [CrossRef]

- Yu, W.; Yuan, T.; Yao, Y.; Deng, Y.; Wang, X. PLA/Coffee Grounds Composite for 3D Printing and Its Properties. Forests 2023, 14, 367. [Google Scholar] [CrossRef]

- Masssijaya, S.Y.; Lubis, M.A.R.; Nissa, R.C.; Nurhamiyah, Y.; Nugroho, P.; Antov, P.; Lee, S.-H.; Papadopoulos, A.N.; Kusumah, S.S.; Karlinasari, L. Utilization of Spent Coffee Grounds as a Sustainable Resource for the Synthesis of Bioplastic Composites with Polylactic Acid, Starch, and Sucrose. J. Compos. Sci. 2023, 7, 512. [Google Scholar] [CrossRef]

- Hunsub, P.; Ngamprasertsith, S.; Prichapan, N.; Sakdasri, W.; Karnchanatat, A.; Sawangkeaw, R. Production of Protein Hydrolysates from Spent Coffee Grounds via Microwave, Enzymatic, and Subcritical Water Extractions and Their Combination. Biol. Life Sci. Forum 2023, 26, 43. [Google Scholar] [CrossRef]

- Burniol-Figols, A.; Cenian, K.; Skiadas, I.V.; Gavala, H.N. Integration of chlorogenic acid recovery and bioethanol production from spent coffee grounds. Biochem. Eng. J. 2016, 116, 54–64. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Carneiro, L.M.; Teixeira, J.A. Sugars metabolism and ethanol production by different yeast strains from coffee industry wastes hydrolysates. Appl. Energy 2012, 92, 763–768. [Google Scholar] [CrossRef]

- Cruz, M.V.; Paiva, A.; Lisboa, P.; Freitas, F.; Alves, V.D.; Simões, P.; Barreiros, S.; Reis, M.A.M. Production of polyhydroxyalkanoates from spent coffee grounds oil obtained by supercritical fluid extraction technology. Bioresour. Technol. 2014, 157, 360–363. [Google Scholar] [CrossRef] [PubMed]

- Battista, F.; Fino, D.; Mancini, G. Optimization of biogas production from coffee production waste. Bioresour. Technol. 2016, 200, 884–890. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.; Baek, G.; Lee, C. Anaerobic co-digestion of spent coffee grounds with different waste feedstocks for biogas production. Waste Manag. 2017, 60, 322–328. [Google Scholar] [CrossRef]

- Valero, D.; Montes, J.A.; Rico, J.L.; Rico, C. Influence of headspace pressure on methane production in Biochemical Methane Potential (BMP) tests. Waste Manag. 2016, 48, 193–198. [Google Scholar] [CrossRef]

- Qiao, W.; Takayanagi, K.; Shofie, M.; Niu, Q.; Yu, H.Q.; Li, Y.-Y. Thermophilic anaerobic digestion of coffee grounds with and without waste activated sludge as co-substrate using a submerged AnMBR: System amendments and membrane performance. Bioresour. Technol. 2013, 150, 249–258. [Google Scholar] [CrossRef]

- Vítěz, T.; Koutný, T.; Šotnar, M.; Chovanec, J. On the spent coffee grounds biogas production. Acta Univ. Agric. Silvic. Mendel. Brun. 2016, 64, 1279–1282. [Google Scholar] [CrossRef]

- Neves, L.; Oliveira, R.; Alves, M.M. Anaerobic co-digestion of coffee waste and sewage sludge. Waste Manag. 2006, 26, 176–181. [Google Scholar] [CrossRef] [PubMed]

- Abouelenien, F.; Namba, Y.; Kosseva, M.R.; Nishio, N.; Nakashimada, Y. Enhancement of methane production from co-digestion of chicken manure with agricultural wastes. Bioresour. Technol. 2014, 159, 80–87. [Google Scholar] [CrossRef]

- Nguyen, T.A.; Oanh, D.T.Y.; Ngo, T.V.; Nguyen, T.H.; Nguyen, T.T.P.; Bui, T.T.T.; Dam, X.T.; Nguyen, K.A.; Nguyen, M.V.; Nguyen, Q.T. Transforming environmental sustainability: Lime-treated used coffee grounds for innovative eco-friendly epoxy composite materials. Vietnam J. Chem. 2024, 1, 1–15. [Google Scholar] [CrossRef]

