Effect of Clay’s Multilayer Composites Material on the Energy Efficiency of Buildings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Clay

2.1.2. Granular Cork

2.1.3. Sheep Wool

2.1.4. Cement Mortar

2.1.5. Plaster

2.1.6. Preparation of Samples

- Cement mortar–cork composite

- Clay-cork composite

- Clay–wool composite (C-Wo)

- Plaster cork composite

2.1.7. The Studied Multilayer Material

2.2. Methods

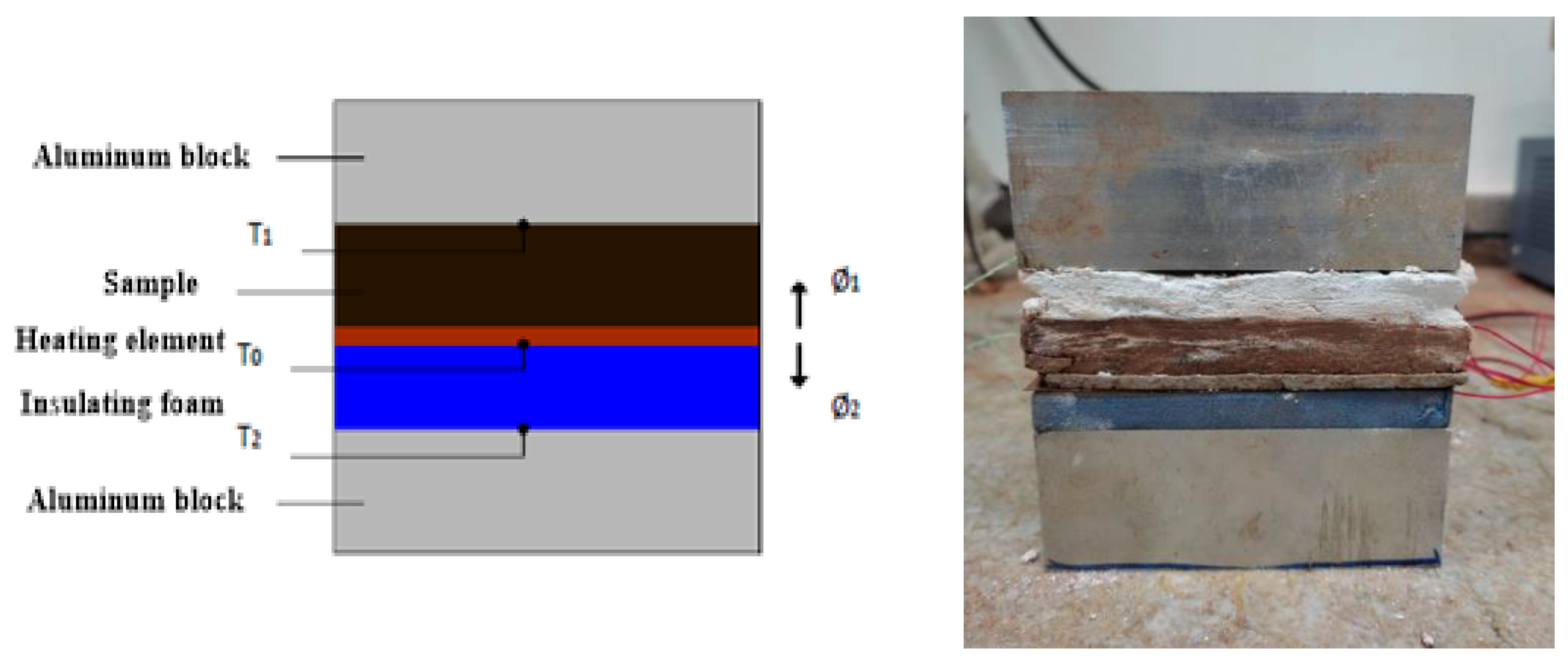

The Asymmetrical Hot Plate Method

- ϕ is the total flux emitted by the resistance (heating element), ϕ1 the heat flux going through the sample, ϕ2 the heat flux passing through the insulating foam.