- de Bomfim, A.S.C.; de Oliveira, D.M.; Voorwald, H.J.C.; de Carvalho Benini, K.C.C.; Dumont, M.-J.; Rodrigue, D. Valorization of Spent Coffee Grounds as Precursors for Biopolymers and Composite Production. Polymers 2022, 14, 437. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, M.; Bairwan, R.D.; Rizg, W.Y.; Khalil, H.P.S.A.; Murshid, S.S.A.; Sindi, A.M.; Alissa, M.; Saharudin, N.I.; Abdullah, C.K. Enhancement of spent coffee grounds as biofiller in biodegradable polymer composite for sustainable packaging. Polym. Compos. 2024, 45, 9317–9334. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable biodegradable coffee grounds filler and its effect on the hydrophobicity, mechanical and thermal properties of biodegradable PBAT composites. J. Appl. Polym. Sci. 2017, 134, 44498. [Google Scholar] [CrossRef]

- Cataldo, V.A.; Cavallaro, G.; Lazzara, G.; Milioto, S.; Parisi, F. Coffee grounds as filler for pectin: Green composites with competitive performances dependent on the UV irradiation. Carbohydr. Polym. 2017, 170, 198–205. [Google Scholar] [CrossRef]

- Lee, H.K.; Park, Y.G.; Jeong, T.; Song, Y.S. Green nanocomposites filled with spent coffee grounds. J. Appl. Polym. Sci. 2015, 132, 2–7. [Google Scholar] [CrossRef]

- de Bomfim, A.S.C.; de Oliveira, D.M.; de Carvalho Benini, K.C.C.; Cioffi, M.O.H.; Voorwald, H.J.C.; Rodrigue, D. Effect of Spent Coffee Grounds on the Crystallinity and Viscoelastic Behavior of Polylactic Acid Composites. Polymers 2023, 15, 2719. [Google Scholar] [CrossRef]

- Jaramillo, L.Y.; Vásquez-Rendón, M.; Upegui, S.; Posada, J.C.; Romero-Sáez, M. Polyethylene-coffee husk eco-composites for production of value-added consumer products. Sustain. Environ. Res. 2021, 31, 34. [Google Scholar] [CrossRef]

- Haile, A.; Gelebo, G.G.; Tesfaye, T.; Mengie, W.; Mebrate, M.A.; Abuhay, A.; Limeneh, D.Y. Pulp and paper mill wastes: Utilizations and prospects for high value-added biomaterials. Bioresour. Bioprocess. 2021, 8, 35. [Google Scholar] [CrossRef] [PubMed]

- Semple, K.E.; Zhou, C.; Rojas, O.J.; Nkeuwa, W.N.; Dai, C. Moulded pulp fibers for disposable food packaging: A state-of-the-art review. Food Packag. Shelf Life 2022, 33, 100908. [Google Scholar] [CrossRef]

- Singh, A.K.; Itkor, P.; Lee, M.; Shin, J.; Lee, Y.S. Promoting sustainable packaging applications in the circular economy by exploring and advancing molded pulp materials for food products: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 11010–11025. [Google Scholar] [CrossRef] [PubMed]

- Tomadoni, B.; Merino, D.; Alvarez, V.A. Biodegradable Materials for Planting Pots. Adv. Appl. Bio Degrad. Green Compos. 2020, 68, 85–103. [Google Scholar] [CrossRef]

- Debnath, M.; Sarder, R.; Pal, L.; Hubbe, M. Molded pulp packaging review. Bioresources 2022, 17, 3810–3870. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, C.; Bokka, S.K.; He, Z.; Ni, Y. Molded fiber and pulp products as green and sustainable alternatives to plastics: A mini review. J. Bioresour. Bioprod. 2022, 7, 14–25. [Google Scholar] [CrossRef]

- Didone, M.; Saxena, P.; Brilhuis-Meijer, E.; Tosello, G.; Bissacco, G.; Mcaloone, T.C.; Pigosso, D.C.A.; Howard, T.J. Moulded Pulp Manufacturing: Overview and Prospects for the Process Technology. Packag. Technol. Sci. 2017, 30, 231–249. [Google Scholar] [CrossRef]

- Döhler, N.; Wellenreuther, C.; Wolf, A. Market dynamics of biodegradable bio-based plastics: Projections and linkages to European policies. EFB Bioecon. J. 2022, 2, 100028. [Google Scholar] [CrossRef]

- Baek, B.S.; Park, J.W.; Lee, B.H.; Kim, H.J. Development and Application of Green Composites: Using Coffee Ground and Bamboo Flour. J. Polym. Environ. 2013, 21, 702–709. [Google Scholar] [CrossRef]

- Chaplin, M.F. Fibre and water binding. Proc. Nutr. Soc. 2003, 62, 223–227. [Google Scholar] [CrossRef]

- Bejenari, V.; Marcu, A.; Ipate, A.-M.; Rusu, D.; Tudorachi, N.; Anghel, I.; Şofran, I.-E.; Lisa, G. Physicochemical characterization and energy recovery of spent coffee grounds. J. Mater. Res. Technol. 2021, 15, 4437–4451. [Google Scholar] [CrossRef]

- Bejenari, V.; Lisa, C.; Cernătescu, C.; Mămăligă, I.; Lisa, G. Isothermal Drying Kinetic Study of Spent Coffee Grounds Using Thermogravimetric Analysis. Int. J. Chem. Eng. 2022, 2022, 2312147. [Google Scholar] [CrossRef]

- Lengowski, E.C.; de Muñiz, G.I.B.; de Andrade, A.S.; Simon, L.C.; Nisgoski, S. Morphological, physical and thermal characterization of microfibrillated cellulose. Rev. Árvore 2018, 42, e420113. [Google Scholar] [CrossRef]

- Shawky Sol, A.; Sakran She, M.; Ahmad, F.; Abdel-Atty, M. Evaluation of Paper Pulp and Paper Making Characteristics Produced from Different African Woody Trees Grown in Egypt. Res. J. For. 2017, 11, 19–27. [Google Scholar] [CrossRef][Green Version]

- Małachowska, E.; Dubowik, M.; Lipkiewicz, A.; Przybysz, K.; Przybysz, P. Analysis of Cellulose Pulp Characteristics and Processing Parameters for Efficient Paper Production. Sustainability 2020, 12, 7219. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Özmeral, N.; Işık, M.; Sogancioglu Kalem, M.; Ahmetli, G. Lignocellulose coffee waste-based epoxy composites: Effect of various treatment methods on composite properties. Cellulose 2023, 30, 3589–3609. [Google Scholar] [CrossRef]

- Dang, C.-H.; Nguyen, T.-D. Physicochemical Characterization of Robusta Spent Coffee Ground Oil for Biodiesel Manufacturing. Waste Biomass Valorization 2019, 10, 2703–2712. [Google Scholar] [CrossRef]

- Fermoso, J.; Mašek, O. Thermochemical decomposition of coffee ground residues by TG-MS: A kinetic study. J. Anal. Appl. Pyrolysis 2018, 130, 358–367. [Google Scholar] [CrossRef]

- Chinga-Carrasco, G.; Miettinen, A.; Luengo Hendriks, C.L.; Kristofer, E.; Kataj, M. Structural Characterisation of Kraft Pulp Fibres and Their Nanofibrillated Materials for Biodegradable Composite Applications. In Nanocomposites and Polymers with Analytical Methods; BoD—Books on Demand: Norderstedt, Germany, 2011. [Google Scholar] [CrossRef]

- Safarik, I.; Horska, K.; Svobodova, B.; Safarikova, M. Magnetically modified spent coffee grounds for dyes removal. Eur. Food Res. Technol. 2012, 234, 345–350. [Google Scholar] [CrossRef]

- Le, V.T.; Pham, T.M.; Doan, V.D.; Lebedeva, O.E.; Nguyen, H.T. Removal of Pb(ii) ions from aqueous solution using a novel composite adsorbent of Fe3o4/PVA/spent coffee grounds. Sep. Sci. Technol. 2019, 54, 3070–3081. [Google Scholar] [CrossRef]