- λ1 is the thermal conductivity of the sample to characterize; e1 the thickness of the sample.

- λ2 = 0.04 W/m·K and e2 = 0.01 m are, respectively, the thermal conductivity and thickness of the insulating foam.

- A thermocouple was used to measure the temperature T0 at the center of the heated surface of the sample;

- A second one was used to measure the temperature T1 at the center of the unheated surface of the sample;

- The last thermocouple measured T2 of the unheated side of the insulating foam.

3. Results and Discussion

3.1. Apparent Density Results

3.2. Thermal Conductivity Results

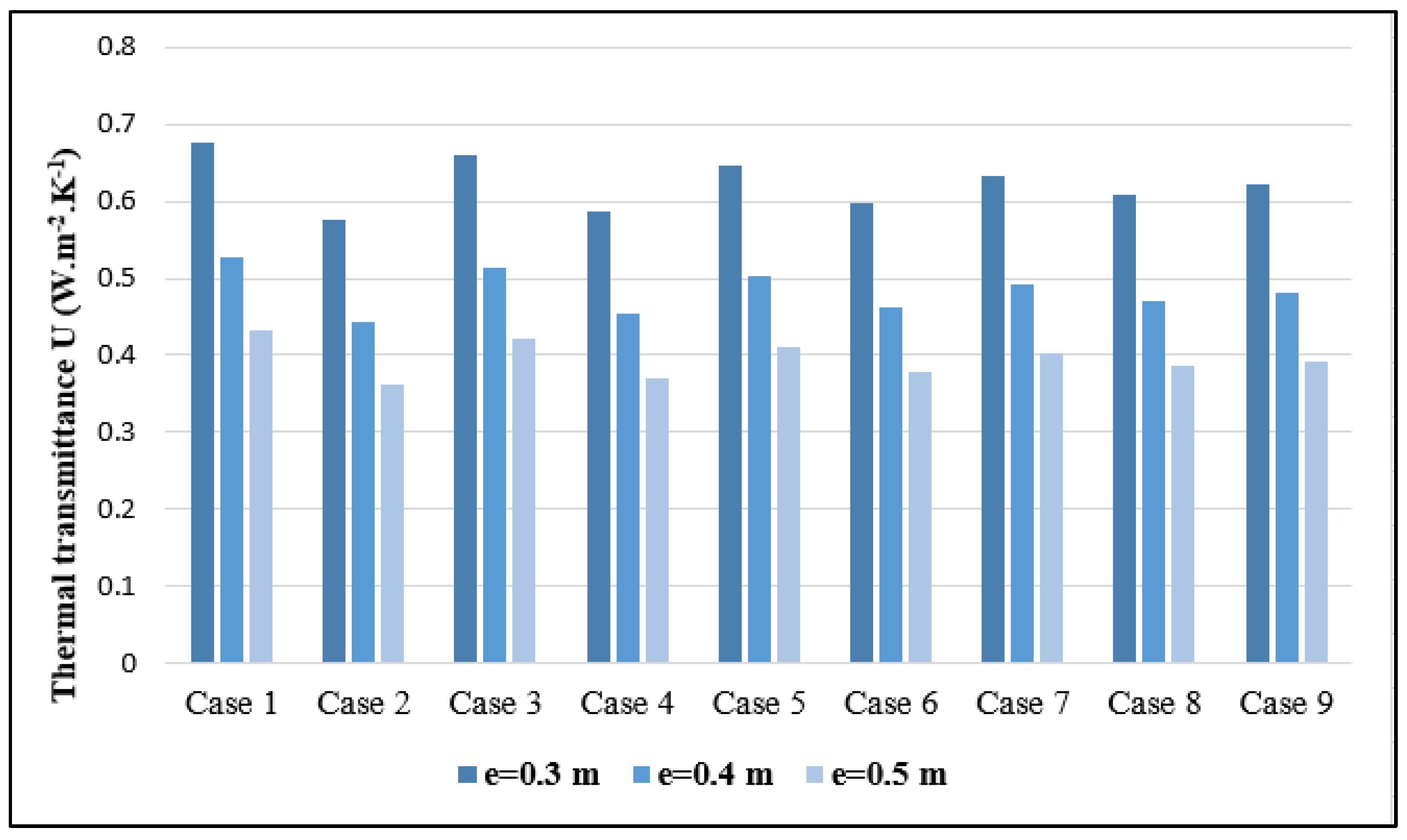

3.3. Thermal Transmittance

3.4. Simulation Using TRNSYS

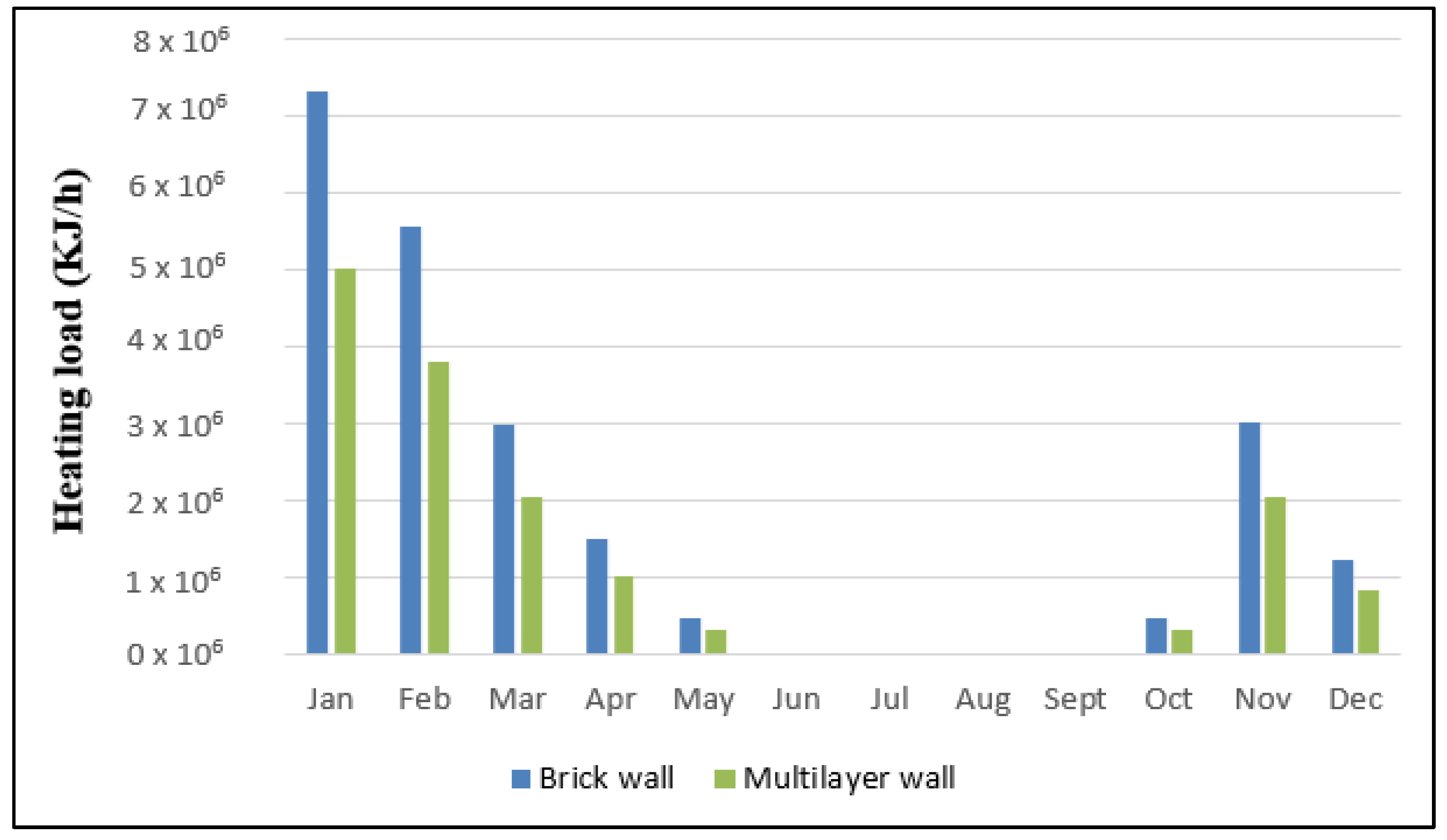

3.5. Contribution of the Developed Composite to Reducing Energy Systems

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Designation | Full Form |

| CM-Co | Cement mortar–cork composite |

| C-Co | Clay–cork composite |

| C-Wo | Clay–wool composite |