- Hanafiah, S.F.M.; Danial, W.H.; Samah, M.A.A.; Samad, W.Z.; Susanti, D.; Salim, R.M.; Majid, Z.A. Extraction and characterization of microfibrillated and nanofibrillated cellulose from office paper waste. Malays. J. Anal. Sci. 2019, 23, 901–913. [Google Scholar] [CrossRef]

- Cervera-Mata, A.; Pastoriza, S.; Rufián-Henares, J.Á.; Párraga, J.; Martín-García, J.M.; Delgado, G. Impact of spent coffee grounds as organic amendment on soil fertility and lettuce growth in two Mediterranean agricultural soils. Arch. Agron. Soil Sci. 2018, 64, 790–804. [Google Scholar] [CrossRef]

- Ronga, D.; Parisi, M.; Barbieri, L.; Lancellotti, I.; Andreola, F.; Bignami, C. Valorization of Spent Coffee Grounds, Biochar and other residues to Produce Lightweight Clay Ceramic Aggregates Suitable for Nursery Grapevine Production. Horticulturae 2020, 6, 58. [Google Scholar] [CrossRef]

- Andreola, F.; Borghi, A.; Pedrazzi, S.; Allesina, G.; Tartarini, P.; Lancellotti, I.; Barbieri, L. Spent Coffee Grounds in the Production of Lightweight Clay Ceramic Aggregates in View of Urban and Agricultural Sustainable Development. Materials 2019, 12, 3581. [Google Scholar] [CrossRef]

- Hospodarova, V.; Singovszka, E.; Stevulova, N. Characterization of Cellulosic Fibers by FTIR Spectroscopy for Their Further Implementation to Building Materials. Am. J. Anal. Chem. 2018, 09, 303–310. [Google Scholar] [CrossRef]

- Savy, D.; Mazzei, P.; Roque, R.; Nuzzo, A.; Bowra, S.; Santos, R. Structural recognition of lignin isolated from bioenergy crops by subcritical water: Ethanol extraction. Fuel Process. Technol. 2015, 138, 637–644. [Google Scholar] [CrossRef]

- Olsson, A.-M.; Salmén, L. The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr. Res. 2004, 339, 813–818. [Google Scholar] [CrossRef]

- Kesari, K.K.; Leppänen, M.; Ceccherini, S.; Seitsonen, J.; Väisänen, S.; Altgen, M.; Johansson, L.-S.; Maloney, T.; Ruokolainen, J.; Vuorinen, T. Chemical characterization and ultrastructure study of pulp fibers. Mater. Today Chem. 2020, 17, 100324. [Google Scholar] [CrossRef]

- Pimentel, G.C.; Sederholm, C.H. Correlation of Infrared Stretching Frequencies and Hydrogen Bond Distances in Crystals. J. Chem. Phys. 1956, 24, 639–641. [Google Scholar] [CrossRef]

- Struszczyk, H. Modification of Lignins. III. Reaction of Lignosulfonates with Chlorophosphazenes. J. Macromol. Sci. Part A Chem. 1986, 23, 973–992. [Google Scholar] [CrossRef]

- Sdrobiş, A.; Cazacu, G.; Totolin, M.; Sdrobi, A. Alkaline solution swelling of fatty acids-modified softwood kraft pulp fibers. Cellul. Chem. Technol. 2011, 45, 329–338. [Google Scholar]

- List, R.; Gonzalez-Lopez, L.; Ashfaq, A.; Zaouak, A.; Driscoll, M.; Al-Sheikhly, M. On the Mechanism of the Ionizing Radiation-Induced Degradation and Recycling of Cellulose. Polymers 2023, 15, 4483. [Google Scholar] [CrossRef]

- Reis, N.; Franca, A.S.; Oliveira, L.S. Performance of diffuse reflectance infrared Fourier transform spectroscopy and chemometrics for detection of multiple adulterants in roasted and ground coffee. LWT—Food Sci. Technol. 2013, 53, 395–401. [Google Scholar] [CrossRef]

- Auguścik-Królikowska, M.; Ryszkowska, J.; Ambroziak, A.; Szczepkowski, L.; Oliwa, R.; Oleksy, M. The structure and properties of viscoelastic polyurethane foams with fillers from coffee grounds. Polimery 2020, 65, 708–718. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of waste and coproducts from the coffee industry for composite material production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef]

- Ramos-Andrés, M.; Andrés-Iglesias, C.; García-Serna, J. Production of molecular weight fractionated hemicelluloses hydrolyzates from spent coffee grounds combining hydrothermal extraction and a multistep ultrafiltration/diafiltration. Bioresour. Technol. 2019, 292, 121940. [Google Scholar] [CrossRef]

- Gafiţanu, C.A.; Filip, D.; Cernătescu, C.; Ibănescu, C.; Danu, M.; Pâslaru, E.; Rusu, D.; Tuchiluş, C.G.; Macocinschi, D. Formulation and evaluation of anise-based bioadhesive vaginal gels. Biomed. Pharmacother. 2016, 83, 485–495. [Google Scholar] [CrossRef] [PubMed]

- Arrigo, R.; Jagdale, P.; Bartoli, M.; Tagliaferro, A.; Malucelli, G. Structure–Property Relationships in Polyethylene-Based Composites Filled with Biochar Derived from Waste Coffee Grounds. Polymers 2019, 11, 1336. [Google Scholar] [CrossRef]

- Wang, Q.; Xiao, S.; Shi, S.Q. The effect of hemicellulose content on mechanical strength, thermal stability, and water resistance of cellulose-rich fiber material from poplar. BioResources 2019, 14, 5288–5300. [Google Scholar] [CrossRef]

- Zhang, N.; Li, S.; Xiong, L.; Hong, Y.; Chen, Y. Cellulose-hemicellulose interaction in wood secondary cell-wall. Model. Simul. Mater. Sci. Eng. 2015, 23, 85010. [Google Scholar] [CrossRef]

- Culețu, A.; Mohan, G.; Duță, D.E. Rheological Characterization of the Dough with Added Dietary Fiber by Rheometer: A Review. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca. Food Sci. Technol. 2020, 77, 13–24. [Google Scholar] [CrossRef]

- Boughanmi, O.; Allegue, L.; Marouani, H.; Koubaa, A. Experimental Investigations of the Influence of Spent Coffee Grounds Content on PLA Based Composite for 3D Printing. Polym. Eng. Sci. 2024, 64, 226–233. [Google Scholar] [CrossRef]

- Boughanmi, O.; Allegue, L.; Marouani, H.; Koubaa, A.; Fouad, Y. Repetitive recycling effects on mechanical characteristics of poly-lactic acid and PLA/spent coffee grounds composite used for 3D printing filament. Polym. Eng. Sci. 2024, 64, 5613–5626. [Google Scholar] [CrossRef]

- Paramatti, M.; Romani, A.; Pugliese, G.; Levi, M. PLA Feedstock Filled with Spent Coffee Grounds for New Product Applications with Large-Format Material Extrusion Additive Manufacturing. ACS Omega 2024, 9, 6423–6431. [Google Scholar] [CrossRef]

- Li, S.; Shi, C.; Sun, S.; Chan, H.; Lu, H.; Nilghaz, A.; Tian, J.; Cao, R. From brown to colored: Polylactic acid composite with micro/nano-structured white spent coffee grounds for three-dimensional printing. Int. J. Biol. Macromol. 2021, 174, 300–308. [Google Scholar] [CrossRef]

- Beltrán-Sanahuja, A.; Benito-Kaesbach, A.; Sánchez-García, N.; Sanz-Lázaro, C. Degradation of conventional and biobased plastics in soil under contrasting environmental conditions. Sci. Total Environ. 2021, 787, 147678. [Google Scholar] [CrossRef]