| P-Co | Plaster–cork composite |

| ϕ | Heat flux (W·m−2) |

| ϕ1 | heat flux going through the sample |

| ϕ2 | heat flux passing through the insulating foam |

| λ | Thermal conductivity (W·m−1·K−1) |

| φ | Apparent density(Kg·m−3) |

| y | Volume fraction |

References

- Minke, G. Building with Earth: Design and Technology of a Sustainable Architecture; Birkhäuser: Basel, Switzerland, 2013; ISBN 978-3-0346-1262-3. [Google Scholar]

- Mounir, S.; Khabbazi, A.; Khaldoun, A.; Maaloufa, Y.; Elhamdouni, Y. Thermal Inertia and Thermal Properties of the Composite Material Clay-Wool. Sustain. Cities Soc. 2015, 19, 191–199. [Google Scholar] [CrossRef]

- Yang, S.; Wi, S.; Lee, J.; Lee, H.; Kim, S. Biochar-Red Clay Composites for Energy Efficiency as Eco-Friendly Building Materials: Thermal and Mechanical Performance. J. Hazard. Mater. 2019, 373, 844–855. [Google Scholar] [CrossRef] [PubMed]

- Oti, J.E.; Kinuthia, J.M.; Robinson, R.B. The Development of Unfired Clay Building Material Using Brick Dust Waste and Mercia Mudstone Clay. Appl. Clay Sci. 2014, 102, 148–154. [Google Scholar] [CrossRef]

- Charai, M.; Sghiouri, H.; Mezrhab, A.; Karkri, M.; Elhammouti, K.; Nasri, H. Thermal Performance and Characterization of a Sawdust-Clay Composite Material. Procedia Manuf. 2020, 46, 690–697. [Google Scholar] [CrossRef]

- Meng, X.; Yan, B.; Gao, Y.; Wang, J.; Zhang, W.; Long, E. Factors Affecting the in Situ Measurement Accuracy of the Wall Heat Transfer Coefficient Using the Heat Flow Meter Method. Energy Build. 2015, 86, 754–765. [Google Scholar] [CrossRef]

- Del Coz-Díaz, J.J.; Álvarez-Rabanal, F.P.; Alonso-Martínez, M.; Martínez-Martínez, J.E. Thermal Inertia Characterization of Multilayer Lightweight Walls: Numerical Analysis and Experimental Validation. Appl. Sci. 2021, 11, 5008. [Google Scholar] [CrossRef]

- Cooke, G.B. Cork and the Cork Tree-1st Edition. Available online: https://www.elsevier.com/books/cork-and-the-cork-tree/cooke/978-1-4832-1319-4 (accessed on 27 March 2022).