- Royer, S.-J.; Greco, F.; Kogler, M.; Deheyn, D.D. Not so biodegradable: Polylactic acid and cellulose/plastic blend textiles lack fast biodegradation in marine waters. PLoS ONE 2023, 18, e0284681. [Google Scholar] [CrossRef]

| Sample | Sample Image | Ingredients, % | ||

|---|---|---|---|---|

| Spent Coffee Grounds | Paper Pulp | Water | ||

| 1 |  | - | 50 | 50 |

| 2 |  | 40 | 30 | 30 |

| 3 |  | 45 | 27.5 | 27.5 |

| 4 |  | 50 | 25 | 25 |

| 5 |  | 55 | 22.5 | 22.5 |

| 6 |  | 60 | 20 | 20 |

| 7 |  | 65 | 17.5 | 17.5 |

| Sample | Ingredients, % | |

|---|---|---|

| Spent Coffee Grounds | Paper Pulp | |

| 1 | - | 100 |

| 2 | 57.02484 ± 0.016 | 42.97516 ± 0.016 |

| 3 | 62.20738 ± 0.063 | 37.79262 ± 0.063 |

| 4 | 66.68399 ± 0.101 | 33.31801 ± 0.098 |

| 5 | 71.05051 ± 0.141 | 28.94949 ± 0.141 |

| 6 | 74.88531 ± 0.087 | 25.11469 ± 0.087 |

| 7 | 78.7031 ± 0.132 | 21.2969 ± 0.132 |

| Sample | Stage 1 | Stage 2 | Stage 3 | Stage 4 | Residue | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti | Tm | Tf | W | Ti | Tm | Tf | W | Ti | Tm | Tf | W | Ti | Tm | Tf | W | ||

| (°C) | (°C) | (°C) | (%) | (°C) | (°C) | (°C) | (°C) | (°C) | (°C) | (°C) | (%) | (°C) | (°C) | (°C) | (%) | (%) | |

| 1 | 40 | 66 | 99 | 1.26 | 283 | 331 | 349 | 20.01 | - | - | - | - | 467 | 501 | 524 | 10.39 | 68.34 |

| 2 | 55 | 69 | 119 | 2.49 | 263 | 322 | 349 | 29.26 | 349 | 388 | 404 | 8.41 | 446 | 498 | 519 | 11.96 | 47.88 |

| 3 | 51 | 70 | 103 | 3.00 | 262 | 304 | 346 | 31.47 | 346 | 384 | 399 | 7.54 | 399 | 495 | 519 | 14.19 | 43.8 |

| 4 | 50 | 74 | 105 | 3.65 | 262 | 301 | 342 | 32.96 | 342 | 386 | 401 | 10.42 | 401 | 485 | 514 | 11.99 | 40.98 |

| 5 | 49 | 72 | 100 | 3.21 | 266 | 302 | 348 | 34.39 | 348 | 391 | 405 | 11.08 | 405 | 486 | 508 | 11.60 | 39.72 |

| 6 | 55 | 74 | 121 | 4.43 | 260 | 300 | 347 | 34.66 | 347 | 391 | 408 | 11.88 | 408 | 497 | 517 | 11.50 | 37.53 |

| 7 | 48 | 72 | 111 | 5.29 | 262 | 301 | 345 | 35.43 | 345 | 393 | 406 | 12.15 | 406 | 503 | 512 | 11.93 | 35.2 |

| GB | 47.1 | 78.2 | 147.6 | 4.54 | 267 | 297.0 | 335.2 | 42.29 | 369.3 | 386.9 | 407.1 | 14.59 | 407.1 | 450.8 | - | 16.73 | 21.85 |

| Sample | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|

| Daverage (μm) | 491.8 ± 47.9 | 542.1 ± 77.1 | 589.4 ± 19.8 | 657.5 ± 82.6 | 779.6 ± 19.5 | 836.8 ± 76.0 |

| daverage (μm) | 20.4 ± 2.7 | 25.7 ± 3.7 | 13.9 ± 2.5 | 20.8 ± 3.3 | 20.0 ± 3.2 | 26.1 ± 3.7 |