- Silva, S.; Sabino, M.; Fernandes, E.; Correlo, V.; Boesel, L.; Reis, R.L. Cork: Properties, Capabilities and Applications. Int. Mater. Rev. 2005, 50, 345–365. [Google Scholar] [CrossRef] [Green Version]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance Evaluation and Research of Alternative Thermal Insulations Based on Sheep Wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Cherki, A.; Remy, B.; Khabbazi, A.; Jannot, Y.; Baillis, D. Experimental Thermal Properties Characterization of Insulating Cork–Gypsum Composite. Constr. Build. Mater. 2014, 54, 202–209. [Google Scholar] [CrossRef]

- ISO 6946:2017(En), Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. Available online: https://www.iso.org/obp/ui/#iso:std:iso:6946:ed-3:v2:en (accessed on 26 December 2021).

- Mounir, S.; Khabbazi, A.; Elwardi, F.Z.; Elharrouni, K.; Maaloufa, Y. Energy Efficiency and Impact Carbon of a Multilayer Material Composed of Ecological Additives. Energy Procedia 2019, 157, 419–427. [Google Scholar] [CrossRef]

- AMEE. Règlement Thermique de Construction au Maroc (RTCM); AMEE: Dundee, Scotland, 2011. [Google Scholar]

- El Wardi, F.Z.; Khabbazi, A.; Cherki, A.-B.; Khaldoun, A. Thermomechanical Study of a Sandwich Material with Ecological Additives. Constr. Build. Mater. 2020, 252, 119093. [Google Scholar] [CrossRef]

- Tahir, M.Z.; Jamaludin, R.; Nasrun, M.; Nawi, M.; Baluch, N.H.; Mohtar, S. Building energy index (bei): A study of government office building in malaysian public university. J. Eng. Sci. Technol. 2017, 12, 192–201. [Google Scholar]

- Qawasmeh, B.R.; Al-Salaymeh, A.; Ma’en, S.S.; Elian, N.; Zahran, N. Energy Rating for Residential Buildings in Amman. Int. J. Therm. Environ. Eng. 2017, 14, 109–118. [Google Scholar] [CrossRef]

- Monna, S.; Coccolo, S.; Kämpf, J.; Mauree, D.; Scartezzini, L. Energy Demand Analysis for Building Envelope Optimization for Hot Climate. In Proceedings of the PLEA 2016—36th International Conference on Passive and Low Energy Architecture, Los Angeles, CA, USA, 11–13 July 2016. [Google Scholar]

| Chemical Component | Percentage of the Component (%) |

|---|---|

| SiO2 | 59.6 |

| Al2O3 | 22.4 |

| Fe2O3 | 6.69 |

| CaO | 0.0777 |

| MgO | 0.97 |

| K2O | 2.53 |

| TiO2 | 0.832 |

| P2O5 | 0.458 |

| P.F | 5.34 |

| Cases | Layer 1 (CM-Co) | Layer 2 (C-Co) | Layer 3 (C-Wo) | Layer 4 (P-Co) |

|---|---|---|---|---|

| Case 1 | 0.015 m | 0.243 m (90%) | 0.027 m (10%) | 0.015 m |

| Case 2 | 0.015 m | 0.027 m (10%) | 0.243 m (90%) | 0.015 m |

| Case 3 | 0.015 m | 0.216 m (80%) | 0.054 m (20%) | 0.015 m |

| Case 4 | 0.015 m | 0.054 m (20%) | 0.216 m (80%) | 0.015 m |

| Case 5 | 0.015 m | 0.189 m (70%) | 0.081 m (30%) | 0.015 m |

| Case 6 | 0.015 m | 0.081 m (30%) | 0.189 m (70%) | 0.015 m |

| Case 7 | 0.015 m | 0.162 m (60%) | 0.108 m (40%) | 0.015 m |

| Case 8 | 0.015 m | 0.108 m (40%) | 0.162 m (60%) | 0.015 m |

| Case 9 | 0.015 m | 0.135 m (50%) | 0.135 m (50%) | 0.015 m |

| Sample Series | (Kg·m−3) | |

|---|---|---|

| Cement mortar–cork | 1 | 1160 |

| (y = 0.4) | 2 | 1205 |

| (w/g = 0.5) | 3 | 1189 |

| Ave 1 | 1185 | |

| Clay–cork | 1 | 1114 |

| (y = 0.491) | 2 | 1106 |

| (w/g = 0.25) | 3 | 1108 |

| Ave 1 | 1109 | |

| Clay–wool | 1 | 1779.5 |

| (y = 0.124) | 2 | 1778 |

| (w/g = 0.3) | 3 | 1780 |

| Ave 1 | 1779 | |

| Plaster–cork | 1 | 470.86 |

| (y = 0.509) | 2 | 475.39 |

| (w/g = 0.7) | 3 | 470.17 |

| Ave 1 | 472.14 |

| Sample Series | λ composite (W·m−1·K−1) | |

|---|---|---|

| Cement mortar–cork | 1 | 0.252 |

| (y = 0.4) | 2 | 0.242 |

| (w/g = 0.5) | 3 | 0.249 |

| Average | 0.25 | |

| Clay–cork | 1 | 0.25 |

| (y = 0.491) | 2 | 0.24 |

| (w/g = 0.25) | 3 | 0.26 |

| Average | 0.250 | |

| Clay–wool | 1 | 0.2 |

| (y = 0.124) | 2 | 0.18 |

| (w/g = 0.3) | 3 | 0.19 |

| Average | 0.19 | |

| Plaster–cork | 1 | 0.125 |

| (y = 0.509) | 2 | 0.125 |

| (w/g = 0.7) | 3 | 0.123 |

| Average | 0.124 |

| The Total Thickness of the Wall | Sample Series | U (W·m−2·K−1) |

|---|---|---|

| e = 0.3 m | Case 1 | 0.675 |

| Case 2 | 0.575 | |

| Case 3 | 0.661 | |

| Case 4 | 0.586 | |

| Case 5 | 0.647 | |

| Case 6 | 0.597 | |

| Case 7 | 0.634 | |

| Case 8 | 0.609 | |

| Case 9 | 0.621 | |

| e = 0.4 m | Case 1 | 0.526 |

| Case 2 | 0.444 | |

| Case 3 | 0.514 | |

| Case 4 | 0.453 | |

| Case 5 | 0.503 | |

| Case 6 | 0.462 | |

| Case 7 | 0.492 | |

| Case 8 | 0.471 | |

| Case 9 | 0.482 | |

| e = 0.5 m | Case 1 | 0.431 |

| Case 2 | 0.361 | |

| Case 3 | 0.421 | |

| Case 4 | 0.369 | |

| Case 5 | 0.411 | |

| Case 6 | 0.377 | |

| Case 7 | 0.402 | |

| Case 8 | 0.385 | |

| Case 9 | 0.393 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibn-Elhaj, S.; Mounir, S.; Khabbazi, A.; Sarghini, H. Effect of Clay’s Multilayer Composites Material on the Energy Efficiency of Buildings. J. Compos. Sci. 2022, 6, 151. https://doi.org/10.3390/jcs6050151

Ibn-Elhaj S, Mounir S, Khabbazi A, Sarghini H. Effect of Clay’s Multilayer Composites Material on the Energy Efficiency of Buildings. Journal of Composites Science. 2022; 6(5):151. https://doi.org/10.3390/jcs6050151

Chicago/Turabian StyleIbn-Elhaj, Sara, Soumia Mounir, Abdelhamid Khabbazi, and Hind Sarghini. 2022. "Effect of Clay’s Multilayer Composites Material on the Energy Efficiency of Buildings" Journal of Composites Science 6, no. 5: 151. https://doi.org/10.3390/jcs6050151

APA StyleIbn-Elhaj, S., Mounir, S., Khabbazi, A., & Sarghini, H. (2022). Effect of Clay’s Multilayer Composites Material on the Energy Efficiency of Buildings. Journal of Composites Science, 6(5), 151. https://doi.org/10.3390/jcs6050151