| Elements, % | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | GB | |

| C | 27.70 | 45.64 | 48.72 | 44.95 | 56.31 | 49.27 | 51.25 | 65.39 |

| N | 1.51 | 2.49 | 2.69 | 2.45 | 2.52 | 2.96 | 1.71 | 4.56 |

| O | 45.47 | 37.05 | 35.27 | 37.91 | 31.71 | 35.74 | 34.77 | 28.79 |

| Na | 0.80 | 0.27 | 0.21 | 0.20 | 0.22 | 0.19 | 0.12 | 0.09 |

| Mg | 0.19 | 0.12 | 0.11 | 0.14 | 0.17 | 0.12 | 0.10 | 0.18 |

| Al | 11.19 | 6.10 | 5.71 | 6.19 | 3.58 | 5.08 | 5.15 | - |

| Si | 12.07 | 6.84 | 6.04 | 6.79 | 3.89 | 5.35 | 5.51 | 0.05 |

| P | 0.12 | 0.11 | 0.10 | 0.12 | 0.14 | 0.10 | 0.07 | 0.07 |

| S | 0.14 | 0.11 | 0.09 | 0.07 | 0.17 | 0.09 | 0.09 | 0.16 |

| K | 0.50 | 1.06 | 0.92 | 0.98 | 0.99 | 0.95 | 1.08 | 0.55 |

| Ca | 0.33 | 0.21 | 0.16 | 0.20 | 0.30 | 0.15 | 0.18 | 0.16 |

| Sample | Δν (cm−1) | EH (kJ/mol) | R (Å) | ΧIR (%) | |||

|---|---|---|---|---|---|---|---|

| Δν1 | Δν2 | EH (Water Matrix) | EH (SCG Matrix) | R (Water Matrix) | R (SCG Matrix) | A1370/A2926 | |

| A1430/A910 | |||||||

| 1 | 190 | - | 12.94 | - | 2.799 | - | 0.12/0.24 |

| 2 | 291 | 280 | 20.93 | 20.14 | 2.774 | 2.776 | 0.27/0.12 |

| 3 | 213 | 308 | 15.32 | 22.15 | 2.792 | 2.770 | 0.28/0.11 |

| 4 | 194 | 257 | 13.95 | 18.48 | 2.796 | 2.781 | 0.25/0.16 |

| 5 | 180 | 306 | 12.94 | 22.00 | 2.799 | 2.770 | 0.26/0.11 |

| 6 | 194 | 290 | 13.95 | 20.85 | 2.796 | 2.774 | 0.27/0.18 |

| 7 | 153 | 338 | 11.00 | 24.30 | 2.805 | 2.763 | 0.21/0.21 |

| GC | 342 | 24.59 | 2.763 | ||||

| Sample | γ, % | G′, MPa |

|---|---|---|

| 1 | 0.01 | 0.814 |

| 2 | 0.01 | 0.126 |

| 3 | 0.005 | 0.368 |

| 4 | 0.005 | 0.472 |

| 5 | 0.005 | 0.170 |

| 6 | 0.01 | 0.102 |

| 7 | 0.005 | 0.466 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bejenari, V.; Danu, M.; Ipate, A.-M.; Zaltariov, M.-F.; Rusu, D.; Lisa, G. Composite Materials Based on Spent Coffee Grounds and Paper Pulp. J. Compos. Sci. 2024, 8, 491. https://doi.org/10.3390/jcs8120491

Bejenari V, Danu M, Ipate A-M, Zaltariov M-F, Rusu D, Lisa G. Composite Materials Based on Spent Coffee Grounds and Paper Pulp. Journal of Composites Science. 2024; 8(12):491. https://doi.org/10.3390/jcs8120491

Chicago/Turabian StyleBejenari, Victoria, Maricel Danu, Alina-Mirela Ipate, Mirela-Fernanda Zaltariov, Daniela Rusu, and Gabriela Lisa. 2024. "Composite Materials Based on Spent Coffee Grounds and Paper Pulp" Journal of Composites Science 8, no. 12: 491. https://doi.org/10.3390/jcs8120491

APA StyleBejenari, V., Danu, M., Ipate, A.-M., Zaltariov, M.-F., Rusu, D., & Lisa, G. (2024). Composite Materials Based on Spent Coffee Grounds and Paper Pulp. Journal of Composites Science, 8(12), 491. https://doi.org/10.3390/jcs8120491